Patents

Literature

55results about How to "Solve the problem of partial load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

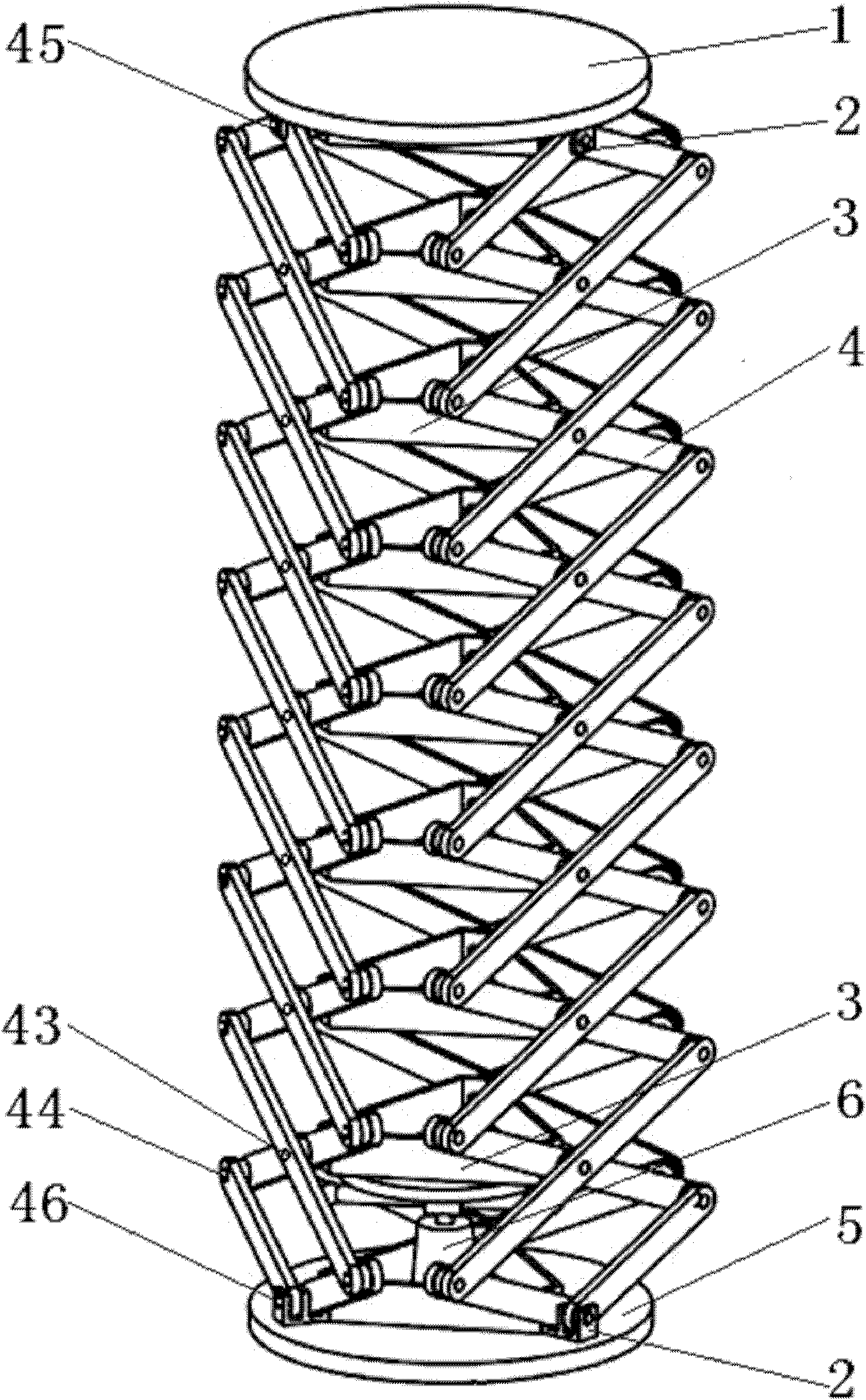

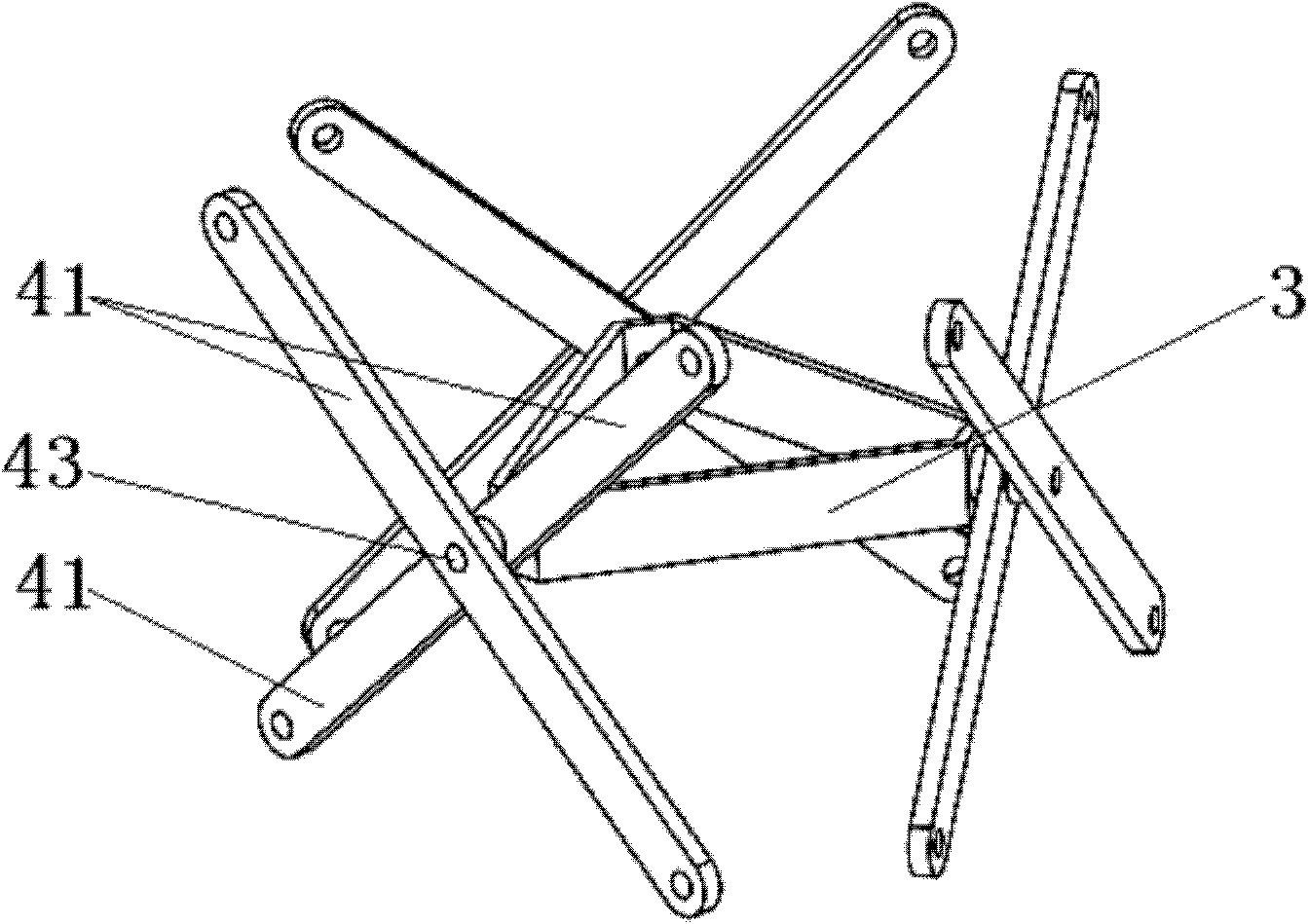

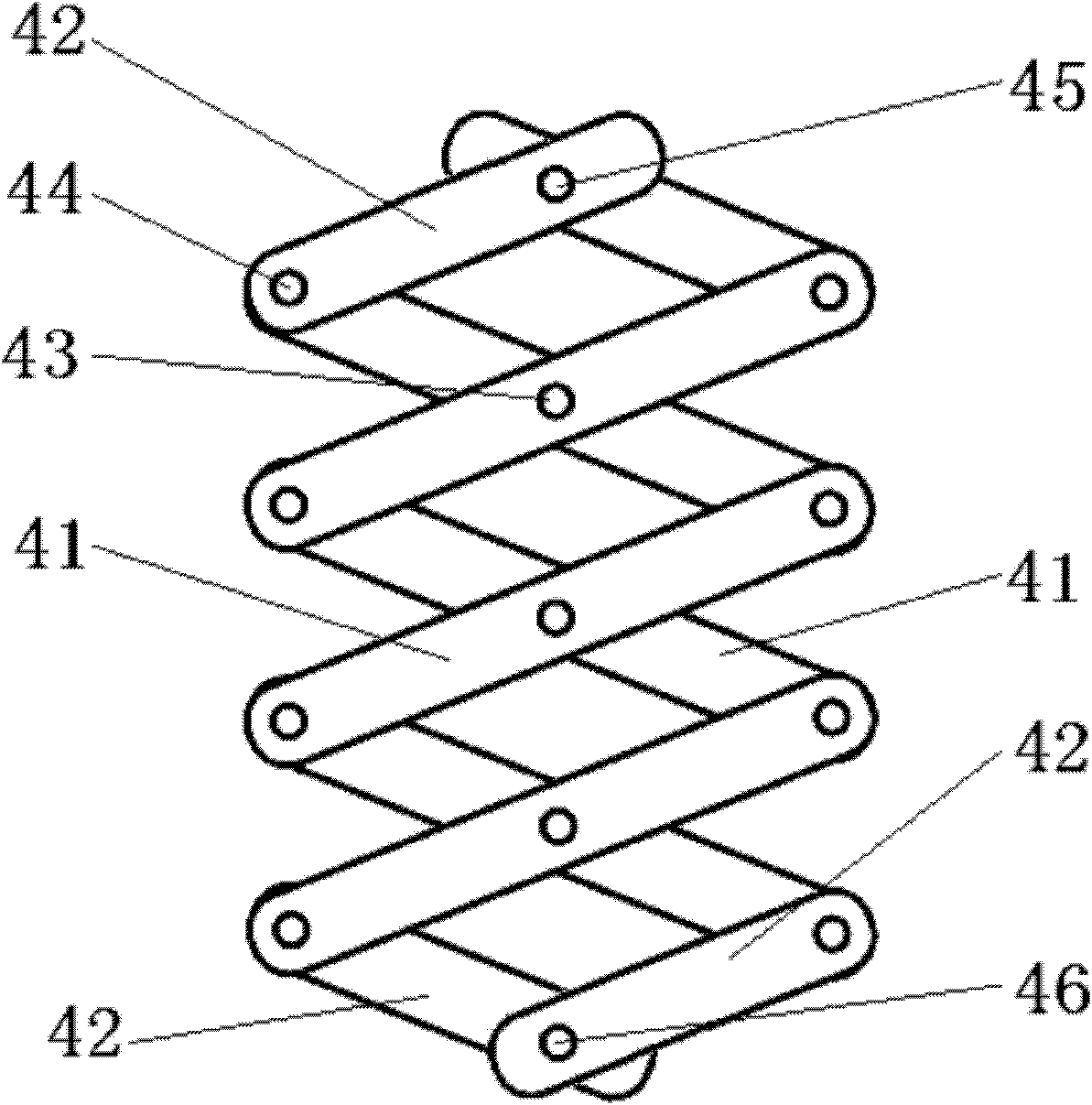

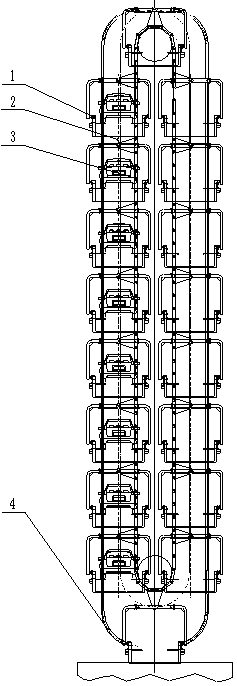

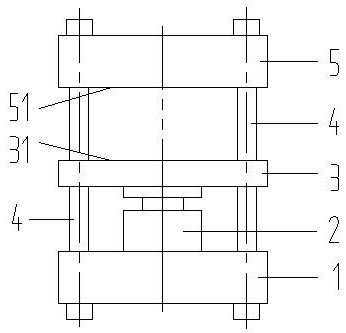

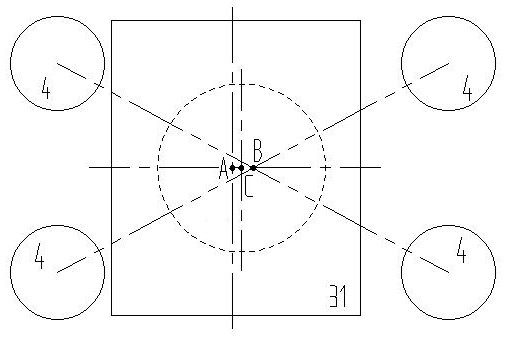

Pivot fixed multi-face constrained scissor-type lifting mechanism

ActiveCN102180427AImprove overall stabilityIncreased stiffness and stabilityLifting framesTriangular prismEngineering

The invention belongs to the field of lifting equipment, and in particular relates to a pivot fixed multi-face constrained scissor-type lifting mechanism. Three groups of scissor-type trusses are vertical to a base; the bottom ends of the three groups of scissor-type trusses are connected with three epsilon-type connecting pieces which are fixed on the base in a regular triangle manner respectively so as to form rotation pairs, and the top ends of the three groups of scissor-type trusses are connected with three epsilon-type connecting pieces which are fixed on the lower plane of a supportingplatform in the regular triangle manner respectively so as to form rotation pairs; the three groups of scissor-type trusses are in regularly triangular prism arrangement between the supporting platform and the base; an angle between the plane on which each group of scissor-type truss is placed and the plane on which the adjacent scissor-type truss is placed is 60 degrees; among the three groups of scissor-type trusses, central hinging points of crossed connecting rods of scissor layers are connected with the corresponding peaks of the regularly triangular connecting pieces so as to form rotation pairs; and a driving device supports the regularly triangular connecting piece of the first scissor layer on the base so as to drive the whole lifting mechanism to lift. The pivot fixed multi-faceconstrained scissor-type lifting mechanism has a stable structure and high rigidity, and is applicable to environments having requirements such as large loading capacity, working height and the like which cannot be met by general lifting equipment.

Owner:TSINGHUA UNIV

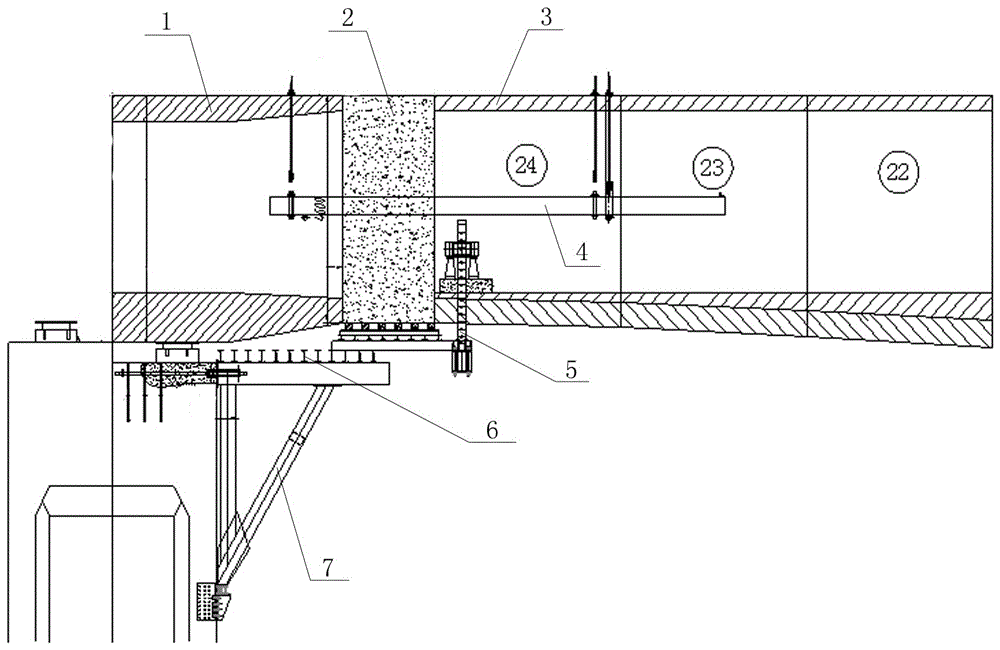

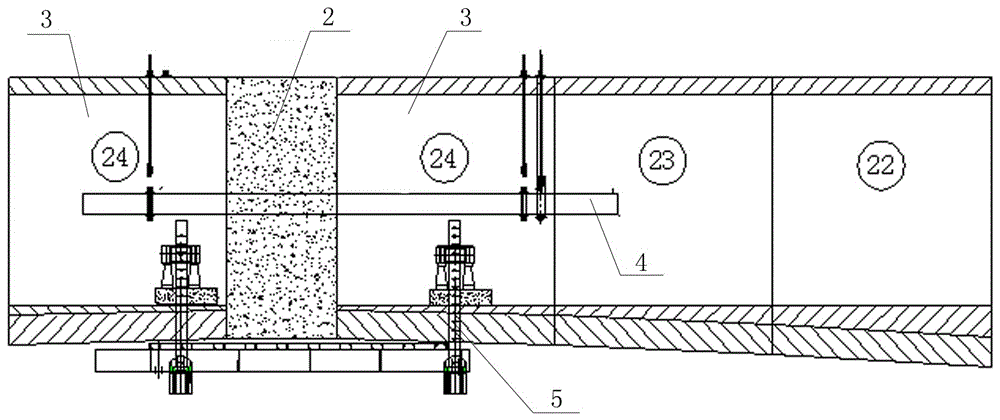

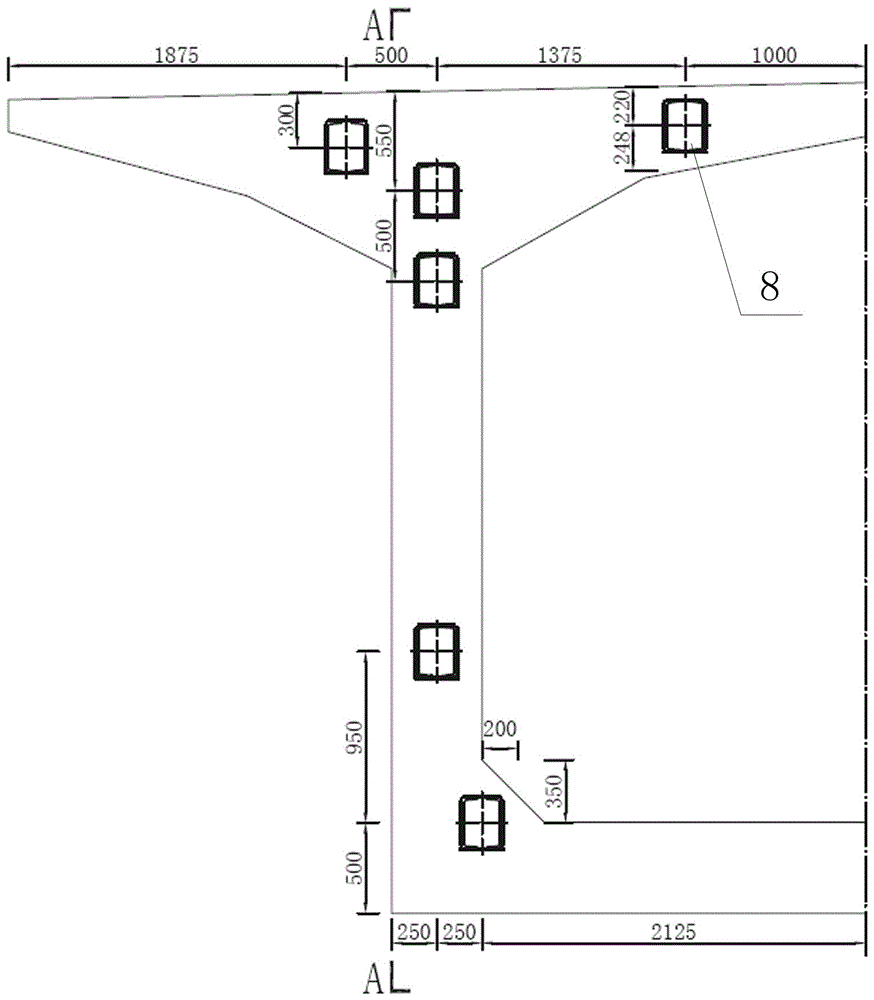

Construction method for joint section of continuous rigid frame aqueduct

ActiveCN106284080ASolve cantilever beam eccentric loadConducive to load distribution uniformityBridge erection/assemblyBridge materialsRigid frameCantilever

The invention belongs to the technical field of the construction of continuous rigid frame aqueducts, and particularly relates to a construction method for a joint section of a continuous rigid frame aqueduct. In order to solve the problems that because water flows through the continuous rigid frame aqueduct, integral force of the continuous rigid frame aqueduct is higher than that of a highway bridge or a railway bridge, so that the continuous rigid frame aqueduct cannot be constructed by a conventional joint method, the invention further provides the construction method of the joint section of the continuous rigid frame aqueduct. The construction method comprises the following steps of performing side span joint construction and a middle span joint construction, wherein side span joint construction is firstly performed, and then the middle span joint construction is performed; and before the joint construction, disassembling a hanging basket module and performing construction by a hoisting frame, wherein the joint construction process comprises the following steps of mounting the hanging basket, mounting a joint section module, performing strengthening framework construction, performing concrete construction, performing prestress construction and performing mud jacking. According to the construction method disclosed by the invention, a conventional hanging bracket construction method is changed, before the joint construction, the hanging bracket module is disassembled and the hoisting frame is mounted, so that the problem of offset loading of a cantilever beam caused by gravity of the hanging basket is solved, the operation of the joint construction is facilitated, and the bearing distribution uniformity of the joint section is improved.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY +1

