Patents

Literature

50results about How to "Low coefficient of sliding friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

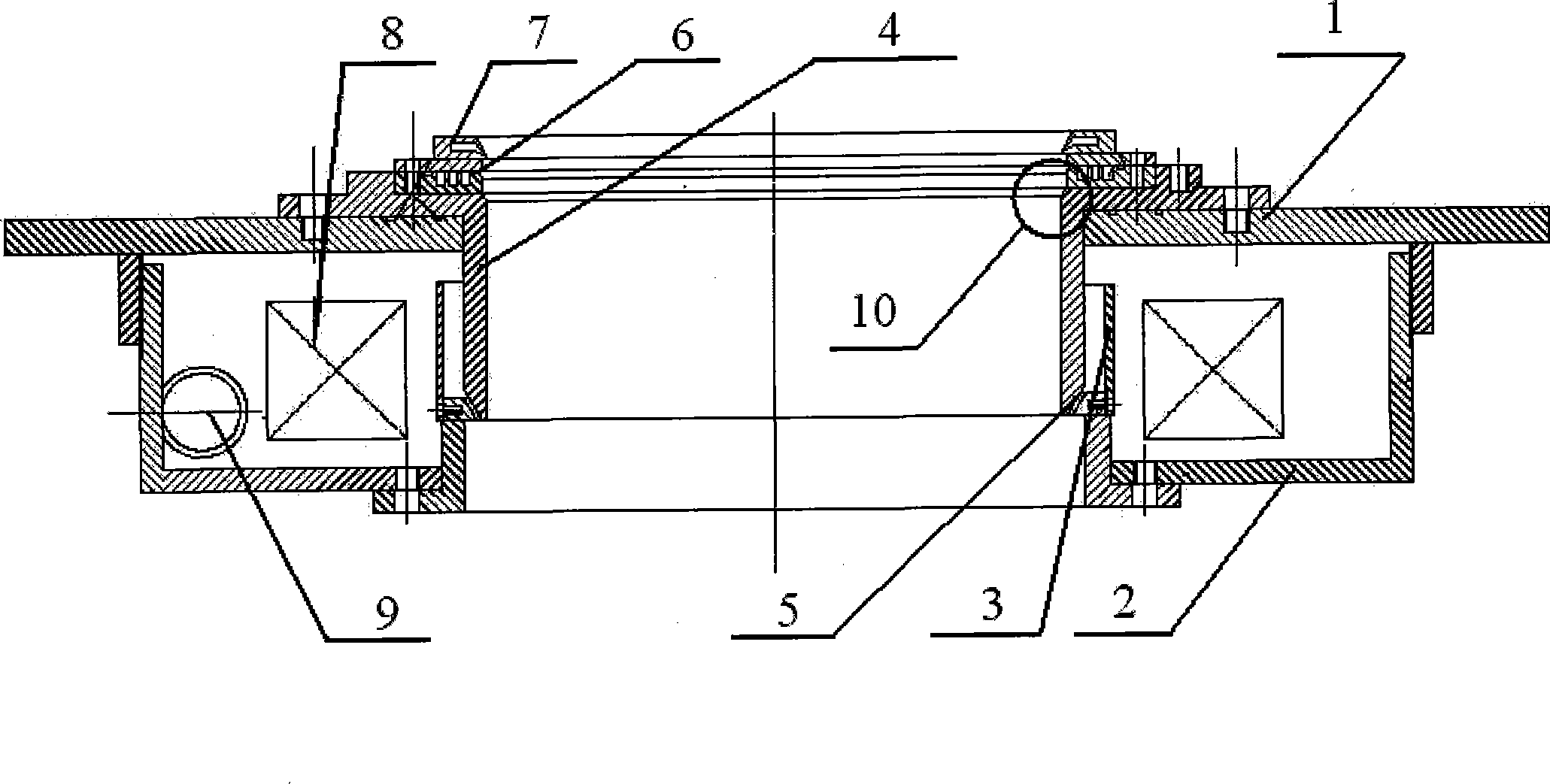

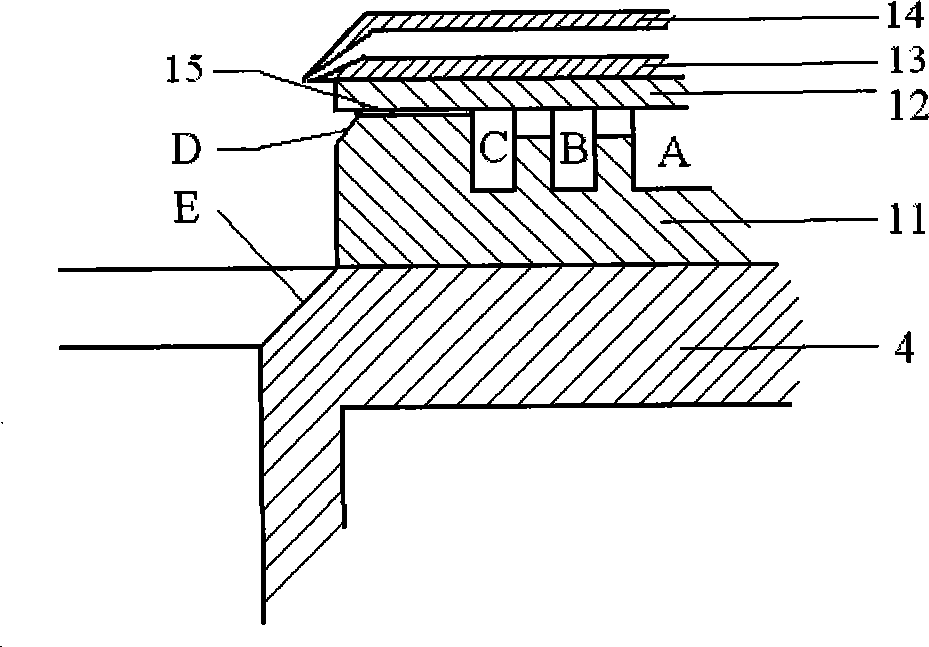

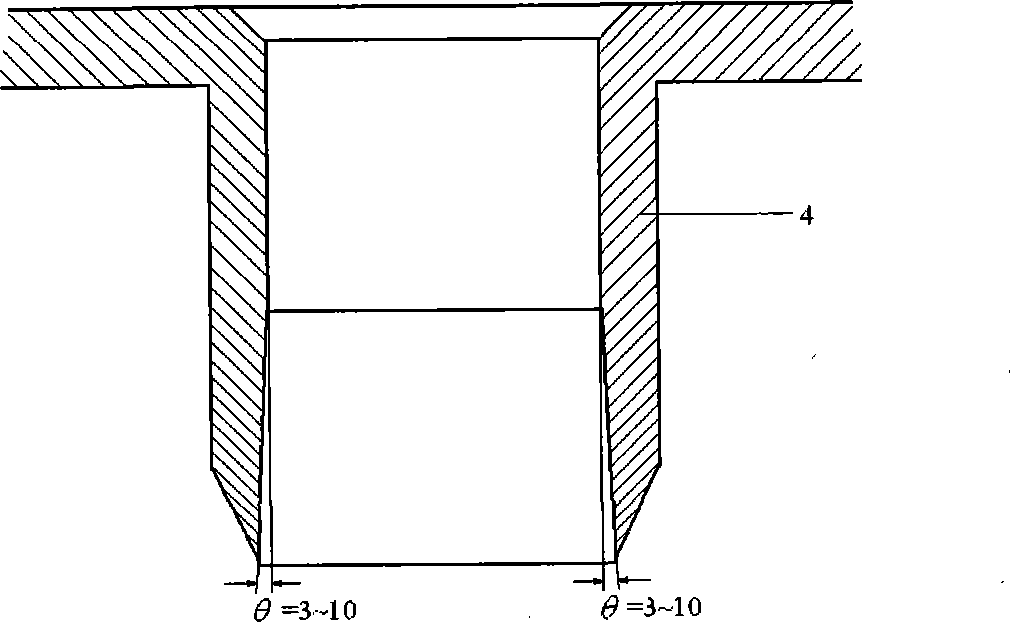

Oil lubricating electromagnetic vertical type semi-continuous casting method and crystallizer of magnesium alloy ingot blank

InactiveCN101239371AReduce interface contact pressureLow coefficient of sliding frictionThin layerConductor Coil

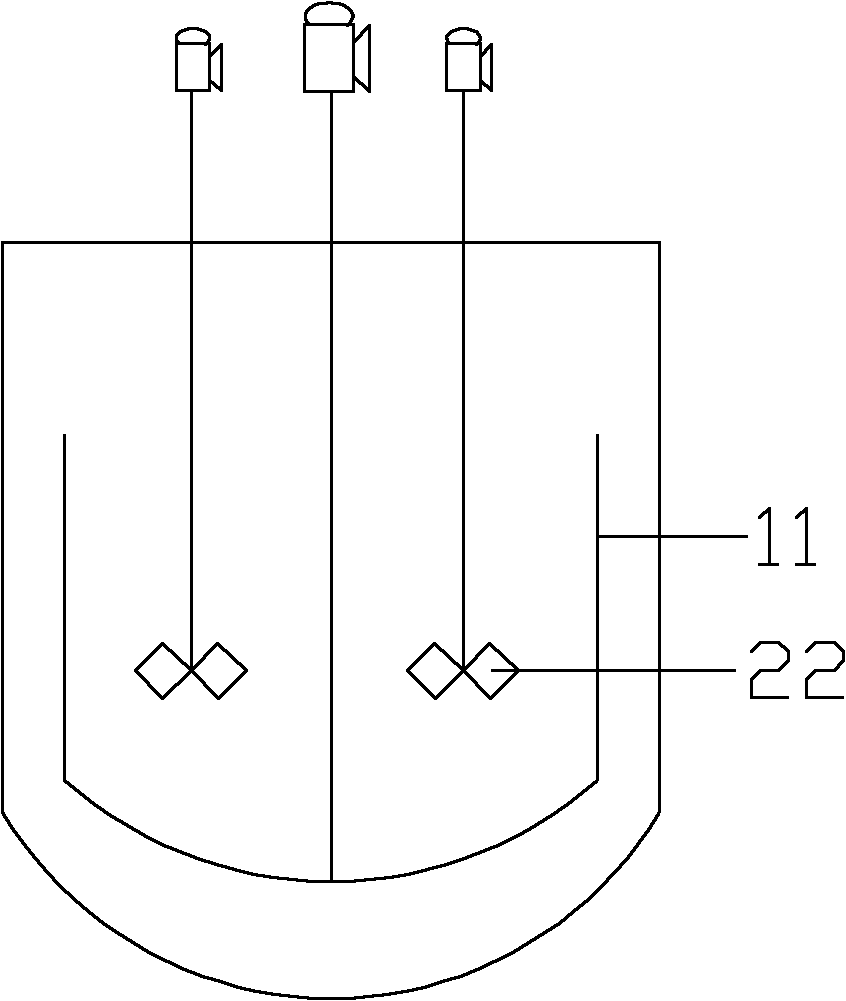

An oily electro-magnetism vertical type semi-continuous casting process for a magnesium alloy ingot blank and a crystallizer are disclosed. The crystallizer comprises a metal liner, a cooling system, an excitation winding, a splash ring and a cover gas ring. The metal liner is disposed at the center of crystallizer. A cavity cooling system is disposed out of the metal liner. The excitation winding is disposed at the lower part in the cooling water cavity. A splash ring is disposed at the upper edge of the crystallizer liner. A cover gas ring is disposed above the splash ring. The invented method comprises following steps: coating a thin layer of lubricant oil on the inner wall of the metal liner, starting the crystallizer cooling system; then starting the low frequency generation power source to supply low frequency alternating current to the excitation winding; inducing the magnesium alloy fluid into the shunting disk disposed in the center of the liner; opening the cover gas ring; starting the casting machine and adjusting the crystallizer liquid level to be stable after the magnesium alloy fluid fills the top of the dummy ingot head; enlarging the cooling water flow, opening and adjusting control valve for controlling the splash ring. The invented proves can improve the surface quality of the magnesium alloy ingot blank, reduce surface turning quantity thereof, and increase casting speed thereof.

Owner:NORTHEASTERN UNIV

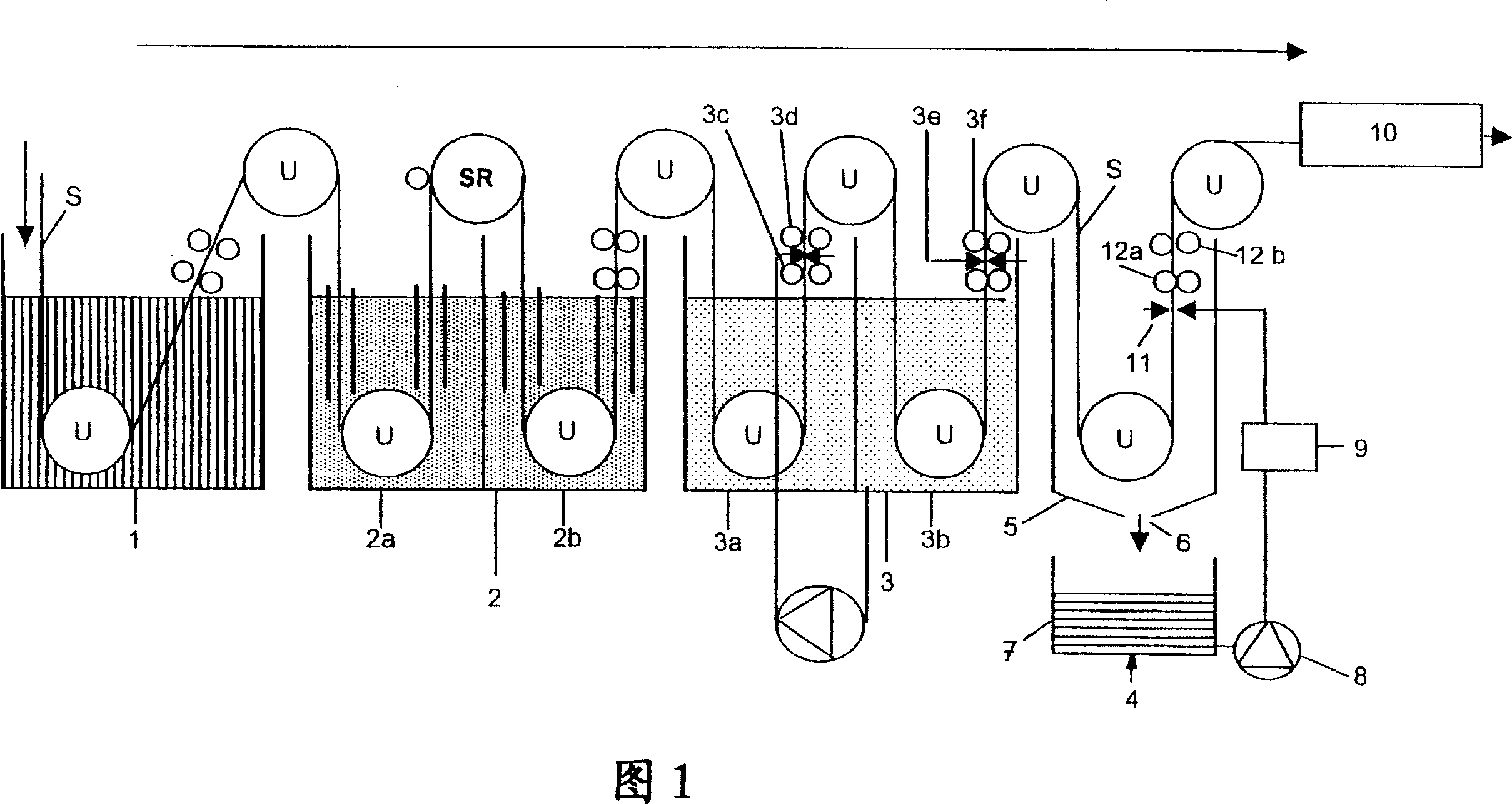

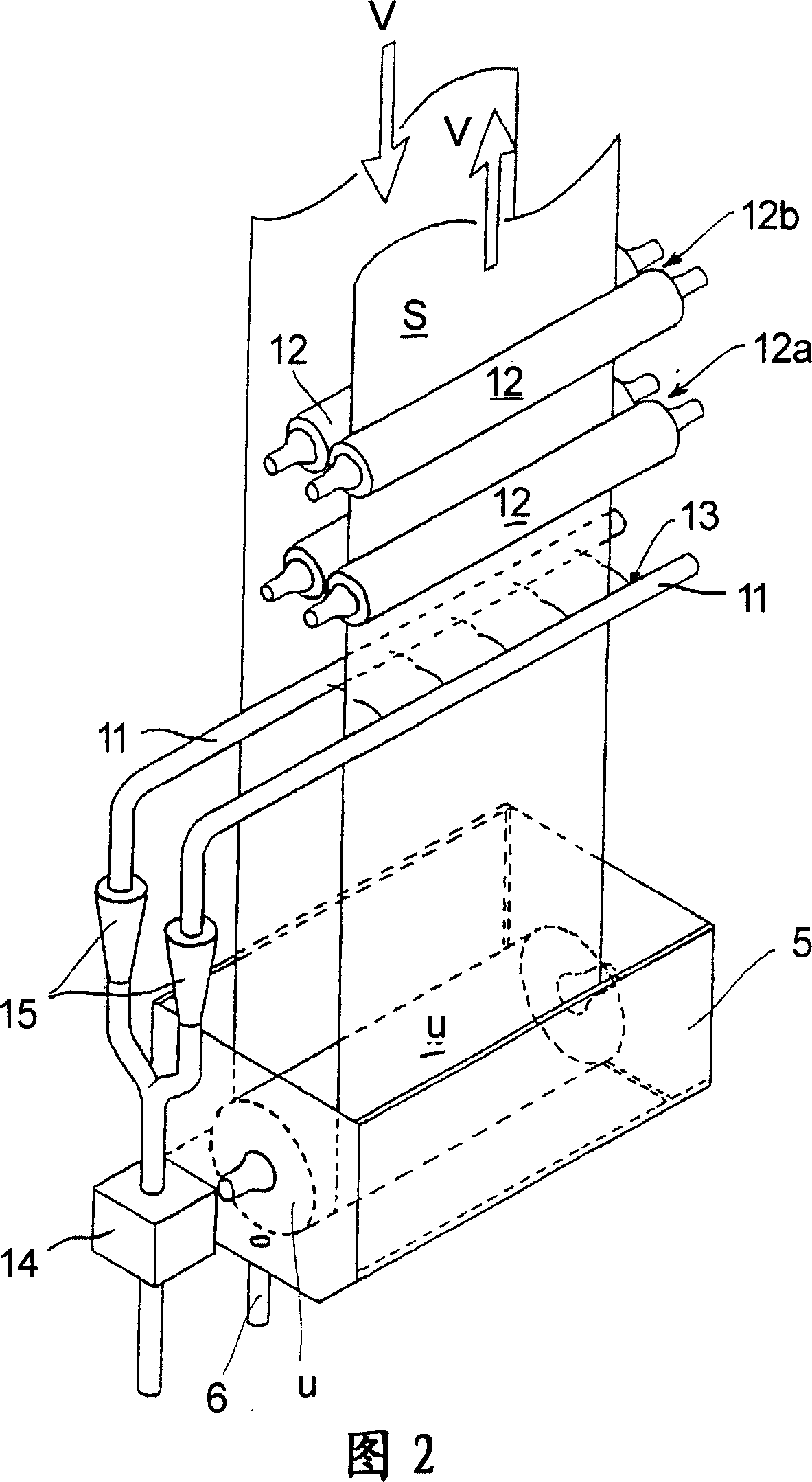

Method for lowering the coefficient of friction of the surface of metal bands with a coating and device for applying a metallic coating onto a steel band

InactiveCN1935391ALow coefficient of sliding frictionHot-dipping/immersion processesLiquid surface applicatorsCoated surfaceTin plating

The invention provides a method for lowering the coefficient of friction of the surface of metal bands with a coating, especially of tin-plated or chromium-plated steel bands (S), which are passed through a coating installation at a band speed (v). To be able to lower the coefficient of friction of the surface of the coating even at high band speeds through the coating installation, according to the invention, an aqueous solution of a tenside is sprayed onto the coated metal band passed at the band speed (v) after the coating process. The invention further provides a device for applying a metallic coating onto a steel band, especially in a band tin-plating installation or band chromium-plating installation.

Owner:THYSSENKRUPP AG

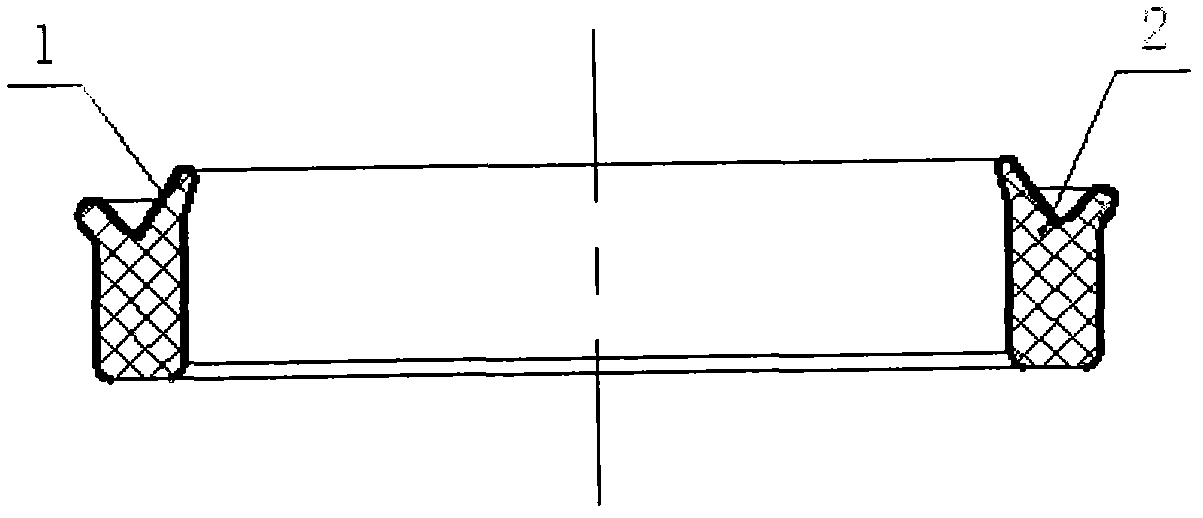

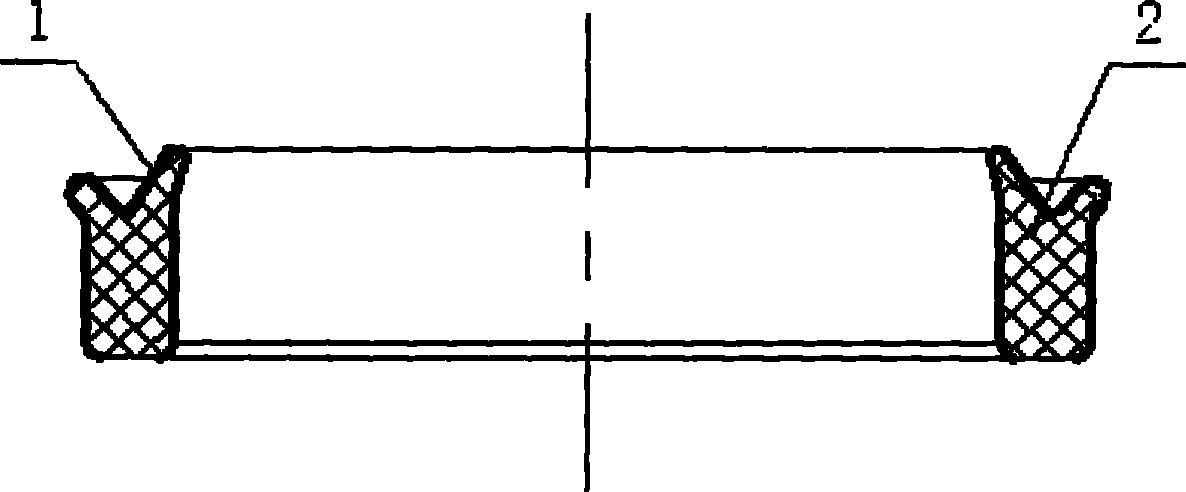

Anti-friction sealing ring

The invention discloses an anti-friction sealing ring, and belongs to a sealing device. The anti-friction sealing ring comprises a Yx type sealing ring, wherein an anti-friction coating layer is coated on the sliding surface of the Yx type sealing ring; and the anti-friction coating layer is a polytetrafluoroethylene composite material coating layer. The anti-friction sealing ring is prepared from the following raw materials by the following steps of: adding copper powder with purity of over 99.7 percent and graphite powder with purity of over 99.85 percent into a 1.5 to 2 mass percent of KH-560 silane coupling agent and acetone respectively; performing ultrasonic oscillation; placing in a drying box, taking out after the acetone is evaporated, grinding and screening with a 200-mesh screen; heating PAN-based carbon fiber and preserving heat; oxidizing and cooling along with a furnace; mixing 6 to 8 percent of copper powder, 2 to 3 percent of graphite powder, 4 to 6 percent of carbon fiber and the balance of polytetrafluoroethylene powder and mixing in a ball mill; heating to melt and coating on the surface of the polyurethane Yx type sealing ring; and cooling and forming to form the anti-friction sealing ring. The anti-friction sealing ring has the advantages of simple structure, good sealing effect, small sliding friction coefficient and capability of reducing the sticking and slipping phenomenon of a hydraulic cylinder.

