A vacuum-based salt solution heat pump regeneration system

A regeneration system, salt solution technology, applied in air conditioning systems, heat recovery systems, space heating and ventilation, etc., can solve the problems of long time, high energy consumption, steam cannot be discharged smoothly, etc., to reduce energy consumption, pressure regulation smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

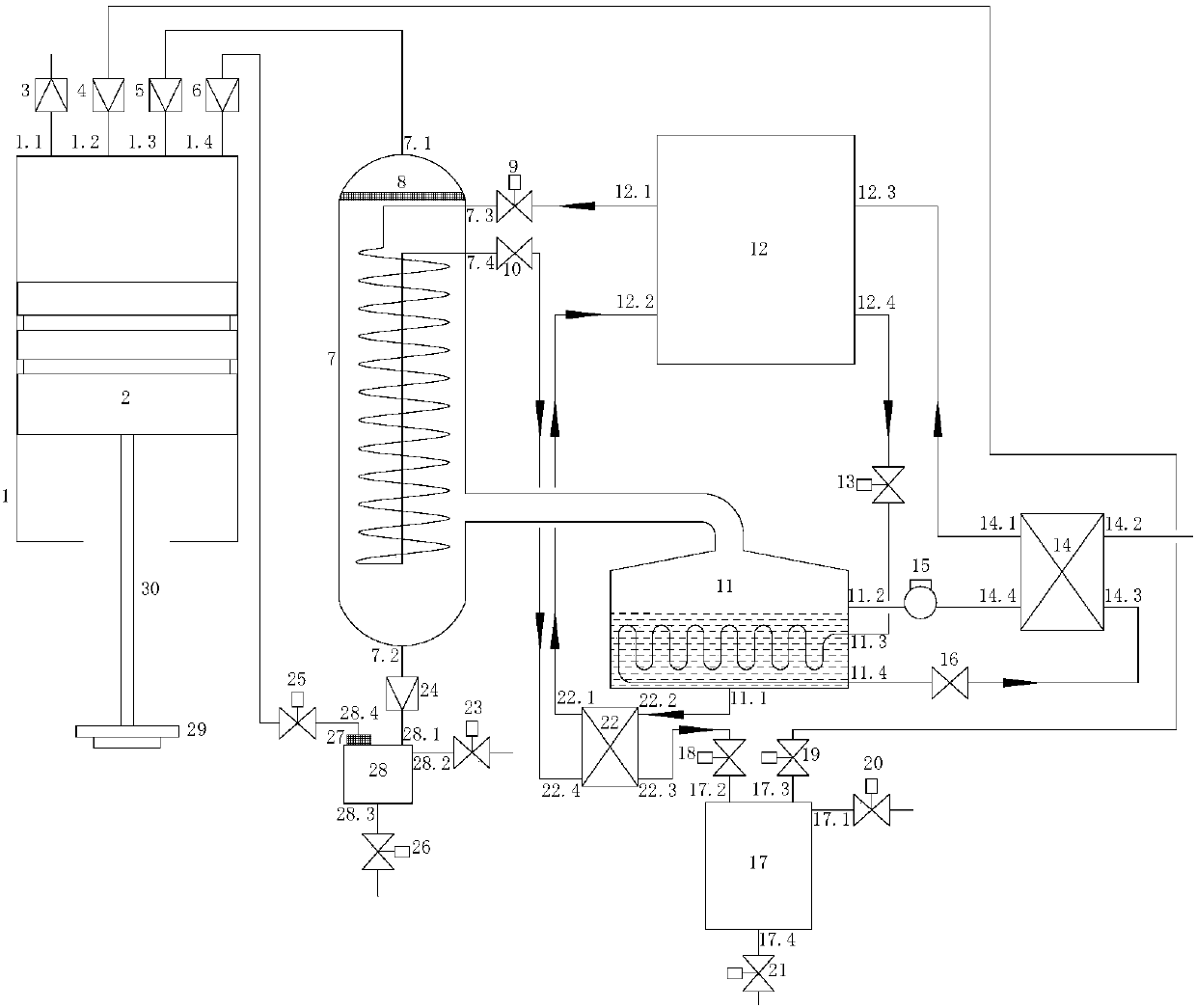

[0022] Attached below figure 1 The specific structure and operation process of the present invention will be described in detail.

[0023] The invention is a salt solution heat pump regeneration system based on vacuum.

[0024] The specific structural description of the vacuum maintenance mechanism: the vacuum maintenance mechanism includes a cylinder 1, a piston 2, a water catcher 7, a first water barrier 8, a regenerator 11, a regeneration solution tank 17, a condensed water tank 28, and a weight plate 29 , connecting rod 30, one-way valve one 3, one-way valve two 4, one-way valve three 5, one-way valve four 6, solenoid valve eight 25, solenoid valve four 19, specific structure description: cylinder 1 is exhausted through the cylinder in turn The port 1.1 and the one-way valve 3 are connected to the atmosphere. There is a piston 2 in the cylinder 1, and the piston 2 is connected to the weight plate 29 through the connecting rod 30; The first water retaining grid 8 is set, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com