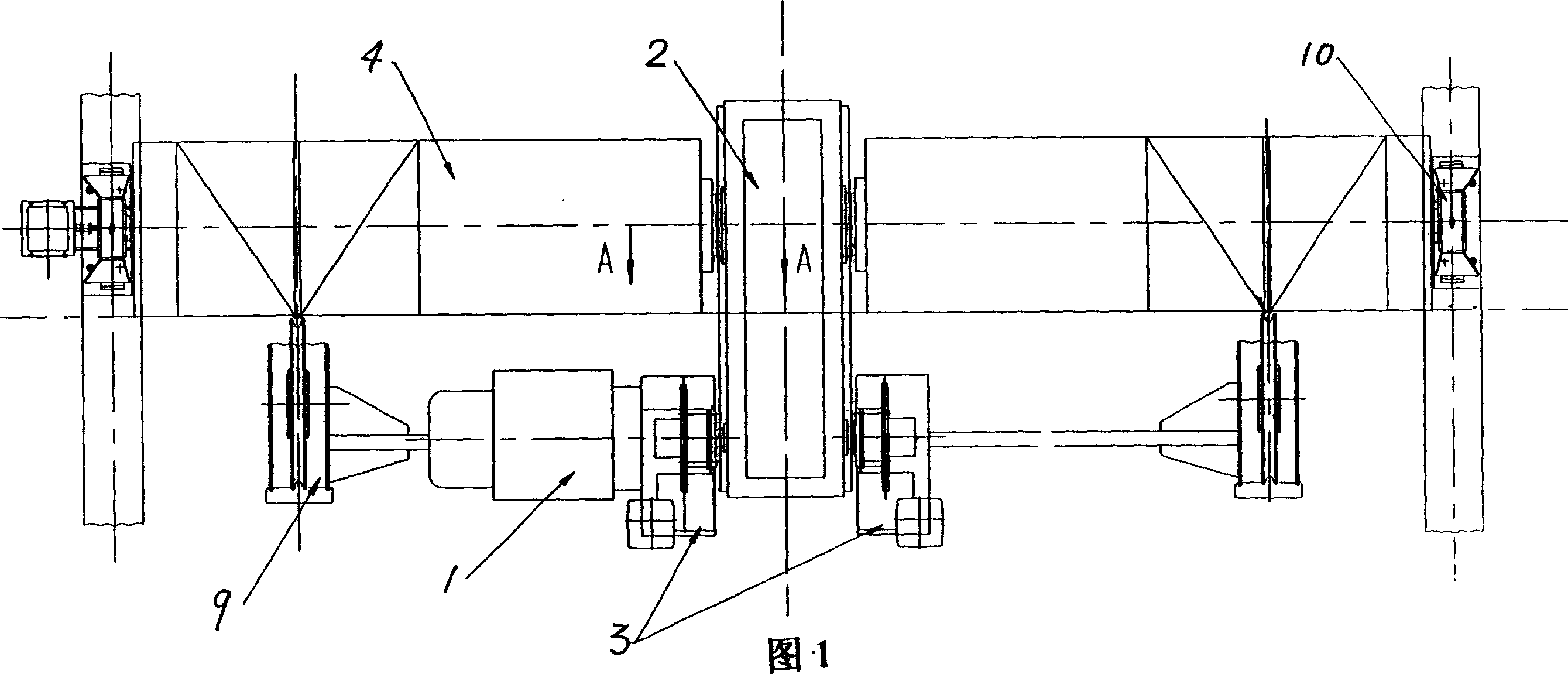

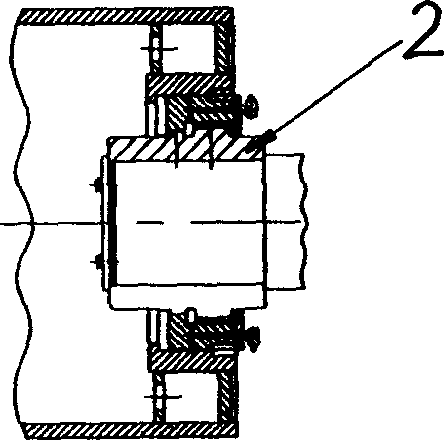

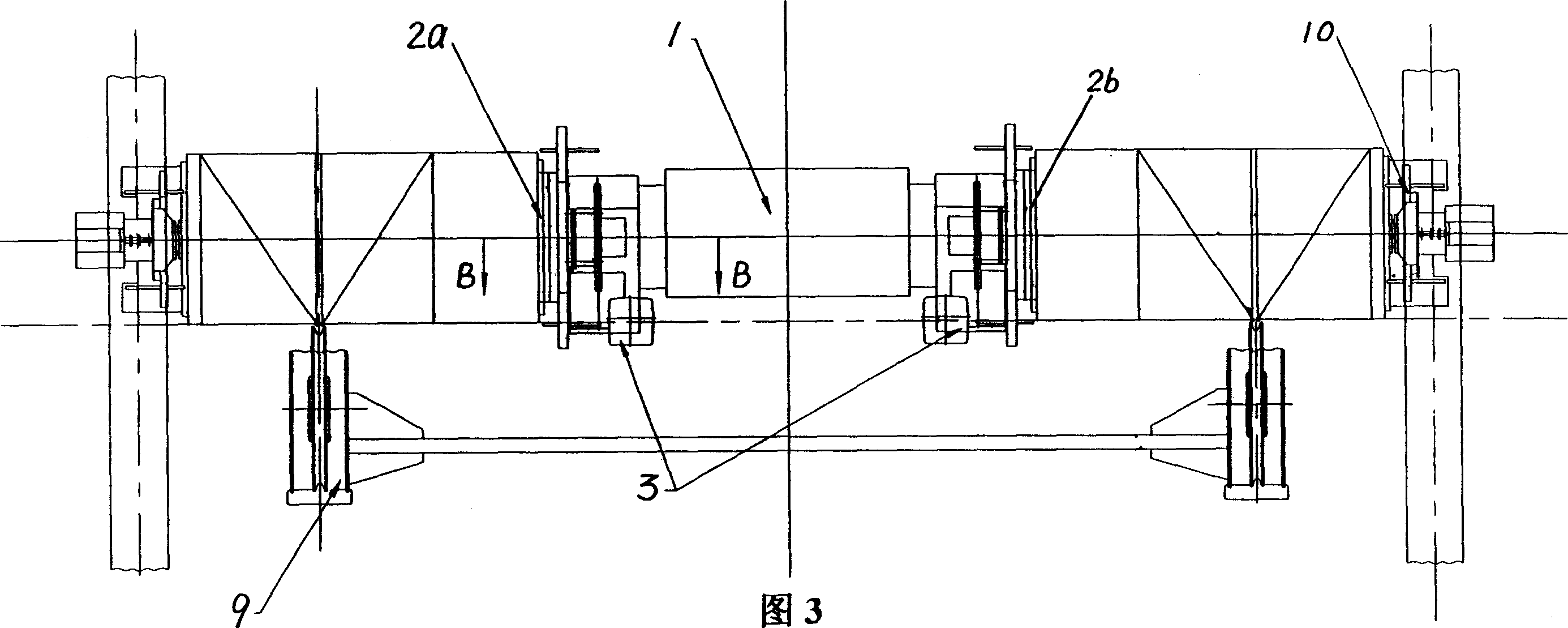

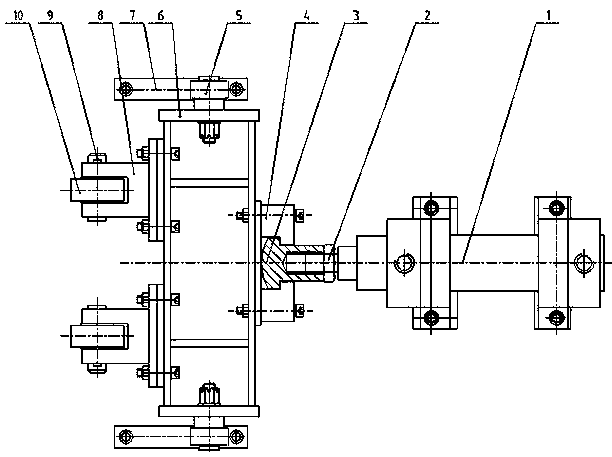

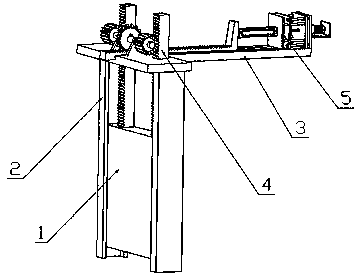

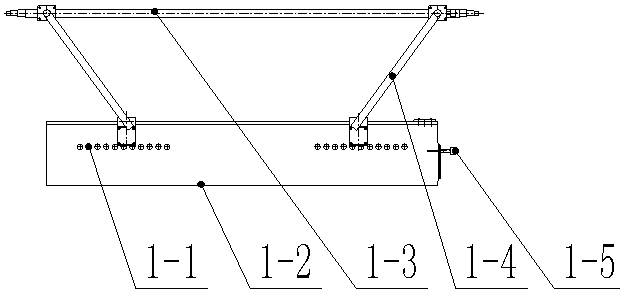

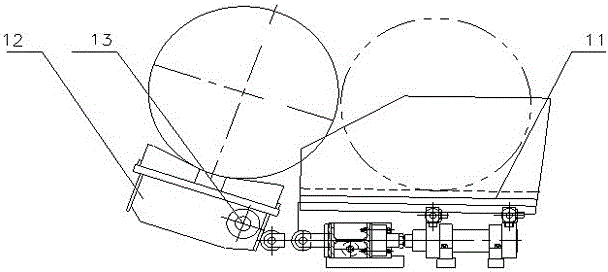

Lifting mechanism for storage yard container crane

InactiveCN1840463ASolve the problem of partial loadUniform weightWinding mechanismsVehicle frameReduction drive

The invention discloses a yard container crane heize device, which is characterized by the following: the double side of the heize device installs two cable drums connect to the decelerator; the central bearing of the two cable drums are fixed on both extremities of supporting rack; the armored rope on the surface of cable drum is the symmetrical double end arrangement; the lower part of the two cable drums (4,5) installs sling boarding or sling; two blocks are installed on the sling boarding or the two extremities of the sling; the double armored rope on the surface of cable drum cross the corresponding block directly; the whole device is placed in the middle of the small car frames, which uses the sling central lines as baseline; the armored rope crosses from the small car frame to sling top sheave; the motor activation decelerator takes the sling up and down by armored rope twisting on the double-drum. The invention improves the mechanical efficiency of the whole device, which reduces the cost.

Owner:SHANGHAI PORT MACHINERY HEAVY IND

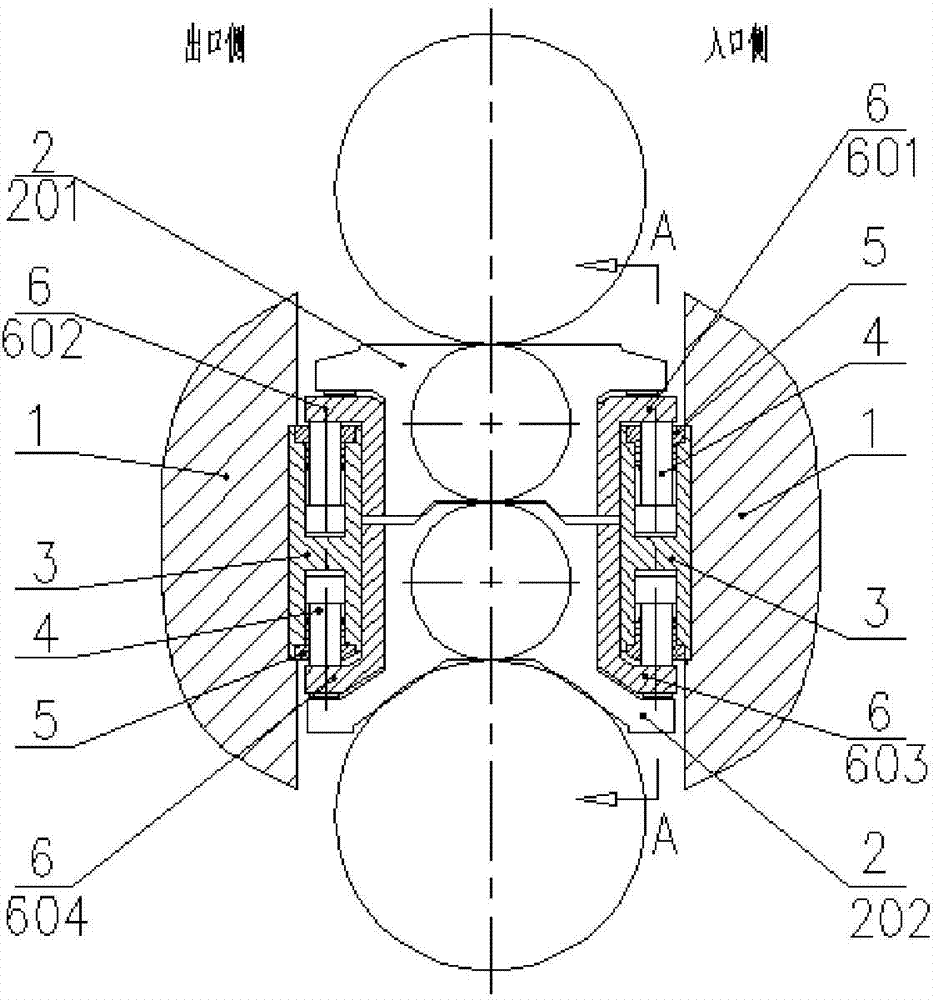

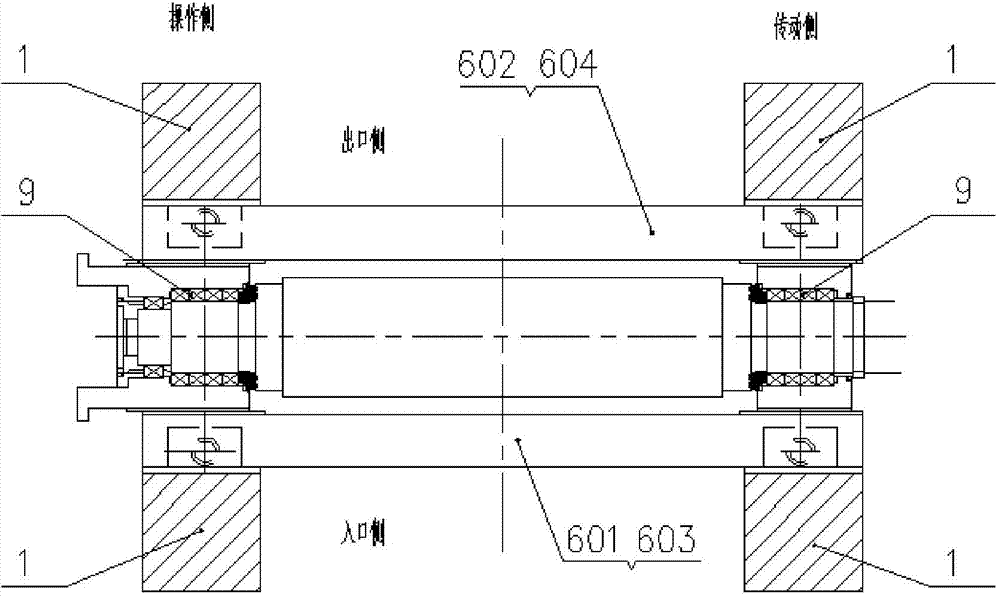

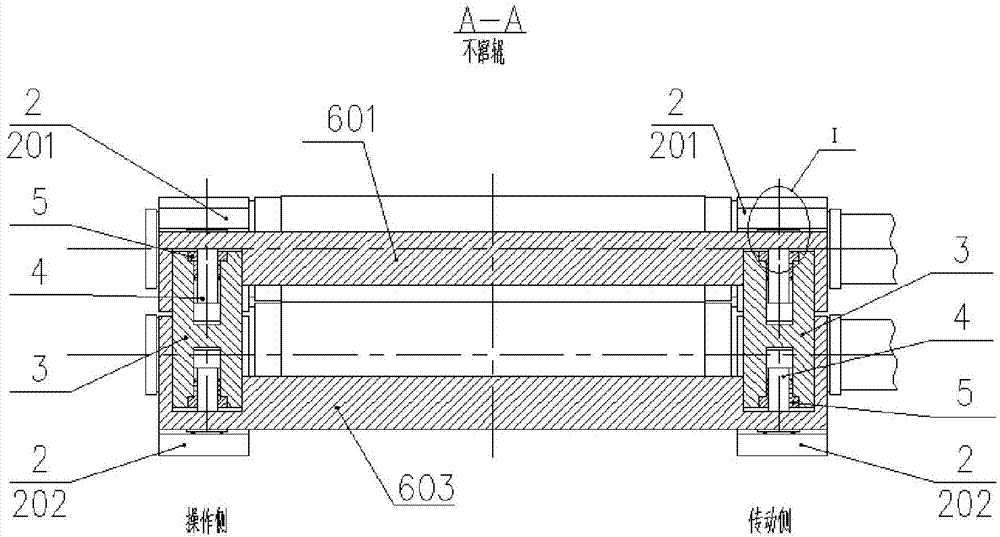

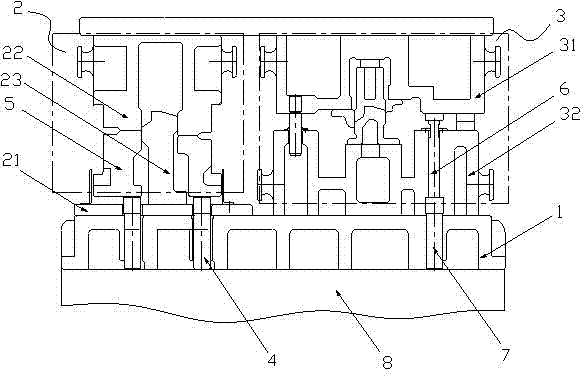

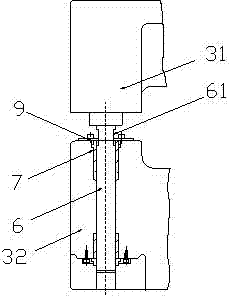

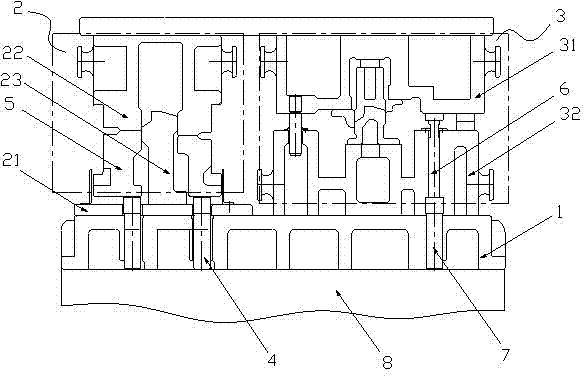

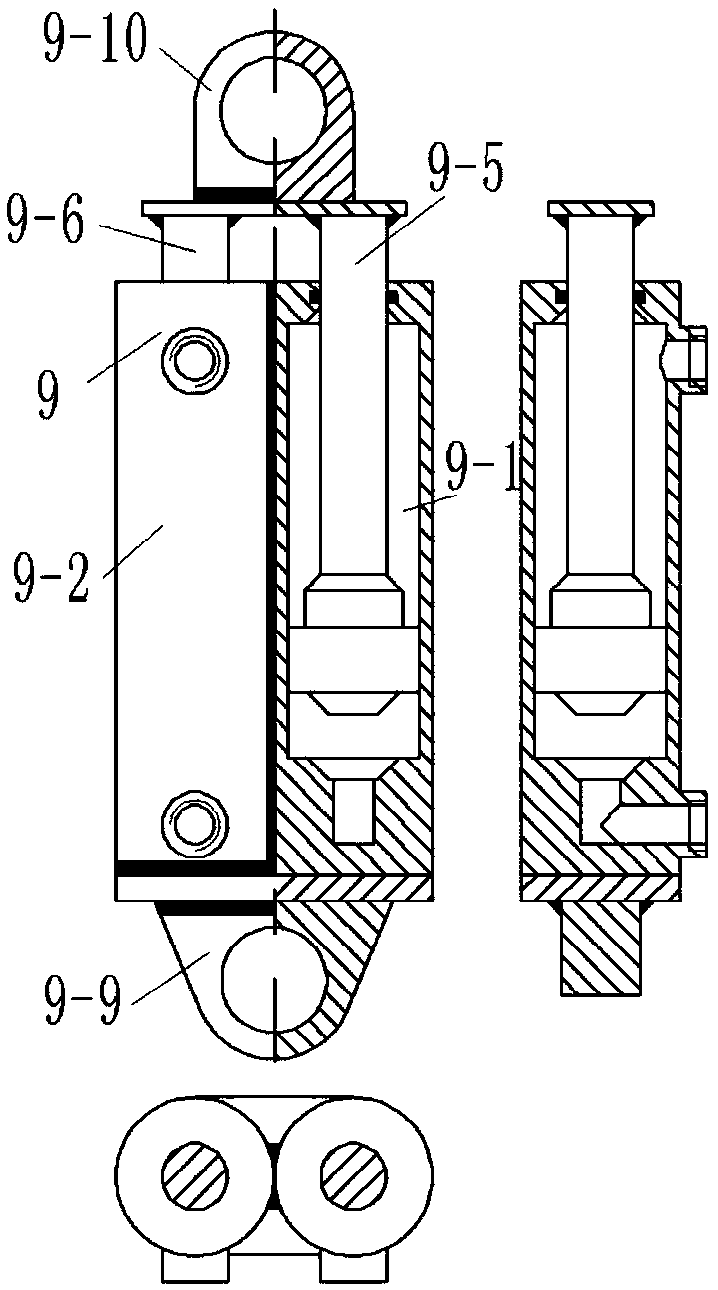

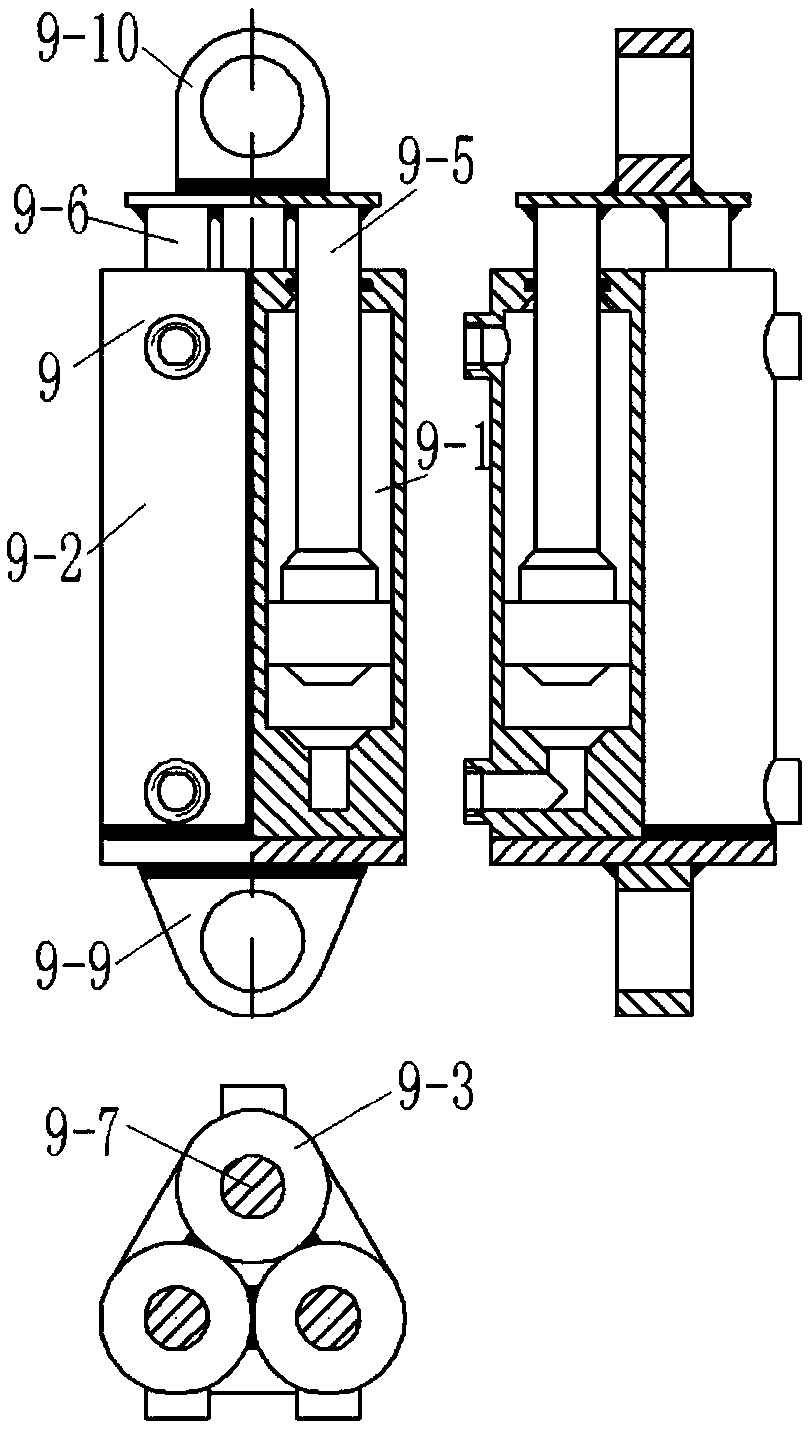

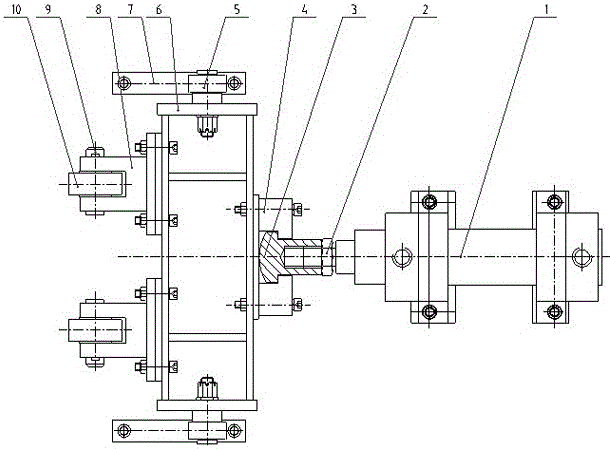

Working roller bending device for double-roller rolling machine and roller bending force control method

ActiveCN104741385AReduce maintenanceReduce in quantityMetal rolling stand detailsRolling equipment maintainenceHydraulic cylinderDifferential pressure

The invention discloses a working roller bending device for a double-roller rolling machine and a roller bending force control method. The rolling machine comprises an arch, a working roller and a supporting roller. The roller bending device comprises a roller bending mechanism for supplying a roller bending force to the working roller; the roller bending mechanism is provided with roller bending blocks and a roller bending beam, wherein the roller bending block are fixedly mounted in a window of the arch and symmetrically arranged at two sides of a working roller bearing block; a piston rod and an end cover are arranged at two ends of each roller bending block; the roller bending blocks, the piston rods and the end covers form a roller bending hydraulic cylinder; the piston rods act on the roller bending beam. According to the roller bending device, a fixed single oil cylinder is adopted according to the structure, and micro differential pressure control is performed; compared with the prior art, the roller bending device has the advantages that the capacity is fully utilized, the maintenance points are few, and the quantity of the oil cylinders is decreased.

