Patents

Literature

132results about How to "Improve cooling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

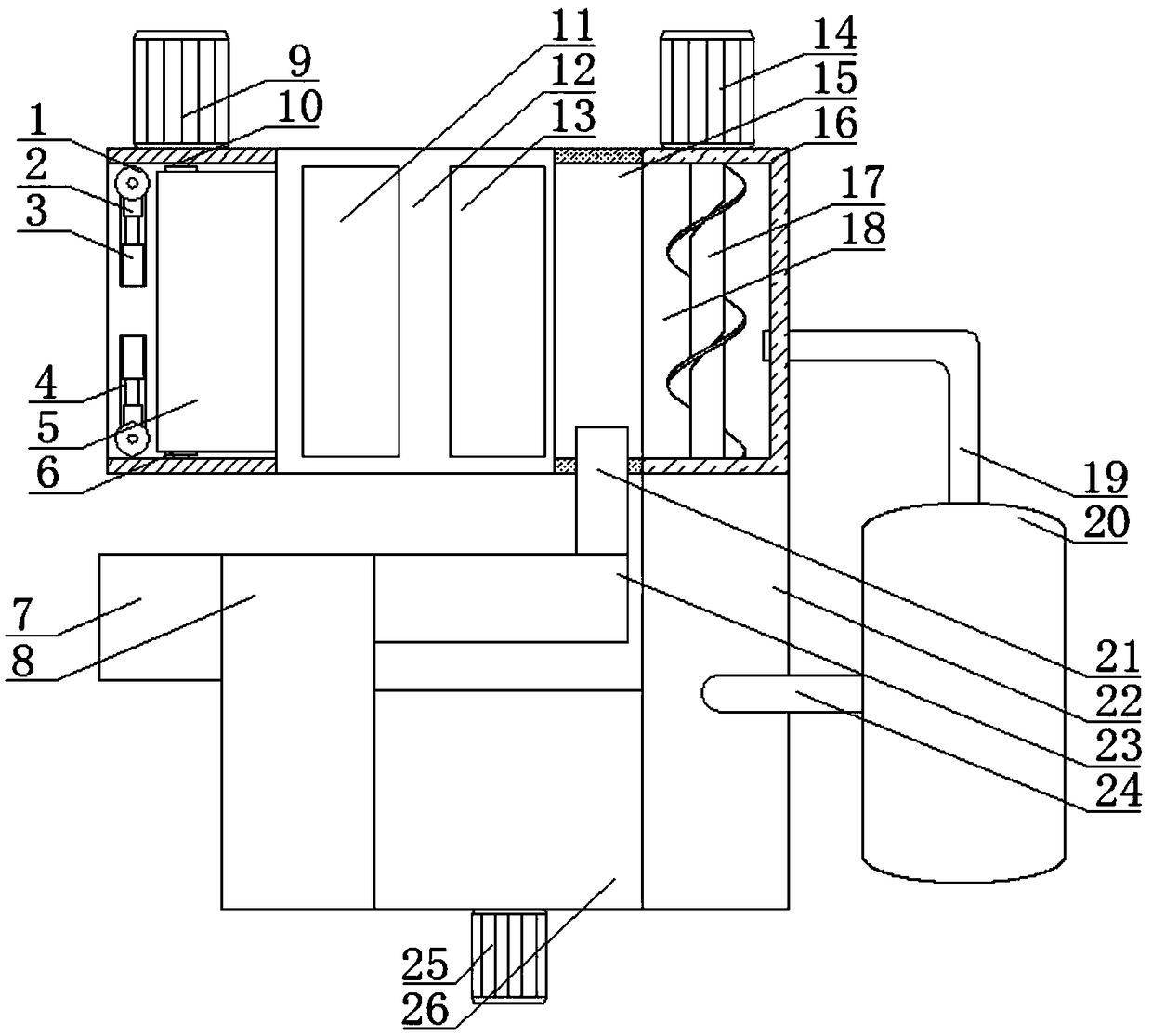

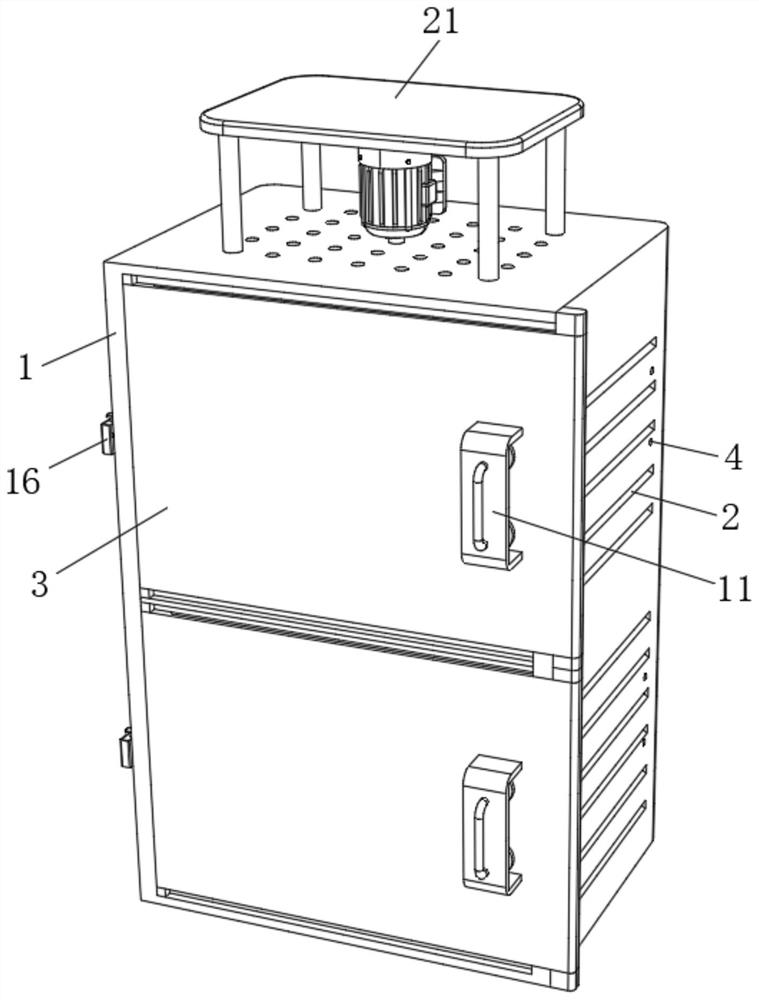

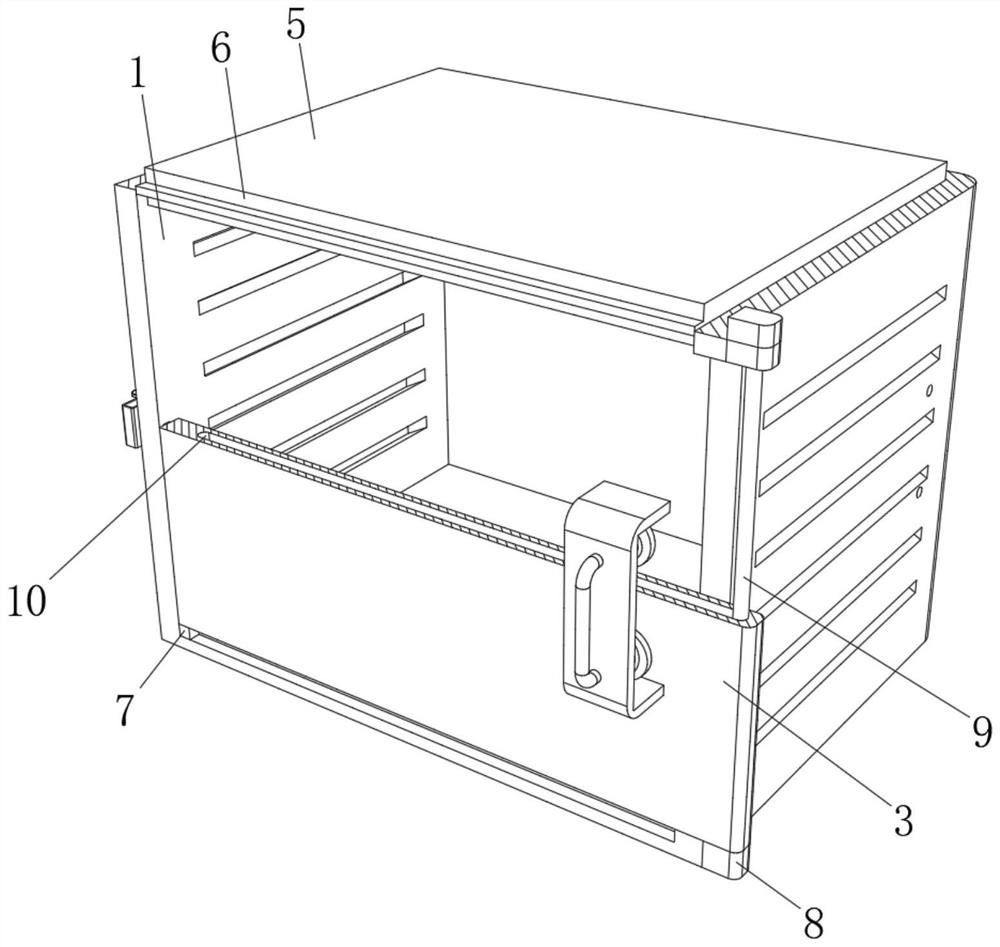

Dustproof and heat radiation type electric power equipment power distribution cabinet

ActiveCN106972382AImprove cooling efficiencyQuick releaseSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsImpellerElectric power equipment

The invention discloses a dustproof and heat radiation type electric power equipment power distribution cabinet comprising a cabinet body, a heat radiation blower, a negative pressure blower, a water tank and a drying agent placing box. The water tank is fixedly connected on the upper part of the cabinet body. The negative pressure blower is fixedly connected in the middle of the upper side wall body of the water tank. The air inlet end of the negative pressure blower is fixedly communicated with the upper side wall body of the water tank. The output end of the negative pressure blower is fixedly communicated with an output pipe. The beneficial effects of the dustproof and heat radiation type electric power equipment power distribution cabinet are that when a temperature sensor in the cabinet body senses certain temperature, the negative pressure blower is enabled to be electrified and started, and the air is secondarily filtered so that the dust in the air can be effectively reduced. The drying agent placing box can be rapidly detached and installed by detaching and installing a bolt component, and cleaning is facilitated. When the drying agent requires to be replaced, the drying agent box is directly pulled out and a new drying agent box is put in so that replacing is rapid and operation is convenient. A propeller impeller is enabled to rotate by the air entering an air pipeline so that fan blades are enabled to rotate, and the heat radiation efficiency in the cabinet body can be enhanced.

Owner:珠海市万晟电气有限公司

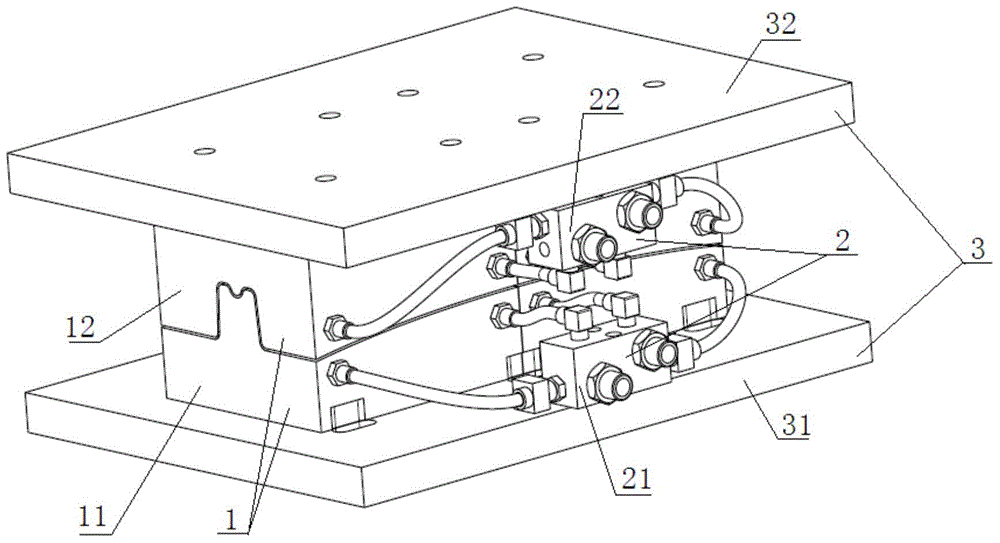

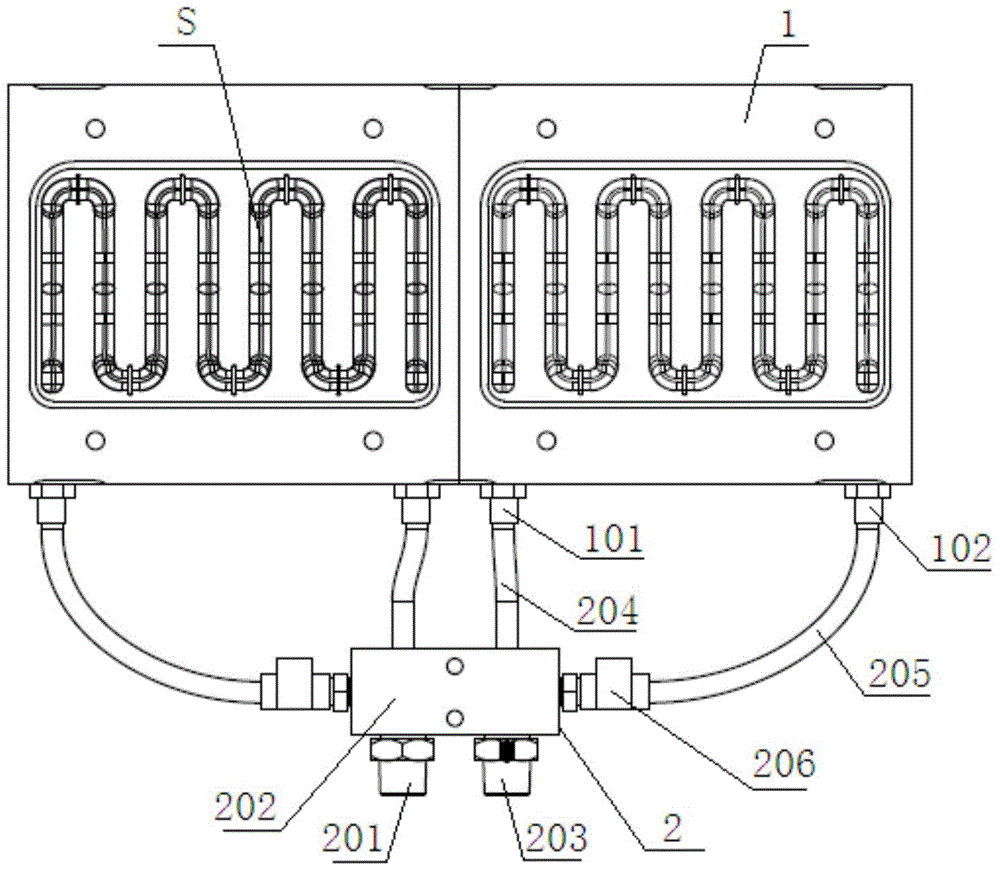

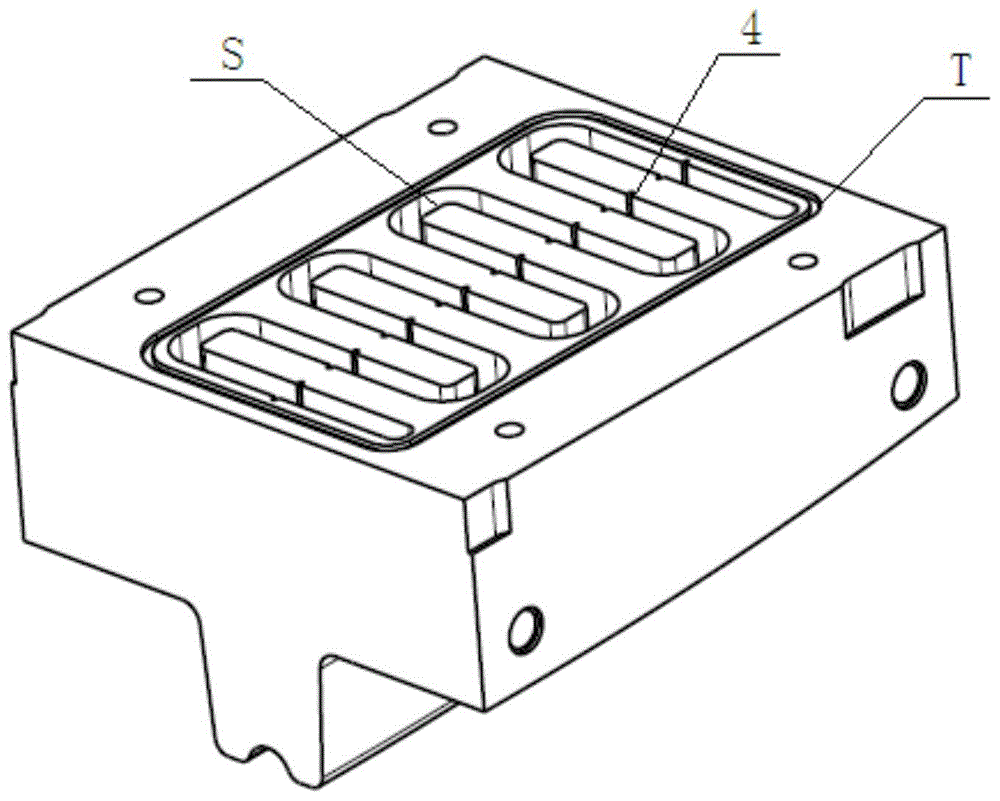

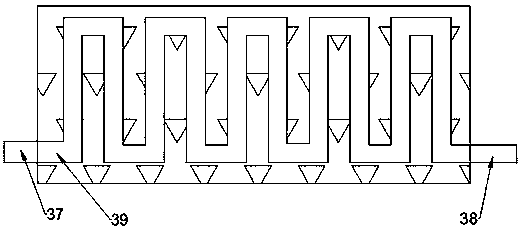

Hot stamping die of snakelike cooling water channel type

InactiveCN104923660AImprove processing efficiencyShorten the manufacturing cycleShaping toolsHot stampingWater channel

The invention discloses a hot stamping die of a snakelike cooling water channel type, and the hot stamping die comprises a convex die insert and a concave die insert, which are arranged in a paired manner. The convex die insert is provided with a convex part so as to enable the cross section of the convex die insert to be convex. The concave die insert is provided with a concave part so as to enable the cross section of the concave die insert to be concave. The interiors of the convex and concave die inserts are respectively provided with a snakelike cooling water channel, and the depths of the snakelike cooling water channels are set in a manner that the bottoms of the snakelike cooling water channels are close to surface where the convex die insert with the concave die insert. The hot stamping die is simple in machining mode, has no cooling dead zone, and is uniform in cooling degree and speed. Moreover, the sizes of the inserts are not limited, thereby simplifying the structure of the die, improving the machining efficiency, achieving a good cooling effect, facilitating the assembly and maintenance, and reducing the cost.

