Unmanned aerial vehicle real-time tension detection device and tension detection method thereof

A tensile force detection and unmanned aerial vehicle technology, which is applied to measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of easy vibration of the nose structure, small rigidity of the section, and low structural strength, etc., and achieve accurate real-time Tensile test method, few moving parts, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

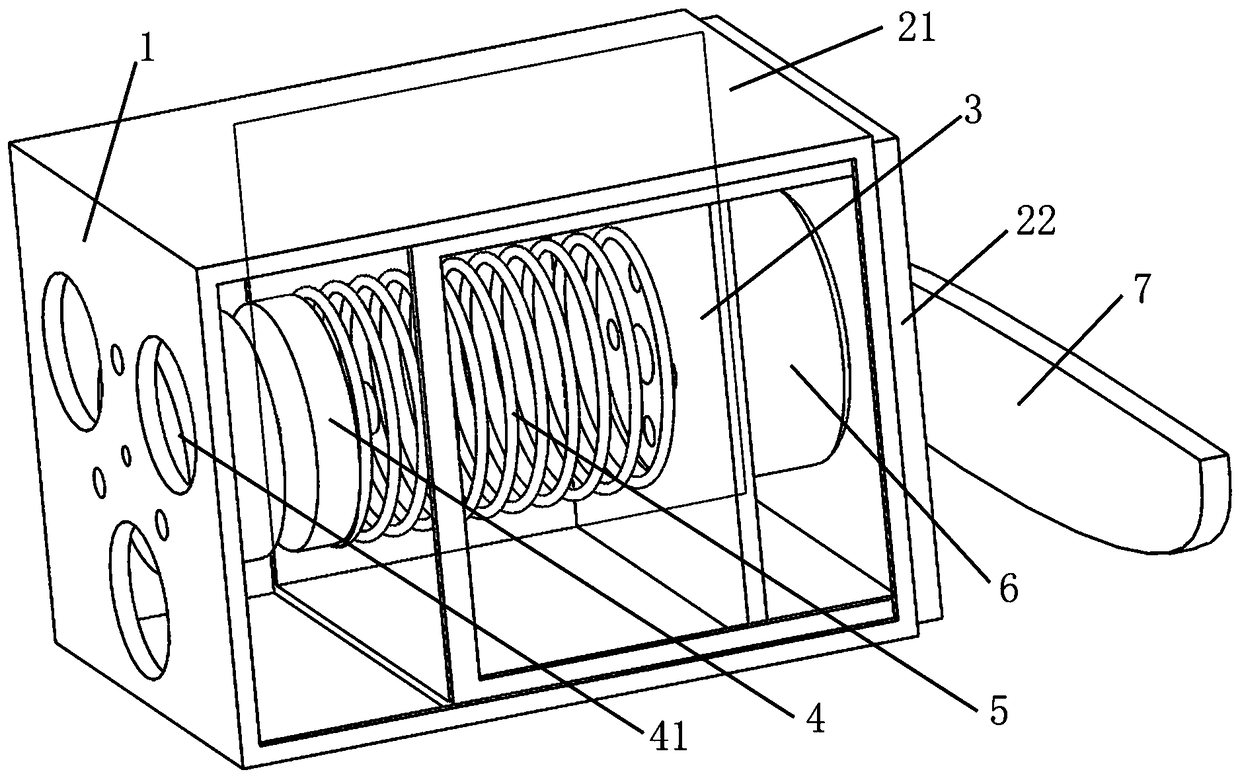

[0052] like figure 1 As shown, the UAV real-time tension detection device of the present invention includes a mounting base 1, a first fixed sleeve 21, a second fixed sleeve 22, a motor mount 3, a tension sensor 4, a spring 5, a motor 6, and a paddle 7 , attitude sensor 41;

[0053] The installation base 1 is fixed on the fuselage, and the tension sensor 4 is fixed on the installation base 1;