Owner:CISDI ENG CO LTD

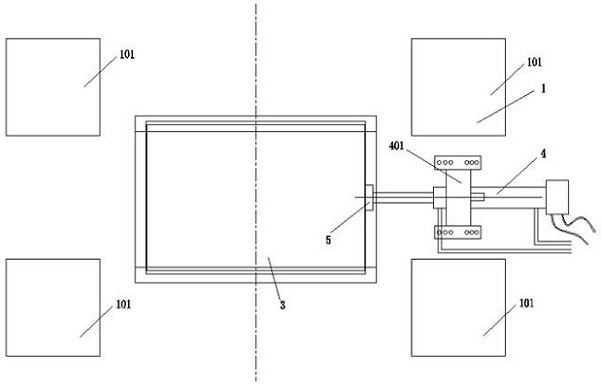

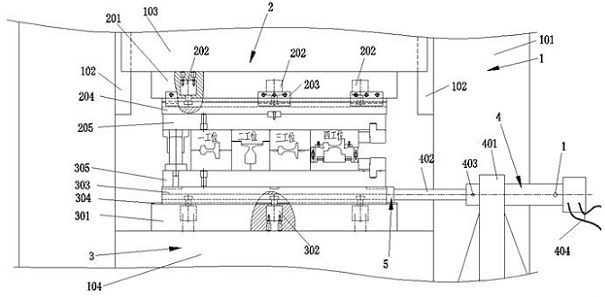

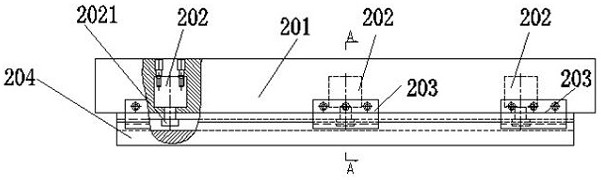

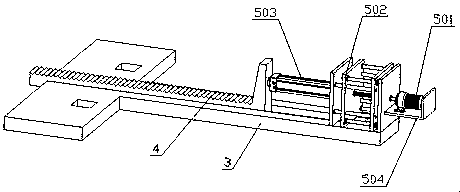

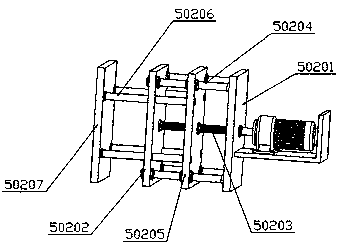

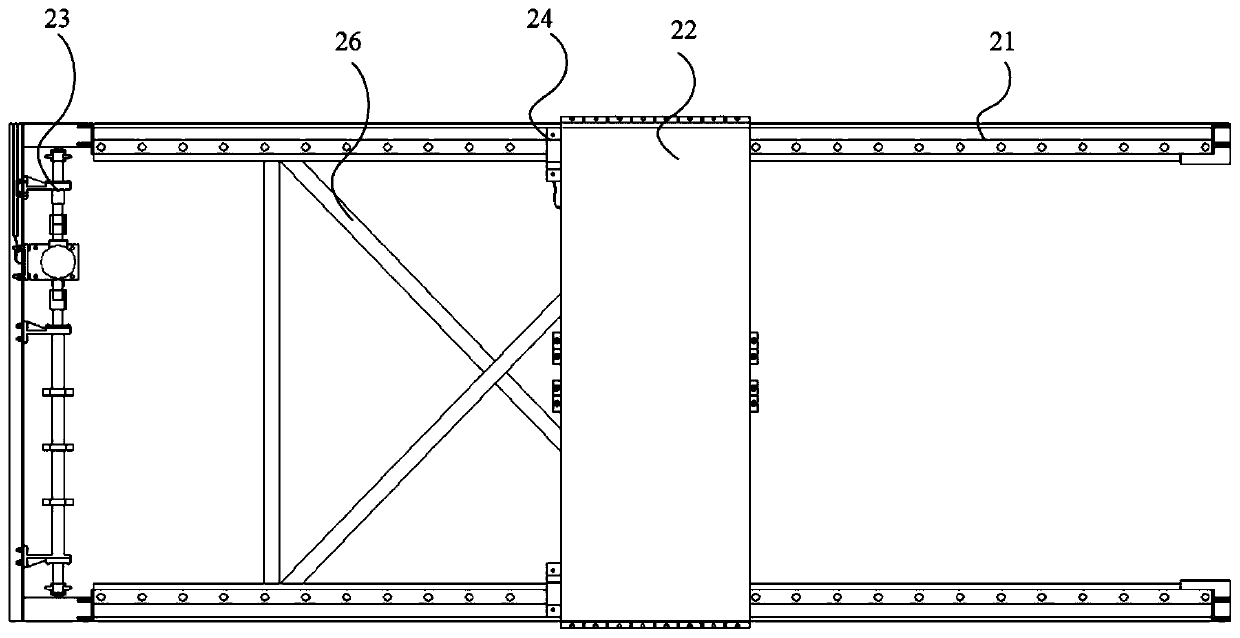

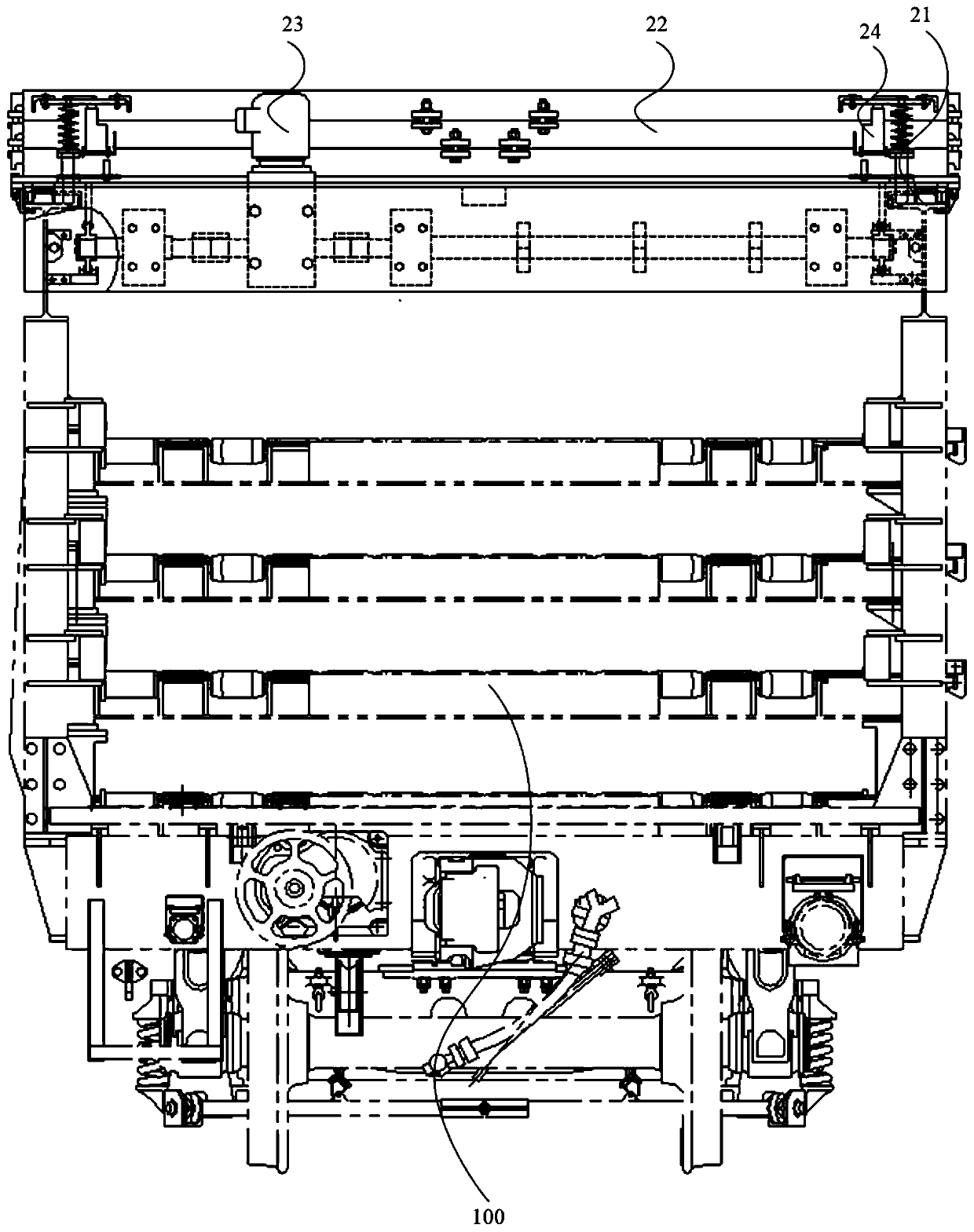

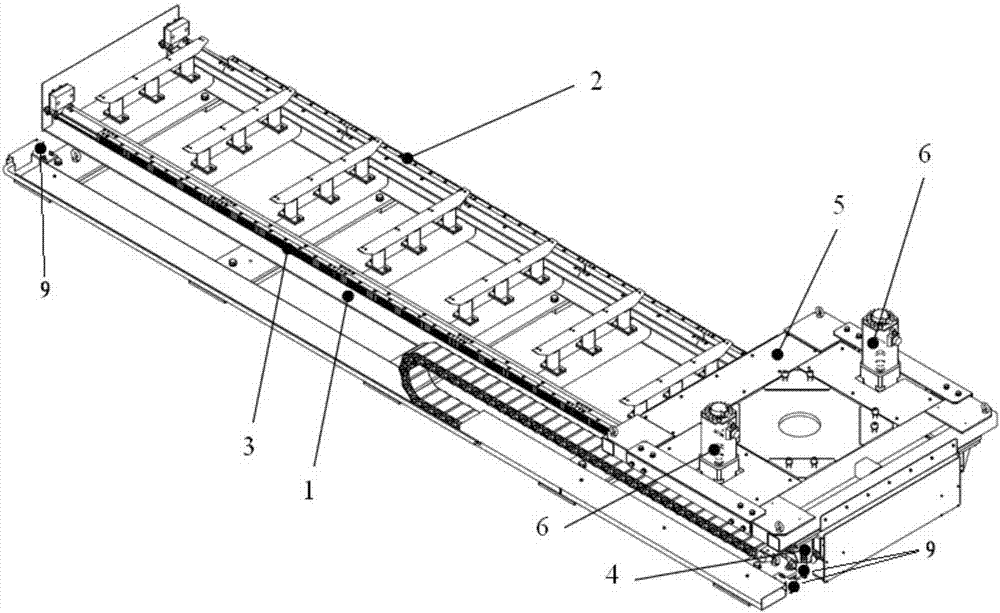

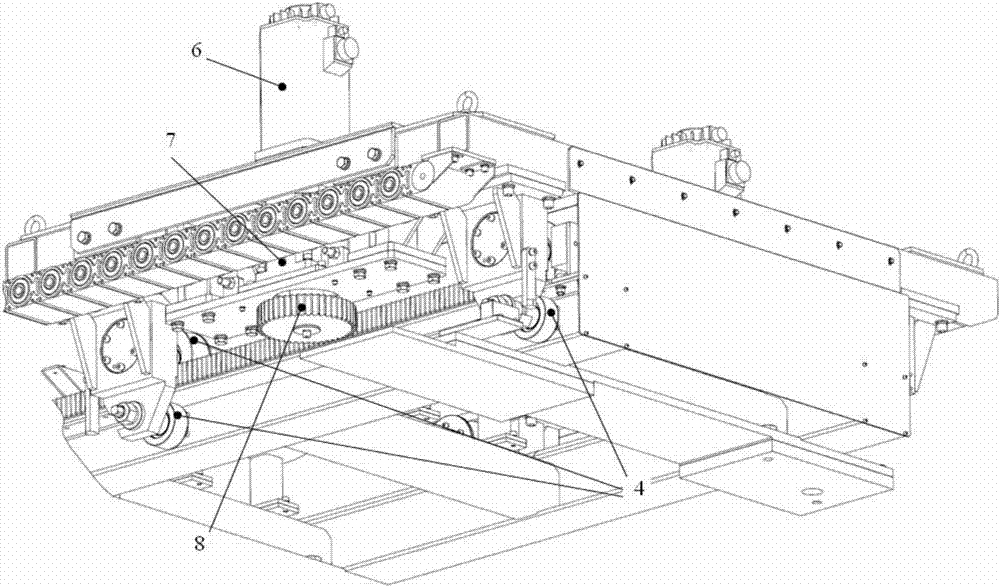

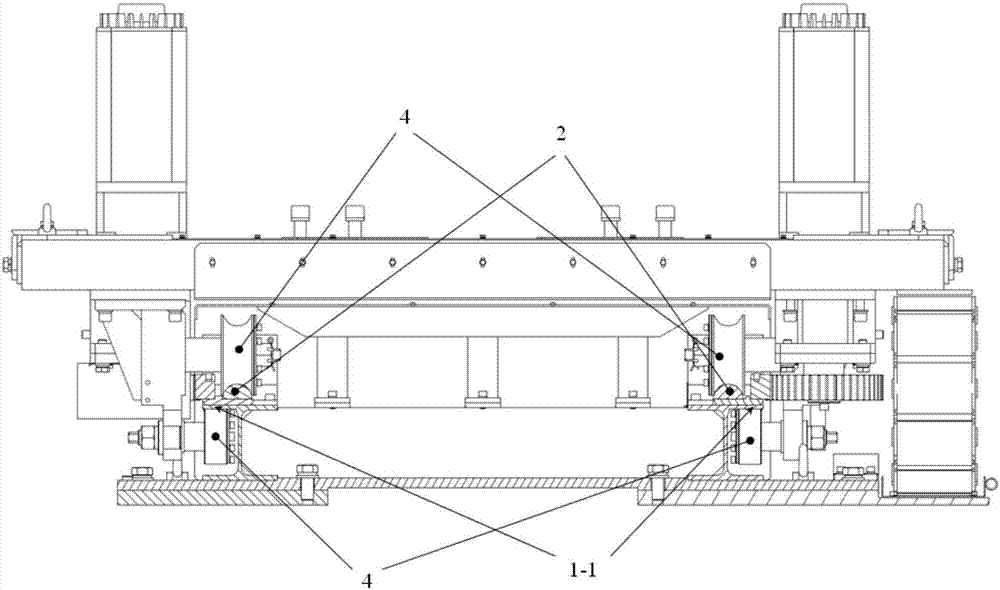

Transverse rapid die changing method and device for multi-station die

PendingCN112742972ASolve the problem of partial loadSolve the service lifeShaping toolsSlide plateMachine

The invention provides a transverse rapid die changing method and device for a multi-station die. The method comprises the following steps that S1, an upper die and a lower die are opened; S2, a press machine sliding block falls down; S3, an upper clamping oil cylinder and a lower clamping oil cylinder are loosened; S4, an upper sliding plate, the upper die, the lower die and a lower sliding plate are connected into a whole; S5, a transverse die changing servo oil cylinder is dragged to a preset position to stop; S6, the upper die and the lower die are replaced with new upper dies and new lower dies; S7, the transverse die changing servo oil cylinder extends and resets; S8, the upper clamping oil cylinder and the lower clamping oil cylinder are clamped in place; and S9, the press machine sliding block moves upwards to a working station, and die changing is completed. According to the method and the device, the problem of unbalance loading of a press machine and the problem of out-of-tolerance caused by insufficient pressure can be effectively solved, and meanwhile, the die changing efficiency is improved.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

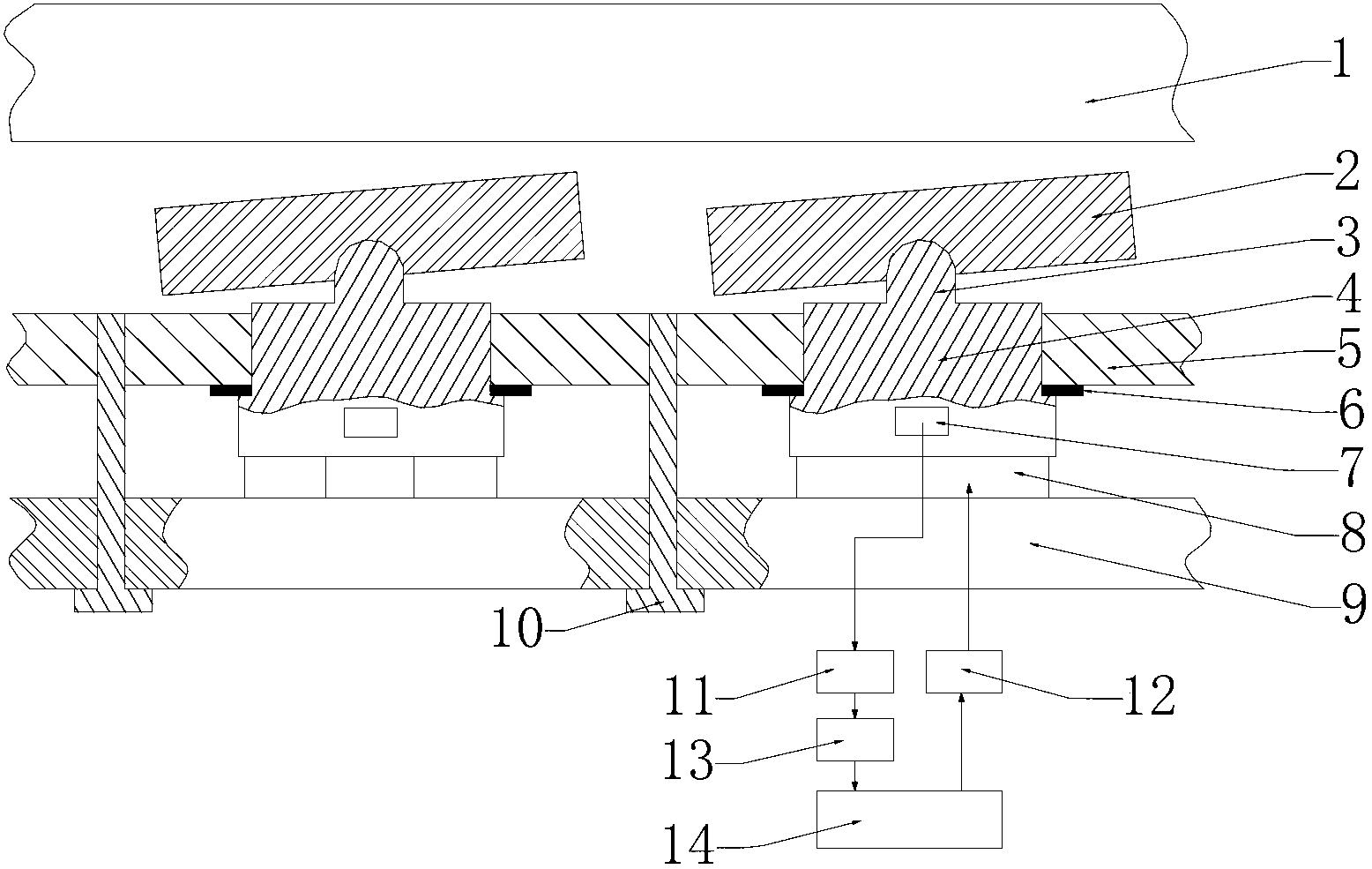

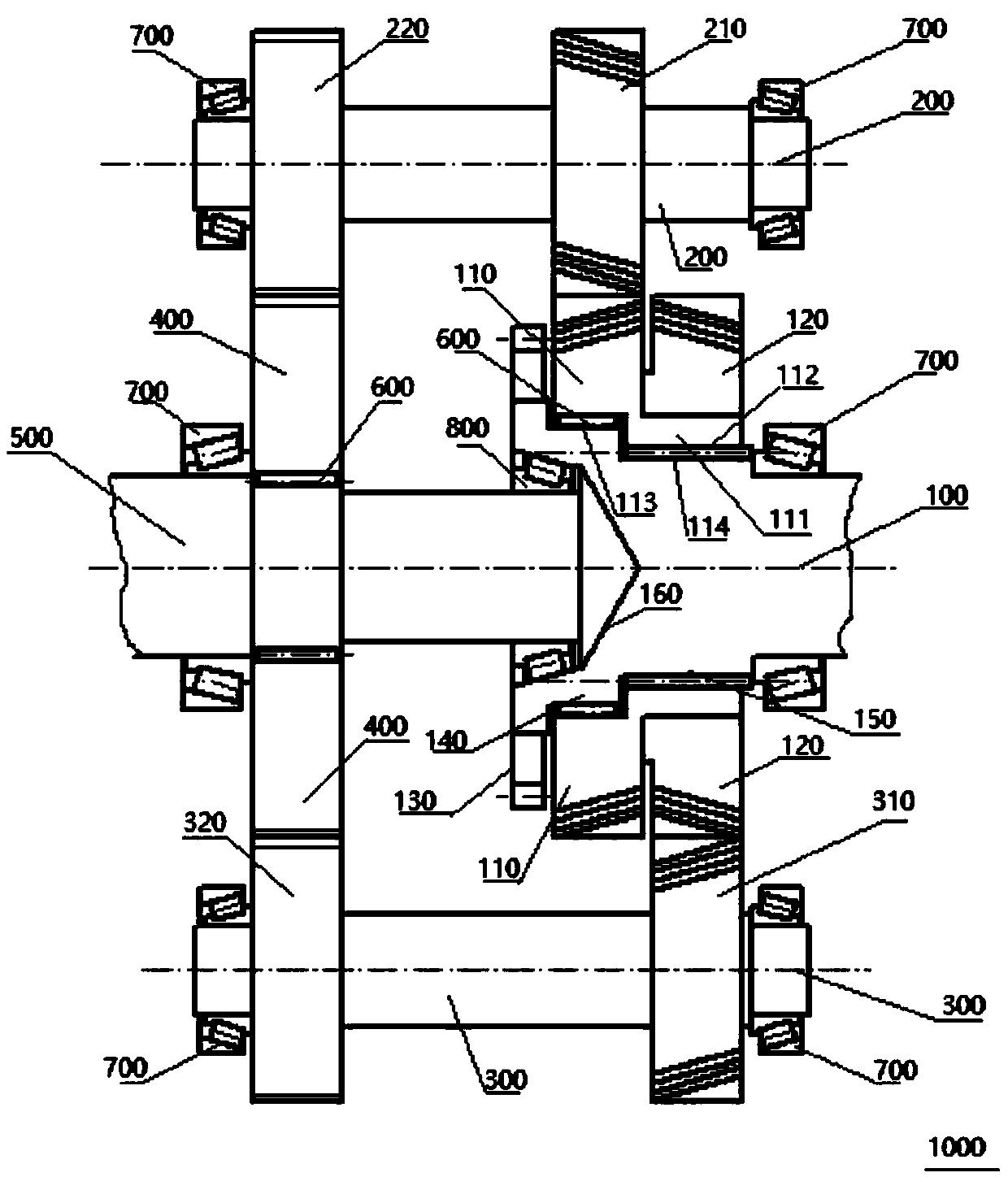

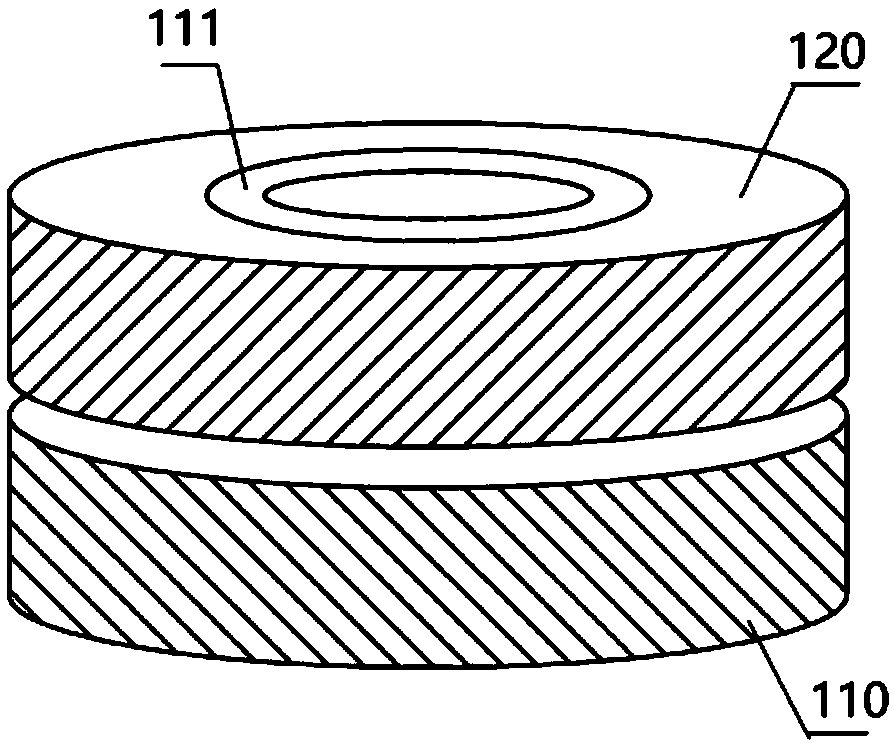

Intelligent tilting pad thrust bearing device

InactiveCN103075421ASimple structureEasy to installSliding contact bearingsEngine lubricationNegative feedbackSignal conditioning circuits