Owner:XUZHOU UNIV OF TECH

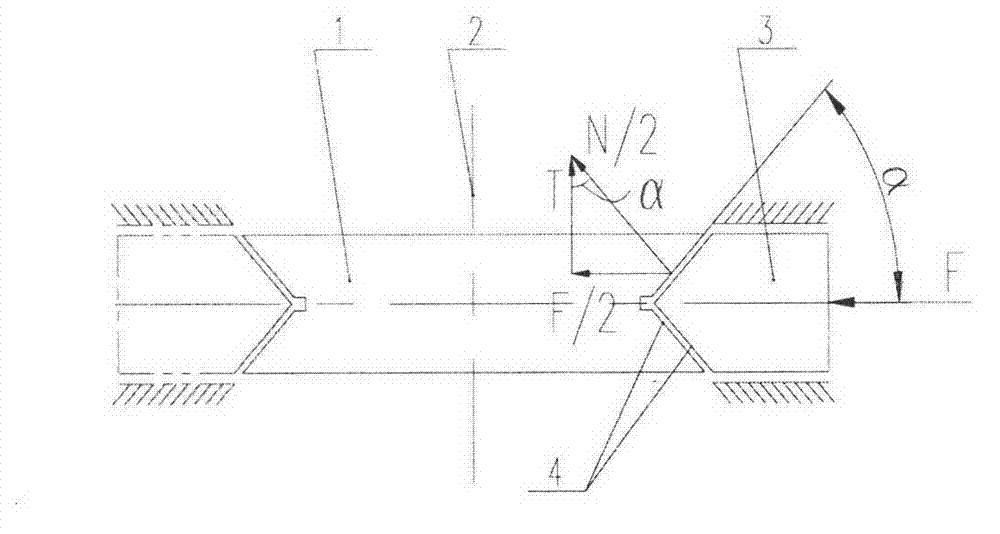

Conical surface friction brake for industry and automobiles

ActiveCN102808873ALarge braking torqueSuper boostBraking membersDrum brakesBrake torqueFriction torque

The invention relates to a friction brake for industry and automobiles, which is structurally characterized in that a brake friction pair consists of a brake pressure stressing piece and a stressed piece, wherein the friction surfaces of the brake pressure stressing piece and the stressed piece adopt conical surfaces, and another mode relative to the existing drum brake that the cylindrical surface and the disk brake adopt the end surfaces to produce friction torque is adopted, and the conical surface friction brake belongs to the technical field of mechanical devices and transportation. As the conical surface friction brake has the characteristics of the realization of being automatically reinforcing and changing the included angles between the brake acting force and the conical surfaces, so as to adjust the size of the torque, and the like, the friction brake can improve the interchangeability of the brake parts, widen the friction material selecting range, save the energy sources, and increase the brake torque, as a result, the friction brake has wide application prospect in the industry and the automobile brakes.

Owner:四川劲兴制动科技有限公司

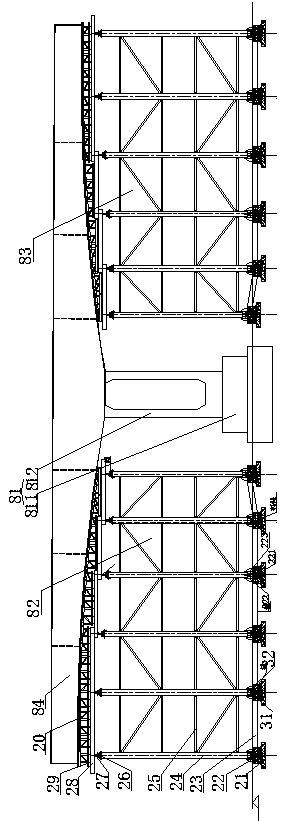

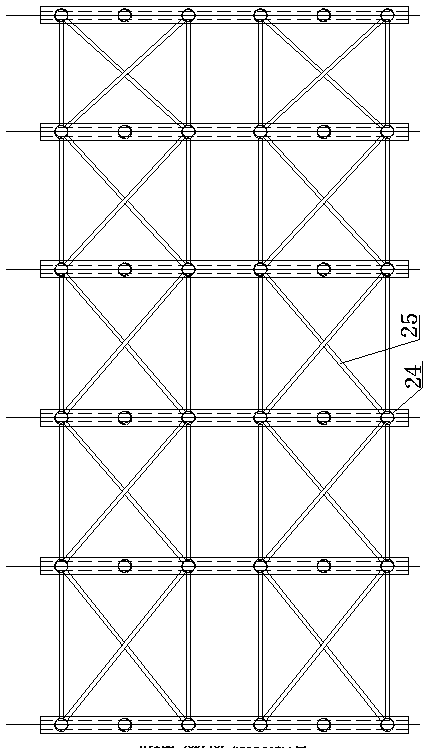

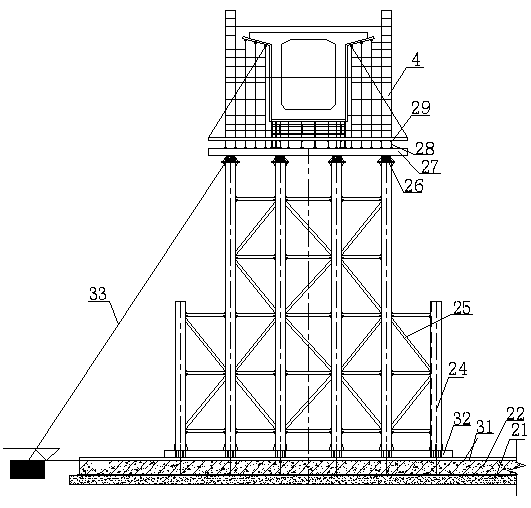

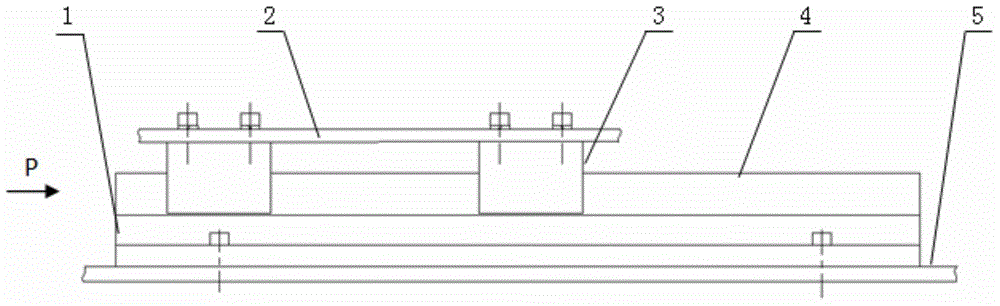

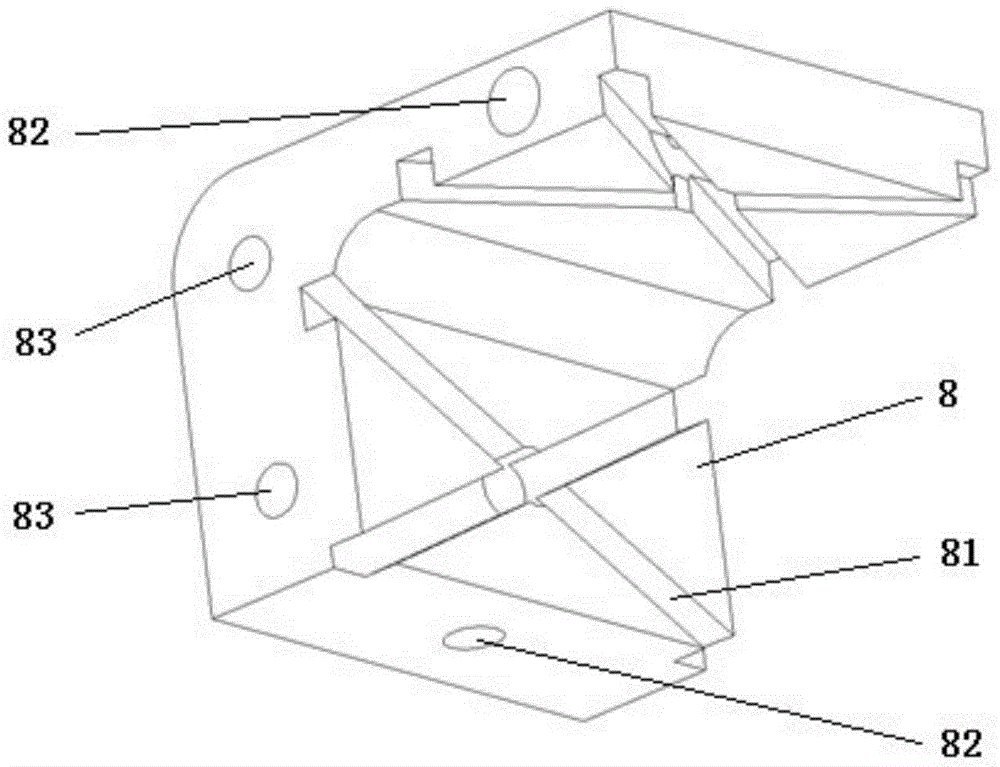

Construction support device and construction method for bridge adjacent to business line

PendingCN110725209AAchieve supportEasy to moveBridge erection/assemblyConstruction engineeringArchitectural engineering

The invention discloses a construction support device and a construction method for a bridge adjacent to a business line. The construction support device for the bridge adjacent to the business line comprises a middle support (81) used for supporting the middle of the bridge, a side support group used for supporting the side face portion of the bridge and a disc buckle frame (84) arranged on the side support group and used for supporting a template on the side face portion of the bridge. The construction support device for the bridge adjacent to the business line realizes supporting for the template on the side face portion of the supported bridge through the disc buckle frame (84), realizes supporting for the middle of the supported bridge through the middle support (81), and realizes moving for the bridge through the side support group, thereby realizing construction for the bridge far away from an existing rail traffic business line, and improving construction efficiency of the bridge.

Owner:中铁十局集团第八工程有限公司 +1

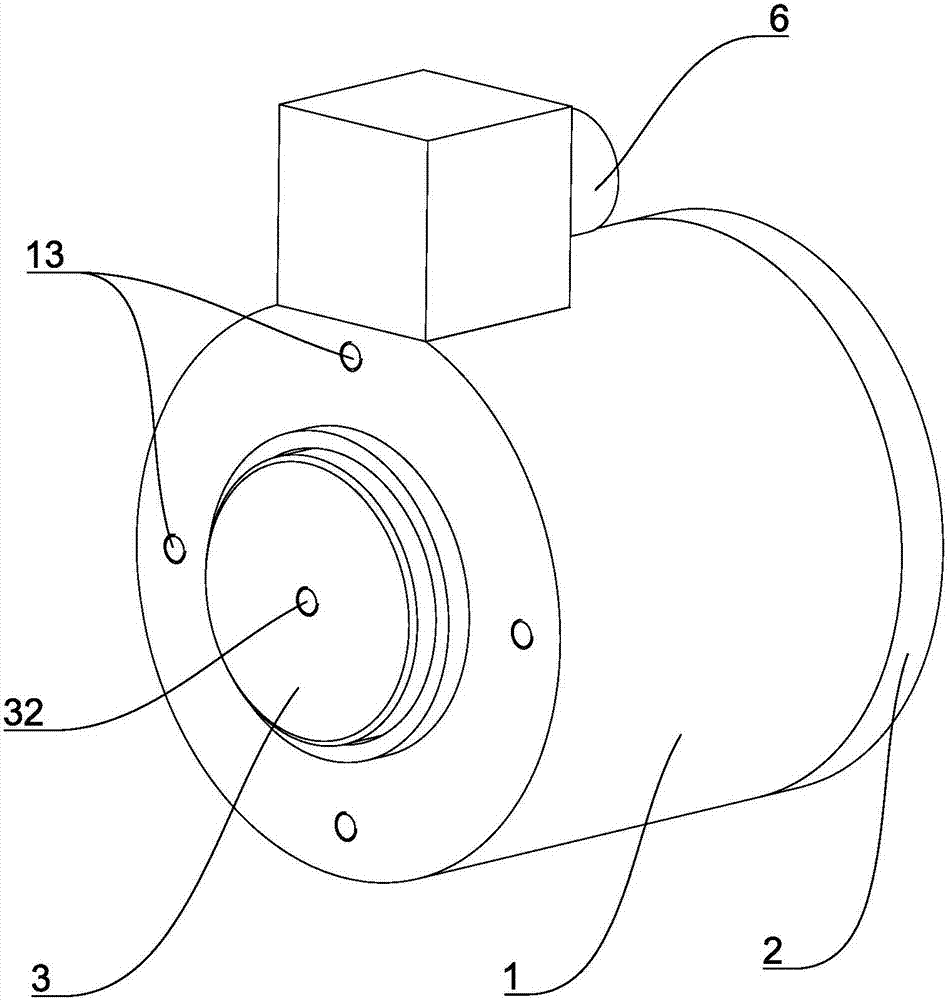

Wide-temperature-range large-suction pushing-pulling electromagnet and manufacturing method thereof

ActiveCN105761876ASmooth slidingSmall motion sensitivityMagnetsInductances/transformers/magnets manufacturePush pullEngineering

The invention discloses a wide-temperature-range large-suction pushing-pulling electromagnet and a manufacturing method thereof. The electromagnet comprises a shell, a rear sealing cover, a movable iron core, a winding framework, a coil and an electric connector socket, the winding framework is positioned in a first groove in the shell and fixedly connected with the shell through the rear sealing cover for sealing, and the coil is wound in a winding groove of the winding framework and enables two poles of the coil to penetrate the shell to be electrically connected with the electric connector socket. One end of the movable iron core is positioned in a magnetic core hole of the winding framework and connected with the rear sealing cover through a resetting spring while the other end of the same penetrates a first through hole in the shell and extends to the outer side of the shell, the shell, the rear sealing cover and the movable iron core are made of electromagnetic pure iron, and the winding framework is made of aluminum bronze. The electromagnet has the advantages of simple structure, small size, large suction and flexibility, and the electromagnet can work stably in an environment with a wide temperature range and rain and other environments. The manufacturing method has the advantages of simple process, convenience in assembly and high working efficiency.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

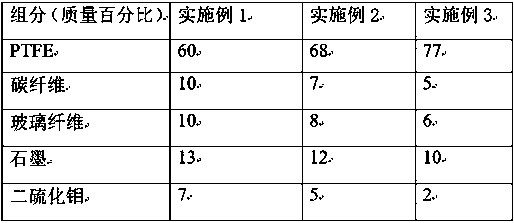

Wear-resistant PTFE composite material and preparation method thereof

InactiveCN109486069AReduce coefficient of frictionBalance of Mechanical PropertiesReciprocating motionGraphite

The invention discloses a wear-resistant PTFE composite material. The wear-resistant PTFE composite material is characterized by being prepared from the following components in percent by mass: 60-77%of PTFE, 5-10% of carbon fibers, 6-10% of glass fibers, 10-13% of graphite and 2-7% of molybdenum disulfide. The design balances the mechanical properties and friction property of the material, improves the wear resistance of the material to the maximum extent while reducing the tensile performance to the minimum extent, reduces the sliding friction coefficient of the product and improves the dimensional stability of the product effectively and prolongs the service life effectively. The formula is suitable for a sealing part which is good in wear resistance and bearing capacity or a frictionstructural part needing to reciprocate, so that the friction noise can be reduced, the grinding amount entering a circulating region is reduced, and the risk of strain breakage in assembly and use isreduced.

Owner:NANJING COMPTECH COMPOSITES CORP +1

Unmanned aerial vehicle real-time tension detection device and tension detection method thereof

PendingCN108444631AThe technical effect of no relative rotationReasonable structureApparatus for force/torque/work measurementElectric machinePropeller

The invention discloses an unmanned aerial vehicle real-time tension detection device and a detection method thereof, and belongs to the technical field of force measurement. The unmanned aerial vehicle real-time tension detection device comprises a first fixed sleeve, a second fixed sleeve, an installing base, a motor fixing seat, a tension sensor, a motor, a vibration reduction spring and a propeller, wherein the motor and the propeller are fixed on the motor fixing seat; the first fixing sleeve is connected with a machine body; the second fixing sleeve is internally sleeved or externally sleeved onto the first fixing sleeve and is provided with a position limiting device in the axial direction; the motor fixing seat and the second fixing sleeve are in rigid connection; meanwhile, the motor fixing seat is connected with one end of the tension sensor through the vibration reduction spring; the other end of the tension sensor is fixed on the installing base; the installing base is fixed onto the machine body. The non-circular sleeve type design is used, so that the reverse twisting force generated when the motor and the propeller work can be counteracted; the free movement can be performed in the tension direction; the tension detection function is realized.

Owner:陈俊胤

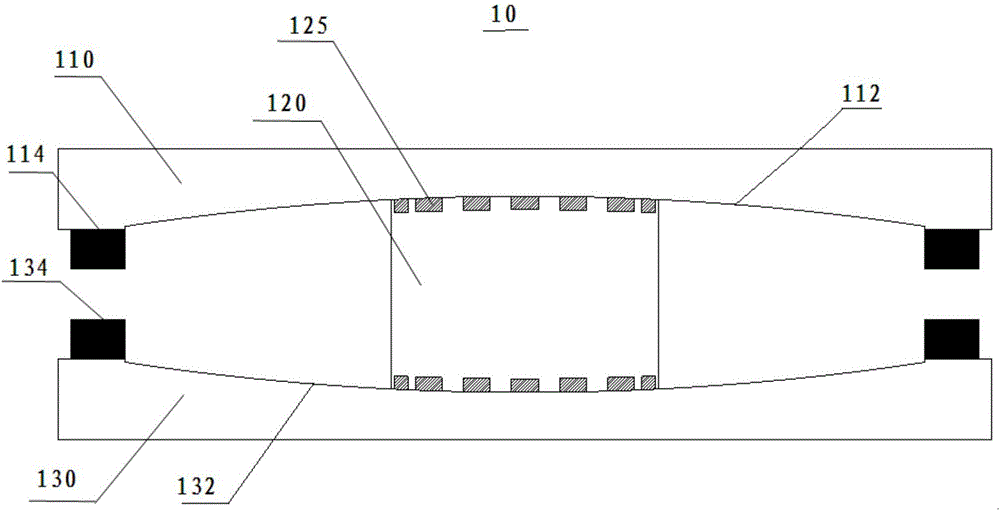

High-stiffness guide structure

InactiveCN104879380AEasy to manufactureLow coefficient of sliding frictionLinear bearingsHigh stiffnessOptical axis

The invention provides a high-stiffness guide structure. The high-stiffness guide structure comprises an optical shaft; the longitudinal section of the optical shaft is locked on the supporting surface of a shaft support by use of a screw; a plurality of sliders mounted at the bottom of a moving part are in fit with the surface of the optical shaft by use of guide sleeves inlaid into the sliders, and therefore, efficient and reliable guide motion of the moving part in the axial direction of the optical shaft is realized. The high-stiffness guide structure is simple in structure, easy to manufacture, simple and convenient to mount, and capable of bearing relatively high loads in the radial direction of the guide shaft, has efficient and reliable guide performance, and is especially suitable for heavy loading and unbalance loading, in particular occasions of great radial loads.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

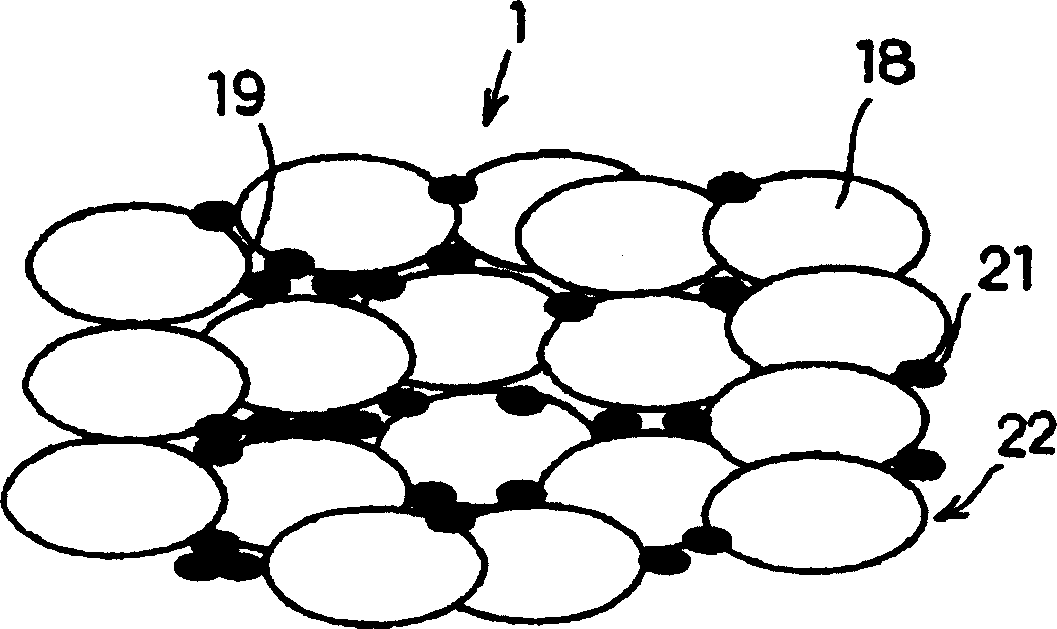

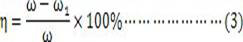

Particle-stabilized nanometer emulsion lubricant for water-based drilling fluids, and preparation method thereof

ActiveCN109666460AGood dispersionImprove adsorption capacityDrilling compositionWater basedVegetable oil

The invention relates to a particle-stabilized nanometer emulsion lubricant for water-based drilling fluids, and a preparation method thereof, wherein the particle-stabilized nanometer emulsion lubricant comprises 30-60% of fatty acids and ester derivatives thereof, 5-25% of a nonionic surfactant, 10-20% of a cationic surfactant, 5-20% of a solid lubricant, and 15-40% of water. According to the present invention, the particle-stabilized nanometer emulsion lubricant has good dispersibility in water-based drilling fluids, can overcome the disadvantages of difficult dispersion and easy oil phaseprecipitation of mineral oil or vegetable oil or other conventional liquid lubricants, can form the stable adsorption film on drill bits, drilling rods and well walls, can effectively reduce the friction coefficient of the friction surface, improve the lubrication performance and reduce the wear, and further can maintain good lubrication performance under extreme pressure or high load.

