High-performance cable production line

A production line, high-performance technology, applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., can solve the problems of high energy consumption, environmental protection, poor quality, etc., to improve production efficiency, improve production quality, Guaranteed cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

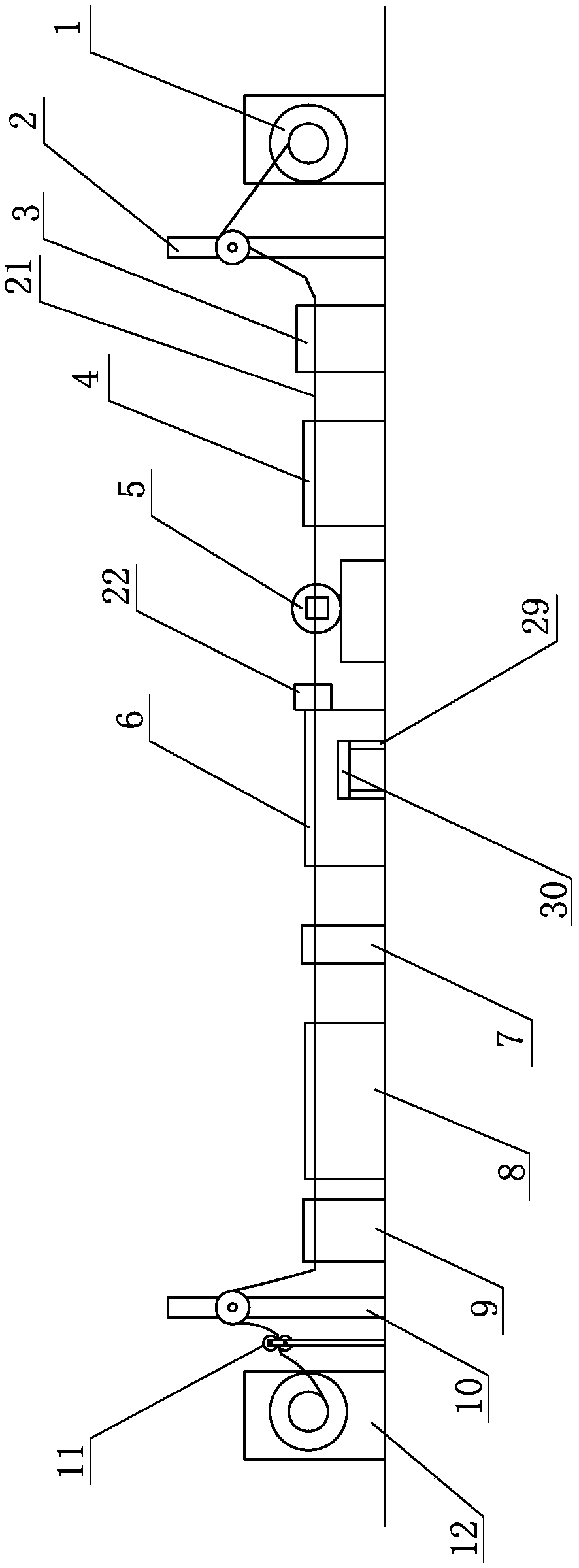

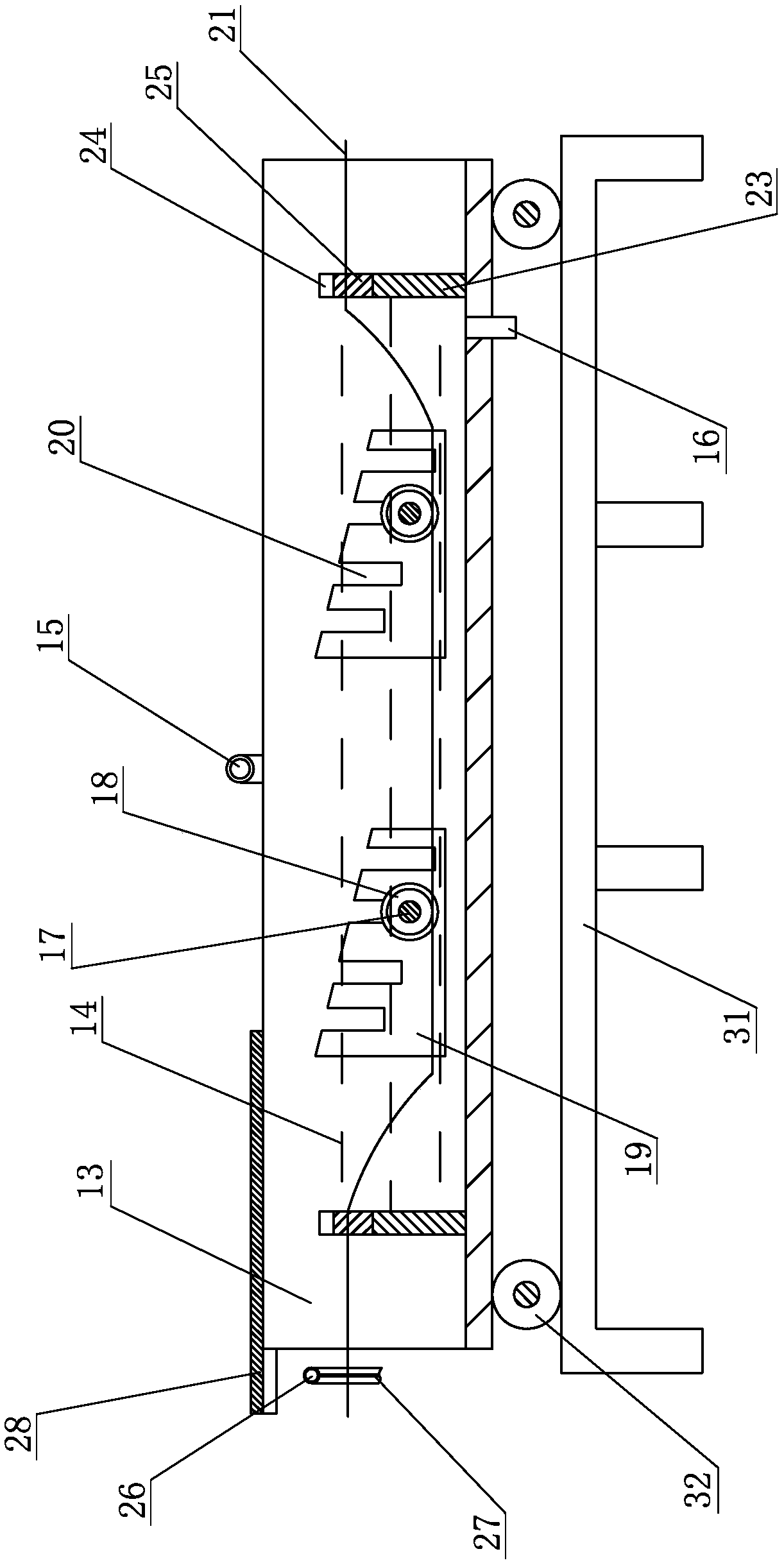

[0022] Embodiment one: see figure 1 , 2 As shown, a high-performance cable production line includes a pay-off rack 1, a front-end wire storage rack 2, a wire spark machine 3, a talcum powder box 4, an insulating sheath extruder 5, and a first cooling machine arranged in sequence from front to back. Water tank 6, wire inkjet printer 7, second cooling water tank 8, tractor 9, rear-end wire storage rack 10, meter counter 11 and wire take-up rack 12, the first cooling water tank and the second cooling water tank are both top The tank body 13 of opening, is provided with cooling water 14 in the described tank body 13, and the top of described tank body 13 is provided with a water inlet pipe 15, and the bottom of described tank body 13 is provided with a water outlet pipe 16; There are at least two sets of transmission mechanisms evenly distributed from front to back, the transmission mechanisms include a transmission stick 17, a transmission wheel 18 and two mounting plates 19, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com