Outer loop fast cooling device for feed production

A technology of rapid cooling and external circulation, which is applied in household refrigeration devices, applications, household appliances, etc., can solve the problems of different feed cold and heat, the cooling effect cannot be guaranteed, and the quality of feed production is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

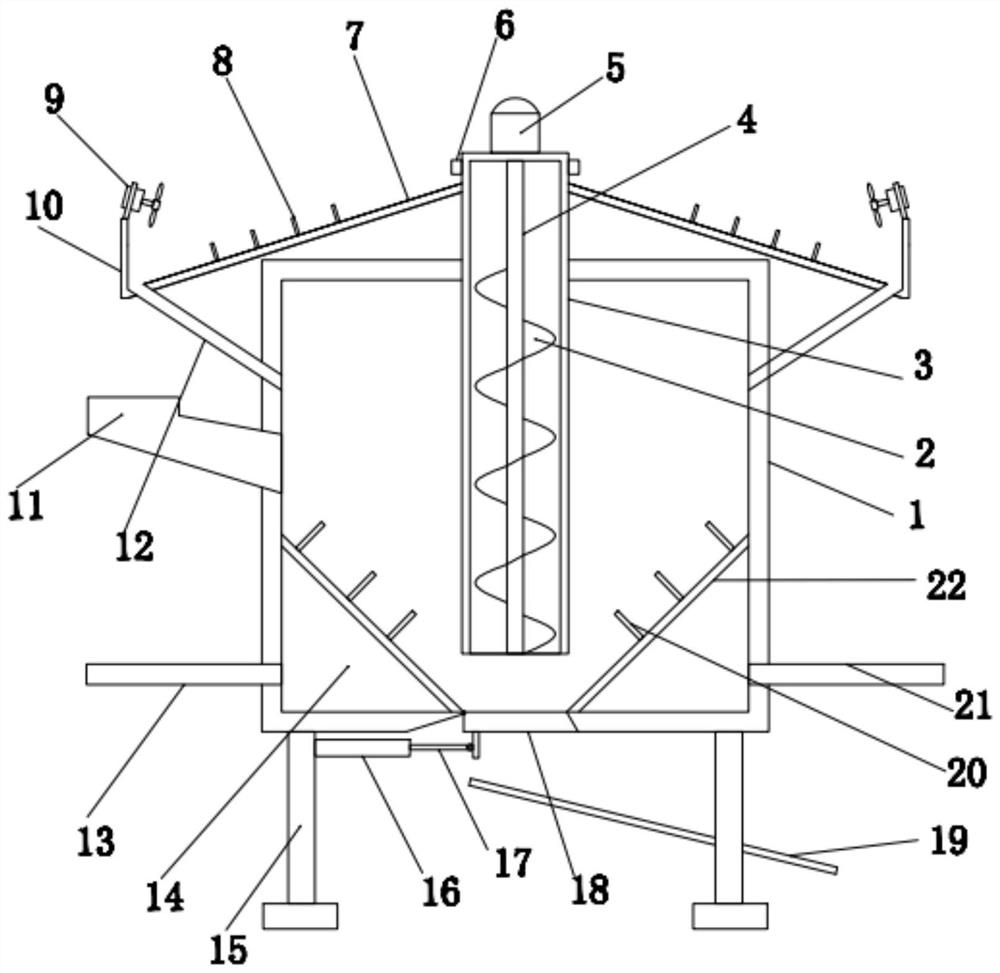

[0024] see Figure 1-3 In an embodiment of the present invention, a rapid cooling device for external circulation feed production includes a cooling box 1 and a plurality of legs 15 arranged in an array on its lower end surface, and a support block is provided at the lower end of each leg 15, The upper left side of the cooling box 1 is provided with a feeding pipe 11 for feeding, the bottom of the cooling box 1 is provided with a discharge assembly, and the cooling box 1 is provided with a first cooling member and a second cooling unit for cooling the material. pieces;

