Patents

Literature

46results about How to "Guaranteed cooling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

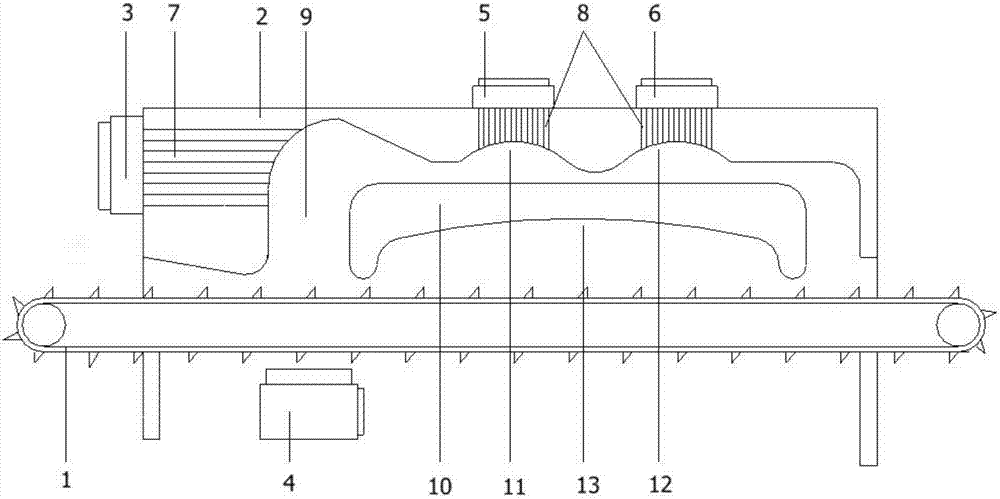

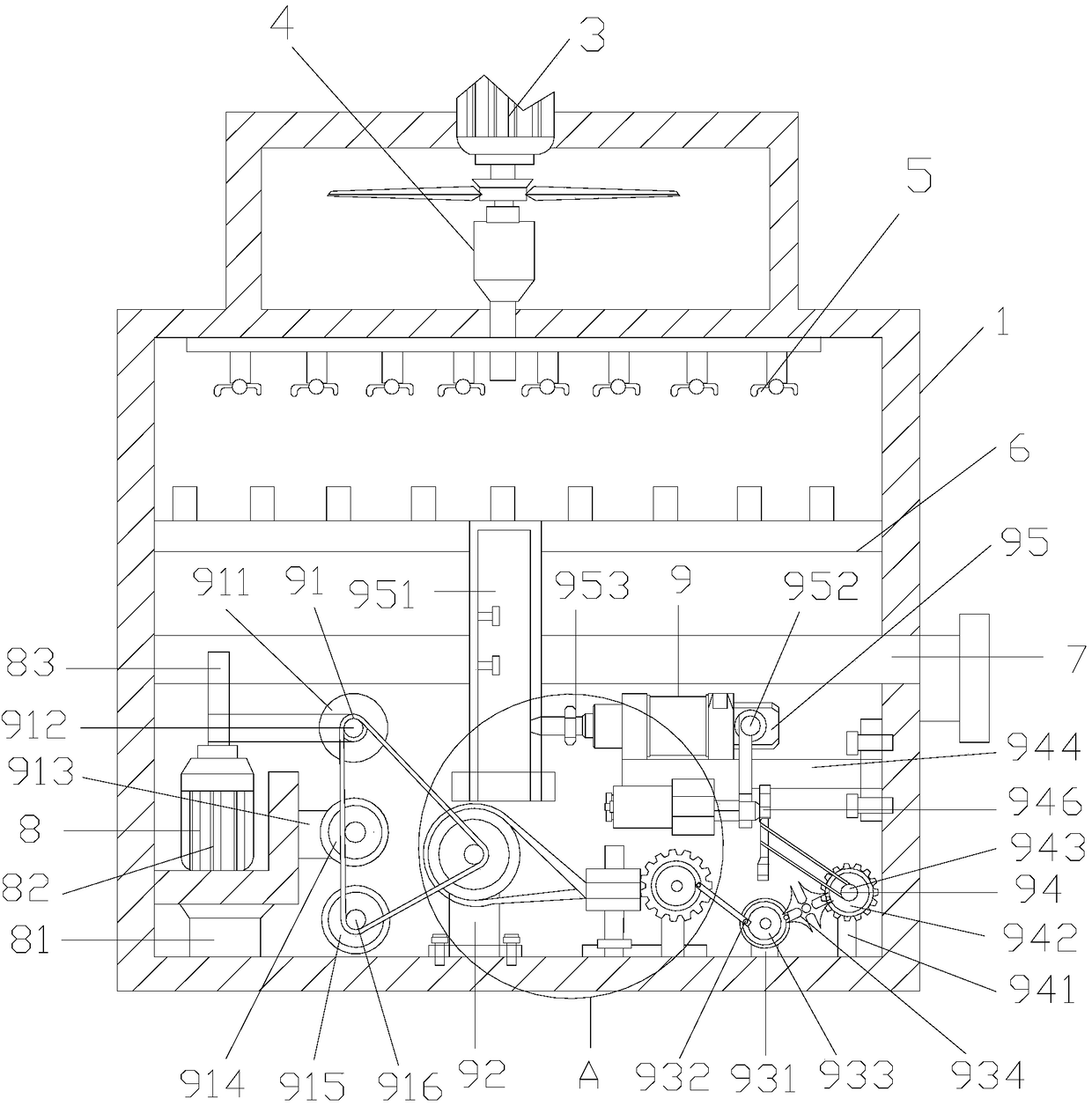

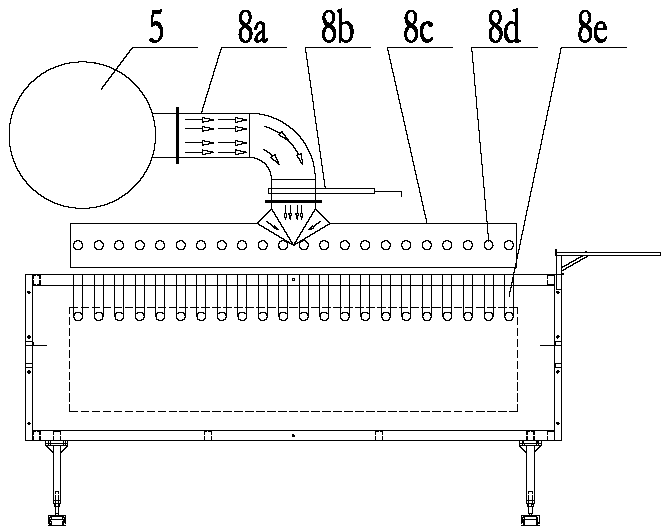

Ceramic energy-saving furnace kiln capable of high-efficiently replaying, recovering and cooling waste heat

ActiveCN106440836AReduce pollutionReduce fuel consumptionEnergy industryIncreasing energy efficiencyCombustionSlow cooling

