Surface fiber Bragg grating sensor with double packaging layers and manufacturing method of surface fiber Bragg grating sensor

A fiber grating and surface-type technology, which is applied in the field of surface-mounted sensors, can solve problems such as being vulnerable to damage, and achieve the effects of reasonable cost, stable performance, and simple manufacturing methods

Inactive Publication Date: 2012-10-03

SOUTH CHINA UNIV OF TECH +1

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Gratings are written on fiberglass, which is very susc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

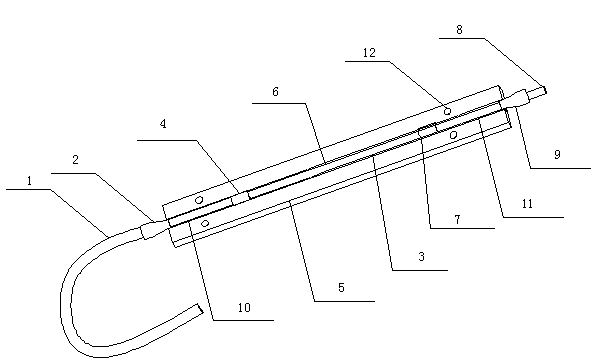

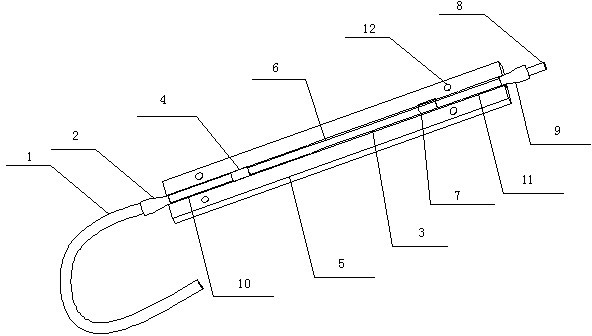

The invention provides a surface fiber Bragg grating sensor with double packaging layers and a manufacturing method of the surface fiber Bragg grating sensor. In the sensor, a first tail fiber is welded at one end of a fiber Bragg grating, a second tail fiber is welded at the other end of the fiber Bragg grating, a first sheath and a second sheath are respectively melted at two ends of a shell and used for reinforcing the connection strength of the first tail fiber, the second tail fiber and the shell, a first support sleeve and a second support sleeve are placed in grooves in the shell, the fiber Bragg grating is adhered on a grating support frame, the grating support frame is placed on the first support sleeve and the second support sleeve, two ends of the grating support frame are fixedly adhered in the shell, and the middle of the grating support frame is suspended so that requirements on monitoring surface strains of various structures are met. The manufacturing method includes that two ends of a steel wire adhered with the grating are fixed, and the middle of the steel wire is suspended, so that errors caused by transverse strain are effectively avoided, and influences to measurement results due to the transverse strain are effectively eliminated.

Description

technical field [0001] The invention relates to a surface-attached sensor, in particular to a surface-type double-layer packaged optical fiber grating sensor for bridge health monitoring and a manufacturing method thereof. Background technique [0002] The monitoring of stress, strain and deformation of civil engineering structures requires various types of sensing materials. Civil engineering structures are often important structures related to the national economy and people's livelihood, and it is of great significance to ensure their healthy operation. Through various sensors to measure various parameters related to civil engineering structures under the action of external loads, the actual working performance of the structure can be determined from the strength, stiffness, crack resistance and actual damage form of the structure, the bearing capacity of the structure can be estimated, and the structure itself can be determined. The performance of the sensor determines ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01D21/02G01B11/16

Inventor 罗立峰罗广发汤立群黄成造刘云生刘泽佳刘逸平

Owner SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com