Owner:BAOSHAN IRON & STEEL CO LTD

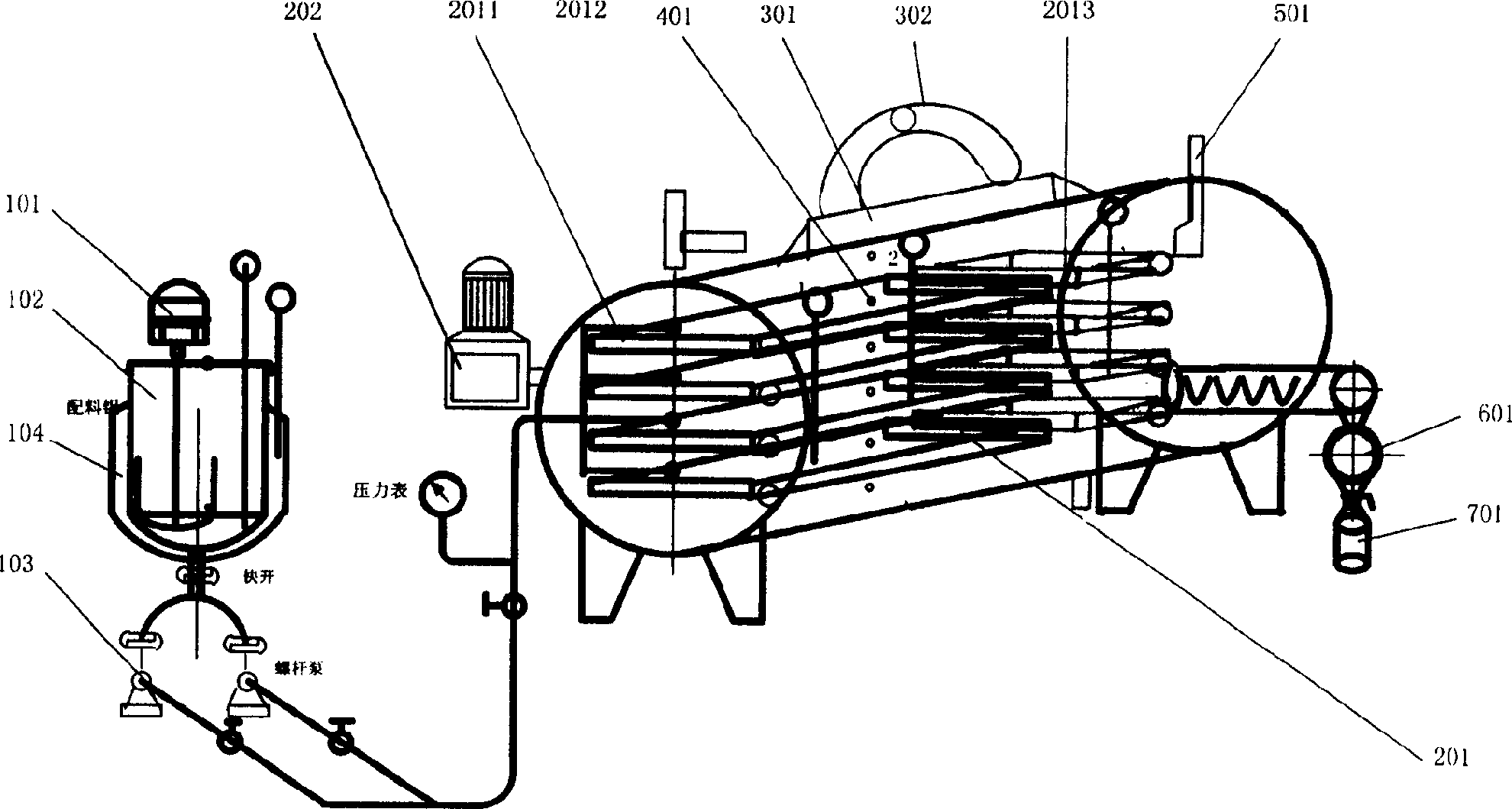

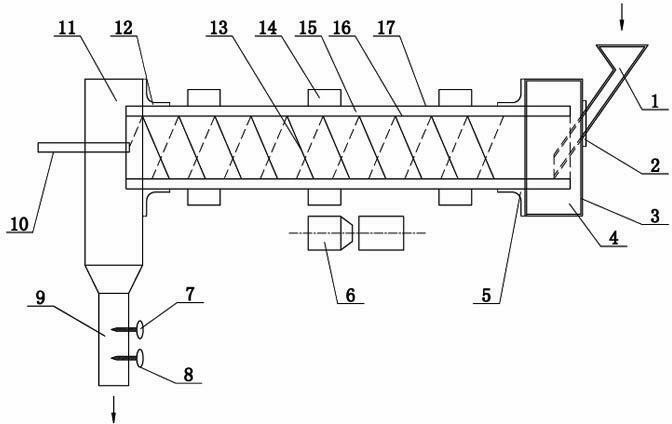

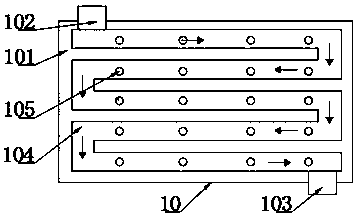

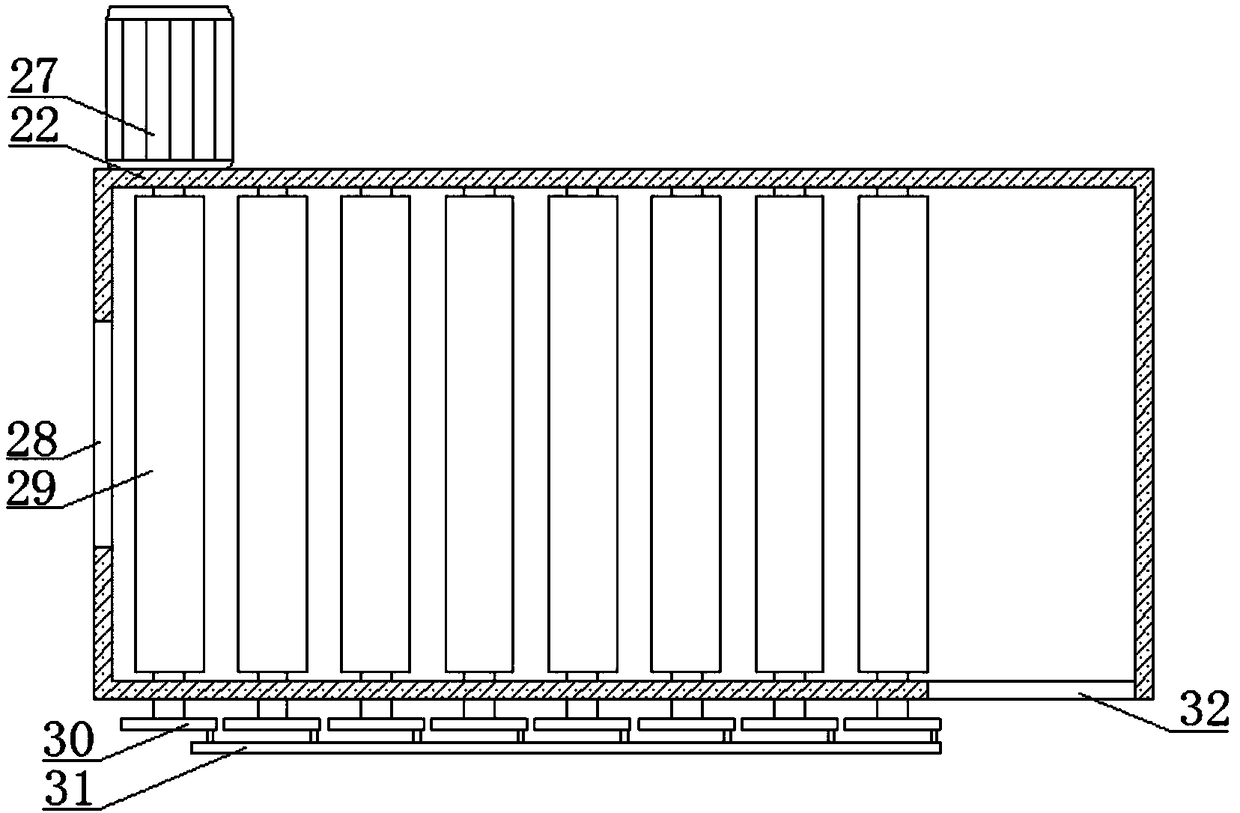

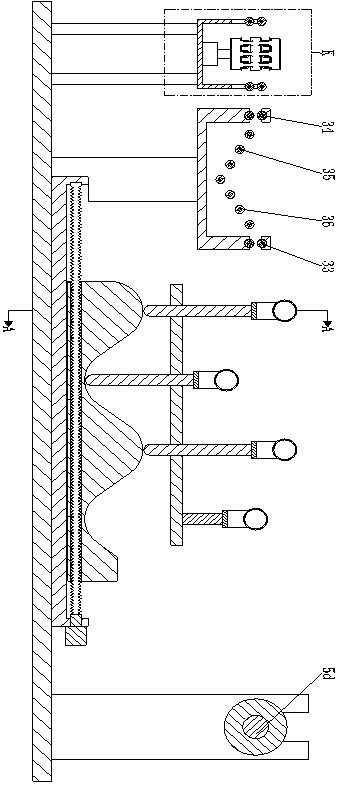

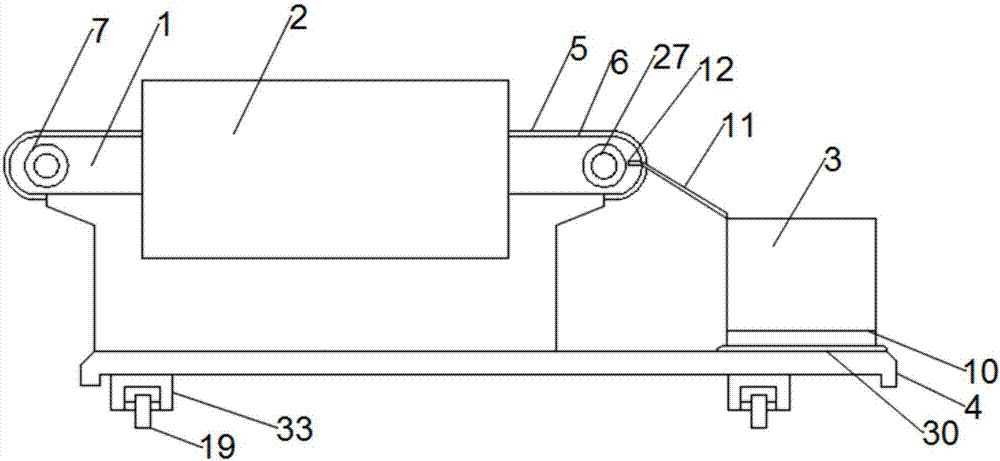

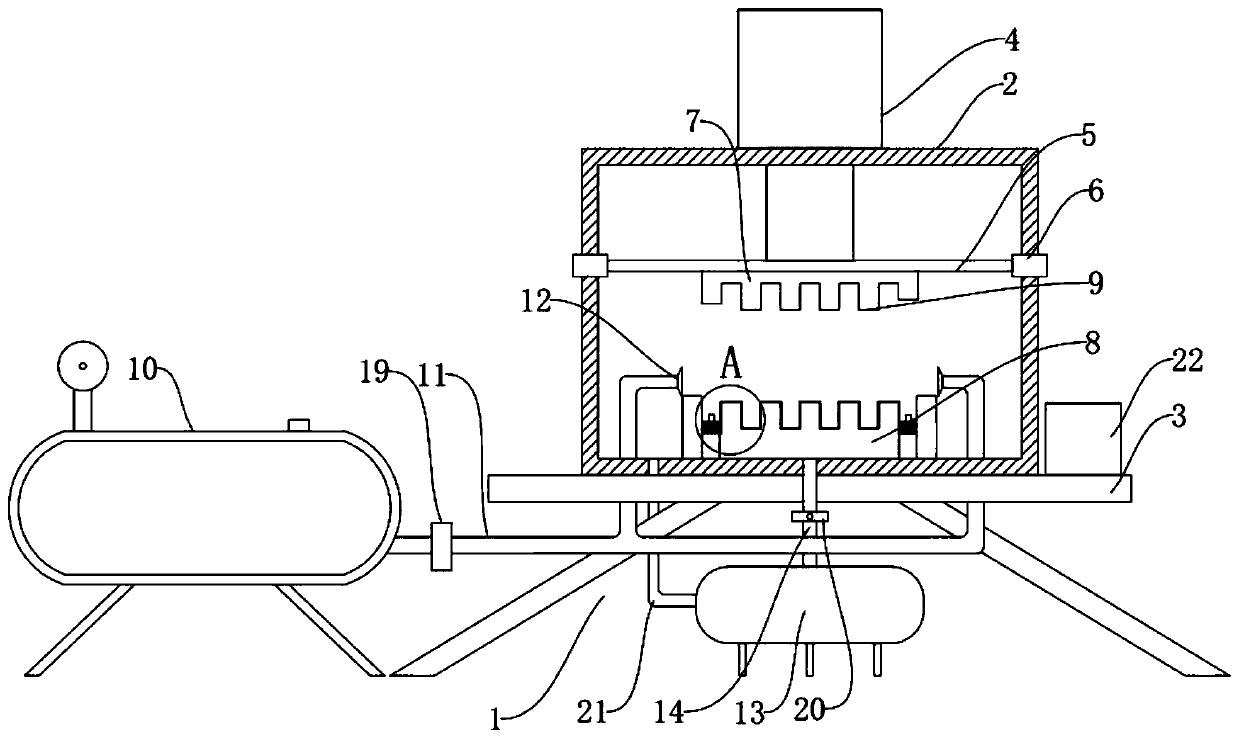

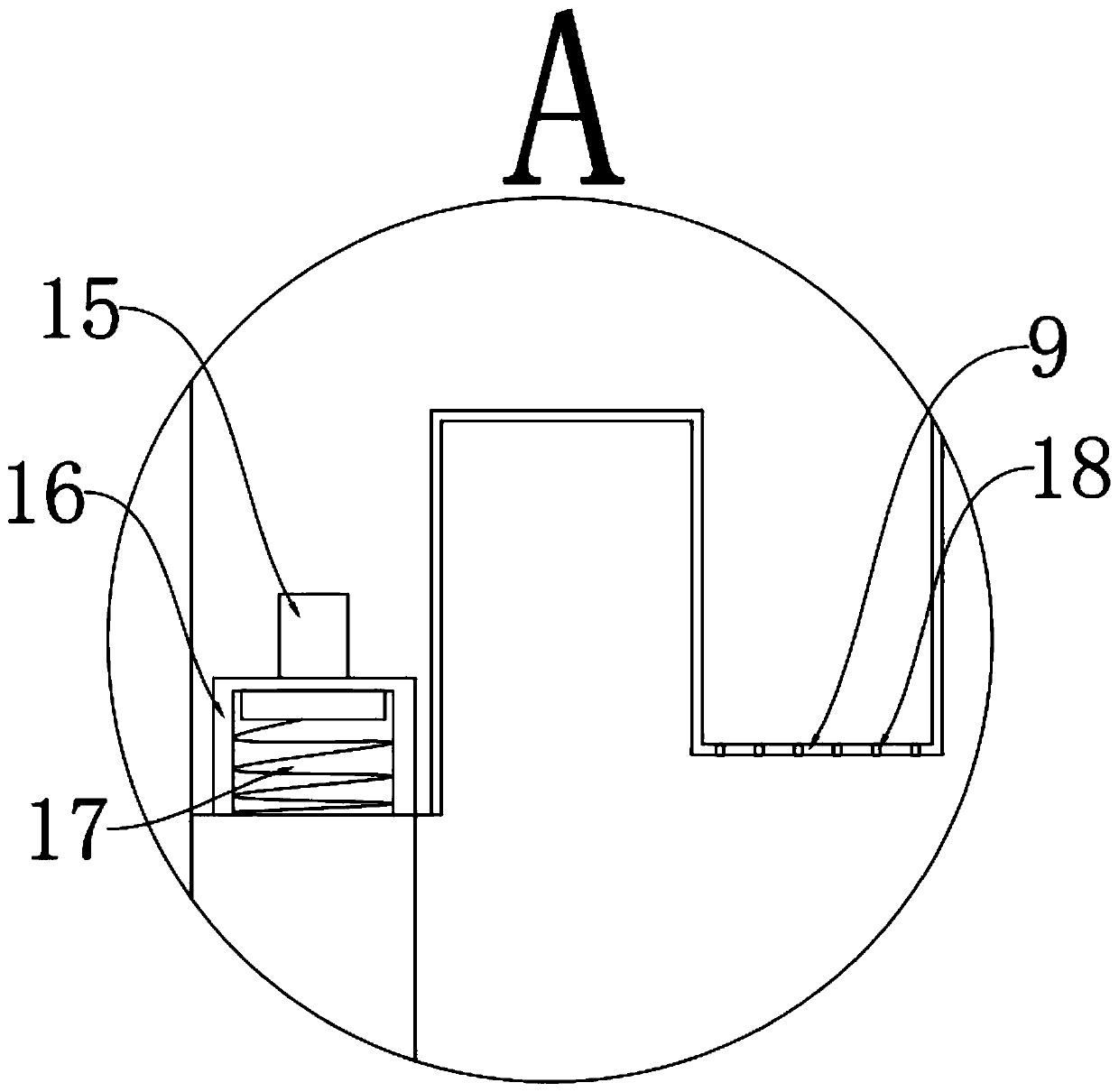

Automatic continuous-band freezing drier at vacuum low temperature

InactiveCN1854657AImprove product qualityPerfect solubilityDrying solid materials without heatDrying machinesEngineeringDistributor

The invention comprises a charging device, a drying belt driving device and a vacuum plant. The charging device includes a charger mixer, a dosage pot and a single-screw pump mounted one by one. The drying belt driving device is disposed in an enclosed vacuum chamber and has several layers of drying belts with the driving device inside. The vacuum plant includes a vacuum distributor and vacuum pipelines.

Owner:上海华琪实业有限公司

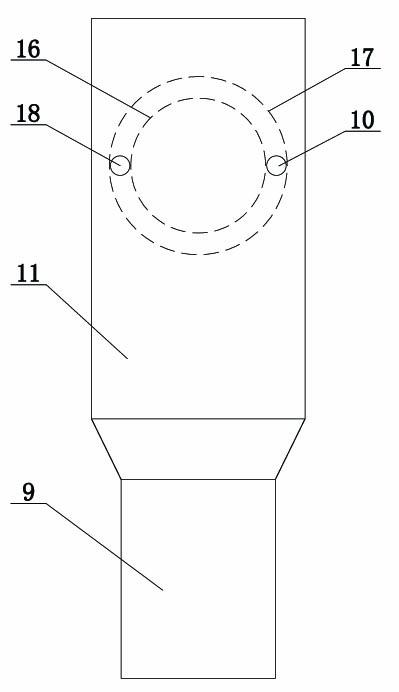

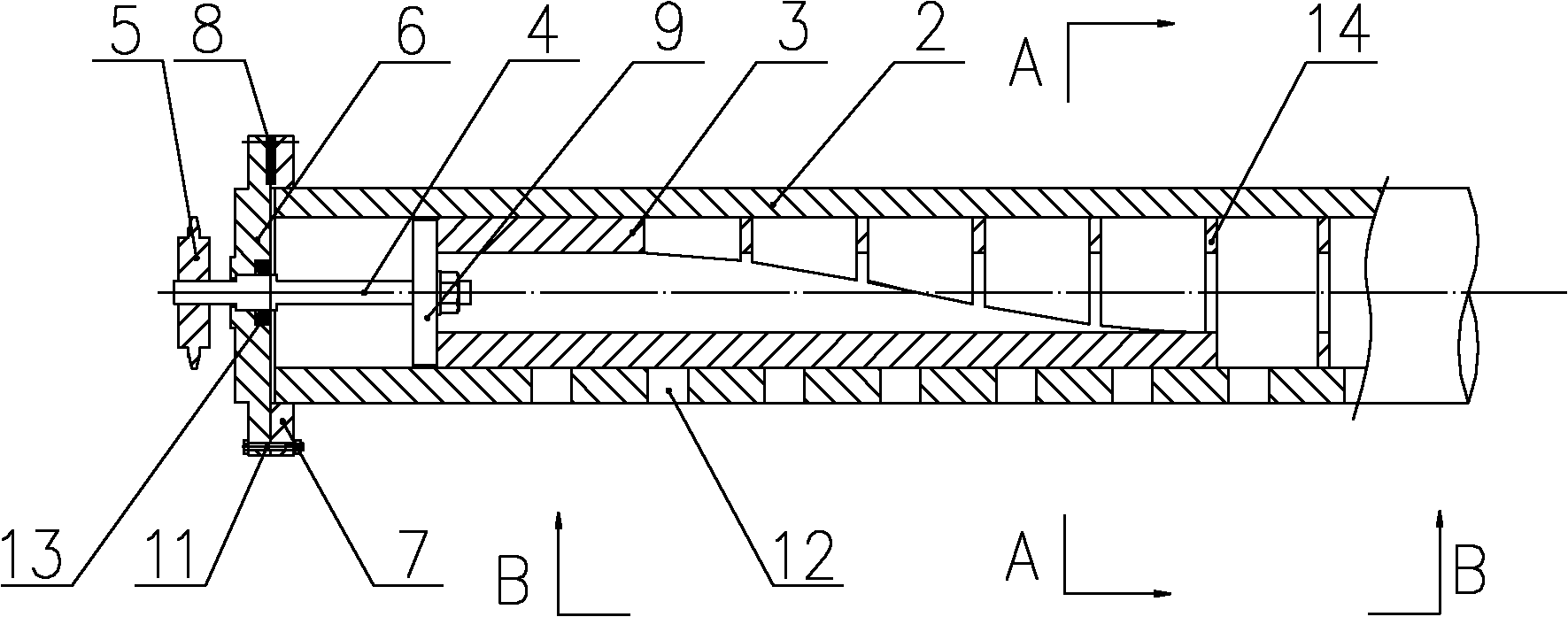

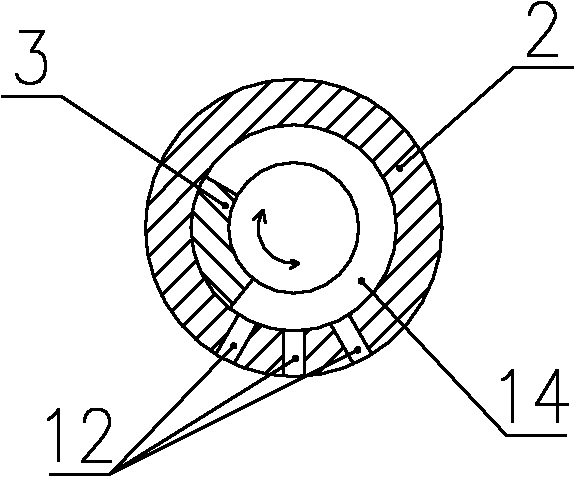

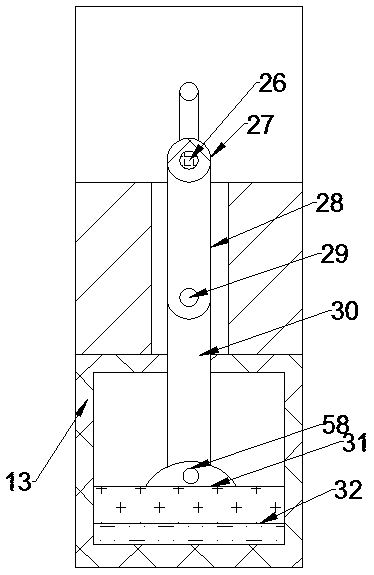

Cooling device for direct reduction iron

InactiveCN102435075AImprove cooling effectExtend walking timeHandling discharged materialThermodynamicsWater flow

The invention relates to a cooling device for direct reduction iron. The cooling device comprises a cooling cylinder, wherein a gear ring is fixed on the outer circumference of the cooling cylinder; a transmission device is used for driving the gear ring to rotate; one end of the cooling cylinder is connected with a feeding hopper, and the other end of the cooling cylinder is connected with a kiln tail box; the lower end of the kiln tail box is provided with a discharging pipe; a water sleeve is fixed on the inner wall of the cooling cylinder; the discharging end of the feeding hopper is arranged in the water sleeve; a cooling water channel is formed between the outer wall of the water sleeve and the inner wall of the cooling cylinder; one end of the cooling water channel is provided a water inlet and a water outlet; and the inner wall of the water sleeve is provided with spiral fins. In the invention, a cooling cylinder shell is forcedly cooled by adopting water sleeve type high-speed water current, and the walking path of the direct reduction iron in the cylinder is controlled by using the spiral fins, so that the walking time of the direct reduction iron in the cylinder is prolonged, the cooling efficiency is greatly increased, the diameter and the length of the cooling cylinder are reduced, the equipment weight is greatly reduced, and the transmission power and power consumption of the equipment are lowered; and meanwhile, no steam is dissipated, so that the environmental pollution is improved greatly.