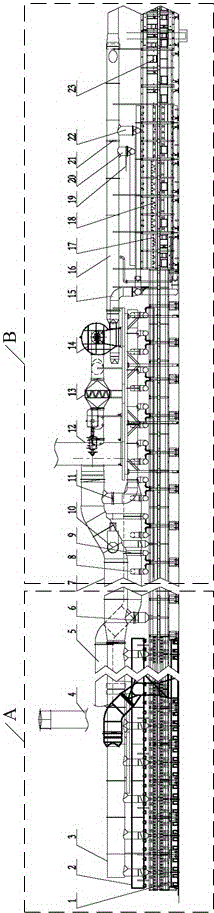

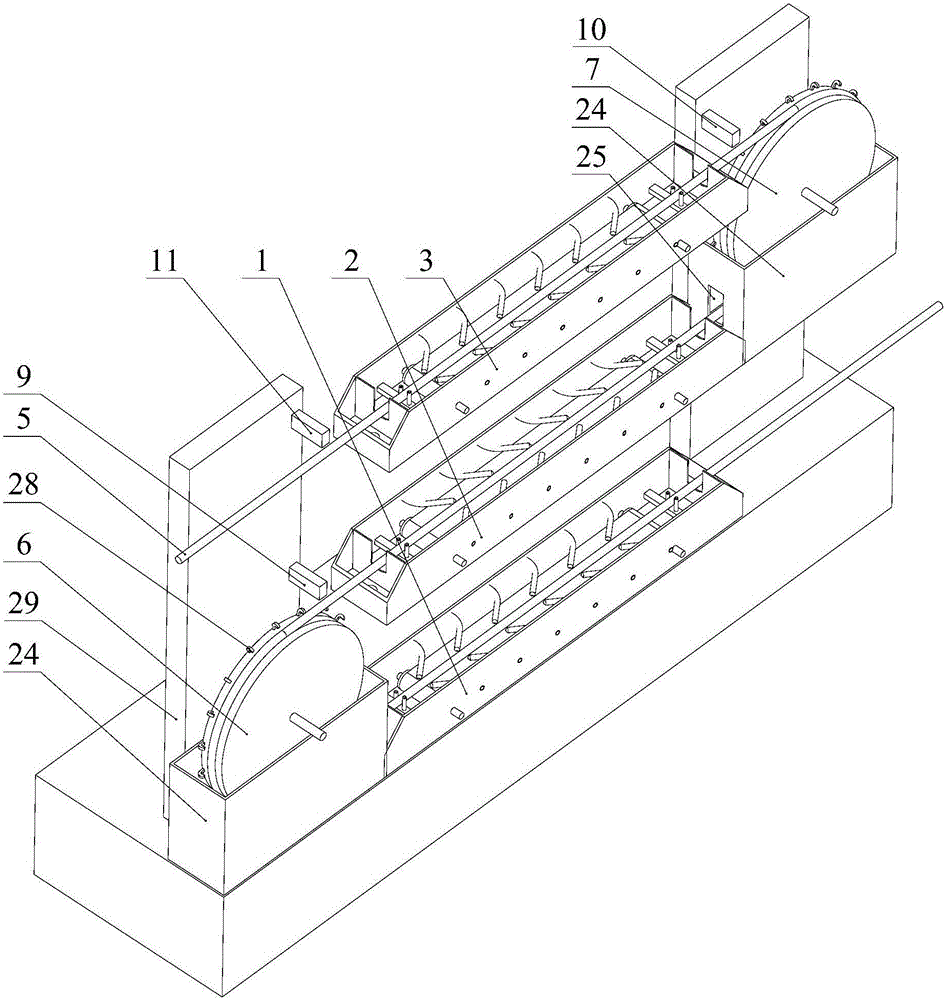

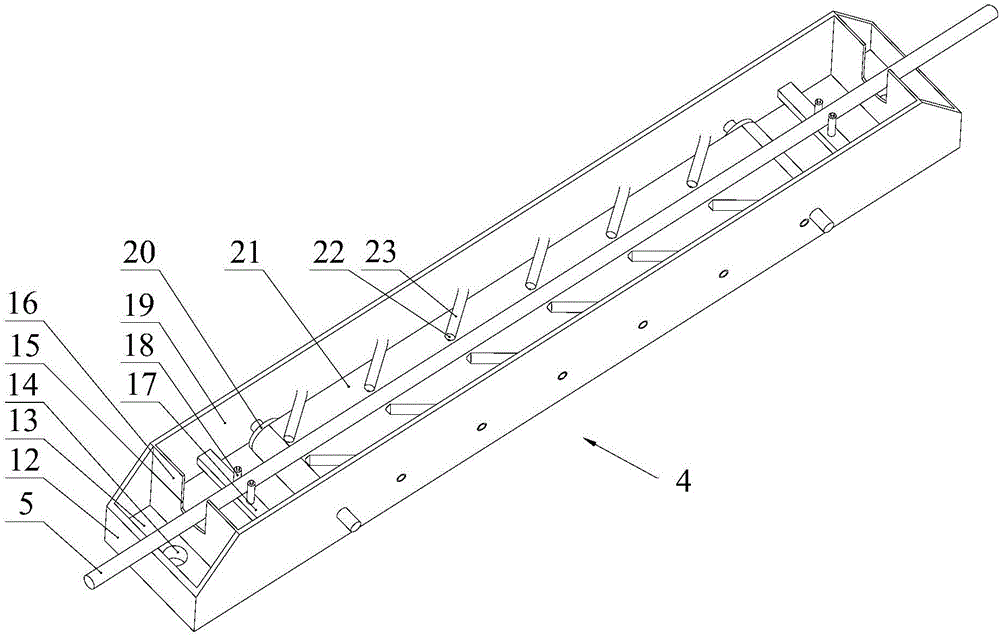

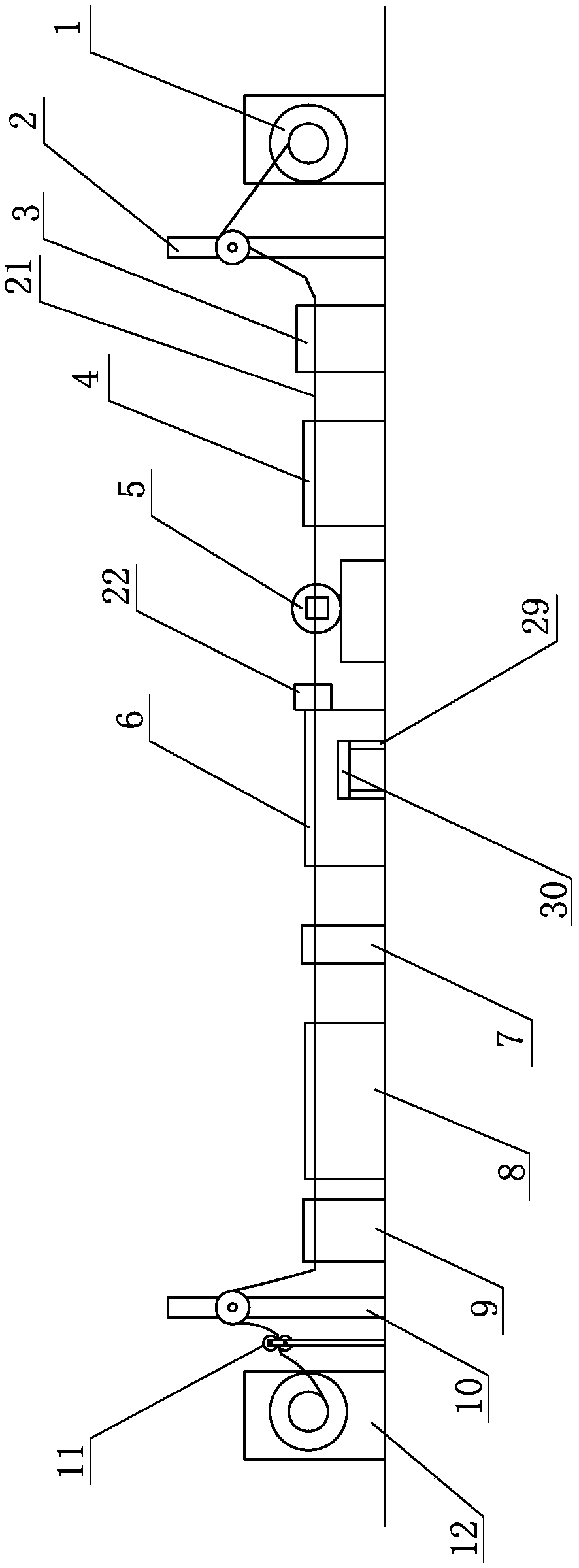

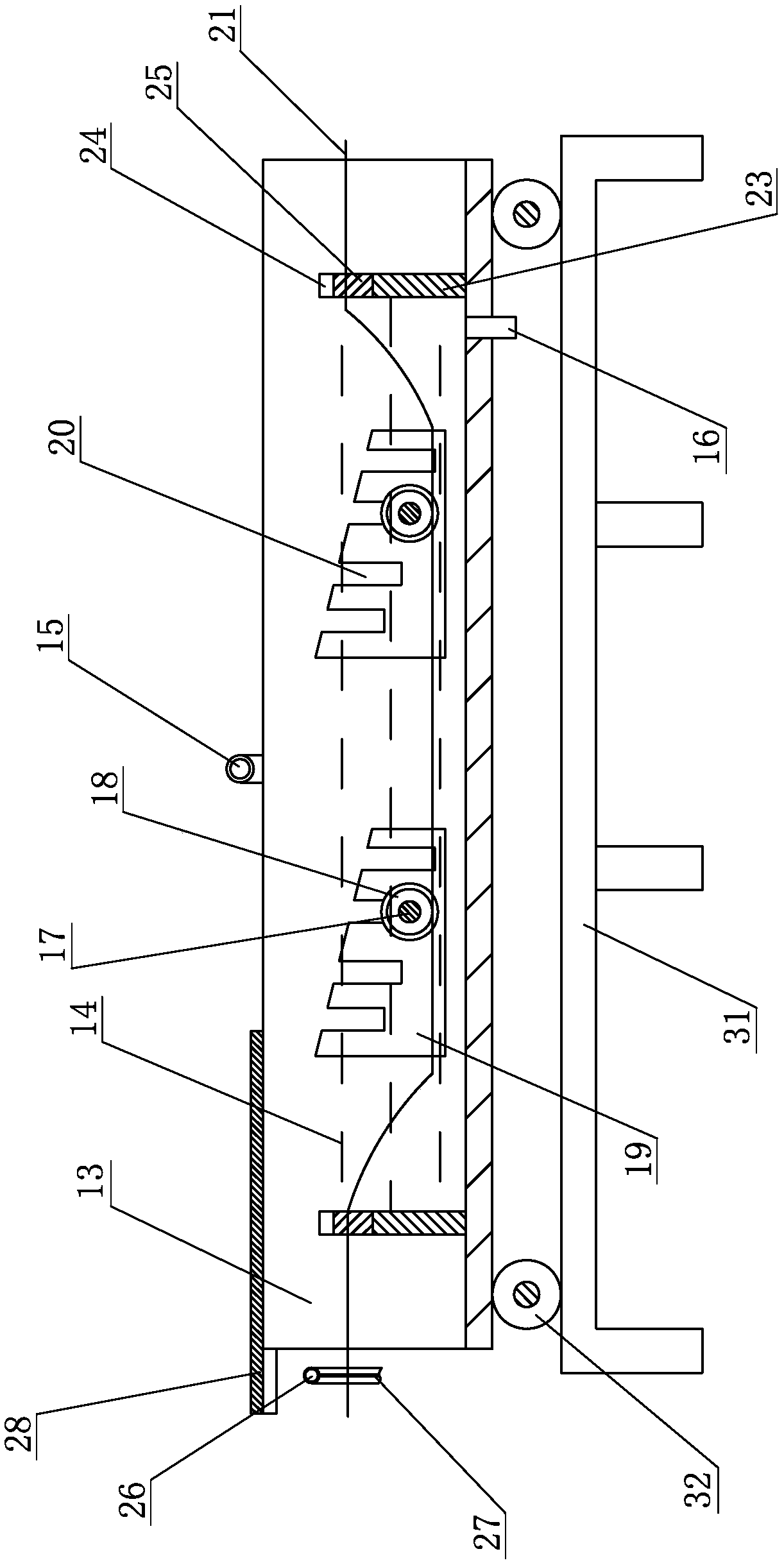

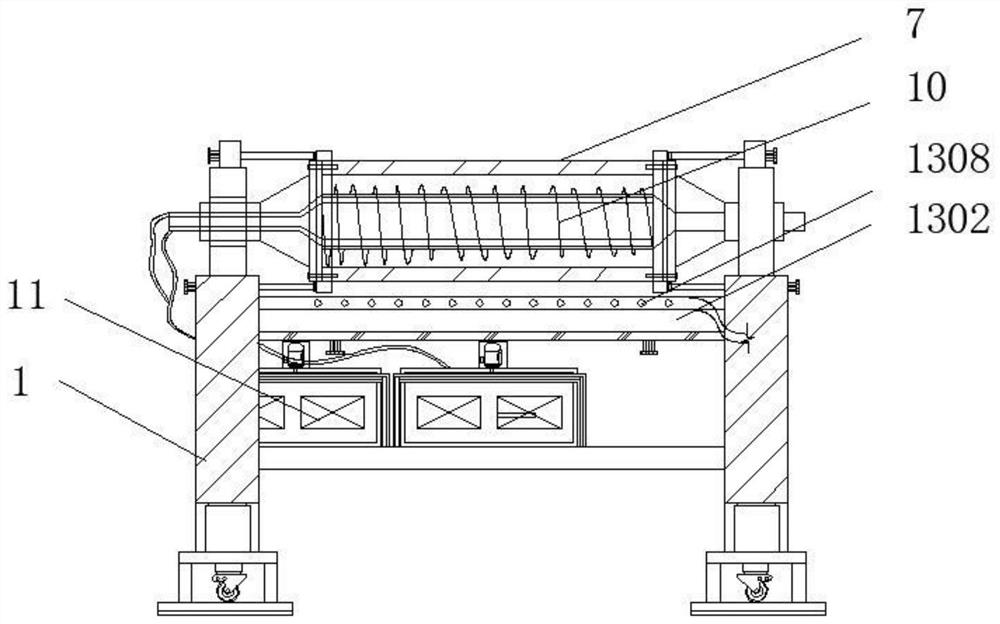

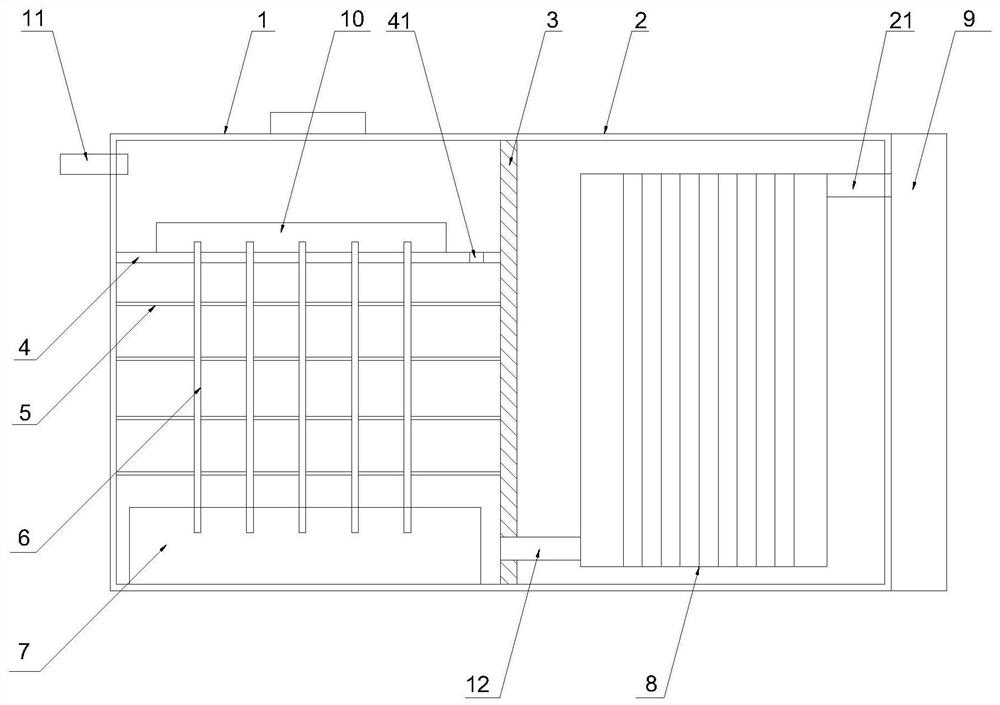

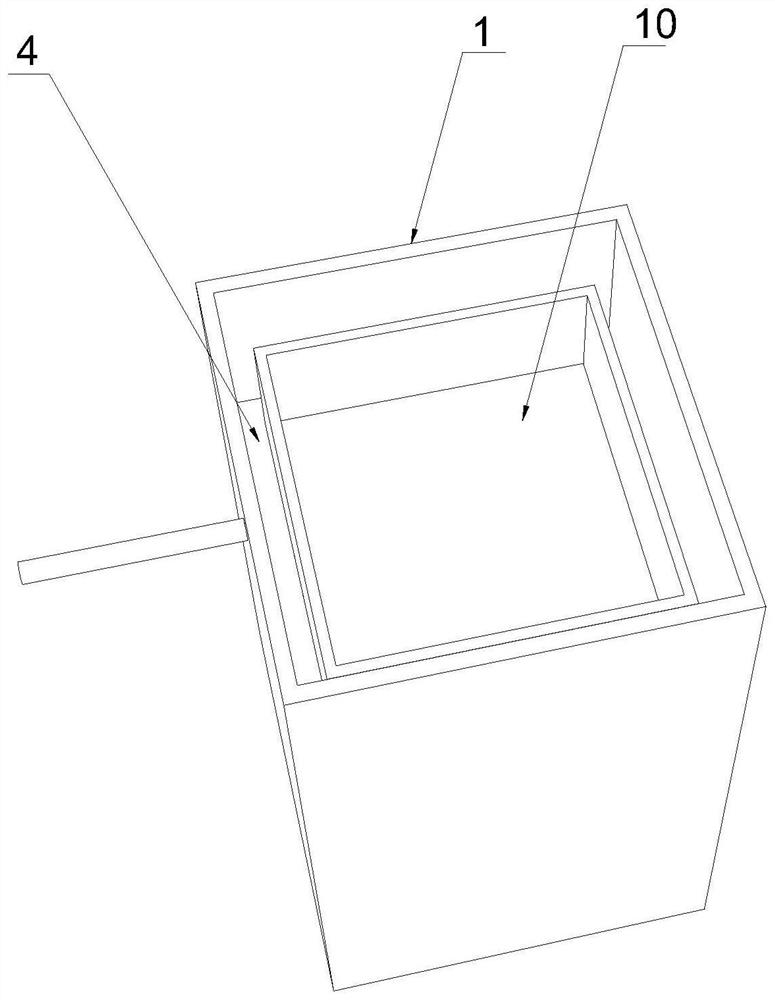

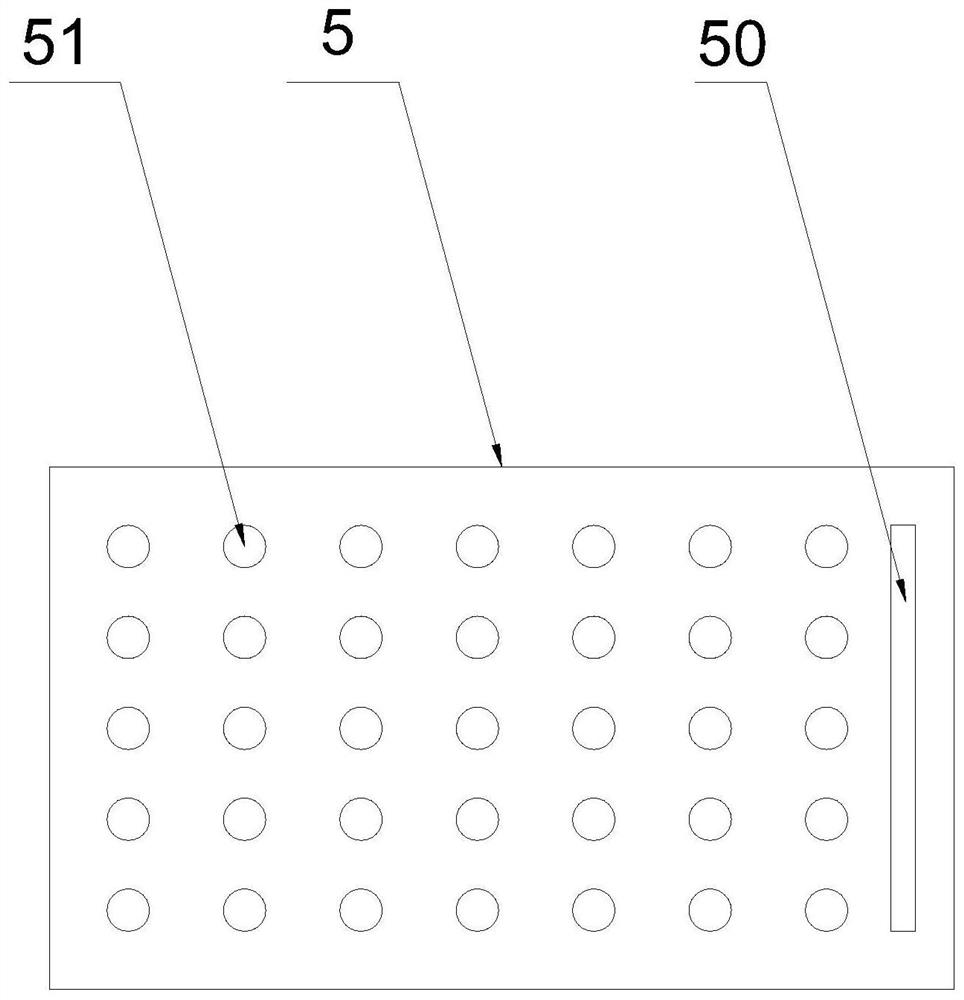

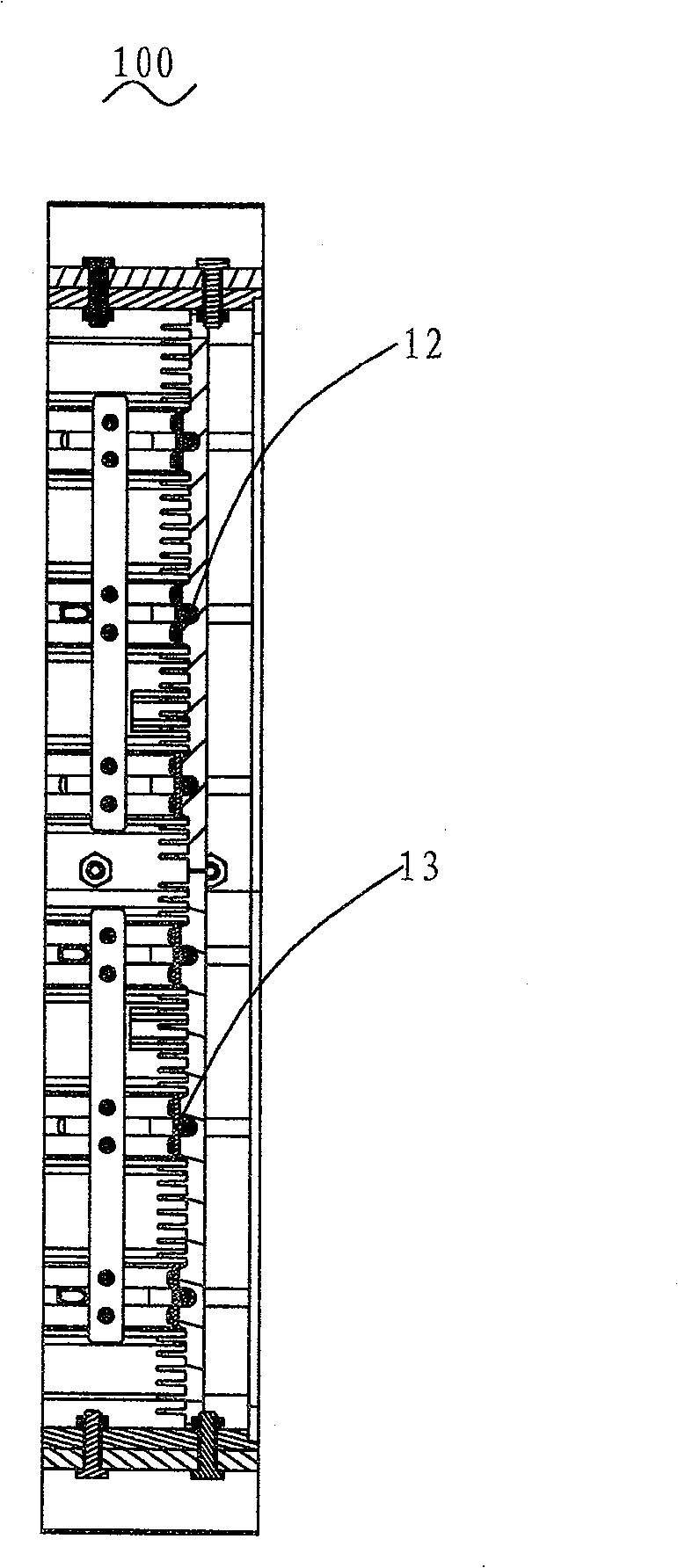

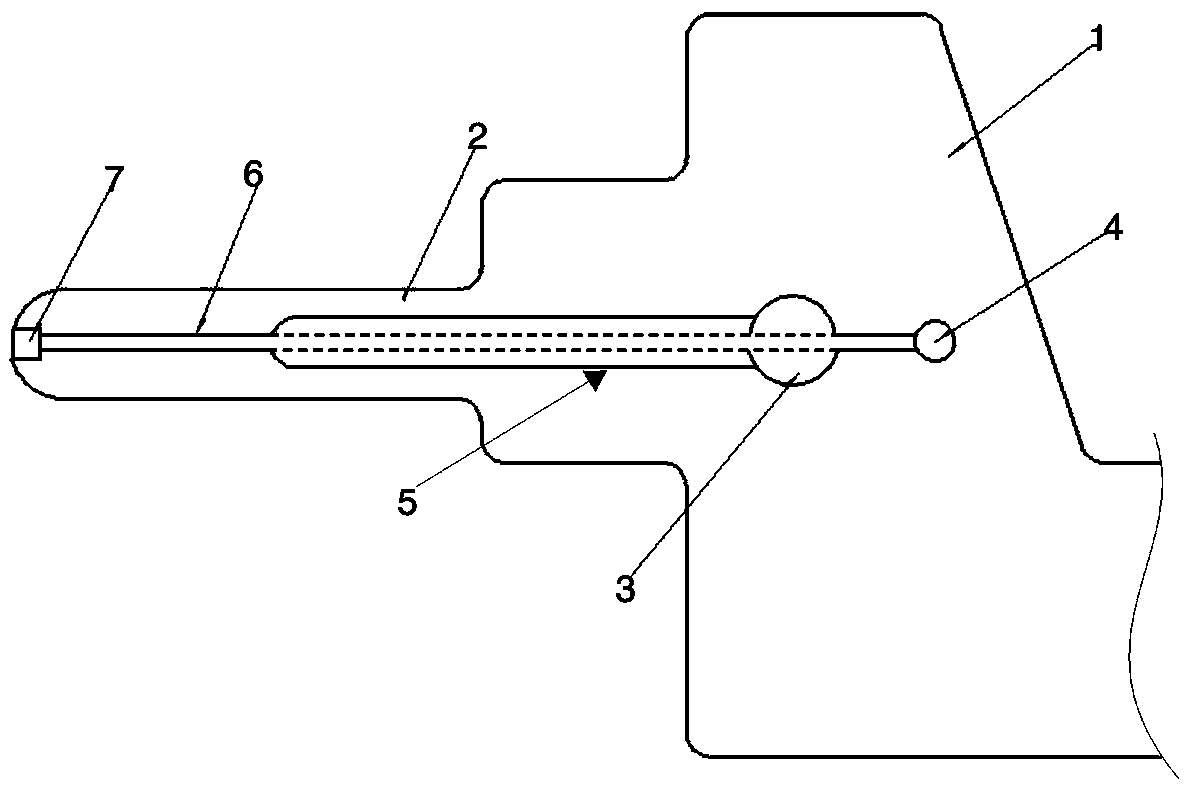

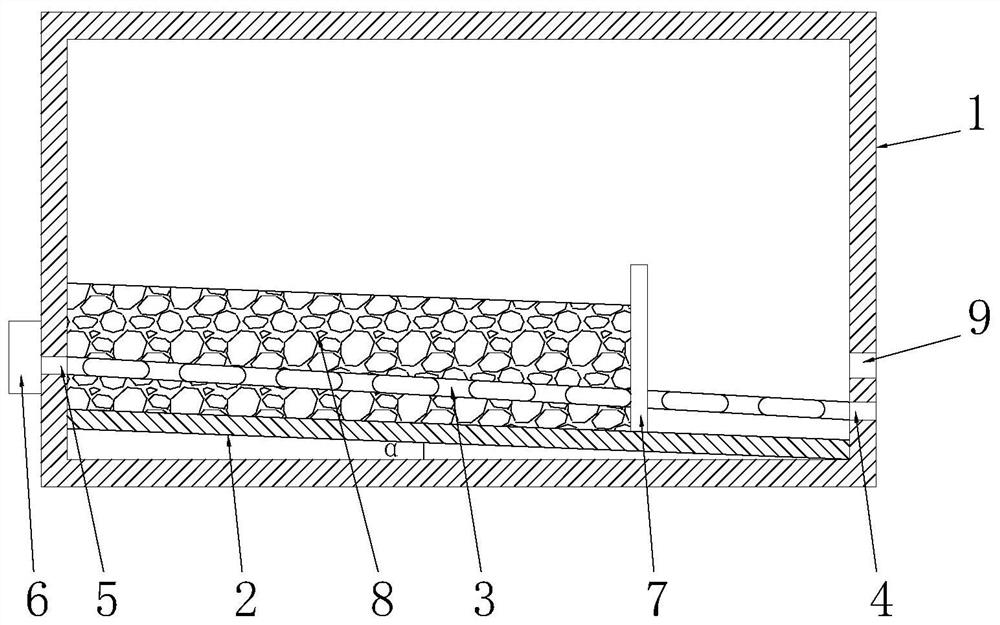

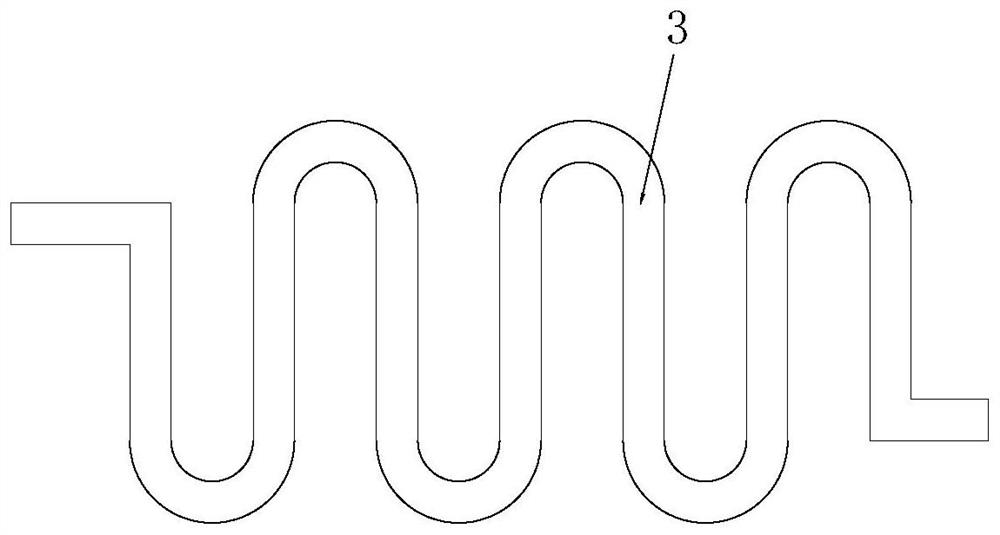

The invention discloses a ceramic energy-saving furnace kiln capable of high-efficiently replaying, recovering and cooling waste heat. The ceramic energy-saving furnace kiln capable of high-efficiently replaying, recovering and cooling the waste heat comprises a rapid cooling zone, a slow cooling zone and a tail cooling zone. Tail cooling zone draught hoods, a tail cooling zone exhaust pipe and a heat-extraction fan are arranged on the tail cooling zone; a slow cooling zone discharge pipe, a plurality of slow cooling zone air supply pipe groups, a plurality of slow cooling zone discharge pipe groups, a slow cooling zone exhaust pipe and a heat exchange fan are arranged on the slow cooling zone; a combustion fan, an air supply main pipe and a nozzle are arranged on the rapid cooling zone; and a rapid cooling zone air supply pipe group and a rapid cooling zone discharge pipe group are arranged on the air supply main pipe. By adopting the ceramic energy-saving furnace kiln capable of high-efficiently replaying, recovering and cooling the waste heat provided by the invention, a pipeline structure for recovering hot air is formed through a high-efficiently continuous replaying manner, cooling heat generated when ceramics are cooled at each stage is fully recycled, the combustion consumption during a drying and sintering process is remarkably reduced, the pollution on the environment caused by a heat source can be effectively reduced, and the product quality can also be improved.