Owner:CHINA PETROLEUM & CHEM CORP +1

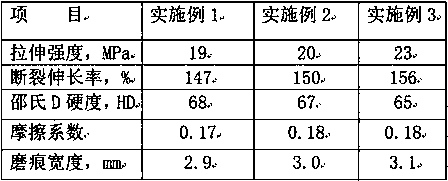

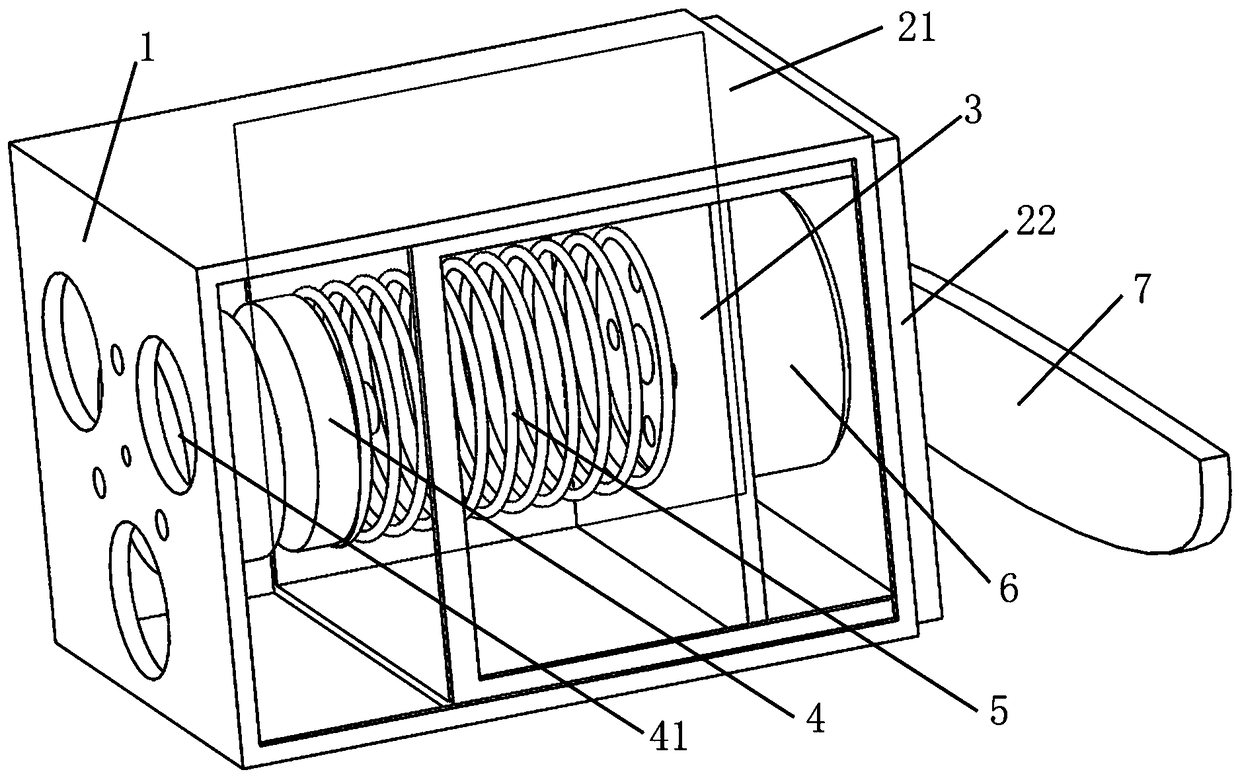

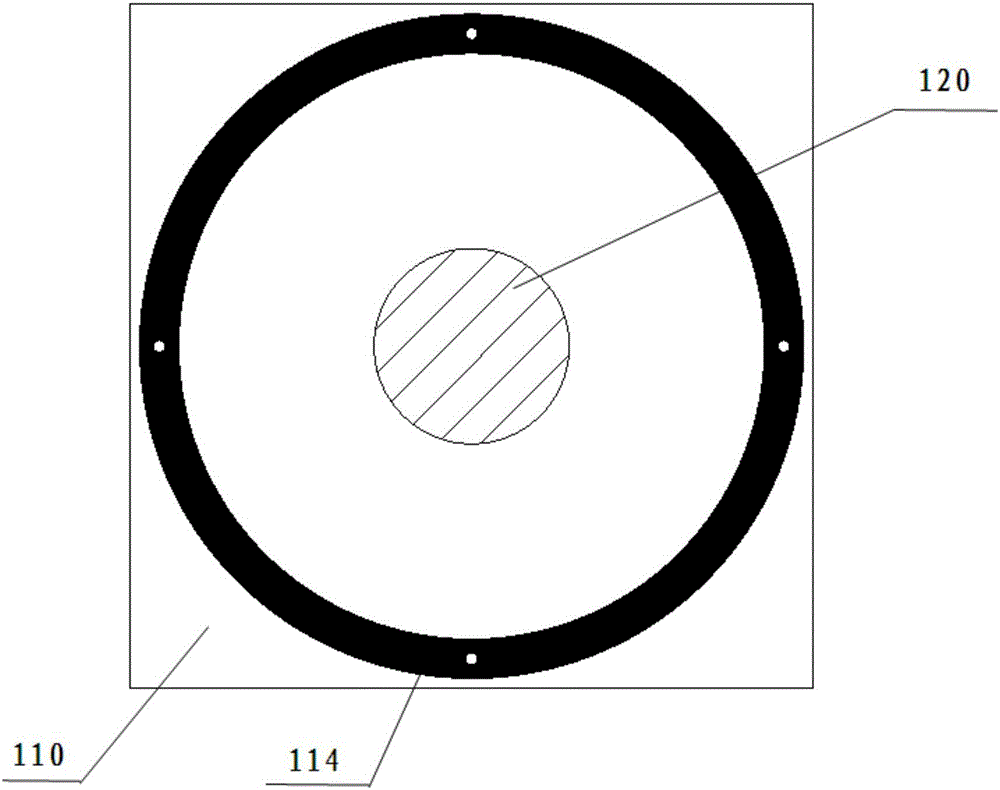

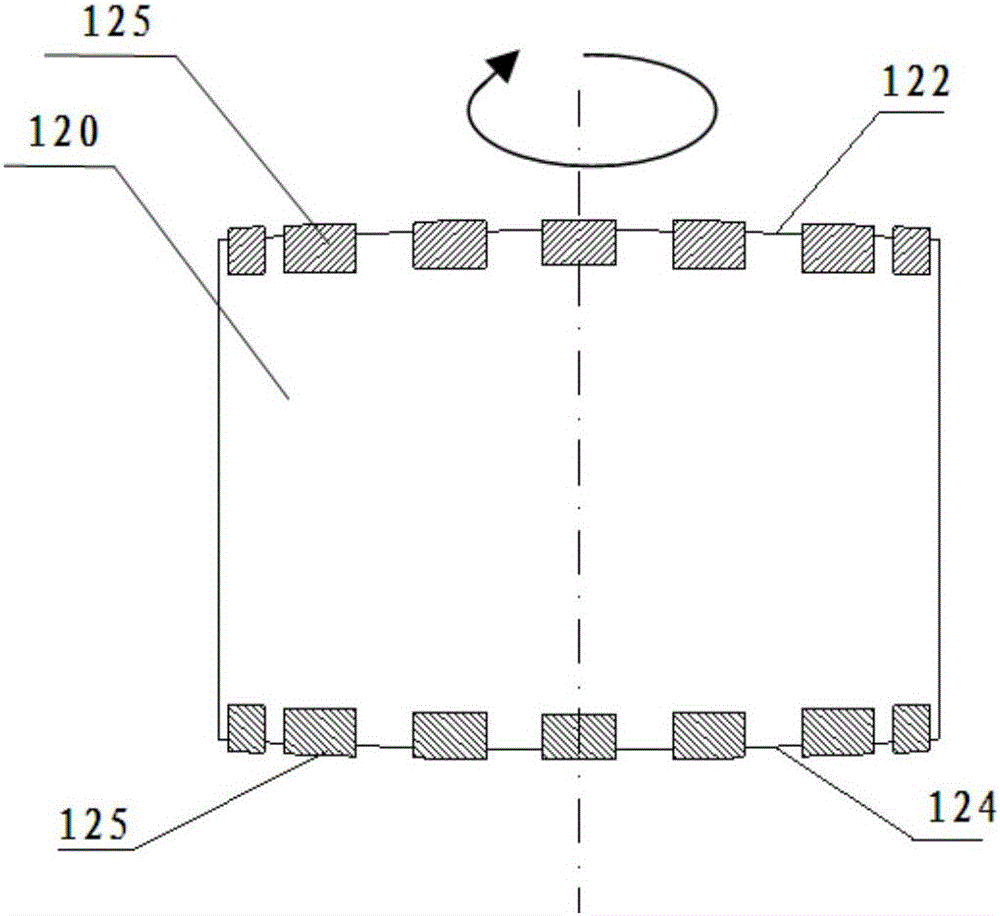

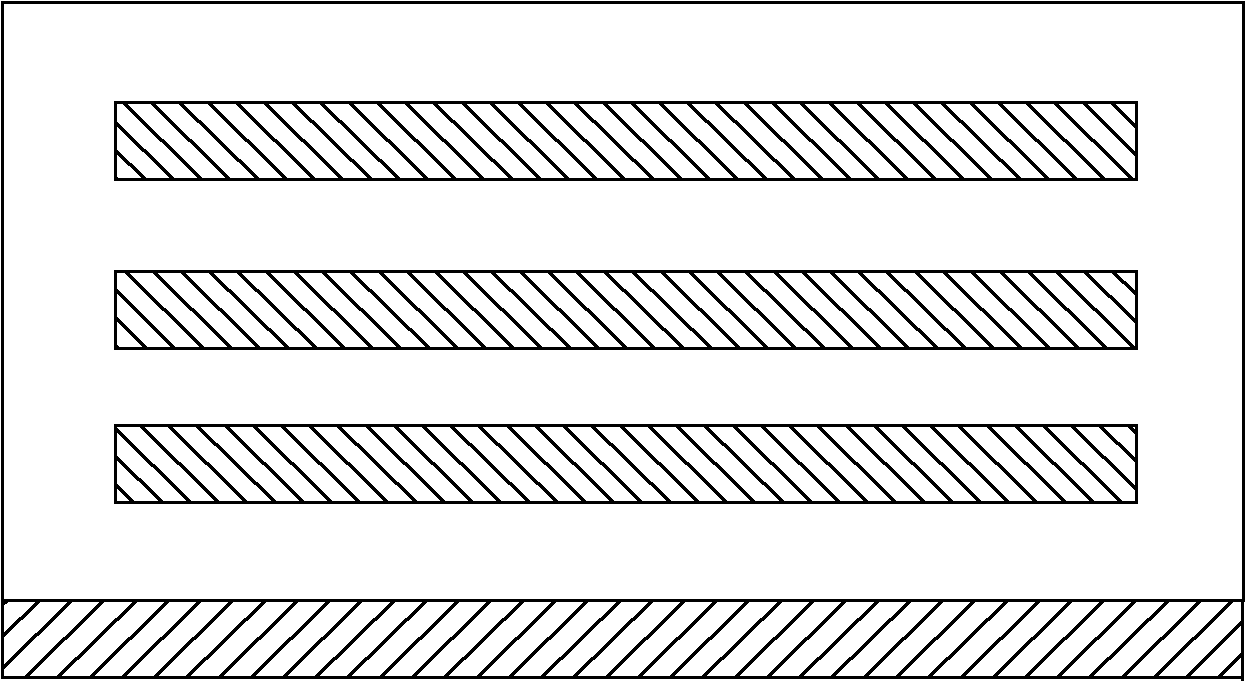

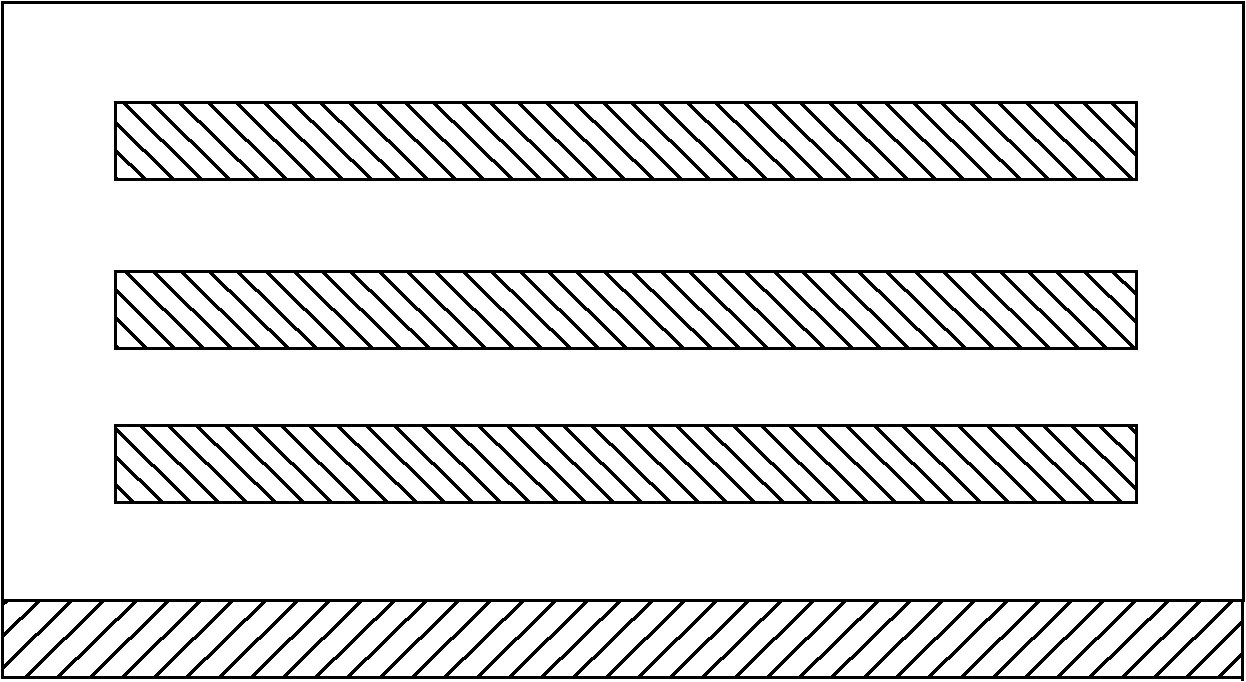

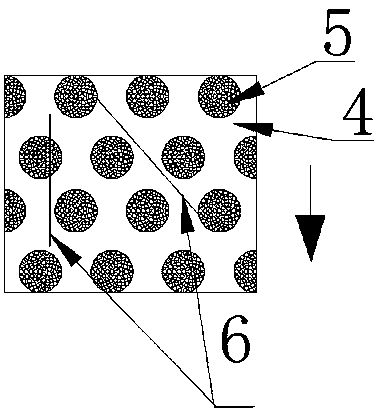

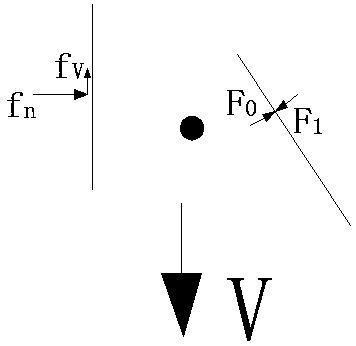

Frictional sliding seat

InactiveCN106759929AImprove stabilityLow coefficient of sliding frictionProtective buildings/sheltersShock proofingEngineeringBlock structure

The invention provides a frictional sliding seat. The frictional sliding seat comprises a first molding plate and a second molding plate which are arranged in separation, and a sliding block structure which is arranged between the first molding plate and the second molding plate. The first molding plate is provided with a first frictional face. The second molding plate is provided with a second frictional face. The first frictional face and the second frictional face are arranged in opposition. The sliding block structure is provided with a first sliding face and a second sliding face which are oppositely arranged. Both of the first sliding face and the second sliding face are provided with a plurality of lubricating blocks. The lubricating blocks of the first sliding face are contacted with the first frictional face when being installed. The lubricating blocks of the second sliding face are contacted with the second frictional face.

Owner:TSINGHUA UNIV

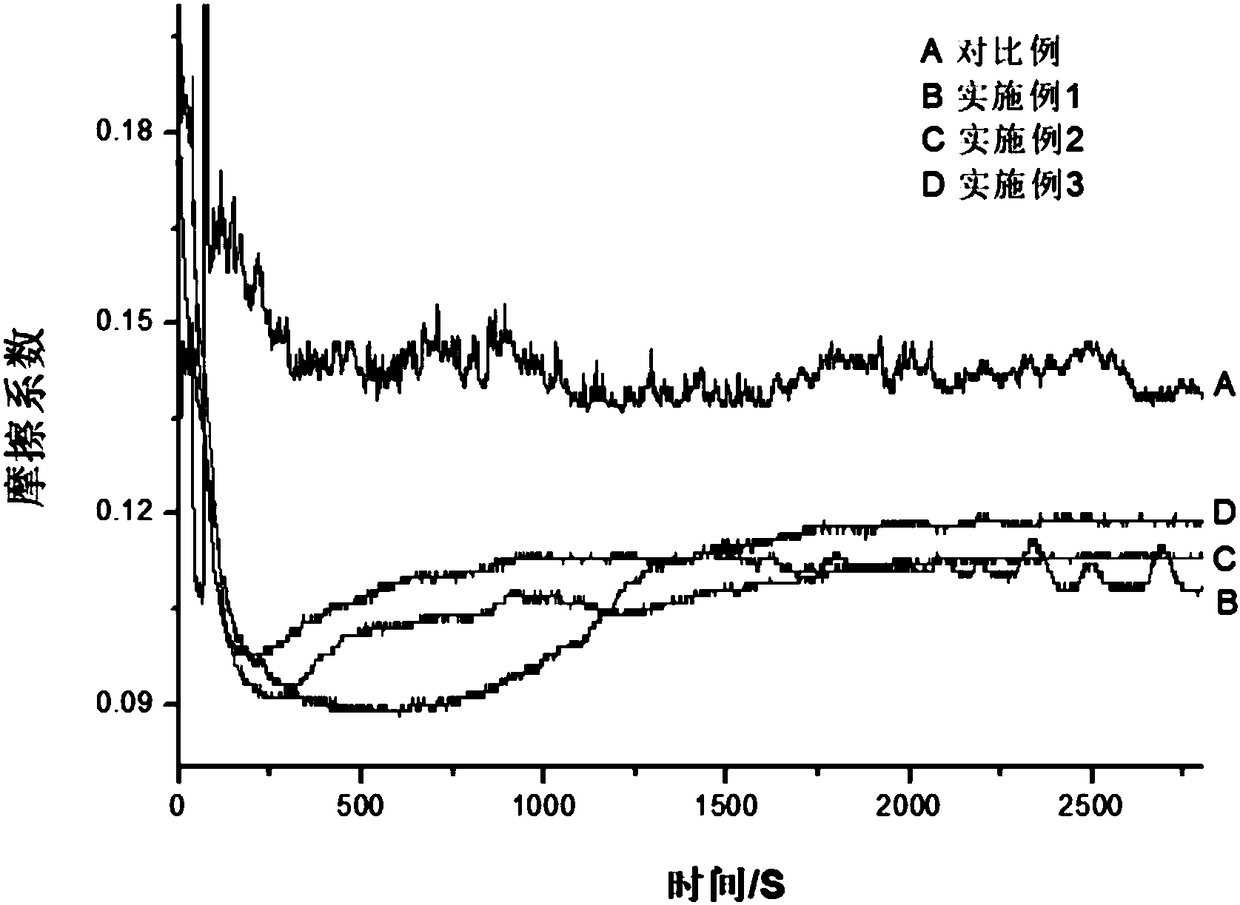

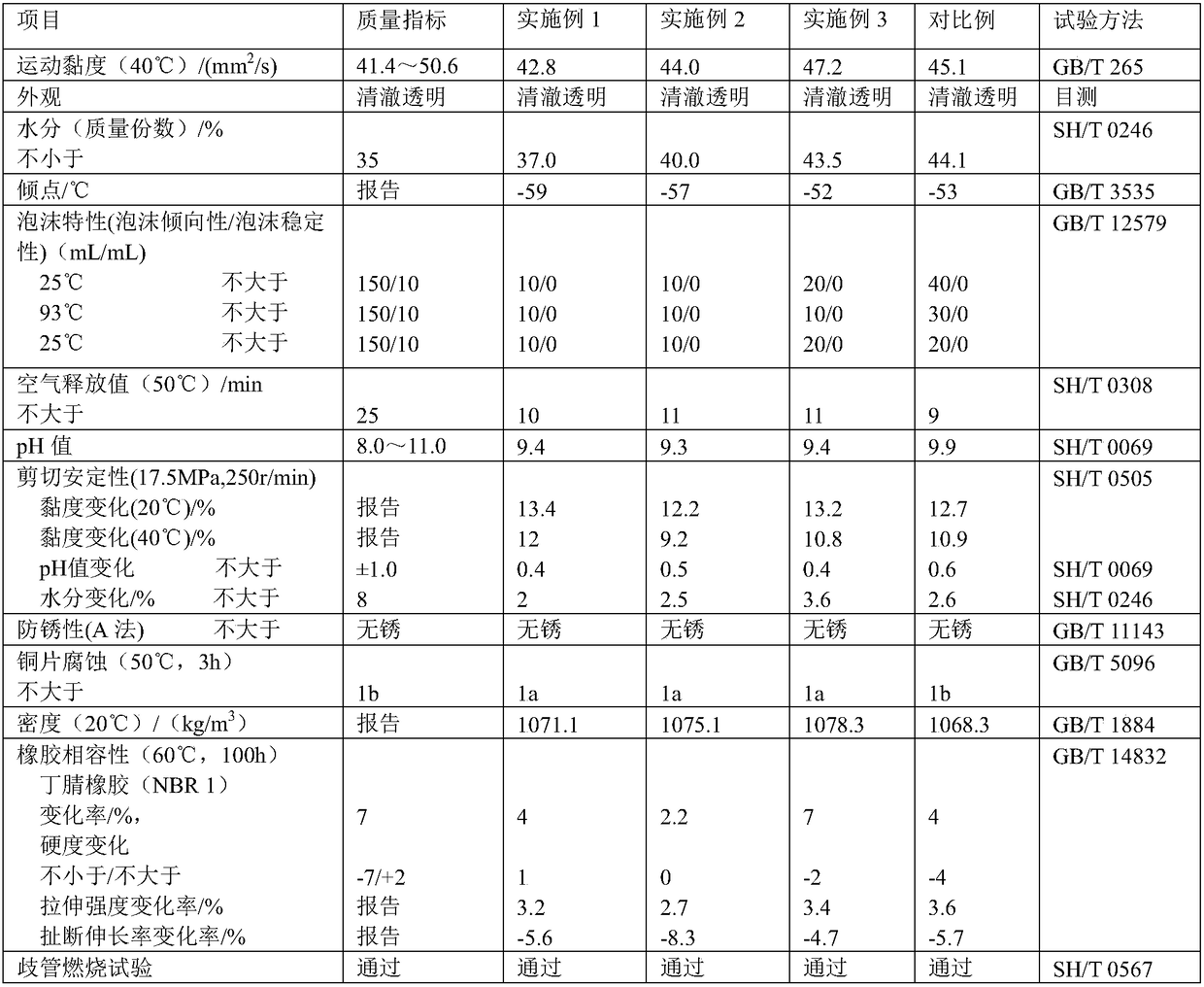

Long-life type water-glycol fire-resistant hydraulic fluid

InactiveCN108485788ASolution to short lifeImprove stabilityLubricant compositionHydraulic equipmentHydraulic fluid

The invention discloses a long-life type water-glycol fire-resistant hydraulic fluid. The long-life type water-glycol fire-resistant hydraulic fluid is characterized by comprising the following main materials by mass: 30-40 parts of water, 35-45 parts of glycol, 10-20 parts of tackifier, 3-10 parts of lubricant, 0.6-1.8 parts of composite corrosion inhibitor, 0.05-0.2 part of chelating agent, 0.002-0.005 part of anti-foaming agent, and 0.001-0.002 part of coloring agent; the lubricant is fatty acid amine salt, and the composite corrosion inhibitor is a mixture of mercaptobenzothiazole, sodiummolybdate and methylbenzotriazole. The long-life type water-glycol fire-resistant hydraulic fluid is excellent in stability, has a good lubricating property and a long service life, comprehensively balances the various performances of the fire-resistant hydraulic fluid, meets the actual use requirement of hydraulic equipment, and is particularly suitable for the use requirement of the hydraulic equipment under the high temperature and open fire accessible working environment.