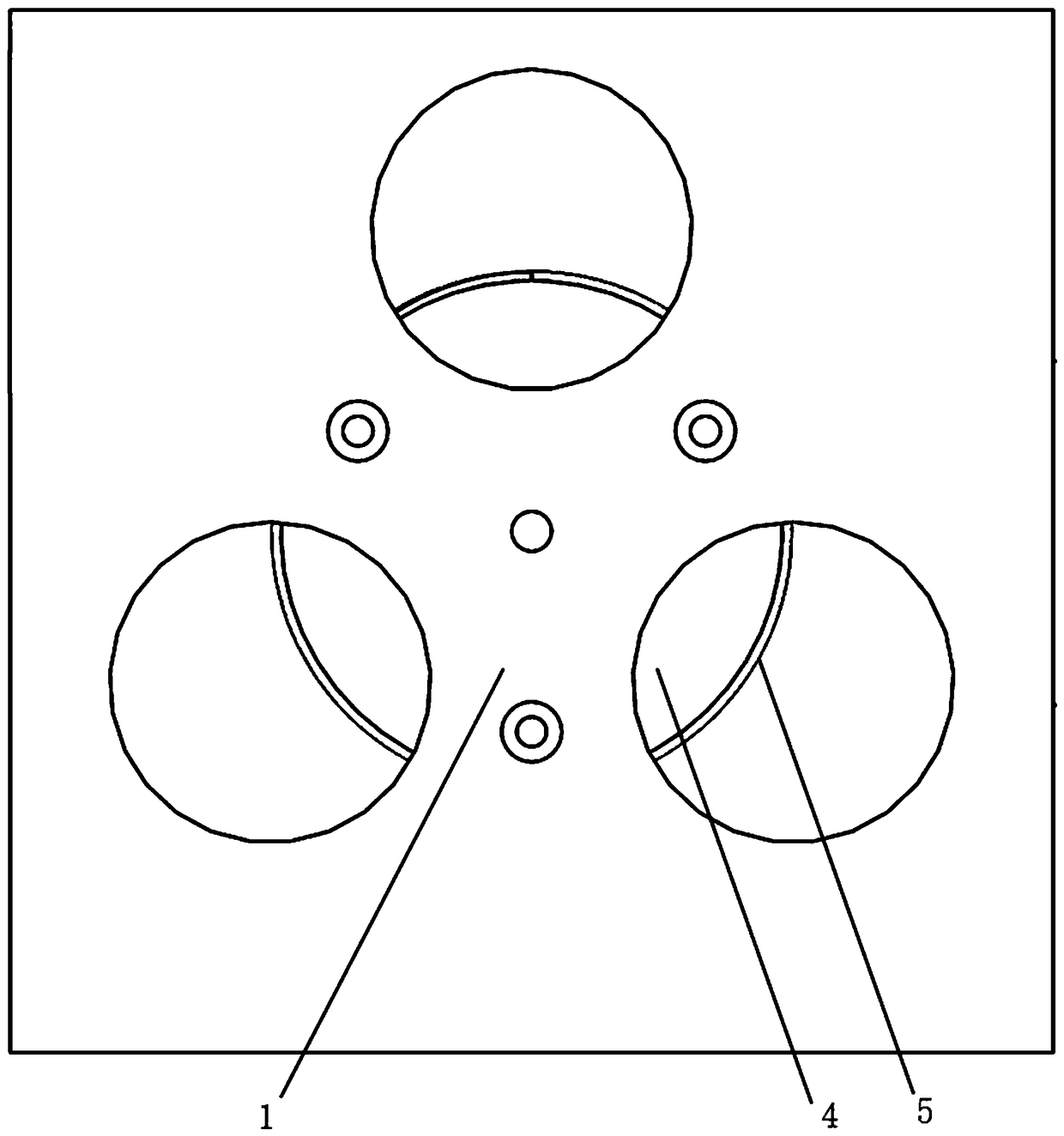

[0054] figure 2 An enlarged view of the installation base 1 in the specific embodiment is given;

[0055] The first fixing sleeve 21 is fixed on the fuselage;

[0056] The paddle 7 is connected with the motor shaft directly or through an intermediate gear transmission;

[0057] The motor is mounted on the motor mount 3, and the motor mount 3 is mounted on the second fixed sleeve 22;

[0058] The second fixing sleeve 22 is embedded or embedded in the first fixing sleeve 21. During actual operation, the two can slide relative to each other. The first fixing sleeve 21 and the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness coefficient | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com