Material-overturning-type rice cooling bin

A technology for cooling silo and rice, applied in application, grain processing, grain milling, etc., can solve the problems of increasing the crushing rate, affecting the polishing effect, affecting the quality of rice, etc., to prolong the falling time, improve the heat exchange efficiency, improve the The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

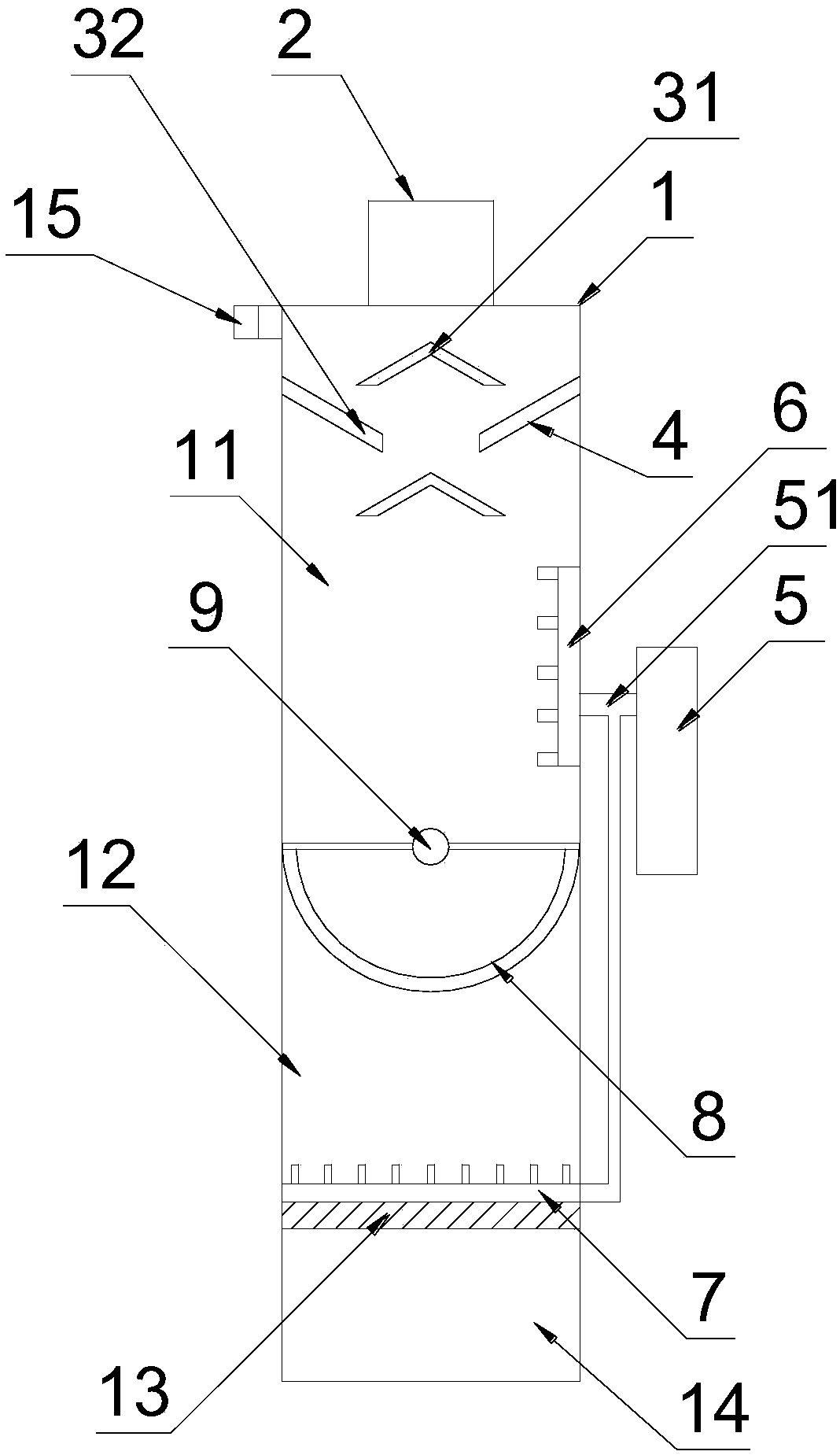

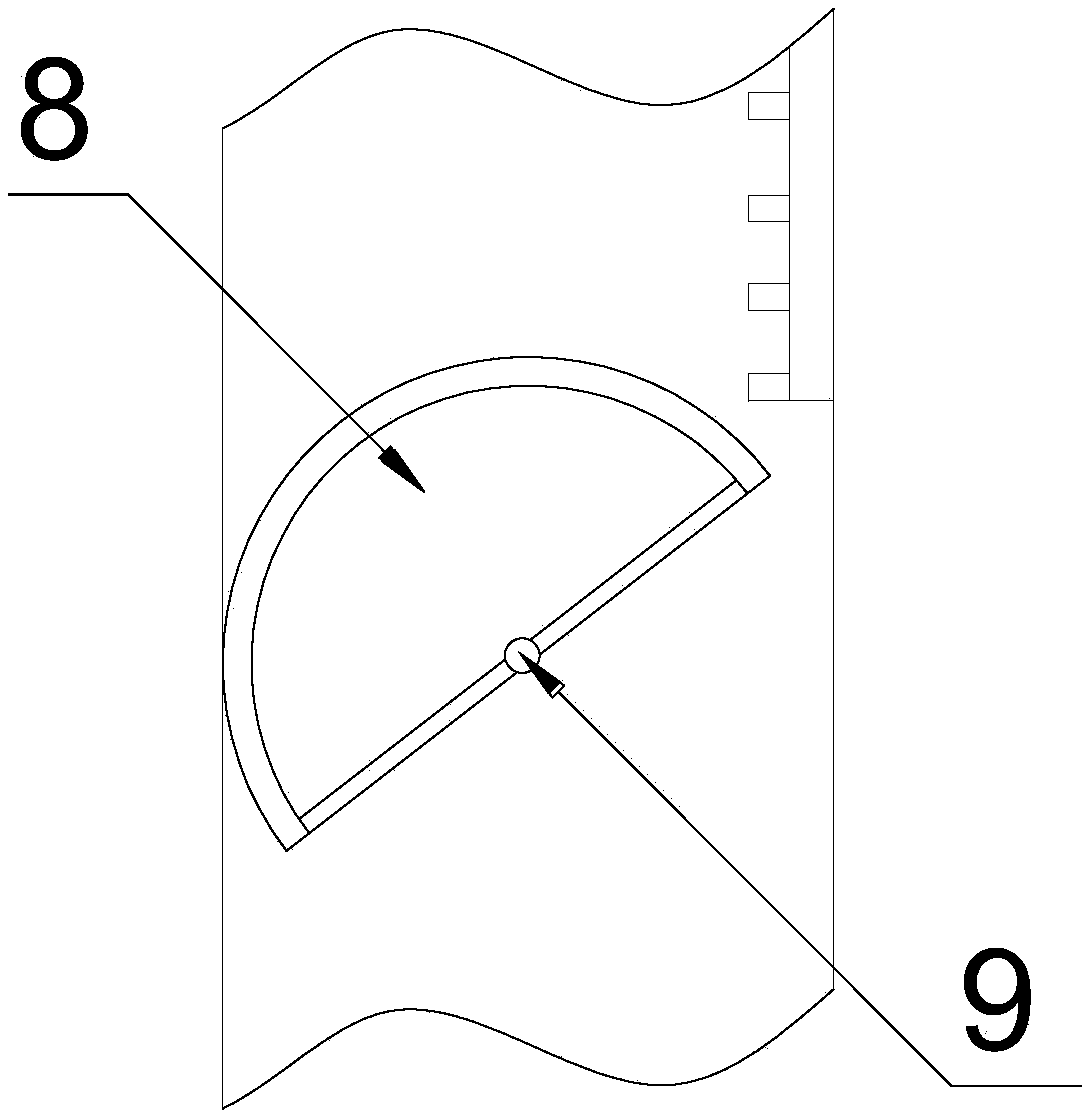

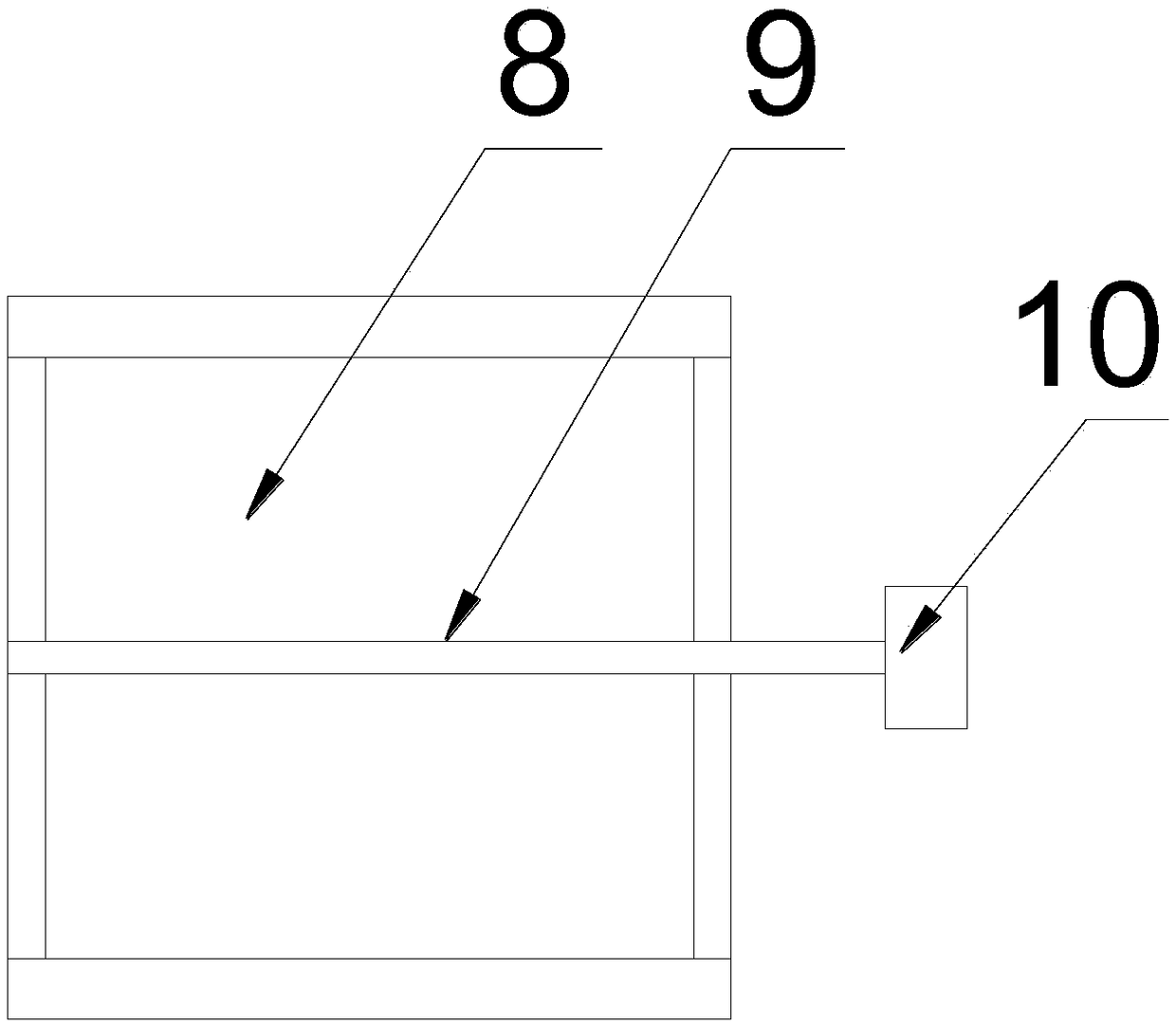

[0021] Such as Figure 1-3 as shown, figure 1 It is a structural schematic diagram of a kind of material-turning type rice cooling warehouse proposed by the present invention, figure 2 It is the working schematic diagram of the turning type rice cooling storehouse that the present invention proposes, image 3 It is a schematic diagram of the material turning plate in the material turning type rice cooling bin proposed by the present invention.

[0022] refer to Figure 1-3 , a kind of flipping type rice cooling storehouse that the present invention proposes, comprises cold rice storehouse 1, feeder 2, bulk material tray, guide plate 4, air cooler 5, first cold air duct 6, second cold air duct 7, turn over A material plate 8, a rotating shaft 9, a discharge plate 13 and a softening box 14; wherein, the cold rice bin 1 is divided into an upper cooling bin 11 and a lower cooling bin 12 by a turning board 8;

[0023] A feeder 2 is arranged on the top of the cooling bin 1, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com