Gear modification method based on uniform load distribution

A technology of uniform distribution and load distribution, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as gear failure, gear manufacturing cost increase, meshing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

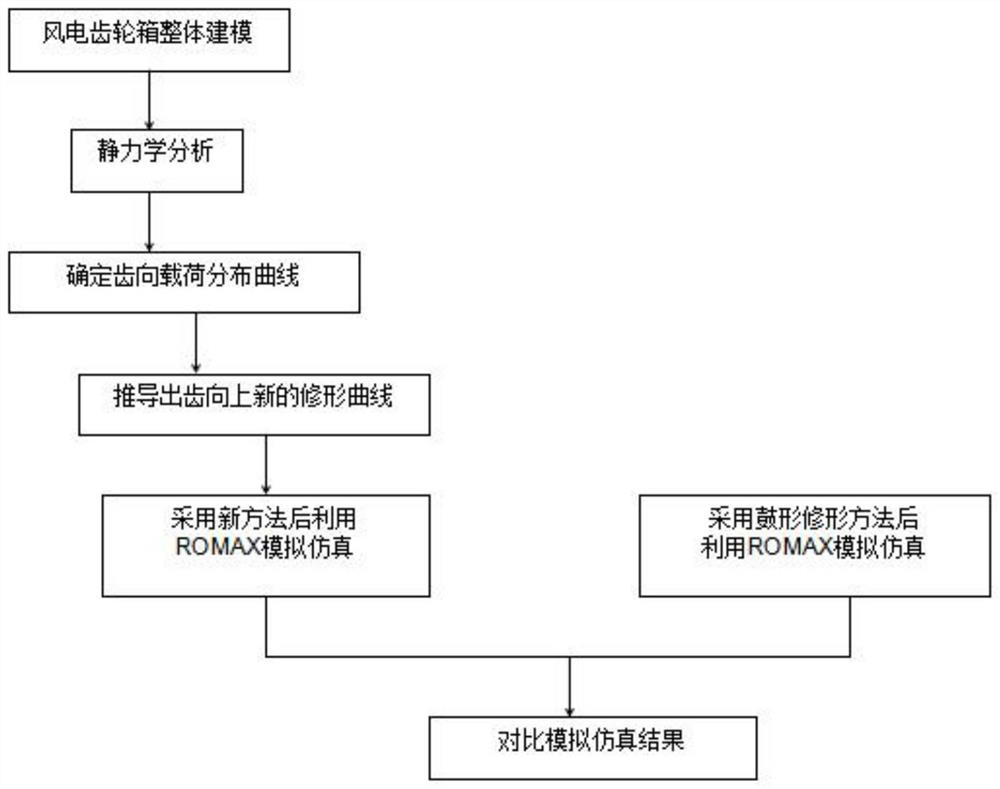

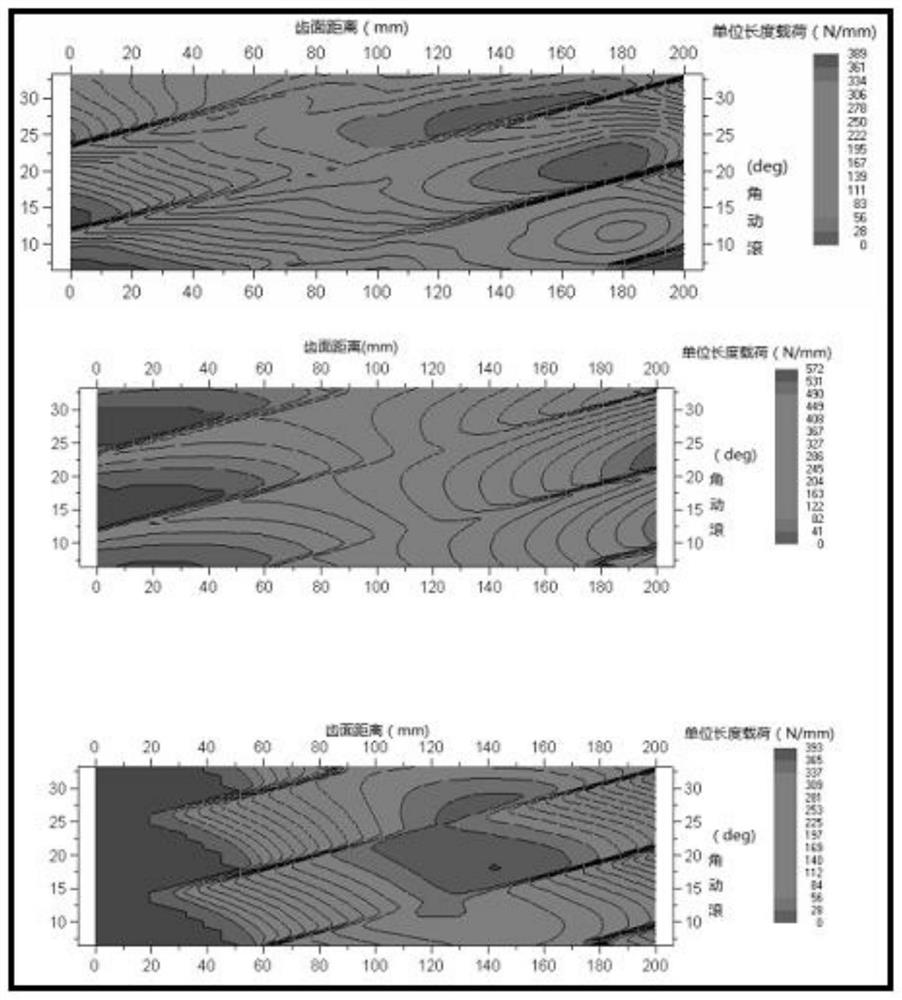

[0014] According to the research on the basic theory and manufacturing process of heavy-duty gear meshing, according to the "bottom-up" thinking, the technical scheme of the present invention is as follows: figure 1 . This route starts with the static analysis of the gearbox, seeks the load distribution curve based on the tooth direction, and compares the