The invention discloses an intelligent tilting pad thrust bearing device, which comprises a thrust disc, pads, jacking blocks, guide discs, rubber washers, piezoelectric ceramic stacks, bolts, a base, strain gauges, a strain signal conditioning circuit, piezoelectric ceramic power supplies, an AD (Analog-Digital) converter and a controller, wherein the controller is matched with the AD converter and the strain gauges for measuring bearing capacity of the pads, takes the bearing capacity as negative feedback, controls the piezoelectric ceramic stacks to generate micrometric displacement, actively adjusts gaps among the pads and the thrust disc, and changes the thickness of a lubricating film. The device is simple in structure, easy to mount and convenient to control, can timely find and quickly solve the problem of unbalance loading of a tilting pad thrust bearing, and can prolong the life of the tilting pad thrust bearing greatly.

Owner:XI AN JIAOTONG UNIV

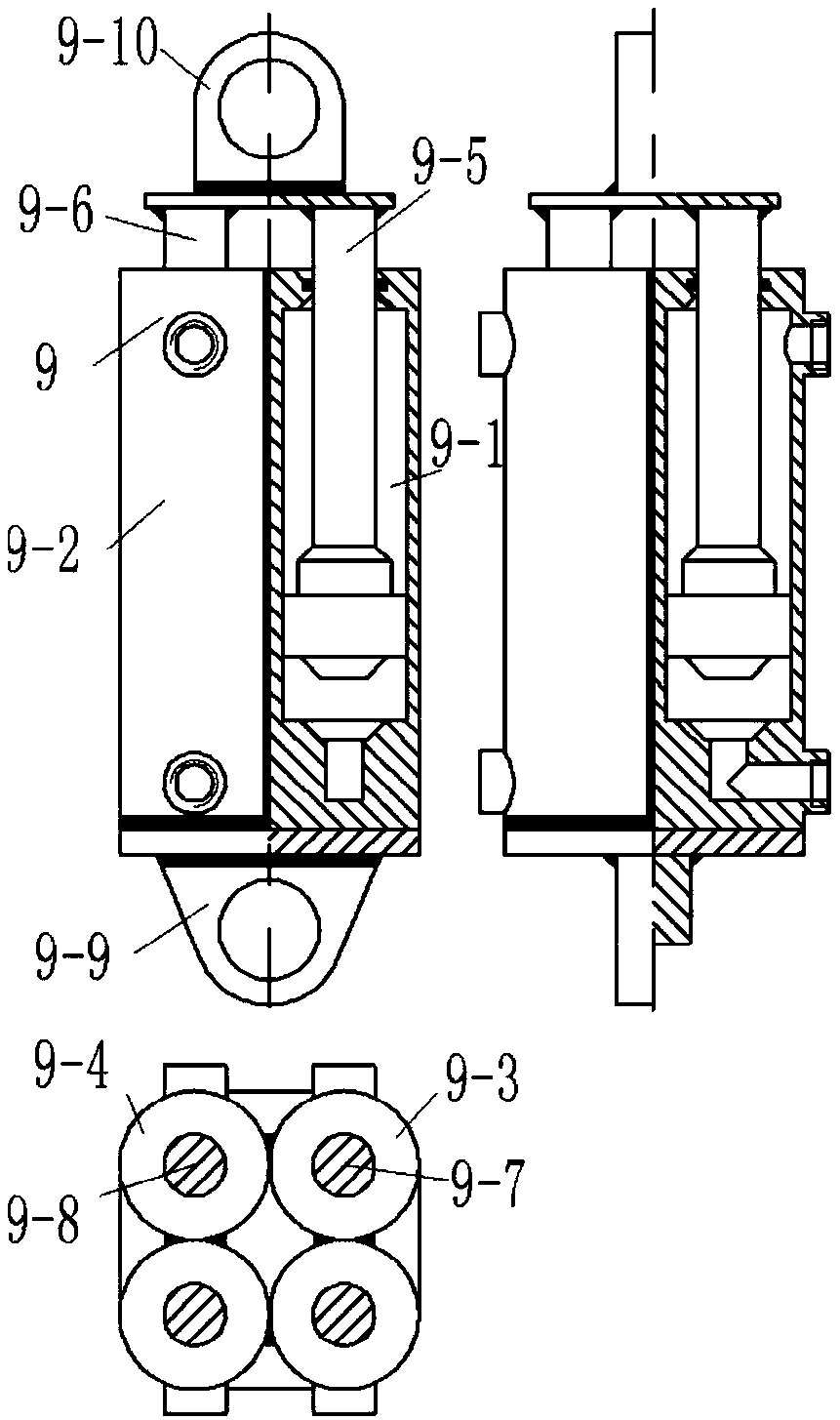

Sleeve uninstalling device

InactiveCN103624105ASolve storage problemsSolve the problem of partial loadHydraulic cylinderProduction rate

The invention relates to a sleeve uninstalling device which is characterized by comprising a hydraulic cylinder, an oil cylinder joint, a clamp plate, first wheels, a frame body, rails, a pedestal, a second wheel, a collecting basket and a trolley bracket, wherein the hydraulic cylinder is fixed, the hydraulic cylinder is connected with the clamp plate through the oil cylinder joint, then the clamp plate is connected with the frame body, the frame body is connected with the pedestal, the first wheels are arranged on both sides of the frame body, the lower ends of the first wheels are provided with the rails, the second wheel is arranged on the pedestal, the collecting basket is arranged on a stand above the hydraulic cylinder, the hydraulic cylinder is arranged on a base plate of the stand, the trolley bracket is fixed on the frame body through a hinge pin, and runs perpendicular to a plane on which the collecting basket is located. The sleeve uninstalling device disclosed by the invention can store sleeves, so that sleeves are not required to be lifted away one by one every time. By using the sleeve uninstalling device disclosed by the invention, sleeves can be stored together, and then are integrally lifted away, so that time and manpower resources are saved, and the productivity of units is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

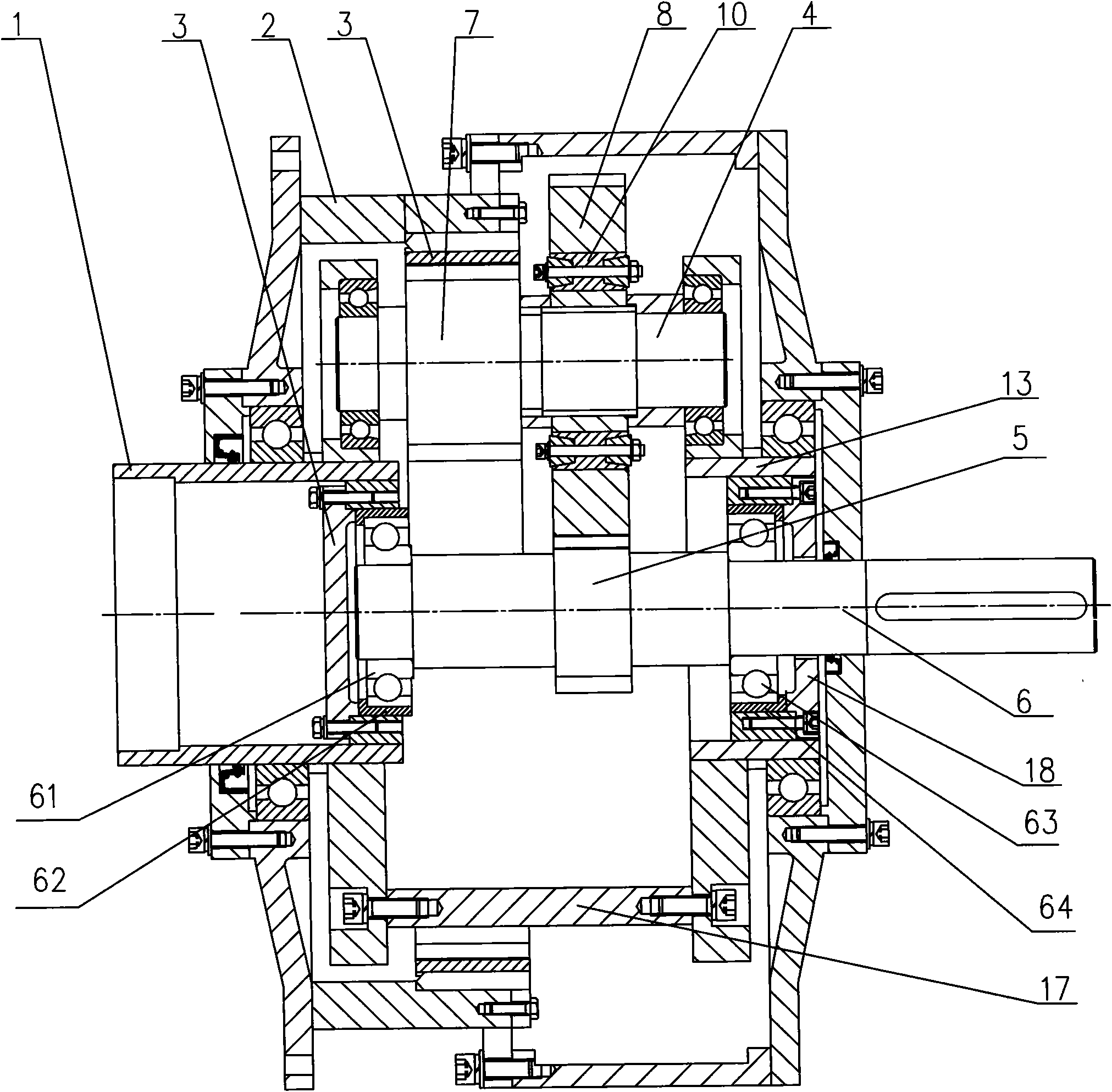

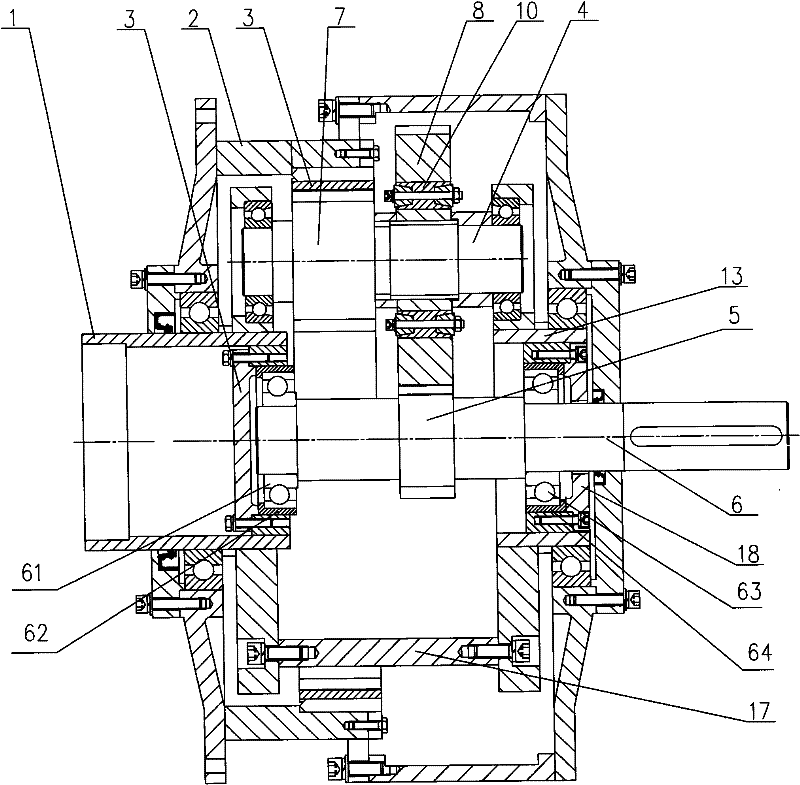

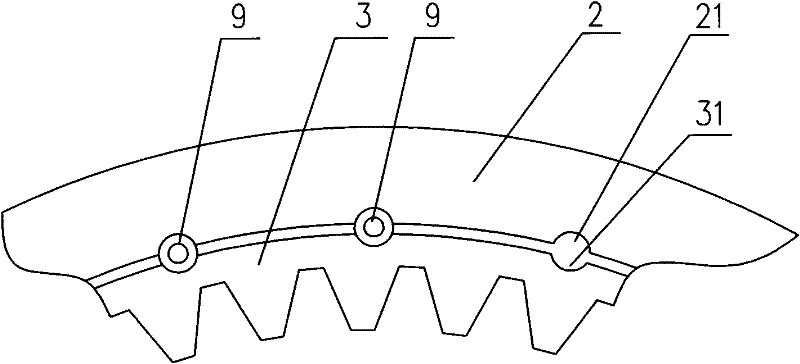

Low-noise planetary gearbox of wind driven generator

InactiveCN101782047ASolve installation difficultiesSolve the problem of partial loadGear vibration/noise dampingToothed gearingsWind drivenWind force

The invention relates to a speed increasing box, in particular to a low-noise planetary gearbox of a wind driven generator, which comprises an input shaft, a box body, an inner gear ring, a planet gear shaft, a center shaft and a planet carrier. The input shaft is fixedly connected with the planet carrier in a coaxial way. More than two planet gear shafts are uniformly distributed on the planet carrier through bearings. A large planetary gear and a small planetary gear are fixedly arranged on the planet gear shaft. The inner gear ring is fixed and arranged inside the box body. The small planetary gear is normally engaged with the inner gear ring. A sun gear is fixed and arranged on the center shaft. The large planetary gear is normally engaged with the sun gear. The input shaft is connected with the box body through the bearing. The outer diameter of the inner gear ring is smaller than the inner diameter of the box body. A plurality of box body pin grooves are uniformly distributed on the inner wall of the box body in the circumferential direction. The outer wall of the inner gear ring is provided with an inner gear ring pin groove. An elastic pin is embedded between the box body pin groove and the inner gear ring pin groove. The low-noise planetary gearbox of the wind driven generator has the advantages of low noise, long service life, strong shock resistance capability and low production and processing difficulty.

Owner:王光顺

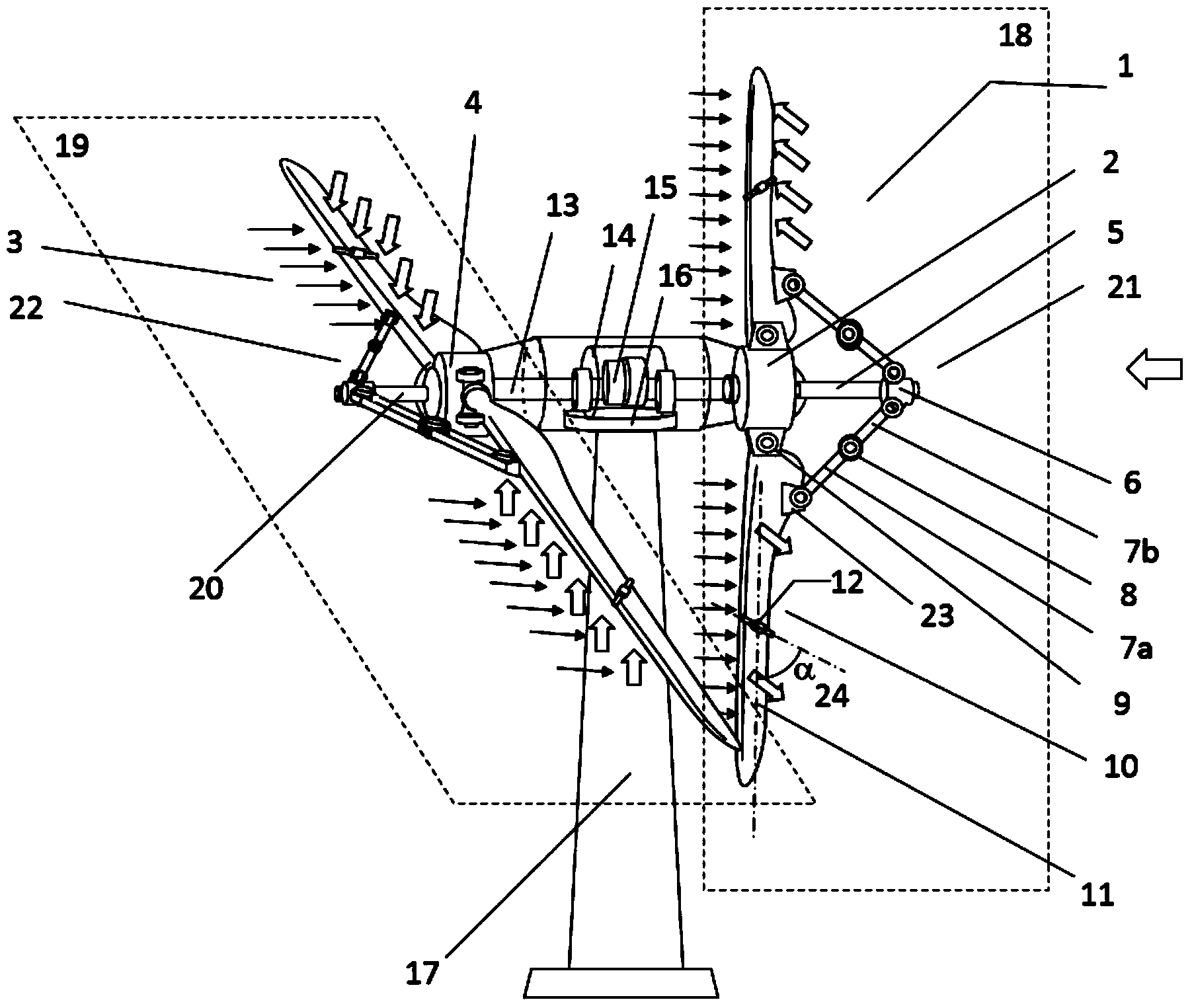

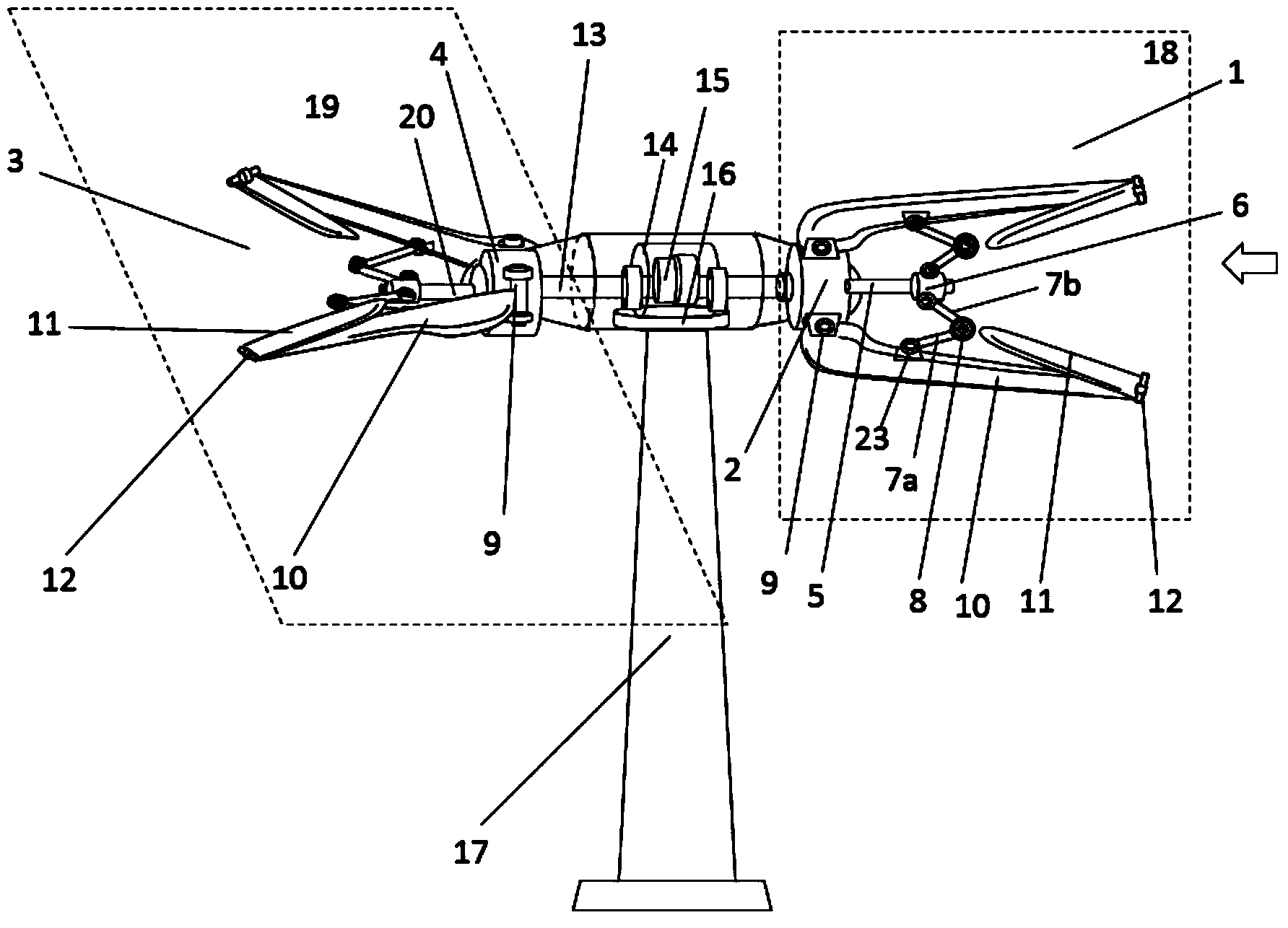

Foldable dual-row coaxial-blade wind driven generator device

InactiveCN104234925AReduce the overall heightImprove securityMachines/enginesWind energy generationElectricityWind driven

The invention discloses a foldable dual-row coaxial-blade wind driven generator device. The foldable dual-row coaxial-blade wind driven generator device comprises two rows of blade assemblies, wherein each row of blade assemblies comprises two two-segment foldable blades and a blade folding device; main blades are fixed-pitch blades; the roots of the main blades are hinged to a wheel hub through lug connecting seats; the other positions of the main blades are connected with the blade folding devices; the two rows of blades are arranged crossly and orthogonally after being unfolded; the foldable blades are oblique foldable blades; the power generation rate can be adjusted; the two rows of blades are positioned on the front part and the back part of a fan tower respectively, are connected to the same main shaft through a front wheel hub and a back wheel hub of a fan, and rotate synchronously in the same direction; the folding and unfolding of the blades can be controlled by folding driving devices. The device provided by the invention has the characteristics of simple structure, balanced stress, realization of complete folding and unfolding of the blades, easiness and convenience in controlling, high power generation efficiency and the like, and is a wind power generation device which is suitable for ship wind power, offshore oil platform wind power and the like.