Owner:李世杰 +1

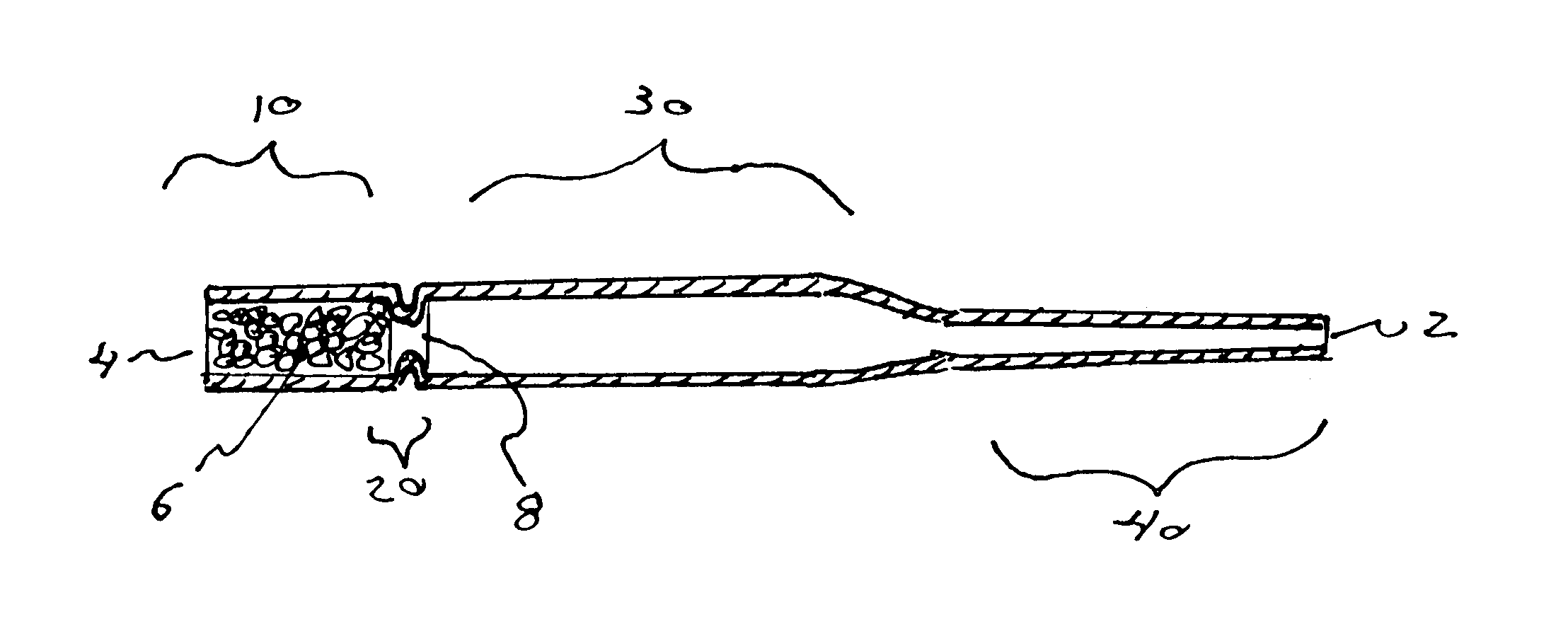

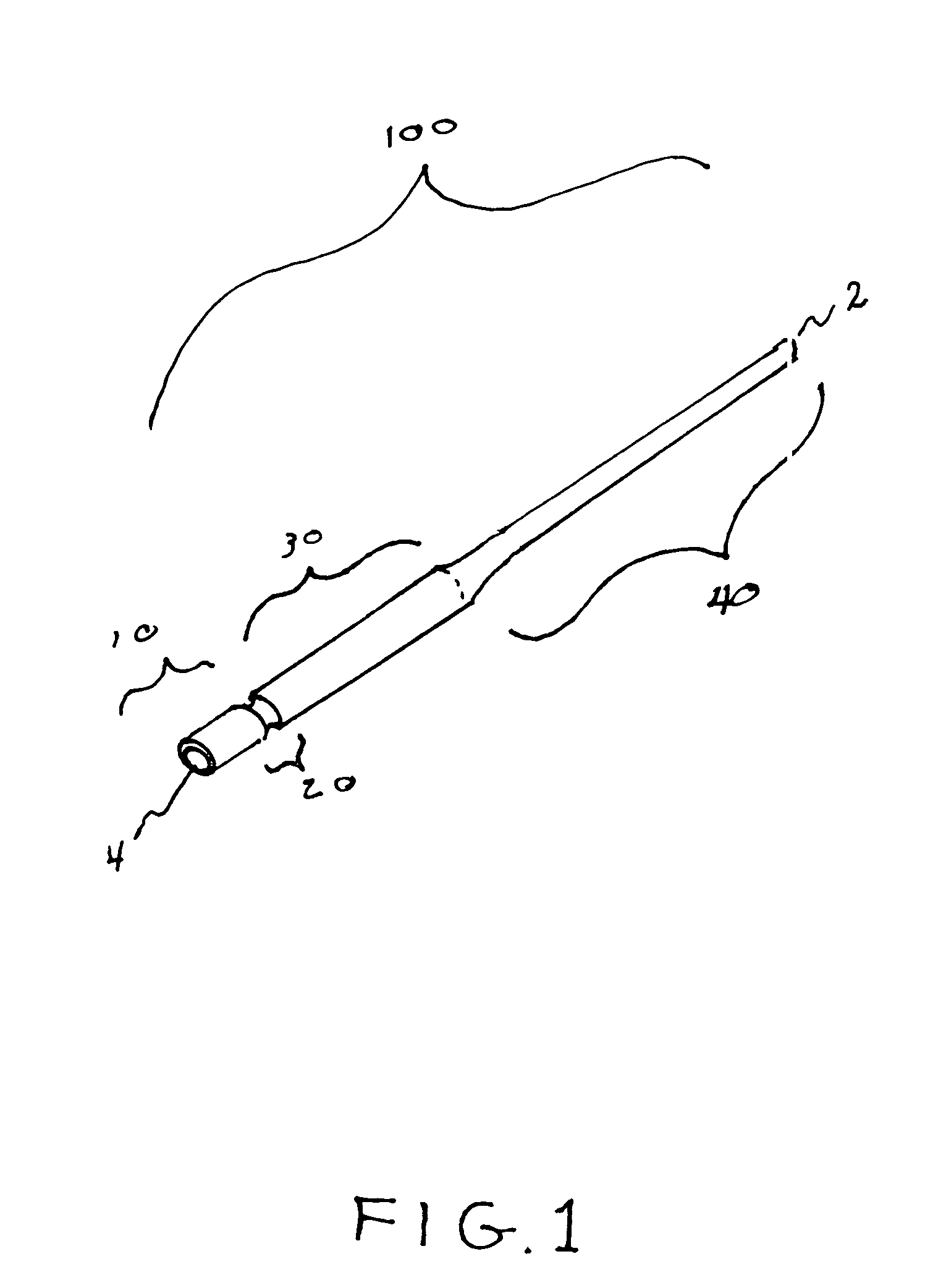

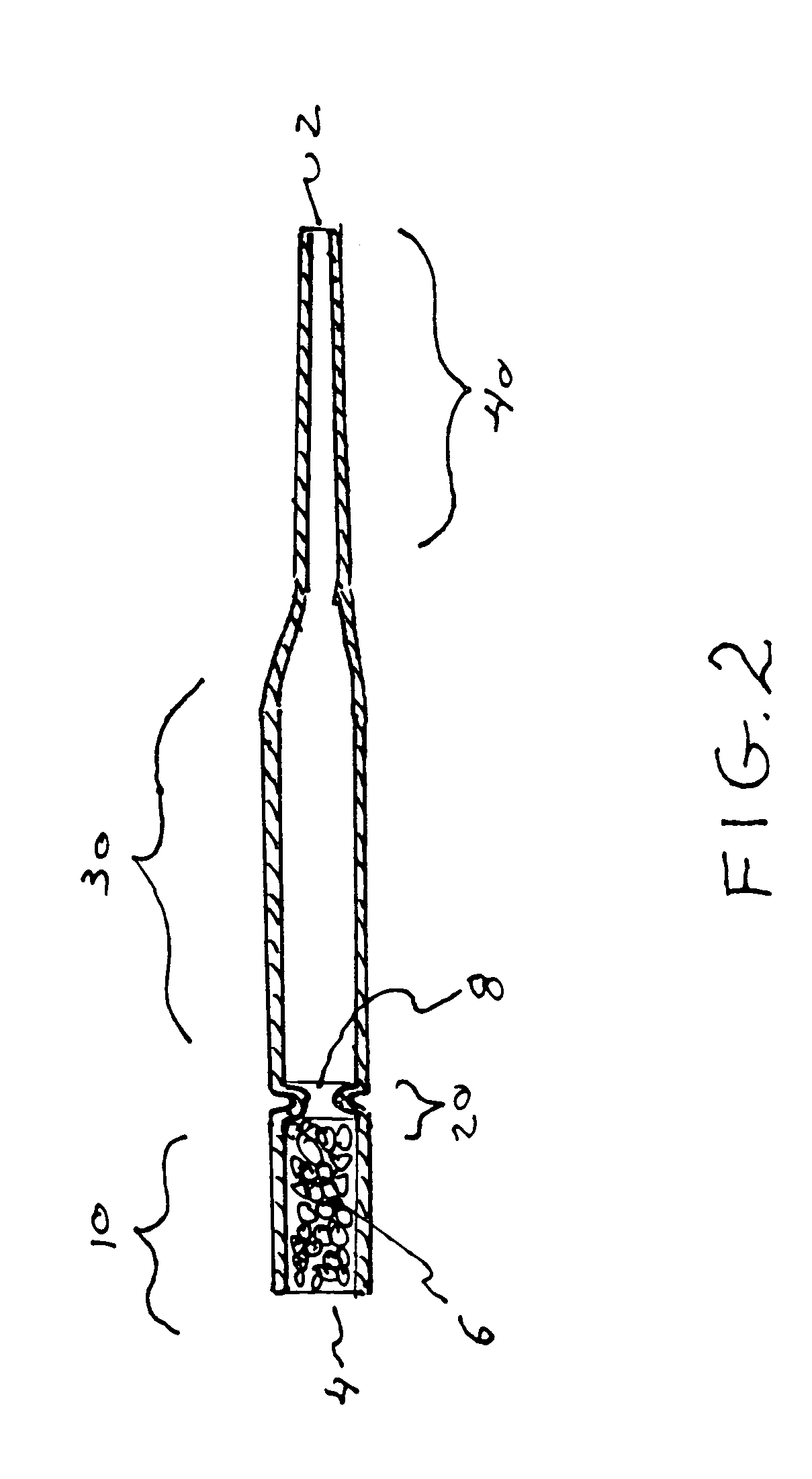

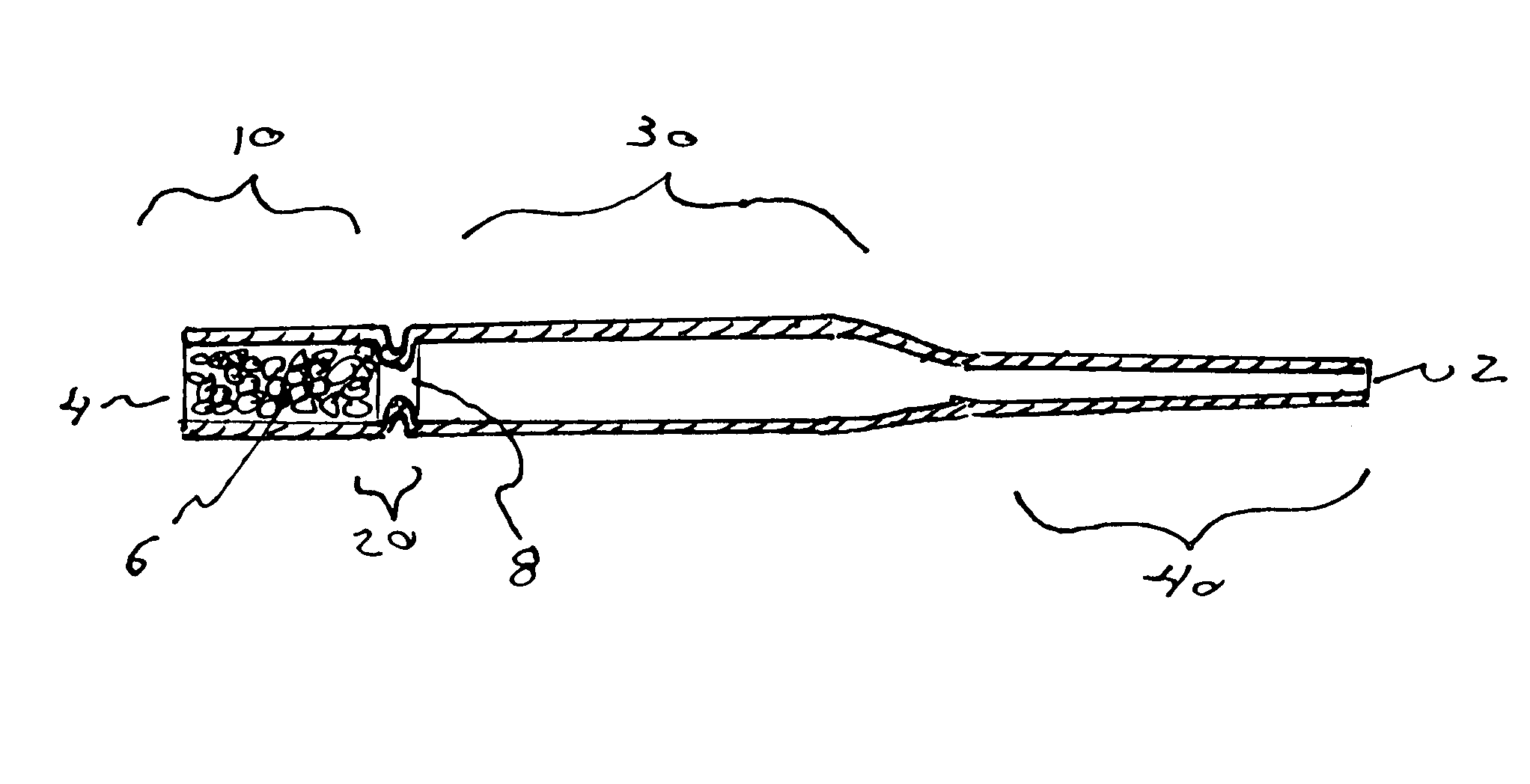

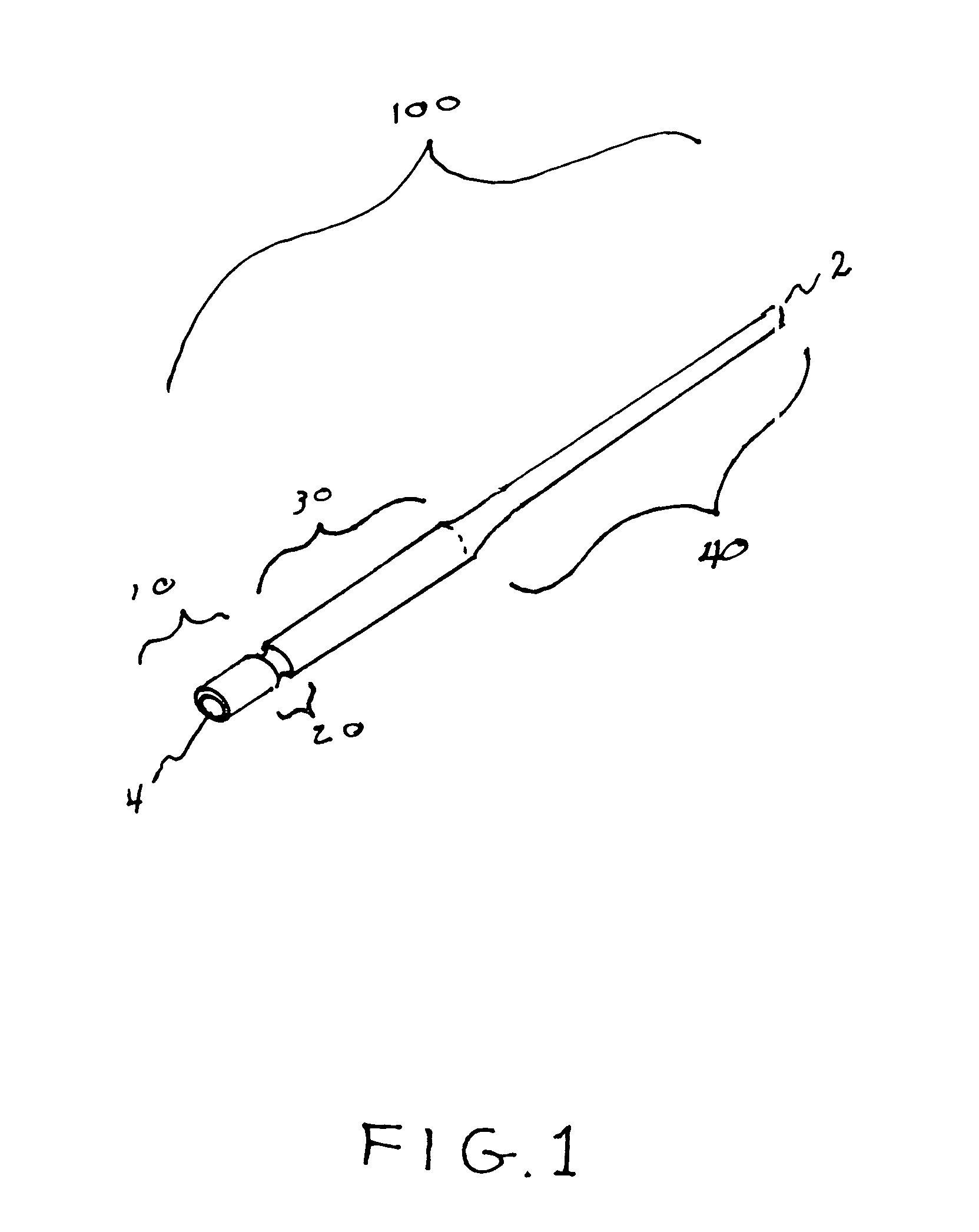

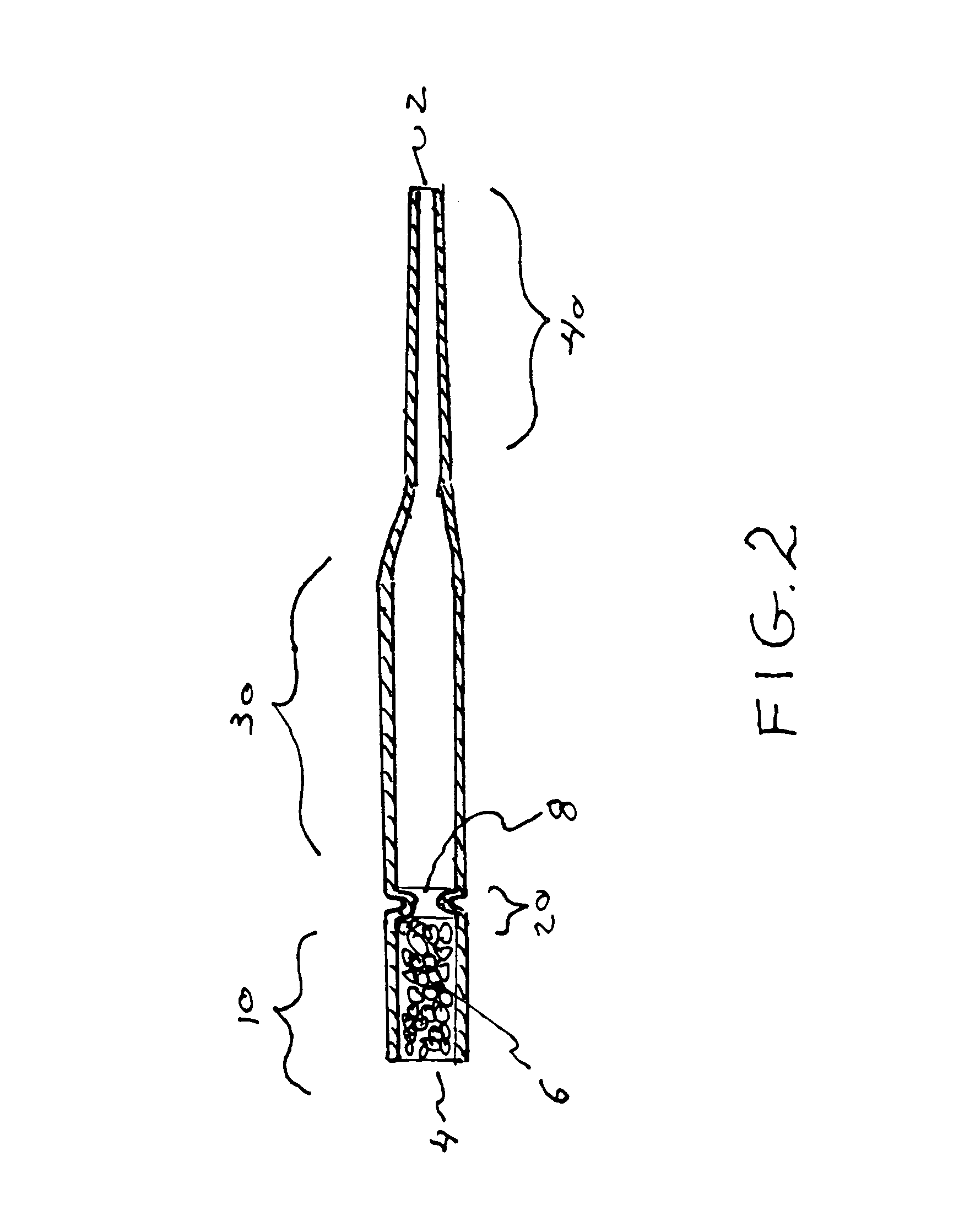

Glass cigarette

InactiveUS20130269716A1Avoiding negative social stigmaEfficient low burn rateTobacco pipesMouth pieceSilicate glass

A glass cigarette with an elongate hollow tubular borosilicate glass member. The glass member has a first open ended cylindrical smoking material retaining portion, a second cylindrical smoke cooling passage portion and a third tapered tubular mouthpiece portion. A restrictor portion joins the first portion to the second portion. The third tapered portion is contiguous with and fixed to the second portion. The mouthpiece is open ended at the tapered end. A preferred embodiment includes the overall length of the glass cigarette is approximately 106 mm.

Owner:HOANG NAM +1

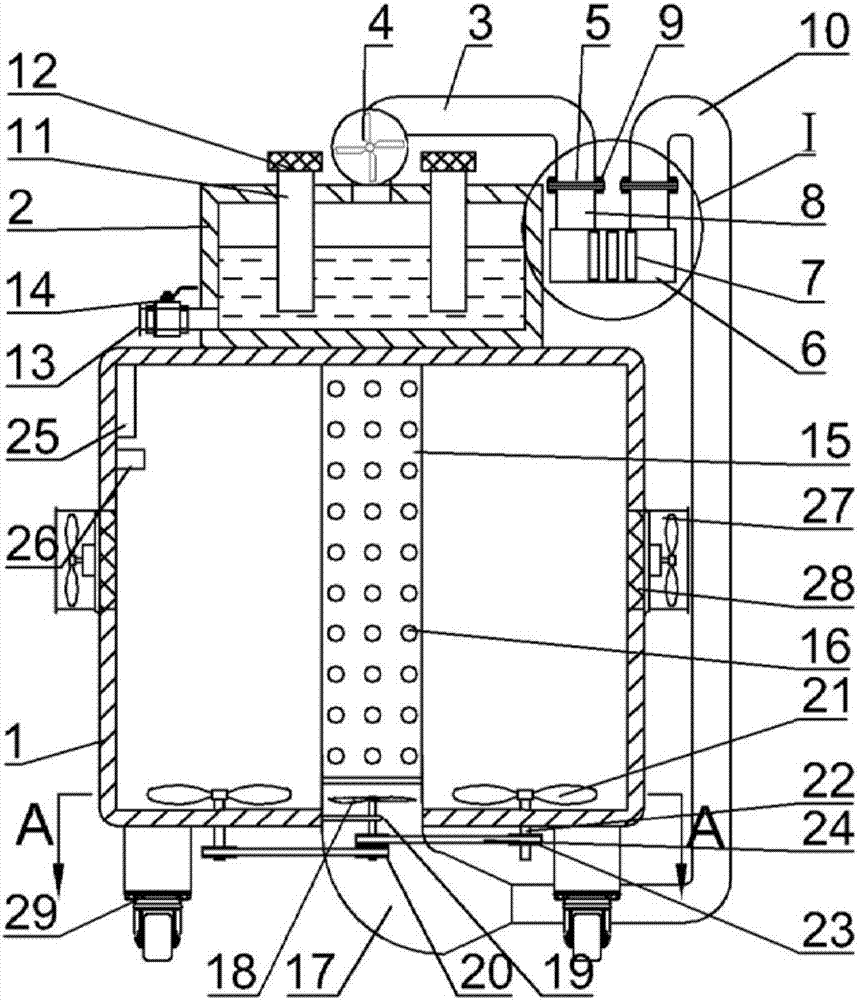

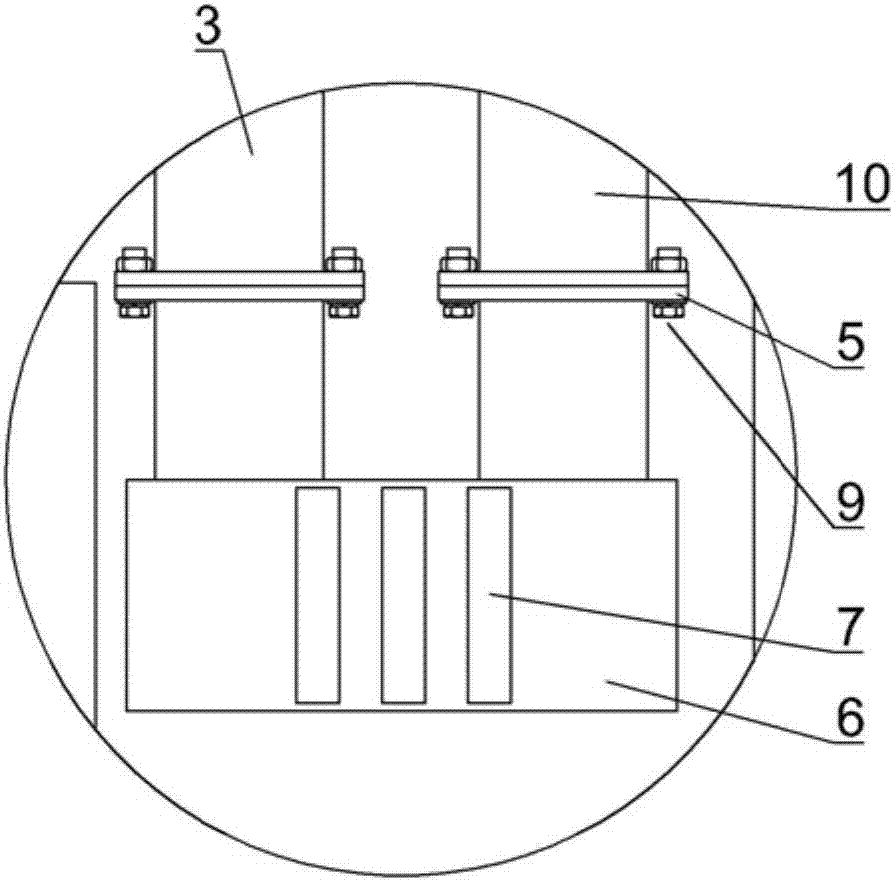

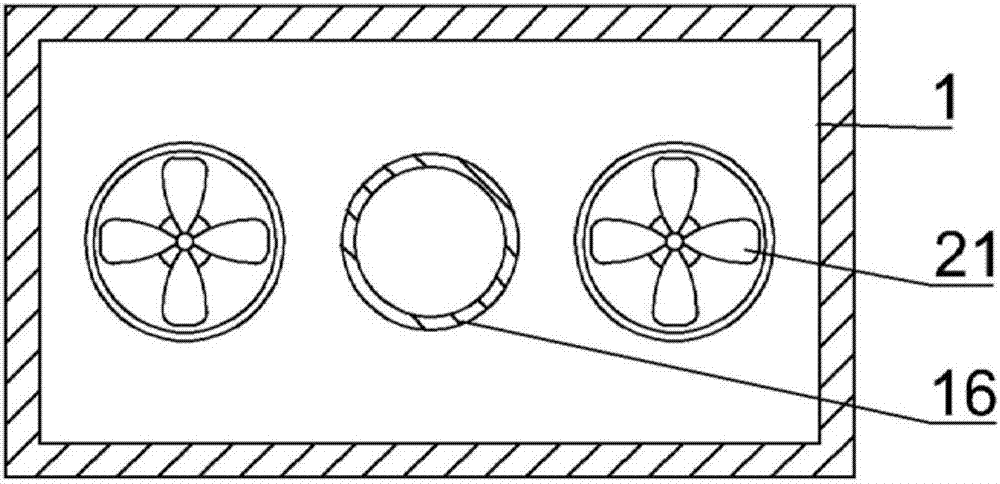

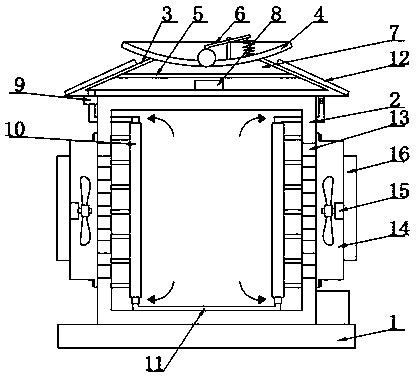

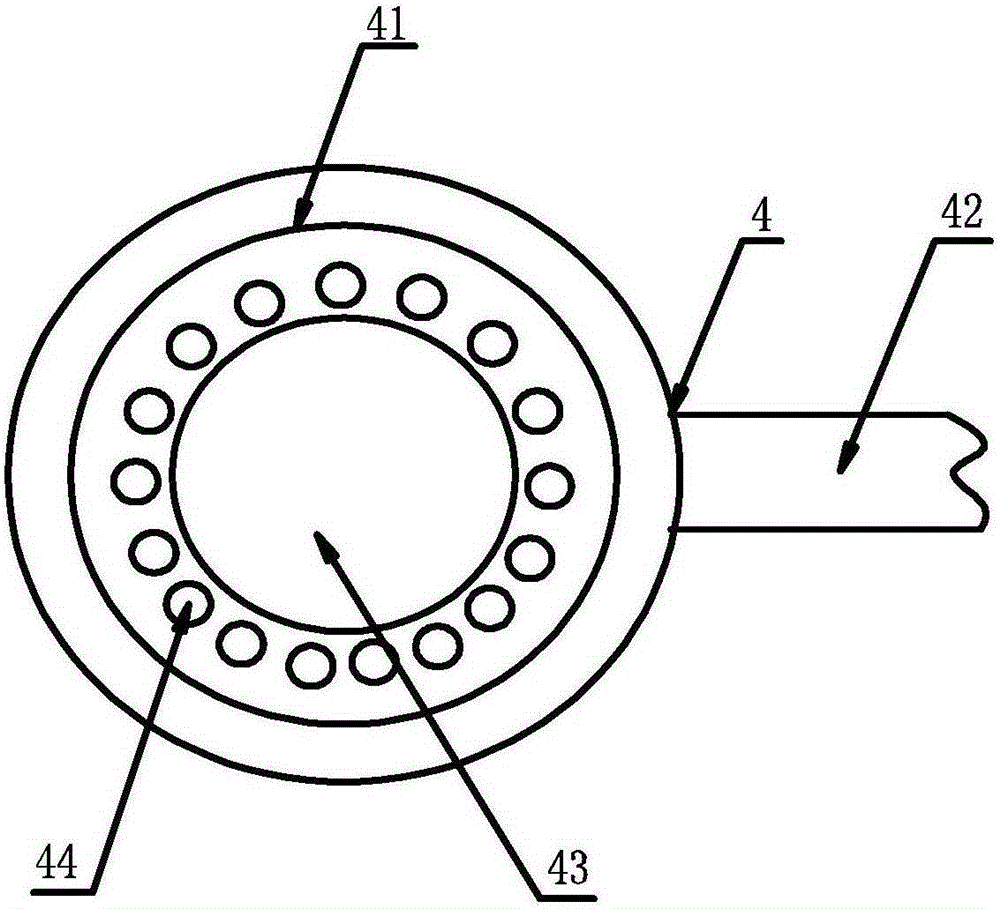

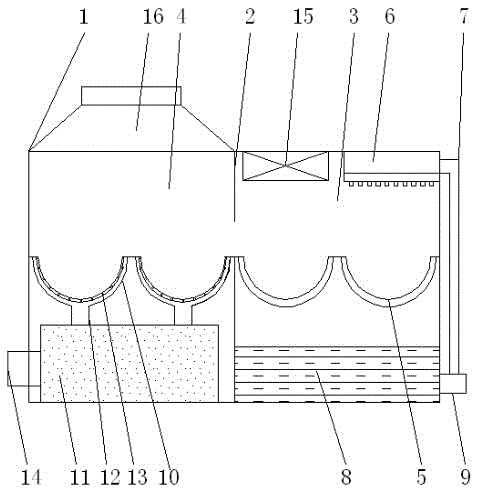

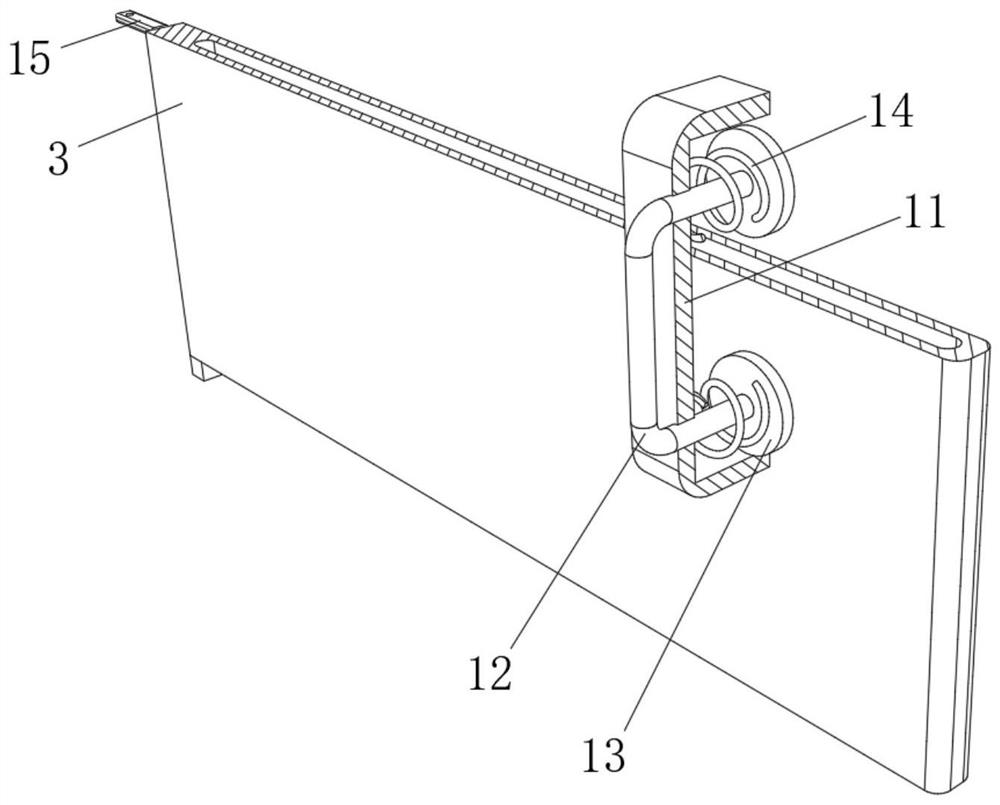

Cooling equipment for box-type substation and box-type substation

InactiveCN111211509AImprove efficiencyImprove cooling qualitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsTransformerAir treatment

The invention discloses cooling equipment for a box-type substation and a box-type substation, and belongs to the technical field of box-type substations. The box-type substation comprises a base anda box-type substation main body; a water storage shell is arranged at the top of the box-type substation main body; the left side and the right side of an inner cavity of the box-type substation mainbody are provided with water cooling block structures of the same structure; fan covers are fixedly arranged on the outer walls of the left side and the right side of the box-type substation main bodythrough screws; vent holes communicated with the fan covers are uniformly formed in the outer walls of the left side and the right side of the box-type substation main body; heat dissipation exhaustfans are arranged in the fan covers through fan brackets; and air treatment mechanisms of the same structure are screwed to the sides, far away from each other, of the fan covers at the left side andthe right side of the box-type substation main body. According to the box-type substation, air cooling and water cooling are matched to improve the cooling efficiency and the cooling quality in the box-type transformer substation main body, high-temperature damage to electrical apparatus elements in the box-type substation main body is avoided, and working stability is guaranteed.

