Online real-time monitoring method for dynamic deflection deformation of wind driven generator blade

A wind-driven generator, deflection deformation technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, signal transmission system, etc., can solve the problems of low detection accuracy, difficulty in online monitoring, poor anti-interference, etc., to achieve The range of temperature and humidity changes is large, ensuring real-time acquisition and realizing the effect of real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

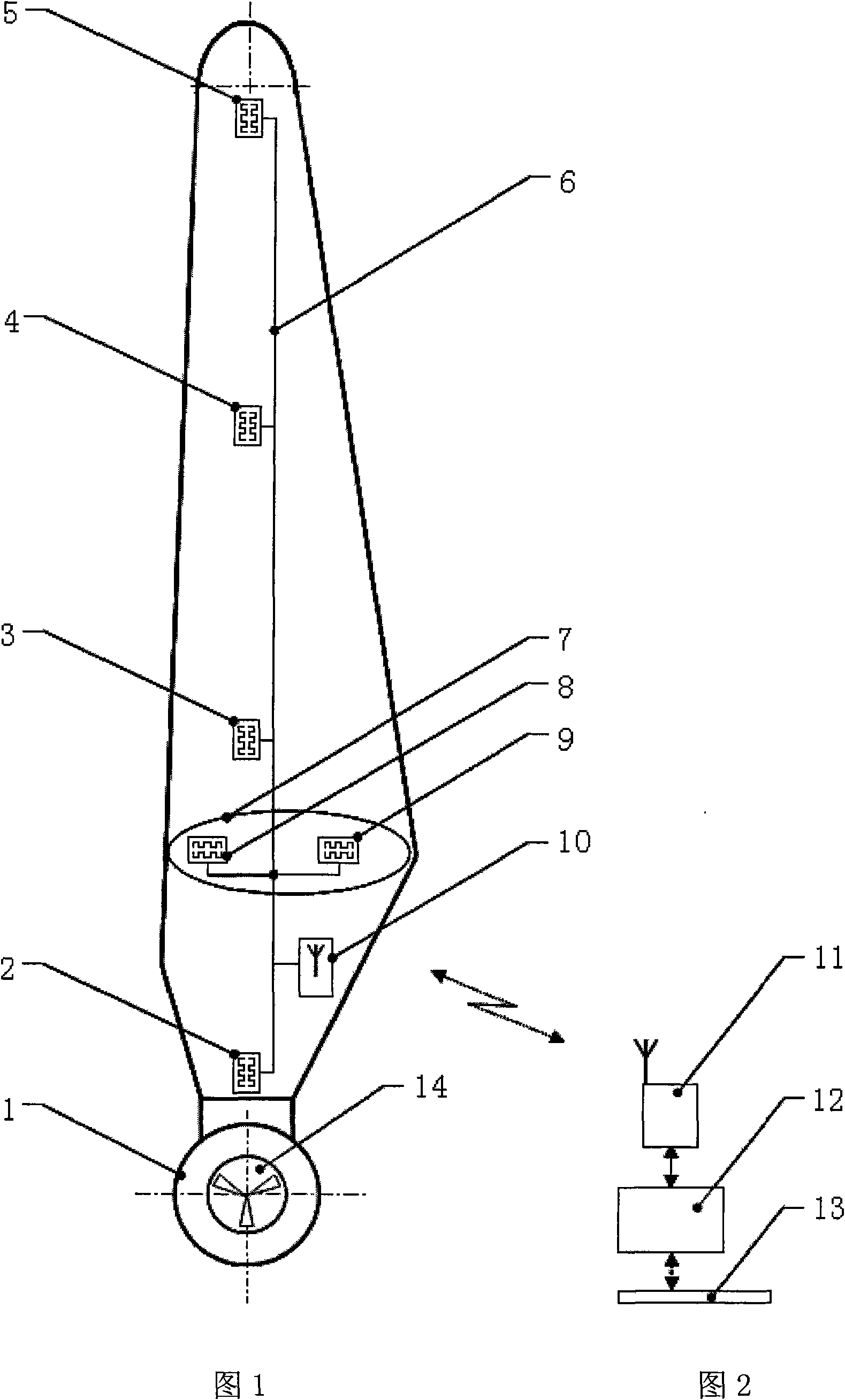

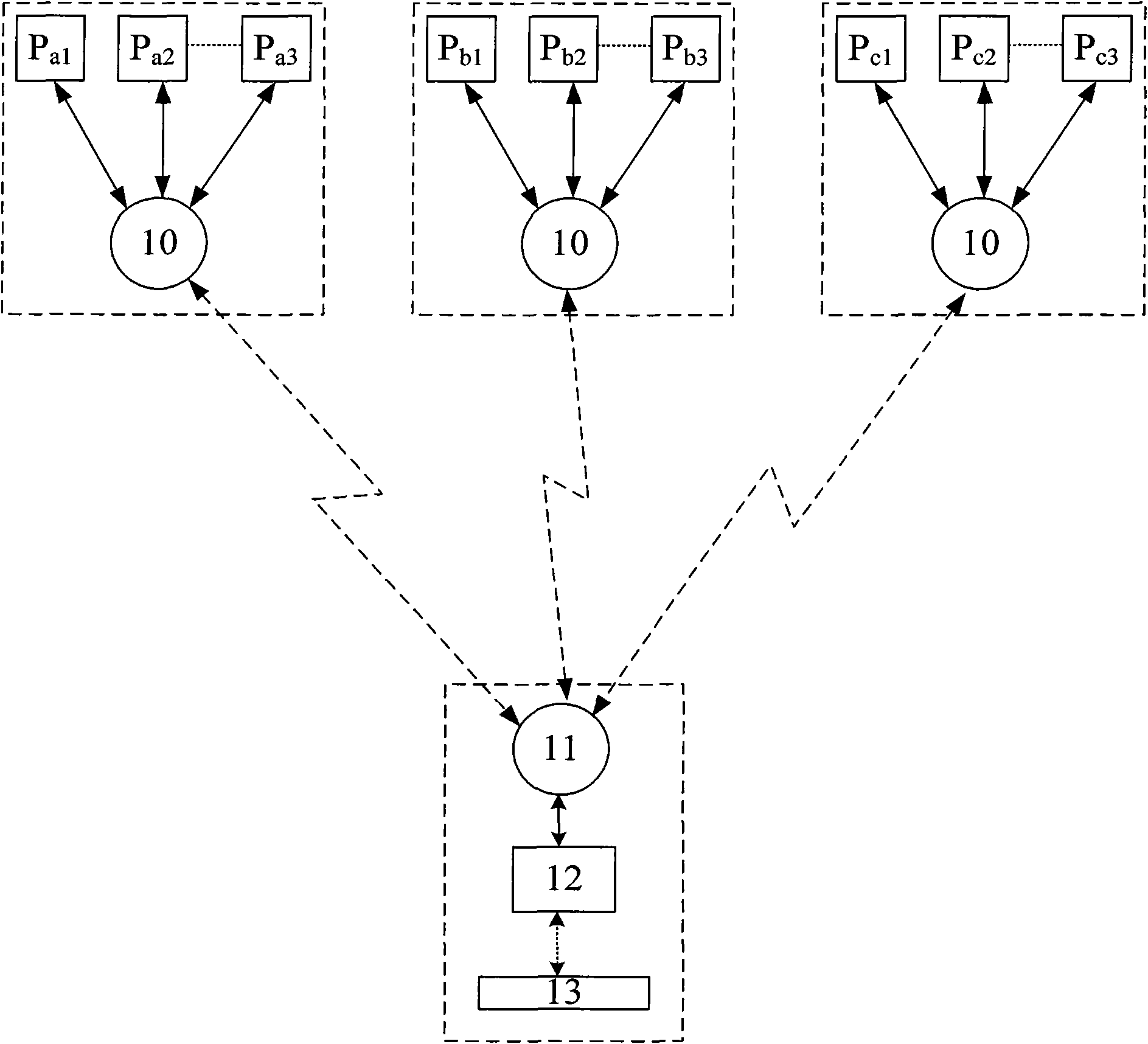

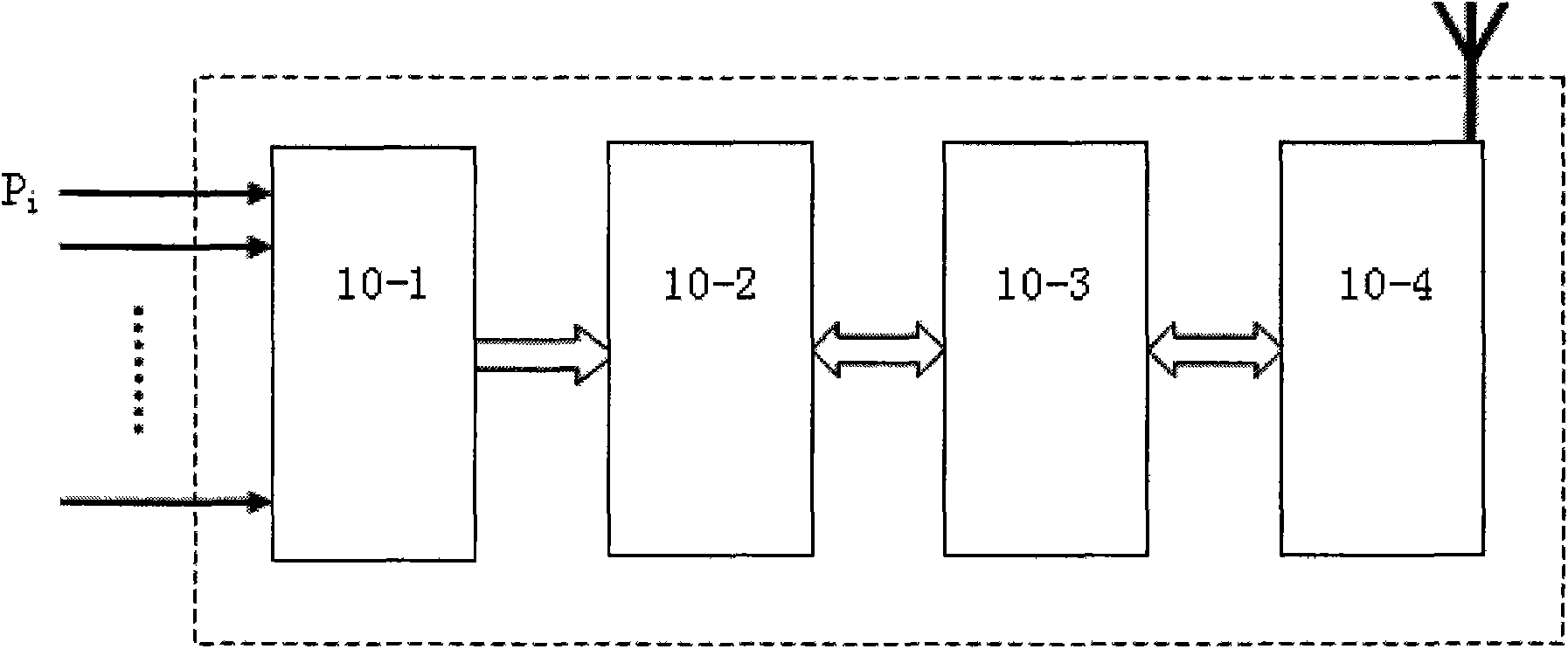

[0029] Such as figure 1 As shown, a wind turbine has multiple blades, and the blades are installed on the hub 1. According to the structure of the blades, detection points for longitudinal deformation, lateral deformation, and keel deformation are selected on each blade, and strain gauges are attached to the detected points. In the present invention, the first longitudinal strain detection strain gauge 2, the second longitudinal strain detection strain gauge 3, the third longitudinal strain detection strain gauge 4, and the fourth longitudinal strain detection strain gauge 5 are installed at intervals in the longitudinal strain direction of the blade. 7 and a transverse strain detection strain gauge 8 and a second transverse strain detection strain gauge 9 are installed on the top. The signal conditioning and wireless transmitter 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com