Owner:TSINGHUA UNIV

Method for balancing loads during mold production

ActiveCN102416421ASolve the unbalanced load of the air cushion of the pressGood protectionShaping toolsMaterials scienceAir cushion

The invention provide a method for balancing loads during mold production, which aims to solve the problem that jointly-mounted mold air cushions are influenced by unilateral loads so as to protect the air cushions of pressing machines and improve the effective using pressure of the pressing machines and the quality stability of workpieces. The method for balancing the loads during mold production comprises the following steps that: a drawing formation mold and a repairing, punching, turning and reshaping mold are arranged on the same operating platform; a binder ring of the drawing formationmold is pressed against an air cushion push rod which passes through the drawing formation mold from bottom to top; in the key point, a balancing rod is arranged between an upper die and a lower die of the repairing, punching, turning and reshaping mold; the bottom of the balancing rod is pressed against a balancing push rod which passes through the lower die of the repairing, punching, turning and reshaping mold from bottom to top; and the air cushion push rod and the balancing push rod have the same travel and are moved synchronously. By the method for balancing the loads during mold production, the problem of unbalanced loading of the air cushions of the pressing machines is effectively solved by using the balancing rod; and the method is extremely high in practicability.

Owner:CHERY AUTOMOBILE CO LTD

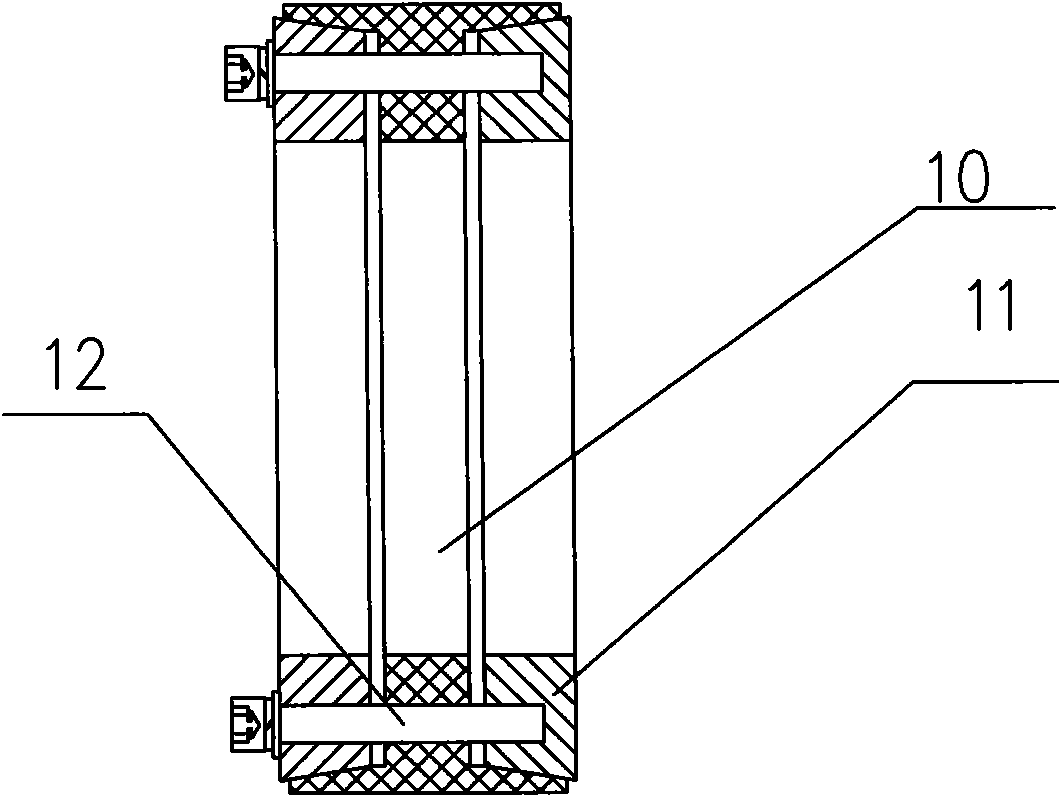

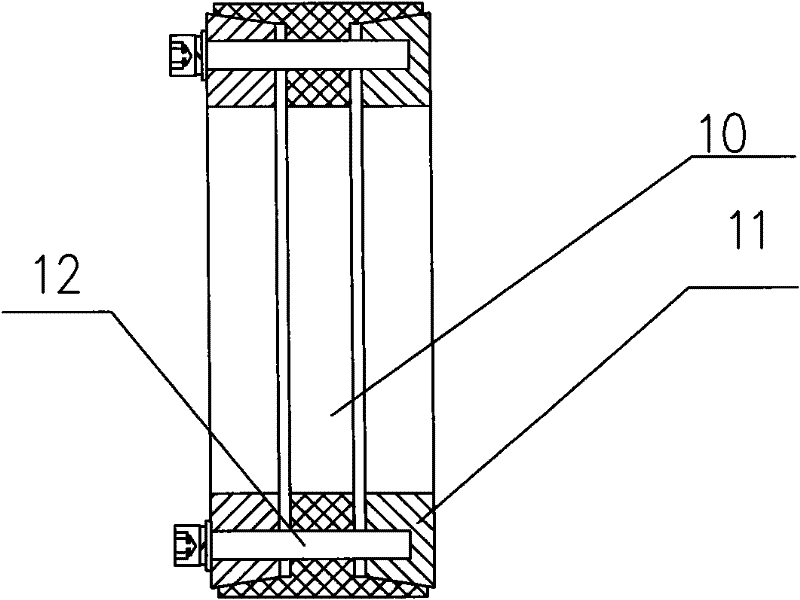

Energy-saving lifting system of combined cylinder

InactiveCN109253120ASolve the problem of partial loadTroubleshoot out-of-sync issuesServomotor componentsServomotorsHydraulic cylinderHigh energy

The invention provides an energy-saving lifting system of a combined cylinder, aiming to solve the problems of eccentric loading and asynchronism in double-cylinder lifting of engineering machinery. The combined cylinder for the system comprises at least two hydraulic cylinders in welding, the hydraulic cylinder bodies are welded, the tops of piston rods of the hydraulic cylinders are welded and share the same lug, rod cavities of the hydraulic cylinders are communicated with each other, and thus, synchronous lifting without eccentric loading of the combined cylinder can be realized. The energy-saving lifting system of the combined cylinder has the advantages of realizing synchronous lifting without eccentric loading, having high energy utilization rate and low cost, needing no pilot oil sources, being simple and reliable, and the like.

Owner:TAIYUAN UNIV OF TECH

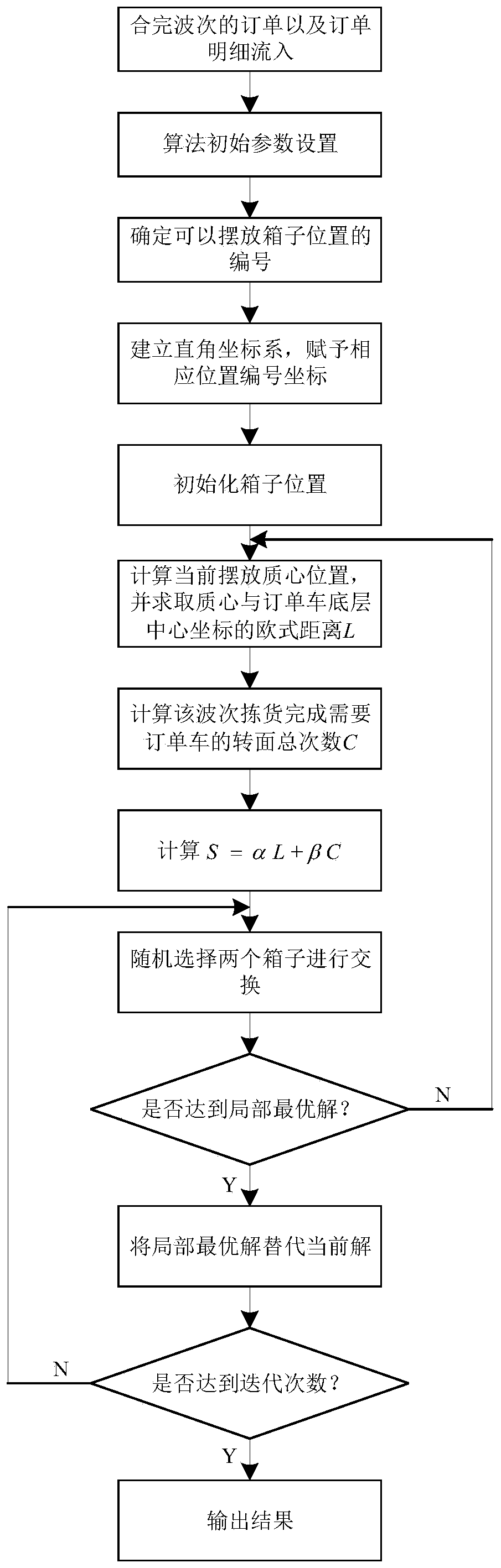

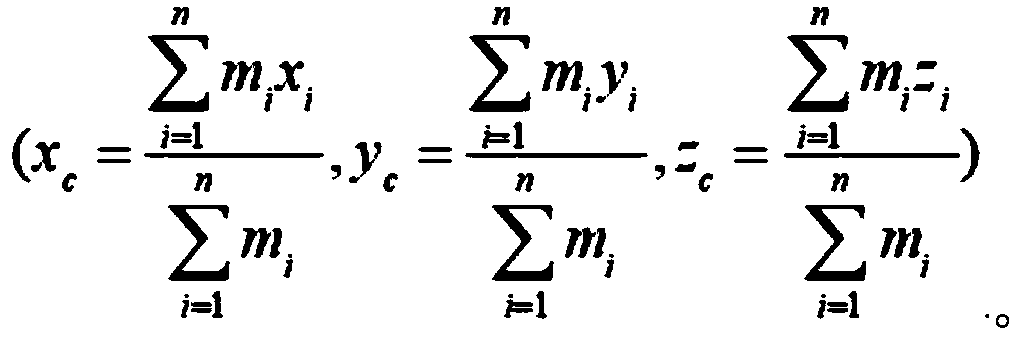

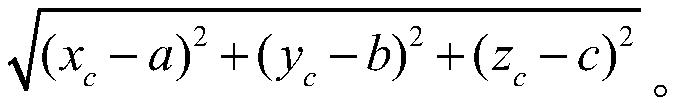

Order vehicle AB surface segmentation algorithm based on hill climbing method

InactiveCN110288158ASolve the problem of partial loadReduce the number of turnsForecastingArtificial lifeLogistics managementComputer science

The invention relates to the technical field of logistics storage, in particular to an order vehicle AB surface segmentation algorithm based on a hill climbing method, which comprises the following steps of: 1, inputting an order of which the wave number is combined and corresponding order details; 2, according to the box type in the step 1, determining the serial number of each box position where the order vehicle can be placed; 3, giving the coordinates to the positions, where the boxes can be placed, in the step 2; step 4, initializing the position of the box in the wave in the step 1; 5, calculating the position of the currently placed center of mass, and solving the distance L between the center of mass and the center coordinate of the bottom layer of the order vehicle; step 6, calculating the total number of times of surface turning of the order vehicle required by the wave order picking completion as C; 7, respectively endowing L and C with a certain proportion, and summing S; 8, randomly selecting two boxes for position exchange, and repeating the steps 5-7 until an optimal solution is searched; by means of the hill climbing method, the unbalance loading problem of the order vehicle is solved, the number of times of turning of the order vehicle at the picking station is optimized, and then the picking efficiency is improved.

Owner:ALOG TECH CO LTD

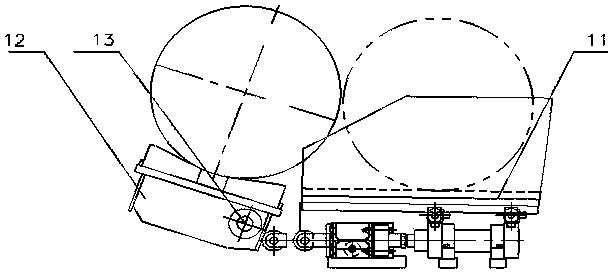

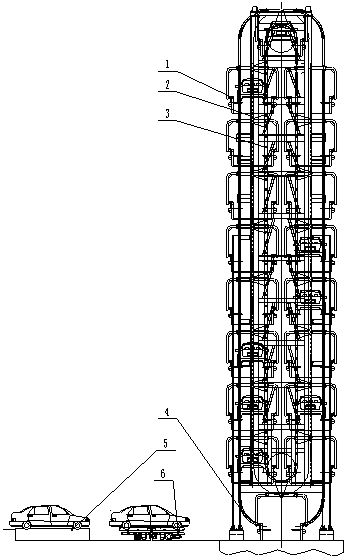

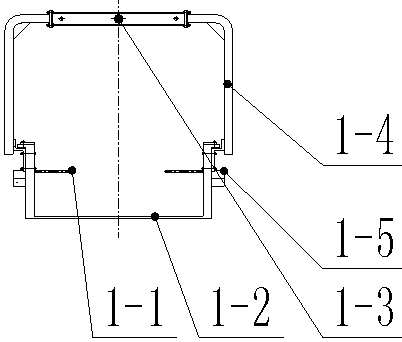

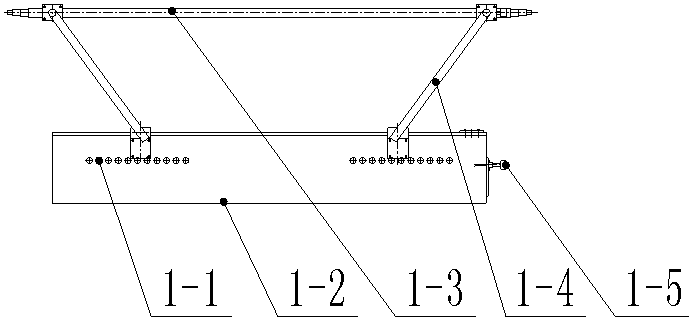

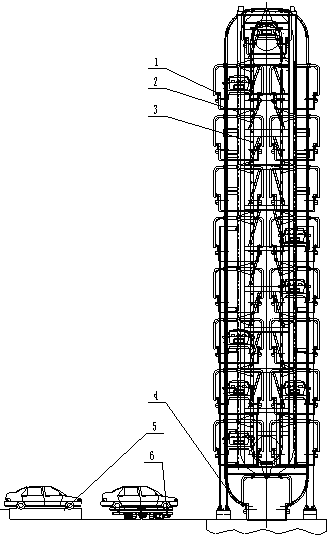

A Vertical Circulation Stereoscopic Parking Garage Suitable for Comb-tooth Carriage Carts

Provided is a vertical circulating stereo garage applicable to a comb-finger carriage trolley. Each parking platform of the stereo garage is formed by the fact that comb plates and guide wheels are arranged on the front upper plane and the rear upper plane of a trolley operation table, and driving shafts are hinged to hoisting rods on two sides. The height between the comb plates and the trolley operation tables is equal to the height allowing the comb-finger carriage trolley to pass. The comb-finger carriage trolley is of a front-back or left-right or in-situ rotary displacement structure, and the purpose that a vehicle is transferred between an in-out garage table and a parking table located at an entrance / exit is achieved. When the stereo garage is in an unbalance loading critical state, the vehicle is transferred from one parking platform to another parking platform through the comb-finger carriage trolley, and unbalance loading structure balance is achieved. According to the vertical circulating stereo garage, the vehicle parking and picking time of the garage is effectively shortened, the vehicle parking and picking efficiency is improved, meanwhile, the unbalance loading problem of the stereo garage is solved, the power of a power motor is lowered, and realistic practical value is achieved.

Owner:TAIYUAN UNIV OF TECH

Flashboard lifting device used for energy storage power station

PendingCN109235383AAvoid raising inconsistenciesReduce damage rateBarrages/weirsPower stationEngineering

The invention discloses a flashboard lifting device used for an energy storage power station, and belongs to the technical field of energy storage power stations. In the technical scheme, the flashboard lifting device comprises a flashboard and flashboard racks on the two sides of the flashboard, the flashboard is slidingly connected with the flashboard racks, a base is arranged at the tops of theflashboard racks, fixedly connected with the flashboard racks, and provided with a lifting mechanism, one end of the lifting mechanism is connected with the flashboard, the flashboard is driven by the lifting mechanism to ascend and descend, the other end of the lifting mechanism is connected with a driving mechanism, and the driving mechanism is arranged on the base. In the technical scheme, theflashboard lifting device has the advantages that the design is simple, using is convenient, when the flashboard is lifted, the two sides of the flashboard are uniformly stressed, synchronous ascending or descending is realized, it is avoided that since stress is not uniform, the two sides of the flashboard are lifted without uniformity, in this way, the probability of flashboard damage or sliding groove damage is lowered, and working efficiency is improved.

