A vacuum pump simulation loading system

A technology of loading system and vacuum pump, which is applied in the testing of pumps, pump devices, machines/structural components, etc., can solve the problems of deviation in the verification of the whole engine and the verification effect is not in line with reality, and achieve stable air supply and pressure regulation, The effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

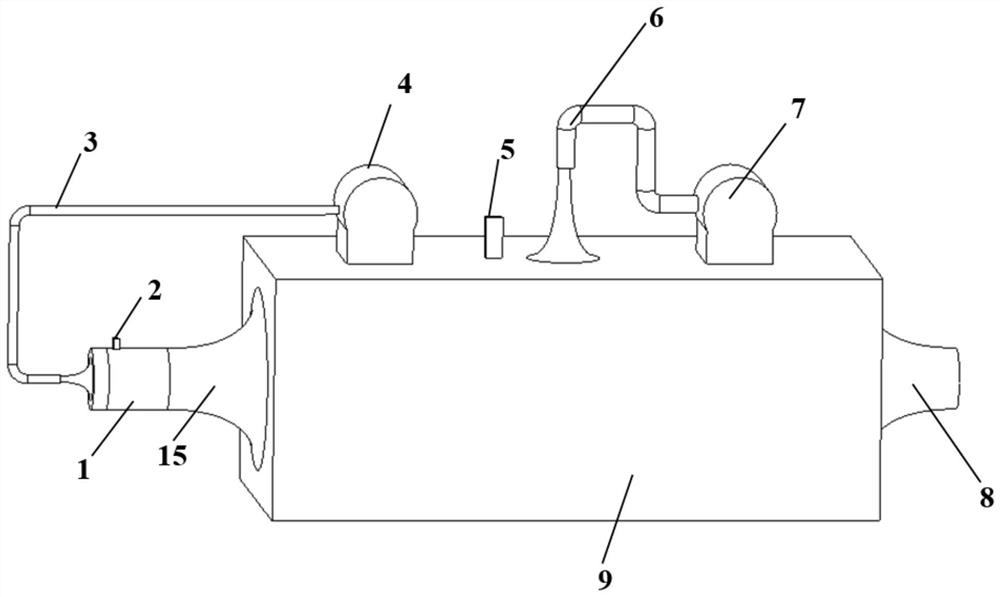

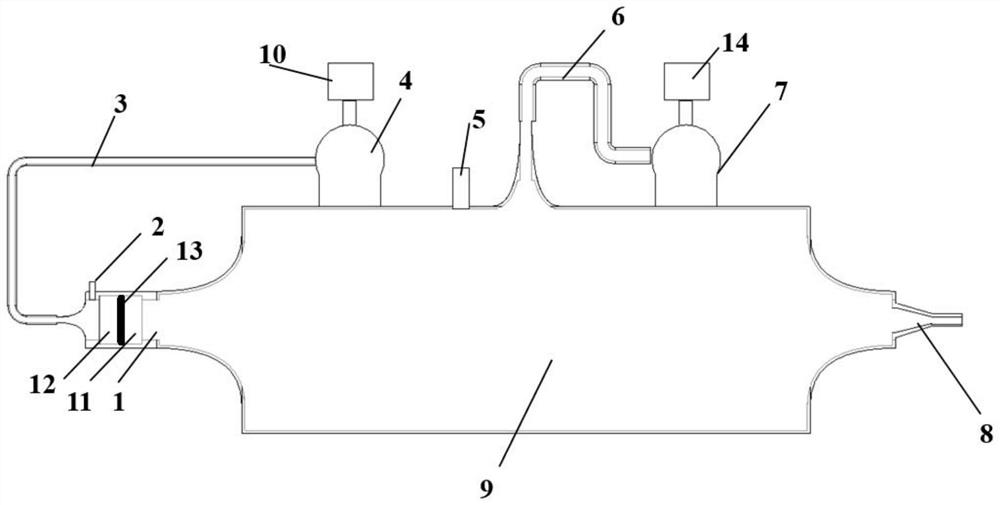

[0017] Such as figure 1 and 2 As shown, the present invention provides a vacuum pump simulation loading system, which includes: a vacuum tank 9 and an air pumping end 8 thereon, and the air pumping end 8 is connected to the vacuum pump, wherein: it also includes: a measurement and control end 15, an air supply An air pump 7 and a pressure regulating air pump 4; a pressure balance module 1 is arranged at the measurement and control end 15, and a left cavity 12, a right cavity 11 and a diaphragm 13 between them are arranged in the pressure balance module 1, And the diaphragm 13 deforms and shifts in the corresponding cavity according to the vacuum degree difference between the left cavity 12 and the right cavity 11; Supplementary gas is provided, and the pressure regulating air pump 4 is gas-connected with the left cavity 12, and provides or extracts the gas of the left cavity 12 according to the degree of vacuum in the left cavity 12, and the right cavity 11 It is gas-connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com