Owner:DLT TECH CO LTD

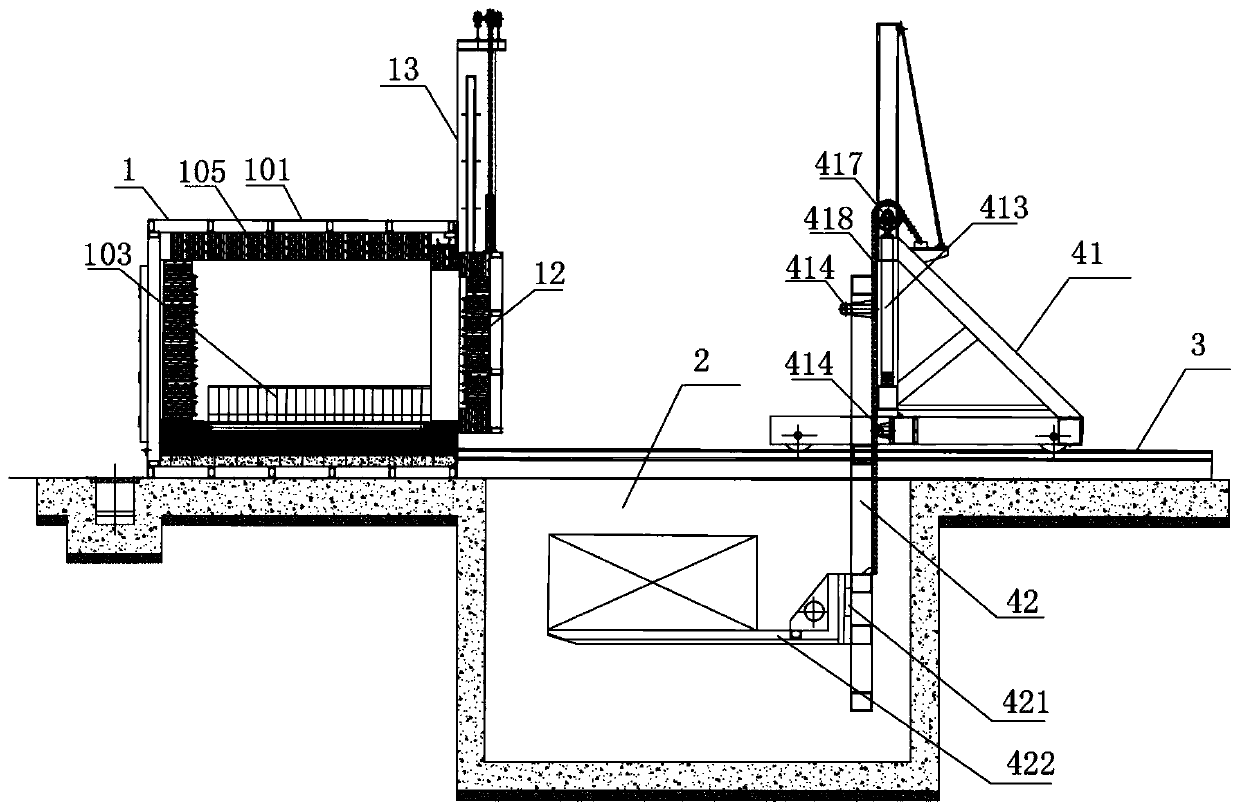

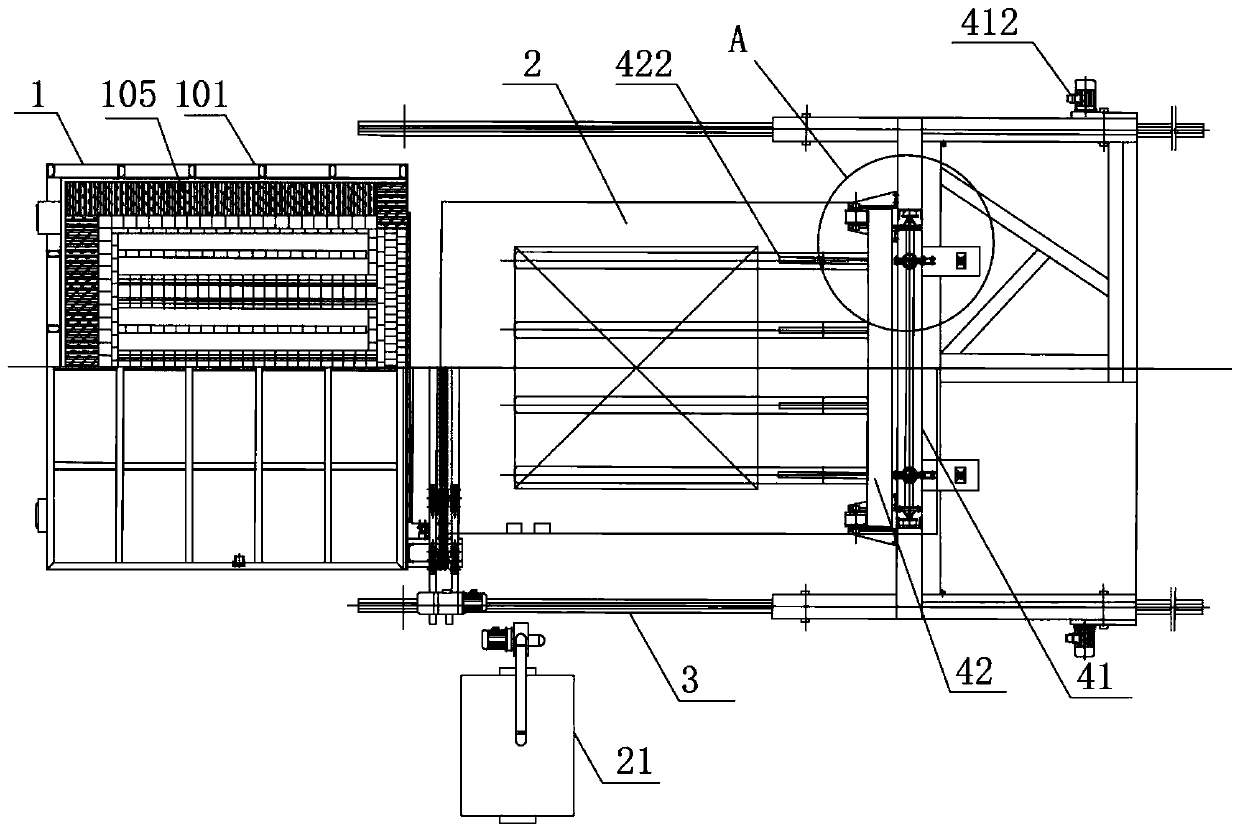

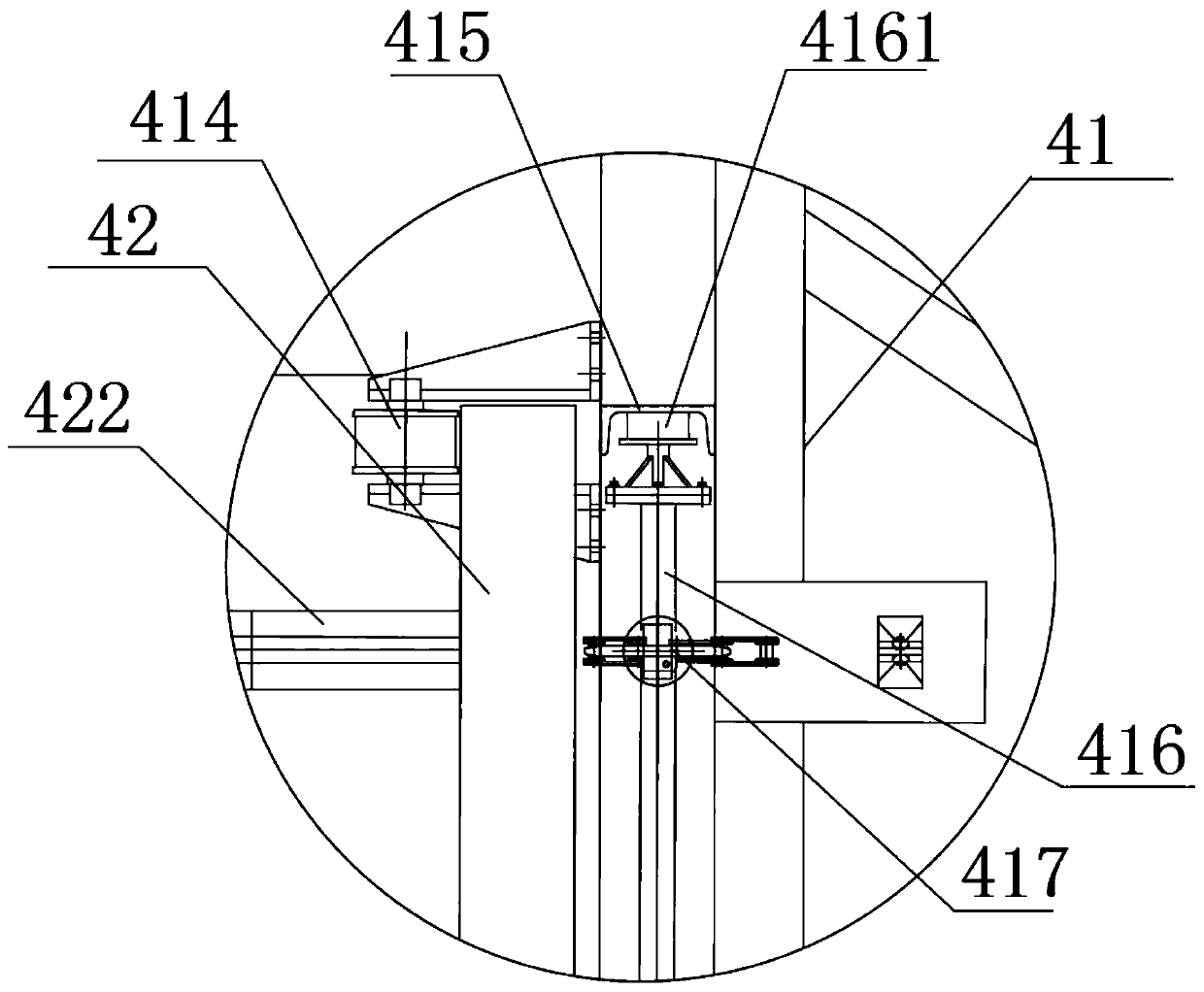

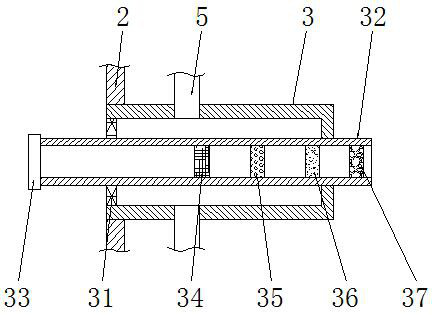

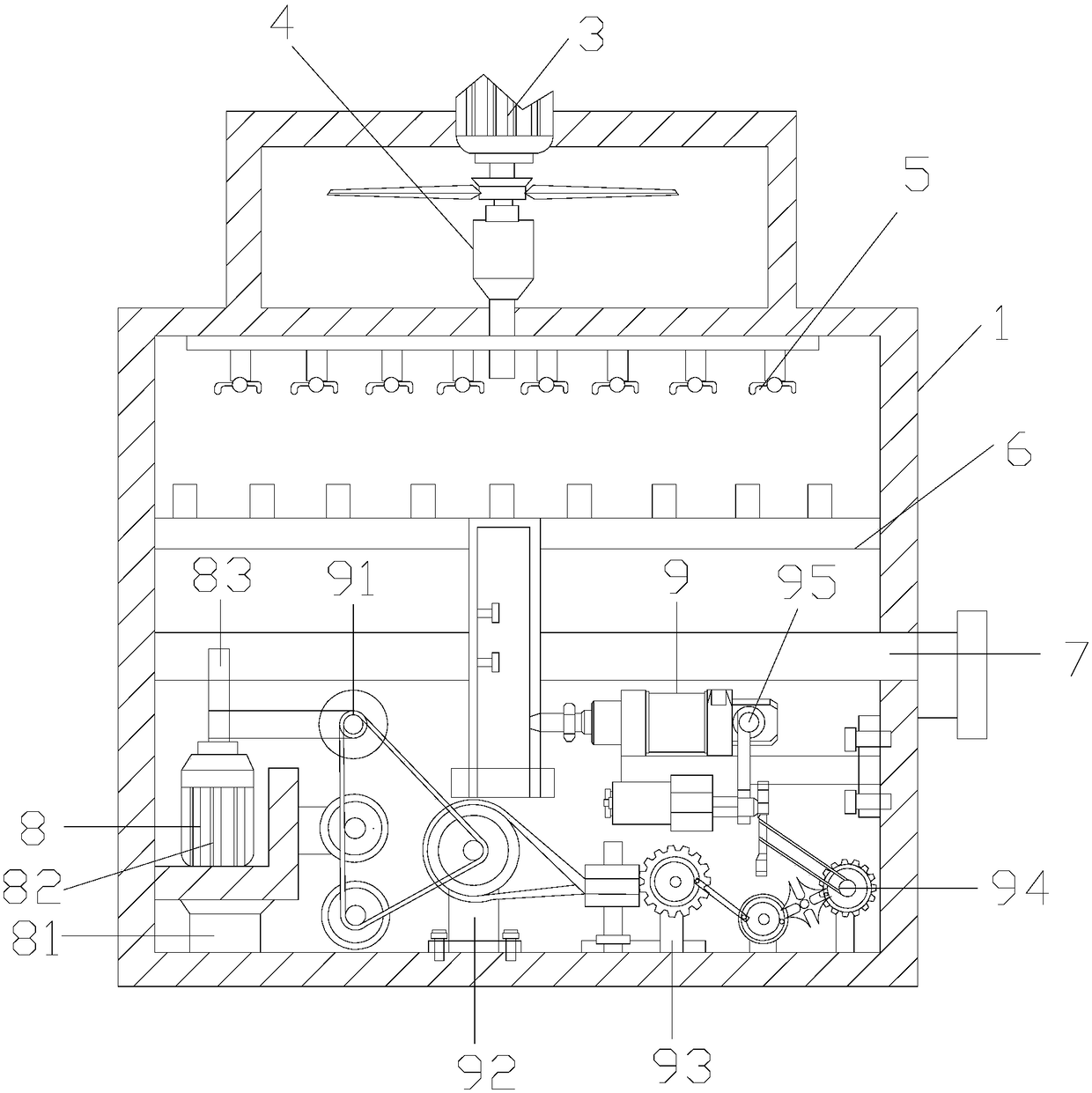

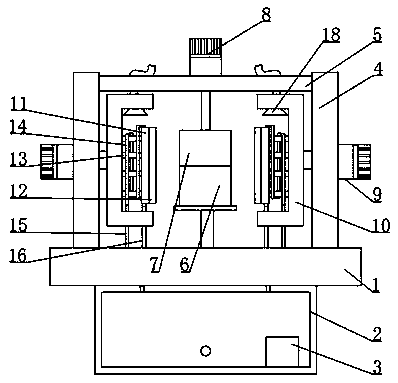

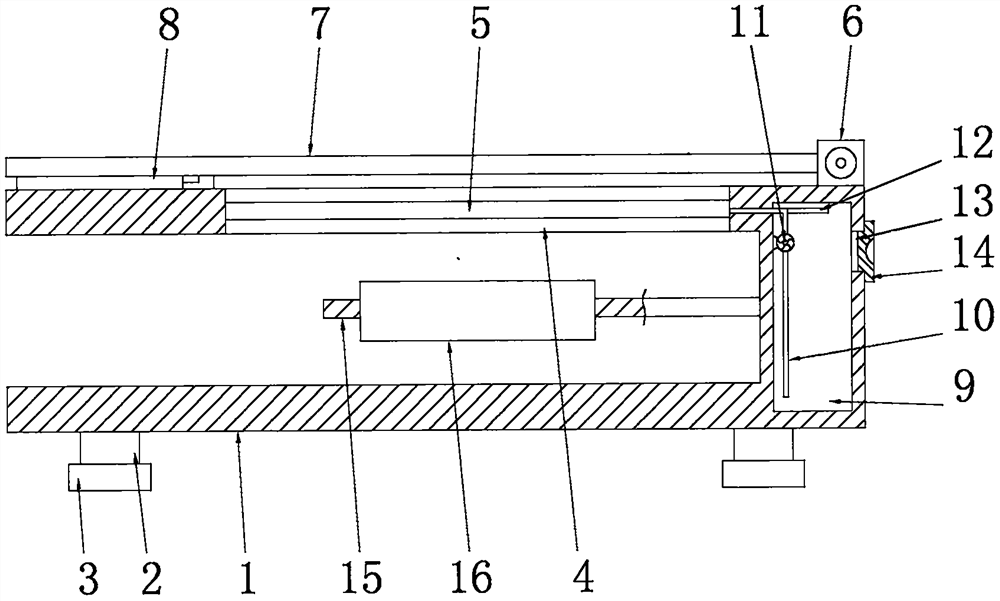

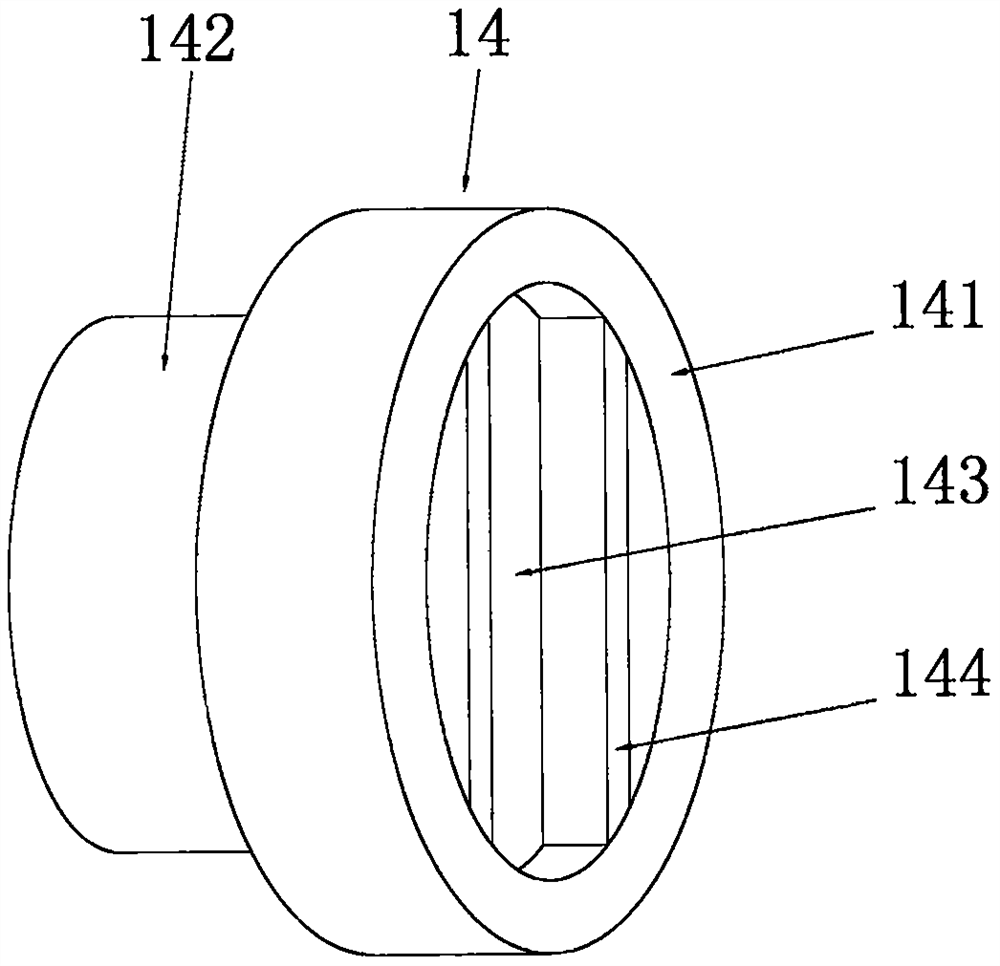

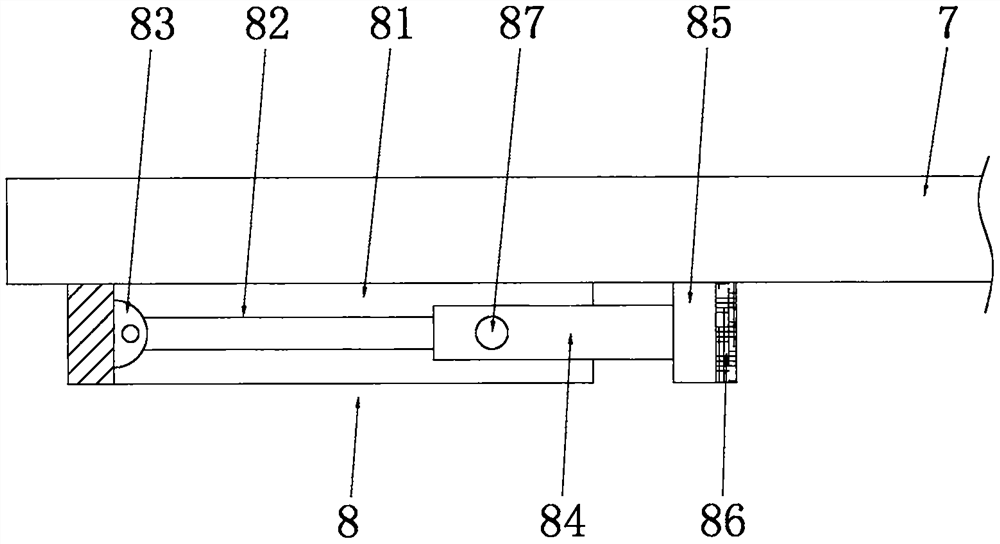

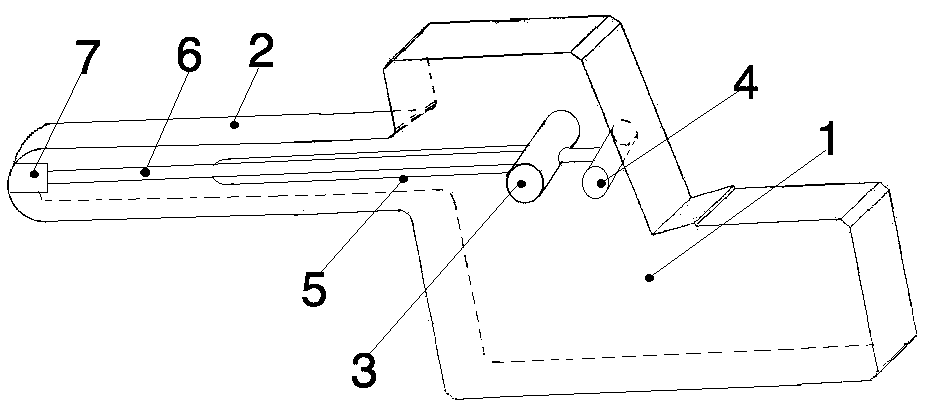

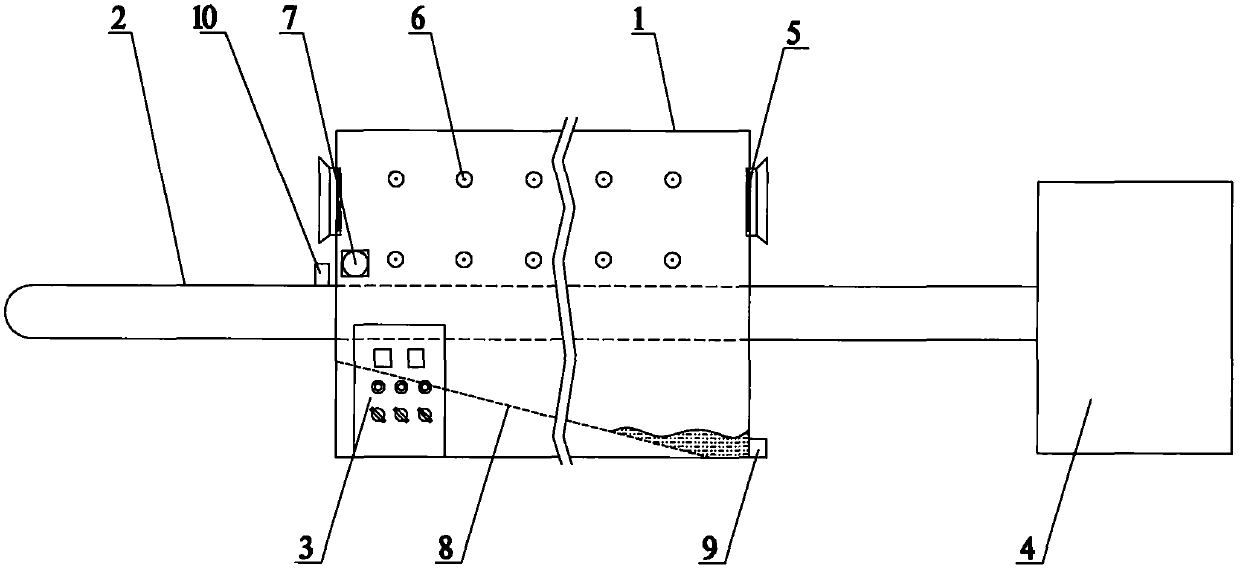

Special quenching system for box type quenching furnace

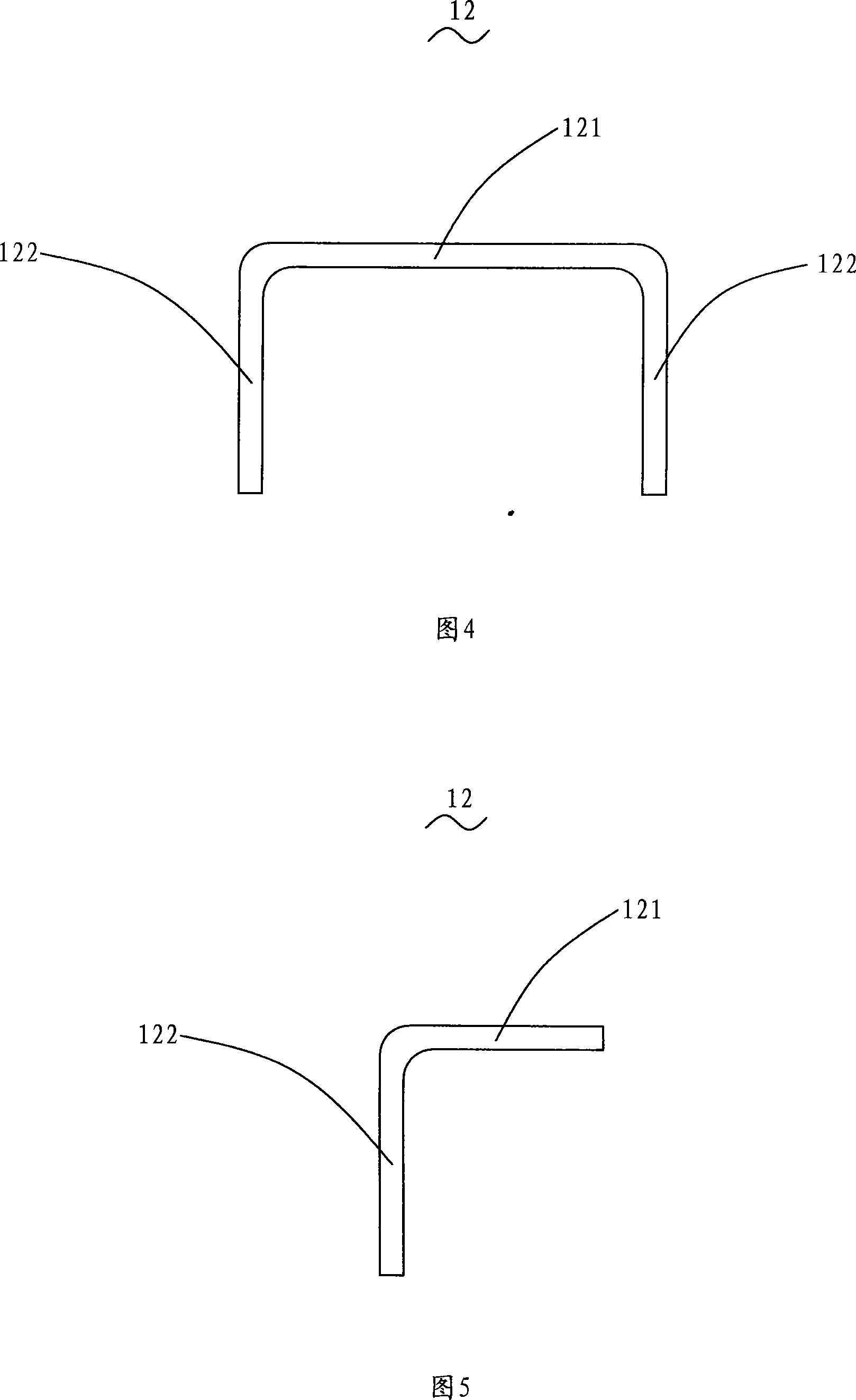

PendingCN111560504AGuaranteed cooling effectConsistent qualityFurnace typesHeat treatment furnacesClassical mechanicsPortal frame

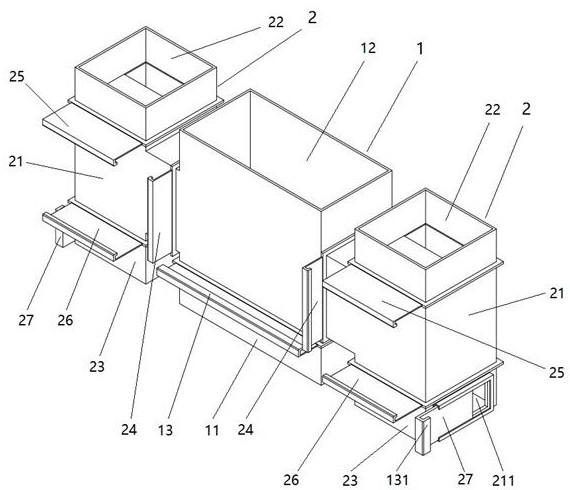

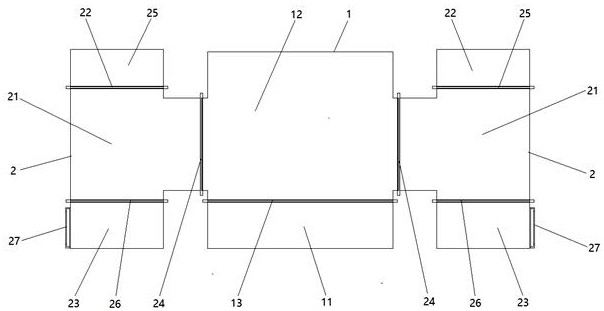

The invention relates to a special quenching system for a box type quenching furnace. The special quenching system comprises a quenching furnace, a quenching pool and a feeding device, the quenching pool is arranged at one end of the quenching furnace, feeding guide rails are arranged on the two sides of the quenching pool, and the feeding device is arranged on the feeding guide rails; the feedingdevice comprises a portal frame and a lifting frame, two sets of guide wheels are arranged at one end of the portal frame, the lifting frame is arranged between the two sets of guide wheels, a fixingseat is arranged at the lower end of the lifting frame, a shoveling claw is arranged on one side of the fixing seat, a sliding rail is arranged on the portal frame, a driving air cylinder is arrangedat the lower end of the portal, a piston rod of the driving air cylinder is connected with a lifting plate, movable wheels are arranged at two ends of the lifting plate, the movable wheel is arrangedon the sliding rail, a fixed pulley is arranged on the lifting plate, a chain is arranged on the fixed pulley, one end of the chain is connected with one side of the middle of the portal frame, the other end of the chain is connected with the top of the fixed seat, and a mounting seat is driven by the driving air cylinder to rise, so that the chain pulls the lifting frame to rise under the actionof the fixed pulley. Workpieces in the furnace are rapidly transferred to the quenching pool for quenching, and the quality of products in the same furnace is basically consistent.

