LED screen based on natural wind air-cooling heat dissipation technology

A natural wind and screen technology, applied in the field of LED screens, can solve the problem of reduced heat dissipation of LED screens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

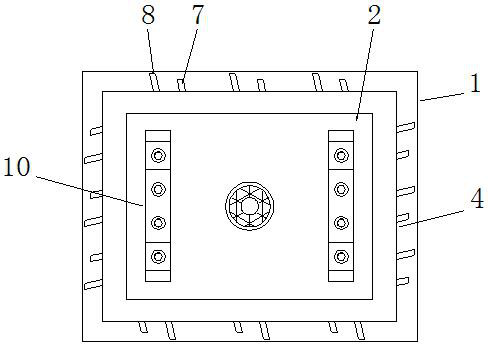

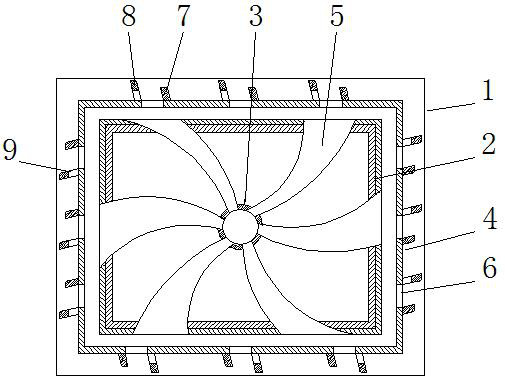

[0029] See Figure 1-2 , a LED screen based on natural wind air-cooled heat dissipation technology, comprising a screen body 1, the rear side end of the screen body 1 is fixedly connected to a rear shell 2, the outer side of the rear shell 2 is provided with an air intake pipe 4, and the rear shell The middle part of the rear wall of 2 is embedded with a vent pipe 3, the vent pipe 3 is a cylindrical structure with an open front end, the open end of the vent pipe 3 is provided with a first protective net 31, and the outer circular surface of the vent pipe 3 is uniform. There are several heat exchange tubes 5 through which are connected, the heat exchange tubes 5 are arc tubes, the heat exchange tubes 5 are trumpet-shaped structures, and the large-diameter ends of the heat exchange tubes 5 are connected through the air intake pipe 4, and the air intake pipes 4 is an annular pipe, and the outer end of the air intake pipe 4 is evenly provided with a number of air intake holes 6, a...

Embodiment 2

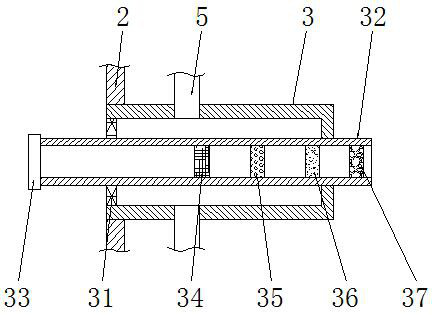

[0032] See image 3 The difference from Embodiment 1 is: the side wall of the ventilation pipe 3 is embedded with a blast pipe 32, the axis of the ventilation pipe 3 coincides with the axis of the blast pipe 32, and the blast pipe 32 is far away from the screen body One end of 1 runs through the first protective net 21 and is equipped with a heat dissipation fan 33. The inner cavity of the blast pipe 32 is provided with a dust filter 34, a first water filter layer 35, a second water filter layer 36 and a third water filter layer. The water filter layer 37, the first water filter layer 35 is a silica gel particle layer, the second filter layer 36 is a calcium chloride particle layer, and the third filter layer 37 is an active carbon particle layer; Draw the outside air, so that the outside air enters the inner cavity of the rear shell 2 through the air blast pipe 32, and the air passes through the dust filter 34, the first water filter layer 35, the second water filter layer 36...

Embodiment 3

[0034] See Figure 4 , the difference from Embodiment 1 is that: the mounting frame 10 includes a first fixing frame 101, the first fixing frame 101 is a U-shaped structure, and the left and right side ends of the first fixing frame 101 are symmetrically provided with a second fixing frame 102, the second fixed frame 102 is an L-shaped structure, the first fixed frame 101 and the second fixed frame 102 are integrally formed, and the first fixed frame 101 is uniformly provided with a plurality of first threaded holes 103, so A first bolt 104 is installed in the first threaded hole 103, a second threaded hole 105 is provided on the second fixed frame 102, a second bolt 106 is installed in the second threaded hole 105, and the second bolt 106 Cooperating with the second threaded hole 105, the rear case 2 can be installed on the second fixed device 102, and at the same time, the first fixing bracket 101 can be installed on the wall through the first bolt 104 and the first threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com