Owner:安徽华明电气设备有限公司

Glass cigarette

InactiveUS8967153B2Avoiding negative social stigmaEfficient low burn rateTobacco pipesSilicate glassEngineering

A glass cigarette with an elongate hollow tubular borosilicate glass member. The glass member has a first open ended cylindrical smoking material retaining portion, a second cylindrical smoke cooling passage portion and a third tapered tubular mouthpiece portion. A restrictor portion joins the first portion to the second portion. The third tapered portion is contiguous with and fixed to the second portion. The mouthpiece is open ended at the tapered end. A preferred embodiment includes the overall length of the glass cigarette is approximately 106 mm.

Owner:HOANG NAM +1

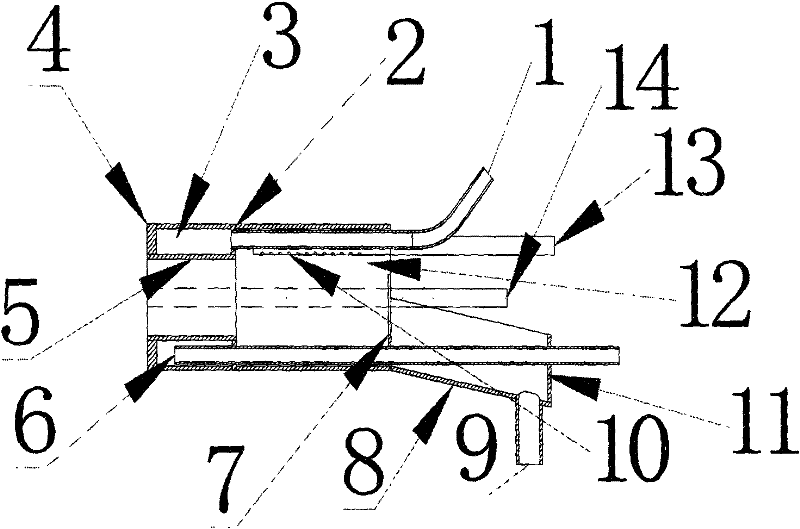

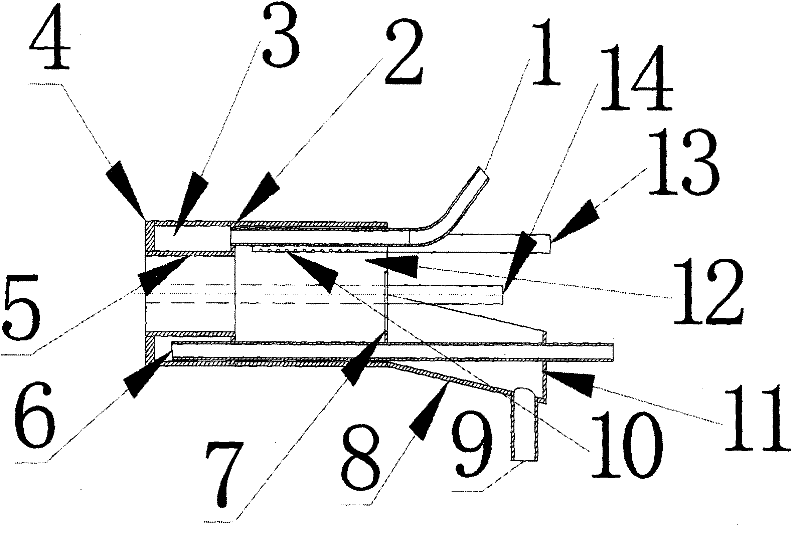

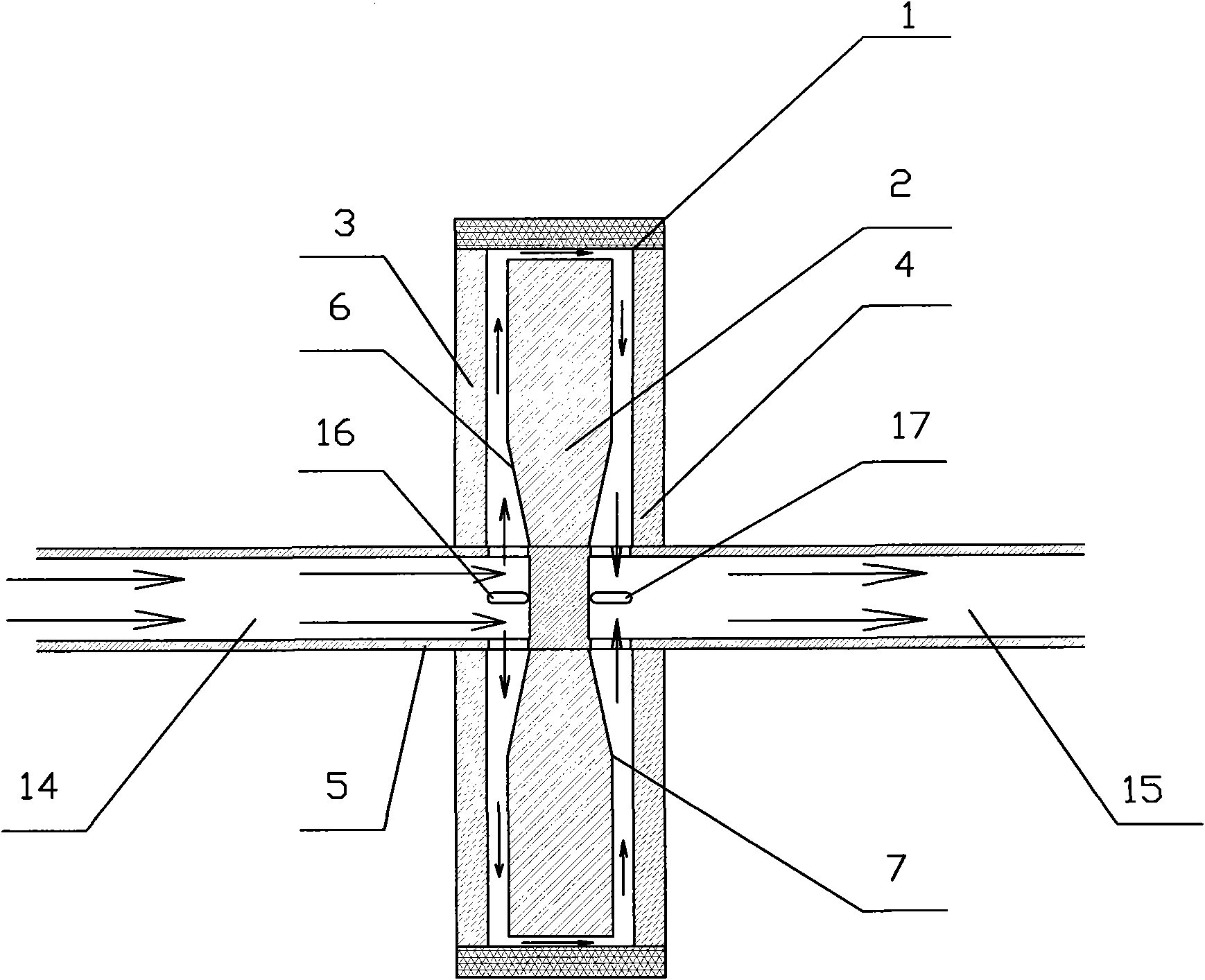

Indirect cooling and direct cooling combined electrode water jacket

InactiveCN102209408AEffective protectionExtended service lifeElectric discharge heatingElectricityGlass melting

The invention discloses an indirect cooling and direct cooling combined electrode water jacket, which belongs to the technical fields of glass melting devices and inorganic material high-temperature electric melting technologies and mainly solves the problem that the conventional direct cooling type or indirect cooling type molybdenum electrode protection device cannot protect a molybdenum electrode well. The indirect cooling and direct cooling combined electrode water jacket is mainly characterized by comprising a water jacket shell, and a direct cooling water jacket water inlet pipe, a direct cooling water jacket water outlet pipe, a direct cooling water collector, a direct cooling water jacket water baffle and a temperature measuring device which are arranged in the water jacket shell, wherein the direct cooling water jacket water inlet pipe is provided with spray holes; the inner side part of the water jacket shell is provided with a closed indirect cooling cavity, an indirect cooling water jacket water outlet and an indirect cooling water jacket water inlet pipe; the closed indirect cooling cavity is formed by an indirect cooling cavity rear baffle, an indirect cooling cavity front baffle, an indirect cooling cavity inner wall pipe and the water jacket shell; and the indirect cooling water jacket water outlet and the indirect cooling water jacket water inlet pipe are connected with the indirect cooling cavity. The indirect cooling and direct cooling combined electrode water jacket has the characteristics of effectively protecting the molybdenum electrode, reducing oxidation of the molybdenum electrode, cooling the wall of a melting furnace and prolonging the service life of the melting furnace, and is mainly used for optical glass melting furnaces or other electrode protection water jackets of electrodes, heated by the molybdenum electrode.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

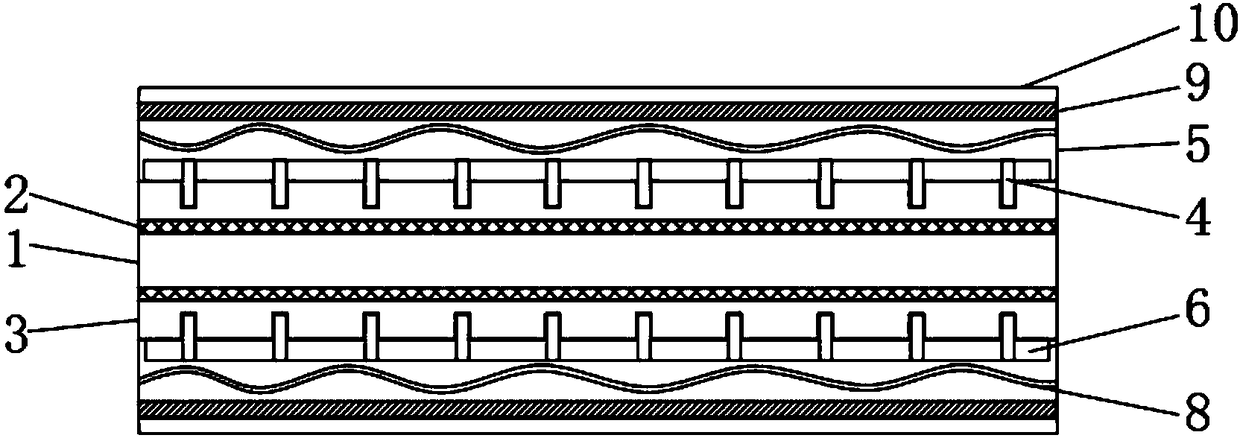

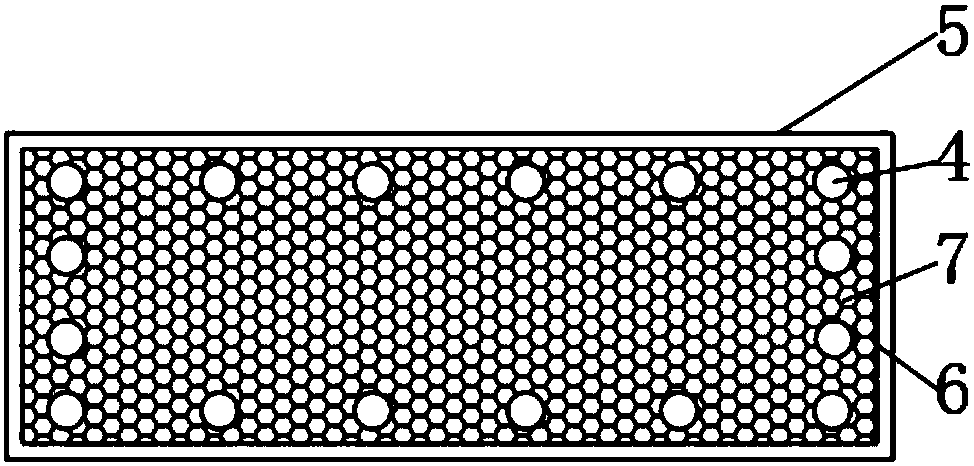

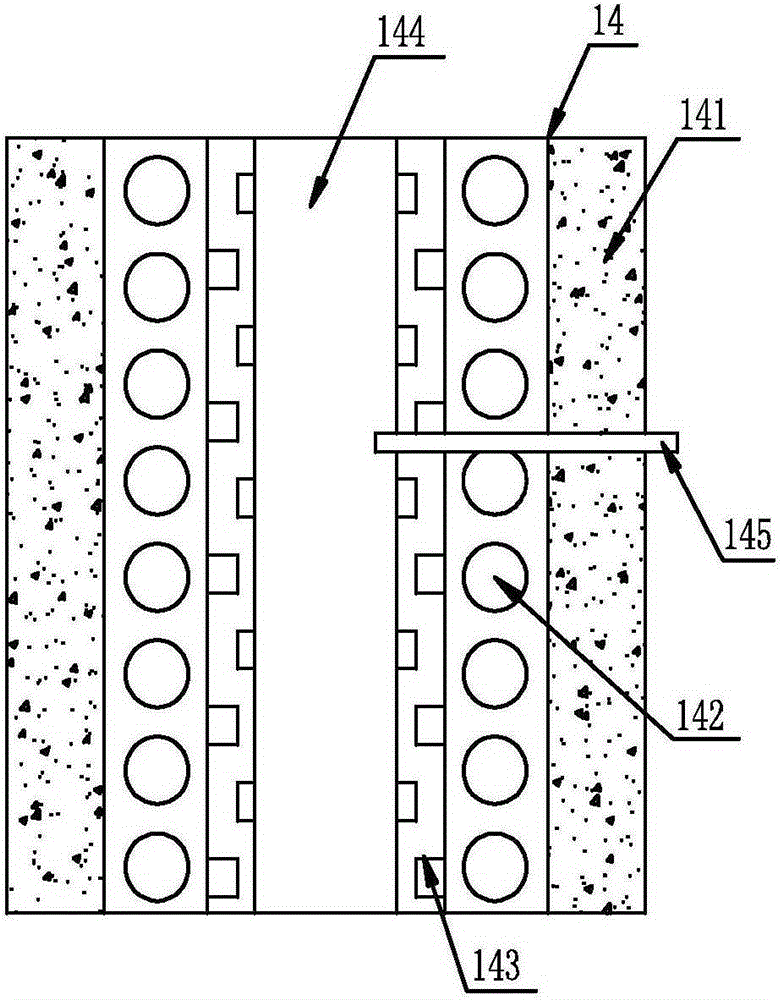

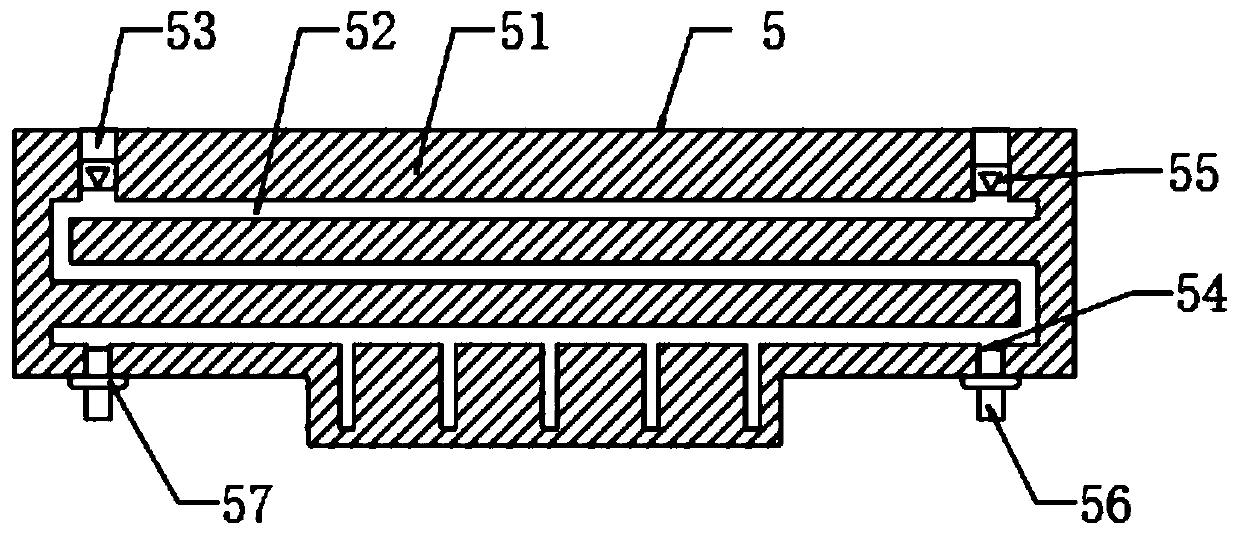

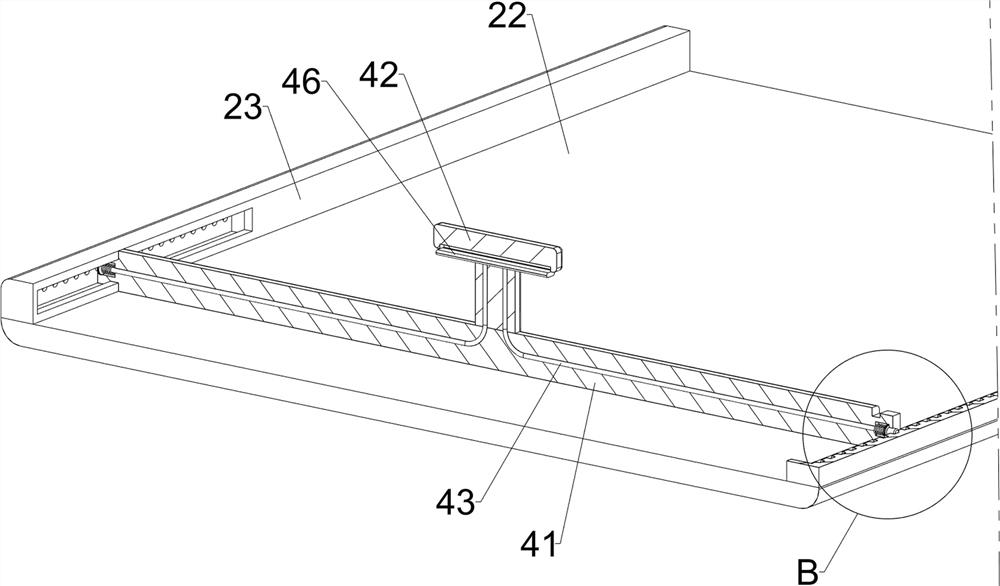

Flexible printed circuit board used for vehicle lamp circuit

PendingCN108495447AImprove cooling efficiencyImprove cooling qualityCircuit thermal arrangementsSoftware engineeringHoneycomb

The invention discloses a flexible printed circuit board used for a vehicle lamp circuit in the flexible printed circuit board technology field. The flexible printed circuit board comprises a flexiblebase material plate. The top and the bottom of the flexible base material plate are provided with bonding layers. One side of each bonding layer, which is far away from the flexible base material plate, is provided with a heat conduction layer. One side of the heat conduction layer, which is far away from each bonding layer, is provided with a heat dissipation layer. The inner cavity of a grooveis vertically provided with a metal heat dissipation rod. The other end of the metal heat dissipation rod is connected to the heat conduction layer. The outer wall of the inner cavity of the groove isuniformly provided with honeycomb heat dissipation holes. A heat dissipation cavity is arranged in the heat dissipation layer. One side of the heat dissipation layer, which is far away from the heatconduction layer, is provided with a heat dissipation fin. The two surfaces of the flexible printed circuit board carry out heat dissipation, heat dissipation efficiency is rapid and heat dissipationquality is high; through arranging the heat conduction layer, the heat generated by the flexible base material plate during usage is conducted away and is transmitted into the heat dissipation layer through the metal heat dissipation rod; and a metal heat dissipation wire uniformly disperses the heat and the heat is timely discharged through the heat dissipation fin so that a whole electrical component can be prevented from being damaged.

