Device for measuring radial force of transient-state hydraulic power of centrifugal pump and measuring method thereof

A technology of measuring device and measuring method, applied in the direction of measuring device, force/torque/work measuring instrument calibration/test, force/torque/work measuring instrument, etc., can solve the problem of pump without measuring device and without perfect rotating coordinate system Impeller radial force measurement and conversion methods, etc., to achieve the effect of measurement, simple structure, measurement and conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The measuring device of the present invention is described in detail below in conjunction with the example and accompanying drawing of the radial force measurement that utilizes this device to carry out:

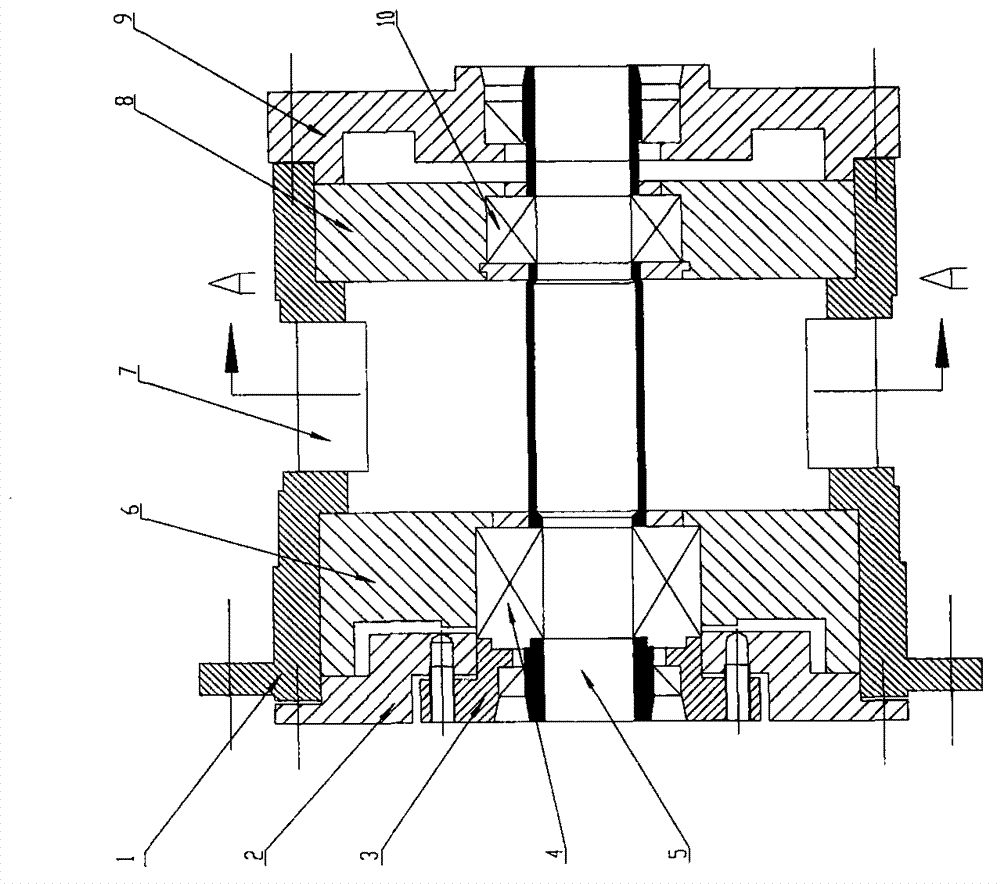

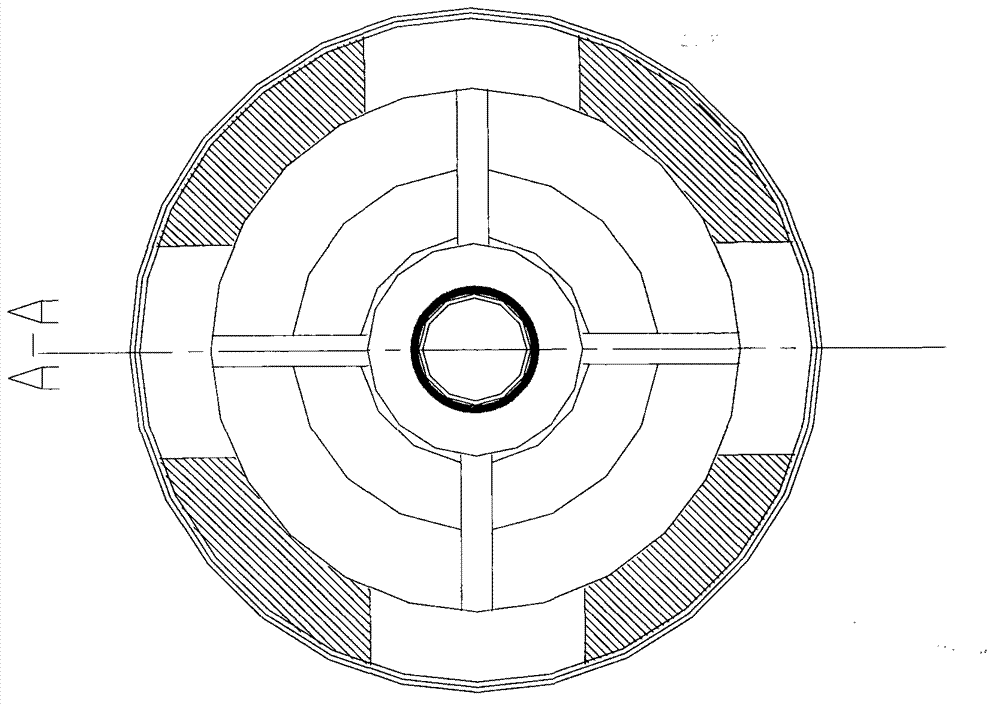

