Online cooling device for packaging bag film and mounting method of online cooling device

A cooling device, packaging bag technology, applied in packaging, transportation and packaging, bag making operations, etc., can solve the problems of low cooling efficiency, high energy consumption, affecting the quality of packaging bag film cooling, etc., to improve cooling efficiency, ensure The effect of cooling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

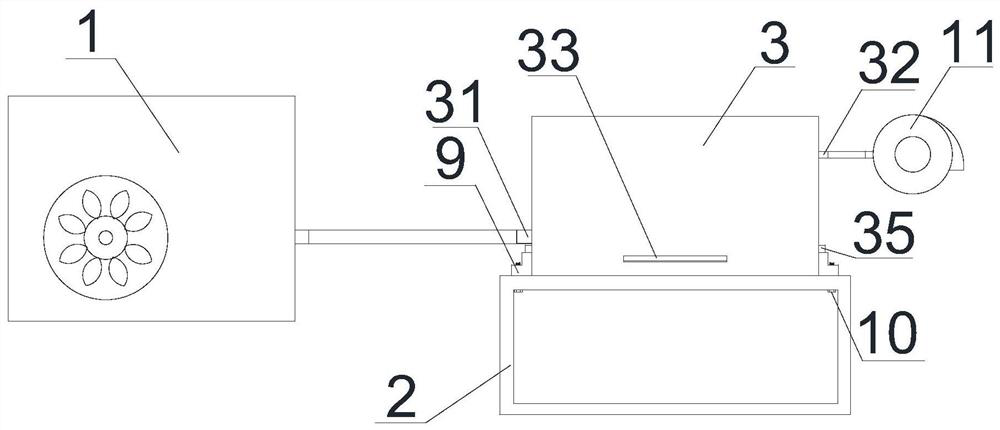

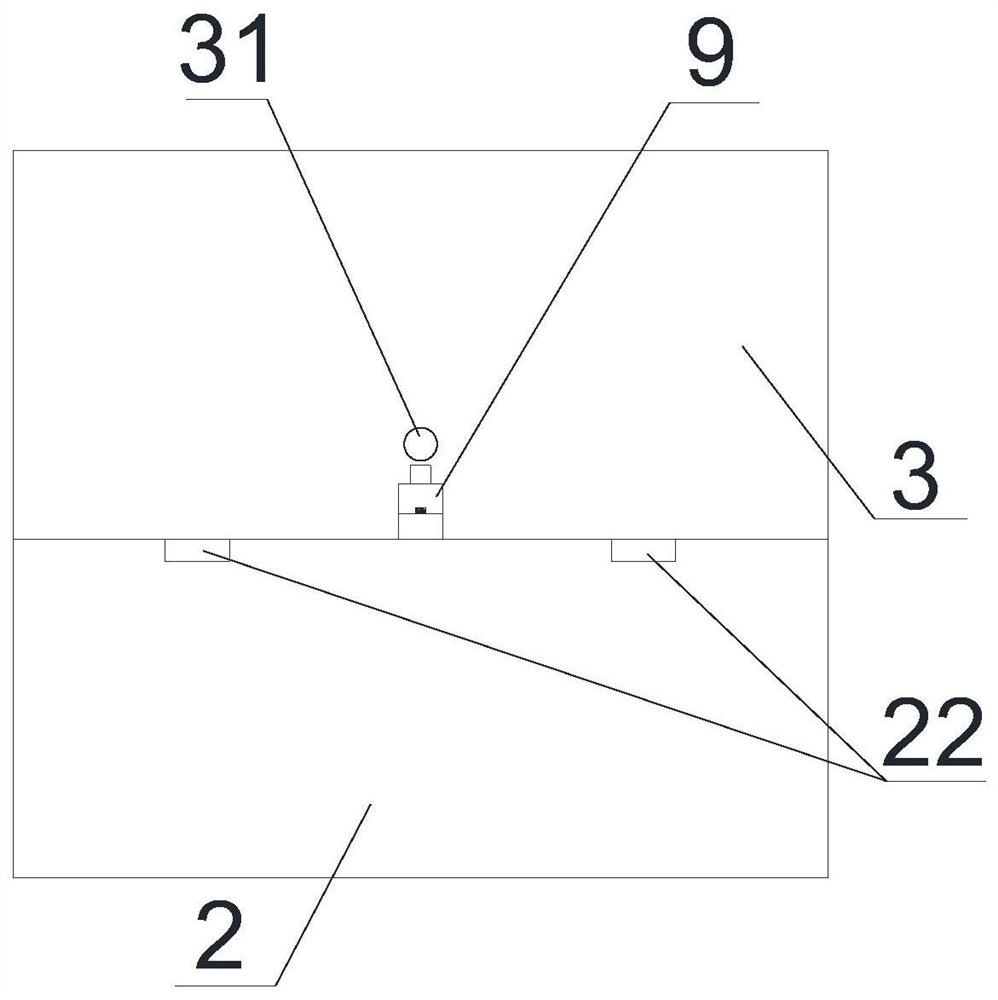

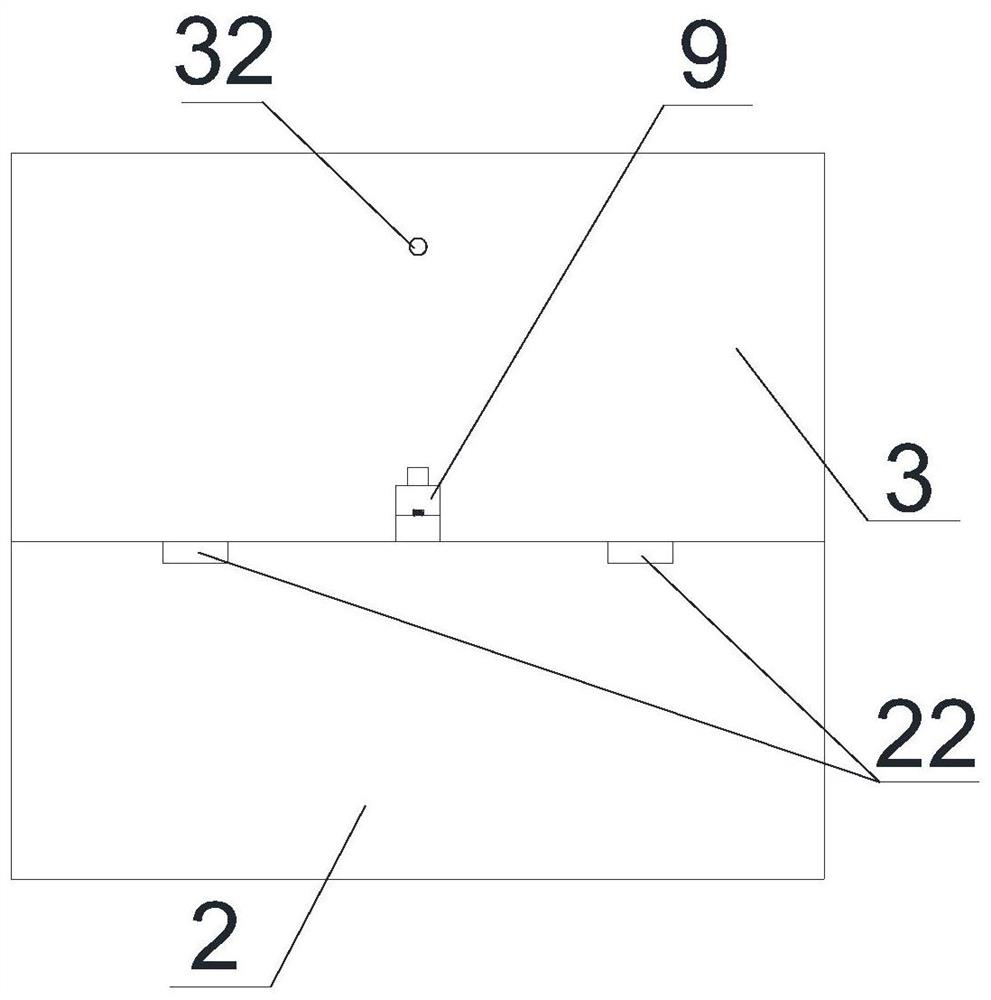

[0029] Embodiment 1: with reference to attached Figure 1-Figure 8 . An online cooling device for packaging bag film, comprising a cooling fan 1, a chassis 2 and a cooling bin 3, the cooling bin 3 is arranged on the upper end of the chassis 2 and one side of the cooling bin 3 is provided with an air inlet 31, the other An air outlet 32 is provided on the side, and the air outlet of the air cooler 1 is connected to the air inlet 31 of the cooling chamber 3 through a pipeline. The front of the cooling chamber 3 has a first packaging bag film through hole 33, and the cooling The back of the warehouse 3 has a second packaging bag film through hole 34 and the first packaging bag film through hole 33 and the second packaging bag film through hole 34 communicate with each other, and the first packaging bag film through hole 33 runs through the cooling compartment 3, the front and back sides of the wall, the second packaging bag film through hole 34 runs through the front and back ...

Embodiment 2