Owner:湖北格润化工有限公司

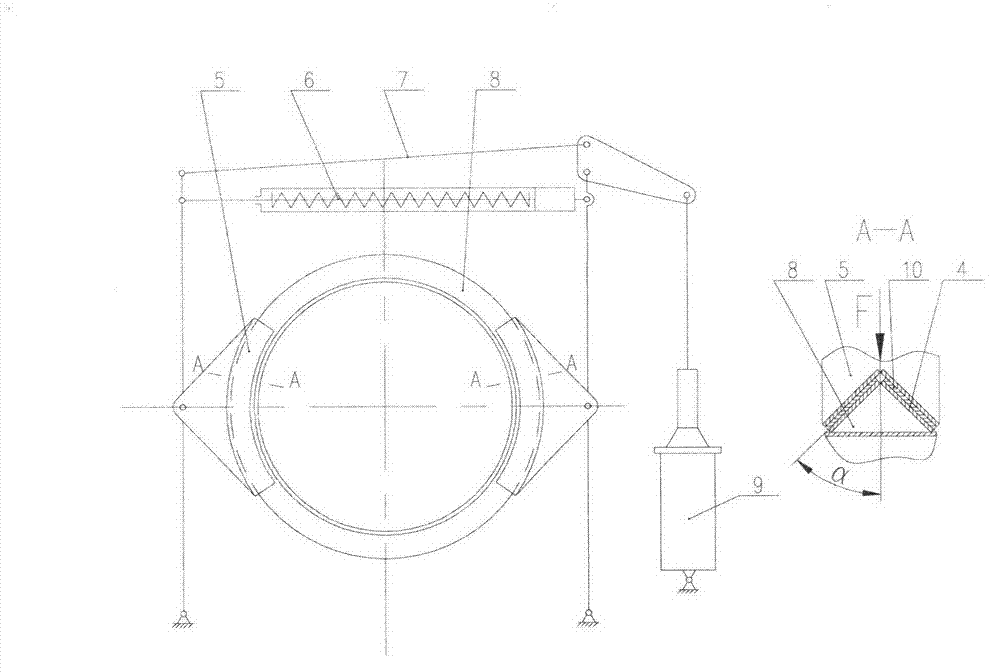

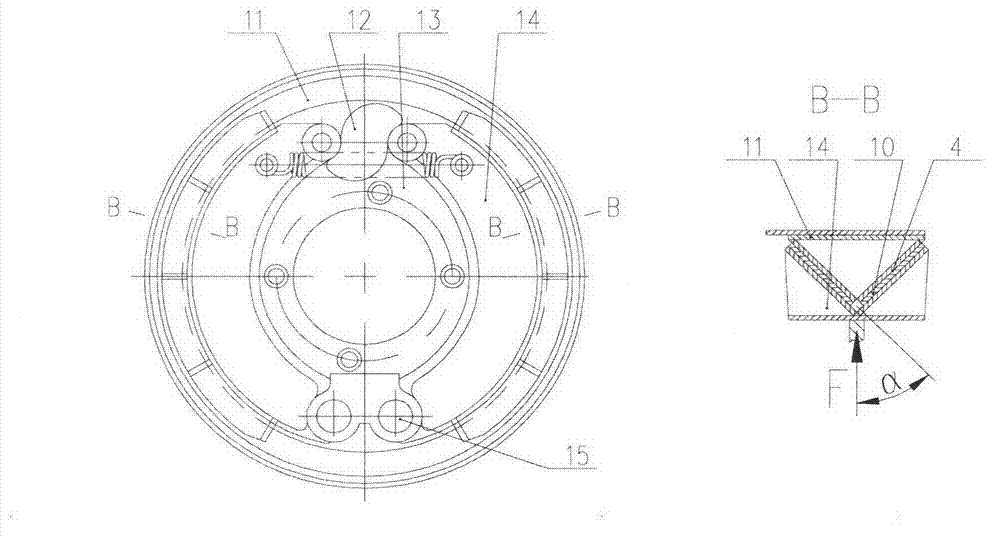

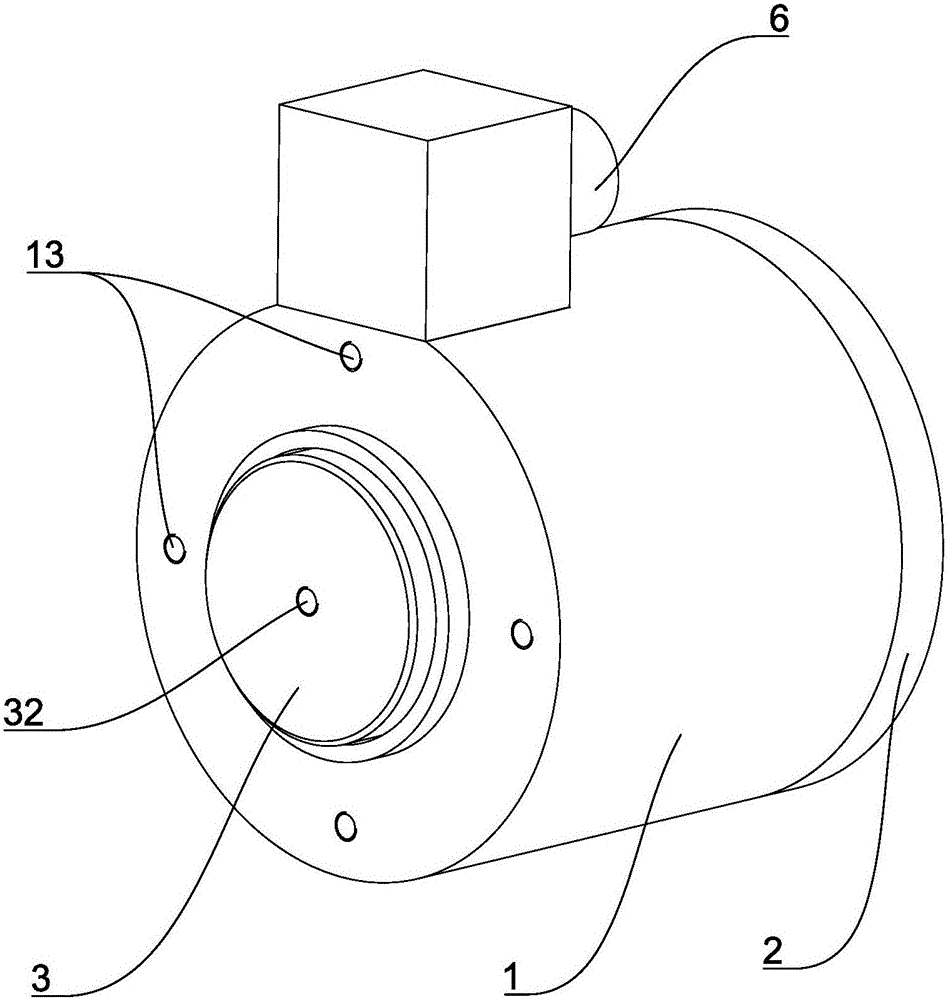

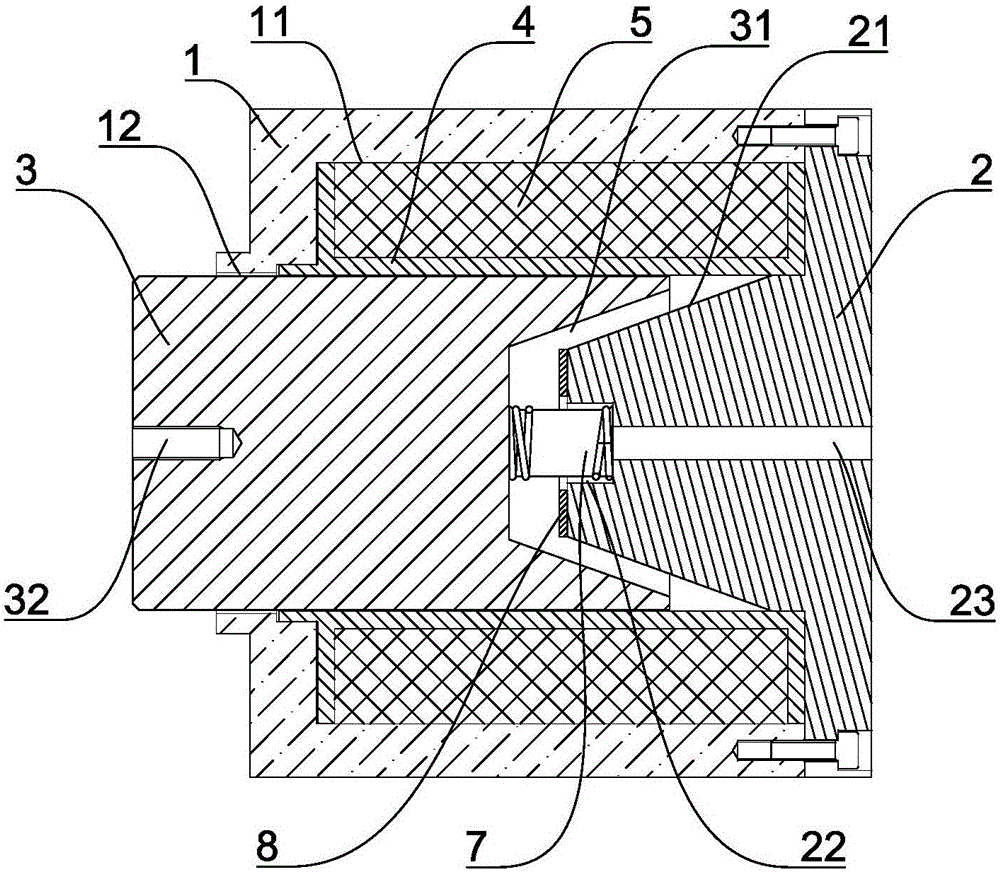

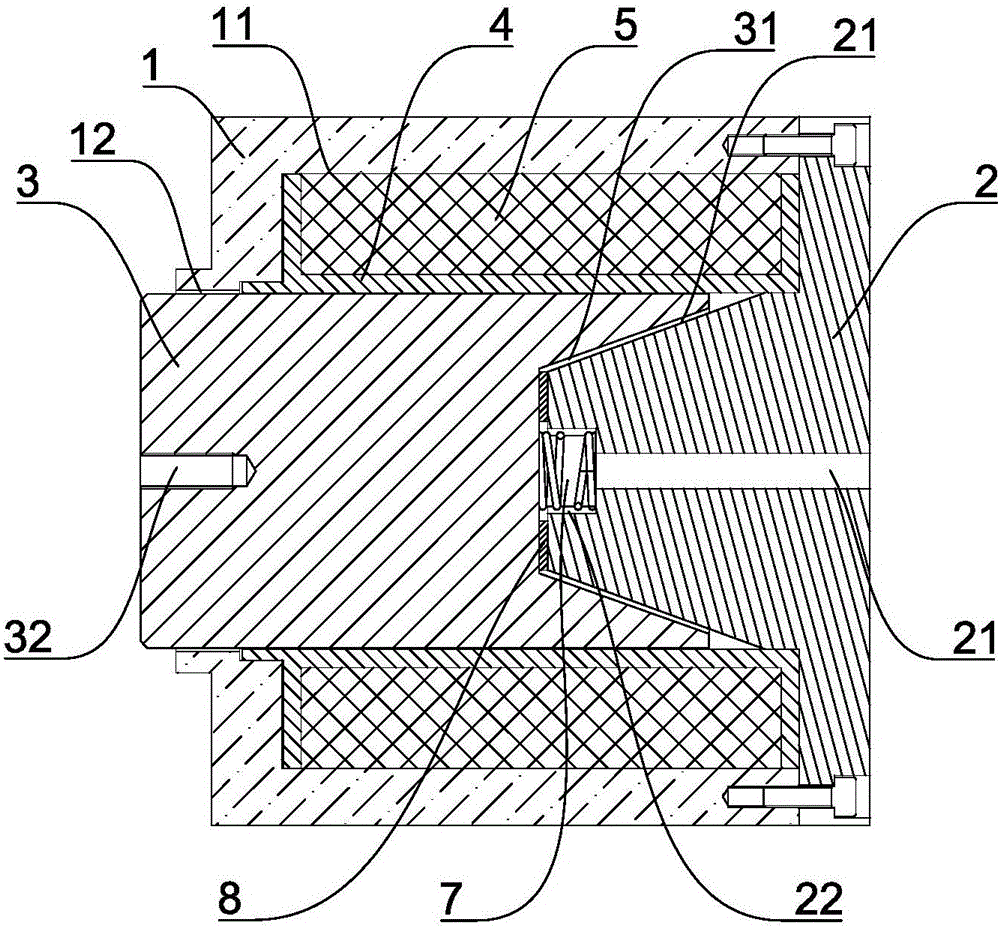

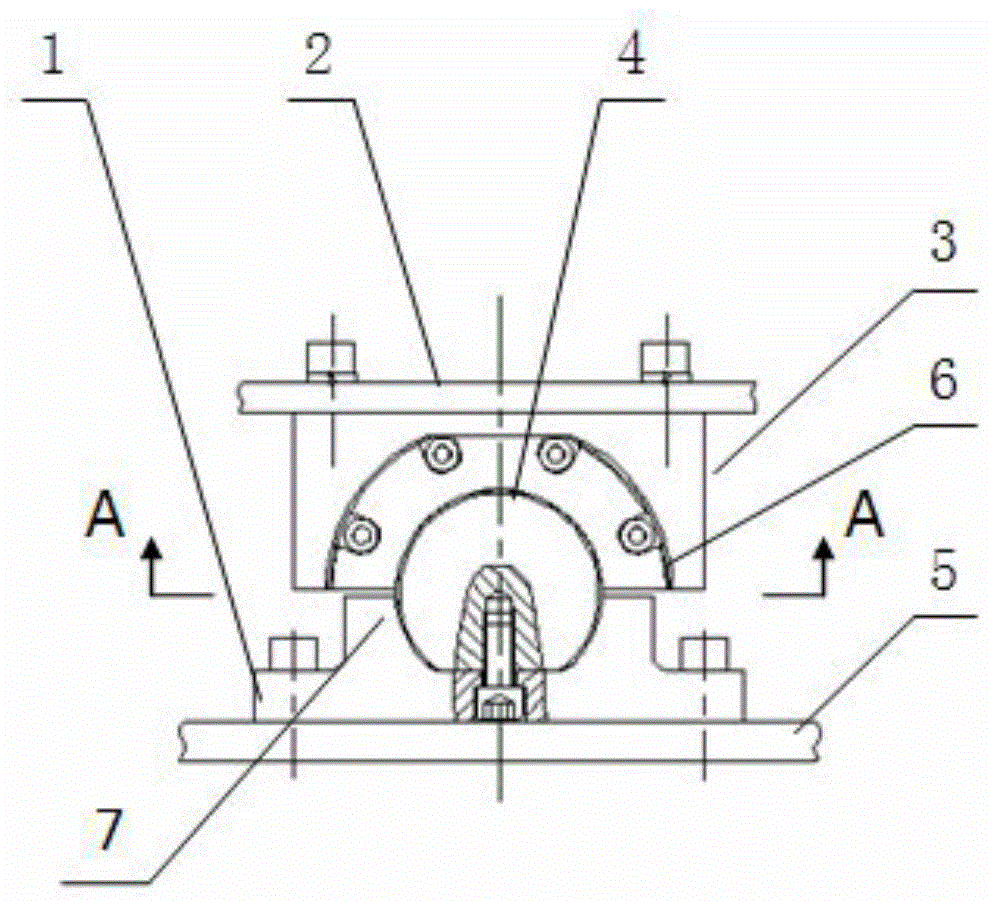

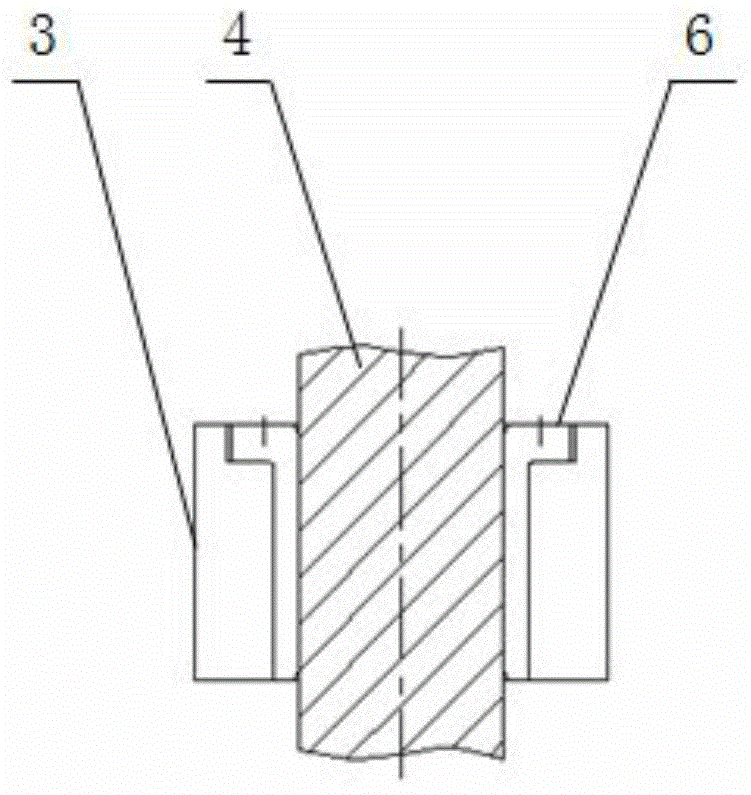

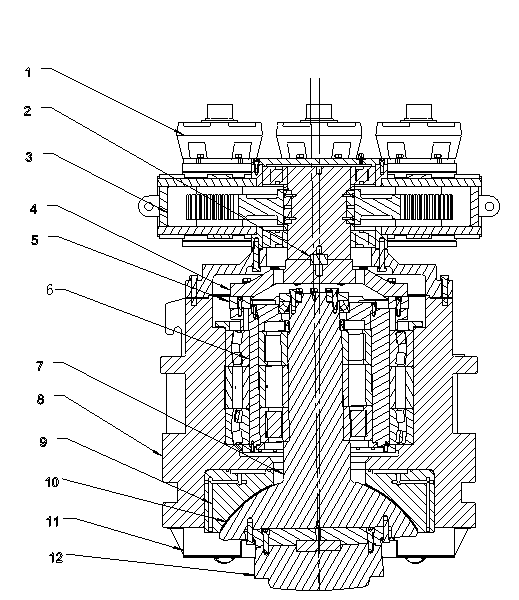

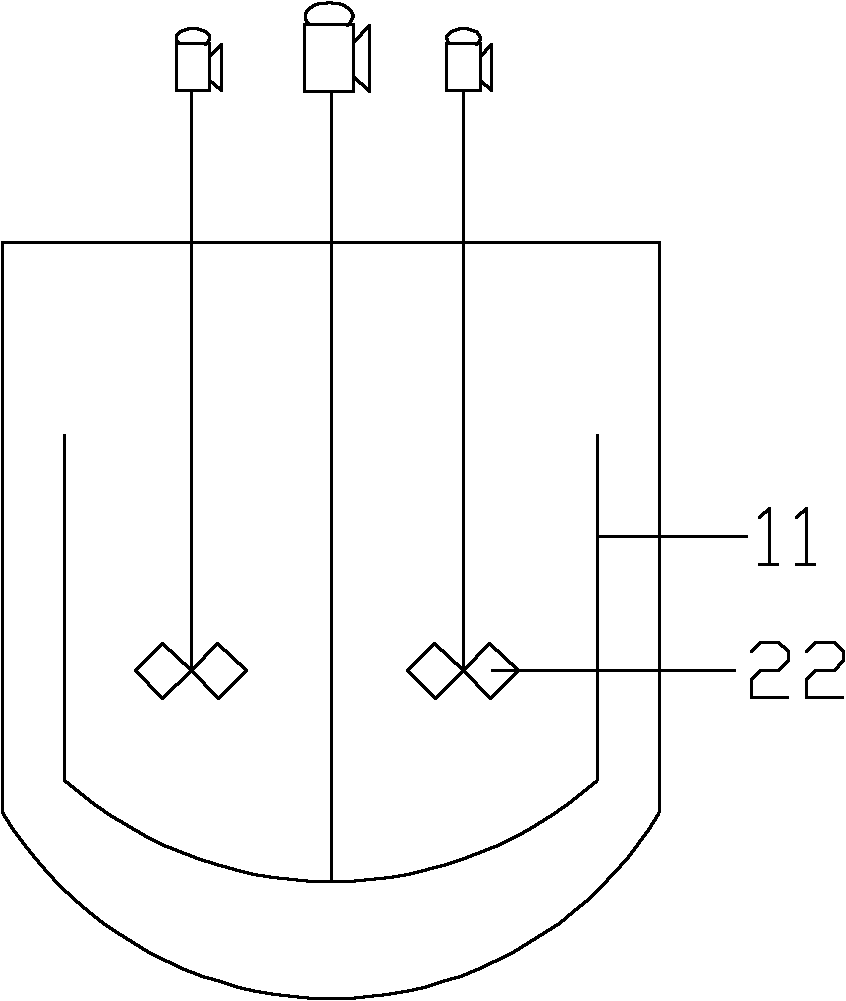

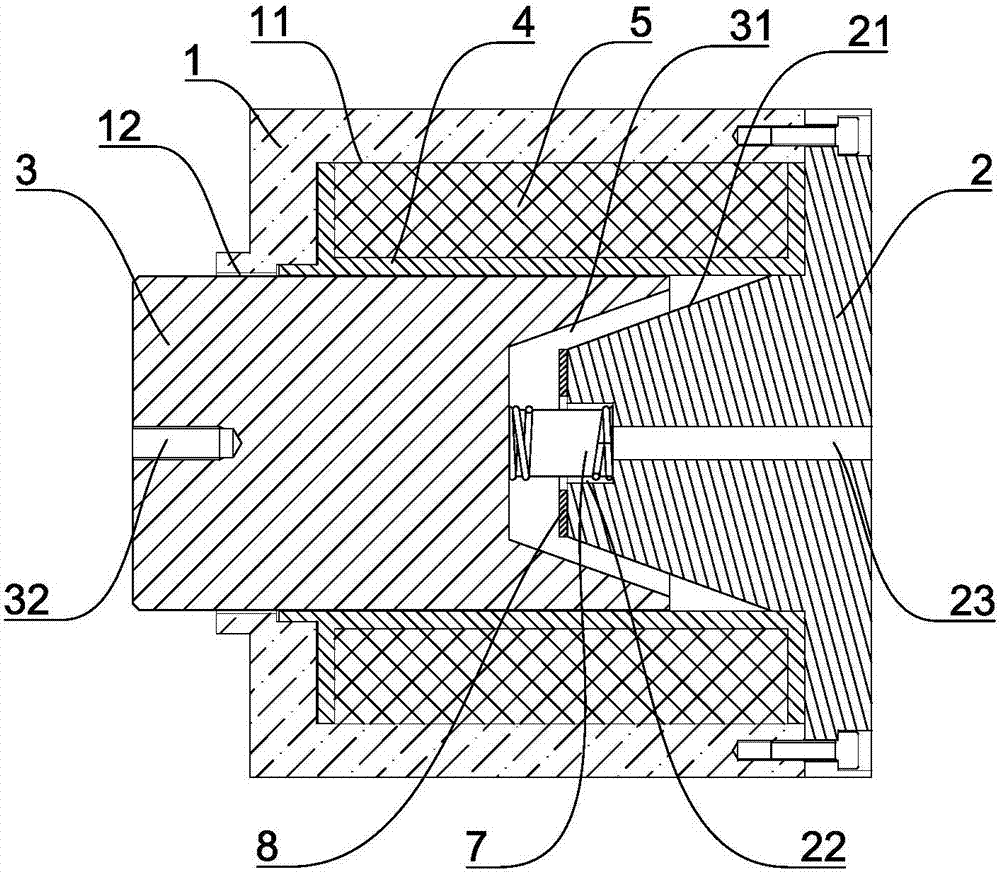

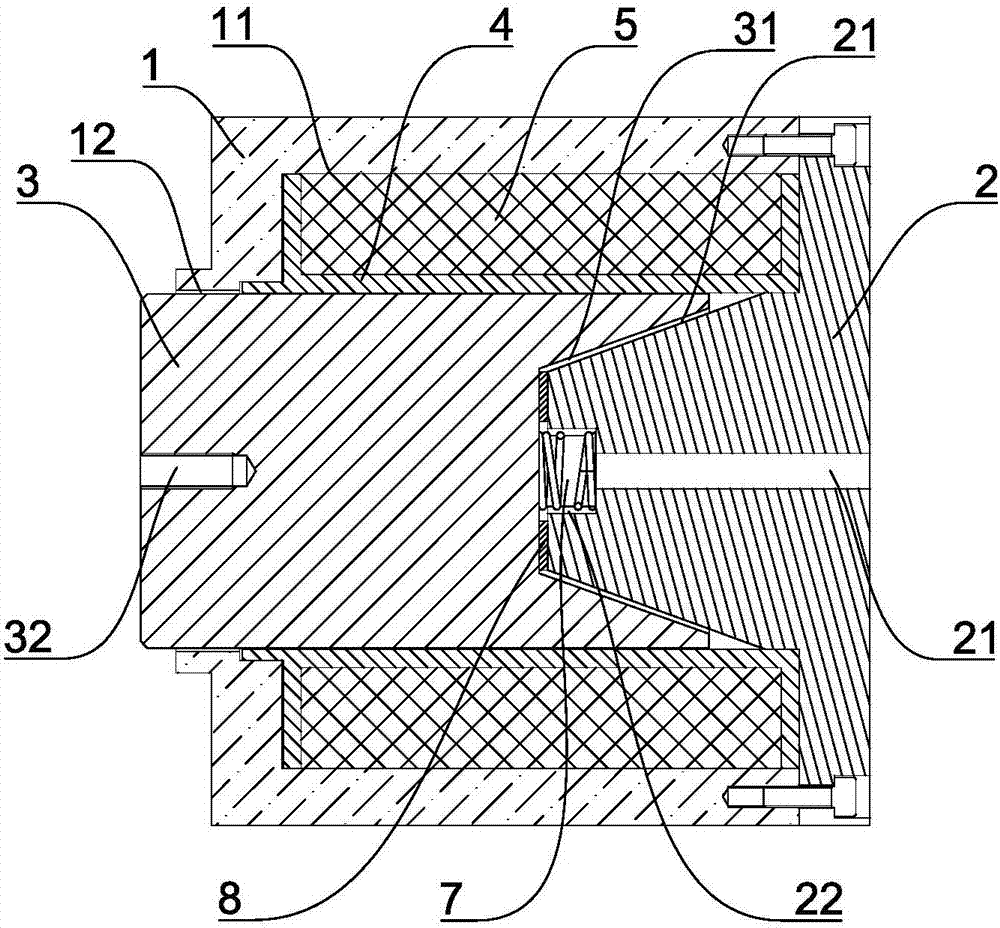

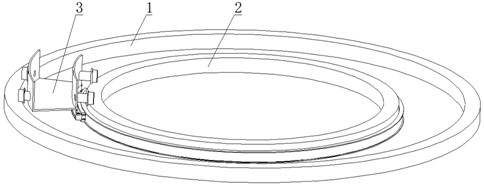

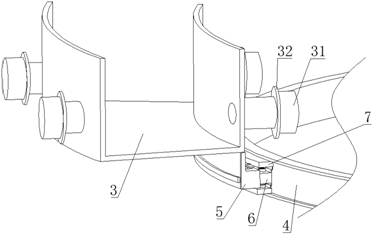

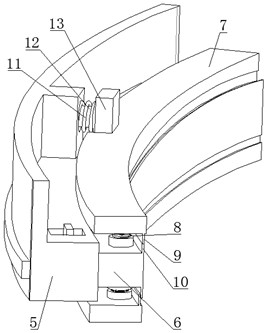

Spherical swing device for large rotary forging press

ActiveCN103317073AReduce frictionGuaranteed reliabilityForging/hammering/pressing machinesFriction gearingsLubricationWear resistant

The invention discloses a spherical swing device for a large rotary forging press. The spherical swing device comprises a fixing seat, driving gear boxes and an oil motor. The driving gear boxes are fixed at the top of the fixing seat, and are fixedly connected with an angle-deflected sleeve spindle set inside the fixing seat through a long driving bond and a connecting tray, a swing spindle is located at the center of the angle-deflected sleeve spindle set, a ball head and a swing head are arranged at the lower end of the swing spindle, and rotational connection is achieved through cooperation of the ball head and a ball bowl. A high molecular wear-resistant layer is arranged on the surface of the ball bowl, one oil supply hole extending from the outside to a contact surface of the ball head and the ball bowl is formed the ball bowl, and an oil receiver with an annular groove is fixed at the bottom of the ball wall along a contact circle