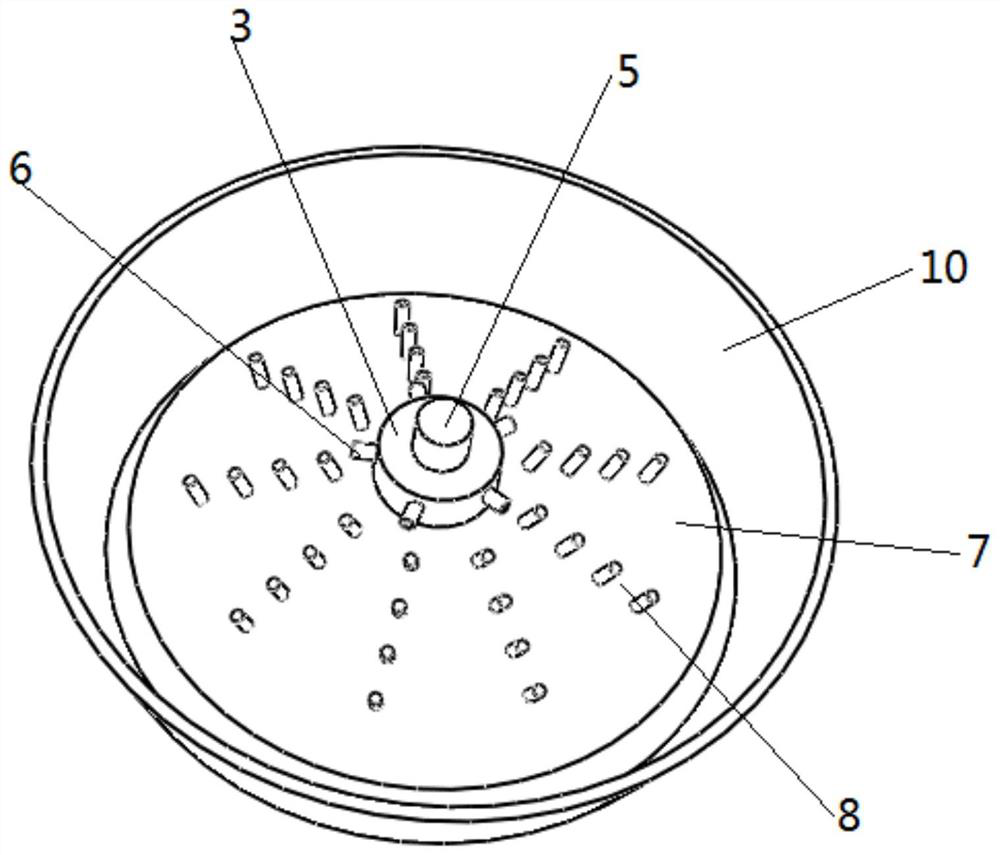

[0025] The first cooling member includes a lifting tube 3 that is installed on the top of the cooling box 1, and the lower end of the lifting tube 3 extends to the inner bottom of the cooling box 1. A rotating shaft 4 is arranged inside the lifting tube 3, and the outer side of the rotating shaft 4 It is equipped with a lifting blade 2 for lifting the material, and the upper end of the rotating shaft 4 is con...

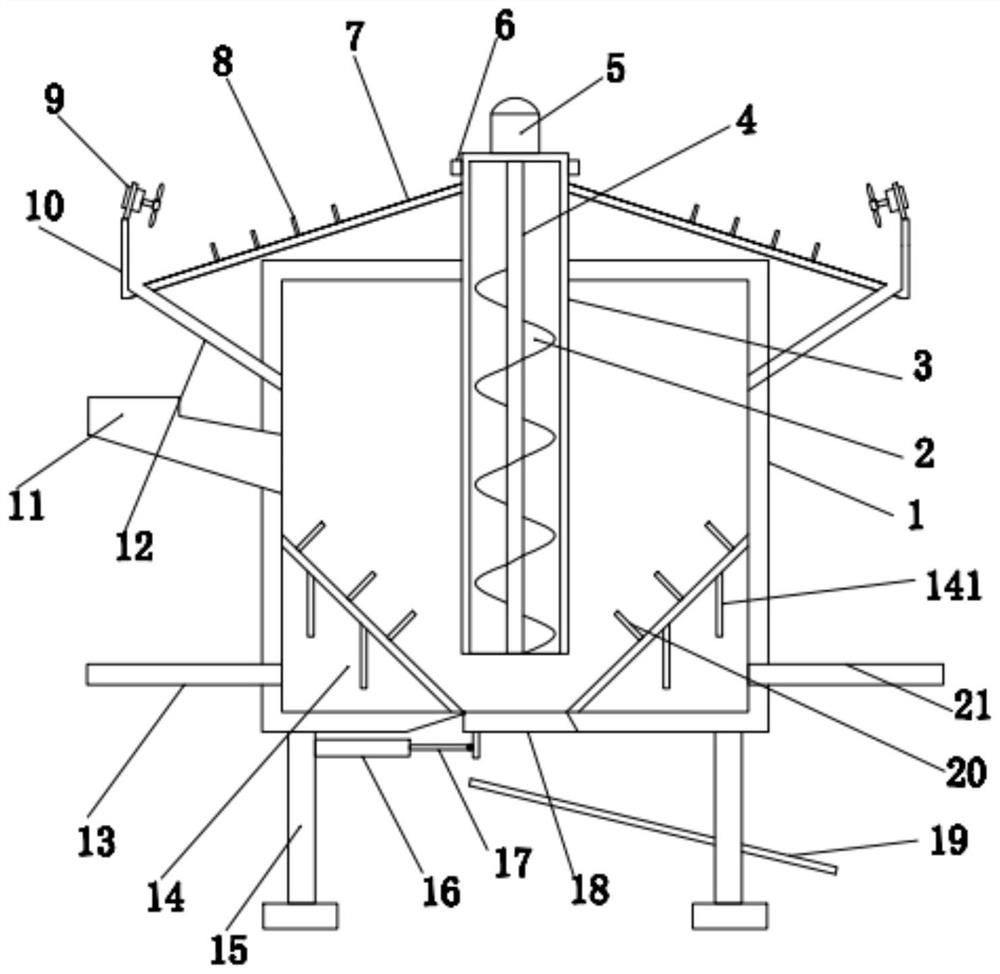

Embodiment 2

[0033] The difference from Embodiment 1 is that: the conical guide hopper 22 is provided with several heat dissipation fins 141 on the side close to the cold water, and the heat dissipation fins are used to increase the heat dissipation area, thereby improving the heat dissipation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com