Multistage circulation cooling device used for plywood

A circulating cooling and plywood technology, which is applied to other plywood/plywood appliances, lamination auxiliary operations, lamination, etc., can solve the problems of inability to realize circulating cooling, unfavorable plywood quality, and unsatisfactory cooling effect, and achieve good cooling effect, The effect of improving yield rate and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

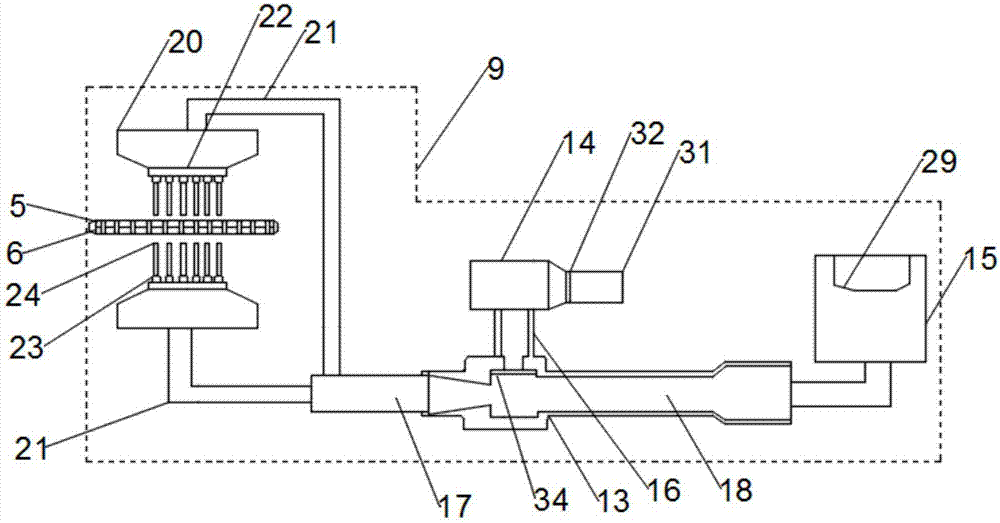

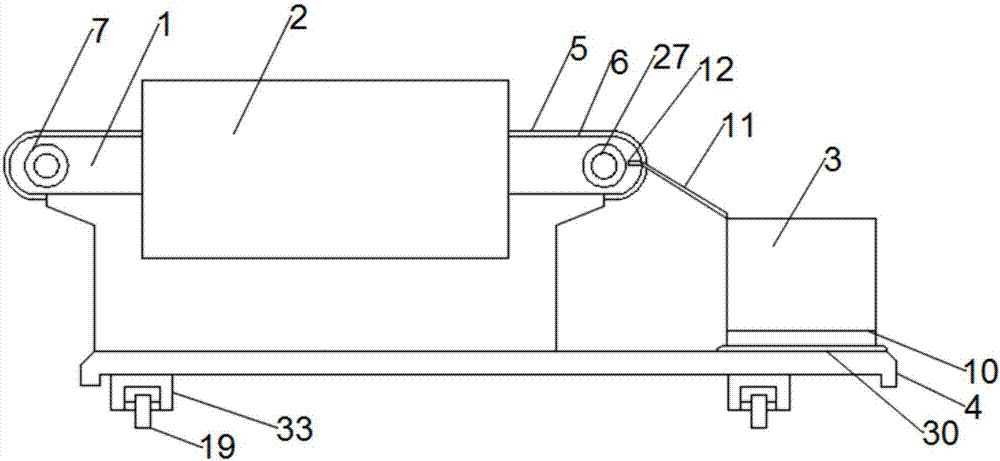

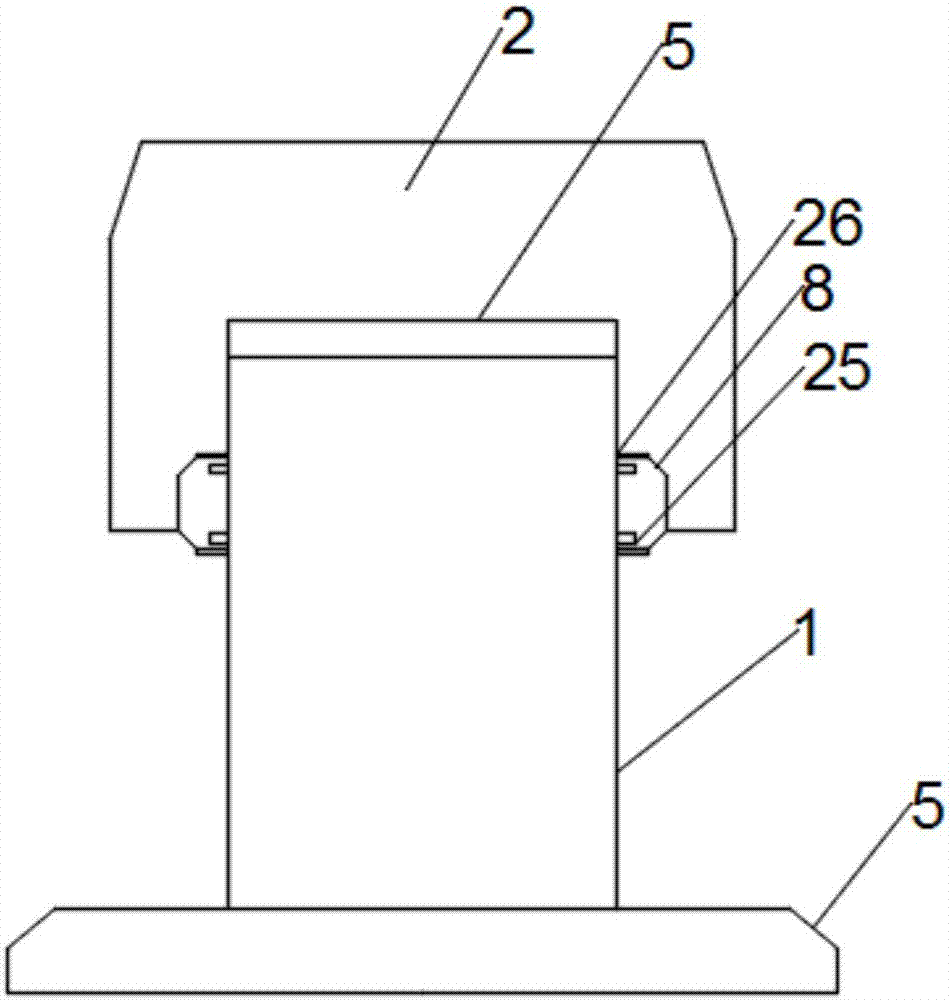

[0023] Such as Figure 1-Figure 5 As shown, the present invention provides a multi-stage circulation cooling device for plywood, comprising a transport platform 1, a cooling box 2, a storage box 3 and a base 4, the surface of the transport platform 1 is provided with a transport plate 5, and the transport plate 5 The bottom end is provided with a transmission plate 6, and the inside of the transport table 1 is provided with a drive shaft 7, and the transmission plate 6 is driven by the drive shaft 7 for transportation, and the two ends of the cooling box 2 are provided with mounting seats 8, and the The cooling box 2 is fixedly installed together through the mounting base 8 and the two sides of the transport platform 1. The inside of the cooling box 2 is provided with a cooling device 9, the inside of the storage box 3 is provided with a rubber protection pad 10, and one end of the storage box 3 is provided There is a connection plate 11, the other end of the connection plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com