Owner:扬州市玄裕电子有限公司

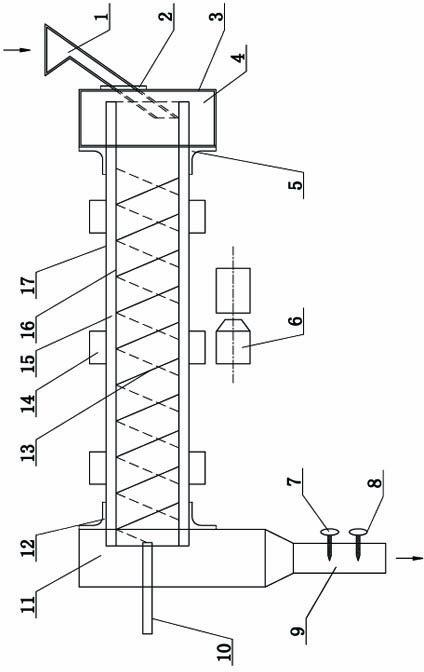

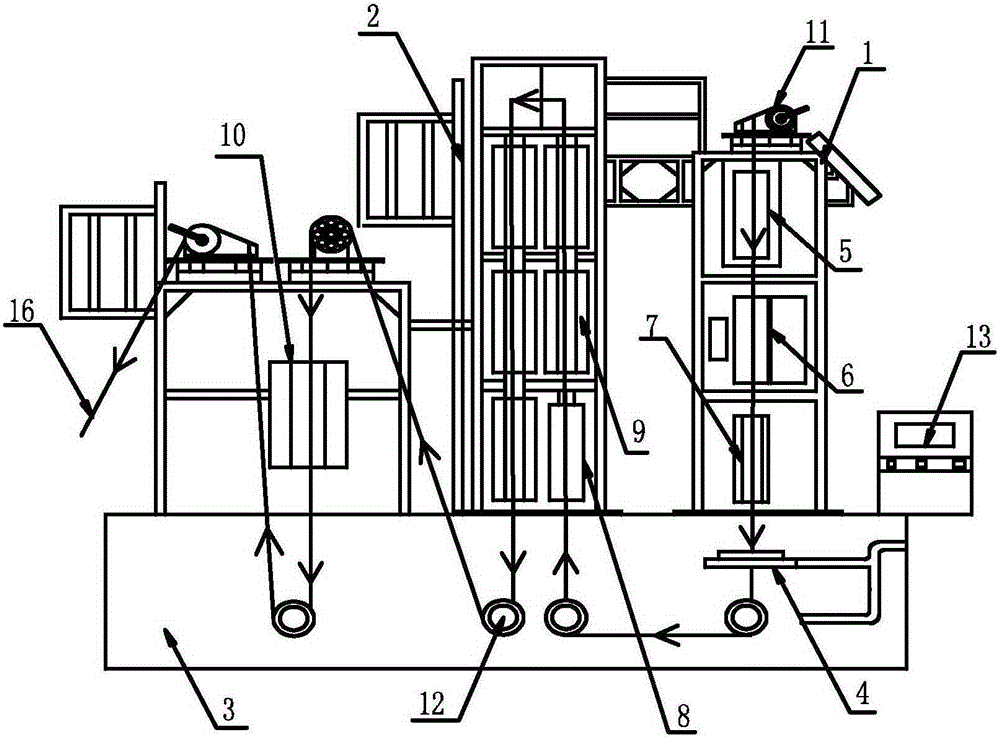

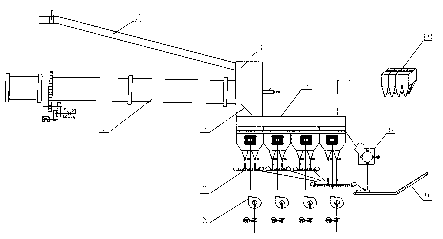

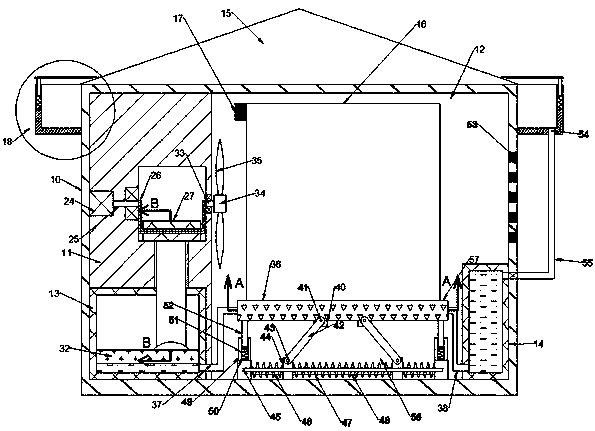

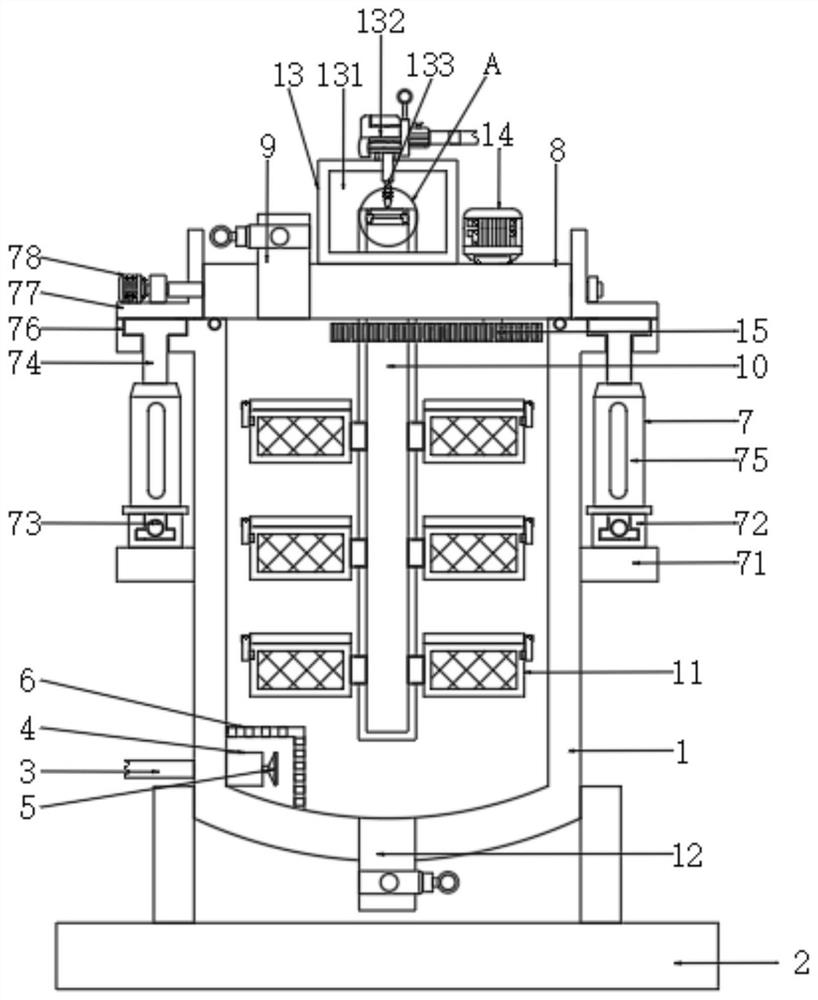

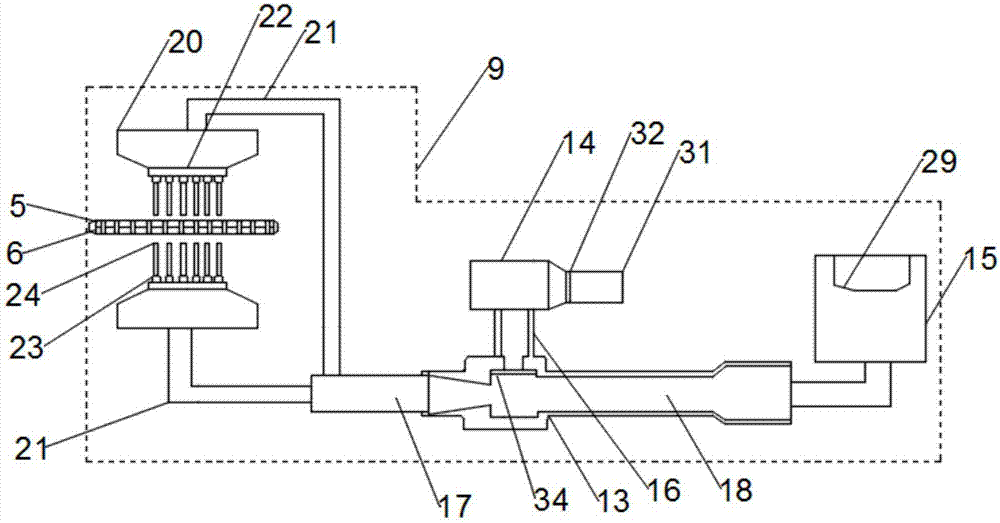

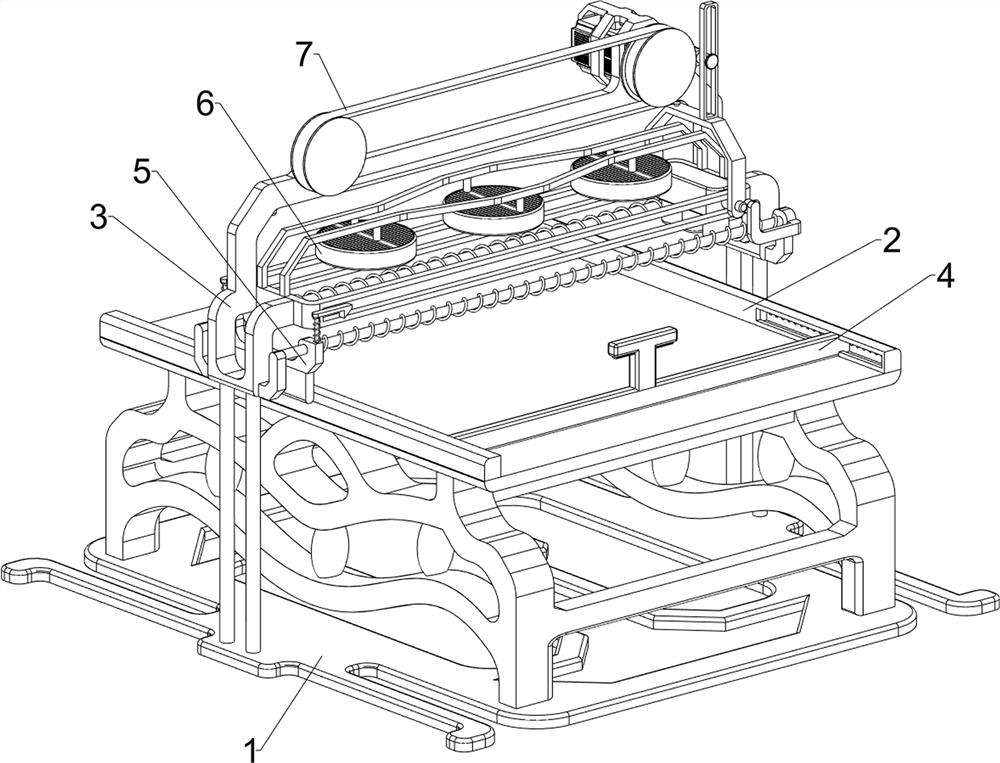

Heat treatment device for round-link chain and application method thereof

ActiveCN105349757AHigh degree of integrationImprove work efficiencyFurnace typesHeat treatment furnacesHardnessLath

The invention discloses a heat treatment device for a round-link chain and an application method thereof. The device comprises a quenching part and a tempering part which are sequentially arranged, wherein first cooling parts are arranged at the quenching part and the tempering part; the quenching part is provided with a quenching temperature regulating box; the tempering part is sequentially provided with an uniform-temperature tempering heating box, at least one tempering temperature regulating box and a differential-temperature tempering heating box; the quenching temperature regulating box is provided with a second cooling part. The device has the characteristics of being high in integration degree and high in working efficiency; after the round-link chain is quenched, an uniform and small low-carbon lath martensite structure can be obtained; the quenching quality is high; the second cooling part and the first cooling parts are correspondingly connected to a cooling source, so that the cooling quality can be improved, and the requirements of each part of the round-link chain on hardness and toughness can be met.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

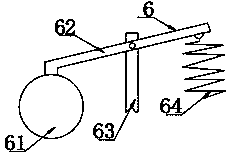

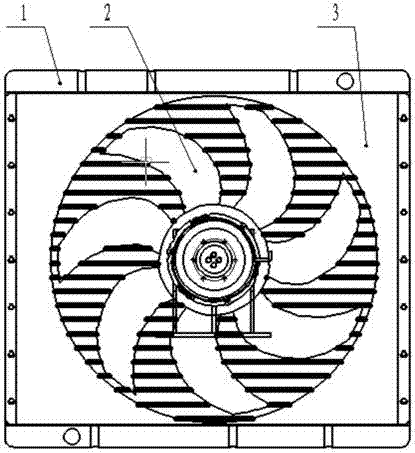

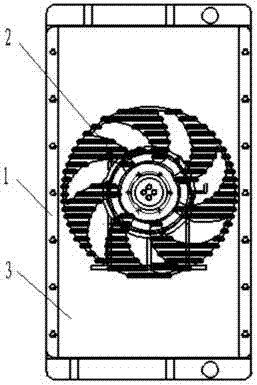

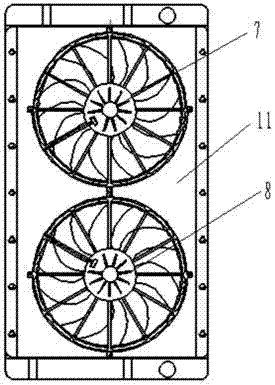

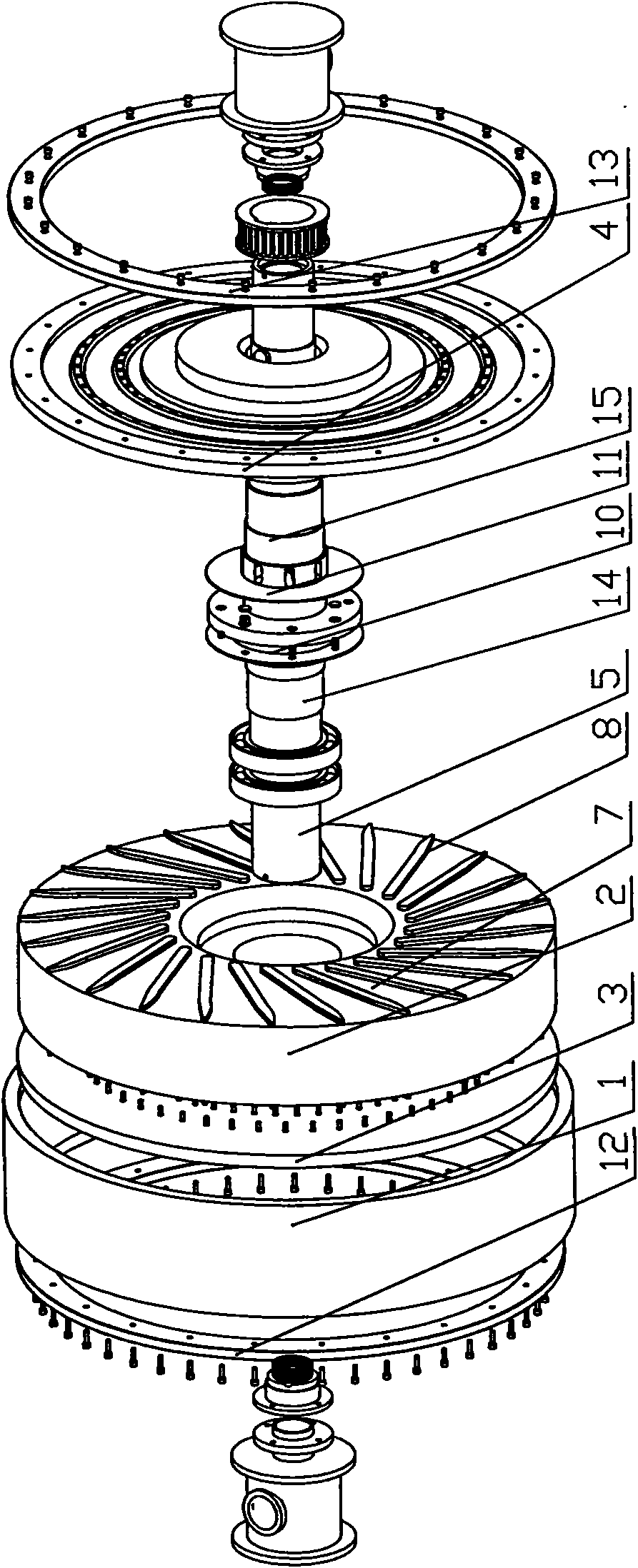

Constant temperature control device of combined type fan electronic control system

ActiveCN104295356AReduce noiseSolve the requestCoolant flow controlMeasurement deviceMechanical fanControl theory

A constant temperature control device of a combined type fan electronic control system comprises a water tank and a mechanical fan cowl arranged at the rear end of the water tank, wherein a mechanical fan air inducing ring is arranged on the mechanical fan cowl; a mechanical fan is fixed in the mechanical fan air inducing ring, and electronic fan cowls are arranged at the front end of the water tank; electronic fan air inducing rings are arranged on the electronic fan cowls; electronic fans are fixed to the electronic fan air inducing rings; the mechanical fan is connected with an electronic control clutch, and the electronic control clutch is connected with a belt wheel; the electronic control clutch is fixed to a clutch support. By means of the constant temperature control device of the combined type fan electronic control system, different working conditions of an engine can be distinguished, the requirement for lower temperature rising and high temperature radiating of the engine are effectively met, the engine power consumed by a cooling system is reduced, fan noise is lowered, the heat efficiency of the engine is high, the steam temperature deviation is stable, and the service life of the engine is prolonged.

Owner:LONGKOU ZHONGYU THERMAL MANAGEMENT SYST SCIAND TECH

Cooling roller

The invention relates to a cooling roller, comprising a copper sleeve, an inner core and two cover plates. A gap between the copper sleeve and the inner core is less than 3mm; the inner core is a solid cylinder structure; two end surfaces of the inner core towards the cover plates are respectively a water inlet surface and a water outlet surface; a plurality of protruded ribs are respectively shaped on the water inlet surface and the water outlet surface; the ribs extend from the centre of the inner core to the periphery of the same; and a diversion groove suitable for cooling medium to pass through is formed between every two adjacent ribs. The cooling roller disclosed by the invention ensures that circulating water on the inner surface of the copper sleeve is rapidly updated and has good dynamic balance performance during high-speed rotation, therefore, the cooling capacity of the cooling roller is obviously improved.

Owner:滨州益谦非晶金属材料科技有限公司

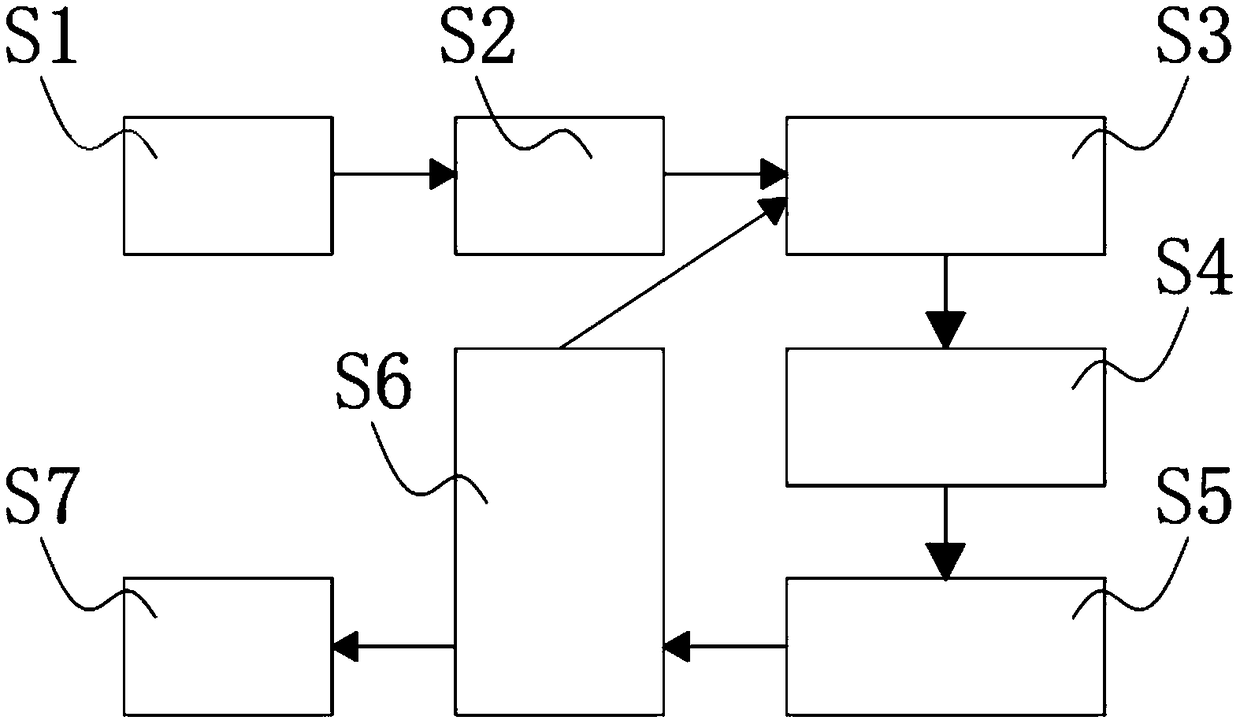

Crushing and recovery processing method of waste wood-plastic composite

ActiveCN109291323AEfficient crushingEasily brokenPlastic recyclingMechanical material recoveryEngineeringLiquid nitrogen

The invention discloses a crushing and recovery processing method of waste wood-plastic composite. The crushing and recovery processing method comprises the following steps: S1, collecting waste wood-plastic material and carrying out primary cleaning on the collected waste wood-plastic material to prevent sundries from being left on the waste wood-plastic material; and S2, adopting a clamping feeding transmission machinery to transmit the cleaned waste wood-plastic material. The clamping feeding transmission machinery can stably transmit the waste wood-plastic material, so that a transverse sawing machinery and a longitudinal sawing machinery can conveniently cut the waste wood-plastic material. With adoption of the crushing and recovery processing method, the waste wood-plastic material can be cut to facilitate transportation and crushing; liquid nitrogen is adopted for cooling to effectively improve the processing efficiency and quality, so that the brittleness of the waste wood-plastic material can be greatly improved to further reduce power required by crushing, energy consumption and noise effectively.

Owner:广东邦英新材料有限公司

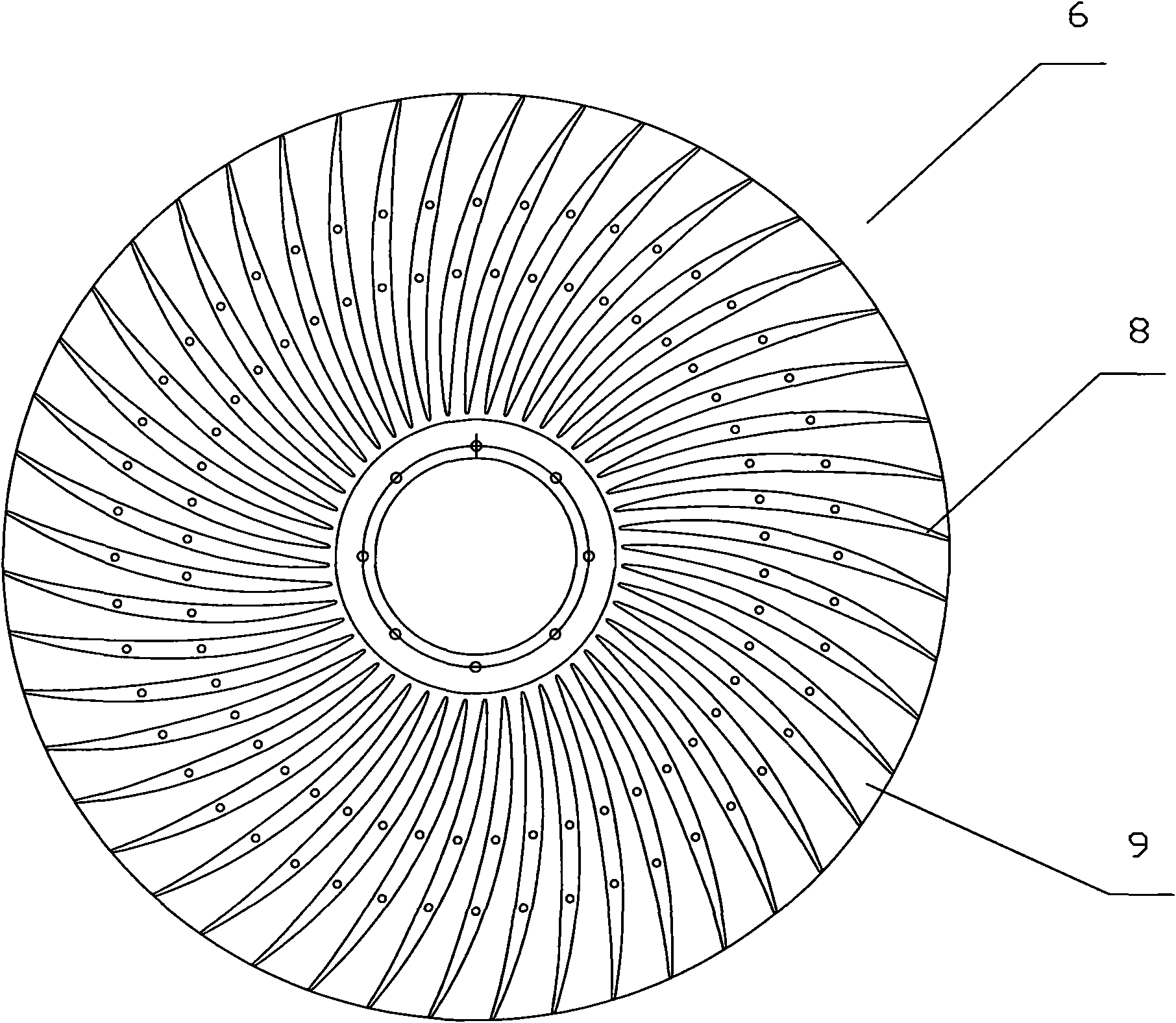

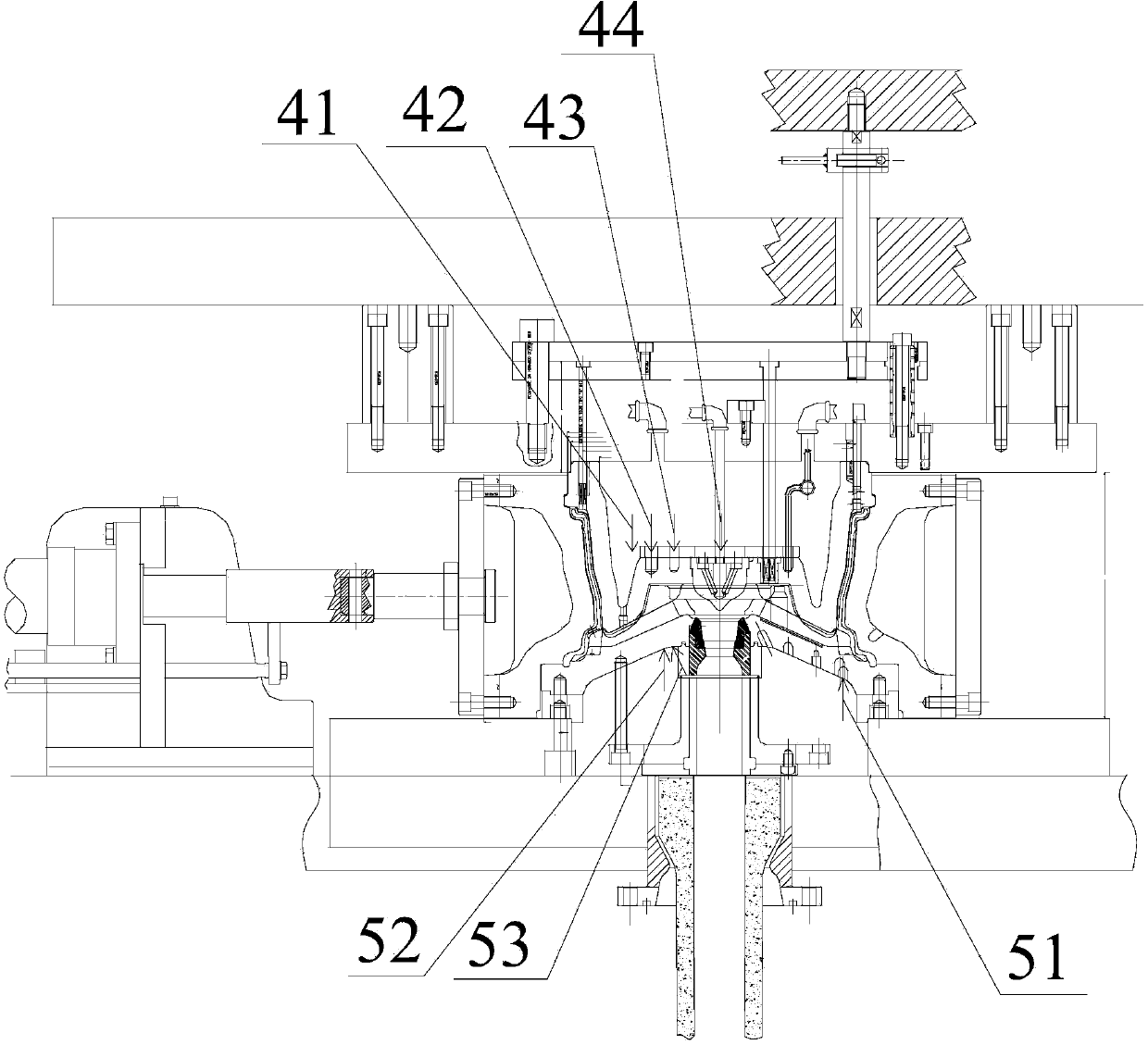

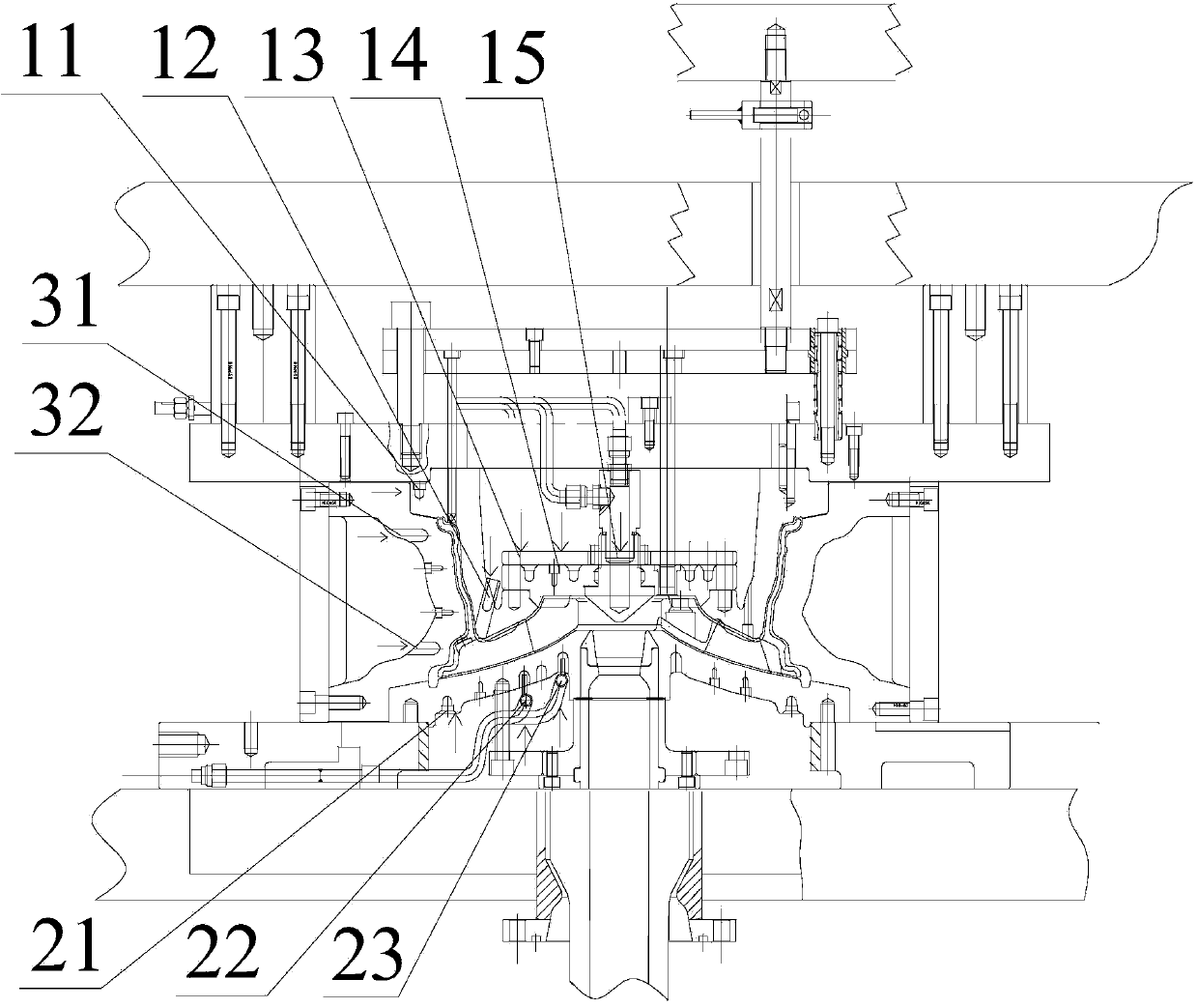

Casting cooling system, casting mold and casting method for aluminum hubs

The invention relates to the field of automobile part casting and discloses a casting cooling system for aluminum hubs. The casting cooling system comprises an upper mold cooling subsystem and a bottom mold cooling subsystem, wherein the bottom mold cooling subsystem comprises a bottom mold feed head air duct, a bottom mold front-hung water-cooling disc and a bottom mold middle-circle water-cooling disc; and the bottom mold front-hung water-cooling disc and the bottom mold middle-circle water-cooling disc are located in positions, which are close to the outer end and the air duct, of the lower part of a bottom mold respectively. The invention further discloses a low-pressure mold for the aluminum hubs. The mold comprises the casting cooling system for the hubs. The invention further discloses a casting method for the aluminum hubs. The casting cooling system, the mold and the casting method have the benefits as follows: a traditional air-cooling system is improved into an air and water mixed cooling system by the aid of the upper mold cooling subsystem, the bottom mold cooling subsystem and a side mold cooling subsystem; and meanwhile, the cooling efficiency and the cooling quality are improved, the production time is shortened, and the production cost is reduced.

