Manufacturing technology of magnetic suspension prestressed reinforced concrete rail beam

A technology of prestressed steel bars and track beams, which is applied to joists, girders, trusses and other directions, can solve the problem of not reaching the high precision of magnetic levitation prestressed reinforced concrete track beams, not overcoming the influence of structural performance and dimensional accuracy, Problems such as low dimensional accuracy, to achieve the effect of reducing errors, reducing the influence of deformation, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

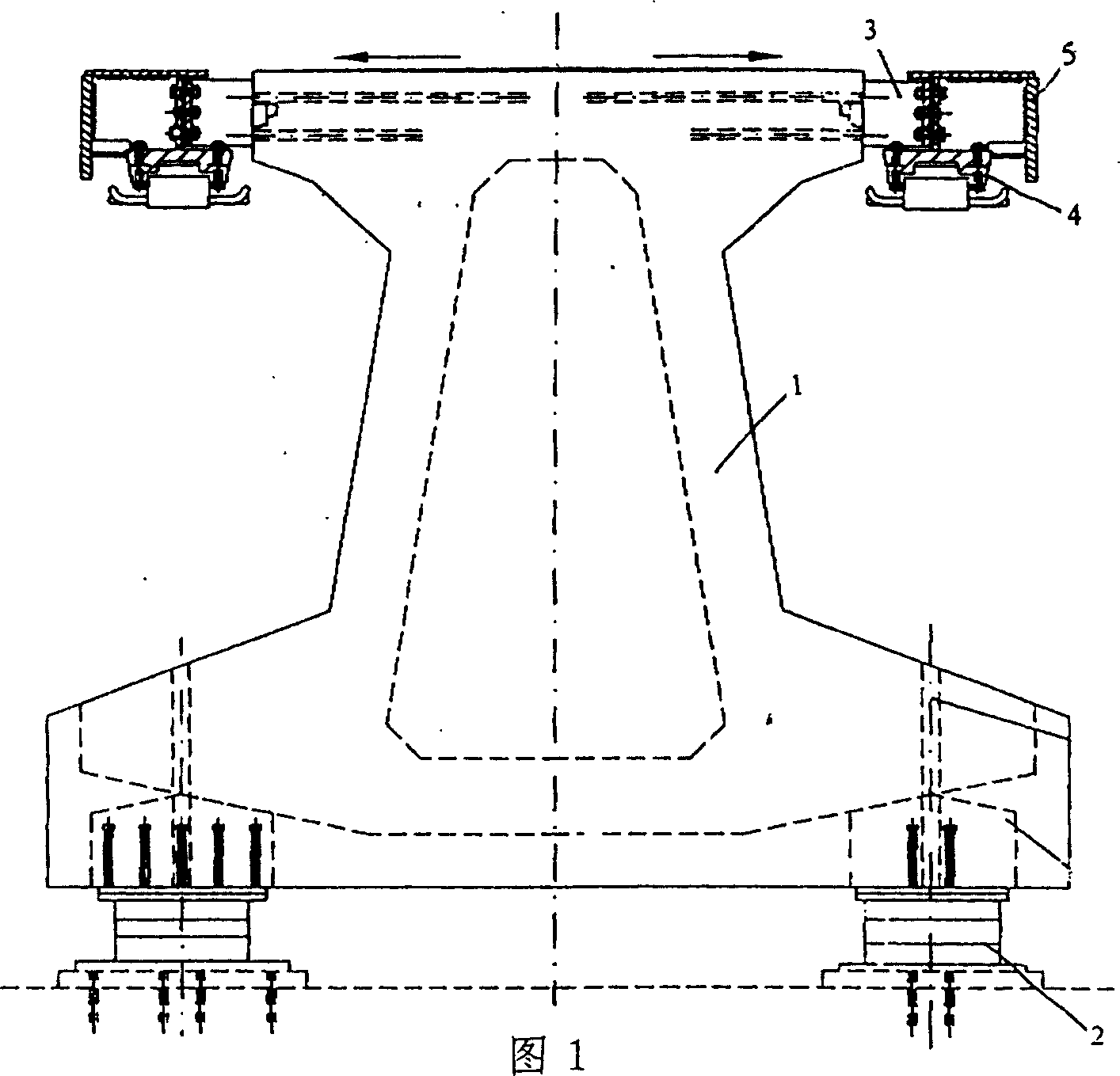

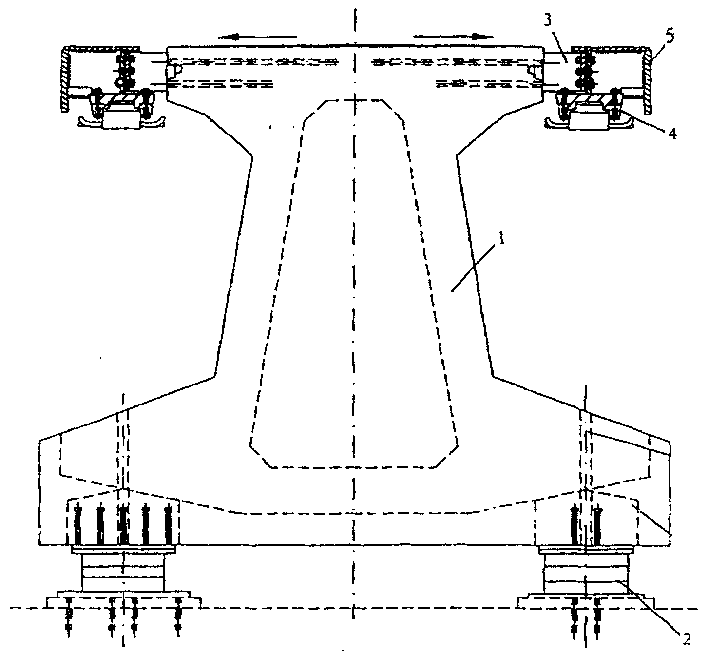

[0030] Referring to Fig. 1 , there is a support 2 at the lower end of the beam body 1, and a connecting part 3, a stator 4 and a functional part 5 at the upper part.

[0031] The manufacturing method technological process of present embodiment track girder is:

[0032] Raw material inspection→steel bar processing→steel bar binding→bottom mold cleaning and support adjustment and positioning→steel bar skeleton hoisting and loading into molds→end mold installation→installation of connectors→installation and adjustment of side formwork→connection of connectors and linear adjustment device→beam upper flange Measurement and positioning of alignment and connectors → flange plate reinforcement binding → pre-tensioned prestressed construction → re-measurement and adjustment of the upper flange alignment of the beam body and connectors → concrete mixing → concrete pouring and pounding → static stop for 6 to 8 hours → alignment of the track beam top Concrete plastering on the surface → c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com