Owner:丹阳市恒泰电炉有限公司

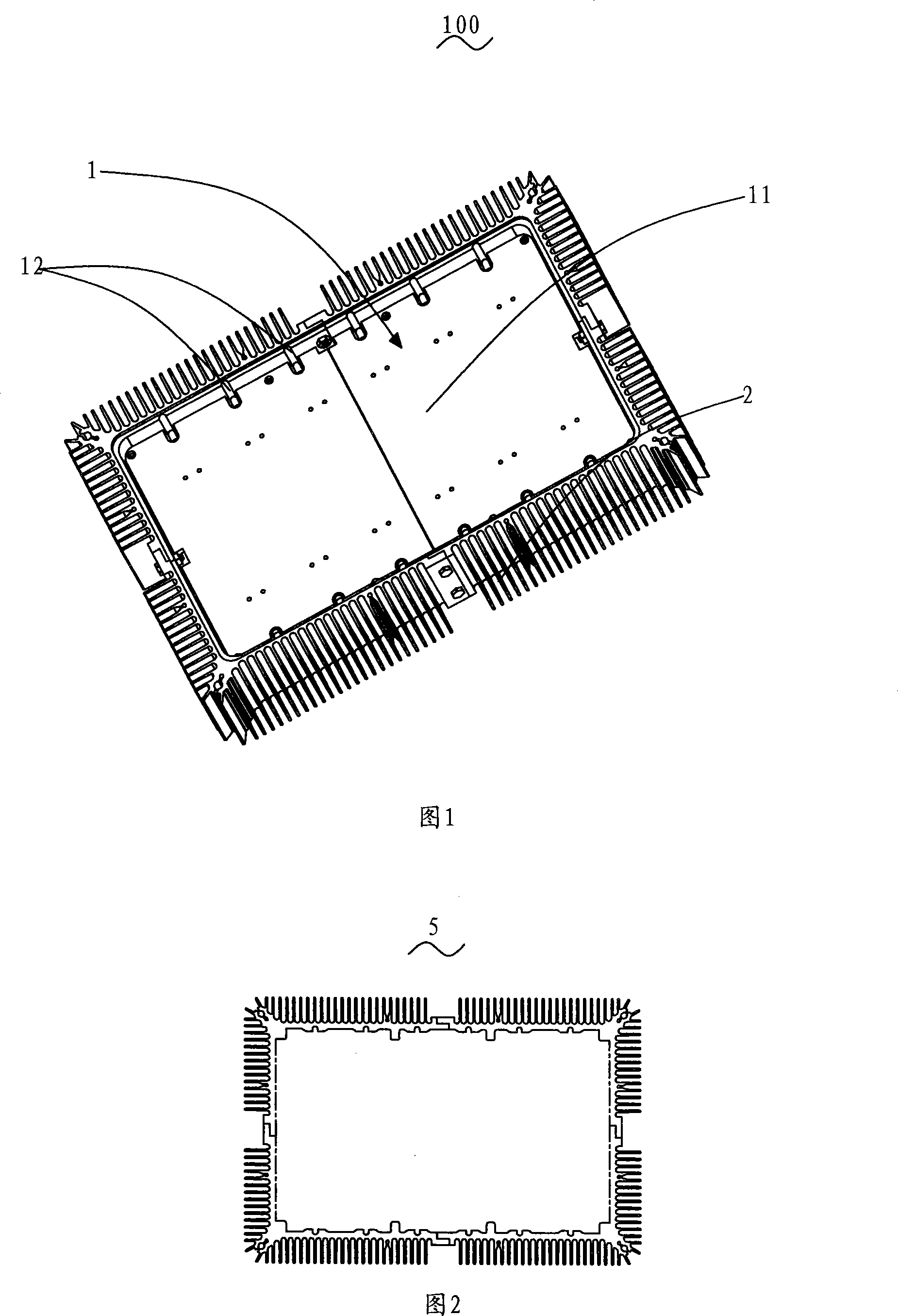

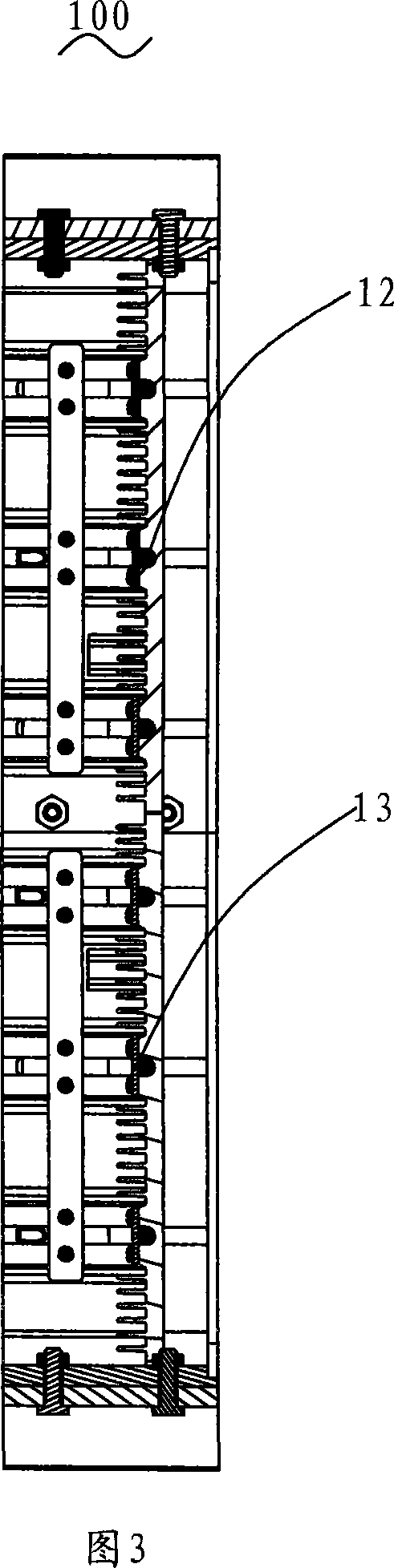

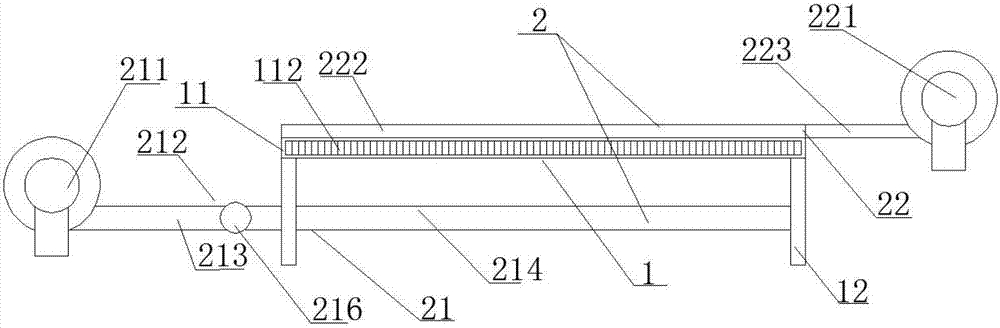

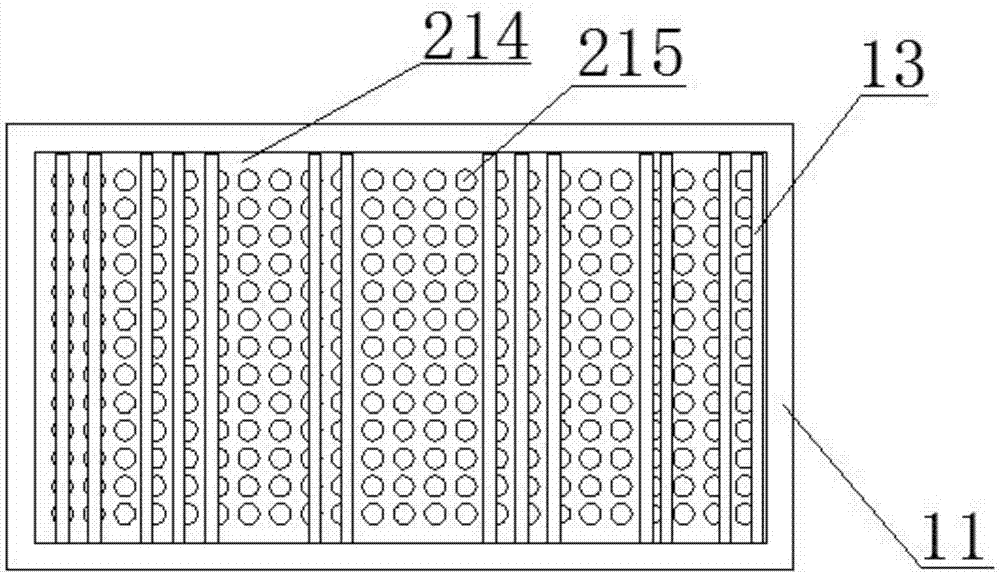

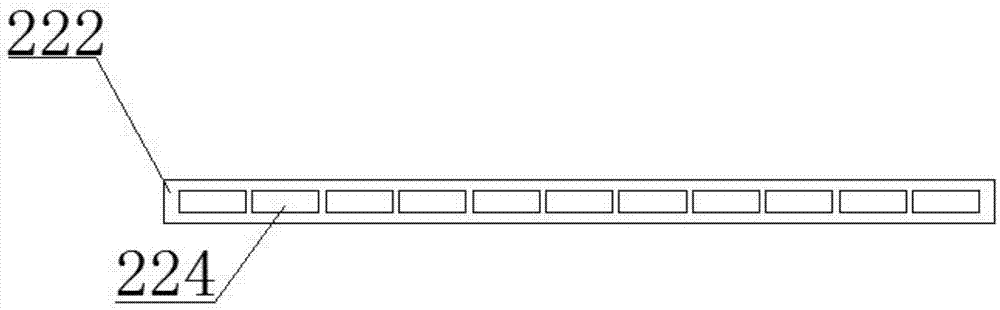

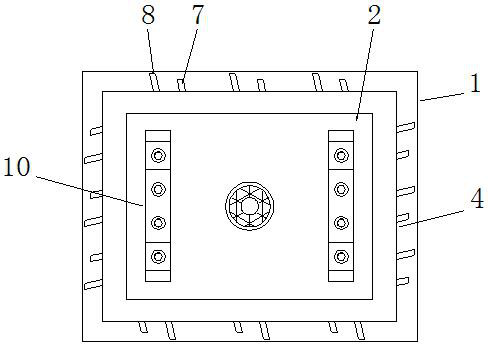

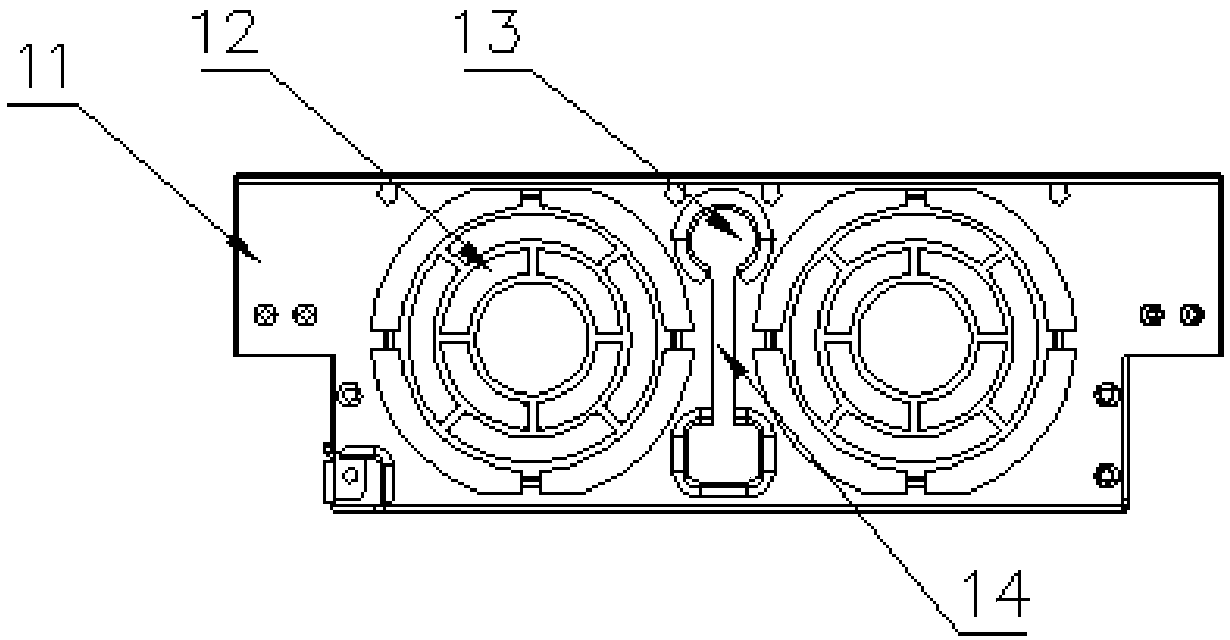

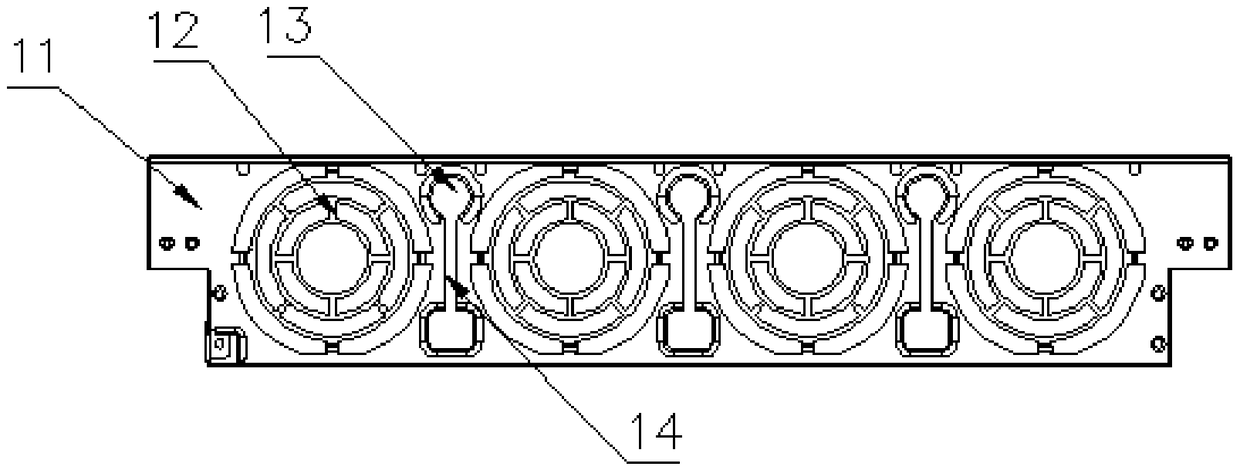

Integral cooling system and LED illumination device with the same

InactiveCN101173759AImprove cooling efficiencyReduce manufacturing costPoint-like light sourceSemiconductor/solid-state device detailsEngineeringContact type

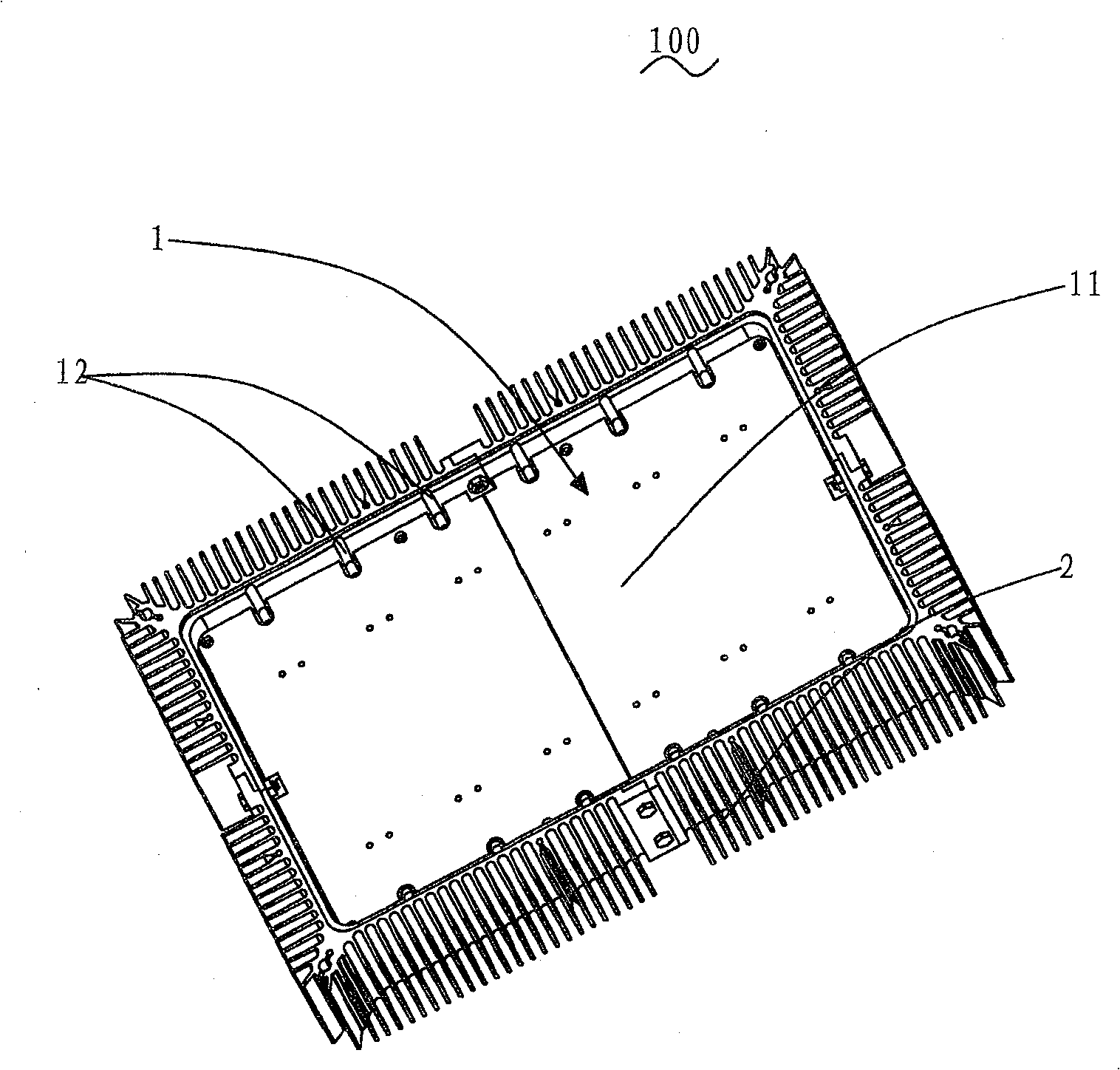

The invention provides an integral heat dissipation system, comprising a heat conduction mechanism and a heat dissipation mechanism, wherein, the heat conduction mechanism comprises a bottom plate used for arranging the heat source and absorbing the heat energy of the heat source and a plurality of heat tubes embedded on the bottom plate, each heat tube is provided with a heat absorption part and a condensation part; the heat dissipation mechanism is a heat dissipation casing; the heat conducting method between the condensation parts of the heat tubes, the heat dissipation surface of the bottom plate and the internal wall of the heat dissipation casing are contact type. The invention has the advantages that the efficiency of heat dissipation is improved by adopting the integral heat dissipation system, wherein, the integral heat dissipation system is provided with the bottom plate with high heat capacity, the heat tubes with high thermoconductivity and the integral type heat dissipation casing; the system volume is reduced and the production cost is decreased under the premise of guaranteeing heat dissipation quality.

Owner:SHENZHEN SED IND

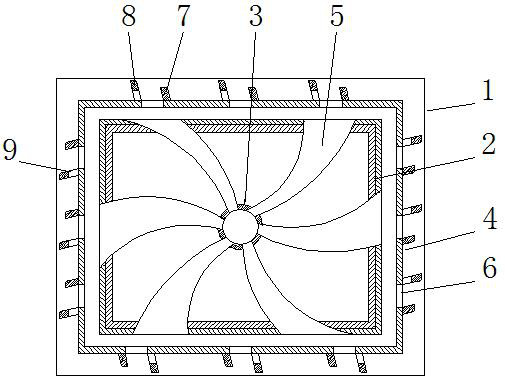

Cooling device capable of cooling multiple forged pieces

InactiveCN107400757AImprove ventilationQuality assuranceFurnace typesHeat treatment furnacesCooling efficiencyAerospace engineering

The invention discloses a cooling device capable of cooling various forgings, which includes a cooling frame and a ventilation device, and is characterized in that: the cooling frame includes a frame, supporting legs and a beam, the frame is square, and the beam is slidably connected to the In the frame, the supporting legs are connected to the bottom of the frame, the ventilation device includes a lower ventilation device and a side ventilation device, the lower ventilation device is arranged under the frame, and the side ventilation devices are evenly distributed around the frame. The beneficial effect of the present invention is that: the present invention can evenly and rapidly ventilate the forgings through the arrangement of the lower ventilation device and the side ventilation device, realize rapid cooling, improve the cooling efficiency and ensure the quality of the forgings.

Owner:四川瑞丰锻造有限公司

LED screen based on natural wind air-cooling heat dissipation technology

InactiveCN111833761AImprove cooling effectEfficient removalCooling/ventilation/heating modificationsIdentification meansCooling effectMechanics

The invention discloses an LED screen based on a natural wind air-cooling heat dissipation technology, which comprises a screen body, the rear side end of the screen body is fixedly connected with a rear shell; the outer side of the rear shell is sleeved with an air inlet pipe, a breather pipe is embedded in the middle of the rear wall of the rear shell, a plurality of heat exchange pipes are evenly connected to the outer circle face of the breather pipe in a penetrating mode, the large-diameter ends of the heat exchange pipes are connected to the air inlet pipe in the penetrating mode, a plurality of air inlet holes are evenly formed in the outer side end of the air inlet pipe, and a second drainage plate and a first drainage plate are arranged on the left and right sides of the outer side ends. In the whole heat dissipation process, the structure of the first drainage plate and the structure of the second drainage plate are used for guiding air flowing near the air inlet pipe; and then flowing air flows in the heat exchange pipe to take away the temperature in the inner cavity of the rear shell, so that the whole device is cooled, no other heat is generated in the whole cooling process, the flowing air completely cools the whole device, and the cooling effect of the whole device can be greatly improved.