Owner:KUNSHAN ZHONGYITE MACHINERY IND

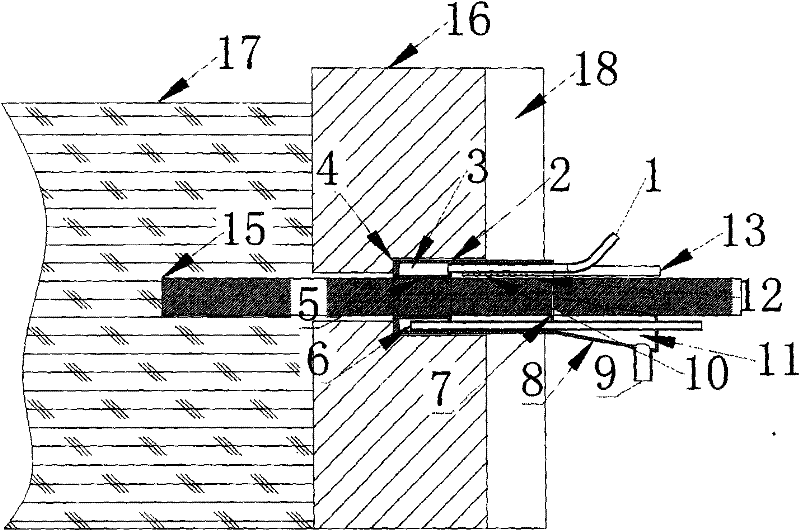

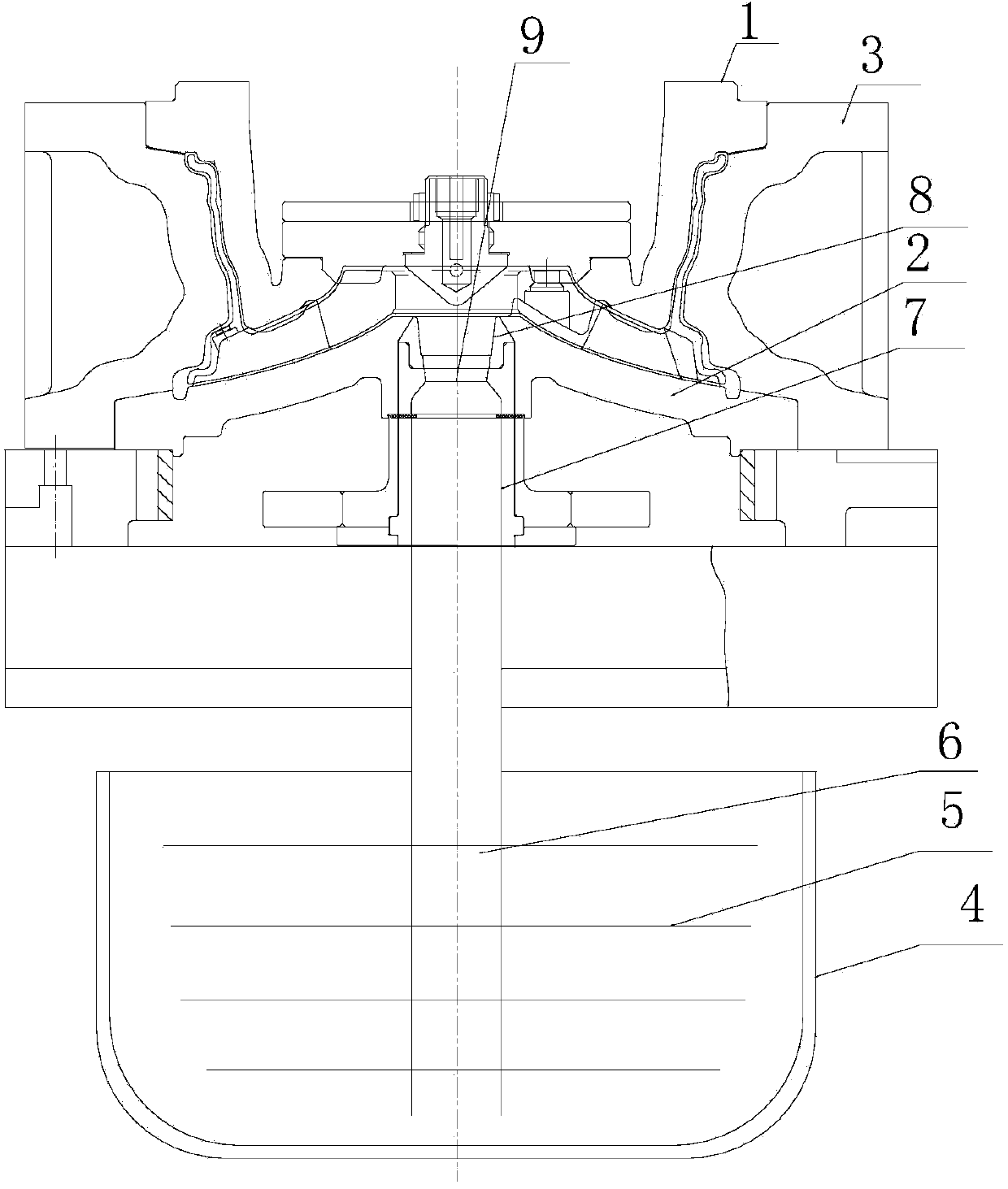

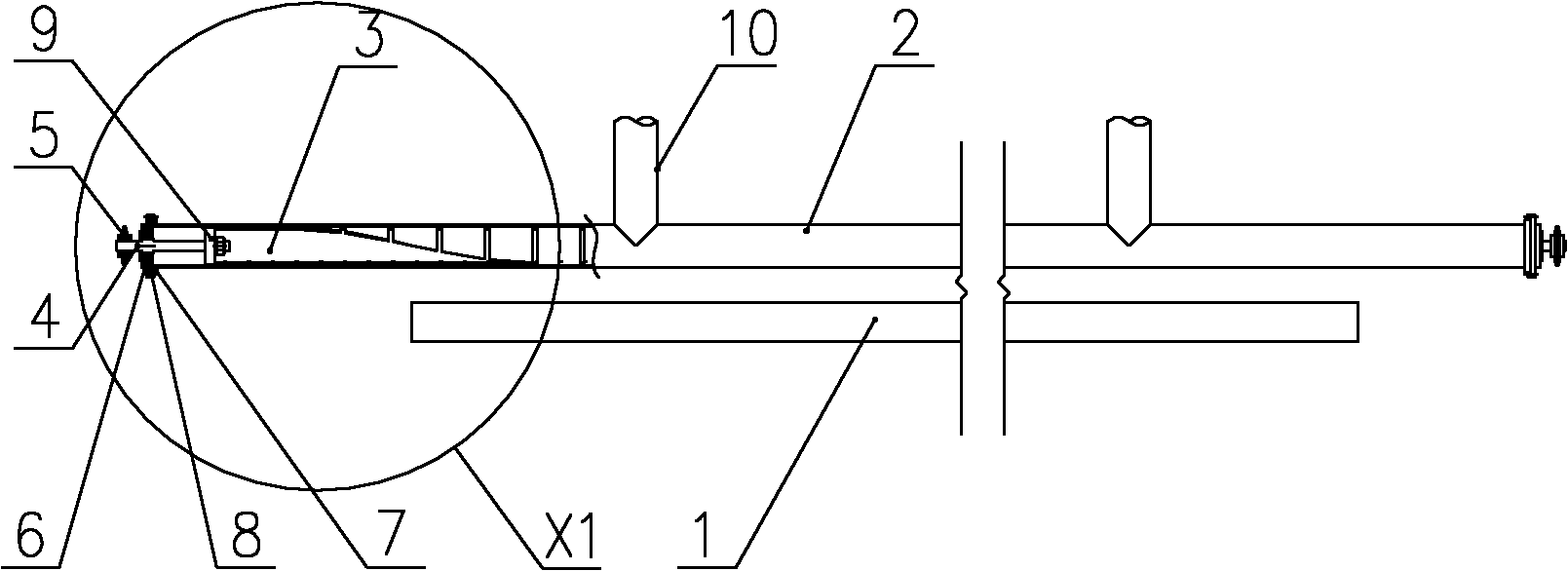

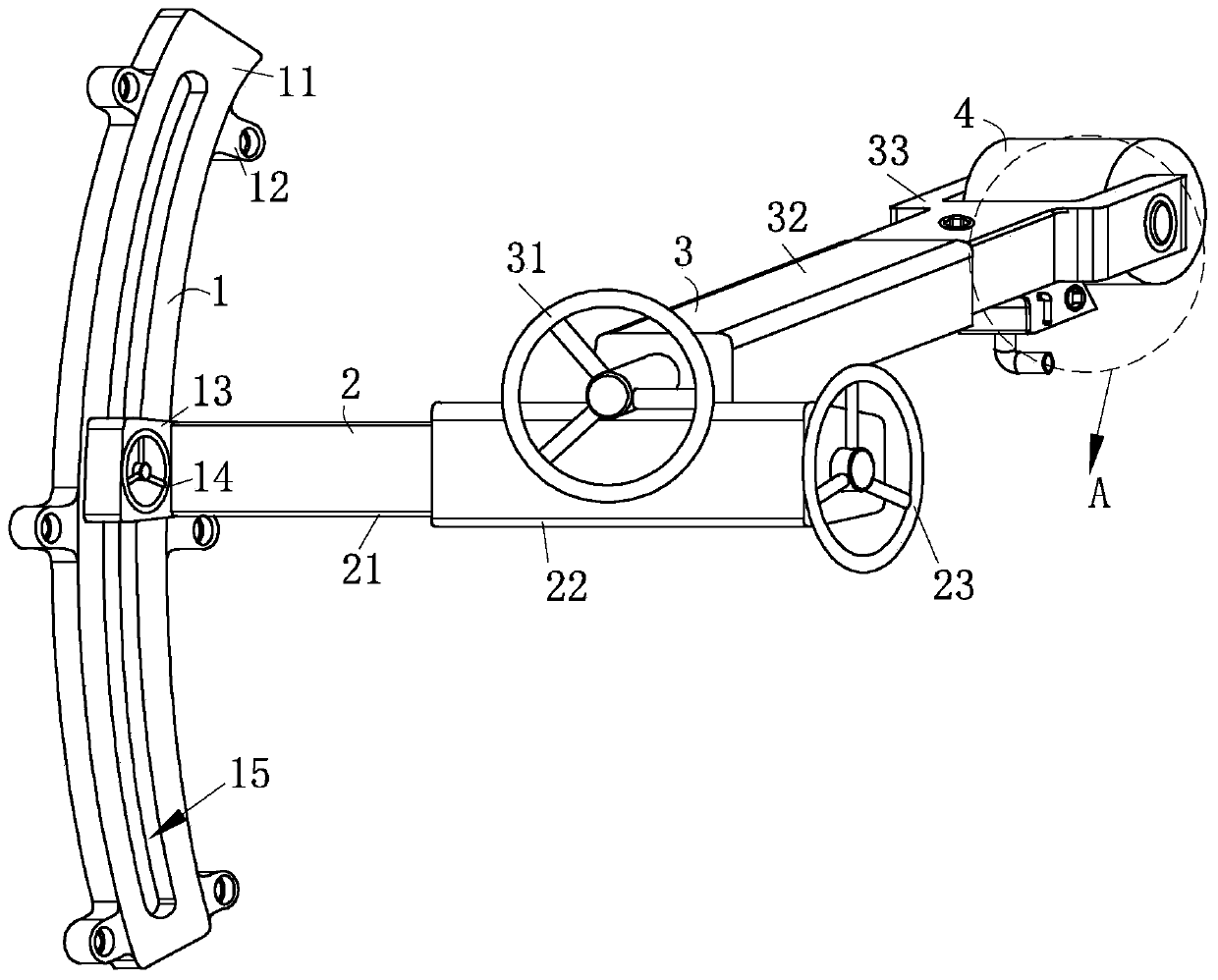

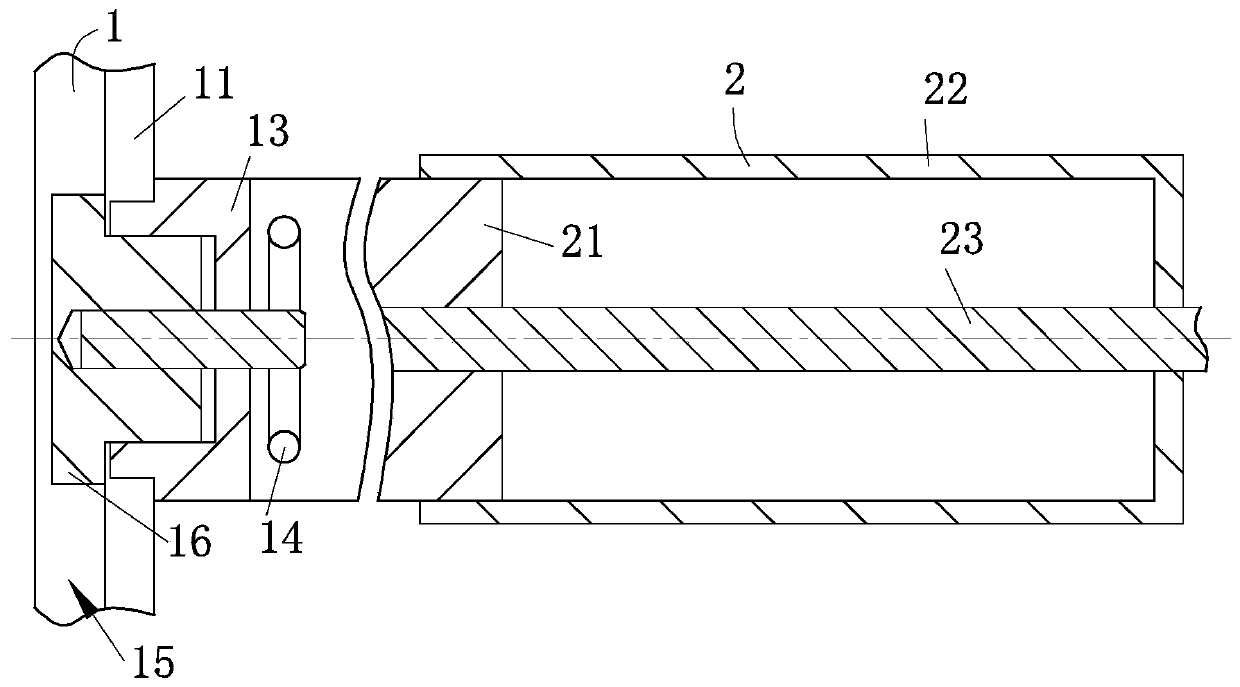

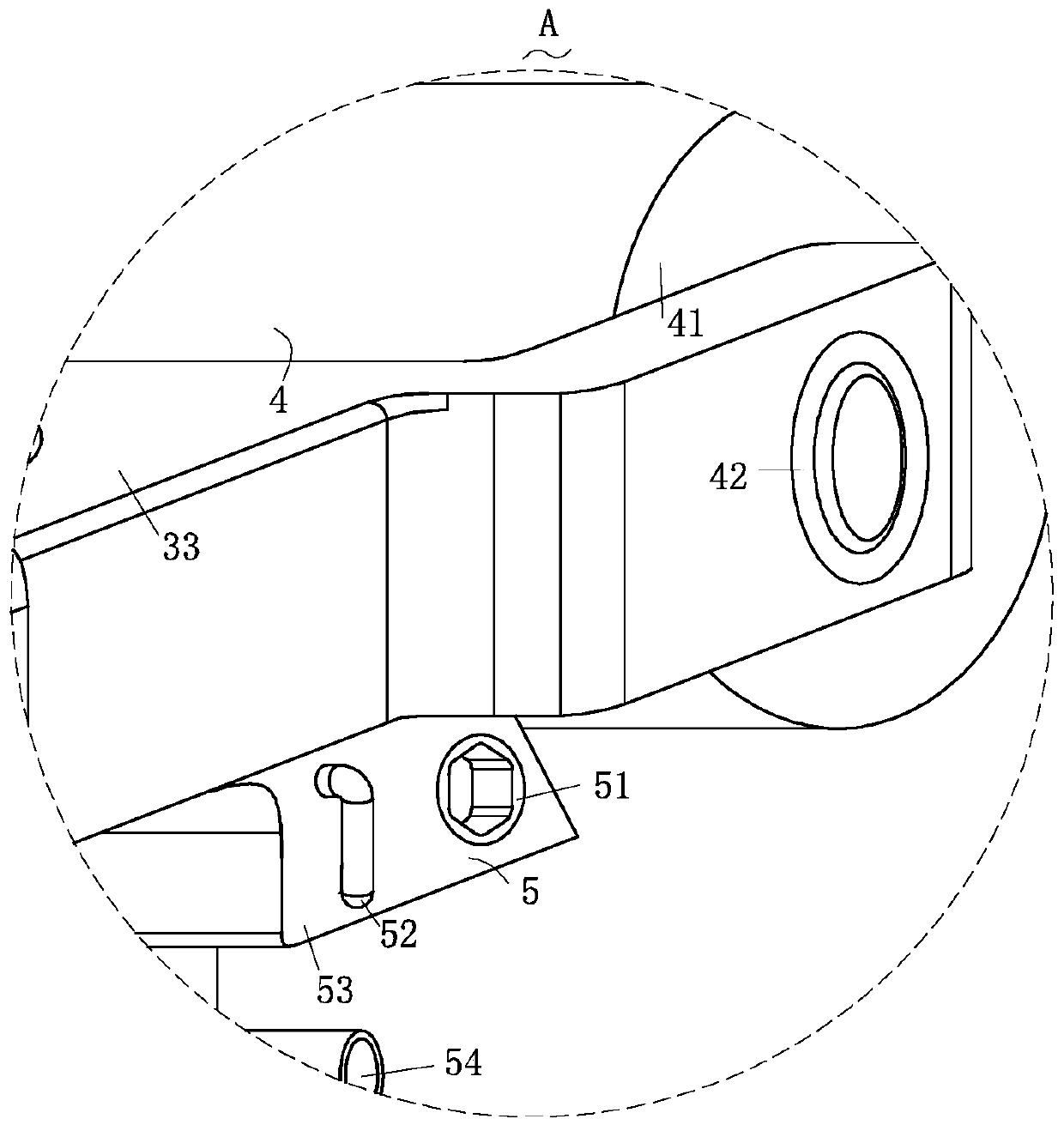

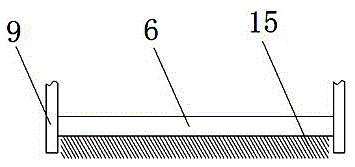

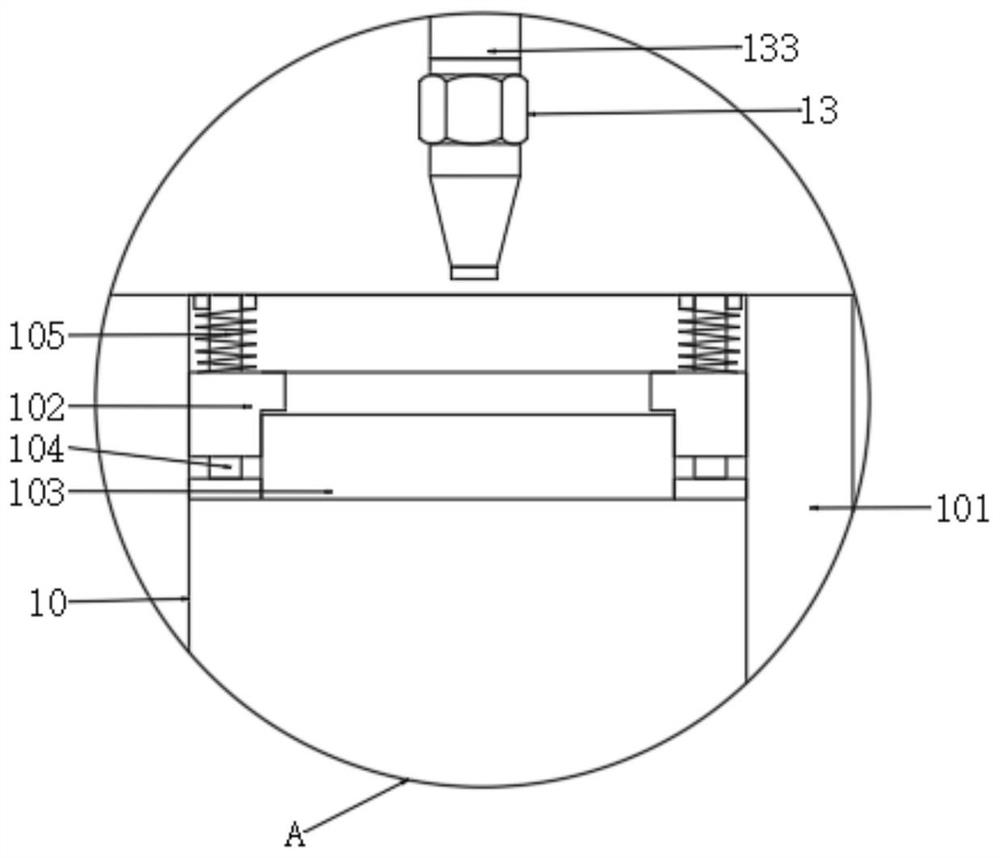

Cooling spray pipe with continuously adjustable jet width

InactiveCN101824523AImprove cooling qualitySimple structureQuenching devicesSuper coolingWater treatment system

The invention relates to a cooling spray pipe with continuously adjustable jet width, which comprises a cooling medium pipeline (10) and a cooling spray pipe (2), wherein cylinder plugs (3) which are movably connected with both ends of the cooling spray pipe (2) are inserted into the two ends; a transmission rod (4) is arranged, wherein one end of the transmission rod is connected with the cylinder plugs (3) and the other end thereof is arranged outside the cooling spray pipe (2) and is connected with a transmission sprocket wheel (5); and a sealing device is also arranged and used for the end surface sealing of the cooling spray pipe (2) and the shaft sealing of the transmission rod (4). The cooling spray pipe with the continuously adjustable jet width mainly has the advantages of having simple structure, facilitating manufacturing and installation, simply deploying a water pipeline, continuously regulating the jet width, being adapted to the quenching and the cooling of steel sheets with different width, effectively reducing the waste of cooling water, reducing the energy consumption of a water treatment system, controlling the water flow on the surface of the steel sheets, effectively preventing the super-cooling of the sides of the steel sheets, and ensuring the lateral uniformity during a steel sheet cooling process.