results of the drum shape modification and the new modification method through Romax simulation analysis to obtain the modification amount of the MW-level wind power gearbox gear. Maximizes gear mesh performance and minimizes mesh errors.

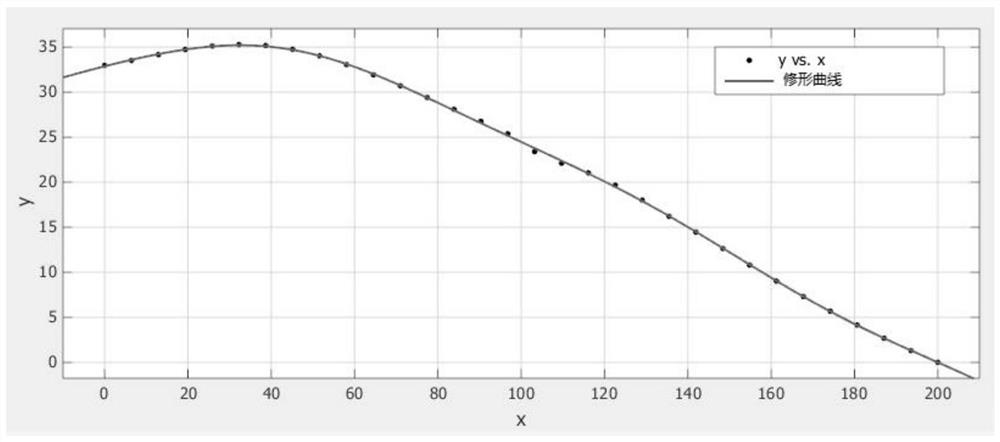

[0015] Since the wind power gearbox is in a complex environment of variable direction and load all year round, it is difficult to solve problems such as unbalanced load, meshing in, and meshing out impact at one time with a single modification method. Therefore, a new comprehensive method of gear modification is proposed for MW-class gearboxes and their actual environment; the modificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com