of the ball bowl head through bolts. The spherical swing device for the large rotary forging press has the advantages that the angle-deflected sleeve spindle set has a function of floating compensation, so that clearance self-compensation after spherical pairs are slightly worn can be achieved; the oil supply hole formed in a ball bowl body serves as a forced lubrication cooling oil channel, so that friction is greatly reduced, and reliability of operation of a large-tonnage rotary forging press is guaranteed.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

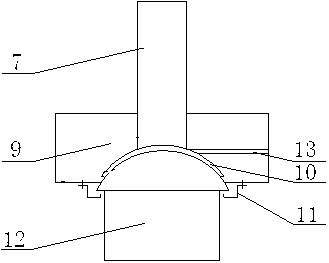

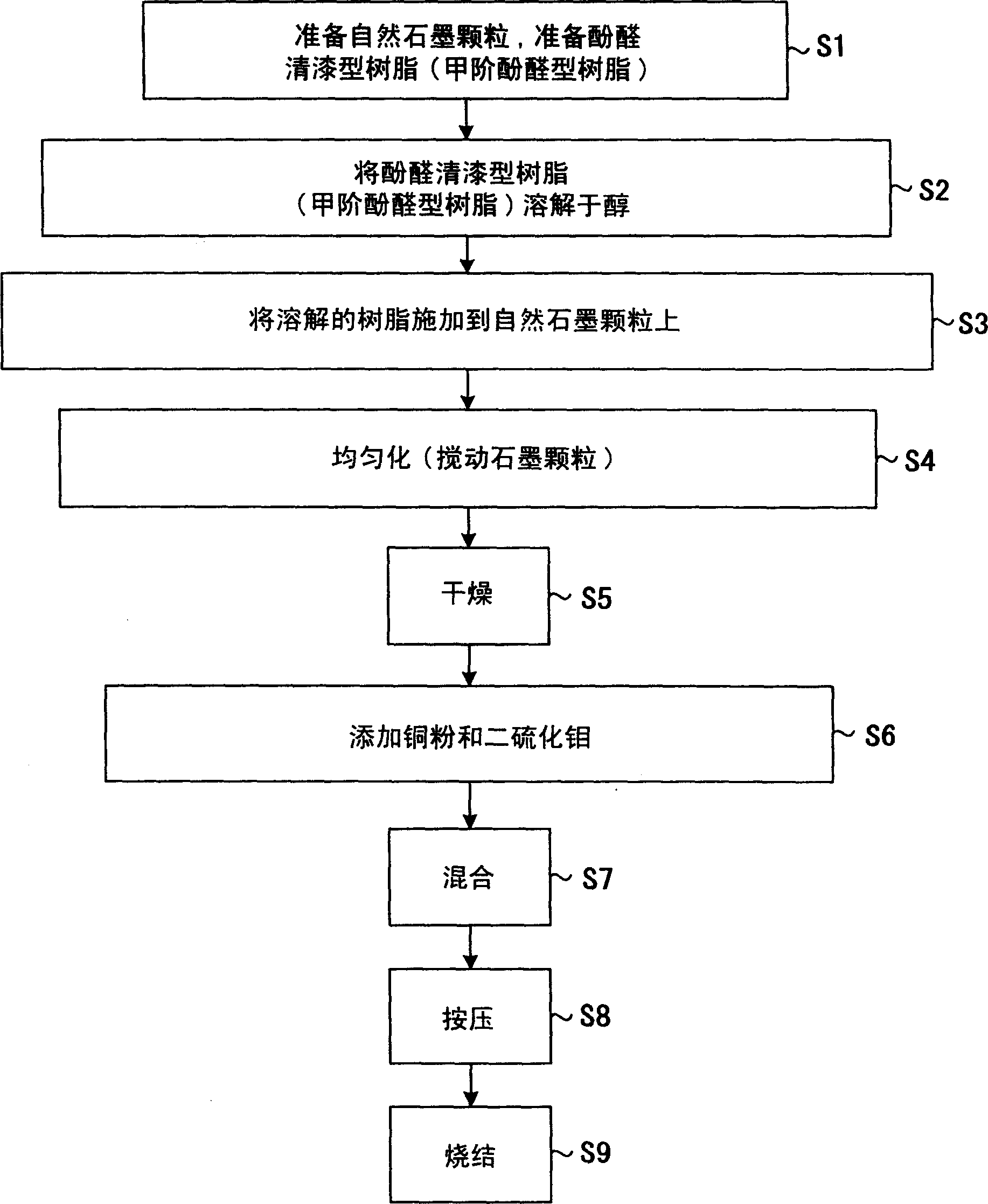

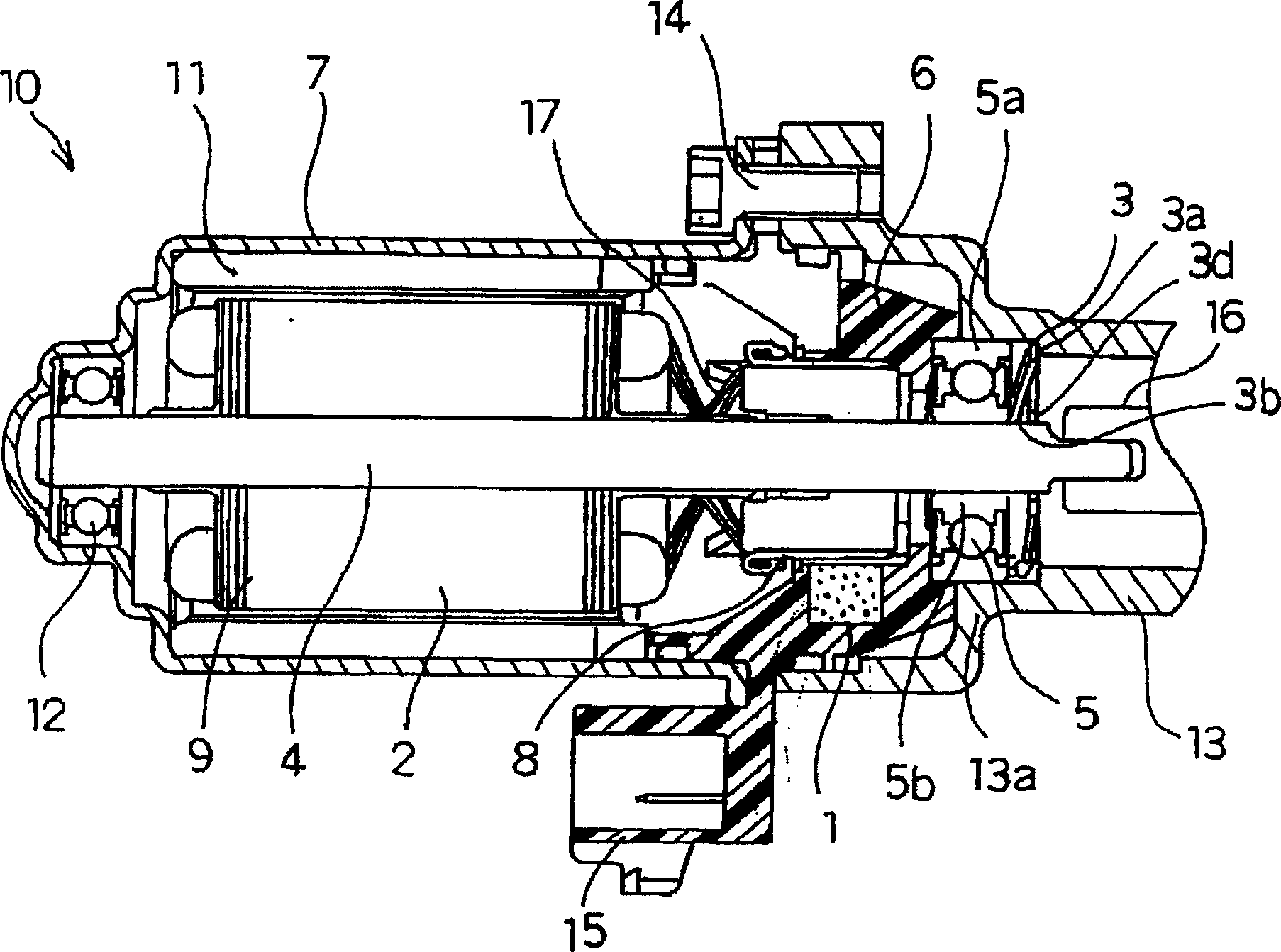

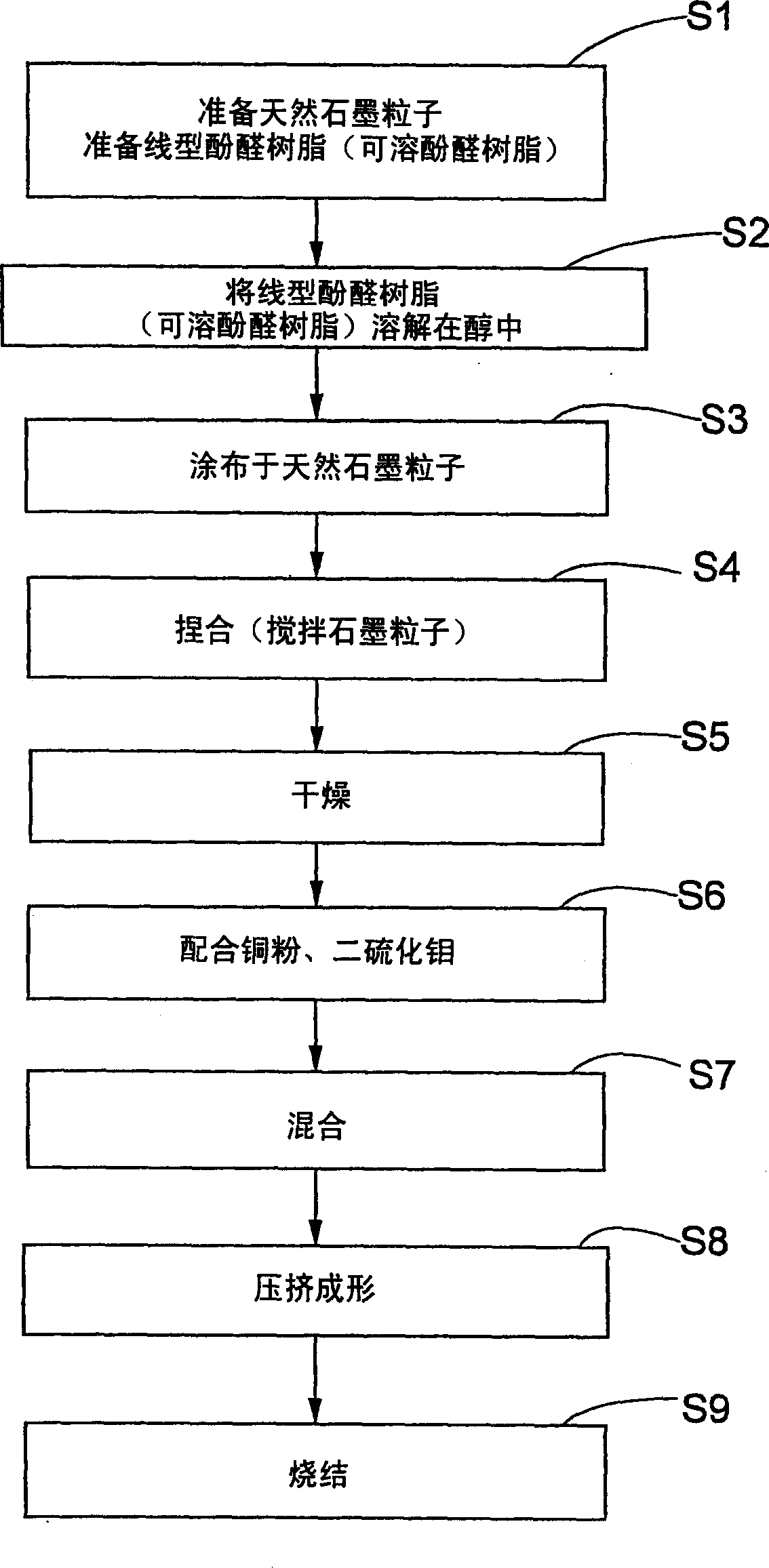

Metal-graphite brush and motor including a metal-graphite brush

InactiveCN1691439AReduce wearLow coefficient of sliding frictionRotary current collectorDC commutatorPorosityBoiling point

A metal-graphite brush for supplying electricity to a coil wound around a core provided at a rotor of a motor is made of sintered material having porosities at a surface of, or inside, the sintered material. The metal-graphite brush is infiltrated by a liquid containing a plurality of kinds of glycol ether having varying numbers of alkylene oxide structure units. The liquid has a boiling point higher than that of water.

Owner:AISIN SEIKI KK +1

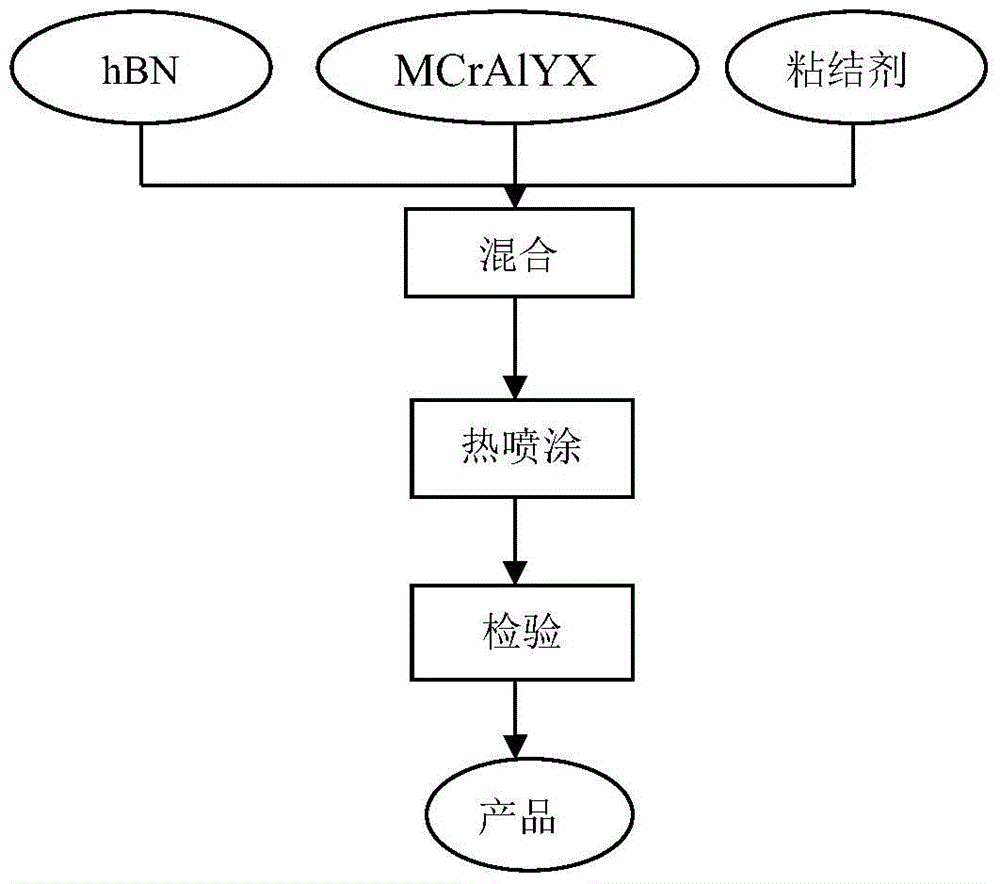

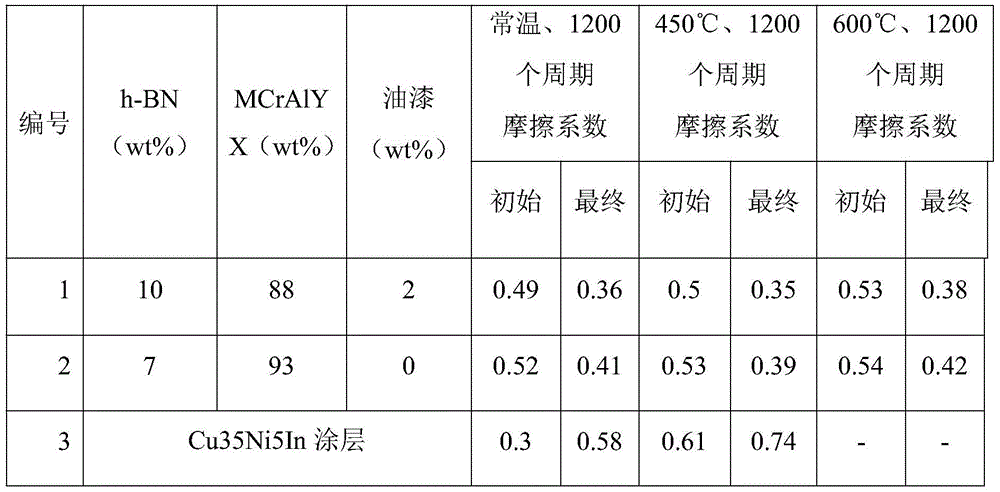

Titanium alloy high-temperature oxidation-resistant anti-fretting wear coating material, coating and preparation method

ActiveCN104357792BLow coefficient of sliding frictionImprove high temperature oxidation resistanceMolten spray coatingHexagonal boron nitrideOxidation resistant