Owner:STATE GRID CORP OF CHINA +2

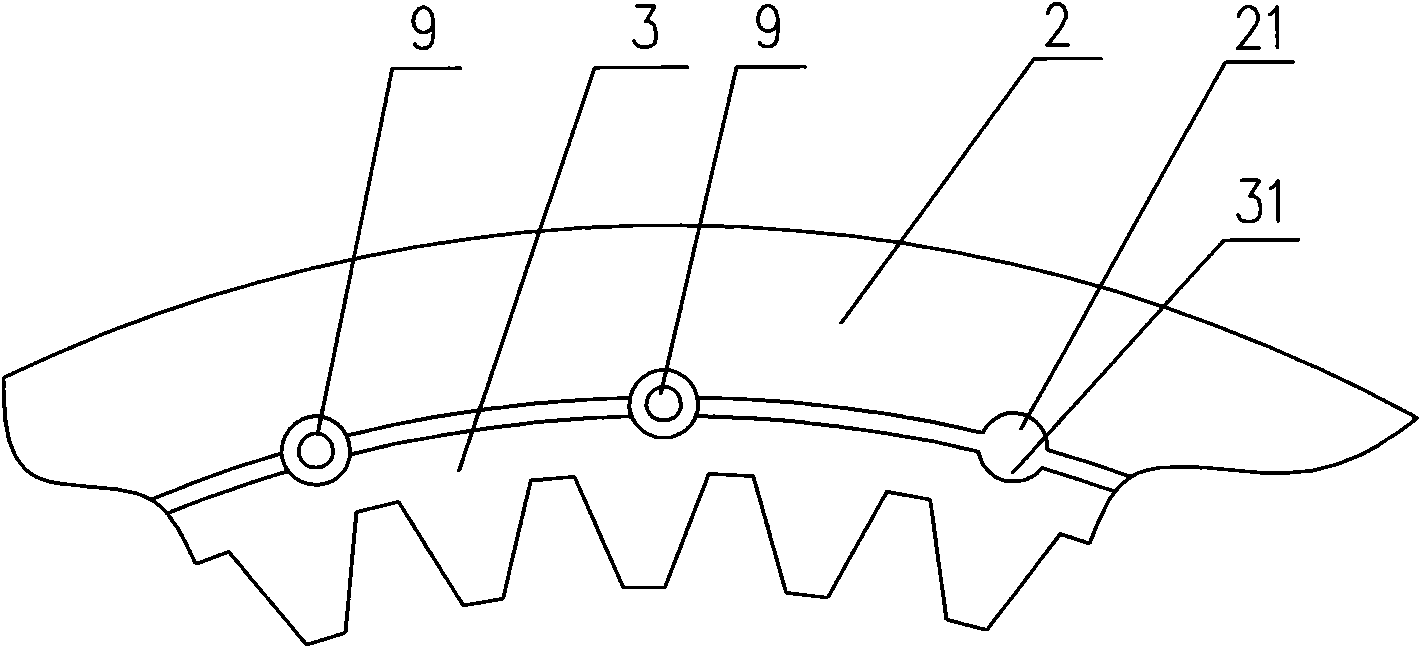

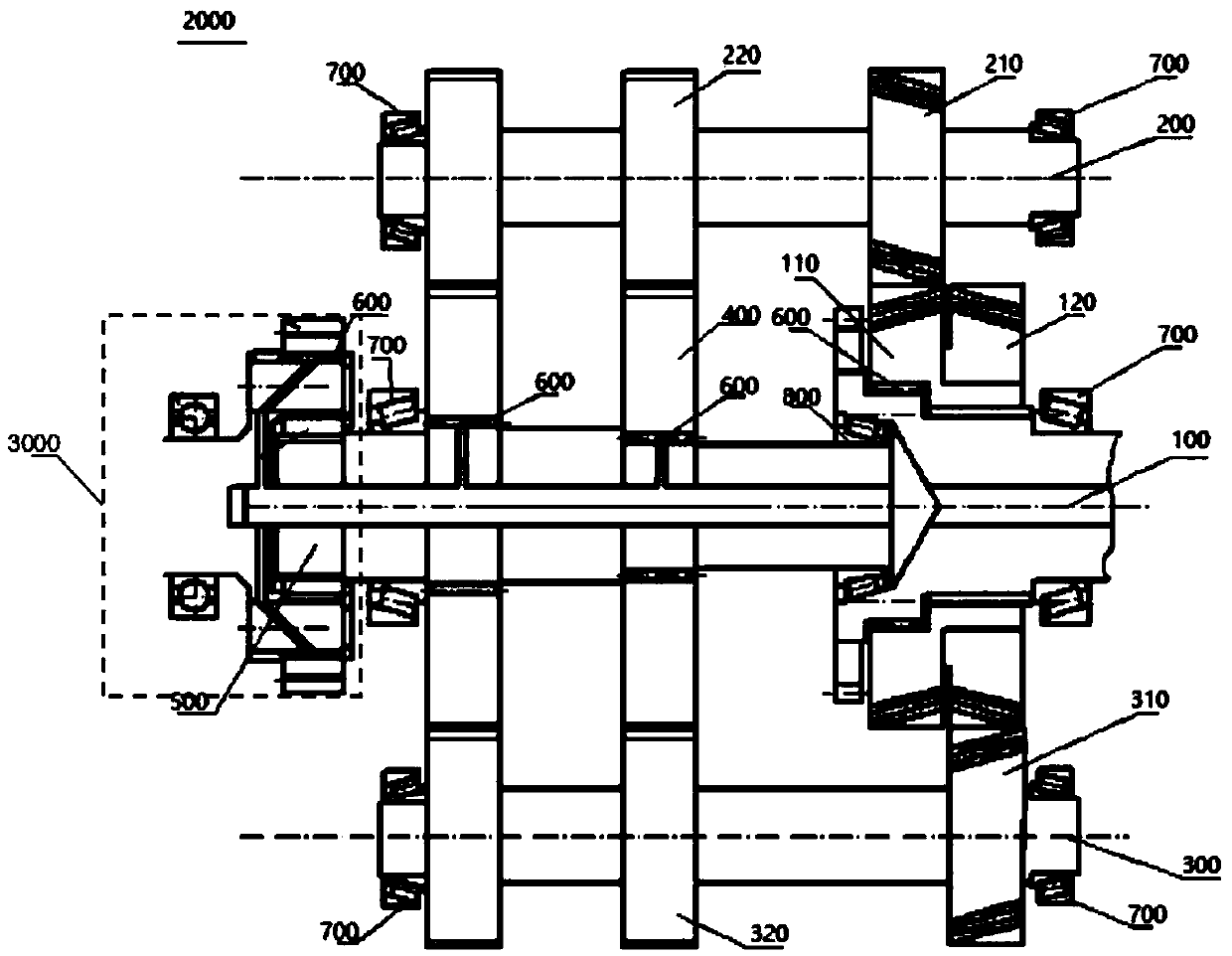

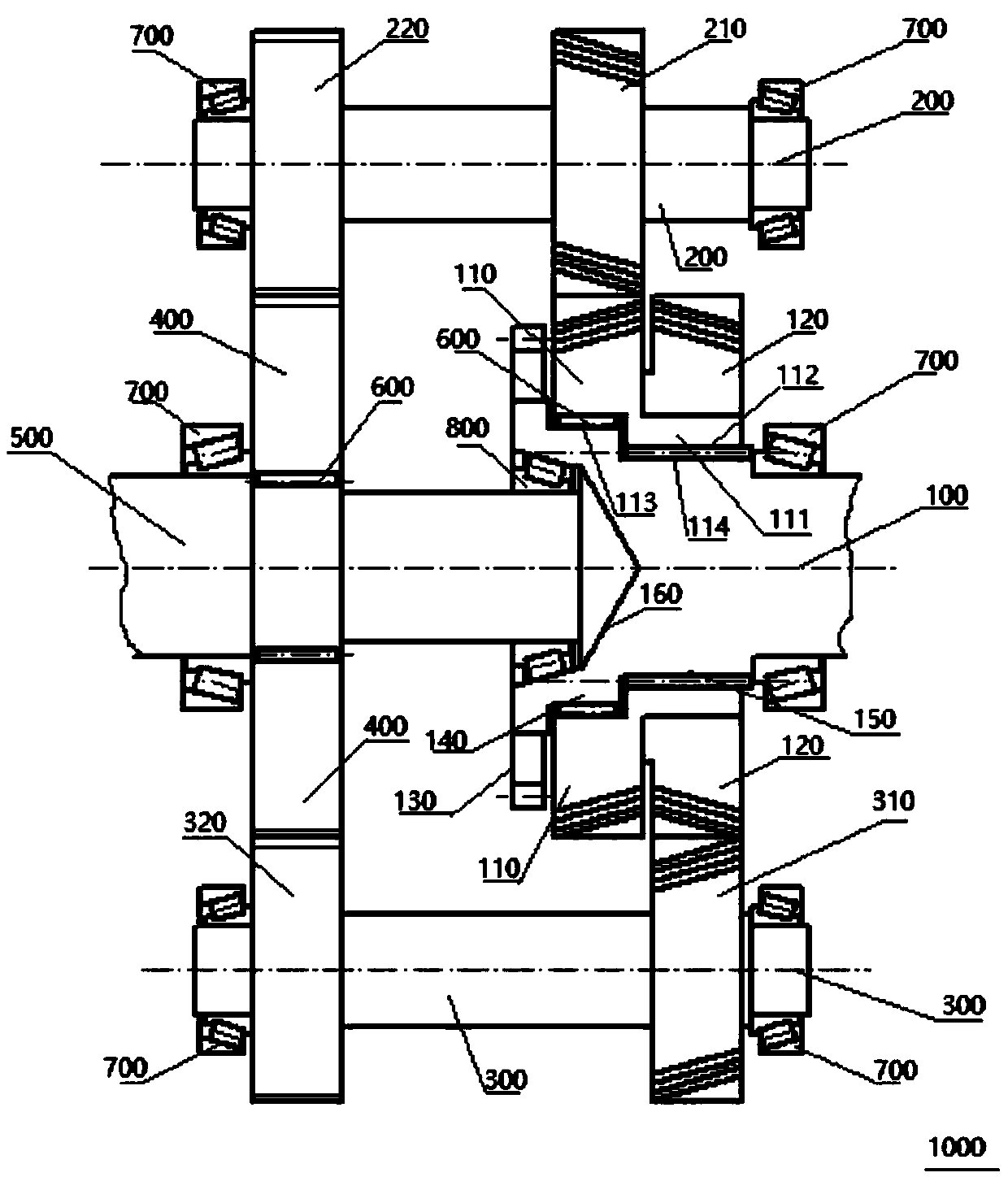

Point-line gear transmission device with full center positioning function and capable of solving double intermediate shaft unbalanced loading problem

PendingCN109630616ASolve problems such as center positioningReduce shockToothed gearingsGearing detailsEngineeringContact strength

The invention discloses a point-line gear transmission device with a full center positioning function and capable of solving a double intermediate shaft unbalanced loading problem. The device comprises an input shaft, a first input gear, a second output gear, a first intermediate shaft transmission gear, a second intermediate shaft transmission gear, an output gear stage gear, a first input gear,a second input gear, a first intermediate shaft gear stage gear and a second intermediate shaft gear stage gear, wherein the first input gear is driven by the input shaft, and a mounting boss is arranged on the first input gear; the mounting boss is sleeved with the second input gear; the first intermediate shaft transmission gear is arranged on a first intermediate shaft, and the second intermediate shaft transmission gear is arranged on a second intermediate shaft; the output gear stage gear is engaged with both the first intermediate shaft gear stage gear and the second intermediate shaft gear stage gear; and at least one of the first input gear, the second input gear, the first intermediate shaft transmission gear, the second intermediate shaft transmission gear, the first intermediateshaft gear stage gear, the second intermediate shaft gear stage gear and the output gear stage gear forms a point-line gear. According to the point-line gear transmission device, the transmission ratio can be increased, the tooth surface contact strength is increased, the noise is lowered, the the double intermediate shaft unbalanced loading problem can be solved through the device, center positioning of the gears of the double intermediate shafts can be achieved, machining and production are facilitated, and the stability is good.

Owner:常州赫尔格力狮传动技术有限公司

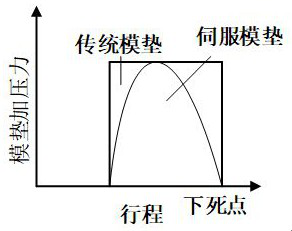

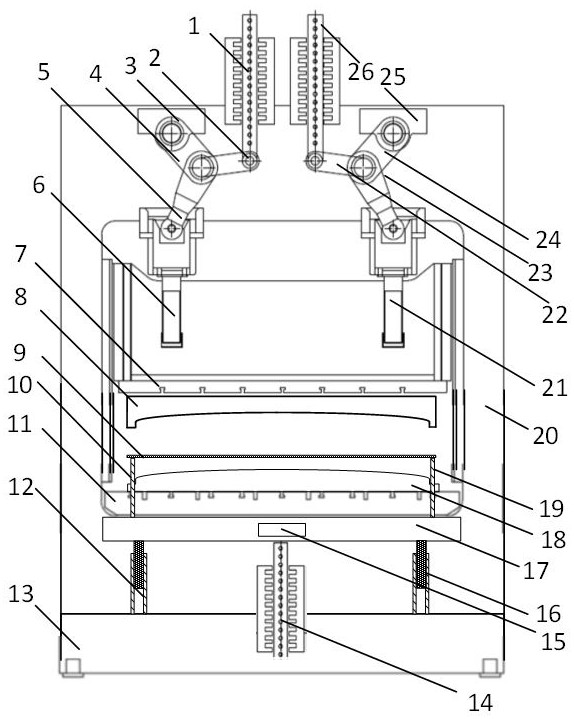

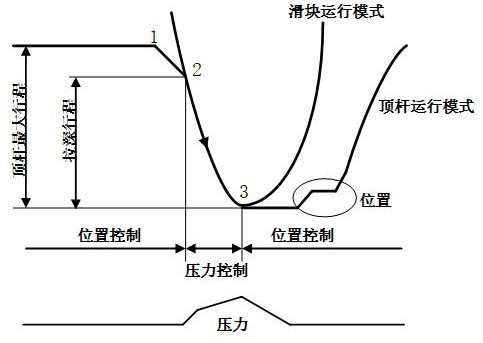

Novel servo press

PendingCN112808917ADouble boost effectSolve the problem of partial loadForging press detailsForging press drivesGear wheelElectric machine

The invention relates to the technical field of forging machinery, in particular to a novel servo press. The servo press is characterized in that a rack is a press rack, two linear motors are arranged above the press rack, a workbench is arranged in the press rack, the workbench comprises an upper workbench and a lower workbench, an upper die moving assembly is arranged above the upper workbench in a vertical sliding mode, a force increasing mechanism is installed between the upper die moving assembly and the two linear motors, and a servo die cushion is installed on the lower workbench and driven by a second linear motor. The servo press has the advantages that a double force increasing effect can be achieved, the left-right balance can be dynamically adjusted, an unbalance loading problem can be solved, the control precision is higher, the structure is simple, a rotating gear and a speed reducer are omitted, so that a transmission gap is eliminated, the size structure is greatly reduced, the impact force is large, the working efficiency is high, the servo die cushion can facilitate the forming process of new materials, the whole press does not have other hydraulic oil, and the safety is greatly improved.

Owner:JINING KELI PHOTOELECTRIC IND CO LTD +1

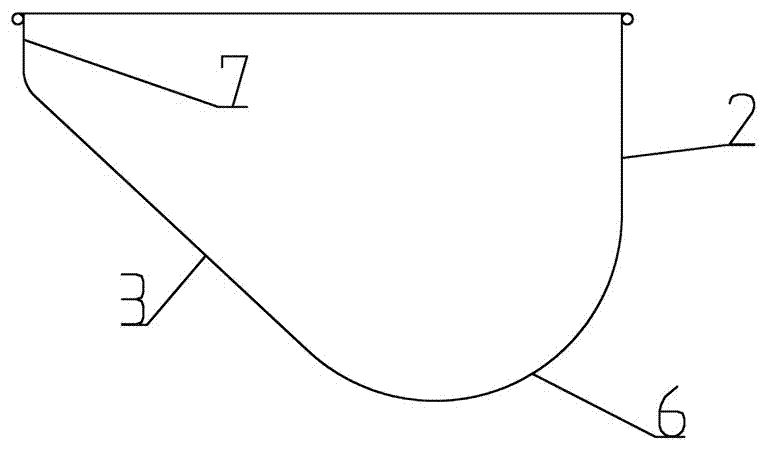

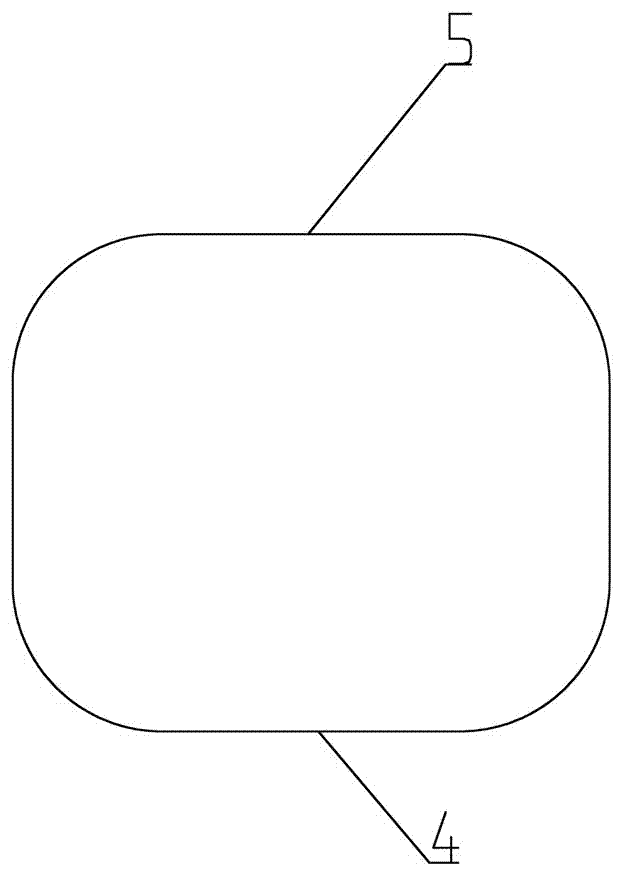

Novel material groove and stretching mold used for machining of novel material groove

ActiveCN107225183AAvoid dead endsAvoid the problem of raw material cost caused by pigs eatingShaping toolsMetal-working feeding devicesEngineeringMachine parts

The invention relates to a novel material groove which comprises a body and an installation machine part fixed to the outside of the body; the body comprises a front plate, a back plate, a left side plate, a right side plate and a bottom plate, and the top end of the back plate is further connected with a folded plate; the front plate, the back plate, the left side plate and the right side plate are all in arc transition with the bottom plate, and the front plate, the back plate, the left side plate, the right side plate and the bottom plate are integrally formed; the folded plate and the back plate as well as the left side plate and the right side plate are also integrally formed, and an opening defined by the front plate, the folded plate connected with the back plate, the left side plate and the right side plate is a round corner rectangle; in use, the included angle of the plane where the opening is located and the horizontal surface is 45 degrees, and the back plate is perpendicular to the horizontal surface; and the ratio of the height from the vertical surface where the highest point of the folded plate is located to the horizontal surface to the height from the vertical surface where the front plate is located to the horizontal surface is 3.5:1, the height of the vertical surface of the front plate is 144 mm, and on this basis, the invention further provides a stretching mold used for machining. The novel material groove has the beneficial effects that the appearance is aesthetic, the machining cost is relatively low, and materials are saved in use.

Owner:SHANDONG JINXING STAINLESS STEEL TECH CO LTD

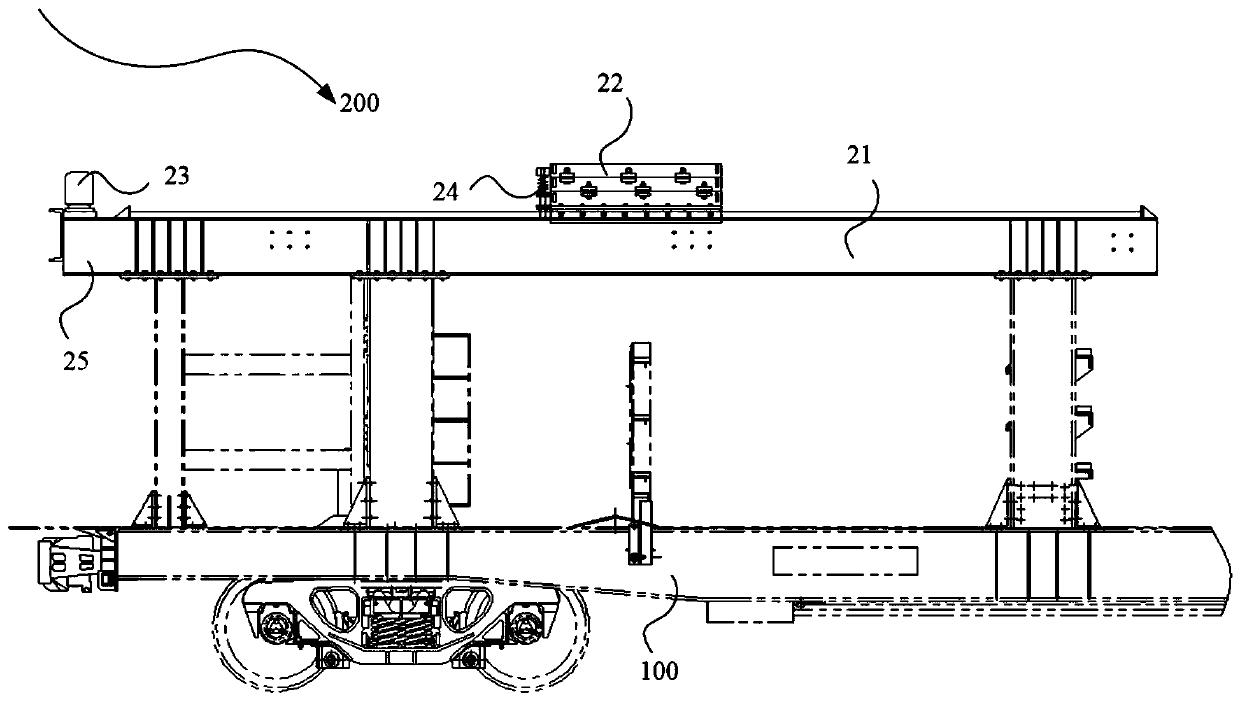

Counterweight device and railway engineering vehicle

PendingCN111252085ASolve the problem of partial loadAvoid unbalanced loadLocomotivesControl theoryAutomotive engineering

The invention provides a counterweight device and a railway engineering vehicle. The counterweight device comprises a track assembly, a counterweight assembly, a power system and a locking device; thetrack assembly is installed on the railway engineering vehicle, the balance weight assembly and the power system are installed on the rail assembly, the power system is connected with the counterweight assembly and is used for driving the counterweight assembly to move on the rail assembly, and the locking device is arranged on the counterweight assembly and is used for locking the counterweightassembly on the rail assembly. The unbalance loading problem of the railway engineering vehicle can be effectively solved.

Owner:CRRC SHENYANG CO LTD

Low-noise planetary gearbox of wind driven generator

InactiveCN101782047BSolve installation difficultiesSolve the problem of partial loadGear vibration/noise dampingToothed gearingsLow noiseWind driven

The invention relates to a speed increasing box, in particular to a low-noise planetary gearbox of a wind driven generator, which comprises an input shaft, a box body, an inner gear ring, a planet gear shaft, a center shaft and a planet carrier. The input shaft is fixedly connected with the planet carrier in a coaxial way. More than two planet gear shafts are uniformly distributed on the planet carrier through bearings. A large planetary gear and a small planetary gear are fixedly arranged on the planet gear shaft. The inner gear ring is fixed and arranged inside the box body. The small planetary gear is normally engaged with the inner gear ring. A sun gear is fixed and arranged on the center shaft. The large planetary gear is normally engaged with the sun gear. The input shaft is connected with the box body through the bearing. The outer diameter of the inner gear ring is smaller than the inner diameter of the box body. A plurality of box body pin grooves are uniformly distributed onthe inner wall of the box body in the circumferential direction. The outer wall of the inner gear ring is provided with an inner gear ring pin groove. An elastic pin is embedded between the box body pin groove and the inner gear ring pin groove. The low-noise planetary gearbox of the wind driven generator has the advantages of low noise, long service life, strong shock resistance capability and low production and processing difficulty.

Owner:王光顺

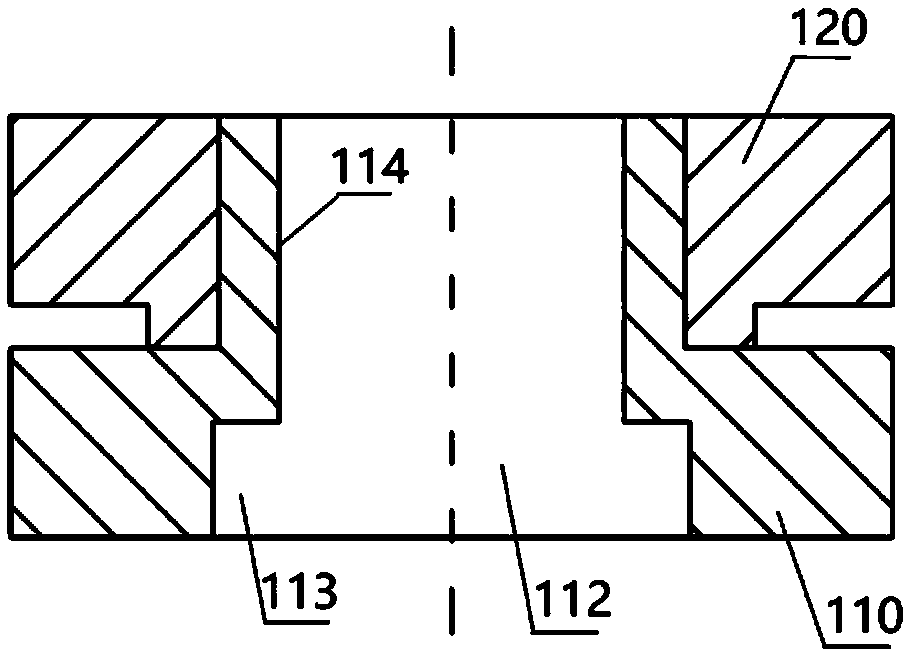

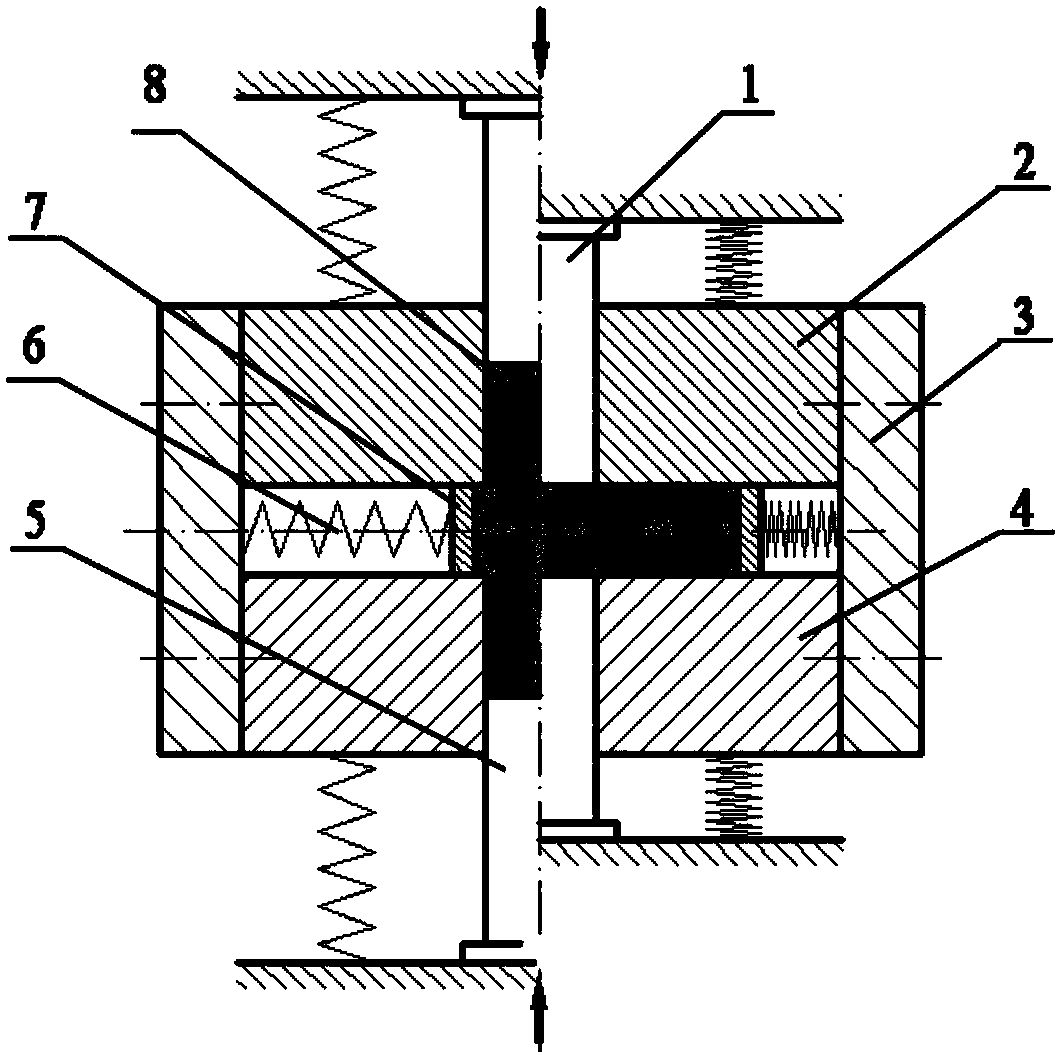

Closed back pressure bidirectional upsetting extrusion forming method for preparing refractory metal ultrafine grain material

ActiveCN105921657BIncrease stiffnessIncrease the cross-sectional areaForging/hammering/pressing machinesStressed stateMaterials science

The invention discloses an enclosed-type back-pressure two-way extrusion-upsetting forming method for manufacturing refractory metal ultrafine-grained material. The forming method is based on a combined concave die forming a cross-shaped channel which is arranged in the manner that a first channel and a second channel are vertically intersected. The forming method comprises following steps: material replacement and die combination; first-pass extrusion-upsetting; pressure relief and die opening; and the step of placing a first-pass extrusion-upsetting specimen to the first channel again and repeating. Compared with the prior art, the enclosed-type back-pressure two-way extrusion-upsetting forming method for manufacturing refractory metal ultrafine-grained material has following beneficial effects: enclosed-die forging technology is introduced to severe plastic deformation technology; based on the principle of a floating concave die, double-punch extrusion-upsetting of a highly-symmetrical structure is obtained; an unbalance loading problem existing in conventional equal channel angular pressing technology is solved; die bulking failure tendency is reduced; material is in the triaxial compressive stress state; deformation capability of low-ductility refractory metal (tungsten, molybdenum and the like) is effectively improved; operation is conducted easily; high practicability is obtained; and the enclosed-type back-pressure two-way extrusion-upsetting forming method is easy to apply.

