Capillary pressure regulator

A capillary pressure and regulator technology, which is applied in the field of pressure regulators, can solve the problem of no capillary pressure regulator, etc., and achieve the effects of reducing the cost, widening the movement range, and improving the water stop guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

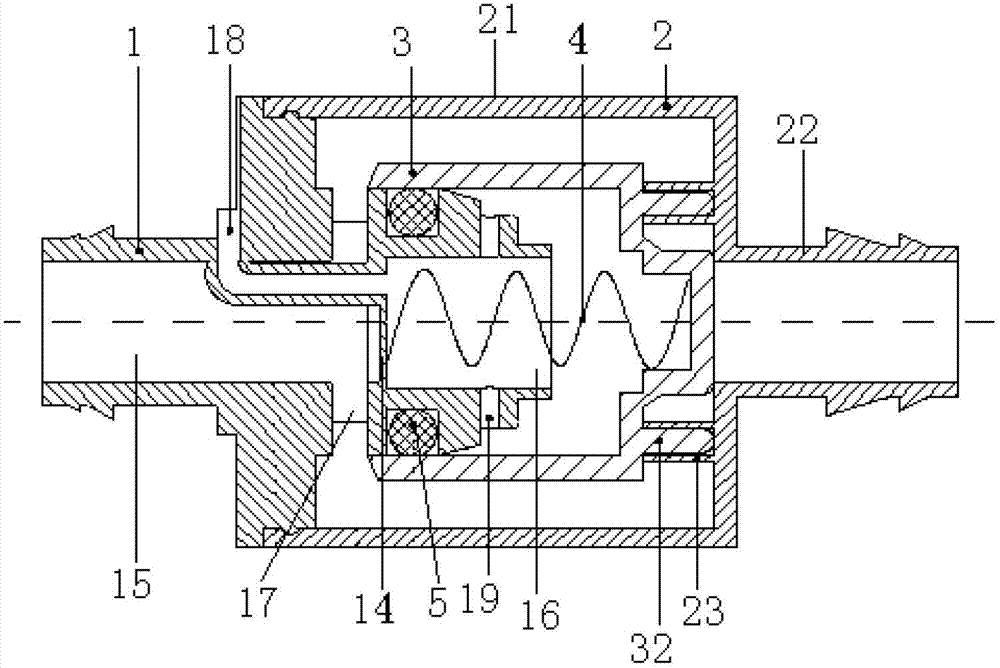

[0026] Such as figure 1 As shown, the present invention includes an upstream deflector 1 , a downstream housing 2 , a pressure regulating assembly 3 and a spring 4 .

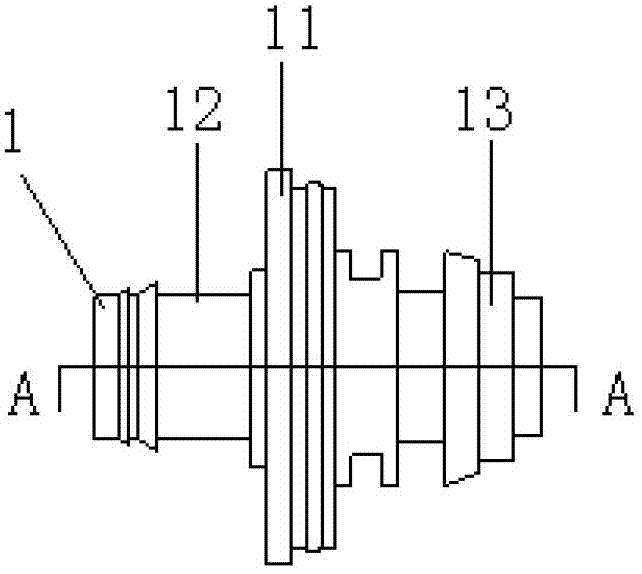

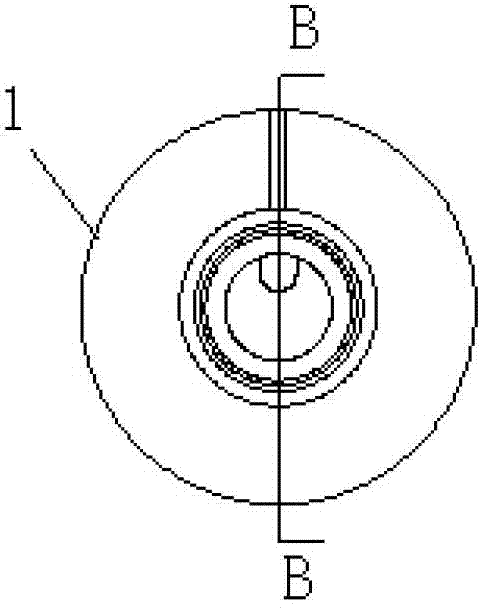

[0027] Such as Figure 1~5 As shown, the upstream guide body 1 of the present invention is a tubular structure, and a through hole is arranged axially inside it. The outer wall diameters of the upstream guide body 1 are different, the diameter at the middle position is large, the diameter at both ends is small, and the middle position is The casing connecting end 11, one of the two ends is used as the water inlet end 12, and the other end is used as the connecting end 13 of the pressure regulating assembly. A barrier 14 is arranged inside the upstream guide body 1 . The barrier 14 is located behind the shell connection end 11 and divides the inside of the upstream guide body 1 into an upper cavity 15 and a lower cavity 16 that are not connected to each other. On the circumferential side wall of the upper cavit...

Embodiment 2

[0035] Such as Figure 12 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the downstream housing 2 includes a first cylinder 21 with the same diameter as the housing connection end 11 of the upstream guide body 1 , and the end of the first cylinder 21 Connect the side wall of the second cylindrical body 22, the central axis of the first cylindrical body 21 is perpendicular to the central axis of the second cylindrical body 22; 21 is a through hole connected inside, and the diameter of the through hole is the same as the inner diameter of the first cylindrical body 21; both ends of the second cylindrical body 22 are water outlets, and the outer wall of the water outlet can be set as a screw lock form. Two symmetrical positioning holes 23 are arranged on the inner wall of the second cylindrical body 22 at intervals. The pressure regulating assembly 3 is arranged in the first cylindrical body 21 and the second cylindrical body 22 . In the initial state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com