Corbel bracket platform for bridge pier and transverse straining beam synchronous construction and construction method of corbel bracket platform

A technology of simultaneous construction and transverse tie beams, applied in bridge construction, bridges, erection/assembly of bridges, etc., can solve the problems of long construction period, slow construction speed, and inability to achieve synchronous construction of piers and transverse tie beams. Safe and controllable, the effect of using less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

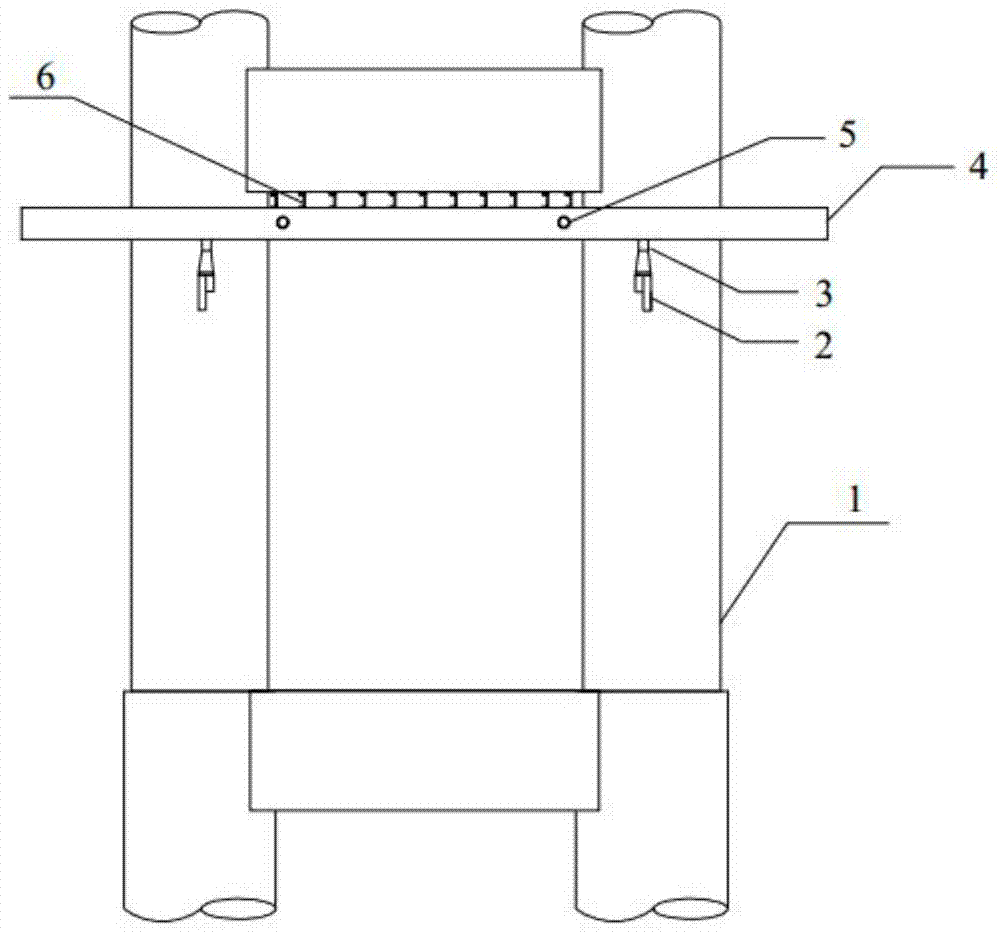

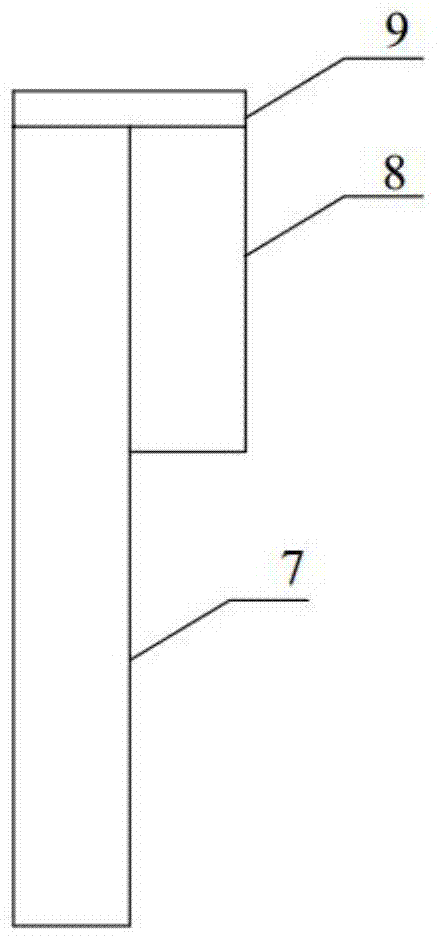

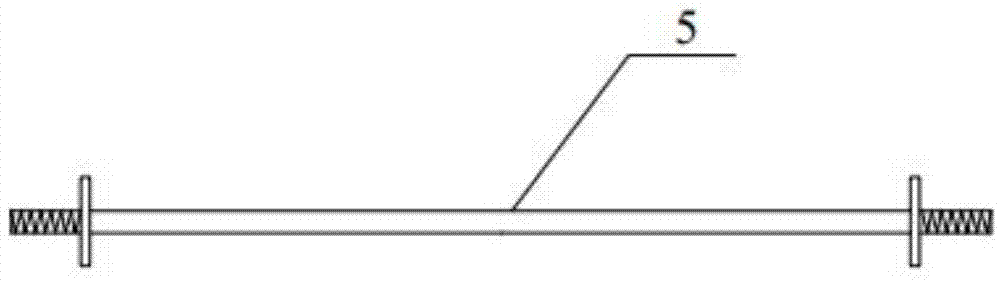

[0035] The corbel bracket platform for synchronous construction of bridge piers and transverse beams according to the present invention includes a pier column model, a corbel, and a transverse beam bracket platform, and each section of the pier column model is composed of two semicircular steel It is assembled from the front and back of the mould, and the horizontal tie beam bracket platform includes jacks, I-beams, tie rods, and distribution beams. The schematic diagram of its structure is as follows: figure 1 Shown: Corbels 2 are respectively welded at the same height in the middle of the semicircular steel molds on both sides of the pier model 1, the jack 3 is installed on the corbel 2, and the I-beam 4 is placed on the jack 3 along the horizontal direction. The I-beams 4 on both sides of the pier model 1 are connected together by tie rods 5 and fastened to the pier model 1, and the distribution beams 6 are placed between the I-beams 4 at equal intervals.

[0036] Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com