Owner:HEFEI UNIV OF TECH

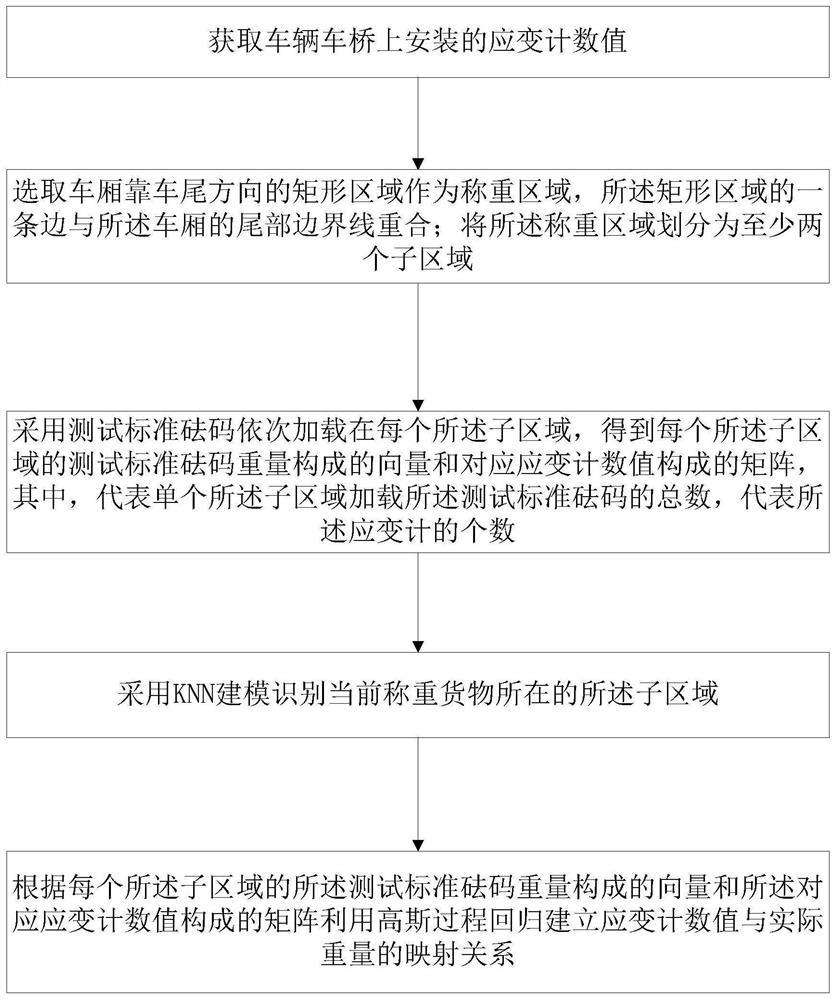

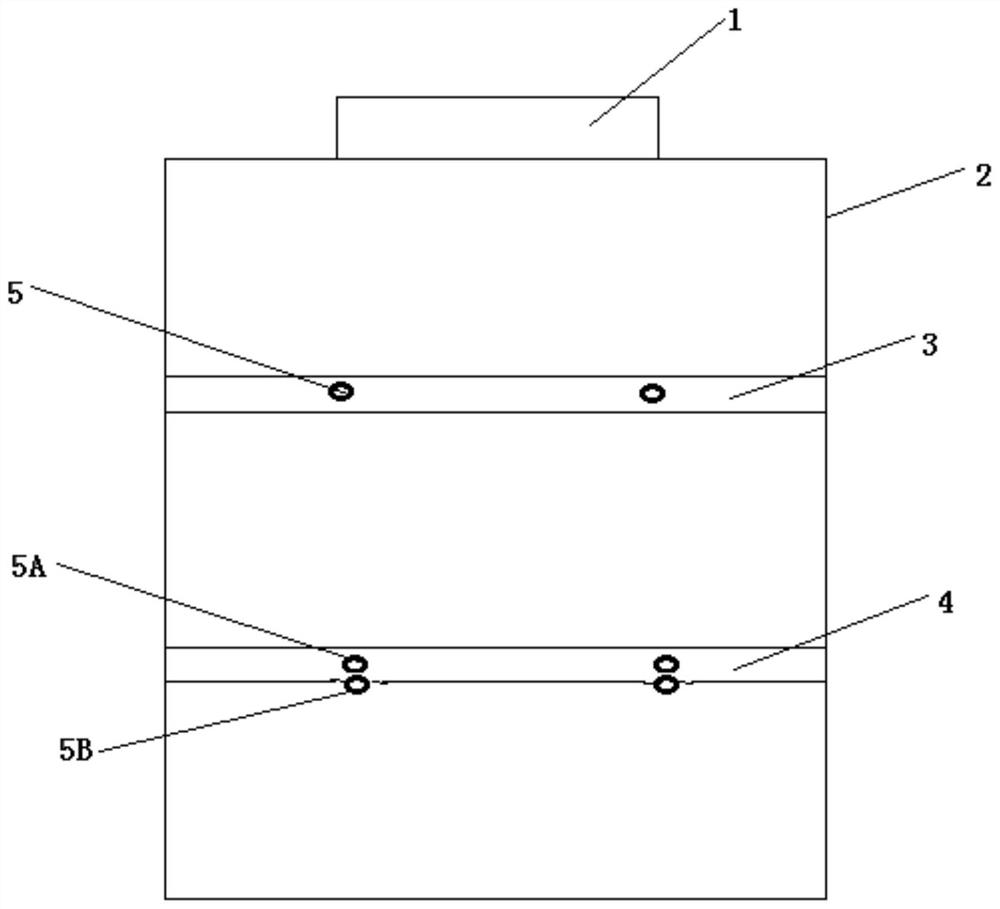

A high-precision vehicle-mounted area weighing method

ActiveCN111121939BSolve the problem of partial loadHigh precisionSpecial purpose weighing apparatusLogistics managementIn vehicle

The invention provides a high-precision vehicle-mounted area weighing method. The high-precision vehicle-mounted area weighing method comprises the following steps: obtaining a strain gauge value installed on a vehicle axle; dividing a weighing area, and dividing the weighing area into at least two sub-areas; sequentially loading a test standard weight in each sub-region to obtain a vector formedby the weight of the test standard weight in each sub-region and a matrix formed by corresponding strain gauge values; adopting KNN modeling to identify the subarea where the current weighed goods arelocated; and establishing a mapping relationship between the strain gauge value and the actual weight by utilizing Gaussian process regression according to a vector formed by the weight of the test standard weight of each sub-region and a matrix formed by the corresponding strain gauge value. The weighing precision reaches 1.5%, high-precision vehicle-mounted weighing is realized in the true sense, and the precision requirement of the current logistics industry on vehicle-mounted weighing is completely met. The unbalance loading problem caused by a common vehicle-mounted weighing scheme is completely overcome.

Owner:深圳市汉德网络科技有限公司

Vertical circulation stereo parking garage operation method for comb-type carrying trolley

ActiveCN108798117AImprove efficiencySolve the problem of partial loadParkingsElectric machineryDrive motor

The invention relates to a vertical circulation stereo parking garage operation method for a comb-type carrying trolley. The vertical circulation stereo parking garage operation method is based on thecomb-type carrying trolley. The specific operation method comprises the steps that when a vehicle is parked, the vehicle is driven on an in-out garage platform, and the vehicle is transferred by thecomb-type carrying trolley from the in-out garage platform and to a parking platform located on the in-out garage position; and when the vehicle is taken, the vehicle is transferred by the comb-type carrying trolley from the parking platform located on the in-out garage position to the in-out garage platform, and the vehicle is driven away from an in-out garage. According to the vertical circulation stereo parking garage operation method, the vehicle parking and taking time of the stereo parking garage is effectively reduced, the parking and taking efficiency is improved, the problem of the unbalance loading of the parking garage is solved, the power of a driving motor is further reduced, and wide practical value is achieved.

Owner:TAIYUAN UNIV OF TECH

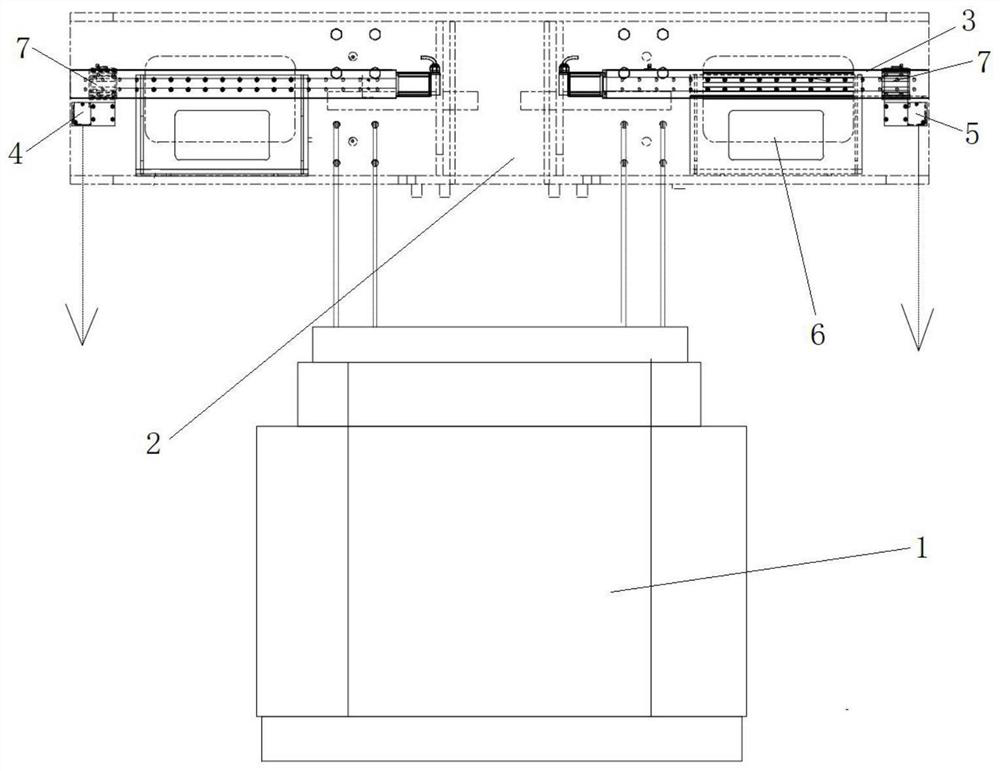

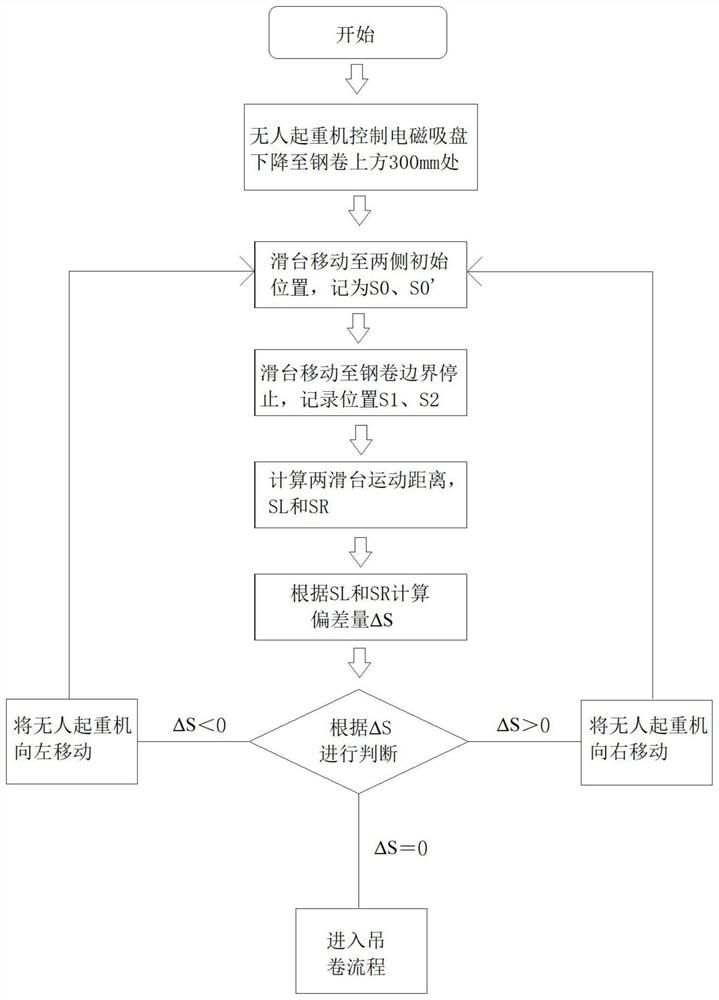

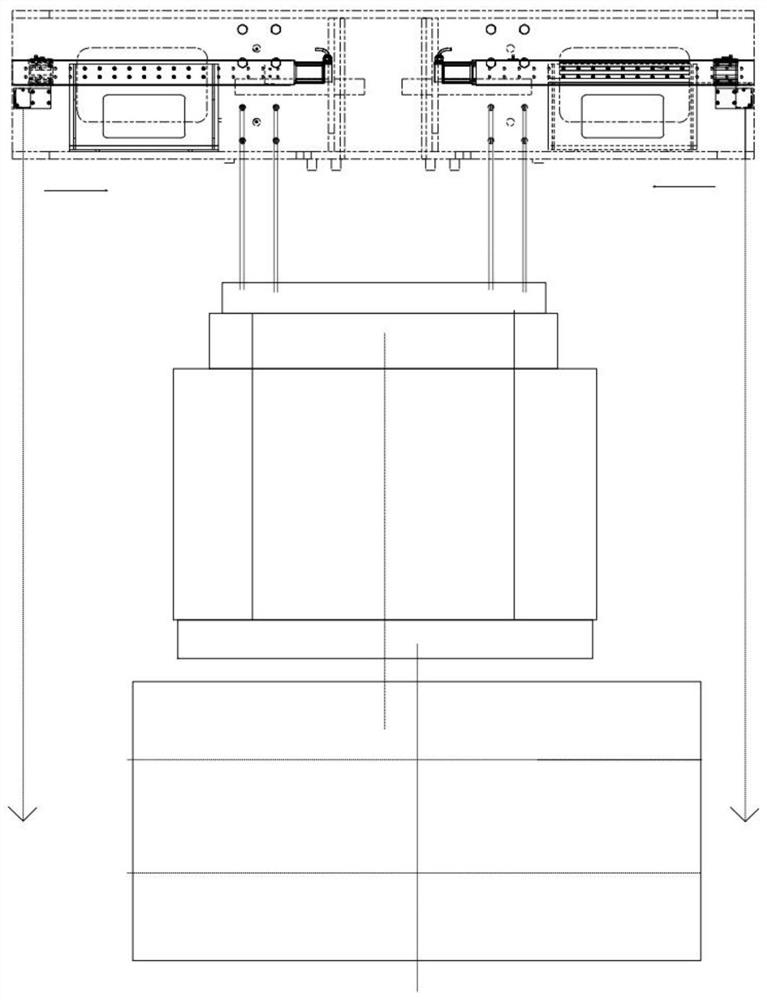

Automatic steel coil finding and transverse centering method for electromagnetic chuck of full-automatic unmanned crane

InactiveCN111924714AIncrease success rateImprove securityLoad-engaging elementsStructural engineeringControl theory

