Cooling device for heat treatment of metal belts

A cooling device and metal strip technology, applied in the field of heat treatment, can solve the problems of difficulty in meeting the production of high-grade metal strip products, difficult to produce metal strips with surface quality, poor uniformity of atomized droplet size, etc., and achieve device safety and reliability. High, ensure product surface quality, ensure the effect of cooling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

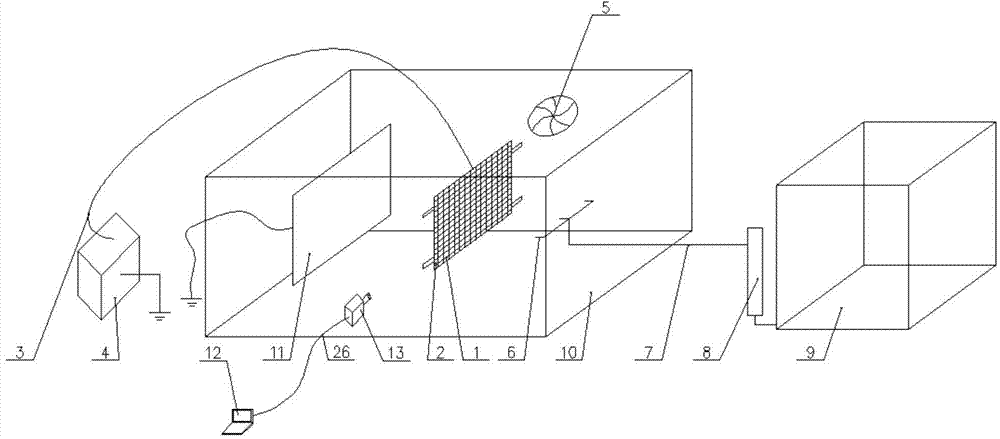

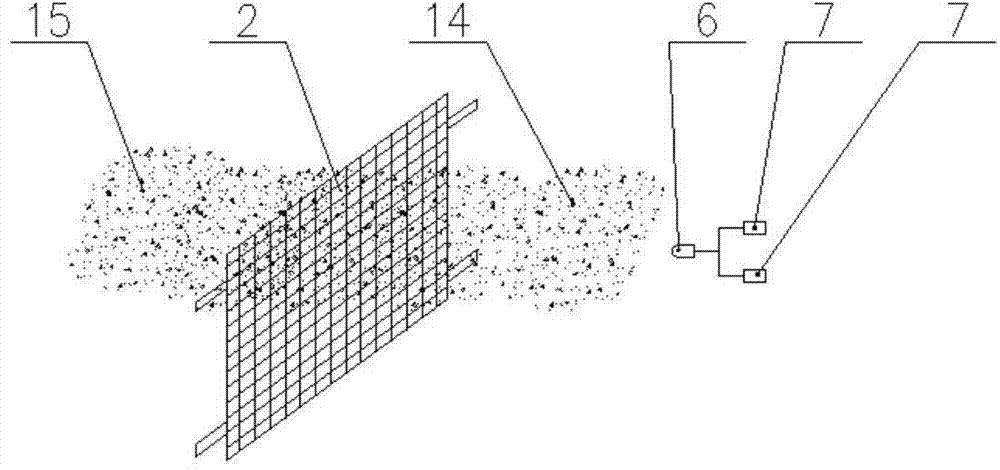

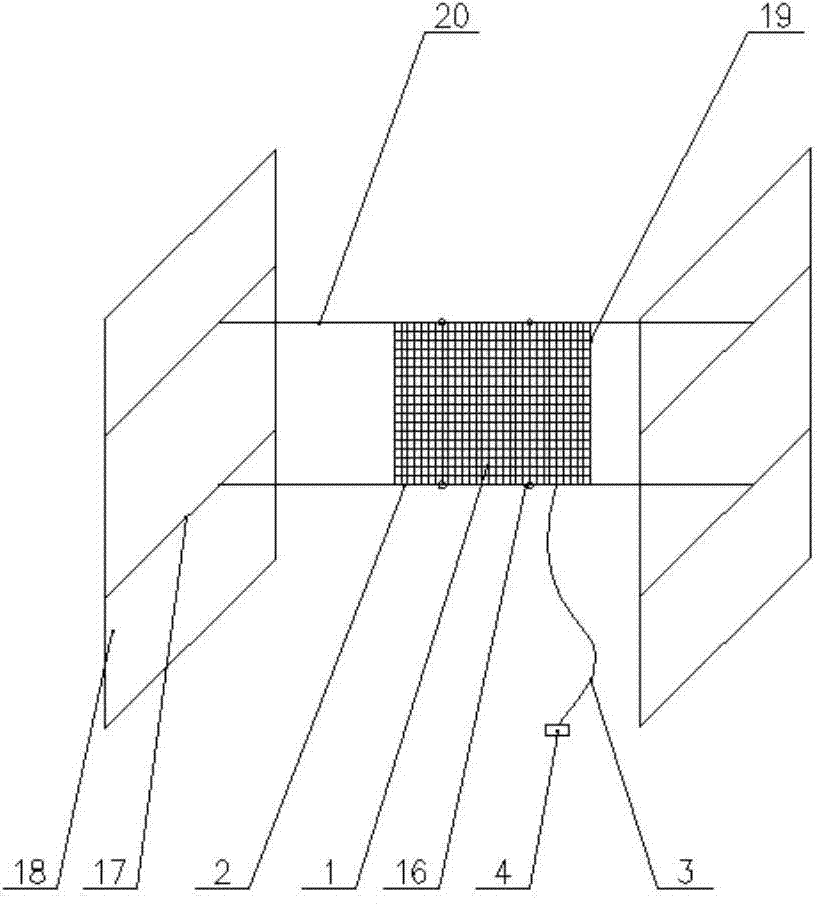

[0027] like Figure 1-5 , Figure 7 As shown, a kind of cooling device 10 (or claiming metal strip surface high-pressure spray cooling device) for metal strip heat treatment of the present invention comprises cooling chamber, spray system 8, high-pressure system 1, and cooling chamber is the wall body that is closed shape Or the outer frame 18, the cooling chamber is provided with the inlet and outlet for the continuous passage of the metal strip 11; the spray system 8 includes a medium supply system 9, a medium supply system pipeline 7 and a nozzle 6, and the medium supply system 9 provides cooling liquid and compressed gas to form gas - liquid medium, the nozzle 6 is communicated with the medium supply system 9 by the medium supply pipeline 7 (the medium supply pipeline 7 through which the gas-liquid medium passes enters the nozzle 6, completes the atomization, and obtains the primary atomized cooling liquid droplets 14 continuously sprayed) The nozzle 6 is located in the c...

Embodiment 2

[0041] like Image 6 As shown, it is basically the same as Embodiment 1, except that the grooves on the insulating ring 21 are distributed vertically.

Embodiment 3

[0043] like Figure 8 As shown, it is basically the same as Embodiment 1, except that: the outer frame is processed with a small hole 25 for fixing the electrode wire; or the electrode wire is fixed on the outer frame by glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com