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

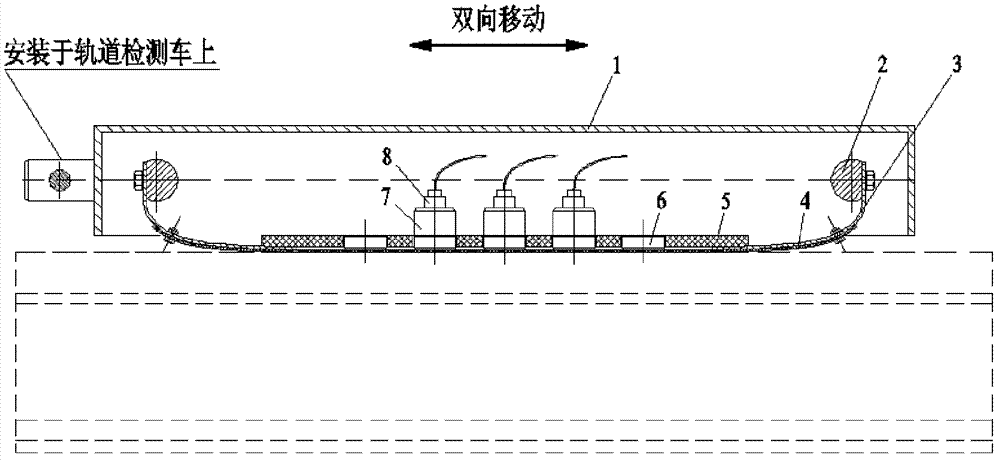

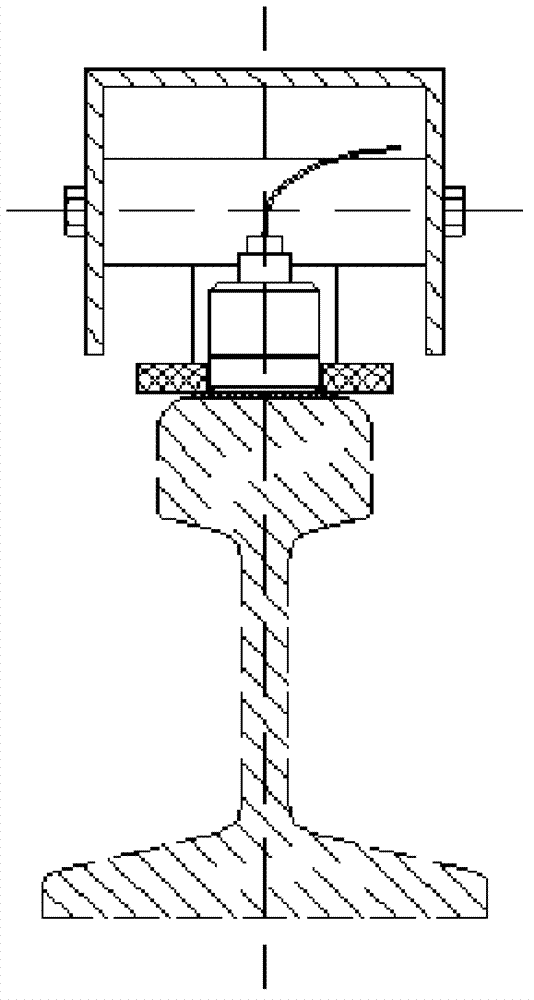

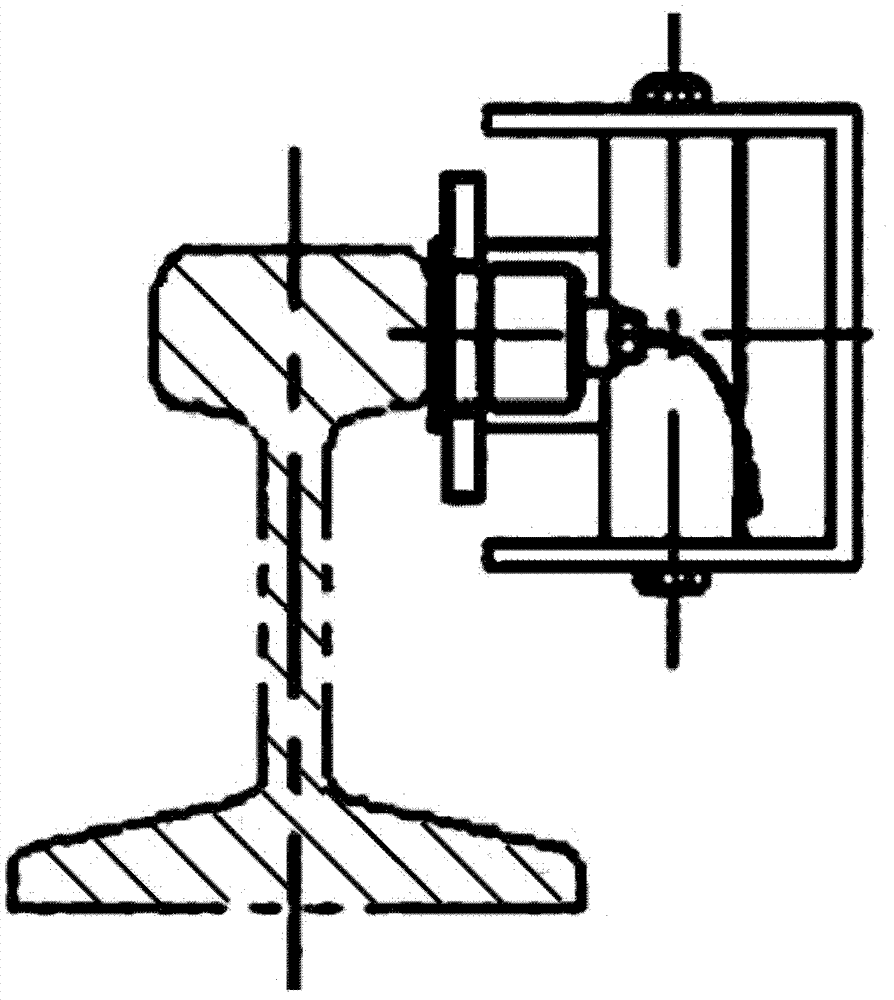

Sliding contact type signal acquisition device for rail detection

ActiveCN102951178AQuality improvementHeat resistantVibration measurement in solidsRailway auxillary equipmentElastic compressionEngineering

The invention discloses a sliding contact type signal acquisition device for rail detection, relating to the field of rail safety detection. The device comprises a bracket, a friction belt and a sensor, wherein the friction belt is arranged on the bracket, a flexible stable bed plate is arranged on the friction belt, and the sensor is arranged on the flexible stable bed plate. The friction belt is a polymer wear-resisting belt which is wear-resisting, heat-resistant, corrosion-resistant, and small in sliding friction coefficient. The friction belt is arranged an elastic compression plate, and a rotary pressure regulating shaft fixes the elastic compression plate on the bracket; and the sensor is arranged on the flexible stable bed plate sequentially through a magnetic compression piece and a magnetic installing seat. The magnetic compression piece and the magnetic installing seat are respectively made of a permanent magnet material or an electromagnet. According to the device disclosed by the invention, through the organic combination of components such as the rotary pressure regulating shaft, the elastic compression plate, the permanent magnet compression piece and the like, an effect that the friction belt is always closely attached to a measured rail surface in the whole moving process is achieved, thereby realizing the high-quality acquisition of vibration signals of steel rails.

Owner:BEIJING MUNICIPAL INST OF LABOUR PROTECTION +1

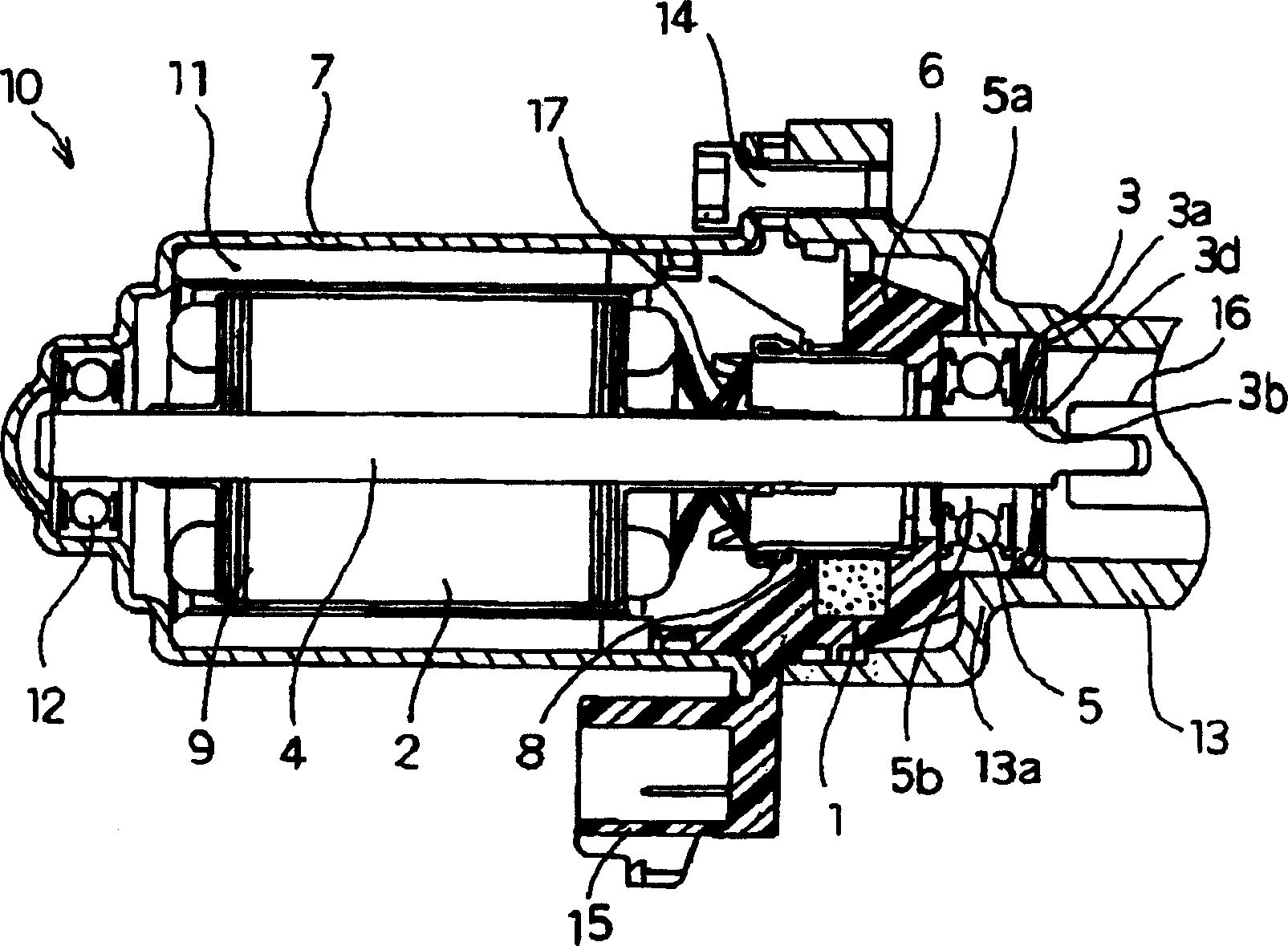

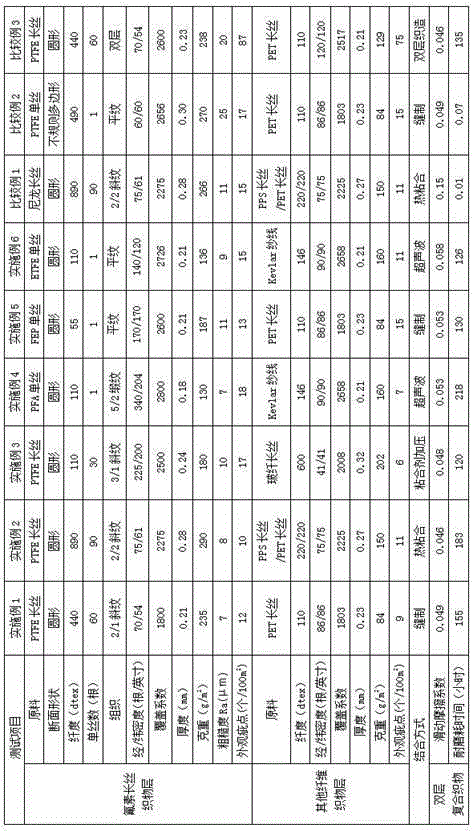

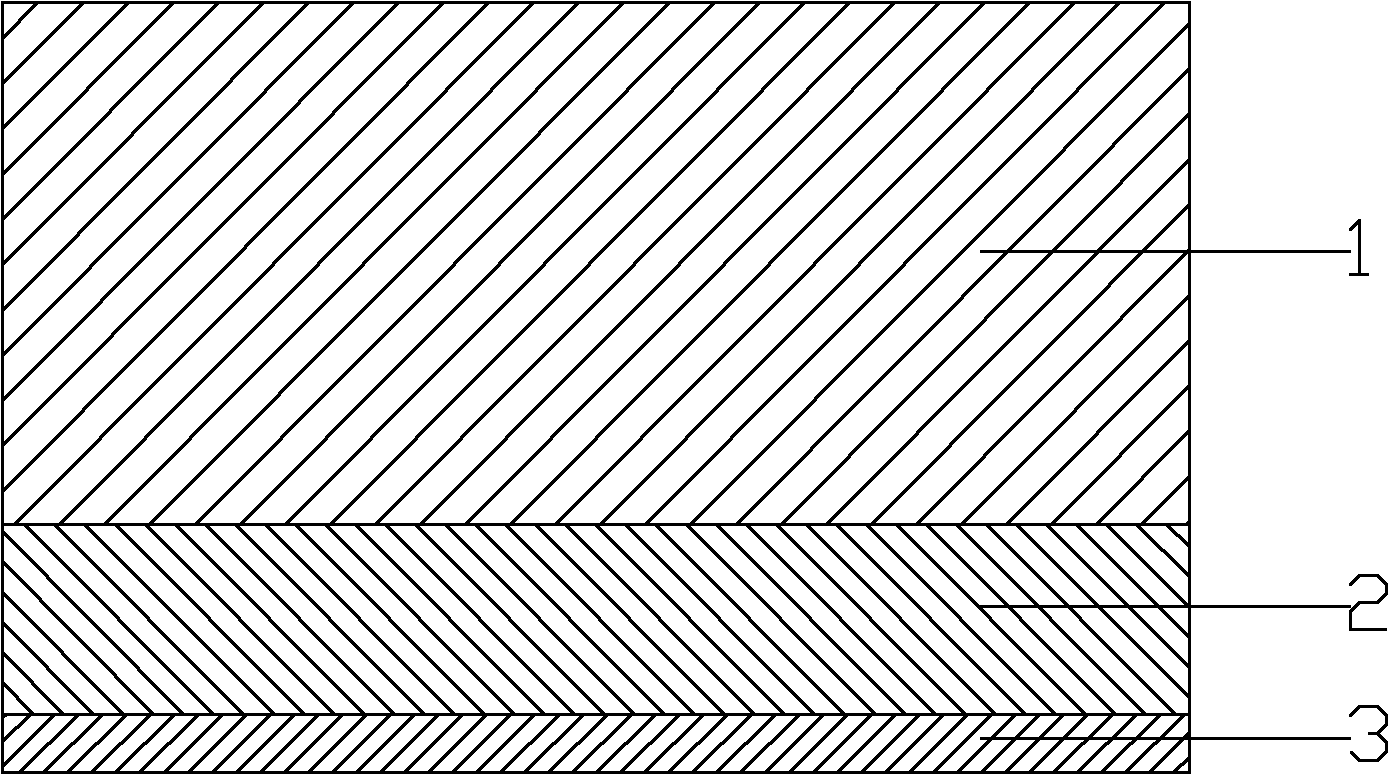

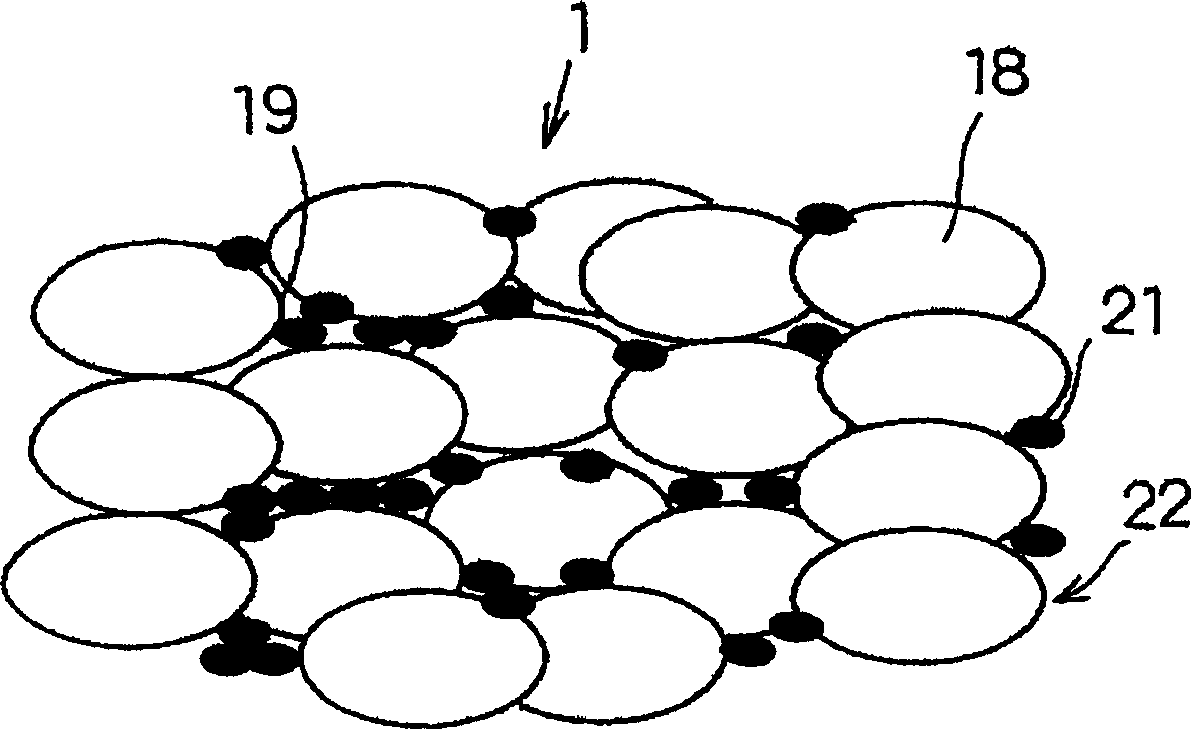

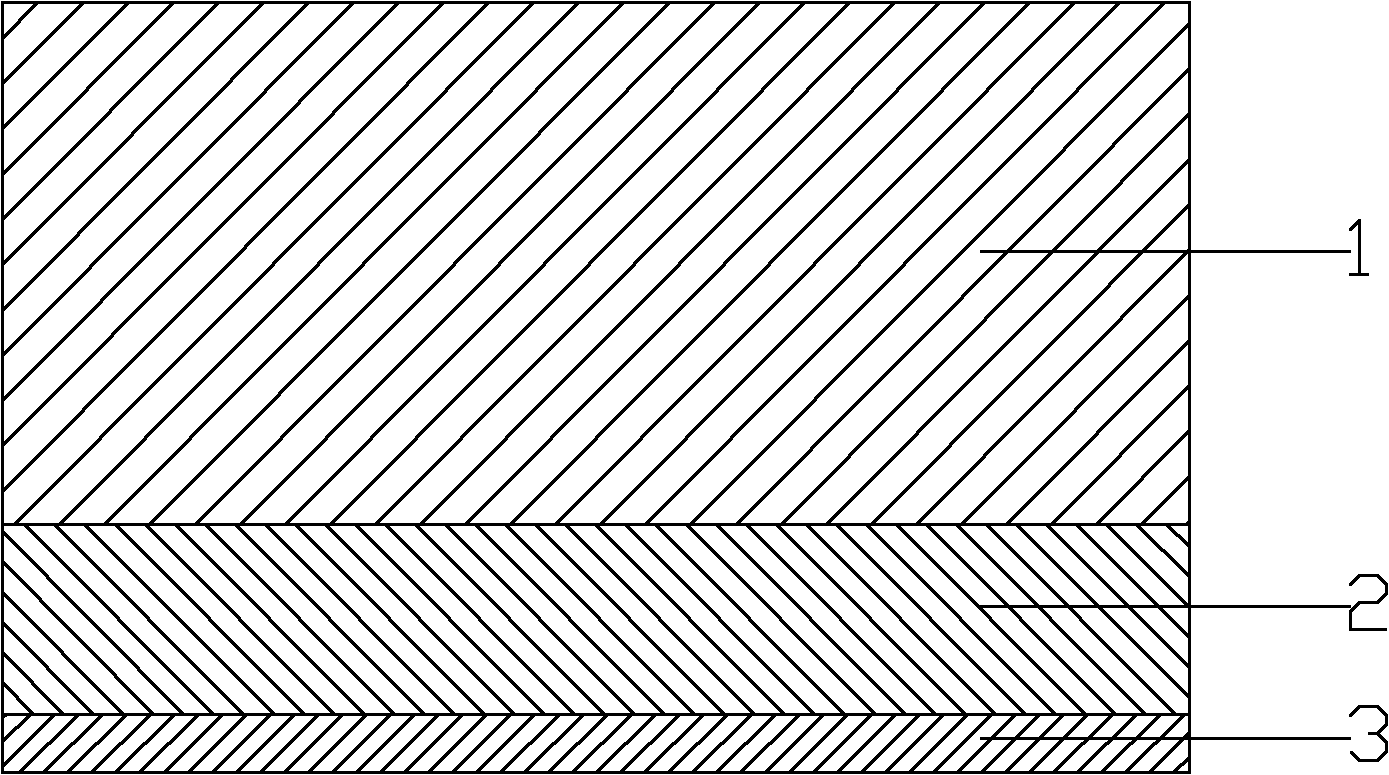

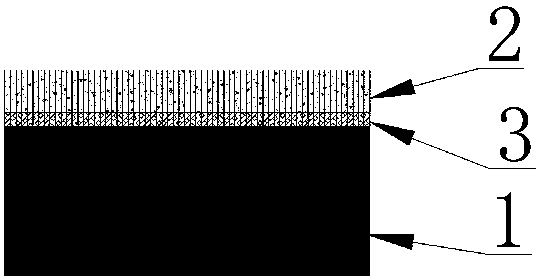

Double-layer composite fabric and a production method and use thereof

The invention provides double-layer composite fabric and a production method and use thereof. The composite fabric comprises a polytetrafluoroethylene filament fabric layer and an other fiber fabric layer. The warp yarn density of the polytetrafluoroethylene filament fabric layer is 70-360 / inch and the covering coefficient of the polytetrafluoroethylene filament fabric layer is 1500-2800; the average roughness of center lines of the surface of the polytetrafluoroethylene filament fabric layer is below 15[mu]m; the number of defects on the surface of the composite fabric is less than 30 every 100m<2>. The double-layer composite fabric has the advantages of fewer defects, low sliding friction coefficient, and durable wear resistance and the characteristics of simple process and low cost and can be applied to mechanical movement parts of sliding bearings.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Method for manufacturing polyurethane bridge support

InactiveCN102848508AEasy to slideImproved resistance to fatigueBridge structural detailsBridge materialsVulcanizationAlcohol

The invention discloses a method for manufacturing polyurethane bridge support. The method mainly includes dewatering polyhydric alcohol, preparing prepolymer, preparing mixture, performing mixing reaction, pouring for formation, demolding, performing post-vulcanization, and bonding. Compared with conventional rubber bridge support, the bridge support manufactured by the inventive method adopts polyurethane material, adopts large adjustable range of the polyurethane material to meet elastic deformation requirement via adjusting hardness, adopts good mechanical property of the polyurethane material to improve fatigue resistance performance, greatly reduces residual deformation quantity and has long service life; in addition, the invention performs product manufacture by adopting pouring formation method to the polyurethane material, the obtained product has stable quality, low contamination, low energy consumption and greatly saved manufacturing cost; and at the same time, the invention adopts polytetrafluoroethylene material or fills polytetrafluoroethylene material to manufacture sliding anti-wear layer, has small sliding friction coefficient, and is in favor of tightly pressing or bearing sliding between the support and box body during bearing force.

Owner:CHONGQING CINWO PLASTICS

Graphitic brush, and motor having graphitic brush

InactiveCN1914783AExtend your lifeLow coefficient of sliding frictionRotary current collectorDynamo-electric machinesBoiling pointMaterials science

A graphitic brush which hardly wears irrespective of temperatures used and which copes with the problem of prolongation of life; and a motor having the graphitic brush. In the graphitic brush for feeding a coil wound on a core provided in the rotor of a motor, the graphitic brush consists of a sintered compact having pores in the surface and in the interior, the pores being impregnated with a liquid having a boiling point higher than that of water.