Owner:唐丙旭

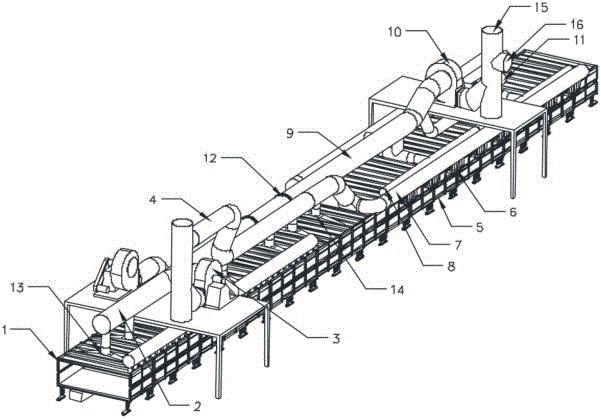

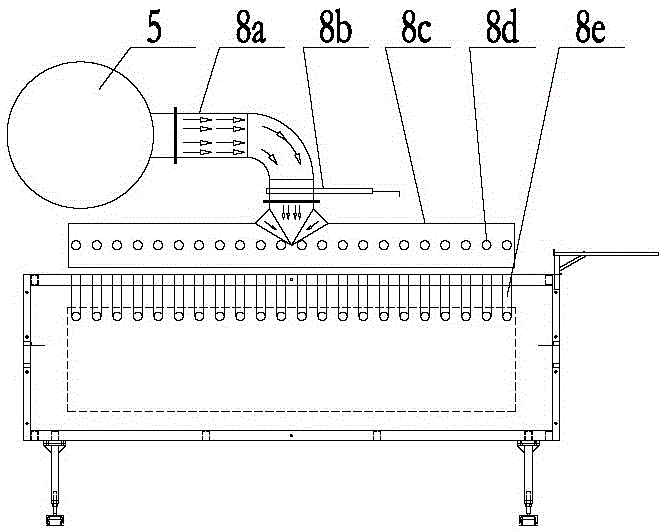

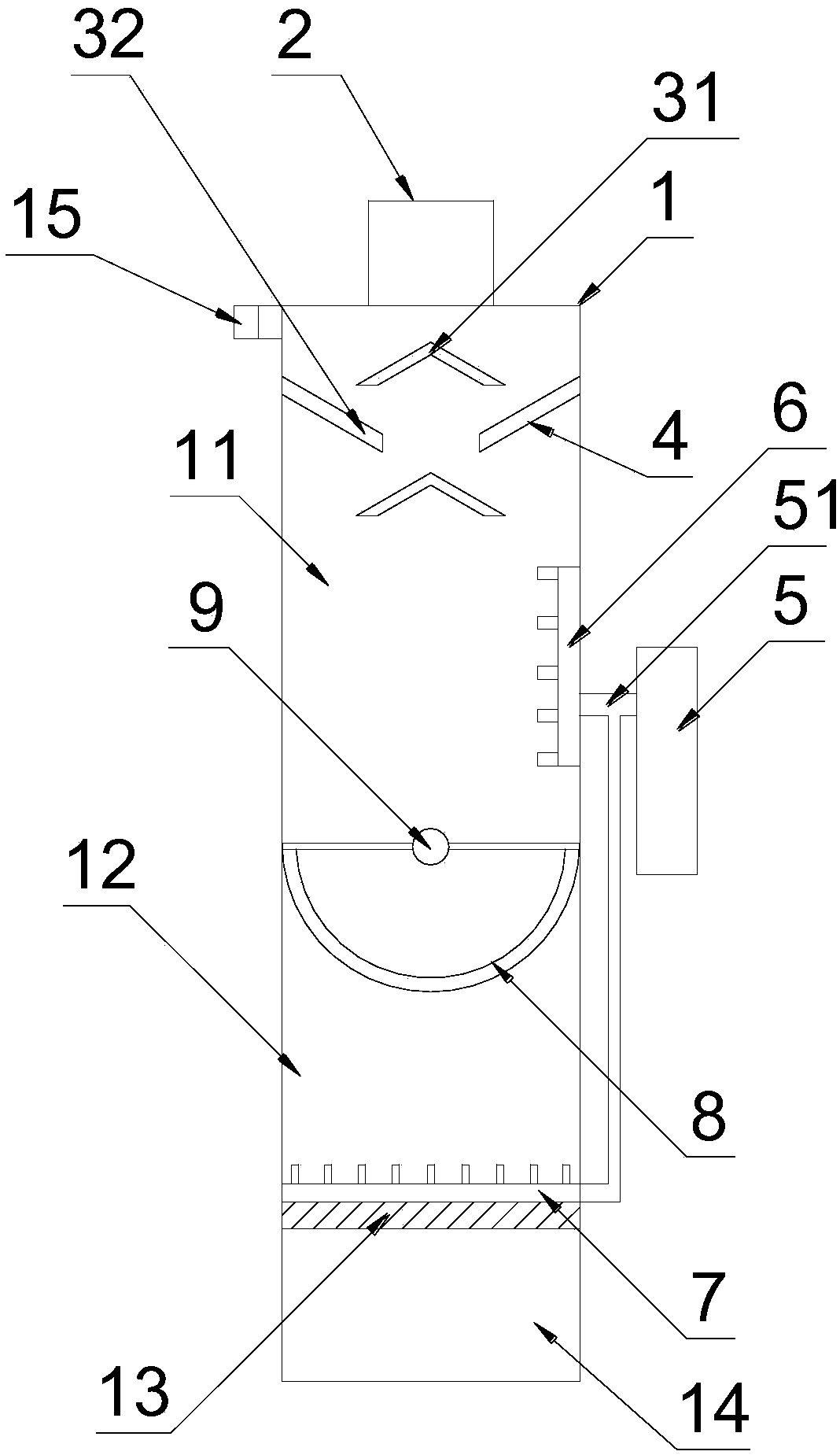

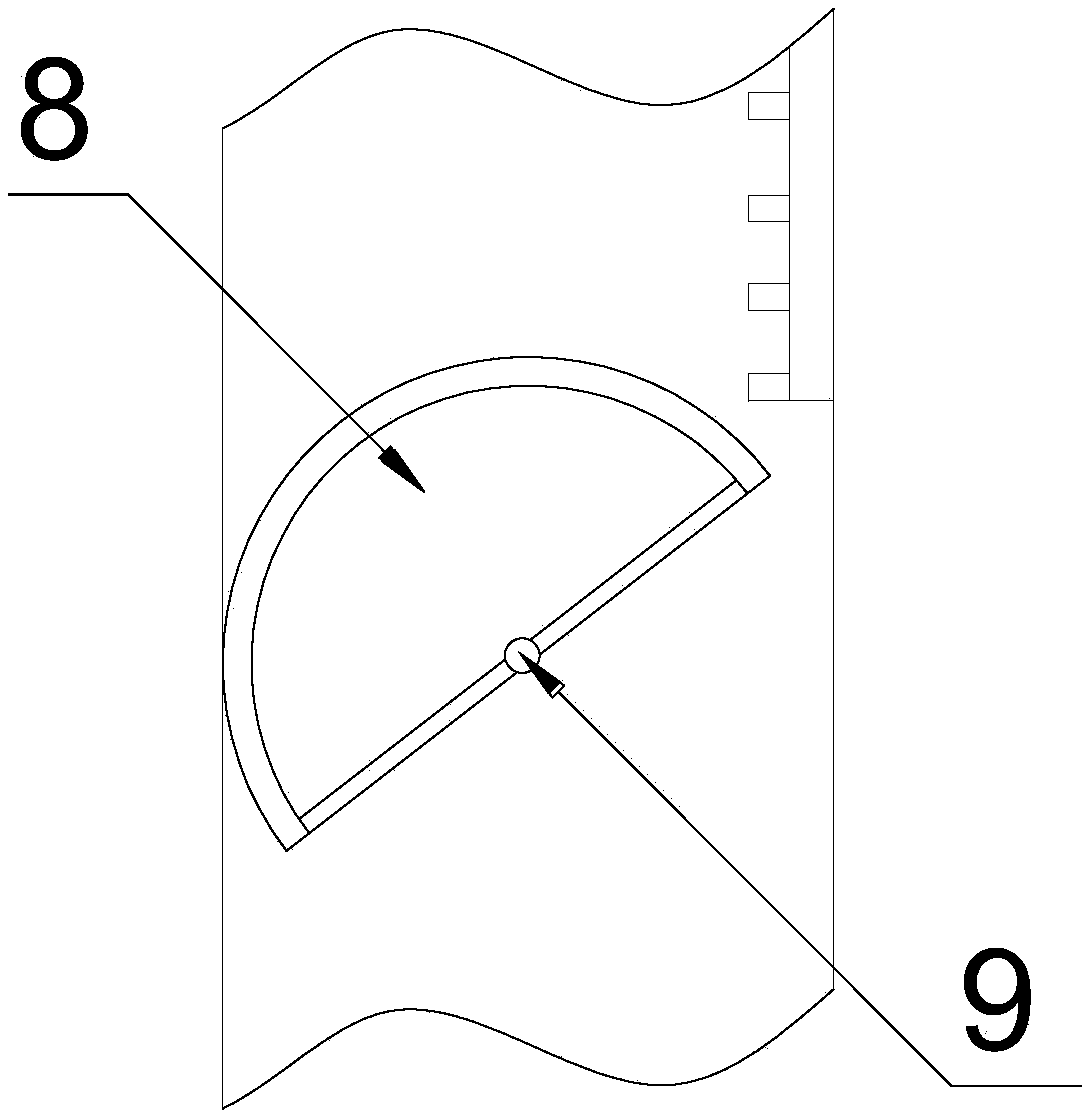

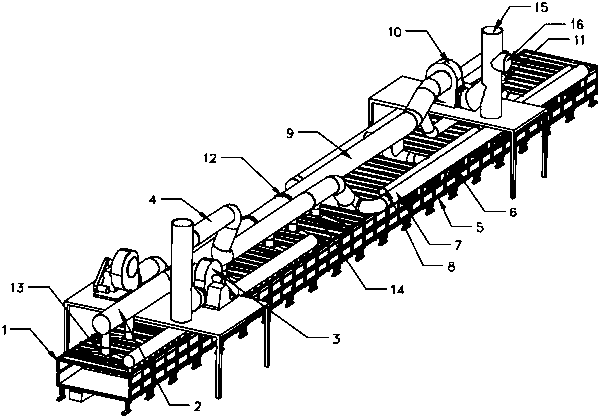

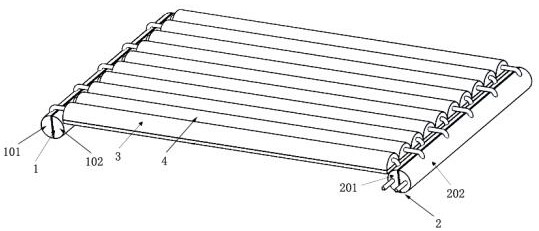

Cooling device for imitated natural air cooling of tea leaves after repeated drying and heating

InactiveCN107232328AImprove cooling efficiencyGuaranteed cooling qualityPre-extraction tea treatmentChillerCooling channel

The invention discloses a cooling device imitating natural air cooling for repeated drying and heating of tea leaves, comprising a mesh conveyor belt, a second arc-shaped groove and a semi-elliptical groove; Below the outlet of the drying box, and the tail end of the mesh conveyor belt is located above the tea packaging workbench; the top of the cooling device housing is fixed at the position corresponding to the second arc-shaped groove opened on the inner wall of the cooling channel A second cooling fan is installed, and the top of the cooling device housing corresponds to the position of the second arc-shaped groove, and a number of miniature air holes communicating with the inner wall of the cooling channel and corresponding to the outlet end of the second cooling fan are opened. In the present invention, a cooling device housing is provided on the mesh conveyor belt of the dried tea leaves for transportation, and a cooling channel is opened inside the cooling device housing. Through the design of the cooling channel, the mesh conveyor belt The tea leaves transported on the conveyor are separated and cooled to speed up the cooling efficiency of the tea leaves and ensure the cooling quality of the tea leaves at the same time.

Owner:贵州开阳益荣茶业有限公司

Cooling device for heat treatment of metal belts

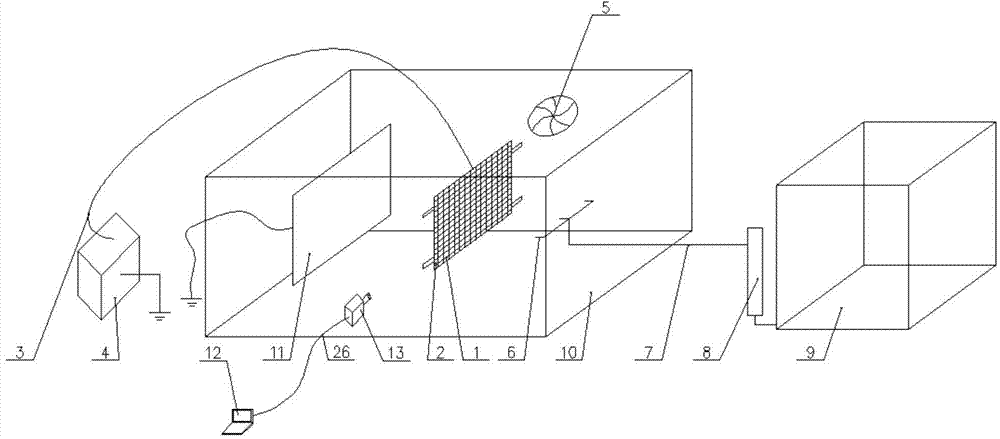

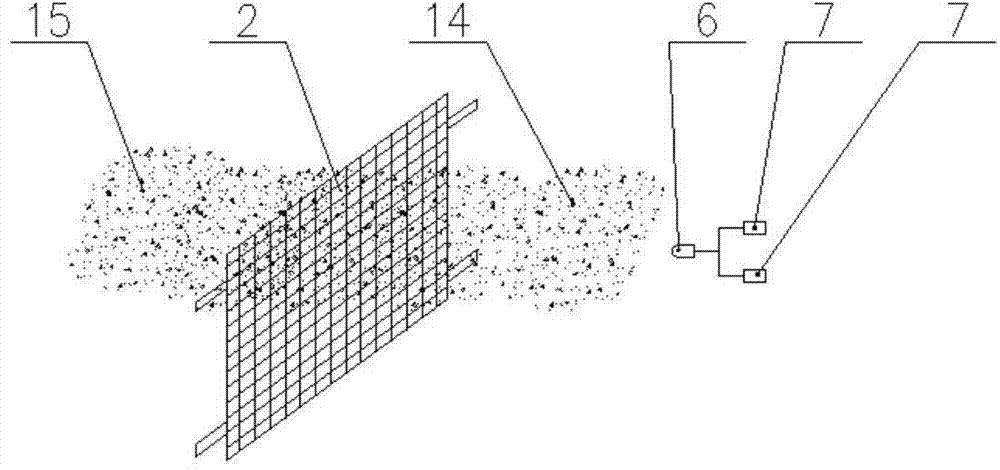

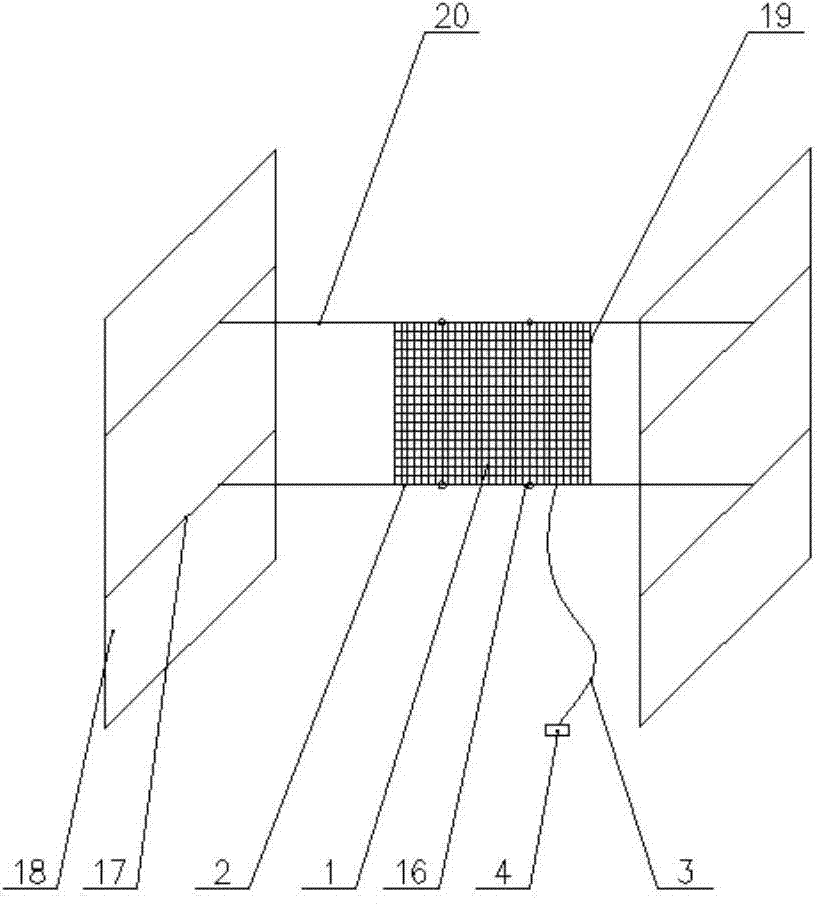

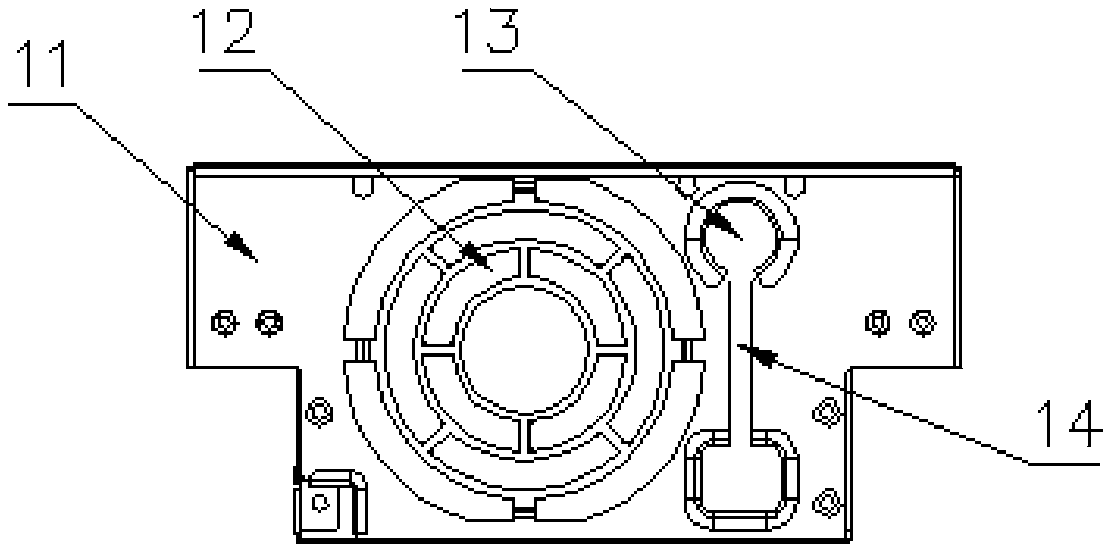

ActiveCN104846186AImprove passabilityGuaranteed cooling uniformityFurnace typesHeat treatment furnacesSpray nozzleCooling chamber

The invention relates to a cooling device for the heat treatment of metal belts. The cooling device for the heat treatment of metal belts is characterized by comprising a cooling chamber, a spray system and a high-voltage system, wherein the cooling chamber is provided with an inlet and an outlet through which a metal belt continuously passes; the spray system comprises a medium supply system, a medium supply system pipe and a nozzle, and a spout of the nozzle faces the metal belt in the cooling chamber; and the high-voltage system comprises a high-voltage power supply, a net electrode and an insulation device; the net electrode is arranged between the metal belt in the cooling chamber and the nozzle, the net electrode is arranged on the inner wall of the cooling chamber by the insulation device, and the net electrode is connected with the high-voltage power supply by a high-voltage power line. According to the invention, atomized droplets can be subjected to charging treatment by high voltage loaded by the net electrode, and under the joint action of surface tension, electric field force, gravity, coulomb force and the like, the sizes of atomized droplets sprayed to the metal belt are more uniform, thereby facilitating the achievement of a good surface quality of the metal belt.

Owner:WISDRI WUHAN WIS IND FURNACE

Server fan support

InactiveCN108966595AMeet Thermal Maintenance RequirementsEasy plug-in maintenanceServersCooling/ventilation/heating modificationsSoftware engineeringRadiation quality

The invention discloses a server fan support. The support comprises front and back support bodies, the front and back support bodies are connected via a connecting piece, each of the front and back support bodies is provided with air vents, and the upper and lower portions of the front support body are provided with upper and lower wire outlets respectively. The fan support is designed in a cabinet, a fan terminal is fixed to ensure that the fan terminal is electrified safely, via special structural processing, the fan terminal is easy to plug and maintain, it is ensured that the fan support can adapt to both a 2U frame type server and a 4U frame type server, on the premise that the heat radiation quality of the server is ensured, the cabinets share a fan support module, the heat maintenance requirement of the fan is satisfied when the 2U and 4U server fans have fault and cannot be used normally, and the cost of server is reduced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

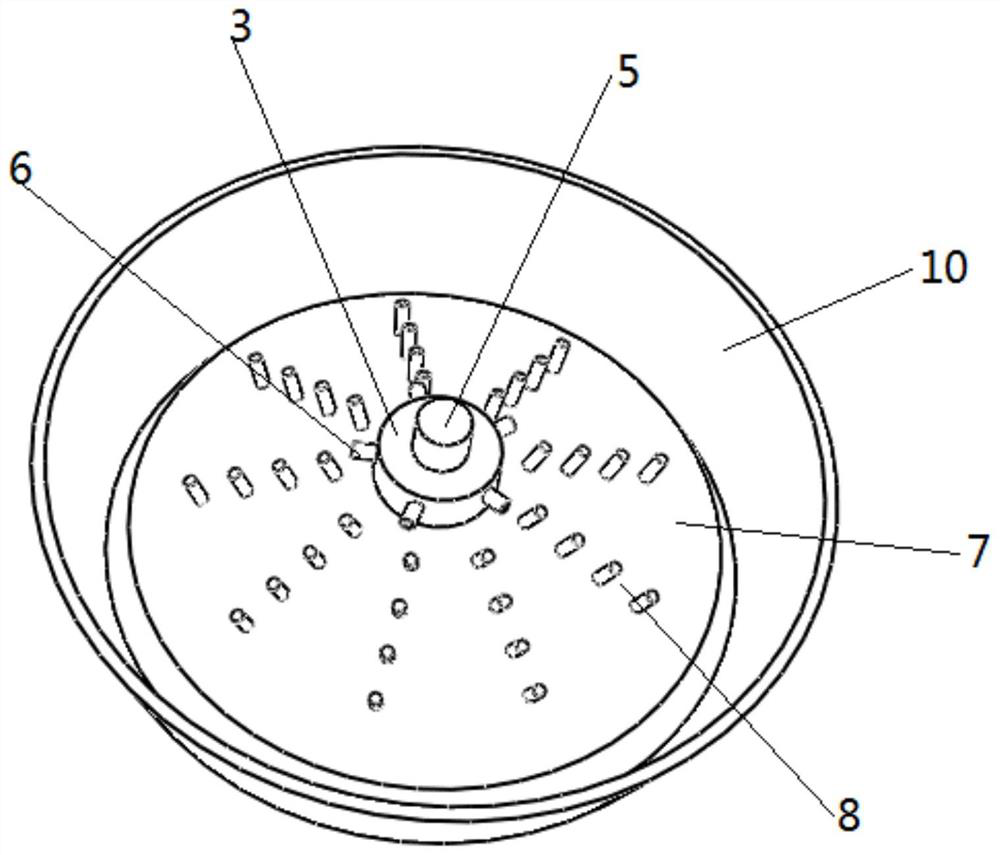

Material-overturning-type rice cooling bin

InactiveCN108160140AEven heat dissipationExtended fall timeGrain millingMaterial scatteringEngineering

The invention discloses a material-overturning-type rice cooling bin. The material-overturning-type rice cooling bin comprises a rice cooling bin body, a feeder, material scattering discs, a guiding plate, an air cooler, first air cooling pipes, second air cooling pipes, a material overturning plate, a rotary shaft, an unloading plate and a softening box. The rice cooling bin body is divided intoan upper portion cooling bin and a lower portion cooling bin by the material overturning plate, the feeder is arranged at the top of the cooling bin body, the air cooler is arranged on the outer sideof the cooling bin body, and an exhaust pipe is arranged on the cooling bin body. The material scattering discs are arranged in the upper portion cooling bin and comprise the first material scatteringdisc and the second material scattering disc, the multiple rows of first air cooling pipes are vertically mounted on the side wall of the upper portion cooling bin, and a plurality of air spraying heads are arranged on the first air cooling pipes correspondingly. The material overturning plate is located below the first air cooling pipes and provided with the rotary shaft, and the rotary shaft penetrates through the air cooling bin body and is connected with a motor. The multiple rows of second air cooling pipes are arranged in the lower portion cooling bin, the unloading plate is arranged atthe bottom of the lower portion cooling bin, and the softening box is arranged below the unloading plate. According to the material-overturning-type rice cooling bin, the heat dissipation efficiencyis high, the heat dissipation effect is good, and the rice quality is high.