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

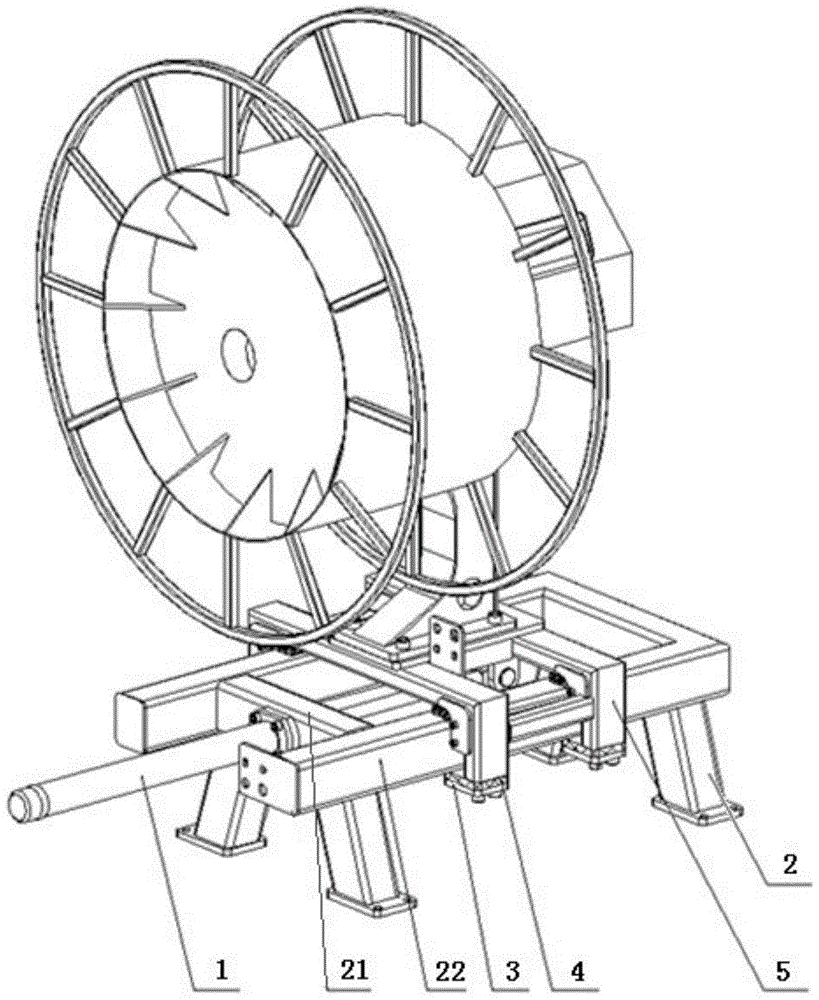

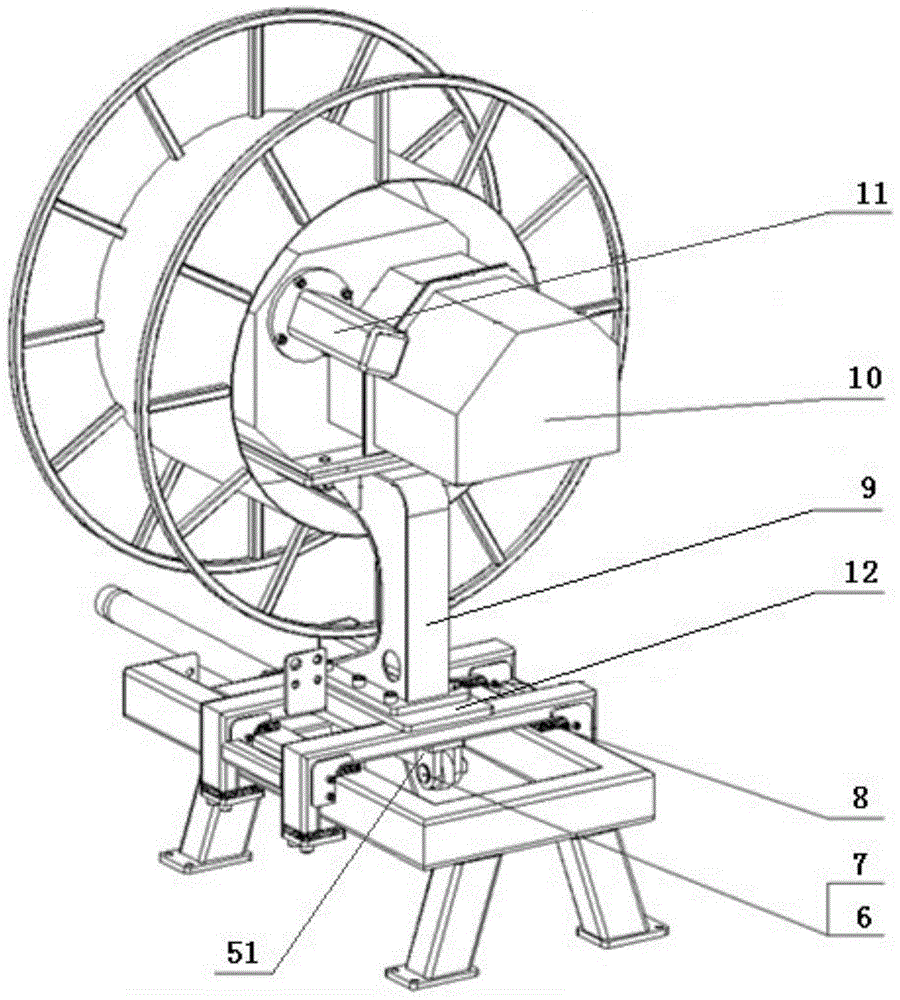

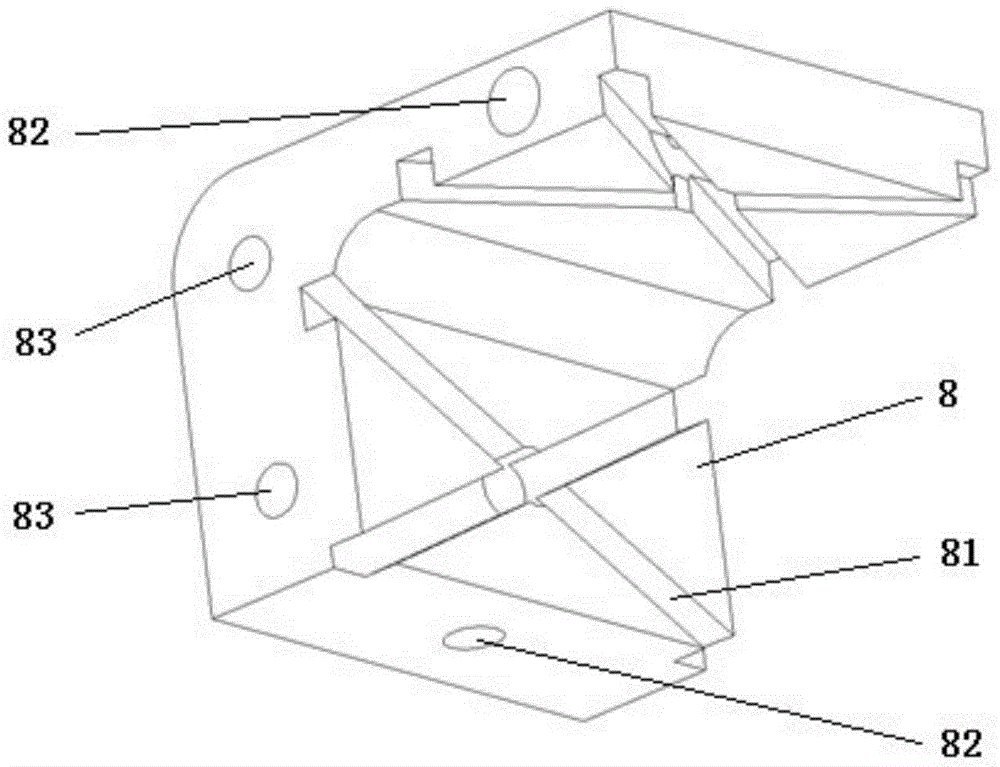

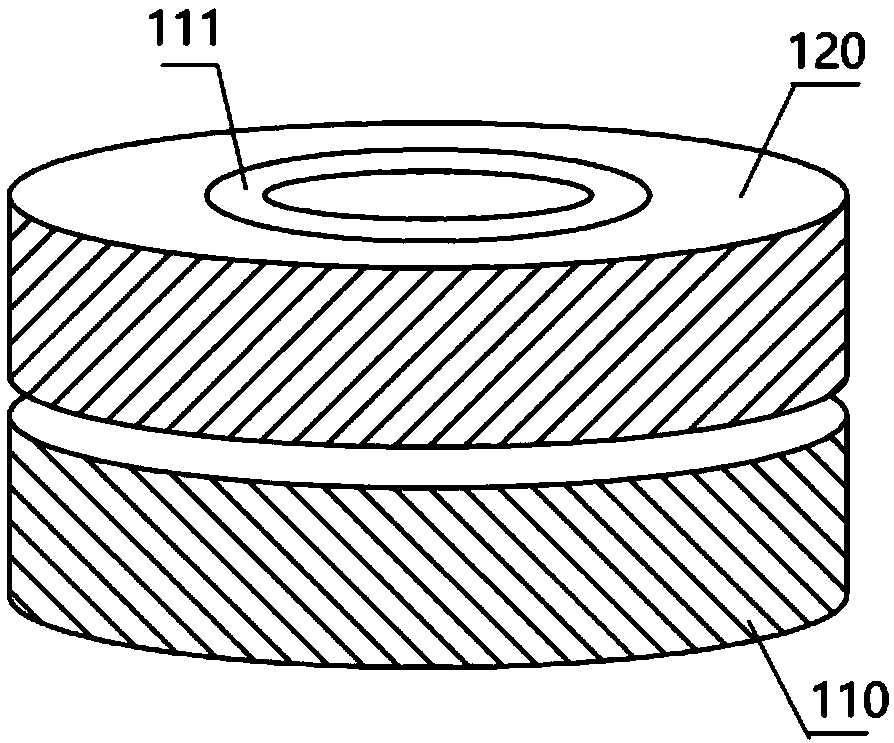

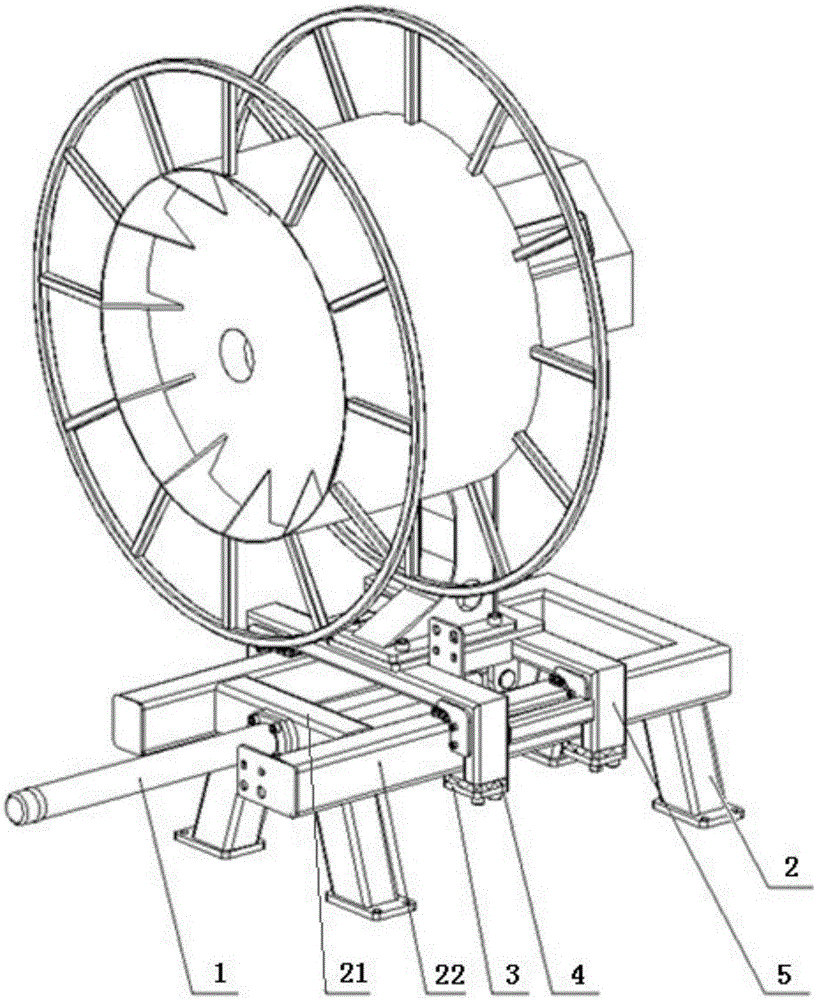

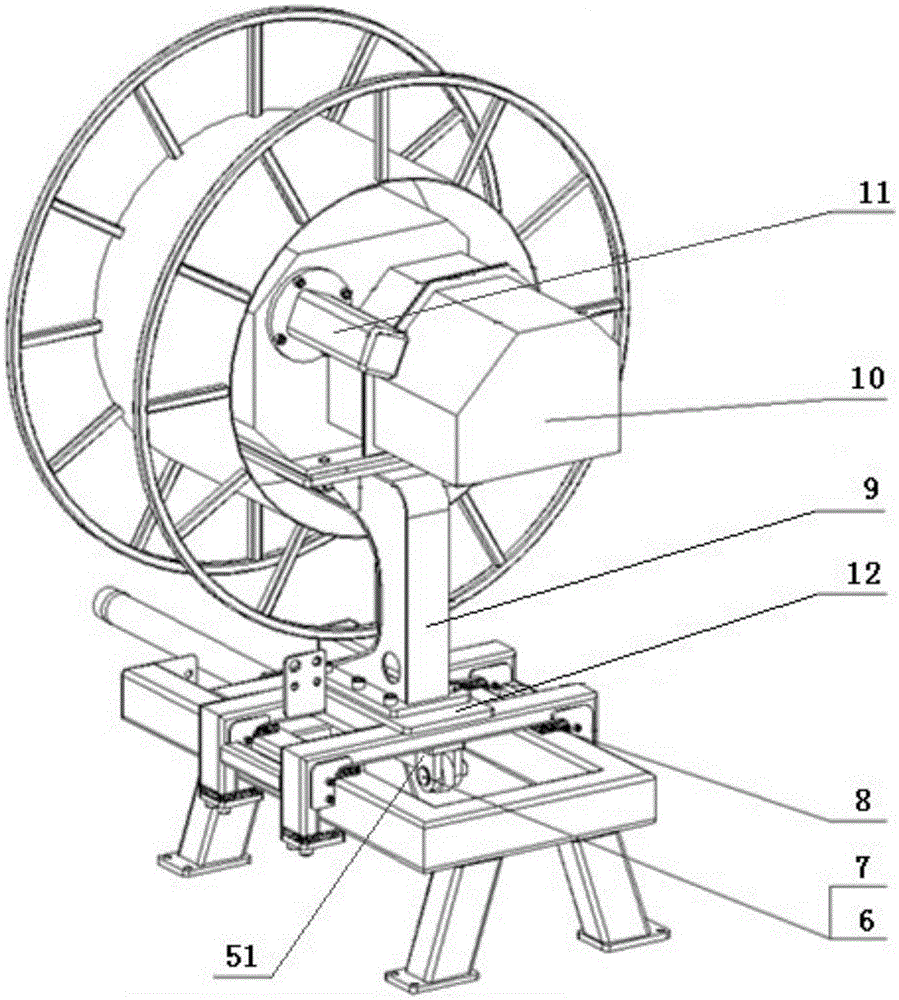

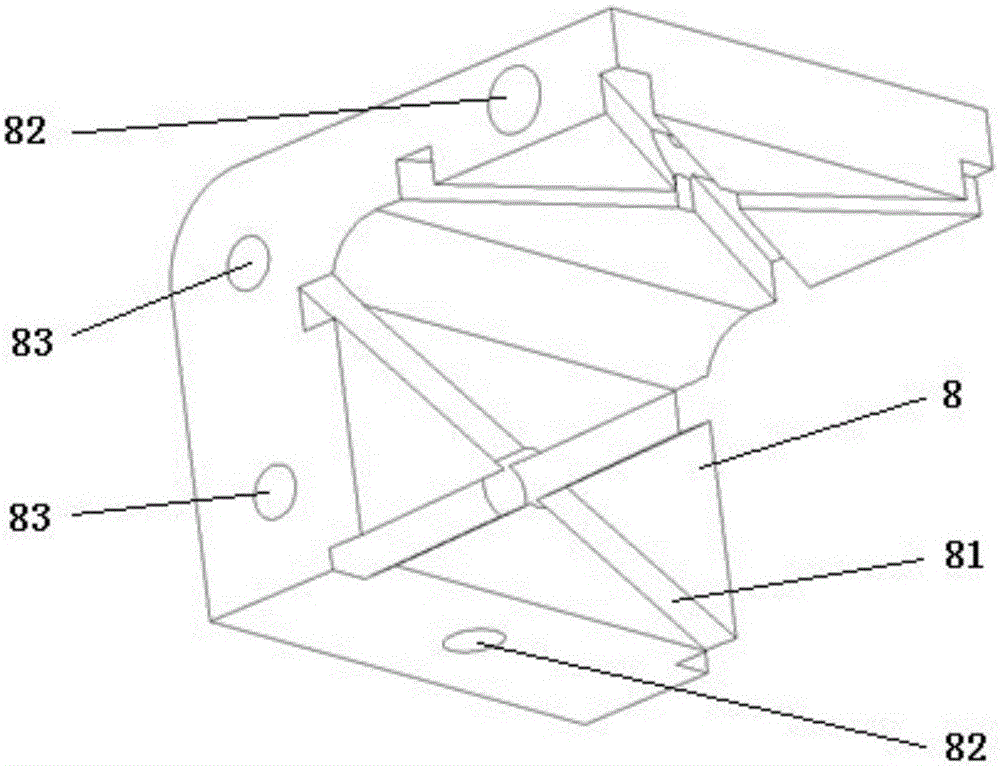

A sliding cable reel device

ActiveCN105084120BSolve the problem of partial loadAvoid safety accidentsFilament handlingEngineeringBlock match

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

Press centering test method

PendingCN114689001ASolve the problem of partial loadImprove pressing precisionMeasurement devicesCompression moldingWorking pressure

The invention discloses a press centering test method, which comprises the following steps of: testing and adjusting a pressing plate and a pressing block under the static state of a press and the working pressure of the press respectively, and quickly finding the central position of the working pressure transmission of a four-column press, namely finding the position of the pressure center on a press workbench; and then, a mold is arranged for compression molding according to the determined pressure center of the press, so that the unbalance loading problem of the mold is avoided, the pressing precision of compression molding is improved, the method can be used for near-net-size molding of parts, and post-processing procedures are saved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

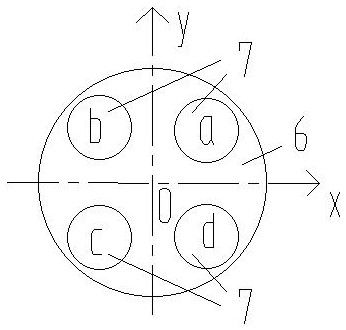

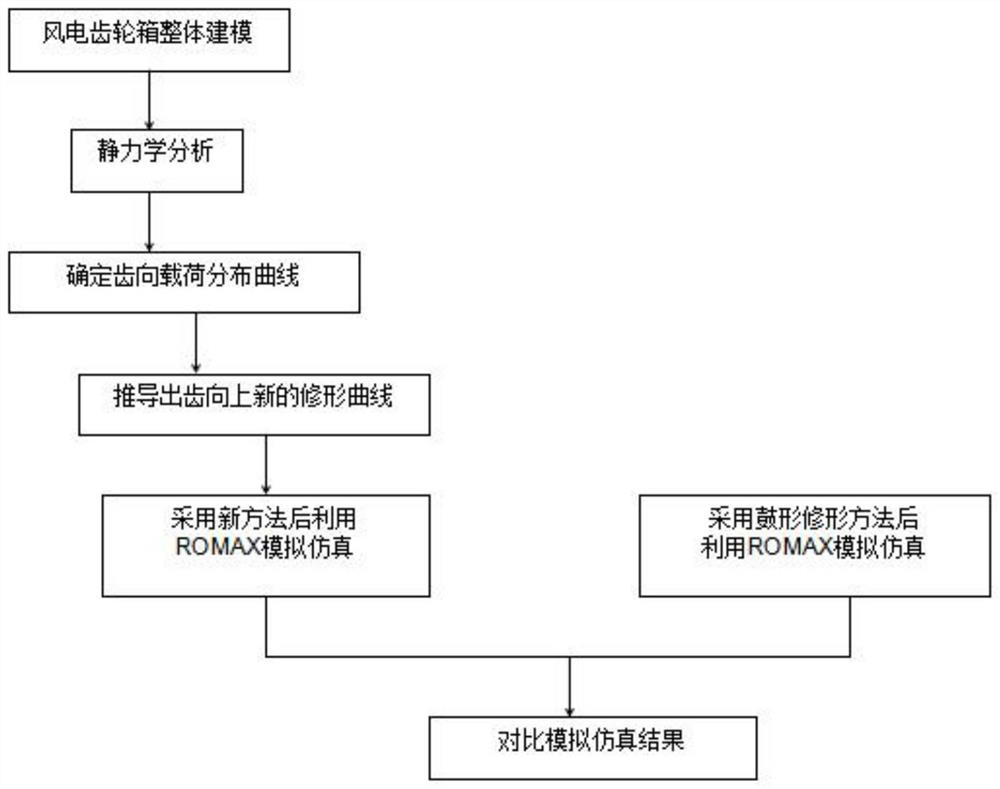

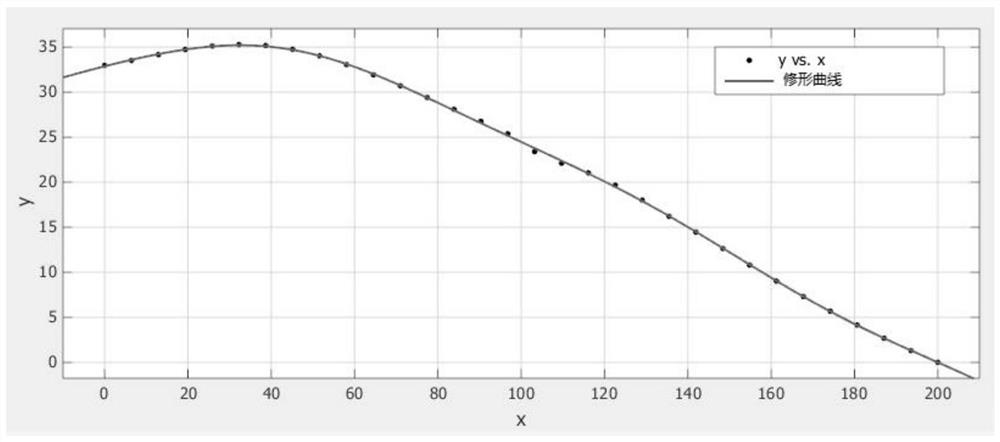

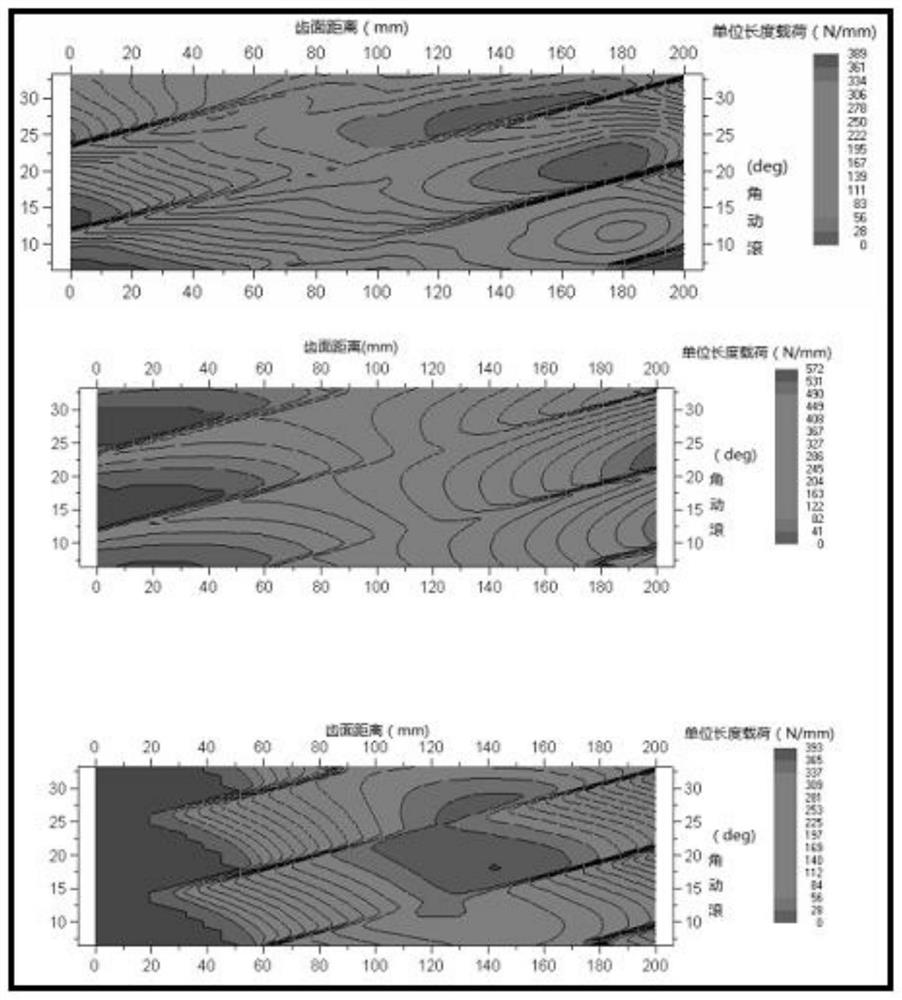

Gear modification method based on uniform load distribution

PendingCN114154274ASolve the problem of partial loadGeometric CADDesign optimisation/simulationGear wheelModelSim

The invention relates to a gear modification method based on uniform load distribution. The method is characterized by comprising the following steps: (1) carrying out integral modeling on the MW-level wind power gear box by utilizing Romax software, carrying out analogue simulation on a model under a rated working condition, and determining a tooth upward load distribution curve; (2) deducing a corresponding modification curve and a specific modification amount according to the obtained load distribution curve; and (3) verifying the comprehensive gear modification method based on uniform load distribution under an equivalent load working condition. Aiming at the practical application condition of the MW-level wind power gear box, the invention provides a gear modification comprehensive method according to a tooth direction load distribution curve, and tests prove that the problems of unbalance loading of a heavy-duty gear and non-uniform distribution of tooth direction loads can be better solved.

Owner:NINGXIA YINXING ENERGY

A sleeve unloading device

InactiveCN103624105BSolve storage problemsSolve the problem of partial loadProduction rateHydraulic cylinder

The invention relates to a sleeve uninstalling device which is characterized by comprising a hydraulic cylinder, an oil cylinder joint, a clamp plate, first wheels, a frame body, rails, a pedestal, a second wheel, a collecting basket and a trolley bracket, wherein the hydraulic cylinder is fixed, the hydraulic cylinder is connected with the clamp plate through the oil cylinder joint, then the clamp plate is connected with the frame body, the frame body is connected with the pedestal, the first wheels are arranged on both sides of the frame body, the lower ends of the first wheels are provided with the rails, the second wheel is arranged on the pedestal, the collecting basket is arranged on a stand above the hydraulic cylinder, the hydraulic cylinder is arranged on a base plate of the stand, the trolley bracket is fixed on the frame body through a hinge pin, and runs perpendicular to a plane on which the collecting basket is located. The sleeve uninstalling device disclosed by the invention can store sleeves, so that sleeves are not required to be lifted away one by one every time. By using the sleeve uninstalling device disclosed by the invention, sleeves can be stored together, and then are integrally lifted away, so that time and manpower resources are saved, and the productivity of units is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Speed changer provided with self-adaptive transmission device and both having single and double intermediate shaft advantages

PendingCN109630625ASolve the problem of partial loadSolve problems such as center distance variationToothed gearingsGearing detailsGear wheelSelf adaptive

Owner:常州赫尔格力狮传动技术有限公司

Sliding type cable drum device

ActiveCN105084120ASolve the problem of partial loadAvoid safety accidentsFilament handlingEngineeringBlock match

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

Dual power drive mobile device

ActiveCN105099072BSolve the problem of partial loadImprove dynamic performanceMechanical energy handlingLinear motionMotor drive

The invention discloses a two-motor drive mobile device, and belongs to the technical field of smelting equipment. The mobile device has the advantages of relatively high carrying capacity, relatively high running speed, relatively high running acceleration, relatively stable dynamic property, relatively high impact resistance, relatively compact overall structure and relatively high running accuracy. According to the two-motor drive mobile device, a bracket is arranged on a fixed plane; both guide rails and rotary motion-linear motion transformation mechanisms are arranged on the brackets; two pairs of guide rails are arranged in parallel along the length direction of the bracket; two rotary motion-linear motion transformation mechanisms are arranged in parallel along the length direction of the bracket; a plurality of guide wheels are arranged at the bottom of the mobile platform; two drive motors are arranged at the top of the mobile platform; the guide wheels are attached to the guide rails; each drive motor is articulated with individual rotary motion-linear motion transformation mechanisms respectively; and the two drive motors move reversely and synchronously. The two-motor drive mobile device is used for bearing the smelting equipment.

Owner:HARBIN BOSHI AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com