Owner:AISIN SEIKI KK

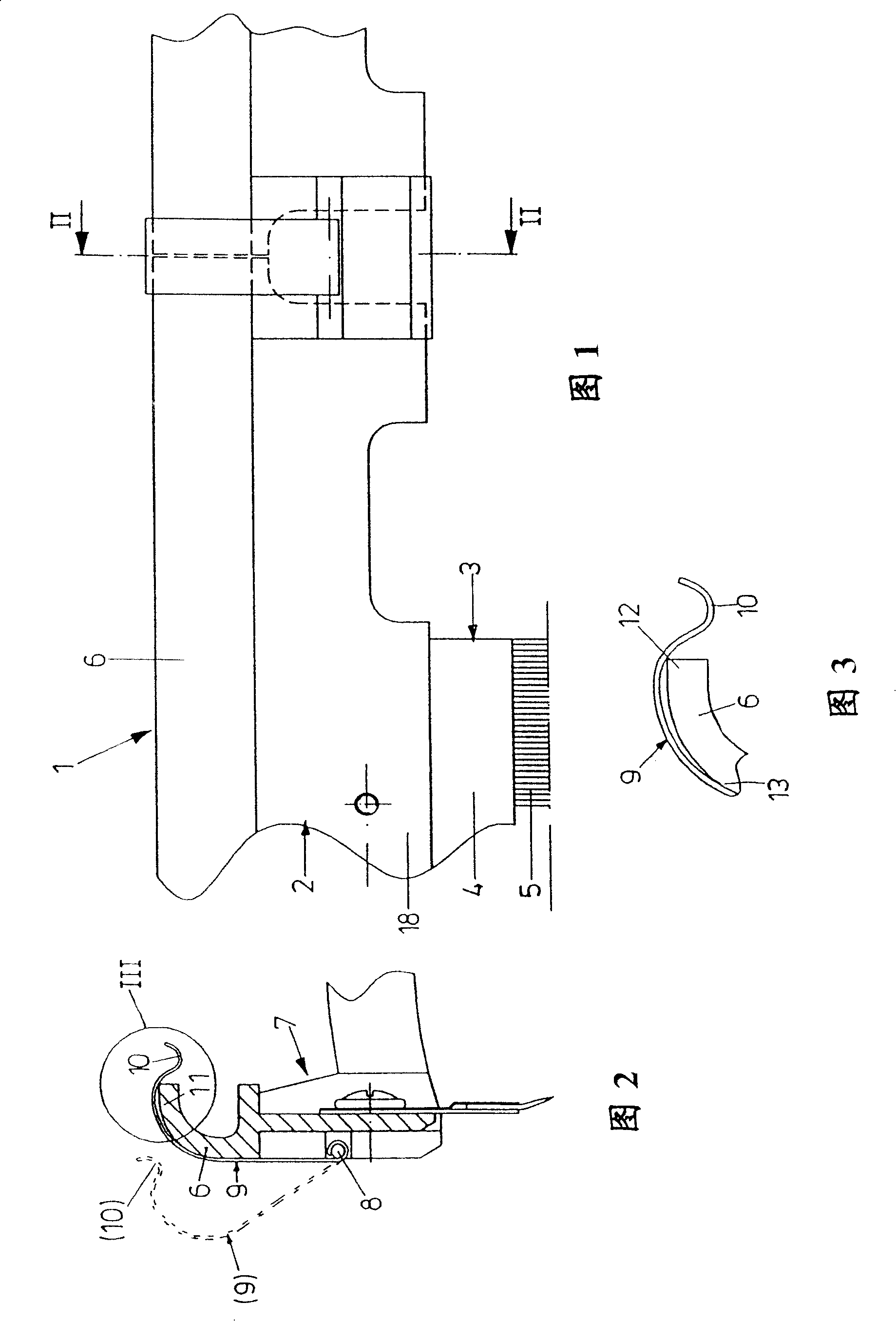

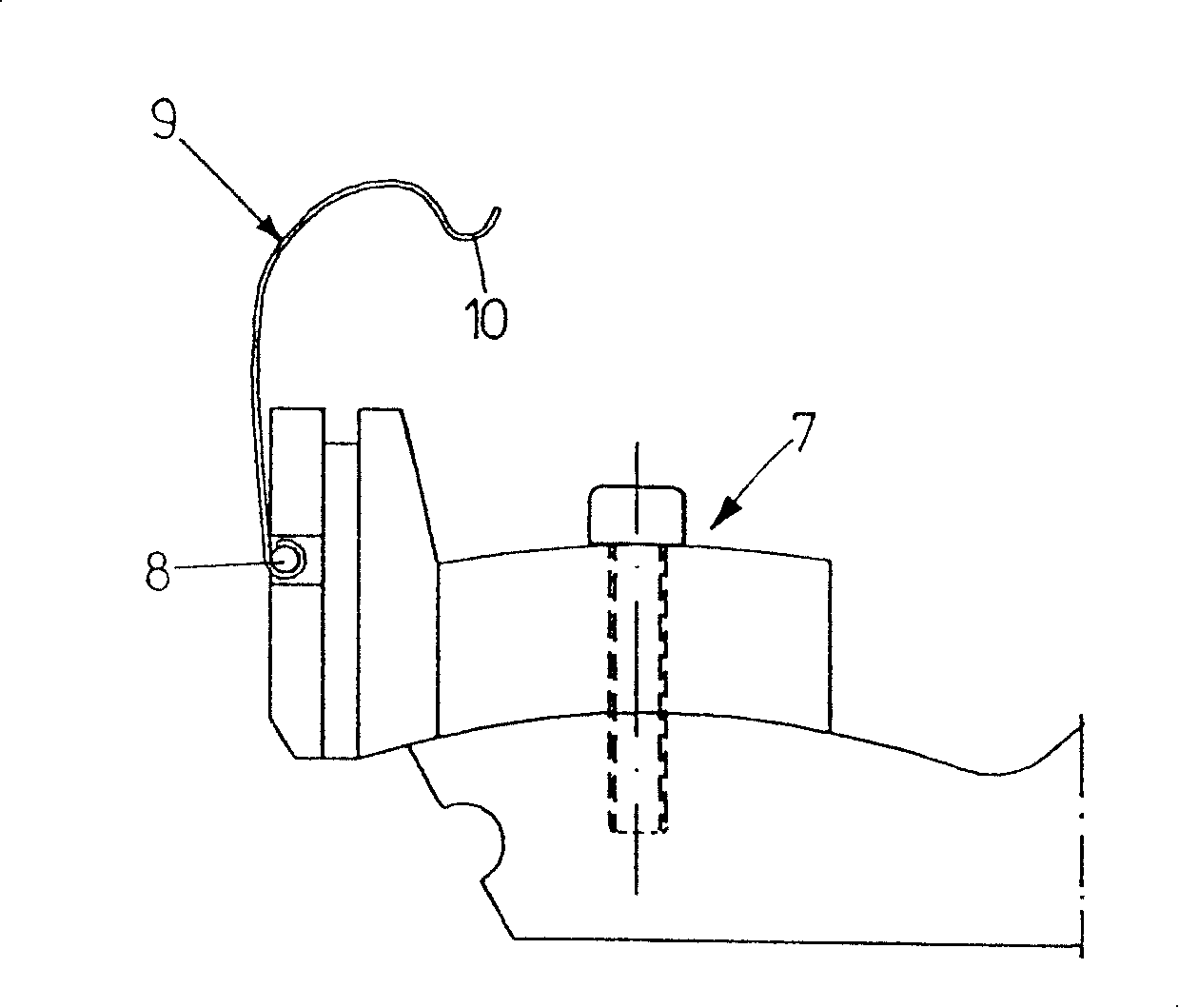

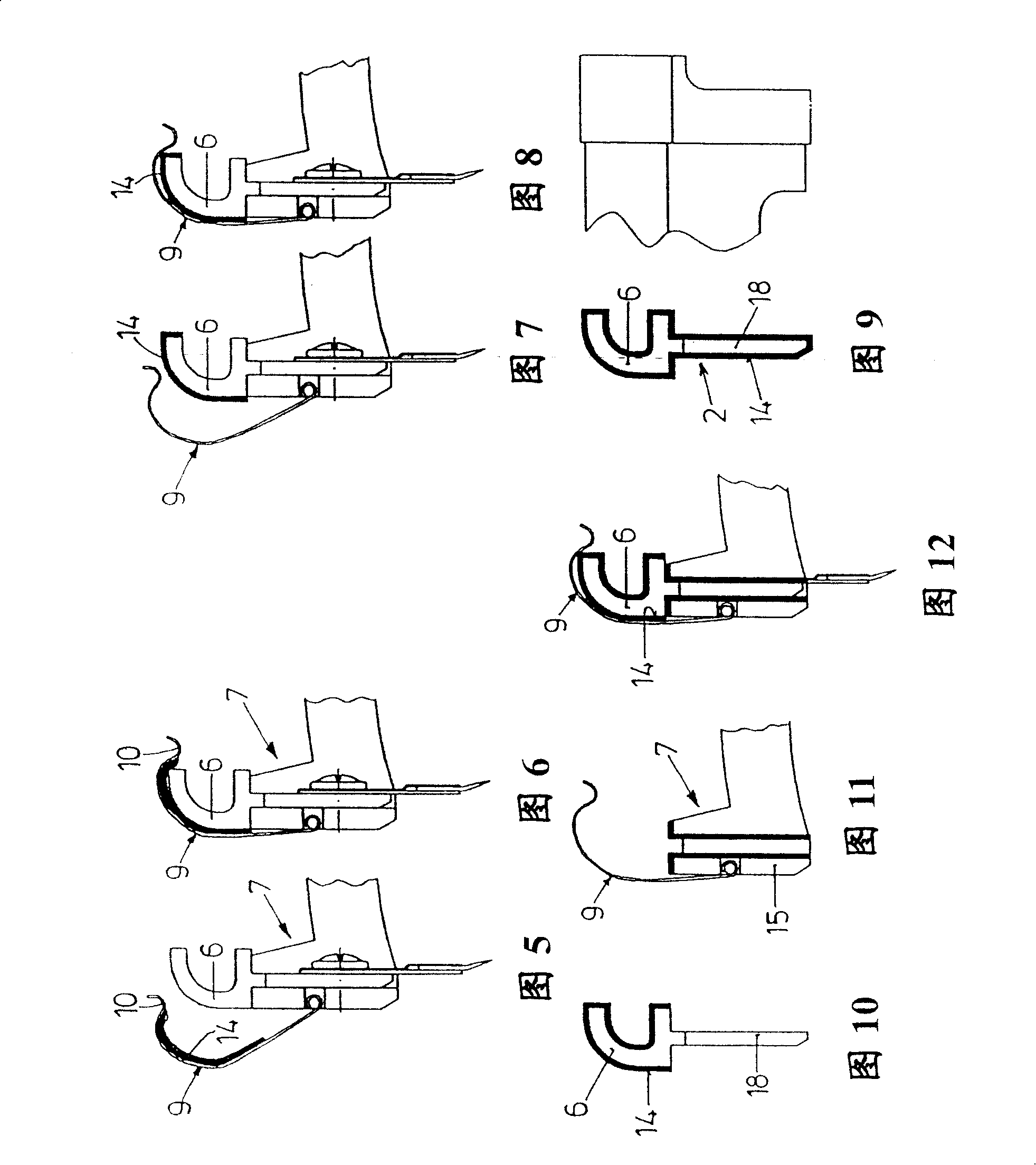

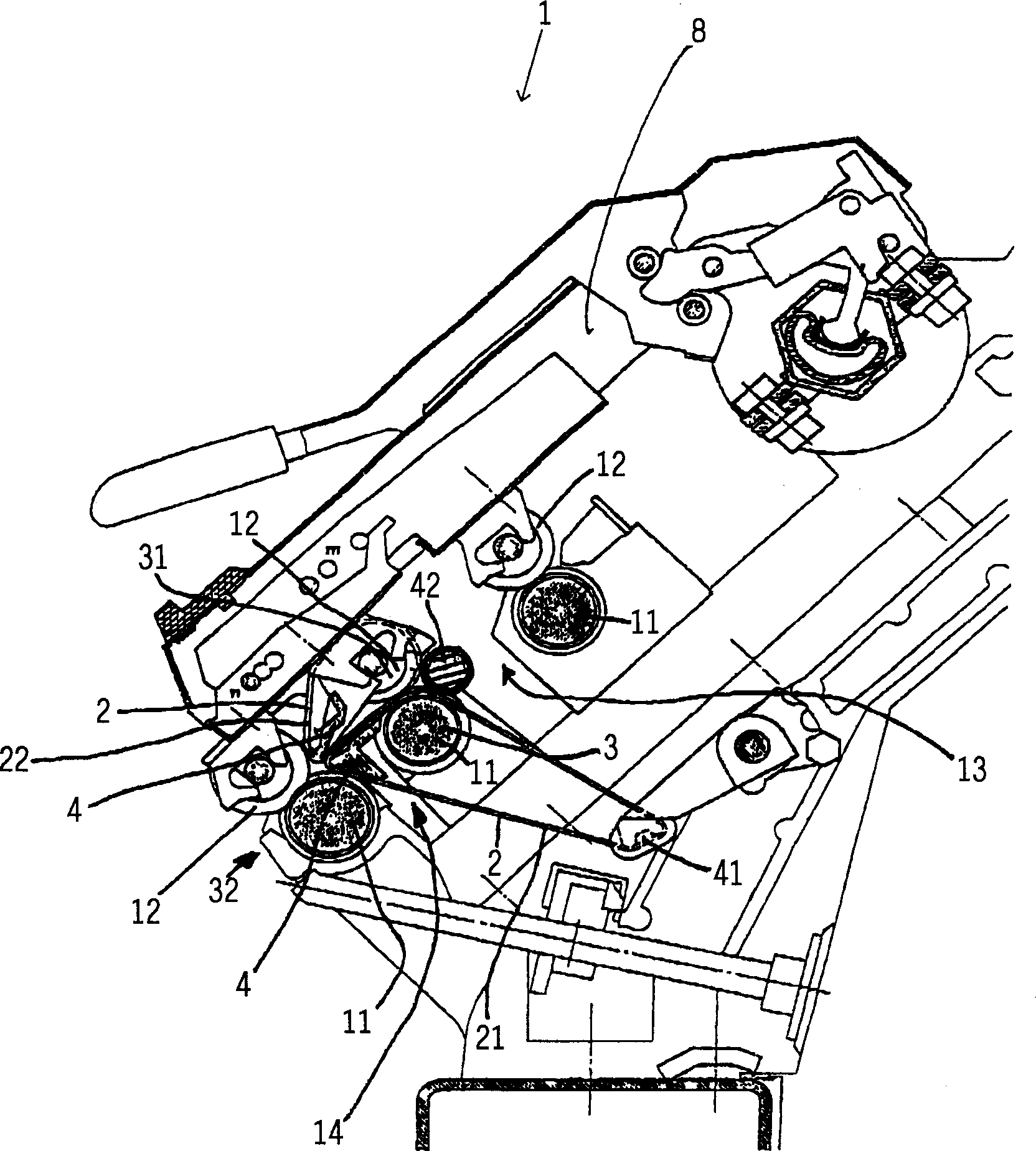

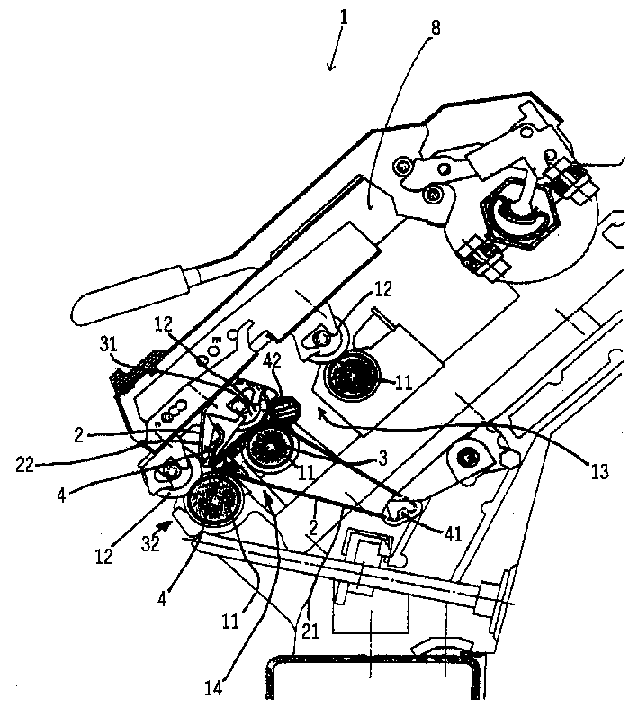

Top comb and top comb holder for a textile combing machine, and the combing machine

InactiveCN100398711CImprove wear resistanceReduce vibrationCombing machinesEngineeringMechanical engineering

The invention relates to a top comb (1) for a textile combing machine, whereby the top comb (1) comprises a top comb plate (2), on the base body of which a pin stripe (3) may be fixed. A retaining section (6) is embodied on the upper face of the base body (18), by means of which the top comb (1) may be fixed thereto with a retainer clamp (9) of a corresponding top comb holder (7). According to the invention, a wear protector is arranged between top comb (1) and top comb holder (7), in particular a plastic with good stability and good surface friction properties.

Owner:STAEDTLER & UHL

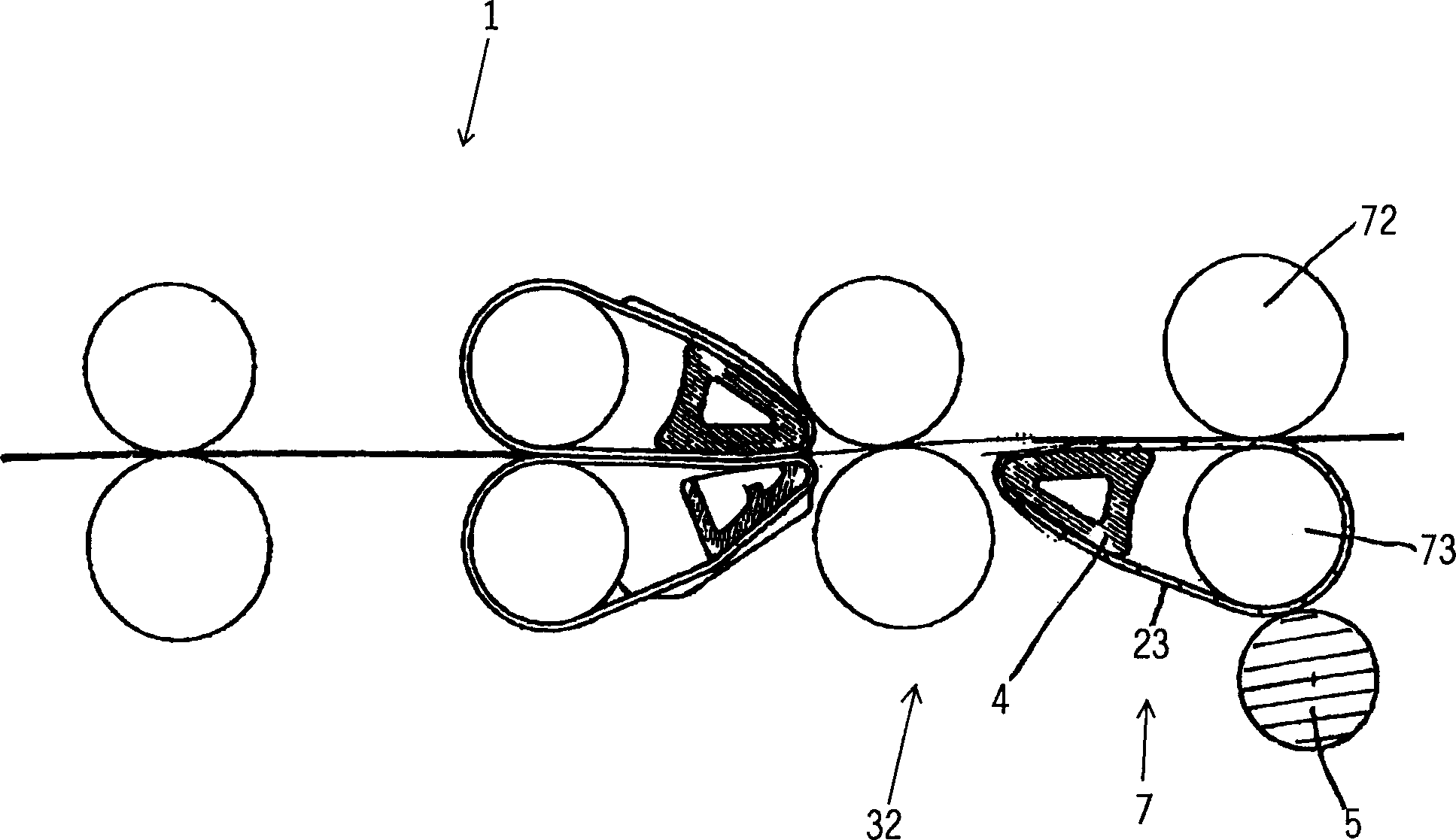

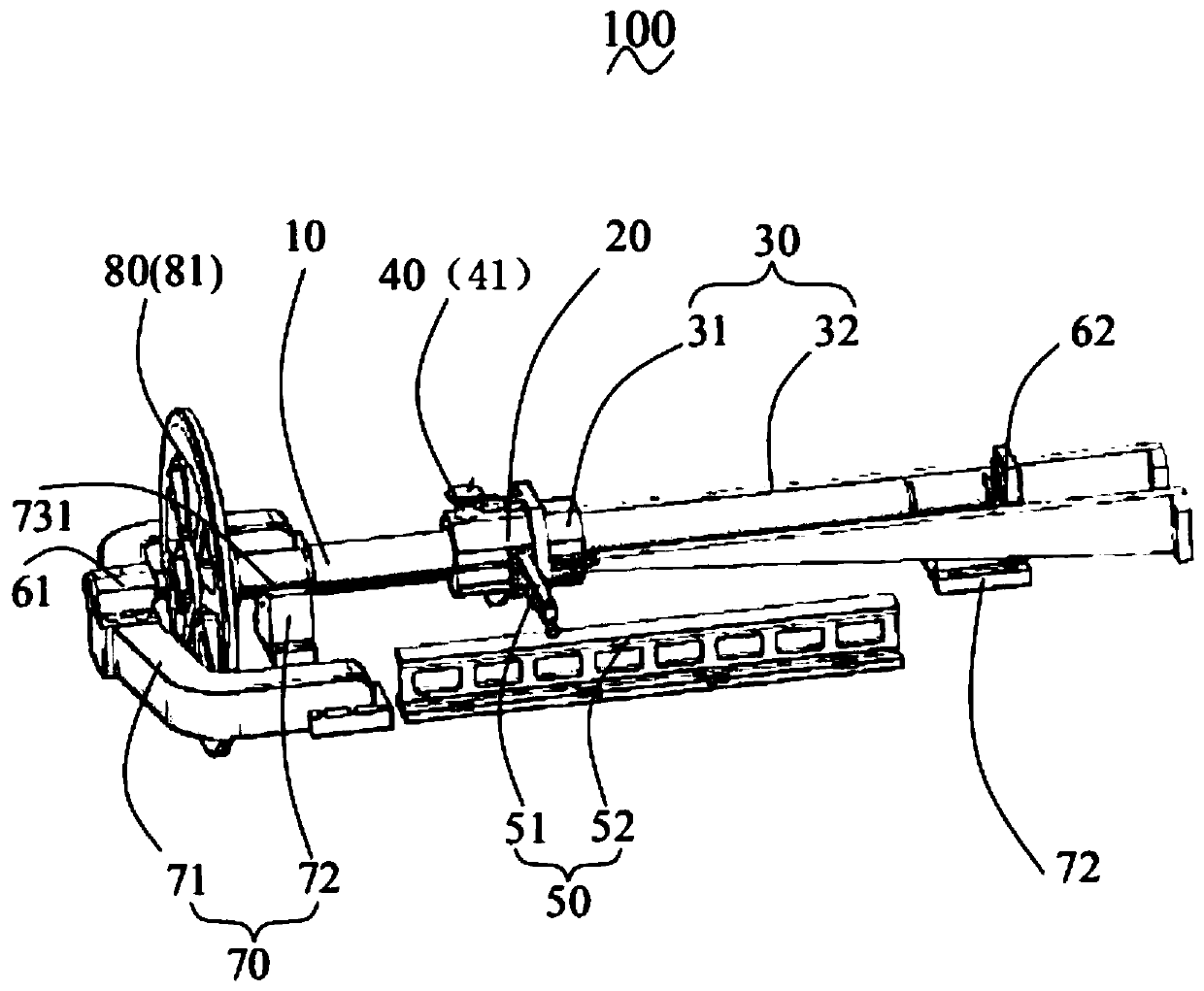

Drawing frame for a spinning machine

InactiveCN1448557AReduce frictionReduce coefficient of frictionDrafting machinesContinuous wound-up machinesFiberDrive shaft

The drawing frame especially for a ring spinning frame has at least two sets of drawing frame cylinders and the apron band for guiding a fiber. A guide means (4, 41) acts so as to guide and slide the apron band (2, 21, 22, 23). Simultaneously, a combination of materials having little friction with the apron band (2, 21, 22, 23) is aimed at. In an advantageous practical embodiment, the apron band (2, 21, 22, 23) can have an additional part engaging with a notch of a shaft (3), and the apron band (2, 21, 22, 23) can be pressed to the driven shaft (3) by a pressing roll.