[0035] Embodiment 2: on the basis of embodiment 1, with reference to appended Figure 9 and Figure 10. The front and the back of the cooling bin 3 are respectively provided with a brush assembly 12, wherein one brush assembly 12 is located at the film through hole 33 of the first packaging bag, and the other brush assembly 12 is located at the film through hole 33 of the second packaging bag. place; the brush assembly 12 is composed of a brush plate 121, a screw rod 122 and a nut 123, the lower end of the brush plate 121 is provided with a soft brush head, and the front of the handle in the brush plate 121 is opened There is a screw through hole 124 and the screw through hole 124 runs through the front and back sides of the plate handle, and the screw through hole 124 is a strip-shaped through hole arranged longitudinally; the screw 122 is fixedly installed on the front or back of the cooling chamber 3, and the The brush plate 121 is installed on the outer side of the cooli...

Embodiment 3

[0036] Embodiment 3: on the basis of embodiment 1 and embodiment 2. A method for installing a packaging bag film online cooling device, step 1, a row of rollers on the mold lifter 22 is lifted upwards so that the upper end of the rollers is higher than the upper end surface of the bottom frame 2 of the cooling station in the packaging bag film production line; Step 2: Move the cooling bin 3 into the upper end of the bottom frame 2 from the side of the bottom frame 2 and move the cooling bin 3 to the designated position on the upper end surface of the bottom frame 2 through a row of rollers, and then move the row of rollers on the mold lifter 22 downwards Falling back, the bottom surface of the cooling chamber 3 is in contact with the upper end surface of the bottom frame 2 (the upper end of the roller is lower than the upper end surface of the bottom frame 2 of the cooling station in the packaging bag film production line at this time); step 3, two fixed blocks 9 Placed on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com