Owner:WISDRI WUHAN WIS IND FURNACE

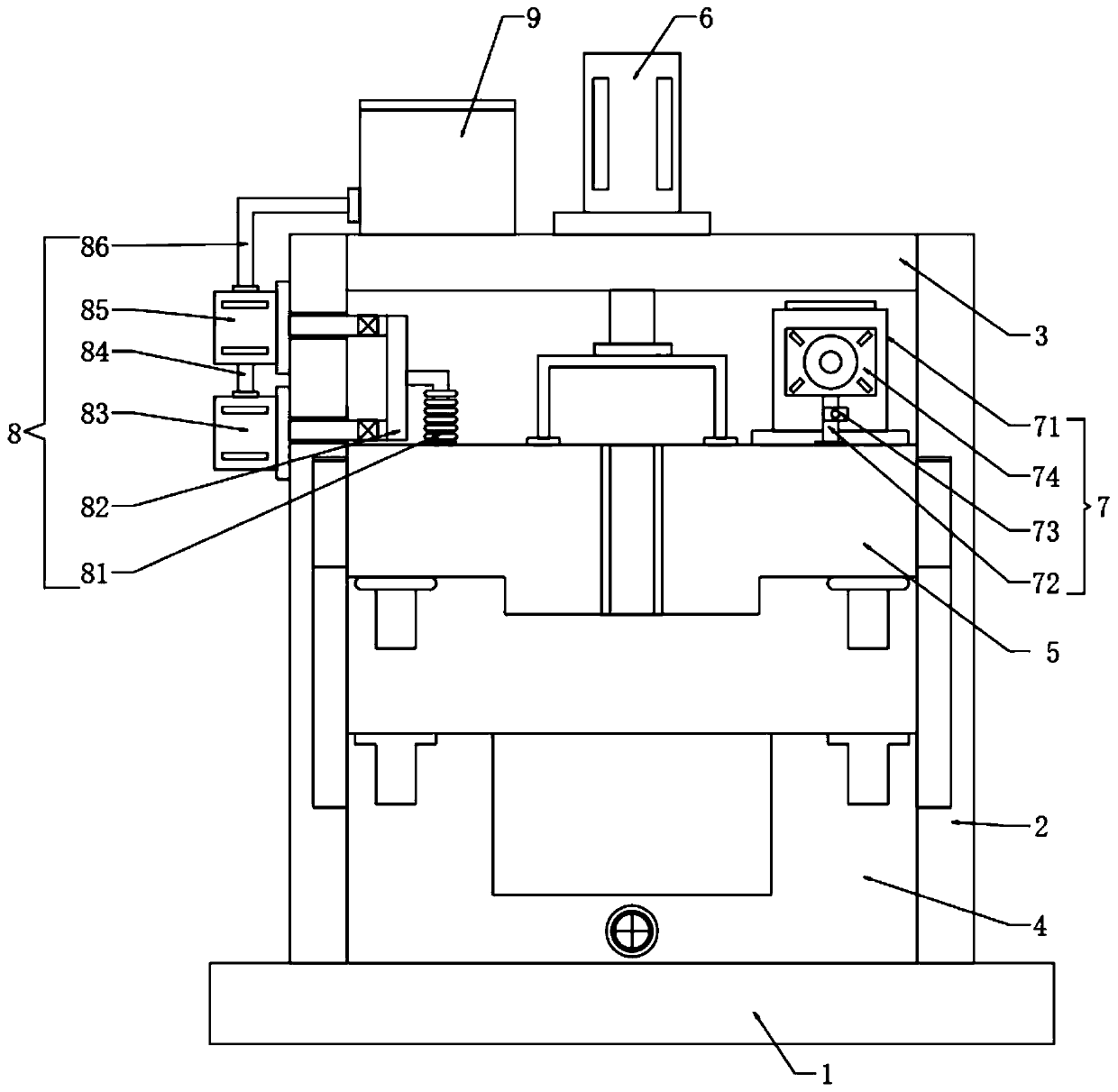

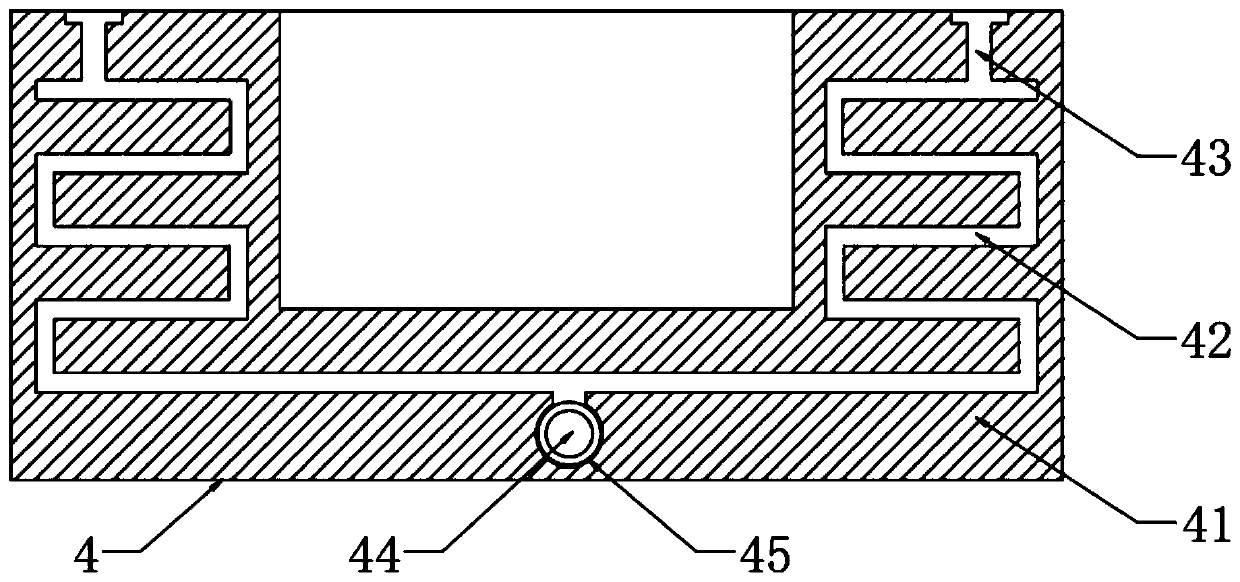

Injection mold with water blowing device and method

The invention discloses an injection mold with a water blowing device in the technical field of injection molds. The injection mold comprises a base, a top plate is fixedly arranged at the top betweentwo groups of brackets, a fixed mold mechanism is fixedly arranged at the top of the base, and a movable mold mechanism matched with the fixed mold mechanism is slidably arranged at the position, close to the upper position, between the two groups of brackets; and a condensate water input mechanism is arranged on the right side of the top of the movable mold mechanism, a water blowing mechanism is connected to the left side of the top of the movable mold mechanism, and a heat recovery mechanism is connected to the other end of the water blowing mechanism. According to the injection mold, an air blowing machine is used for enabling air to enter a rectangular through opening to be in contact with a thermal storage plate layer, air is preheated through the thermal storage plate layer, the preheated air can enable water in a first cooling water channel, a first pipeline connecting channel, a second pipeline connecting channel, a positioning pipe, an outlet water channel, a positioning pipe channel, a second cooling water channel and the like to be discharged from the connecting pipe, meanwhile, the drying effect is achieved, it is guaranteed that the interiors of the movable mold mechanism and the fixed mold mechanism are dry, the dewatering efficiency is good, the quality is high, and energy consumption is low.

Owner:新昌县南明街道益华机械厂

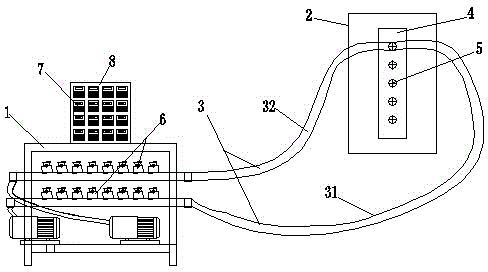

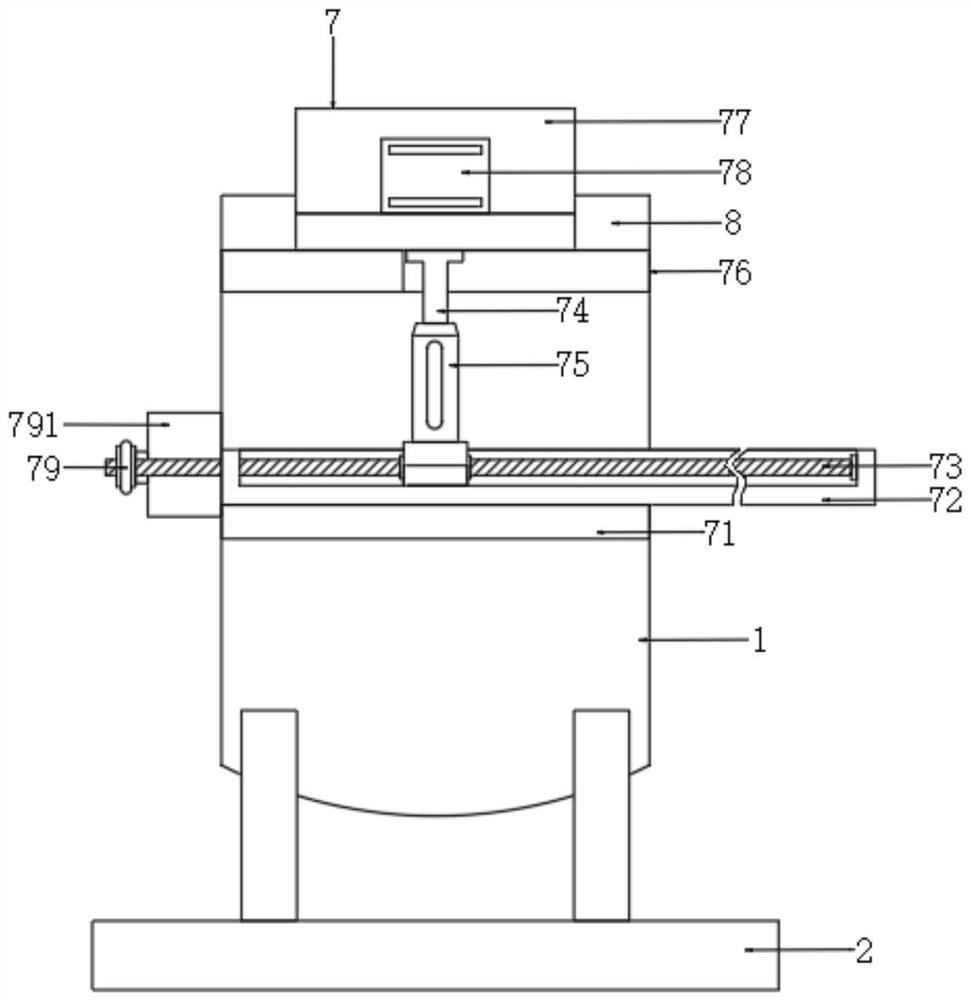

Intermittent cooling water supplying system for die casting mold

The invention relates to an intermittent cooling water supplying system for a die casting mold. The intermittent cooling water supplying system for the die casting mold comprises a machine body (1), and a cooling pipe (3) connected to a mold (2) is arranged on the machine body (1). The mold (2) is provided with a cooling connecting block (4) corresponding to the cooling pipe (3), and the cooling connecting block (4) is provided with a plurality of cooling connectors (5) corresponding to the cooling pipe (3). The cooling pipe (3) is provided with valves (6), and time relays (7) and a control box (8) are further arranged to control the valves (6) to act. According to the intermittent cooling water supplying system for the die casting mold, the time relays are arranged, water is intermittently supplied to the mold by controlling the water supplying time of the cooling water, and thus the heat balance of the mold is guaranteed.

Owner:YANGZHOU RONGTAI IND DEV

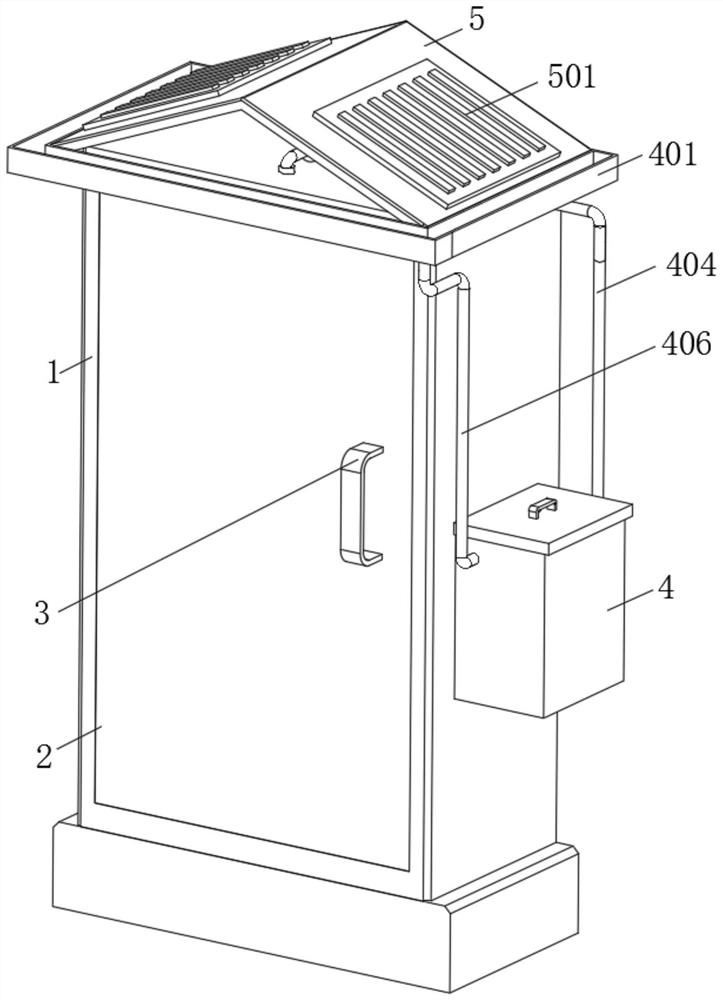

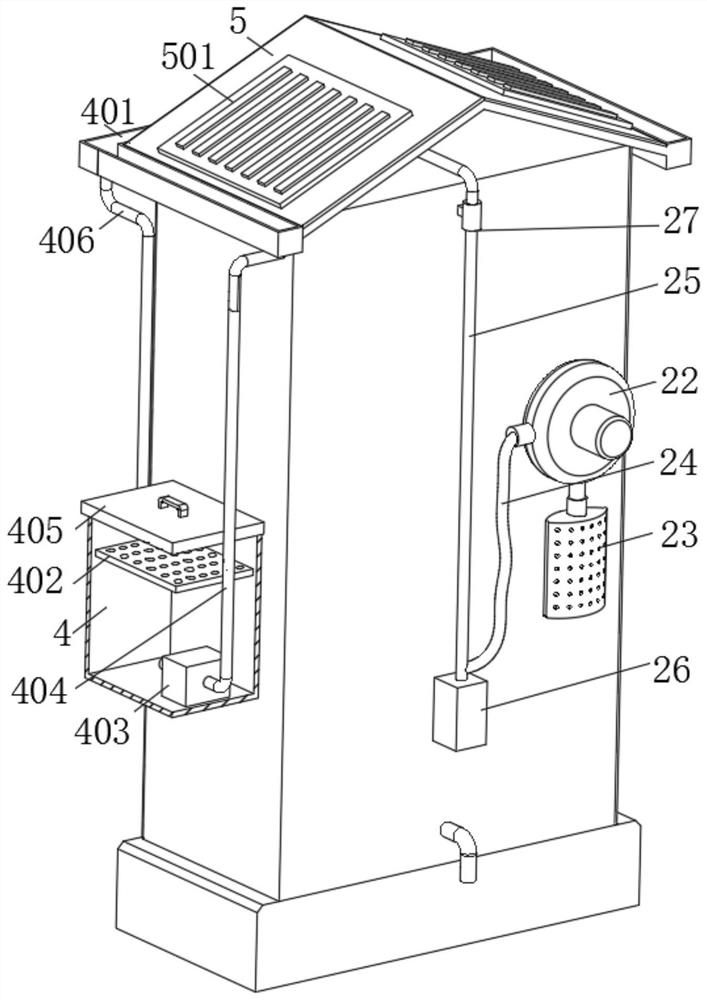

Outdoor high-low voltage power distribution cabinet

PendingCN111952848AExtended service lifeGuaranteed performancePhotovoltaic supportsSubstation/switching arrangement cooling/ventilationSprocketEngineering

The invention discloses an outdoor high-low voltage power distribution cabinet, and the cabinet comprises a power distribution cabinet body, a plurality of electrical elements are fixedly installed onthe inner side wall of the power distribution cabinet body, a motor is fixedly installed on the inner upper wall of the power distribution cabinet body, and the output end of the motor is fixedly connected with a reciprocating screw rod; the outer side wall of the reciprocating lead screw is in threaded connection with a threaded sleeve, a sliding rod is fixedly connected between the upper wall and the bottom wall of the interior of the power distribution cabinet body, one end of each of the multiple transmission shafts penetrates through the inner wall of the equipment box to extend to the exterior of the equipment box and is fixedly connected with a cleaning brush, and the outer side walls of the multiple transmission shafts are fixedly connected with second chain wheels; the outer surfaces of the first chain wheel and the multiple second chain wheels are jointly in transmission connection with a chain, the dust removal quality can be improved, the service life of electrical elements can be prolonged, the heat dissipation quality can be improved, the use performance of the electrical elements can be improved, the service life of the electrical elements can be prolonged, and energy conservation and environmental protection are facilitated.

Owner:宋玉龙

Cement clinker cooling system and method

InactiveCN103322818ASave civil investmentImprove operational reliabilityHandling discharged materialBaghouseChain conveyor

The invention discloses a cement clinker cooling system and method. The cooling system comprises a rotary kiln, a hot kiln hood, an annular cooling machine, a bag-type dust collector, a zipper machine, a crusher and a bucket chain conveyor. The annular cooling machine is divided into three cooling sections. Cement clinker is cooled through the three cooling sections, and hot air generated in each cooling section is utilized. The cement clinker cooling system and method can overcome the defects in the prior art of being large in device investment, floor area and civil engineering investment, more in accessory devices, troublesome in device maintaining and overhauling and the like.

Owner:CITIC HEAVY INDUSTRIES CO LTD

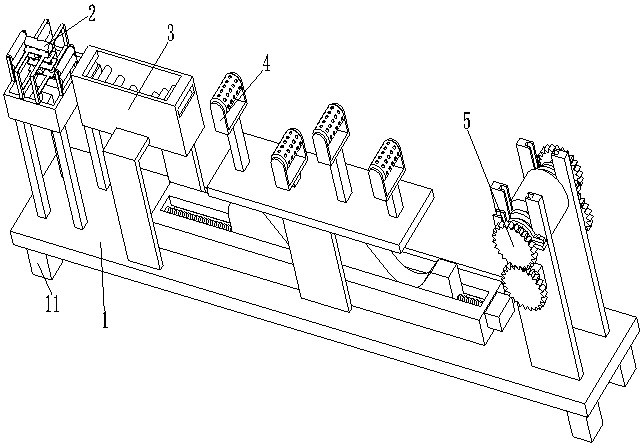

PP winding pipe production equipment with braking component

ActiveCN110815799AAdjustable positionEasy to adjustTubular articlesProcess engineeringMechanical engineering

The invention relates to the field of winding pipe production equipment, in particular to PP winding pipe production equipment with a braking component. The PP winding pipe production equipment comprises a diameter adjusting structure, a first stretching and contracting structure, a second stretching and contracting structure, a guiding structure, a braking structure and a lubricating structure, wherein use of the diameter adjusting structure facilitates to adjust the position of the first stretching and contracting structure rapidly, meanwhile, a bolt of the adjusting position is avoided frombeing subjected to force directly, and the position adjusting efficiency and quality of the first stretching and contracting structure are greatly improved; by means of the arrangement of the brakingstructure, the pressure on cooling water is reduced, the cooling water is made to be poured on the guiding structure better, the water pouring amount is increased, splashing of the cooling water on arubber strip is effectively avoided at the same time, and the rubber strip is avoided from being pasted to the guiding structure; and the lubricating structure is arranged at the end portion of the second stretching and contracting structure and is connected to the braking structure, the use of the lubricating structure facilitates resetting of the braking structure, and by means of the use of the braking structure, the fact that the lubricating structure is driven to lubricate the guiding structure while the cooling water is sprayed is facilitated.

