Method for balancing loads during mold production

A technology of balancing load and mold, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as one-side load of air cushion, achieve good protection, solve the eccentric load of press air cushion, and have good quality stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

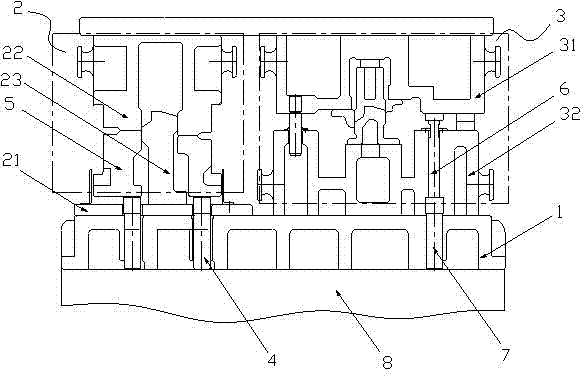

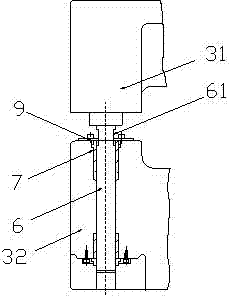

[0015] Such as figure 1 In the joint installation mold shown, two sets of molds are installed on the lower backing plate 1, one set of molds is a drawing forming mold 2, and the other is a trimming and turning mold 3; wherein the drawing forming mold 2 is If an air cushion is required, the press air cushion 8 transmits the power to the auxiliary mold through the air cushion ejector pin 4, that is, the blank holder 5, which provides the blank holder force during the forming process, so that the die 22, the punch 23 and The blank holder ring 5 is used for drawing and blanking. On the other side, the punching and turning mold 3 does not need an air cushion, but in this case, the air cushion 8 of the press is more eccentric, and long-term production will cause greater damage to the air cushion, which will lead to poor press precision and lower product quality. Instability and other quality risks.

[0016] In order to solve this problem, the present embodiment is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com