Owner:定远县冶溪粮食机械有限公司

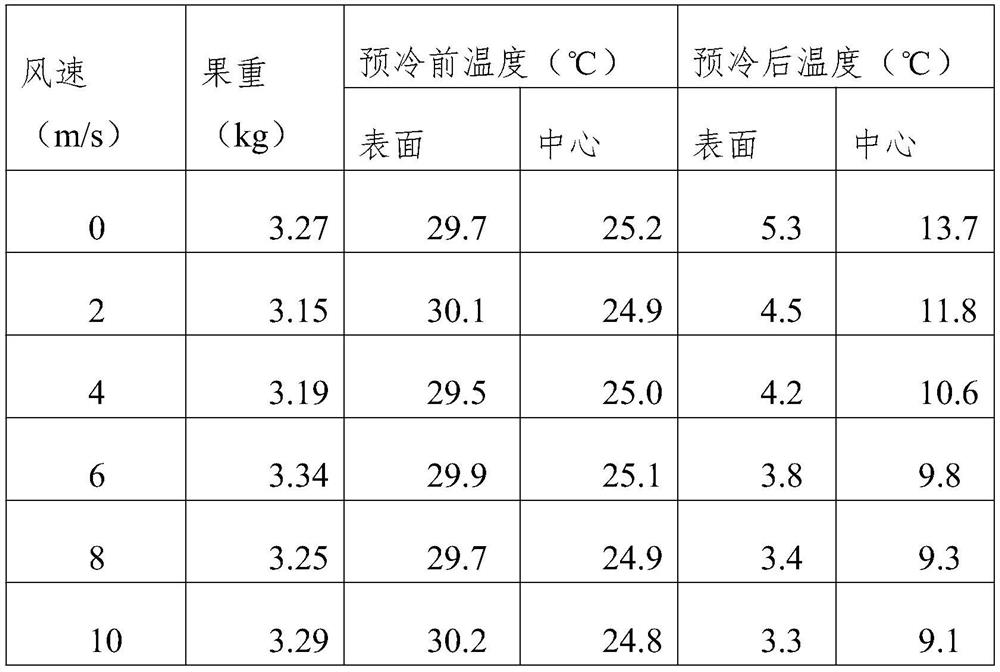

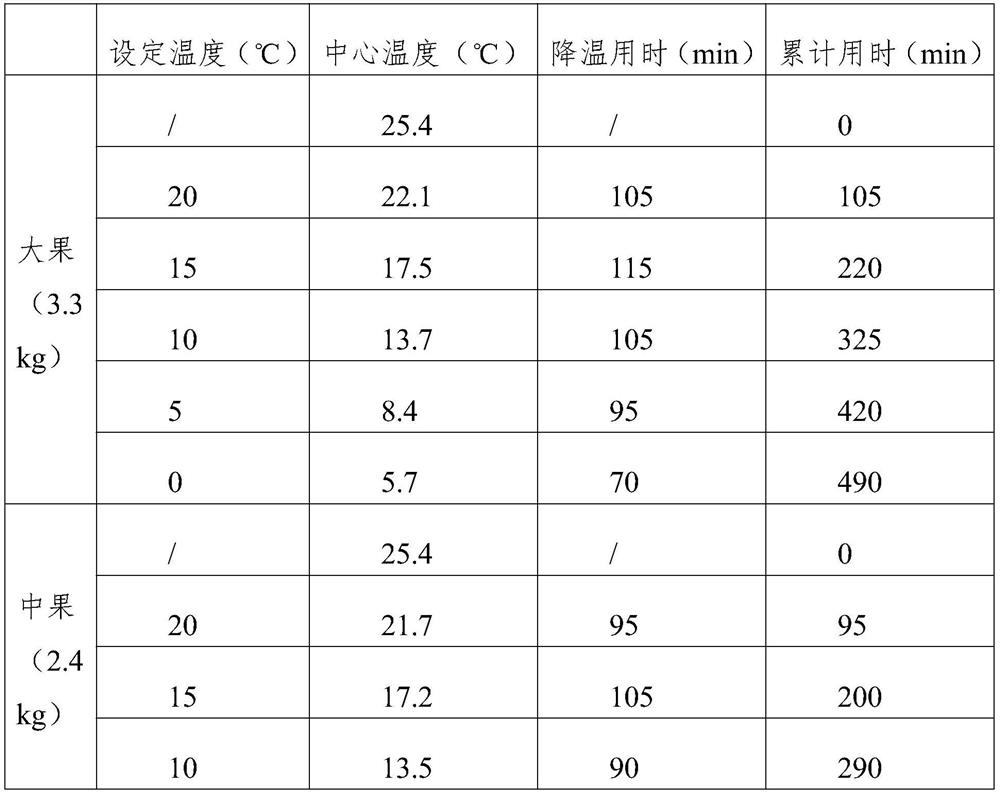

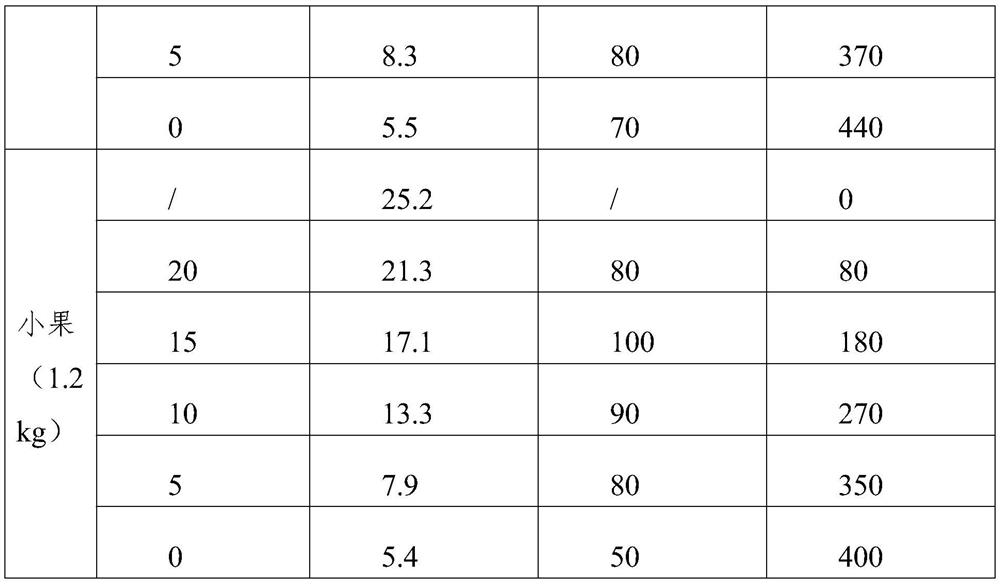

Freezing-fresh-preservation processing method for whole durian fruits

PendingCN111758769AAffect food valueRich flavorFood processingFood ingredient for microbe protectionNutrientChemistry

The invention belongs to the field of food processing and relates to a freezing-fresh-preservation processing method for whole durian fruits. According to the method, through carrying out weight grading on durian fruits and setting precooling and freezing parameters according to different weights, a cooling effect of each durian fruit can be more proper, and energy saving and consumption loweringare achieved while cooling quality is guaranteed; a respiratory action of the durian fruits is gradually decelerated by employing staged strong wind precooling, the durian fruits gradually enter a dormancy stage, cold damage and dewing caused by rapid cooling can be prevented, and meanwhile, the influence on a fresh-preservation effect due to the fact that hoarfrost is formed at a low temperaturedue to the respiratory action of the durian fruits during liquid-nitrogen freezing is also avoided; and by employing indirect liquid-nitrogen freezing, rupture caused by direct contact between the durian fruits and liquid nitrogen can be avoided, temperatures of the durian fruits can be lowered rapidly by evaporation cooling of the liquid nitrogen, an internal ice crystal forming stage is avoided,cell membranes are prevented from being destroyed, nutrients are not lost after thawing, and original flavor, mouth feel and nutritive value of food are maintained.

Owner:广西壮族自治区亚热带作物研究所

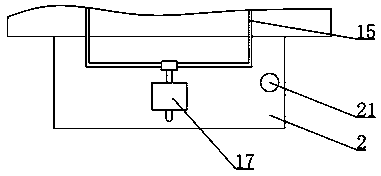

Online cooling device for packaging bag film and mounting method of online cooling device

PendingCN112265328AImprove cooling efficiencyGuaranteed cooling qualityBag making operationsPaper-makingEngineeringMechanical engineering

Owner:杭州金杭包装印业有限公司

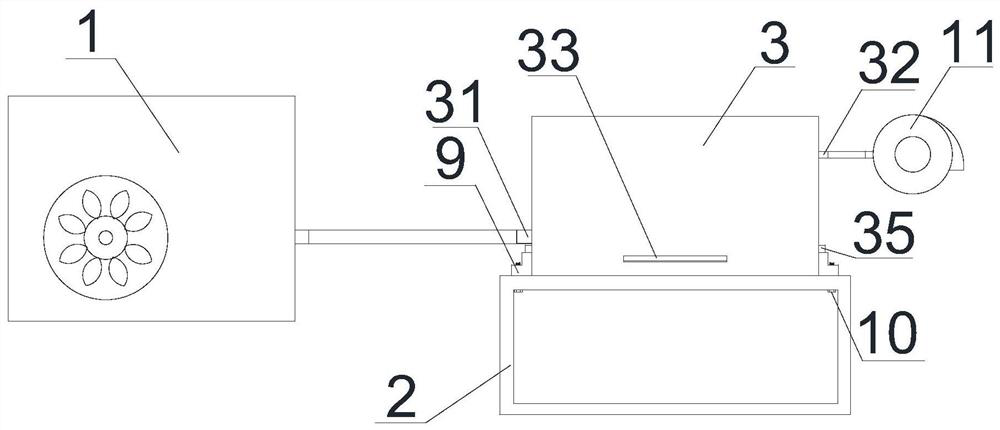

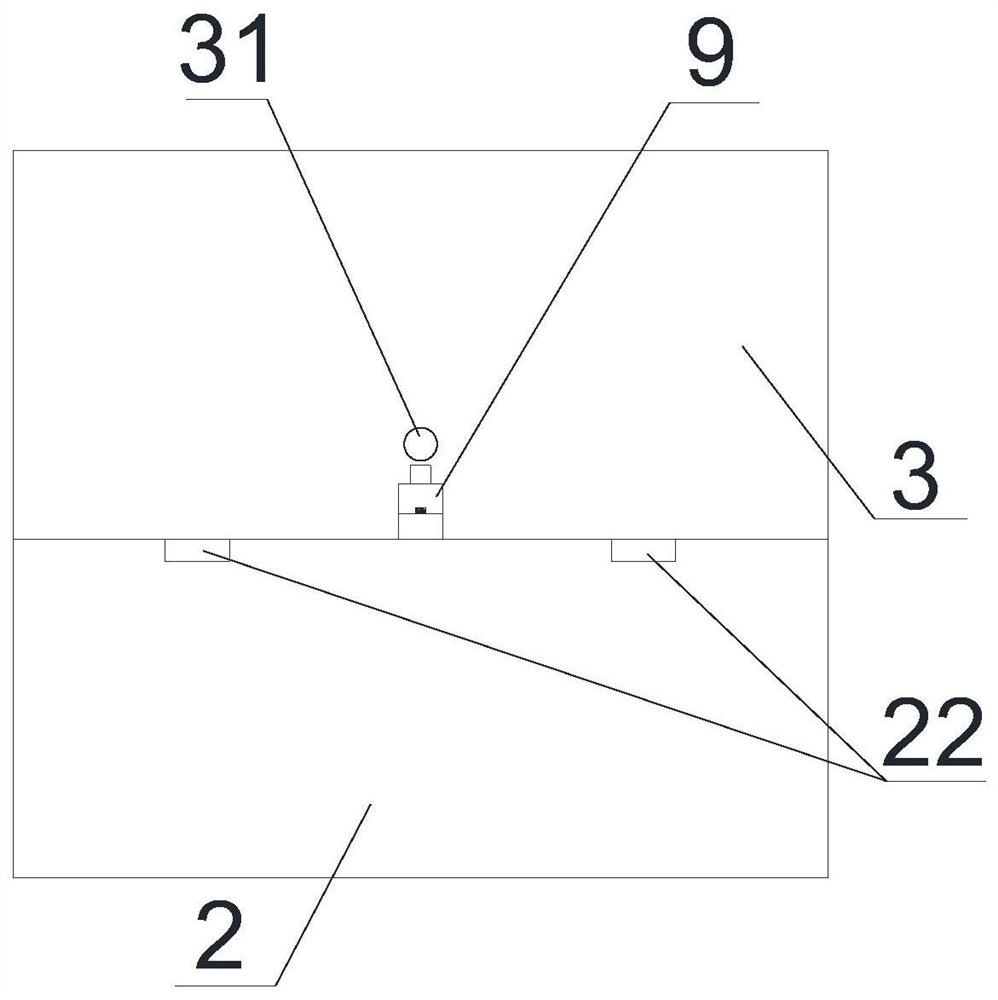

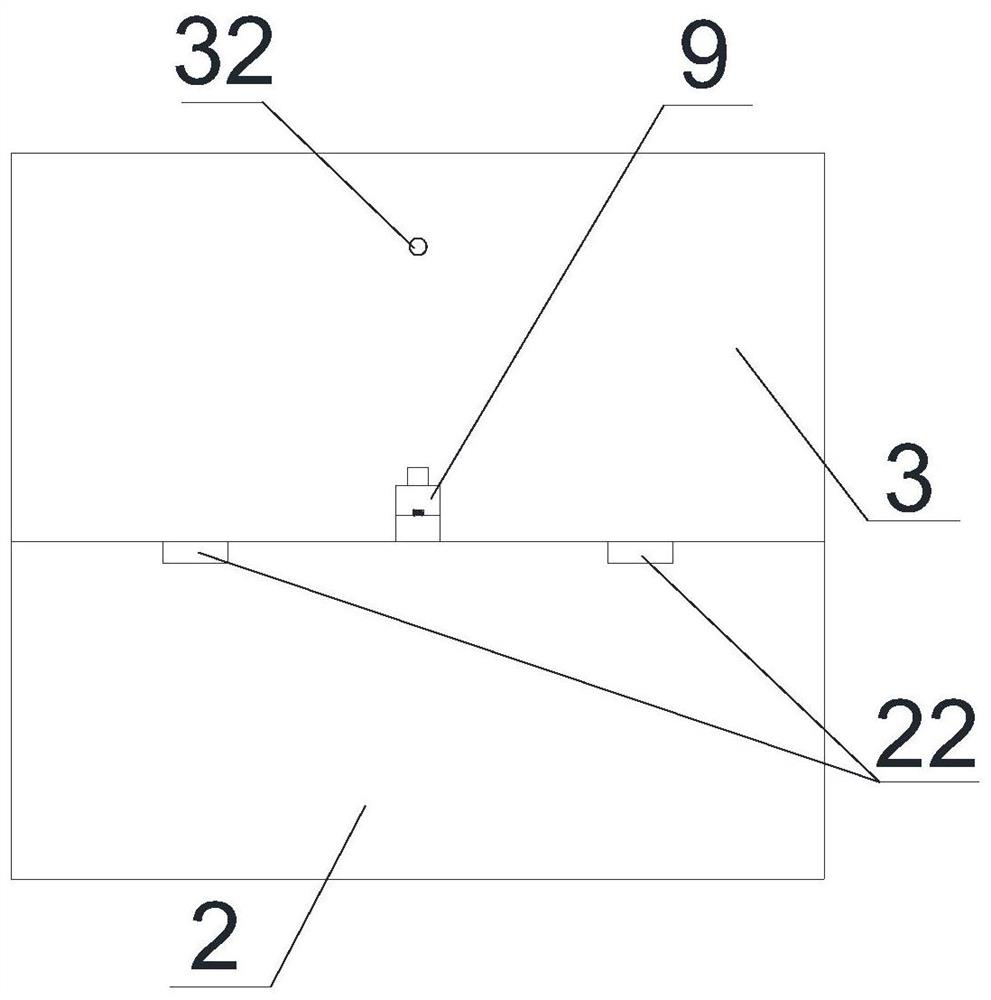

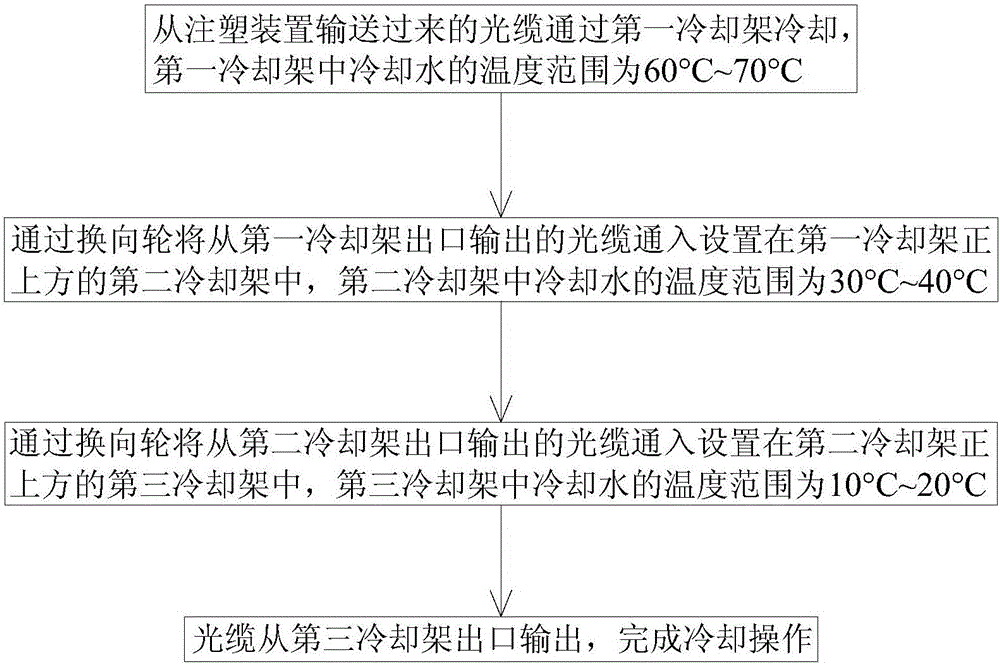

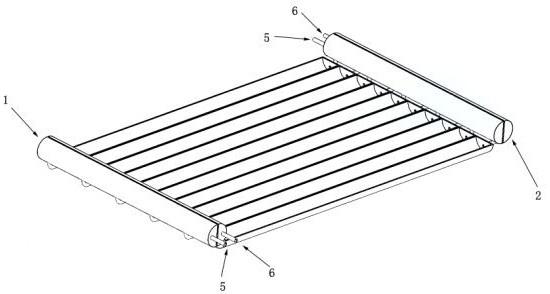

Optical cable manufacturing process

ActiveCN105700092AGuaranteed cooling qualityImprove site utilizationFibre mechanical structuresCooling effectEngineering

The invention discloses an optical cable manufacturing process which includes the steps of cooling optical cables sent from a piece of injection molding equipment through a first cooling rack, introducing the optical cables output from the outlet of the first cooling rack into a second cooling rack right above the first cooling rack through a reversing wheel, introducing the optical cables output from the outlet of the second cooling rack into a third cooling rack right above the second cooling rack through a reversing wheel, and outputting the optical cables from the outlet of the third cooling rack to complete the cooling operation, wherein the temperature of the cooling water in the first cooling rack ranges from 60 DEG C to 70 DEG C, the temperature of the cooling water in the second cooling rack ranges from 30 DEG C to 40 DEG C, and temperature of the cooling water in the third cooling rack ranges from 10 DEG C to 20 DEG C. The three cooling racks are vertically arranged, and the temperature of the cooling water in respective cooling racks is controlled, thereby improving the utilization rate of a place, ensuring cooling efficiency and gradual cooling effect, and guaranteeing the cooling quality of optical cables.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

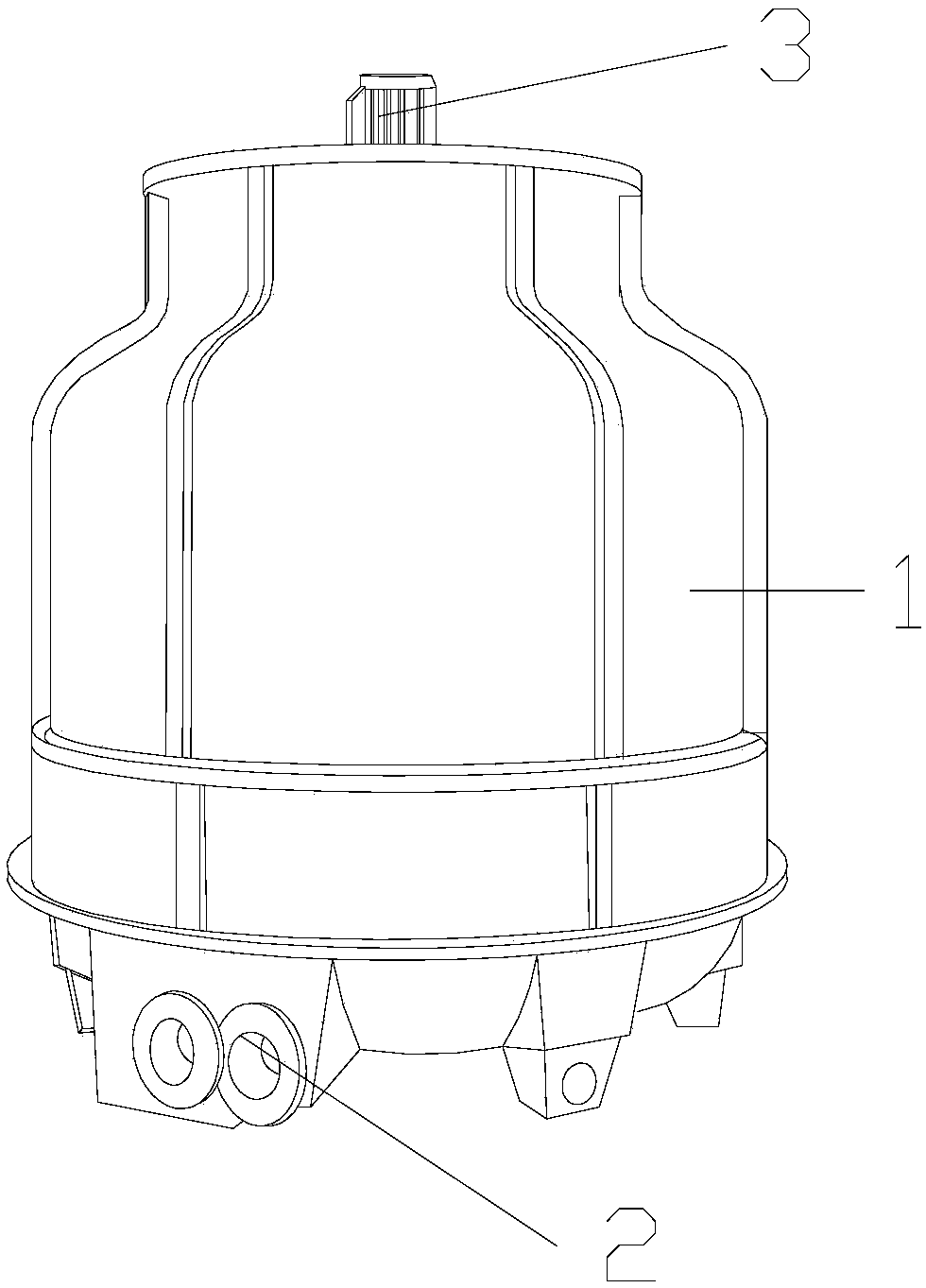

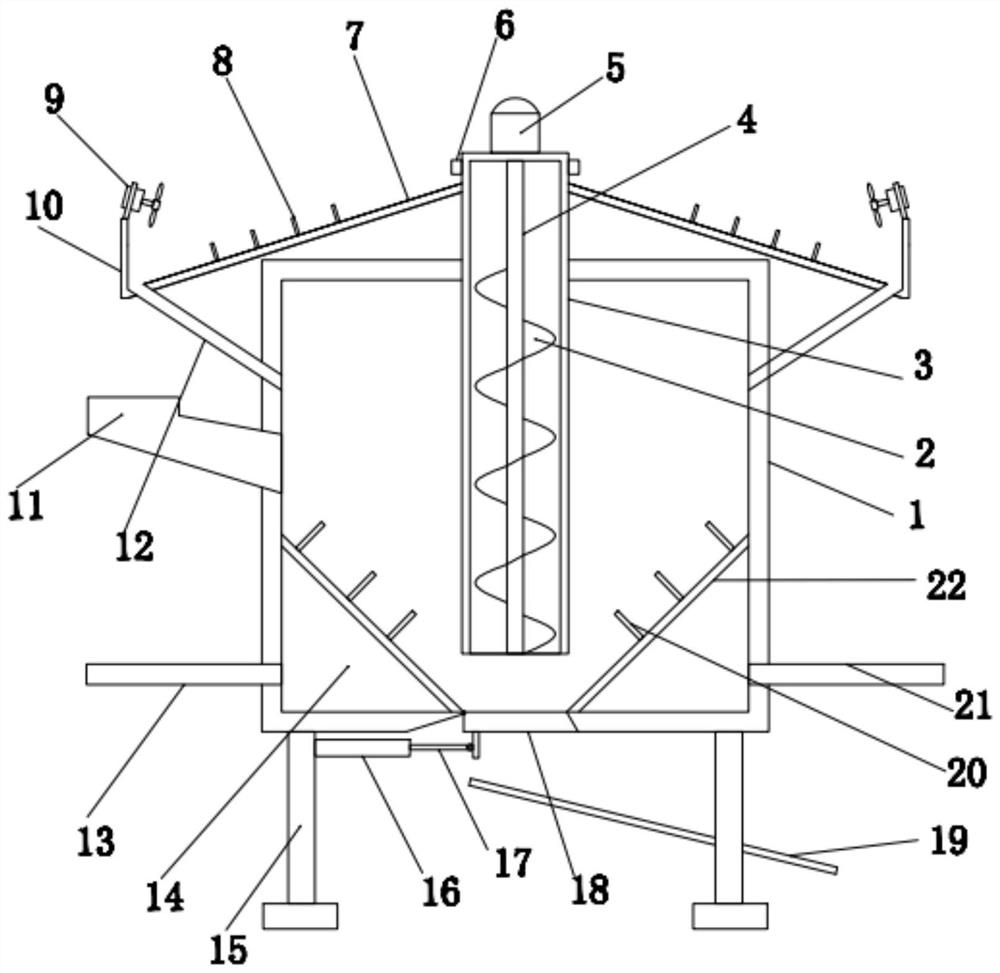

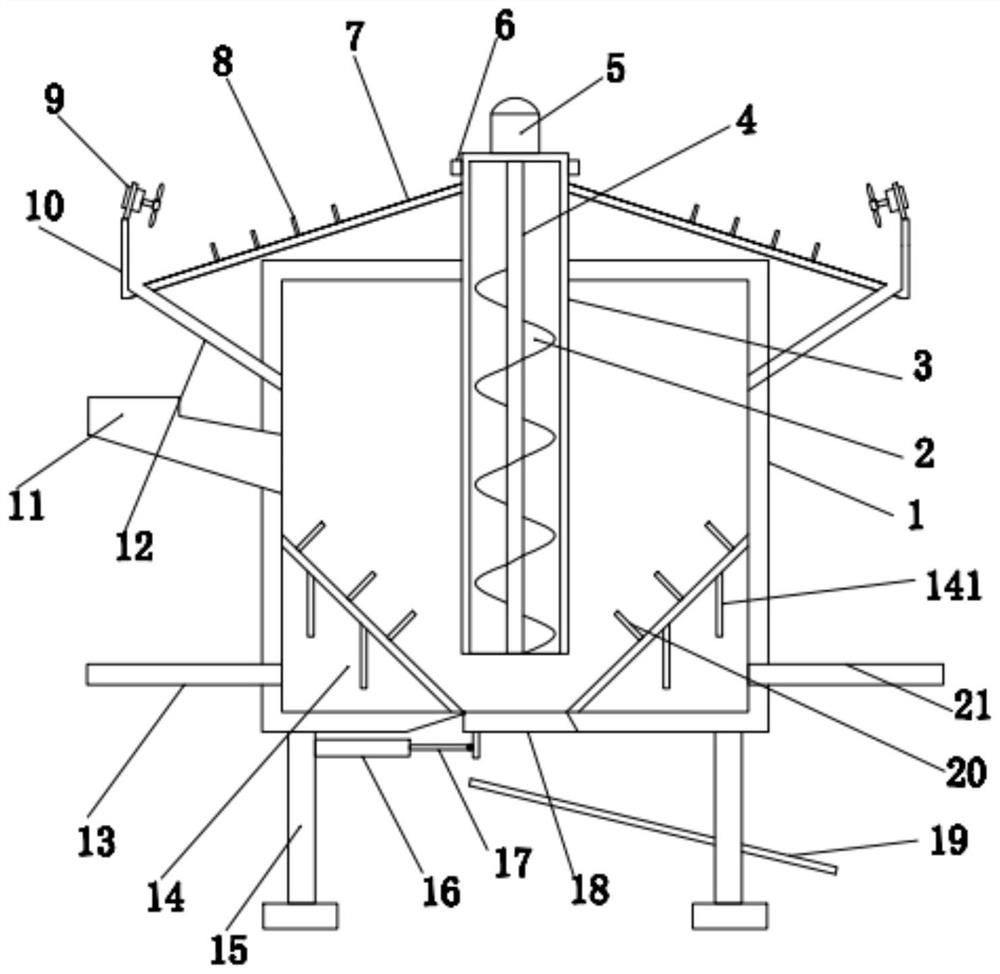

Feed upwind cooling tower

InactiveCN108225046AEvenly stackedGuaranteed cooling qualityDirect contact heat exchangersHeat exchange apparatusCooling towerTower

The invention discloses a feed upwind cooling tower. The feed upwind cooling tower comprises a tower body, an air outlet, a ventilator motor, an air suction system, a cooling tank, a material level device, a discharging mechanism, a material level device motor and a rotary refining mechanism, wherein the cooling tank transversely penetrates through the upper part of a cavity of the inner part of the tower body; the material level device transversely penetrates through the upper part of the cavity of the inner part of the tower body; the discharging mechanism transversely penetrates through themiddle part of the cavity of the inner part of the tower body and penetrates out of the surface of the right end of the tower body; the material level device motor is fixedly connected to a leftmostposition of the inner bottom surface of the tower body and is mechanically connected with the discharging mechanism; the rotary refining mechanism is movably connected to a middle lower position of the cavity of the inner part of the tower body. According to the feed upwind cooling tower disclosed by the invention, feed entering components of a feeder and the cooling tank of the feed upwind cooling tower can be subjected to certain rotary refining treatment, the feed in the cooling tank is enabled to be uniformly stacked, and all feed in the cooling tank can be uniformly cooled, so that the cooling quality of the feed of the feed upwind cooling tower is ensured, and the reliability of the feed upwind cooling tower is effectively improved.