Owner:RIETER INGOLSTADT SPINNEREIMASCHENBAU AG

Optical grating ruling engine indexing system macro-positioning executing mechanism adopting ultrasonic friction-reduction technology

InactiveCN110716254AEliminate crawlingReduce control difficultyDiffraction gratingsPhysicsEngineering

The invention provides an optical grating ruling engine indexing system macro-positioning executing mechanism adopting an ultrasonic friction-reduction technology. The optical grating ruling engine indexing system macro-positioning executing mechanism comprises a lead screw shaft, a nut in threaded fit with the lead screw shaft, a pulling rod assembly fixedly connected with the nut, and an ultrasonic vibrator assembly; and the ultrasonic vibrator assembly comprises an ultrasonic vibrator fixed to the nut and a driving module connected with the ultrasonic vibrator, and the ultrasonic vibrator vibrates under the effect of the driving module to reduce friction between the nut and the lead screw shaft. According to the optical grating ruling engine indexing system macro-positioning executing mechanism adopting the ultrasonic friction-reduction technology, the creeping phenomenon can be eliminated, the positioning precision of the macro-positioning link is improved, and the control difficulty of a whole indexing system is significantly lowered.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method for manufacturing polyurethane bridge support

InactiveCN102848508BEasy to slideImproved resistance to fatigueBridge structural detailsBridge materialsTetrafluoroethylenePolyol

The invention discloses a method for manufacturing polyurethane bridge support. The method mainly includes dewatering polyhydric alcohol, preparing prepolymer, preparing mixture, performing mixing reaction, pouring for formation, demolding, performing post-vulcanization, and bonding. Compared with conventional rubber bridge support, the bridge support manufactured by the inventive method adopts polyurethane material, adopts large adjustable range of the polyurethane material to meet elastic deformation requirement via adjusting hardness, adopts good mechanical property of the polyurethane material to improve fatigue resistance performance, greatly reduces residual deformation quantity and has long service life; in addition, the invention performs product manufacture by adopting pouring formation method to the polyurethane material, the obtained product has stable quality, low contamination, low energy consumption and greatly saved manufacturing cost; and at the same time, the invention adopts polytetrafluoroethylene material or fills polytetrafluoroethylene material to manufacture sliding anti-wear layer, has small sliding friction coefficient, and is in favor of tightly pressing or bearing sliding between the support and box body during bearing force.

Owner:CHONGQING CINWO PLASTICS

A kind of push-pull electromagnet and preparation method thereof

ActiveCN105761876BSmooth slidingSmall motion sensitivityMagnetsInductances/transformers/magnets manufactureElectricityPush and pull

The invention discloses a wide-temperature-range large-suction pushing-pulling electromagnet and a manufacturing method thereof. The electromagnet comprises a shell, a rear sealing cover, a movable iron core, a winding framework, a coil and an electric connector socket, the winding framework is positioned in a first groove in the shell and fixedly connected with the shell through the rear sealing cover for sealing, and the coil is wound in a winding groove of the winding framework and enables two poles of the coil to penetrate the shell to be electrically connected with the electric connector socket. One end of the movable iron core is positioned in a magnetic core hole of the winding framework and connected with the rear sealing cover through a resetting spring while the other end of the same penetrates a first through hole in the shell and extends to the outer side of the shell, the shell, the rear sealing cover and the movable iron core are made of electromagnetic pure iron, and the winding framework is made of aluminum bronze. The electromagnet has the advantages of simple structure, small size, large suction and flexibility, and the electromagnet can work stably in an environment with a wide temperature range and rain and other environments. The manufacturing method has the advantages of simple process, convenience in assembly and high working efficiency.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

A ring cooling trolley sealing device

ActiveCN112923736BGuaranteed cooling qualityEnsure waste heat recovery effectIncreasing energy efficiencyHandling discharged materialEngineeringMechanical engineering

The invention discloses a ring cooling trolley sealing device, belonging to the technical field of metallurgy, comprising an outer guide rail, an inner guide rail and a ring cooling trolley; Sealing components are respectively provided between the guide rails; the sealing components include a sealing frame body fixedly connected with the ring cooling trolley and a sealing ring with a U-shaped cross section; the opening of the sealing ring faces the side of the ring cooling trolley, and it is respectively connected with the inner guide rail. It is connected with the external guide rail; the seal frame body is provided with a radial seal that slides along the radial direction of the seal ring, and the radial seal is slidably engaged with the inside of the seal ring; there is a radial reset between the radial seal and the seal frame body spring. The radial seal is connected with the sealing frame in radial sliding, and is elastically reset by the radial return spring, which offsets the centripetal force of the ring cooling trolley, so that the radial seal is always tightly sealed with the sealing ring to ensure a good sealing effect and running smoothly. Stability, to ensure the cooling quality of hot ore and the effect of waste heat recovery.

Owner:SHANDONG IRON & STEEL CO LTD

Particle-stabilized nanoemulsion lubricant for water-based drilling fluid and preparation method thereof

ActiveCN109666460BGood dispersionImprove adsorption capacityDrilling compositionVegetable oilActive agent

The invention relates to a particle-stabilized nanometer emulsion lubricant for water-based drilling fluids, and a preparation method thereof, wherein the particle-stabilized nanometer emulsion lubricant comprises 30-60% of fatty acids and ester derivatives thereof, 5-25% of a nonionic surfactant, 10-20% of a cationic surfactant, 5-20% of a solid lubricant, and 15-40% of water. According to the present invention, the particle-stabilized nanometer emulsion lubricant has good dispersibility in water-based drilling fluids, can overcome the disadvantages of difficult dispersion and easy oil phaseprecipitation of mineral oil or vegetable oil or other conventional liquid lubricants, can form the stable adsorption film on drill bits, drilling rods and well walls, can effectively reduce the friction coefficient of the friction surface, improve the lubrication performance and reduce the wear, and further can maintain good lubrication performance under extreme pressure or high load.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sideslip-proof liquid lubrication simulation ice plate

ActiveCN109865278AReduce lossImprove conversion efficiencySki bindingsWater-skiingThermoplasticFiber bundle

The invention relates to the field of winter sports product production, and particularly discloses a sideslip-proof liquid lubrication simulated ice plate. The anti-sideslip liquid lubrication simulated ice plate comprises a plate body and is characterized in that the plate body is formed by compounding an sideslip-proof liquid lubrication functional layer, a cementing layer and a high-rigidity substrate material layer from top to bottom in sequence; wherein the sideslip-proof liquid lubrication functional layer comprises low-friction coefficient thermoplastic plastics, holes of clusters are uniformly distributed on the low-friction coefficient thermoplastic plastics, and high-strength cut-resistant untwisted fiber bundles are arranged in the holes in a penetrating manner. The sideslip-proof liquid lubrication simulation ice plate has the characteristics of simple structure, easy processing, easy maintenance and integral recovery, effectively reduces the sliding friction coefficient ofthe simulated ice plate, reduces the possibility of sideslip in the process of stepping on the ground, and improves the fluency of sports of athletes on the simulated ice plate.

Owner:TAISHAN SPORTS IND GRP +1

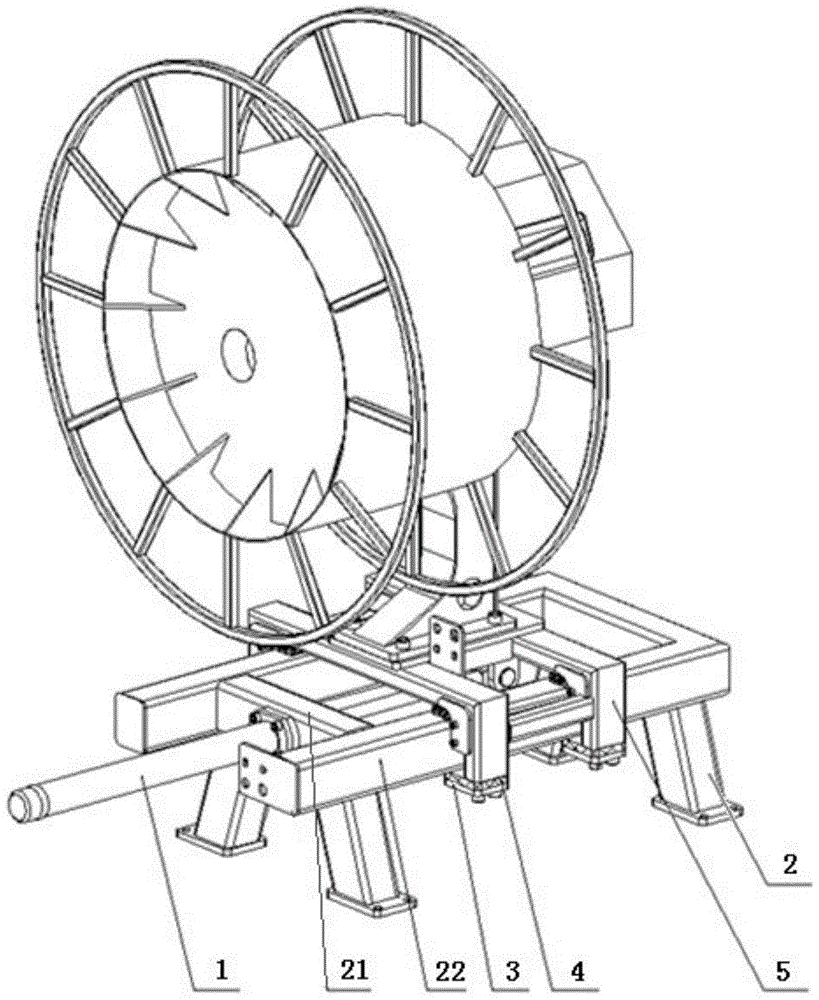

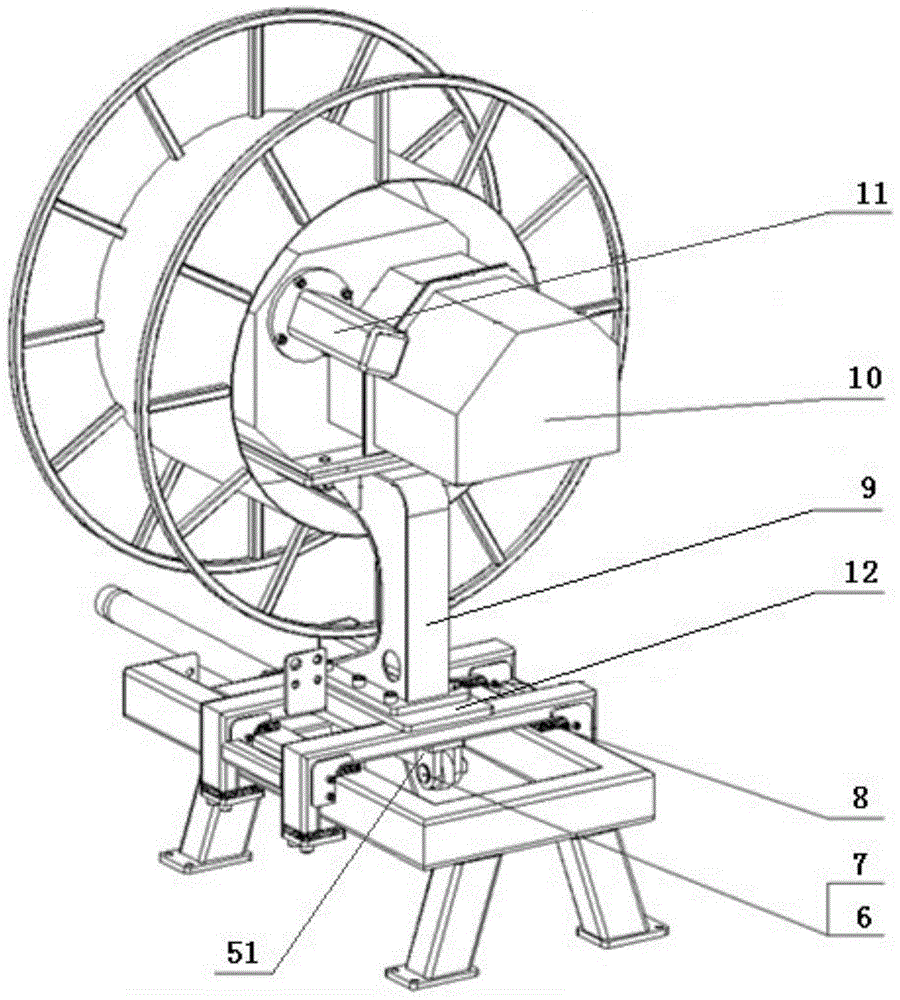

A sliding cable reel device

ActiveCN105084120BSolve the problem of partial loadAvoid safety accidentsFilament handlingEngineeringBlock match

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

High density polyethylene self-lubricating optical fibre cable sheath tube

InactiveCN1219298CLow coefficient of sliding frictionLow costPlastic/resin/waxes insulatorsInsulated cablesHigh densitySilicone oil

A sheathing tube of self-lubricating optical fiber cable is processed after the composite of high-density polythene as the main outer layer material and the sold self-lubricating composite material as the main inner layer material processed by compounded coextrusion, among which the proportion mix of the outer layer material is high-density polythene: 90% and composite reinforcer 10% and that of the inner layer material is silicone resin: 80%, surfactant 10%, silicon oil: 10%.

Owner:福建亚通塑胶有限公司

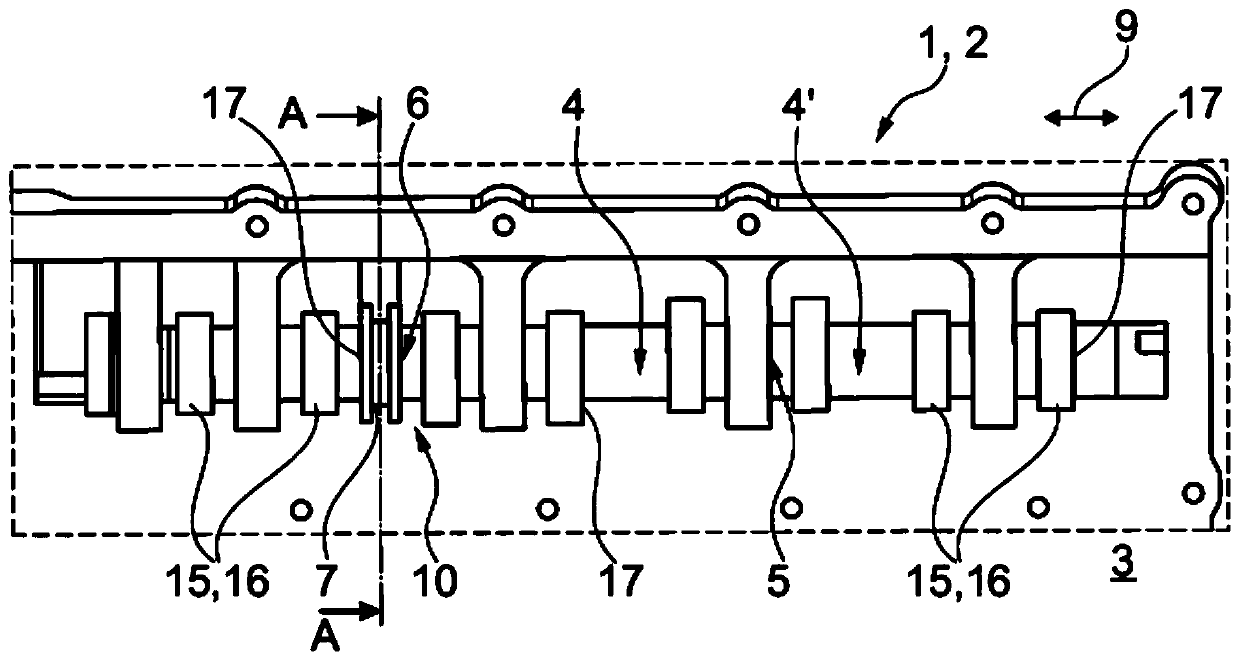

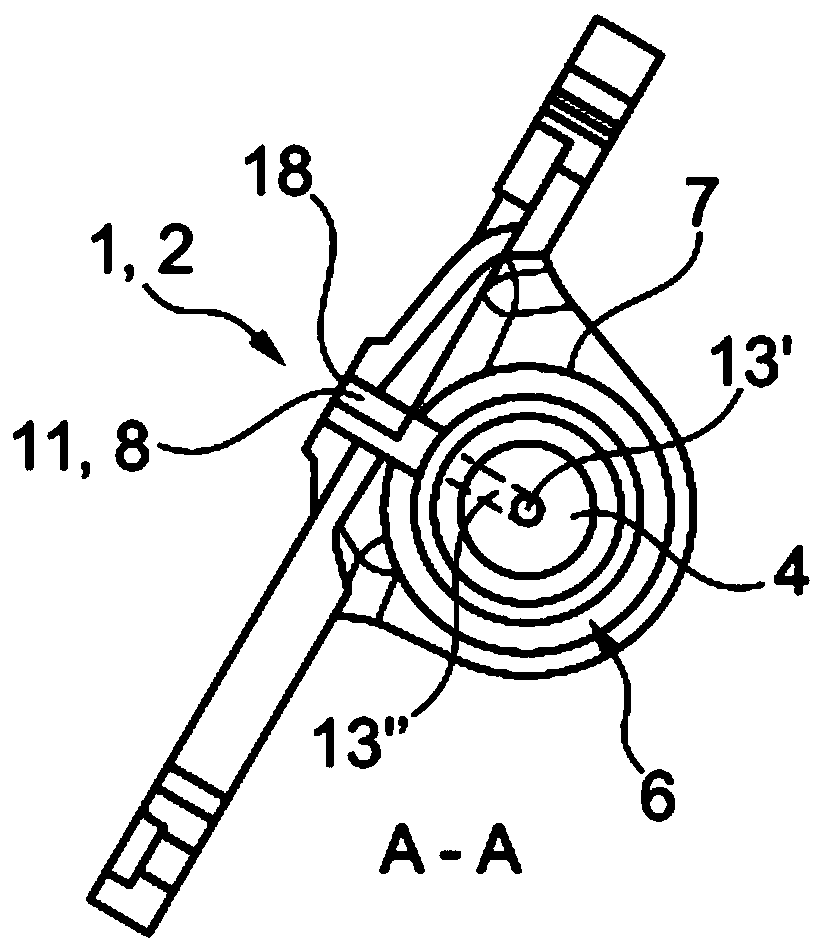

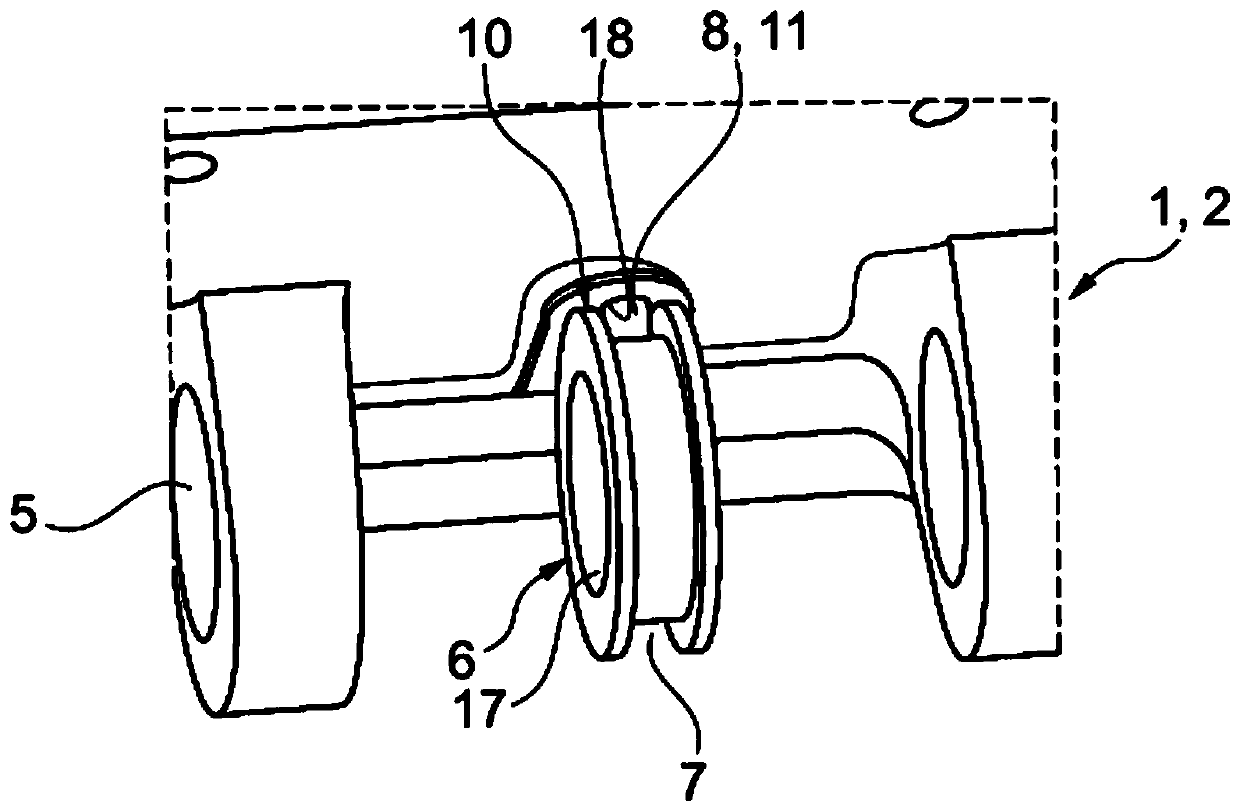

Bearing frame or cylinder head cover for a combustion engine

InactiveCN110388280AWith overwrite functionQuality improvementCasingsValve arrangementsCombustionCylinder head

A bearing frame (1) or a cylinder head cover (2) for an internal combustion engine (3) may include at least one camshaft (4) mounted in tunnel bearings in at least two bearing openings (5) arranged along a bearing channel and completely enclosing at least one of the camshaft (4) and a radial bearing, and at least one axial shaft bearing ring (6) arranged on the camshaft (4). The axial shaft bearing ring (6) may have a ring groove (7) which is open towards the bearing frame (1) or towards the cylinder head cover (2). At least one engagement element (8) may be arranged on the bearing frame (1) or on the cylinder head cover (2), which engagement element (8) may engage into the ring groove (7) and forms an axial bearing (10) for the camshaft (4).

Owner:MAHLE INT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com