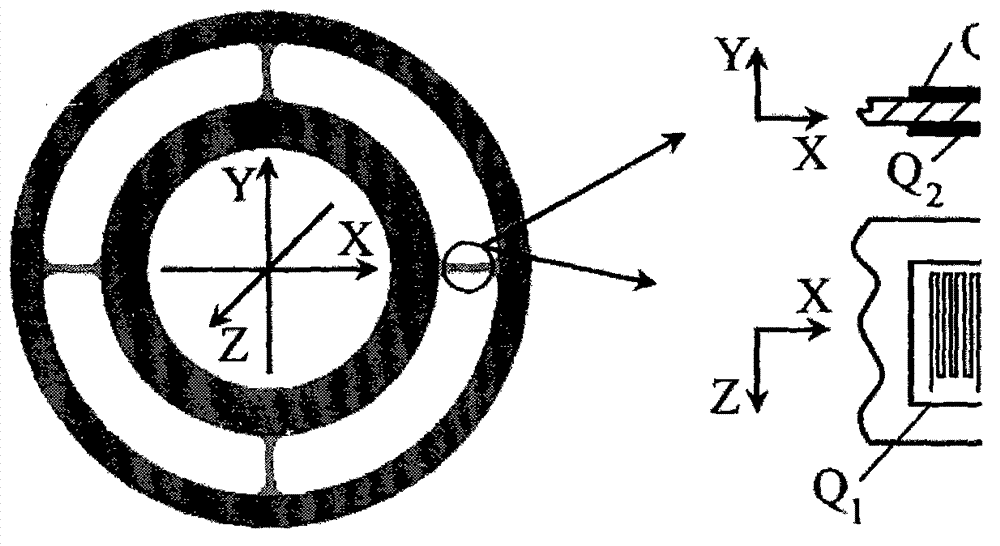

[0014] Such as figure 1 As shown, the present invention includes a device housing (1), a rear fixing ring (2), a pressing plate (3), a tight bearing (4), a shaft cavity (5), a tight bearing elastic support (6), an operating hole ( 7), loose bearing elastic support (8), loose bearing (9) and front fixed ring (10) form. Among them, the device housing (1) is connected with the external fixed end, the rear fixed ring (2) is connected with the device housing (1), the pressing plate (3) is connected with the rear fixed ring (2), and the tight bearing is elastically supported (6) and the loose bearing elastic support (8) are fixedly connected with the housing (1), and the front fixing ring (10) is connected with the device housing (1). The shaft cavity (5) is used to insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com