Owner:南安冠玲工业设计有限公司

High-efficiency injection mold production cooling device

The invention discloses a high-efficiency injection mold production cooling device in the technical field of injection mold production. The device comprises a base, an injection molding lower mold andan injection molding upper mold, top plates are arranged at the tops of supporting plates located on the left side and the right side, two sets of cooling cavities are located on the outer sides of the injection molding lower mold and the injection molding upper mold, a plurality of sets of heat conducting columns are uniformly arranged on the inner walls of one opposite sides of the cooling cavities on the left side and the right side, and cooling circulation pipes are wound on the outer walls of the plurality of sets of heat conduction columns on the left side and the right side. When the cooling cavities on the left side and the right side are attached to each other, the heat conduction rubber is in contact with the injection molding lower mold and the injection molding upper mold, cooling water in a cooling water tank is injected into telescopic water injection hoses on the left side and the right side through a water pump during cooling, heat generated by an injection mold is exported outward through the heat conduction rubber, a water cooling block and the heat conduction columns, so that heat cannot be gathered, the circulating flow of cooling water in the cooling circulation pipe and the water cooling block is matched, so that the high-efficiency water cooling is achieved, moreover, the cooling uniformity is high, and damage to the injection mold is avoided.

Owner:吴中区甪直磊鑫模具厂

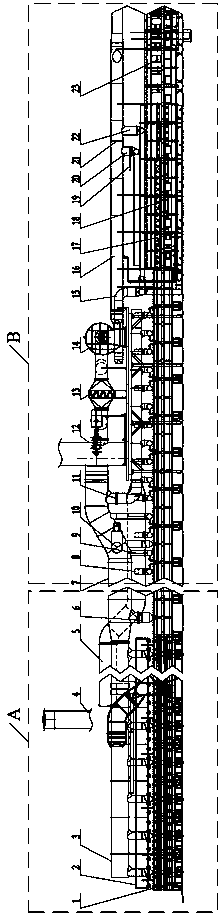

High-performance cable production line

InactiveCN108766665AReduce energy consumptionIncrease productivityInsulating conductors/cablesProduction lineDrive wheel

The invention discloses a high-performance cable production line. The high-performance cable production line is characterized by successively comprising, from front to rear, a pay-off stand, a front-end wire storage rack, a wire electrical discharge machine, a talcum powder box, an insulating sheath extruder, a first cooling water tank, a wire ink-jet printer, a second cooling water tank, a tractor, a rear-end wire storage rack, a length meter and a take-up stand; wherein both the first cooling water tank and the second cooling water tank are tank bodies with opened tops, the tank bodies are provided with cooling water therein, the top of the each tank body is provided with a water inlet pipe, the bottom of the each tank body is provided with a water outlet pipe; at least two sets of transmission mechanisms are uniformly distributed in the tank body from front to rear, the each transmission mechanism comprises a transmission rod, a driving wheel, and two mounting plates, the mounting plates are tilted downwards from rear to front, a plurality of clamping slots are uniformly distributed on the each mounting plate from rear to front, the bottoms of the plurality of clamping slots aretilted downwards from rear to front, and two ends of the transmission rod are clamped in the one group of clamping slots of the two mounting plates. The high-performance cable production line of theinvention has the beneficial effects of capacity for reducing energy consumption and capacity for achieving environmental protection.

Owner:WUXI VIGOROUS ELECTRIC

Outer loop fast cooling device for feed production

PendingCN111811205ARealize circulating coolingGuaranteed cooling qualityDomestic cooling apparatusLighting and heating apparatusCooling effectEngineering

The invention discloses an outer loop fast cooling device for feed production. The outer loop fast cooling device comprises a cooler bin and a plurality of landing legs which are arranged on the lowerend face of the cooler bin and are distributed in array. A support block is arranged at the lower end of each landing legs. A feed pipe used for feed in materials is formed in the left upper side ofthe cooler bin. A discharge assembly is formed in the bottom of the cooler bin. A first cooling component and a second cooling component which are used for cooling the materials are arranged on the cooler bin. The first cooling component comprises a lifting tube which penetrates through the top of the cooling bin. The lower end of the lifting tube extends to the inner bottom of the cooling bin. The outer loop fast cooling device for feed production is designed by aiming at the disadvantages of the prior devices. The circulating cooling of the materials is achieved, the ultimate cooling qualityof the materials is ensured, and the cooling effect is further improved using a combination of an air-cooling method and a water-cooling method. Open-type cooling is adopted in the air-cooling, in addition, a subuliform structure is matched up to assist to disperse the materials, and the cooling effect is further improved.

Owner:安徽省天可饲料有限公司

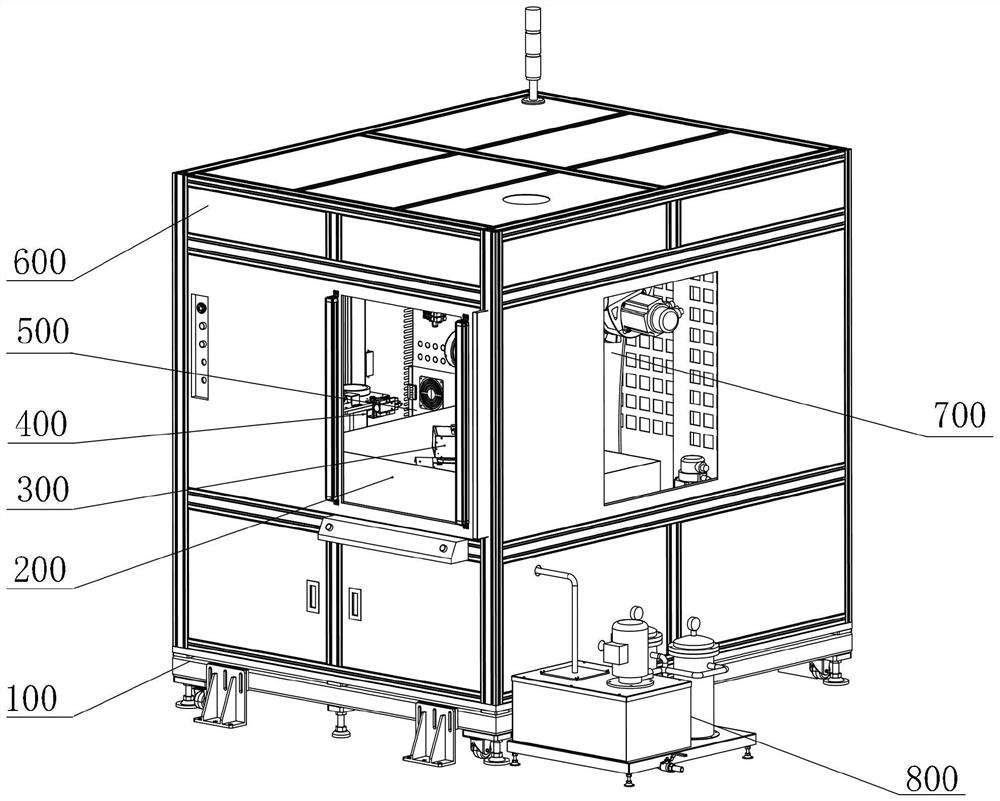

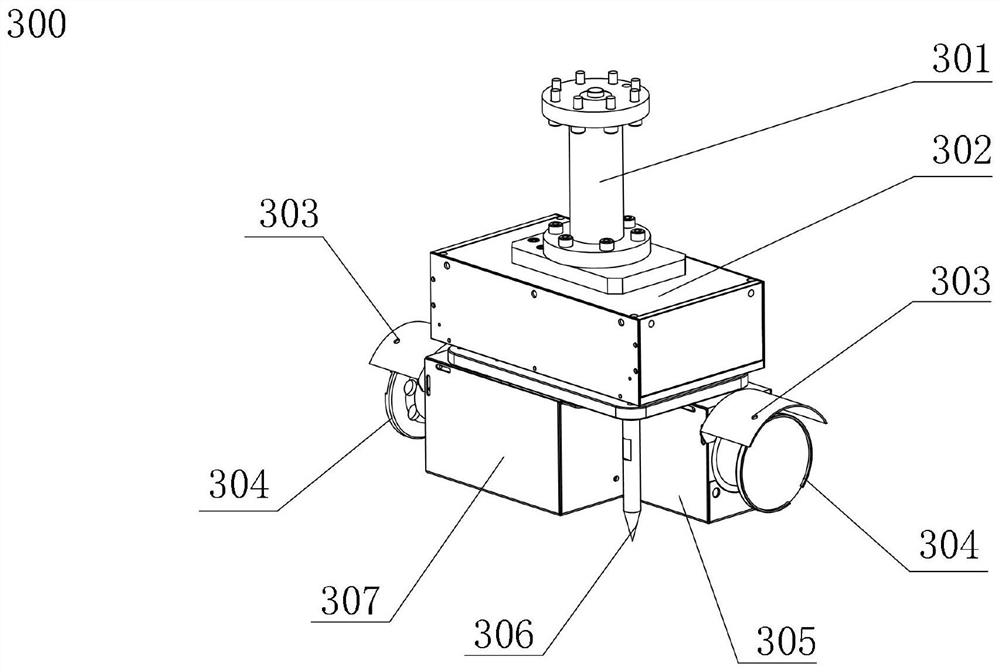

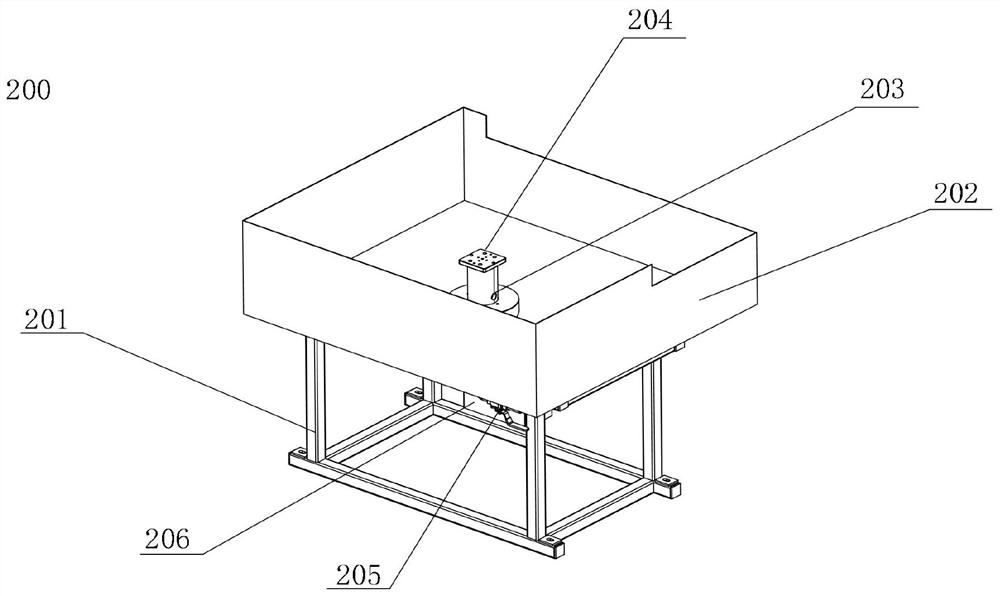

Titanium alloy part grinding equipment and grinding method

PendingCN113649899AAvoid overgrindingGuaranteed grinding qualityGrinding wheel securing apparatusGrinding drivesIndustrial roboticsElectric control

The invention relates to titanium alloy part grinding equipment and a grinding method. The titanium alloy part grinding equipment comprises an industrial robot; a grinding tail end tool, wherein the grinding tail end tool is connected with the execution end of the industrial robot, the industrial robot drives the grinding tail end tool to move freely in the working space, and the grinding tail end tool is used for grinding titanium alloy parts; a grinding working platform, wherein the grinding working platform is used for fixing the titanium alloy parts and is matched with the grinding tail end tool to move to grind the titanium alloy parts; an automatic abrasive paper replacing module, wherein the automatic abrasive paper replacing module is matched with the grinding tail end tool to replace waste abrasive paper on the grinding tail end tool with new abrasive paper; and an electric control system, wherein the electric control system is electrically connected with the industrial robot, the grinding tail end tool, the grinding working platform and the automatic abrasive paper replacing module, and all the components are integrally controlled to act. By means of the titanium alloy part grinding equipment and a grinding method, the titanium alloy parts are automatically polished, and the production efficiency is improved.

Owner:重庆智能机器人研究院

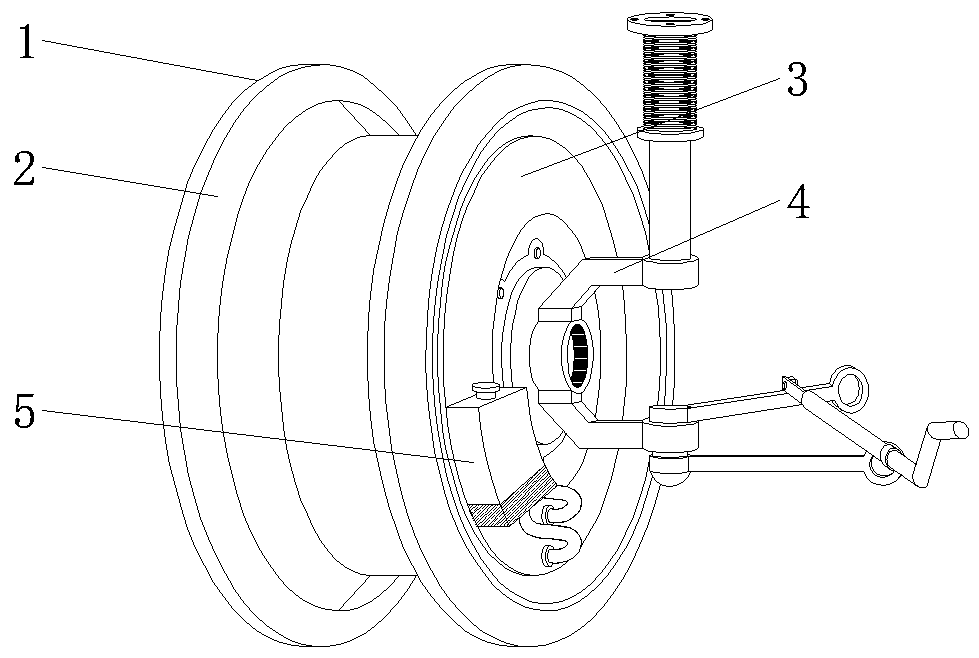

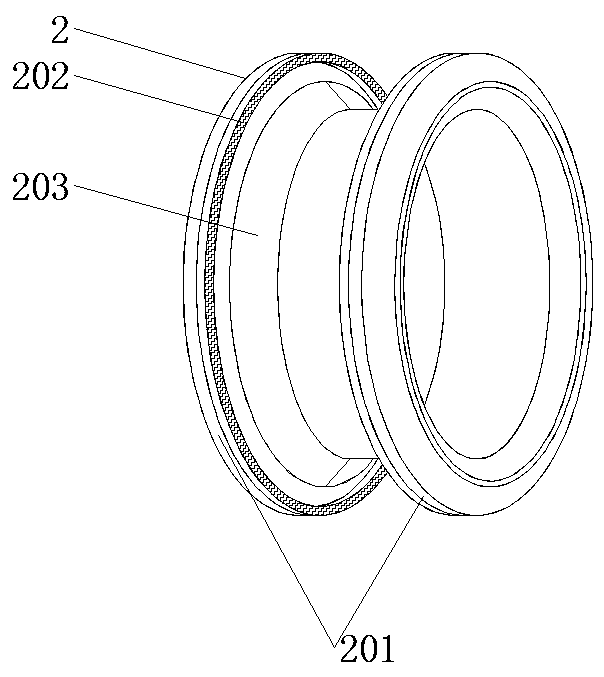

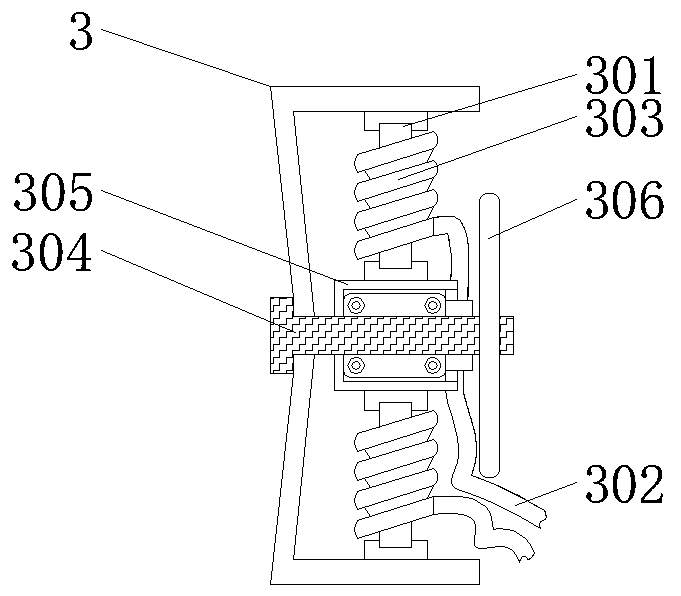

Hub motor and suspension using hub motor

ActiveCN110588327AIncrease contact areaImprove firmnessElectric propulsion mountingMotor depositionEngineeringRefrigeration

The invention discloses a hub motor and a suspension using the hub motor. The hub motor and the suspension using the hub motor comprise a hub motor suspension main body, the hub, a motor box, the suspension and a refrigeration device, wherein the periphery of the hub motor suspension main body is fixedly connected with the hub, the peripheral outer wall of the hub is connected to the peripheral outer wall of the hub motor suspension main body, the motor box is fixedly connected to the inner side of the middle of the hub, the peripheral outer wall of the motor box is connected with the inner side inner wall of the middle of the hub, and the middle of one end of the motor box is in lap joint with the suspension. According to the suspension, through a damping mechanism formed by a damping strut and a damping spring, the stability effect of the suspension itself can be well improved; the refrigeration device can ensure stable operation of a motor in the motor box, and a certain protectionand prevention effect on the motor is achieved; and for the hub, when a tire is installed, the contact area between a tire mounting groove and the tire can be effectively expanded through a limiting ring on the inner side of the hub, the firmness degree of the joint between the tire and the tire mounting groove is improved, and a wide development prospect in the future is achieved.

Owner:东风专用零部件有限公司

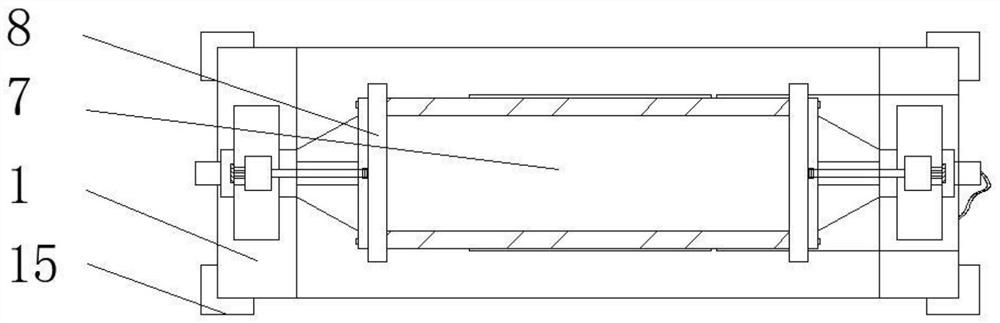

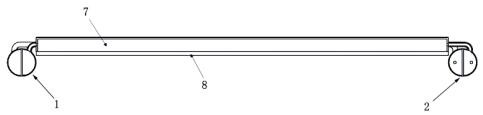

Electromagnetic heating roller capable of accurately positioning

InactiveCN113099567AGuarantee processing qualityGuaranteed cooling qualityInduction heating apparatusPhysicsMachine material

The invention discloses an electromagnetic heating roller capable of accurately positioning. The electromagnetic heating roller comprises bases, limiting assemblies, a winding inner roller, a hollow supporting rod and a control box, first supporting plates are fixed to the upper sides of the bases, fixing blocks are fixed to the upper sides of the first supporting plates, meanwhile, supporting rods are rotationally connected into the fixing blocks, and flanges are fixed to the supporting rods. The flanges are in threaded connection with an outer roller through bolts, a cleaning assembly is fixed between the bases and located on the lower side of the outer roller, a limiting assembly is used for accurately limiting materials and fixed to the upper sides of the supporting rods, the winding inner roller is located in the outer roller, and a stirring assembly is fixed to a cooling assembly. A hollow base is fixed to the lower side of the hollow supporting rod. The electromagnetic heating roller capable of being accurately positioned has the advantages that a machining material can be accurately positioned, the interior of the electromagnetic heating roller can be rapidly cooled, the surface of the electromagnetic heating roller can be automatically cleaned, and the whole device can be driven to move.

