Sliding type cable drum device

A cable and slip-type technology, applied in the field of slip-type cable reel devices, can solve problems such as vehicle eccentric load, and achieve the effects of solving eccentric load, flexible operation, and reducing sliding friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

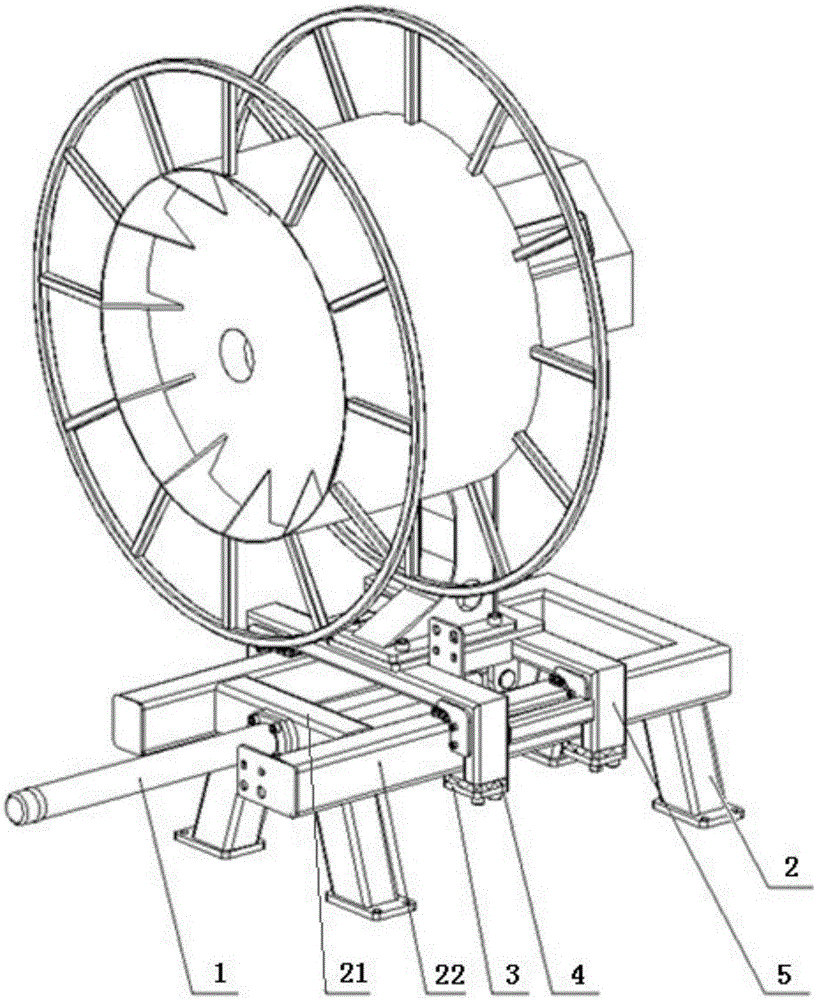

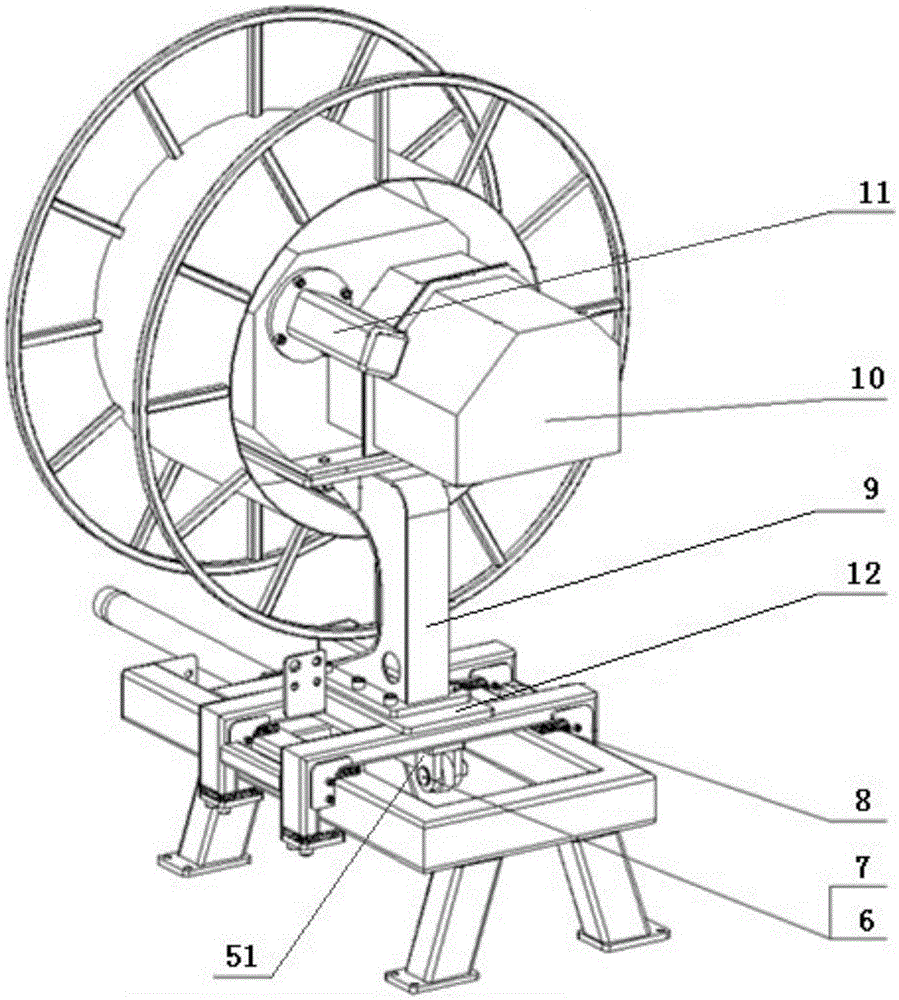

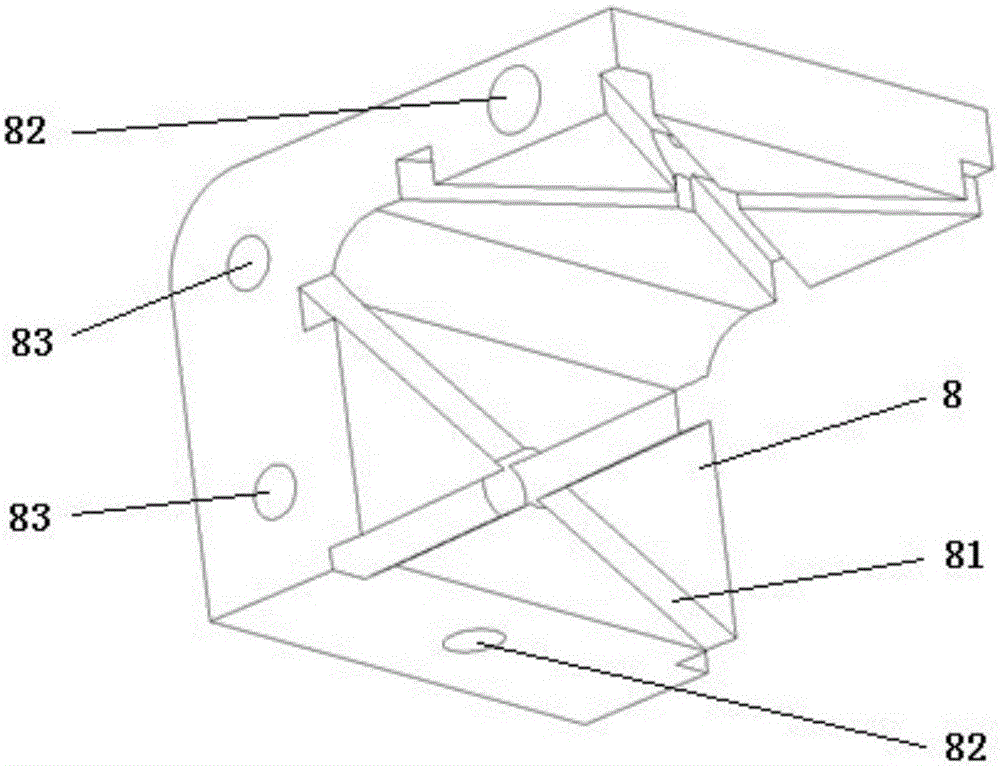

[0028] With reference to the accompanying drawings, the present invention is achieved in the following way: a sliding type cable reel device, which includes an oil cylinder 1, a guide rail chassis 2, a carriage 5, an L-shaped slider 8, a reel support 9, and a reel 10 and the motor 11; the guide rail chassis 2 includes two horizontally arranged and parallel guide rails 22 and two parallel beams 21, the guide rails 22 and the beams 21 are vertically connected to each other; the oil cylinder 1 is arranged parallel to the guide rails 22 and connected to the beam 21 is used to push the slide frame 5 to move along the guide rail 22; the above guide rail 22 is provided with two slide frames 5 whose length direction is all parallel to the crossbeam 21 and the L-shaped slide block 8 provided by the slide frame 5 can be mounted on the guide rail 22 Moving up; above the carriage 5, a reel support 9 and a reel 10 are arranged, and the motor 11 is used to drive the reel 10 to rotate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com