An automatic lubrication device for sliding parts of die-casting molds

A technology for automatic lubrication and die-casting molds, which is applied in the direction of engine lubrication, metering devices, and lubricating parts. It can solve the problems of difficult expansion of multiple lubrication points, high pressure drop in the system, and high power consumption, so as to achieve air pressure stability and reduce Transmission resistance, the effect of reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The purpose and effects of the present invention will become clearer by describing the present invention in detail according to the accompanying drawings and preferred embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

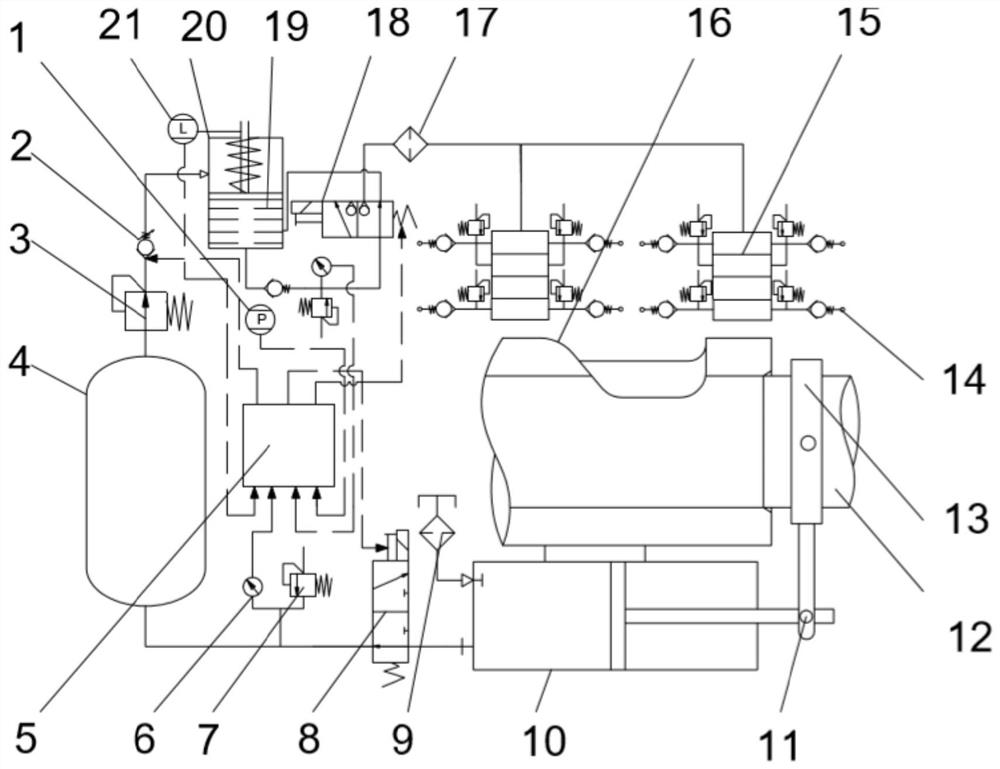

[0028] as attached figure 1 As shown, the automatic lubricating device for die-casting mold sliding parts of the present invention includes a reciprocating piston cylinder 10, a two-position three-way solenoid valve 8 for discharging excess compressed air generated by the reciprocating piston cylinder 10, an air filter 9, a pressure Table 6. Safety device overflow valve used to prevent system overpressure 7, high pressure cylinder 4 used to store compressed air, pressure reducing valve used to adjust the pressure of compressed air 3, used to control the discharge of compressed air in high pressure cylinder 4 Electromagnetic one-way valve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com