Owner:南通盛邦制辊有限公司

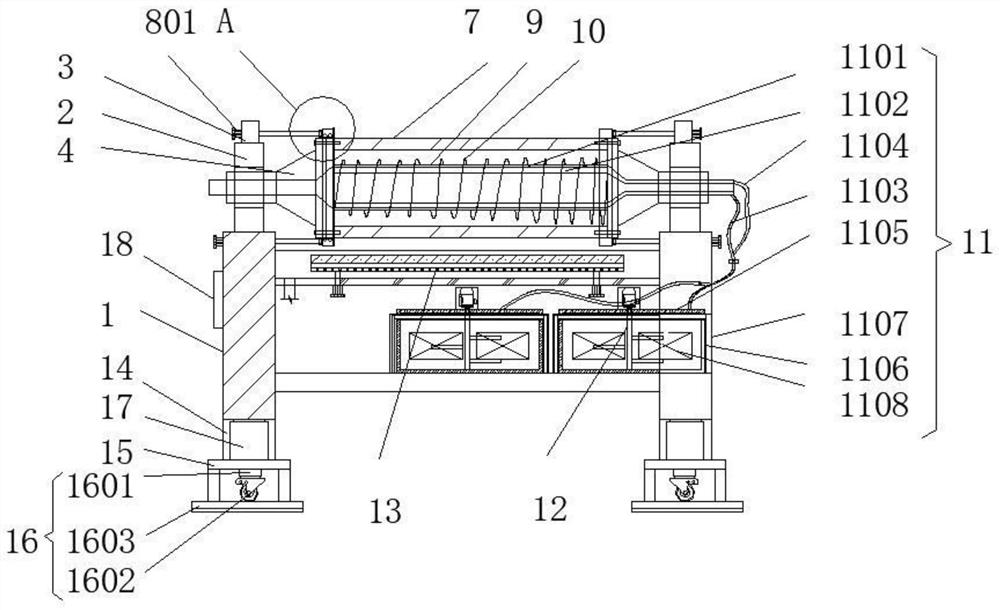

A ceramic energy-saving kiln with high-efficiency relay recovery of cooling waste heat

ActiveCN106440836BReduce pollutionReduce fuel consumptionEnergy industryIncreasing energy efficiencyAir blowerSlow cooling

The invention discloses a ceramic energy-saving kiln for recovering cooling waste heat in high-efficiency relay. Hot air blower; the slow cooling area is equipped with a slow cooling area outlet pipe, multiple slow cooling area air supply pipe groups, multiple slow cooling area outlet pipe groups, slow cooling area exhaust pipes and heat exchange fans; the rapid cooling area is equipped with Combustion-supporting fan, air supply supervisor and burner, the air supply supervisor is equipped with air supply pipe group in quenching area and air outlet pipe group in quenching area. By adopting the present invention, a pipeline structure for recovering hot air is formed in an efficient continuous and relay manner, and all the cooling heat when cooling ceramics at each stage is recycled and utilized, which significantly reduces the fuel consumption in the drying and firing process, and can also effectively reduce the impact of heat sources on Environmental pollution can also improve product quality.

Owner:DLT TECH CO LTD

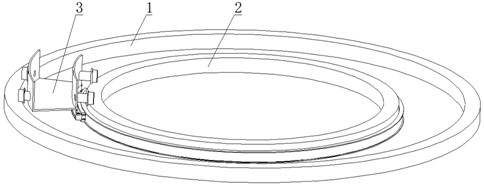

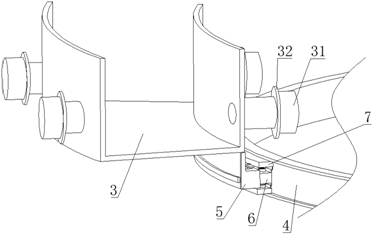

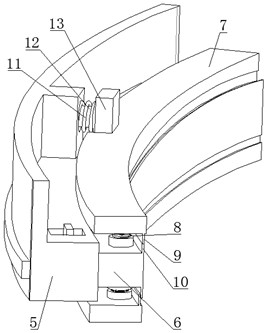

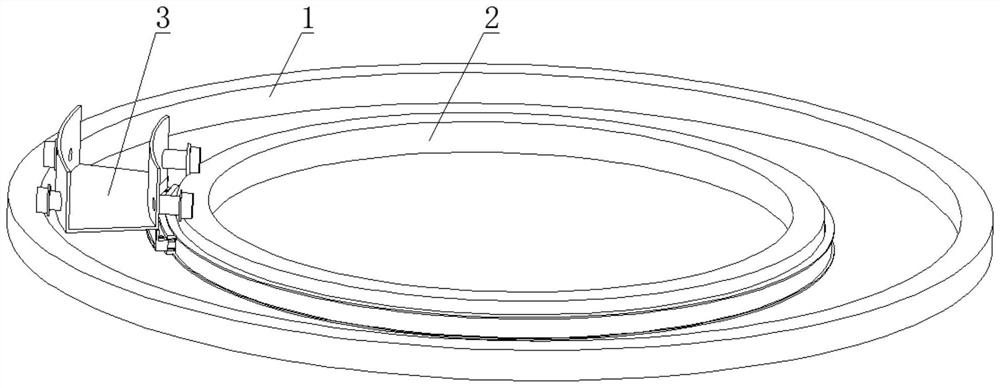

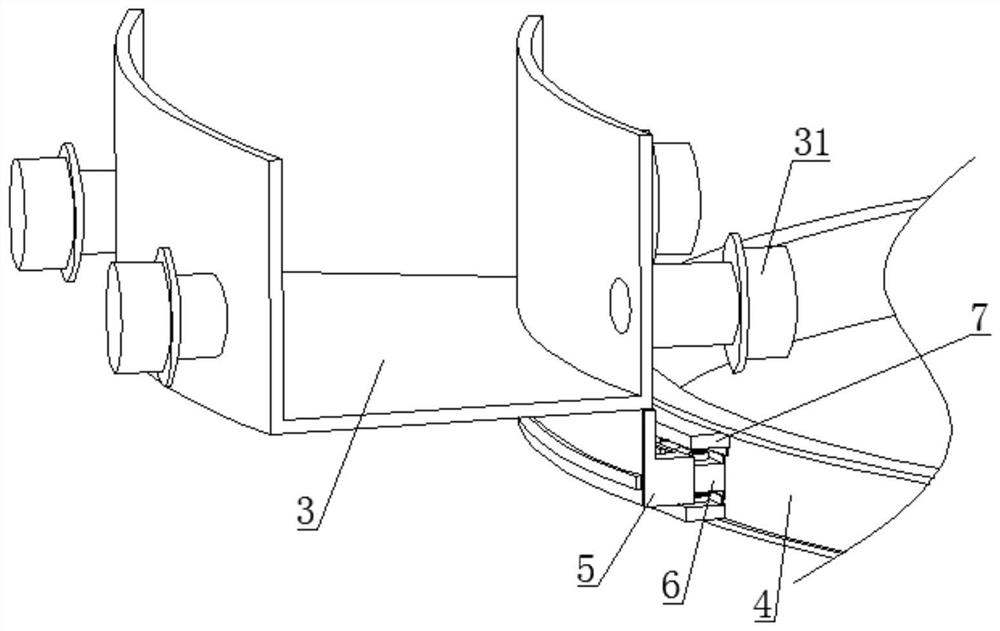

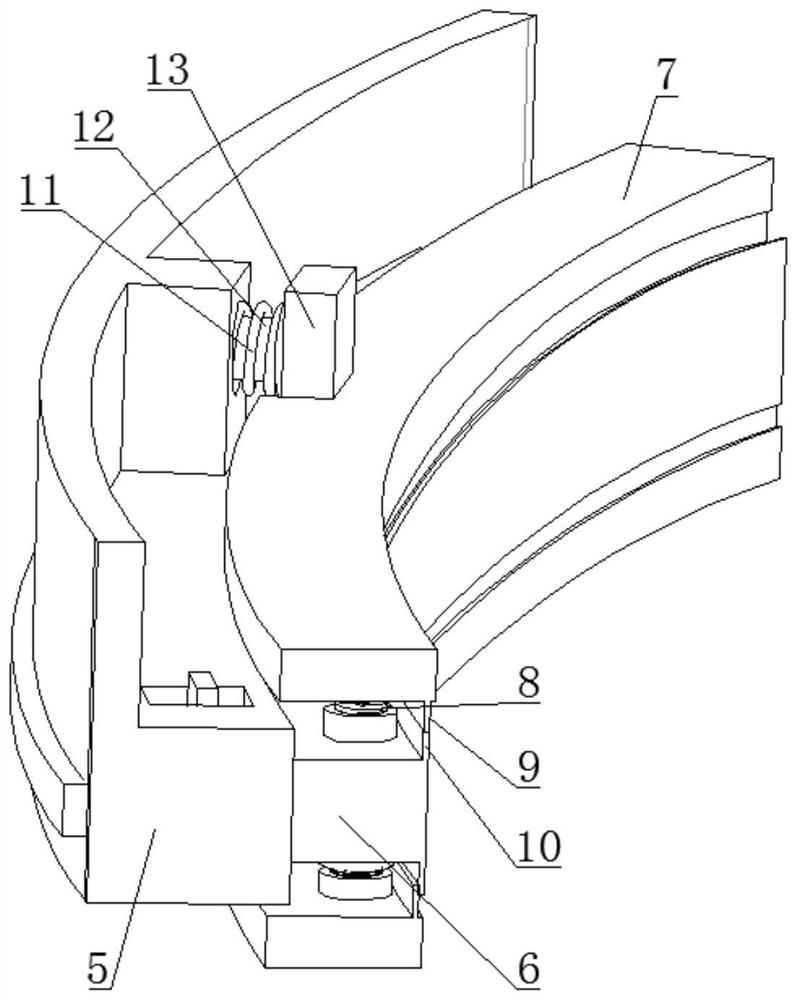

A ring cooling trolley sealing device

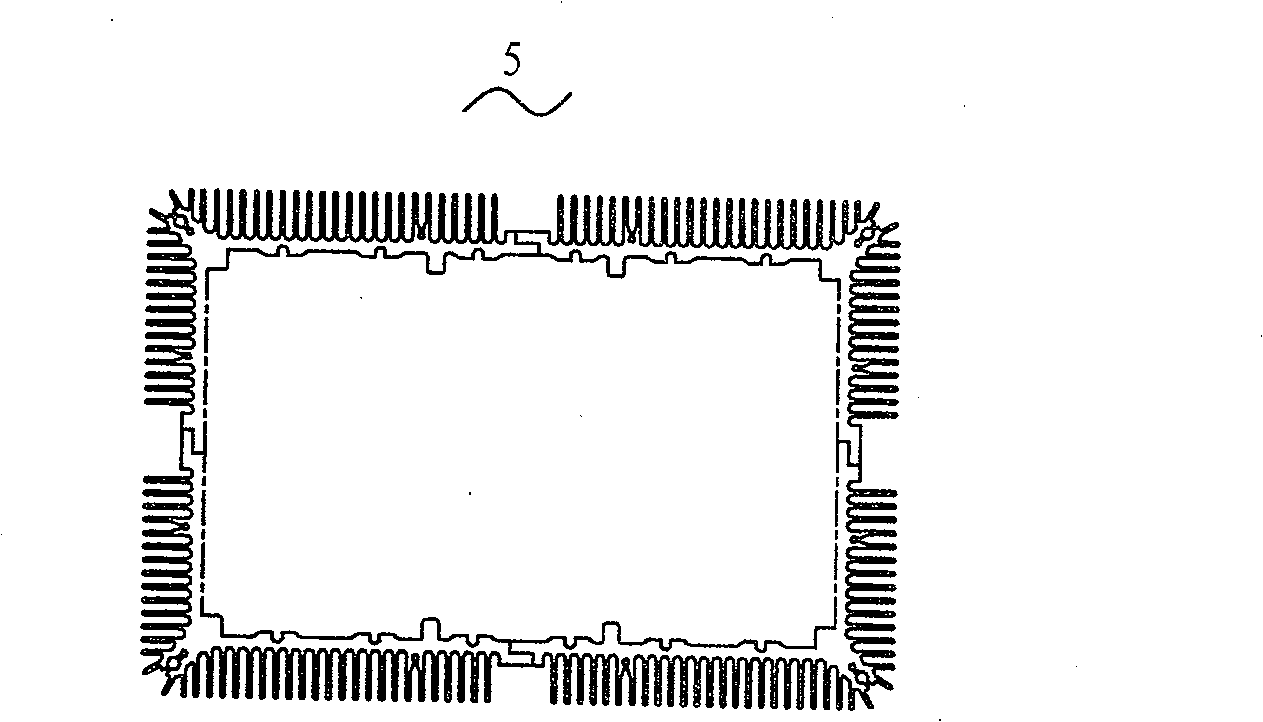

ActiveCN112923736BGuaranteed cooling qualityEnsure waste heat recovery effectIncreasing energy efficiencyHandling discharged materialEngineeringMechanical engineering

The invention discloses a ring cooling trolley sealing device, belonging to the technical field of metallurgy, comprising an outer guide rail, an inner guide rail and a ring cooling trolley; Sealing components are respectively provided between the guide rails; the sealing components include a sealing frame body fixedly connected with the ring cooling trolley and a sealing ring with a U-shaped cross section; the opening of the sealing ring faces the side of the ring cooling trolley, and it is respectively connected with the inner guide rail. It is connected with the external guide rail; the seal frame body is provided with a radial seal that slides along the radial direction of the seal ring, and the radial seal is slidably engaged with the inside of the seal ring; there is a radial reset between the radial seal and the seal frame body spring. The radial seal is connected with the sealing frame in radial sliding, and is elastically reset by the radial return spring, which offsets the centripetal force of the ring cooling trolley, so that the radial seal is always tightly sealed with the sealing ring to ensure a good sealing effect and running smoothly. Stability, to ensure the cooling quality of hot ore and the effect of waste heat recovery.

Owner:SHANDONG IRON & STEEL CO LTD

Cross type heat exchange air cooler

PendingCN113685925AIncrease cooldownImprove cooling qualityMechanical apparatusCondensate preventionThermodynamicsCooling chamber

A cross type heat exchange air cooler comprises a cooling chamber, a treatment chamber and air outlet equipment, all of which are sequentially arranged side by side. The cross type heat exchange air cooler further comprises multiple heat conduction pieces and an ice box; a partition plate is arranged between the cooling chamber and the treatment chamber; a connecting pipe is arranged on the partition plate, and the cooling chamber communicates with the treatment chamber through the connecting pipe; an ice adding hole is formed in the top of the cooling chamber; an air inlet pipe is arranged at the upper end of the cooling chamber; a bearing plate is arranged in the cooling chamber; a water collecting box is placed at the bottom of the cooling chamber; the ice box is placed on the bearing plate; multiple guide plates are arranged in the cooling chamber in the vertical direction at equal intervals; and gas treatment equipment is arranged in the treatment chamber and is connected with the air outlet equipment. According to the cross type heat exchange air cooler, the gas cooling duration is prolonged, the gas cooling quality and cooling speed are improved, the gas temperature is reduced to the maximum extent, and the effect of rapidly reducing the room temperature is achieved.

Owner:浙江铭鑫冷链设备有限公司

Multi-channel air supplement device for dryer cold room

PendingCN114009820AKeep the temperature stableGuaranteed cooling qualityTobacco preparationHot blastAir door

The invention relates to a multi-channel air supplement device for a dryer cold room, and belongs to the technical field of tobacco leaf redrying cooling air supplement. The multi-channel air supplement device of the dryer cold room comprises a main air supply device used for conveying hot air and side face air supplement devices used for supplementing cold air to the main air supply device, the side face air supplement devices are installed on any one or more side faces of the main air supply device, the main air supply device comprises a hot air inlet pipe, a main air outlet pipe and a first air door, and each side face air supplement device comprises an air supplement box, an outdoor air supplement pipe, a hot air return pipe, a second air door, a third air door, a fourth air door and a fifth air door. The multi-channel device can meet the air supplementing requirement under different outdoor air temperature conditions, the temperature in the redryer cold room is kept stable, the tobacco leaf cooling and moisture regaining quality is guaranteed, water and steam energy consumption in the moisture regaining process is reduced, and the device is simple in structure, convenient to install and maintain and convenient and fast to operate.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Integral cooling system and LED illumination device with the same

InactiveCN100549515CImprove cooling efficiencyGuaranteed cooling qualityPoint-like light sourceSemiconductor/solid-state device detailsEngineeringHeat pipe

The present invention provides an integral heat dissipation system, which includes a heat conduction mechanism and a heat dissipation mechanism. The heat conduction mechanism includes a bottom plate and a heat pipe; the heat dissipation mechanism is a heat dissipation shell; Contact heat transfer with the inner wall of the heat dissipation housing; the heat absorbing part of the heat pipe is located near the installation surface of the bottom plate, and the condensation part of the heat pipe is located adjacent to the installation surface of the bottom plate On the side; the heat conduction mechanism includes a plurality of heat pipes, the heat conduction mechanism also includes a heat pipe press plate, and the heat pipe press plate is arranged at a position near the bend of the heat pipe; the condensing part of the arranged heat pipes is fixed with a side plate to fix. The beneficial effects are: the integrated heat dissipation system with the base plate with high heat capacity, the heat pipe with high thermal conductivity and the integrated heat dissipation shell improves the efficiency of heat dissipation; especially the integrated heat dissipation shell ensures the quality of heat dissipation while reducing the heat dissipation of the system. volume and lower production costs.

Owner:SHENZHEN SED IND

Computer heat dissipation device based on composite heat dissipation technology

InactiveCN112068671AReduce the temperatureImprove cooling effectDigital data processing detailsStands/trestlesThermodynamicsCooling effect

The invention discloses a computer heat dissipation device based on a composite heat dissipation technology, which comprises a rack, wherein a heat dissipation hole is formed in the top end of the rack; a cooling assembly is arranged in the heat dissipation hole; a seat plate is arranged at the top end of the rack; one end of the seat plate is hinged to the rack through a hinge seat; a plurality of air permeation holes are uniformly formed in the seat plate; an angle support is arranged on the side, close to the movable end, of the bottom end of the seat plate; a water storage cavity is formedin the side wall of the rack; a frame plate is fixedly connected to the side wall of an inner cavity of the rack; and an air blowing assembly is embedded in the frame plate. The air blowing assemblyblows air into the heat dissipation hole, the air directly blows the cooling assembly, meanwhile, a micro water pump extracts water in the water storage cavity in cooperation with a water inlet pipe to inject the water into the cooling assembly, so that heat exchange with the air can be achieved through the cooling assembly, the temperature of the air is reduced, and low-temperature air penetratesthrough the air permeation holes and directly blows a notebook computer on the seat plate. Therefore, the notebook computer can be cooled, and the cooling effect of the notebook computer can be greatly improved.

Owner:ZIBO VOCATIONAL INST

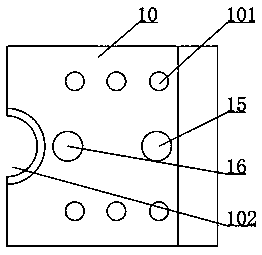

A kind of cooling structure and method of beryllium copper slider

ActiveCN107443694BImprove cooling effectMeet the needs of cooling and heat exchangeCooling effectBeryllium copper

Disclosed is a cooling structure of a beryllium copper sliding block. The cooling structure of the beryllium copper sliding block comprises a sliding block body and a beryllium copper insert, wherein the beryllium copper insert is arranged on the sliding block body. A cooling main water pipe and a cooling main gas pipe are arranged inside the sliding block body, and a cooling auxiliary water pipe and a cooling auxiliary gas pipe are arranged inside the sliding block body and the beryllium copper insert. One end of the cooling auxiliary water pipe is located in the sliding block body and communicated with the cooling main water pipe. The other end of the cooling auxiliary water pipe is located inside the beryllium copper insert and not provided with an outlet. The cooling auxiliary gas pipe penetrates through the cooling main water pipe and the cooling auxiliary water pipe. The end, penetrating out of the cooling main water pipe, of the cooling auxiliary gas pipe is located in the sliding block body and communicated with the cooling main gas pipe, and the end, penetrating out of the cooling auxiliary water pipe, of the cooling auxiliary gas pipe is located in the beryllium copper insert and communicated with a gas valve arranged on the beryllium copper insert. The cooling structure of the beryllium copper sliding block meets the requirement of injection molding products for cooling heat exchange in the curing molding process, improves the cooling effect of a beryllium copper sliding block insert and guarantees the cooling quality of a head molding part of the beryllium copper sliding block insert.

Owner:YANCHENG JIANDE MOLD PLASTIC

Sealing device for annular cooling trolley

ActiveCN112923736AGuaranteed cooling qualityEnsure waste heat recovery effectIncreasing energy efficiencyHandling discharged materialMechanical engineeringWaste heat

The invention discloses a sealing device for an annular cooling trolley, and belongs to the technical field of metallurgy. The sealing device for the annular cooling trolley comprises an external guide rail, an internal guide rail and the annular cooling trolley, wherein the annular cooling trolley is erected between the external guide rail and the internal guide rail, and sealing assemblies are arranged between the annular cooling trolley and the external guide rail and between the annular cooling trolley and the internal guide rail separately; each sealing assembly comprises a sealing frame body fixedly connected with the annular cooling trolley and a sealing ring with a U-shaped section; an opening of each sealing ring faces one side of the annular cooling trolley, and connected with the internal guide rail and the external guide rail separately; a radial sealing piece sliding in the radial direction of each sealing ring is arranged on the sealing frame body, and slidably clamped on the inner side of the sealing ring; and a radial return spring is arranged between each radial sealing piece and the sealing frame body. The radial sealing pieces are in radial sliding connection with the sealing frame body, and the radial sealing pieces and the sealing rings are tightly sealed all the time through elastic return of the radial return springs and counteracting for centripetal force of the annular cooling trolley, so that good sealing effect and operation stability are ensured, and the hot ore cooling quality and the waste heat recovery effect are ensured.

Owner:SHANDONG IRON & STEEL CO LTD

Casting cooling device

InactiveCN110499412AAchieve continuous coolingImprove cooling efficiencyFurnace typesHeat treatment furnacesEngineeringMechanical engineering

The invention relates to the field of automobile part production, in particular to a casting cooling device. The casting cooling device comprises a cooling box, a conveyer belt and a control cabinet.The cooling box is of a sealed box structure. The conveying belt passes through the cooling box in the length direction of the cooling box. One end of the conveyer belt is connected with an annealingfurnace. The control cabinet is arranged at one end of the bottom of the cooling box. The conveyer belt is a steel wire mesh conveyer belt. The two ends of the cooling box are provided with convectionfans. The rotation directions of the two convection fans are identical. The inner walls on the two sides in the cooling box are both provided with atomizing sprayers which are linearly and evenly distributed above the conveyer belt. A temperature sensor is arranged on the side wall at the outlet end of the cooling box and located on one side of the atomizing sprayer. The casting cooling device achieves continuous cooling of the casting and greatly improves cooling efficiency; and besides, a casting is not prone to cracking, cooling is uniform, and the cooling quality of the casting is greatlyimproved.

Owner:NINGBO XIAYI ELECTROMECHANICAL TECH CO LTD

Efficient water-cooling heat dissipation plate

PendingCN111885901AEven heat dissipationGuaranteed cooling qualityCooling/ventilation/heating modificationsWater flowHydrology

The invention discloses an efficient water-cooling heat dissipation plate, and the heat dissipation plate comprises a first water collection tank, a second water collection tank, a first heat dissipation water channel and a second heat dissipation water channel, wherein the first water collection tank comprises a first water inlet tank and a first water outlet tank, the second water collection tank comprises a second water inlet tank and a second water outlet tank, and the first water inlet tank and the second water outlet tank are communicated through the first heat dissipation water channel;and the first water outlet groove is communicated with the second water inlet groove through a second heat dissipation water channel. The invention has the beneficial effects that 1) the first heat dissipation water channel and the second heat dissipation water channel are independently and adjacently arranged, and the water flow directions in the first heat dissipation water channel and the second heat dissipation water channel are opposite, so heat dissipation is uniform, and the heat dissipation quality is guaranteed; 2) the heat dissipation water channels are connected in parallel betweenthe water inlet groove and the water outlet groove, and the flow channels are short, so heat can be quickly taken away by heat-exchanged water, and the heat exchange efficiency is improved.

Owner:ZHEJIANG UNIV OF TECH

A cooling and refrigeration device for japonicus culturing ponds

ActiveCN111264453BReduce the temperatureImprove the breeding environmentPisciculture and aquariaStichopusCold air

The invention discloses a cooling device for japonicus cultivating ponds, which comprises a box body. The outer end of the air intake hole is connected to the blower through through, the top of the bottom plate is provided with a vent pipe, the air inlet end of the vent pipe is connected through the air intake hole, the air outlet end of the vent pipe is connected through the air outlet hole, and the top of the bottom plate is provided with There is an ice layer; the present invention blows air into the ventilation pipe through the blower and the air inlet, and the air exchanges heat with the ice layer through the ventilation pipe, thereby cooling the air, and the low-temperature air is discharged from the air outlet to realize the cooling of the aquaculture pond. The water is cooled, and the whole cooling process is to use cold air to fill the water to cool down, which can realize rapid and sufficient cooling of the water, and can improve the ability of sea cucumbers to resist high temperatures in summer; at the same time, injecting a large amount of air into the pond is beneficial to increase the dissolved oxygen in the pond water. It is beneficial to improve the growth environment of sea cucumber.

Owner:LUDONG UNIVERSITY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com