Owner:江苏八达重工科技有限公司

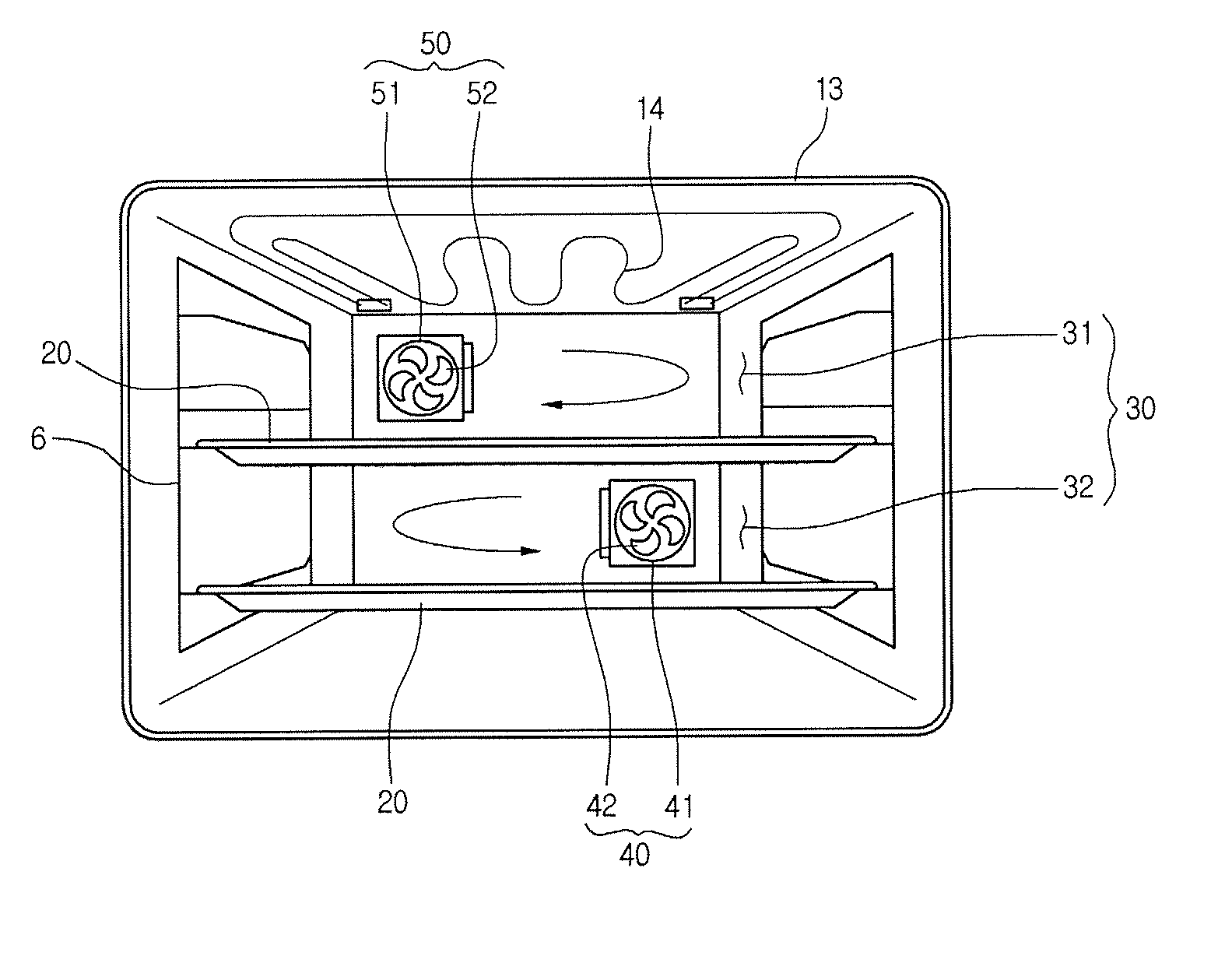

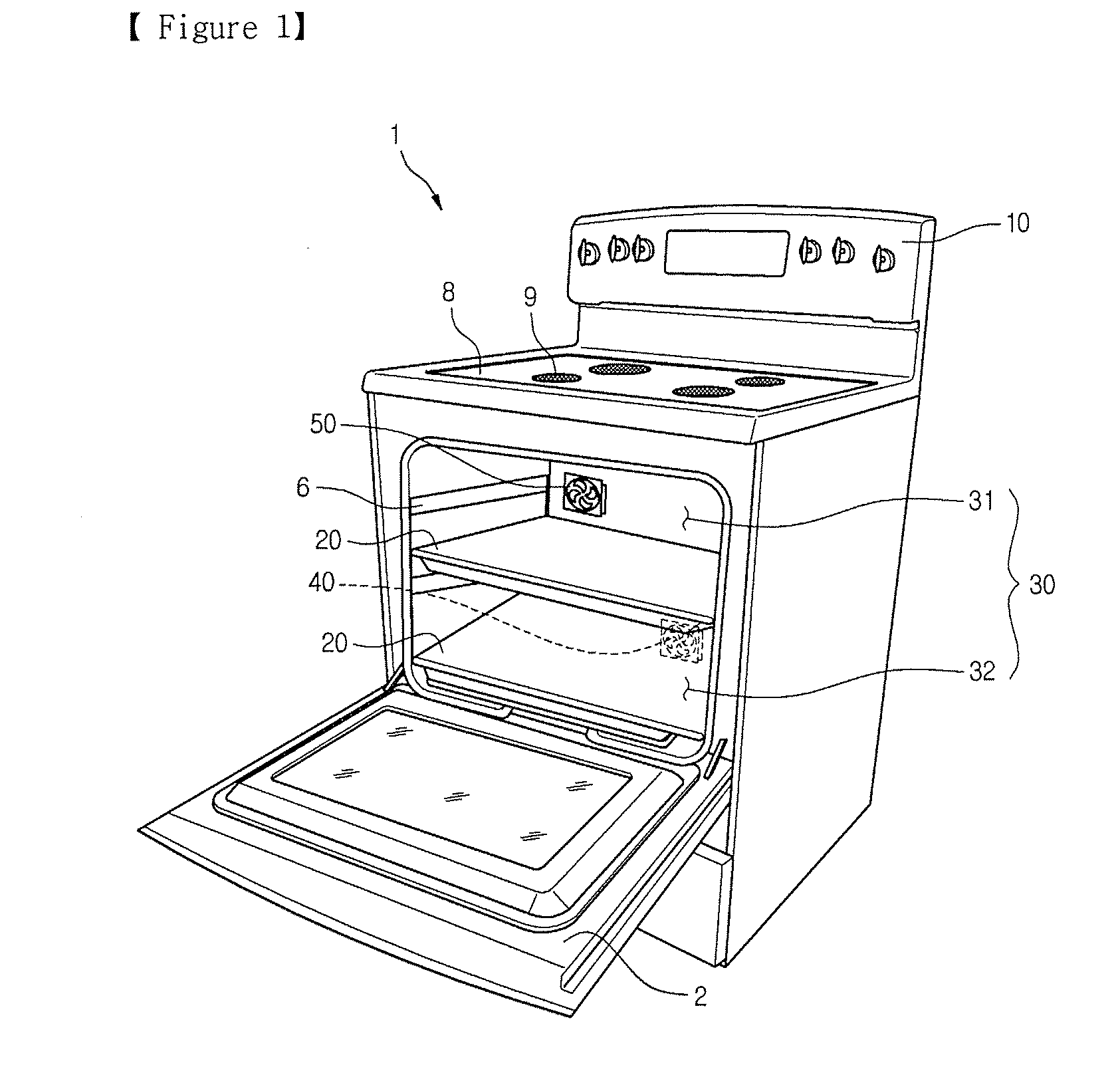

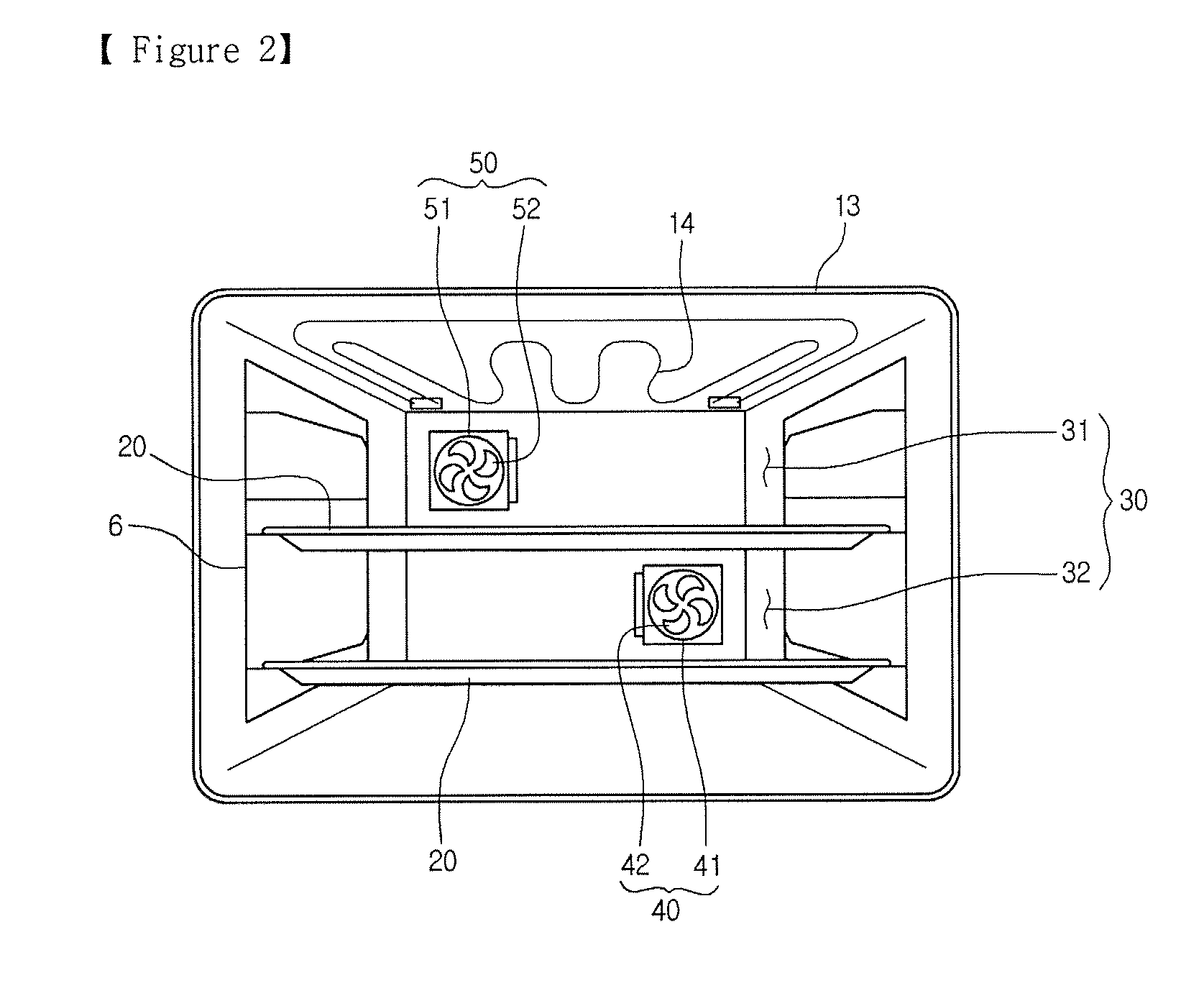

Electric oven and method of operating the same

ActiveUS20070029312A1Improve cooling qualityGood cooking timeDomestic stoves or rangesElectrical heating fuelConvection heaterConvection

An electric oven is provided. The electric oven includes a cavity, a plurality of convection systems each having a convection heater and a convection fan, and a tray dividing the cavity into different spaces. The convection systems are operated for the respective different spaces.

Owner:LG ELECTRONICS INC

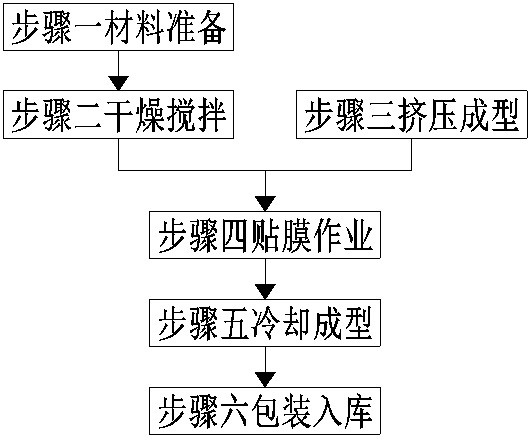

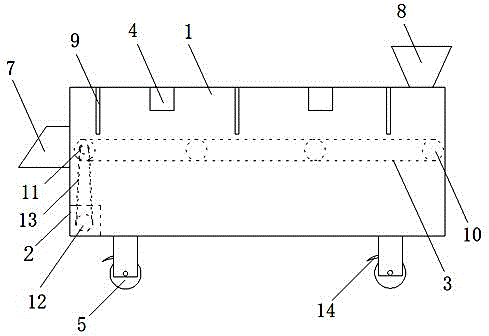

Production process of modified asphalt waterproof coiled material

InactiveCN112757659AUneven windingImprove cooling efficiencyFlat articlesWebs handlingBituminous waterproofingCooling effect

The invention relates to a production process of a modified asphalt waterproof coiled material. The process mainly comprises the following steps of material preparation, drying and stirring, extrusion molding, film pasting operation, cooling molding, packaging and warehousing, and used coiled material cooling molding equipment comprises a bottom plate, a spraying device, a soaking device, a tightening device and a winding device. The process can solve the following problems that when an existing modified asphalt waterproof coiled material is cooled and coiled, a, a traditional cooling mode of the modified asphalt waterproof coiled material is air cooling, and the production efficiency of the modified asphalt waterproof coiled material is reduced due to the fact the air cooling time is long, the cooling effect is poor, the cooling distance needs to be lengthened; and b, when the existing modified asphalt waterproof coiled material is coiled, the modified asphalt waterproof coiled material is in a loose state, the modified asphalt waterproof coiled material is wrinkled when being coiled, and the modified asphalt waterproof coiled material is unevenly coiled.

Owner:郭长记

Cooling device for rice processing

The invention discloses a cooling device for rice processing. The cooling device comprises a cooling chamber, a motor, a conveying belt, an air blower, a roller and a mounting block, and is characterized in that a discharge port and a feed port are formed in the cooling chamber; a limiting rod and a rotating wheel are arranged in the cooling chamber; a driven wheel is arranged on the rotating wheel; the motor is arranged in the cooling chamber, and is provided with a driving wheel; the driving wheel is connected with the driven wheel through a belt; the conveying belt is arranged on the rotating wheel; the air blower is arranged on the inner wall of the cooling chamber; and the roller is arranged on the cooling chamber. The conveying belt is arranged in the sealed cooling chamber, so that the pollution of rice from such impurities as dust in the cooling process can be prevented; as the rice is transported through the conveying belt, the fractionation of the rice in the transportation process is prevented, and the quality of the rice is improved; and a latch is arranged on the roller on the cooling chamber, so that the transfer and the operation of the cooling device are convenient.

Owner:周兆平

Open-air distribution box protection device

InactiveCN110880707AAchieve protectionRealize the shock absorption effectSubstation/switching arrangement cooling/ventilationAnti-seismic devicesElectric machineryMachine

The invention discloses an open-air distribution box protection device. The device comprises a machine shell. A machine body is arranged in the machine shell. The right side of the machine body is provided with a placement cavity for accommodating a distribution box. The outer surface of the right end of the machine shell is provided with a ventilation hole communicating with the outside and the containing cavity. A temperature sensor capable of sensing the temperature of the distribution box is fixedly arranged on the outer surface of the distribution box. The temperature sensor senses the temperature change of the outer surface of the distribution box. A starting or closing signal is transmitted to the motor. The spring is arranged in the machine body. A first water tank is arranged below the motor. According to the open-air distribution box protection device, protection of the power distribution box which is arranged in the open air can be achieved. Meanwhile, damping of the power distribution box which vibrates due to work is achieved through the buffering effect of the third connecting rod and the sliding rail, and therefore the noise reduction effect is achieved.

Owner:YIWU WANJU ELECTRONICS CO LTD

Cooling equipment for electric vehicle parts

The invention relates to cooling equipment for electric vehicle parts. The cooling equipment comprises a cooling outer shell; the internal of the cooling outer shell is divided into a first cooling cavity and a second cooling cavity through a separation plate; a first placing tank is formed in the first cooling cavity; a spraying device is arranged at the top in the first cooling cavity; a water collecting tank is formed in the bottom in the first cooling cavity; a water outlet is formed in one side of the water collecting tank; a second placing tank and a steam device are arranged in the second cooling cavity; the steam device includes a steam collecting tank and a steam channel; the steam collecting tank is formed in the bottom in the second cooling chamber, and is connected with a steam outlet hole through the steam channel; the steam outlet hole is formed in the bottom surface of the second placing tank; and a steam inlet is formed in one side of the steam collecting tank. Compared with the prior art, the cooling equipment has the following advantages: the whole structure is simple and reasonable; and the water cooling treatment is firstly performed, and then, the steam cooling treatment is performed, so that the upper and lower ends of the parts can be uniformly cooled, and the cooling quality is improved.

Owner:JIANGSU ANJIELI ELECTRICAL & MECHANICAL TECH

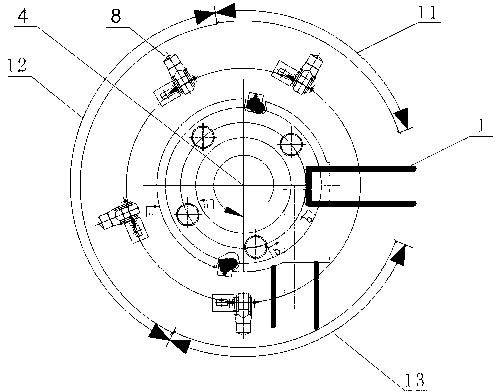

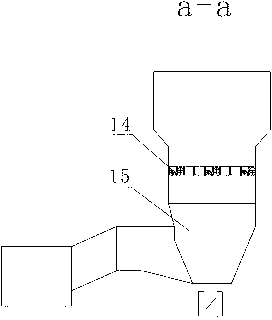

Convenient-to-pickup spinning cooking device and application method

ActiveCN111826838AQuick RetrievalEasy dischargeTextile/flexible product manufactureTextile treatment by spraying/projectingHydraulic cylinderYarn

The invention discloses a convenient-to-pickup spinning cooking device in the technical field of spinning cooking. The spinning cooking device comprises a cooking shell; a pickup adjusting mechanism matched with a shell cover is arranged at a position, close to the upper side, of the outer wall of the cooking shell; a cooling mechanism is fixedly arranged in the center of the top of the shell cover; an assembly column mechanism is movably inserted into the center of the bottom of the cooling mechanism; and a plurality of groups of yarn placing mechanisms with the same structure are arranged onthe outer wall of the assembly column mechanism in an annular array manner. According to the convenient-to-pickup spinning cooking device, the pickup adjusting mechanism is arranged, two groups of hydraulic cylinders are driven, two groups of L-shaped blocks are driven by push rods to move upwards to designated positions; a servo motor is driven, therefore, two groups of T-shaped sliding blocks are enabled to drive the hydraulic cylinders to move towards the front side in a T-shaped sliding groove; and after the shell cover and the assembly column mechanism move towards the front side to thedesignated positions, the servo motor is turned off, a stepping motor is driven to drive a rotating rod II till a hollow column rotates to a longitudinal state, a user can conveniently and rapidly pick up and place materials, and the safety of picking up and placing the materials is greatly improved.

Owner:湖州领先丝带有限公司

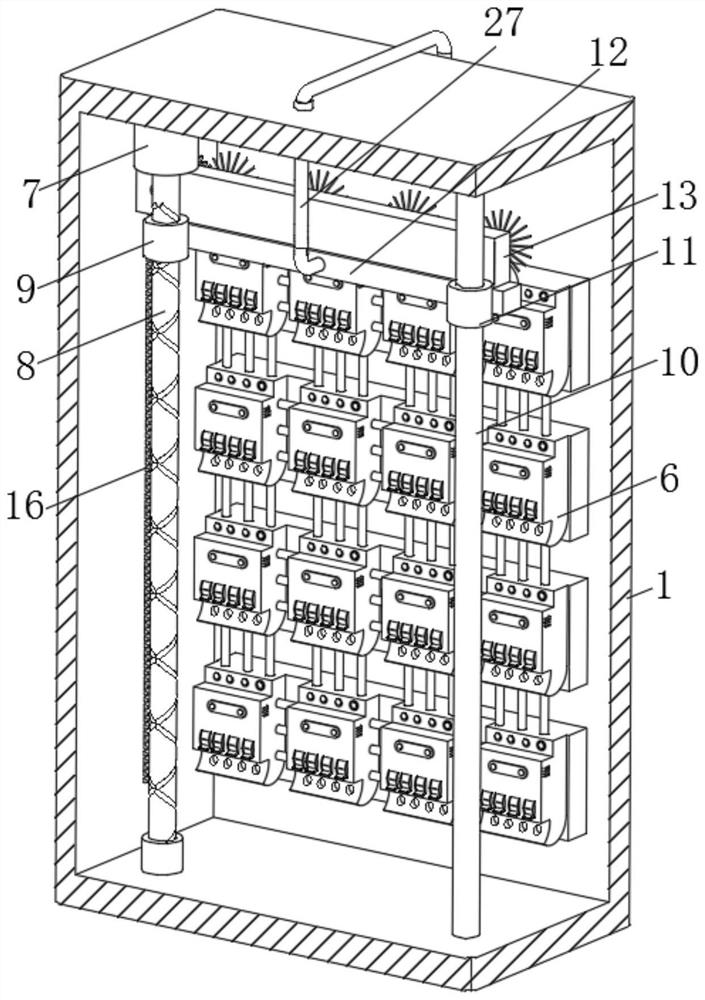

Power distribution cabinet based on substation power transmission

ActiveCN112615272AWith rotation functionSmall footprintSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsControl theoryMechanical engineering

The invention relates to the technical field of substation equipment, and discloses a power distribution cabinet based on substation power transmission. The power distribution cabinet comprises a cabinet body, ventilation openings are formed in the left side surface and the right side surface of the cabinet body, cabinet doors are arranged at the top and the bottom of the front surface of the cabinet body, and locking grooves are formed in the top and the bottom of the left side surface and the right side surface of the cabinet body. A partition plate is fixedly connected to the middle of the inner wall of the cabinet body. According to the power distribution cabinet based on transformer substation power transmission, stabilizing sliding grooves are slidably connected with the outer surfaces of stabilizing rods, so that the cabinet doors have a rotating function, the cabinet doors can be rotated to the right side face of the cabinet body, the space occupied by the cabinet body can be reduced, and obstacles are reduced when a worker maintains electrical apparatus elements in the cabinet body, the movement scope of workers is improved, and thus the maintainence efficiency of the workers is improved; and meanwhile, the power distribution cabinet is simple and convenient in structure and convenient for the working personnel to use, and the situation that the operation is strenuous is avoided.

Owner:南京德嘉电气成套设备有限公司

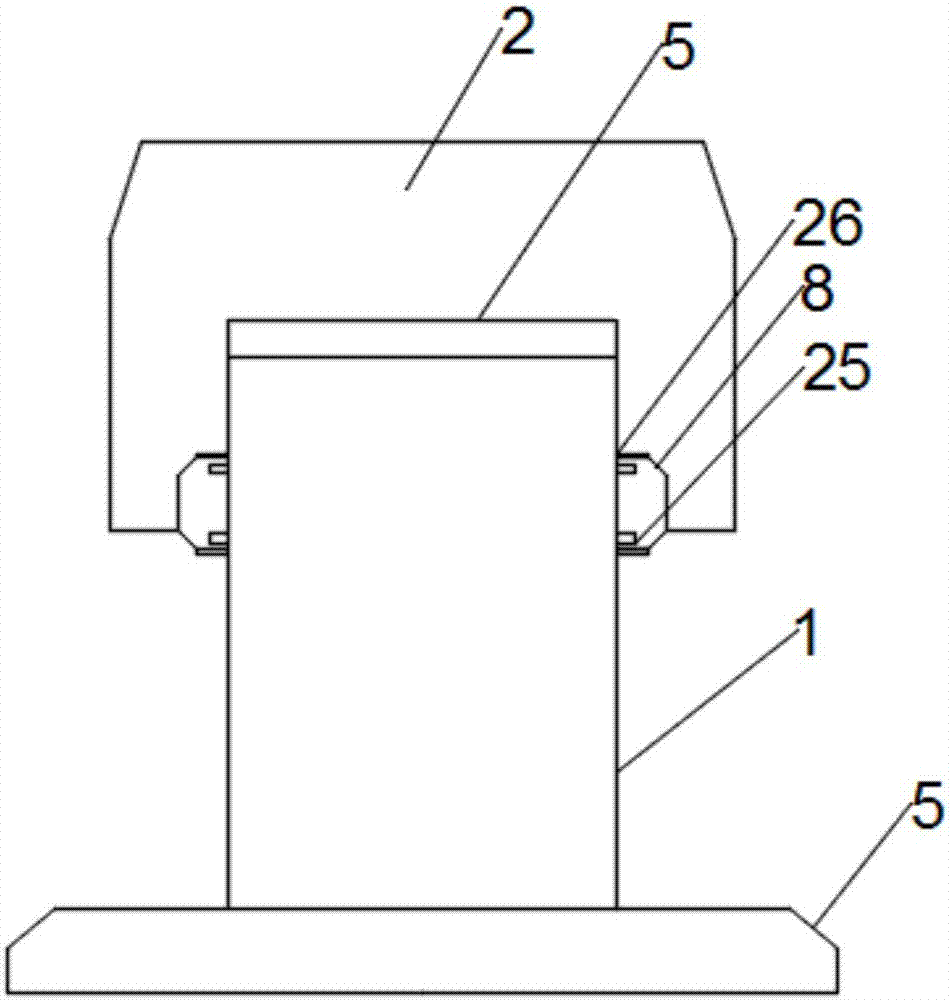

Multistage circulation cooling device used for plywood

InactiveCN107283556AImprove yieldImprove molding qualityOther plywood/veneer working apparatusLamination ancillary operationsDrive shaftCooling effect

The invention discloses a multistage circulation cooling device used for plywood. The multistage circulation cooling device comprises a conveying table, a cooling box, a storage box and a base. A conveying plate is arranged on the surface of the conveying table, and a transfer plate is arranged at the bottom end of the conveying plate. A driving shaft is arranged inside the conveying table. The transfer plate is driven by the driving shaft to conduct conveyance. Mounting bases are arranged at the two ends of the cooling box, and the cooling box and the two sides of the conveying table are fixedly mounted together through the corresponding mounting bases. A cooling device body is arranged inside the cooling box. A rubber protective pad is arranged inside the storage box. A connecting plate is arranged at one end of the storage box. The two sides of the other end of the connecting plate are connected with connecting frames, and the other ends of the connecting frames are connected with the conveying table together. The connecting frames are fixed to the two sides of the transfer plate correspondingly. According to the multistage circulation cooling device, multistage circulation cooling of the plywood can be achieved through uninterrupted cooling of a plurality of cooling pipes; and cooling is even, the cooling effect is good, forming quality of the plywood is improved, production can be facilitated, and the multistage circulation cooling device is worthy of popularization.

Owner:颍上县亚森木业有限责任公司

Mechanical mold with cooling function

The invention discloses a mechanical mold with a cooling function. The mechanical mold with the cooling function comprises a refrigeration cooling device, a gantry support and a mounting plate, wherein the gantry support is arranged at the bottom of the mounting plate, the refrigeration cooling device is arranged at the bottom of the gantry support, a hydraulic extendable rod is arranged at the top of the gantry support, a connecting plate is arranged at the bottom of the hydraulic extendable rod, sliding blocks are arranged on the two sides of the connecting plate, the sliding blocks are slidably arranged on the two sides of the gantry support, an upper mold piece is arranged at the bottom of the connecting plate, injection molding grooves are formed in the upper mold piece and a lower mold piece, and the refrigeration cooling device comprises a magnetic refrigerator, a connecting pipeline, air outlet nozzles, a refrigeration water tank and a refrigeration water pipe. The invention belongs to the technical field of mechanical molds, and particularly provides the mechanical mold with the cooling function. The mechanical mold with the cooling function has the advantages that the structure is simple, the design is reasonable, the efficiency is high, the magnetic refrigerator and the refrigeration water tank are additionally arranged and used in cooperation, the mechanical mold iseffectively cooled, and the quality of a product formed by the mechanical mold is greatly improved.

Owner:SHANDONG JIAOTONG UNIV

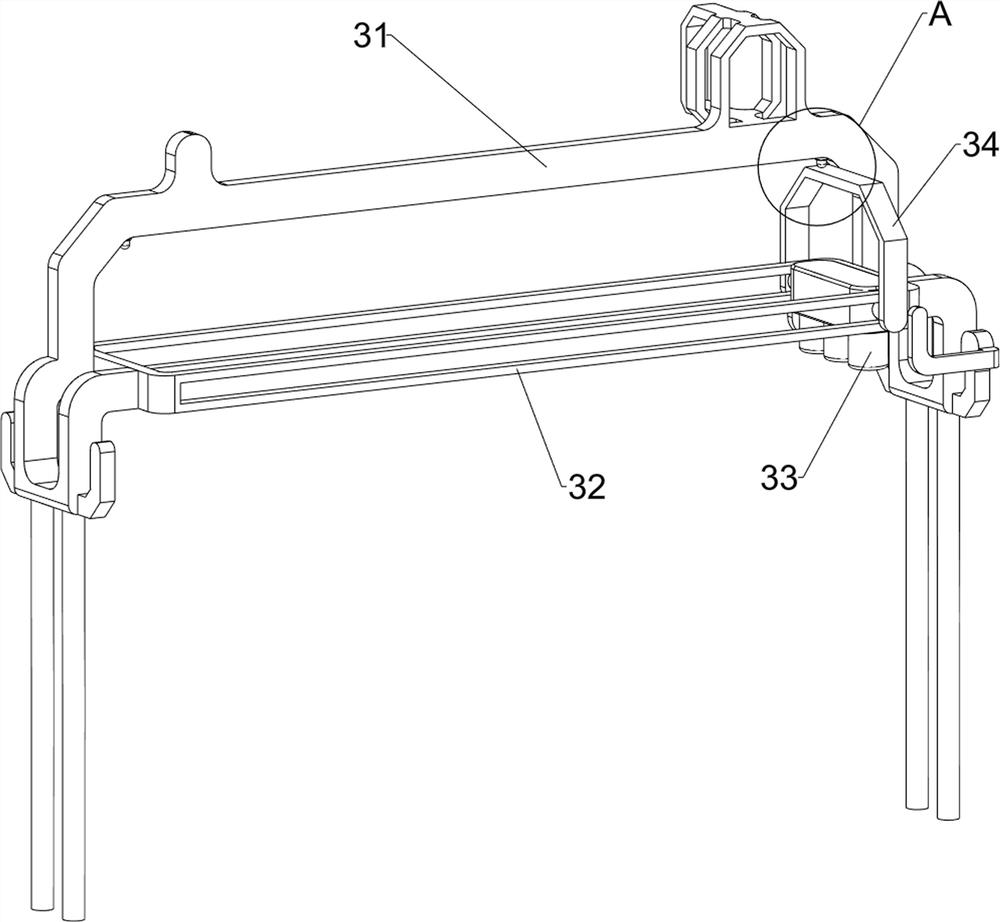

Post-welding rapid cooling equipment for high-end equipment manufacturing

ActiveCN113070611AShort processing cycleImprove cooling qualityWelding/cutting auxillary devicesAuxillary welding devicesTemperature controlWeld seam

The invention relates to cooling equipment, in particular to post-welding rapid cooling equipment for high-end equipment manufacturing. The invention aims to provide the post-welding rapid cooling equipment for high-end equipment manufacturing. The post-welding rapid cooling equipment has a good temperature control effect, improves the welding strength through point cooling, reduces the loss, effectively protects a sealing assembly in a welding part, and does not influence the quality of a welding seam. The invention discloses post-welding rapid cooling equipment for high-end equipment manufacturing. The post-welding rapid cooling equipment comprises a base, a placing assembly, a watering assembly and the like; and the top of the base is provided with the placing assembly and the watering assembly, and the watering assembly is located at the top of the placing assembly. A first connecting rod makes contact with a right button for the first time, a spray head is opened, high-temperature metal begins to be cooled, when the first connecting rod makes contact with a left button, the contact is the second contact, and therefore the spray head is closed.

Owner:山东北易车业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com