Hot stamping die of snakelike cooling water channel type

A technology for hot stamping dies and cooling water channels, applied in the field of stamping dies, can solve the problems that straight water pipes cannot be well close to the surface of the die, difficult deep hole drilling processing, low cooling efficiency, etc., and achieves good cooling effect and saves the use of materials. The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

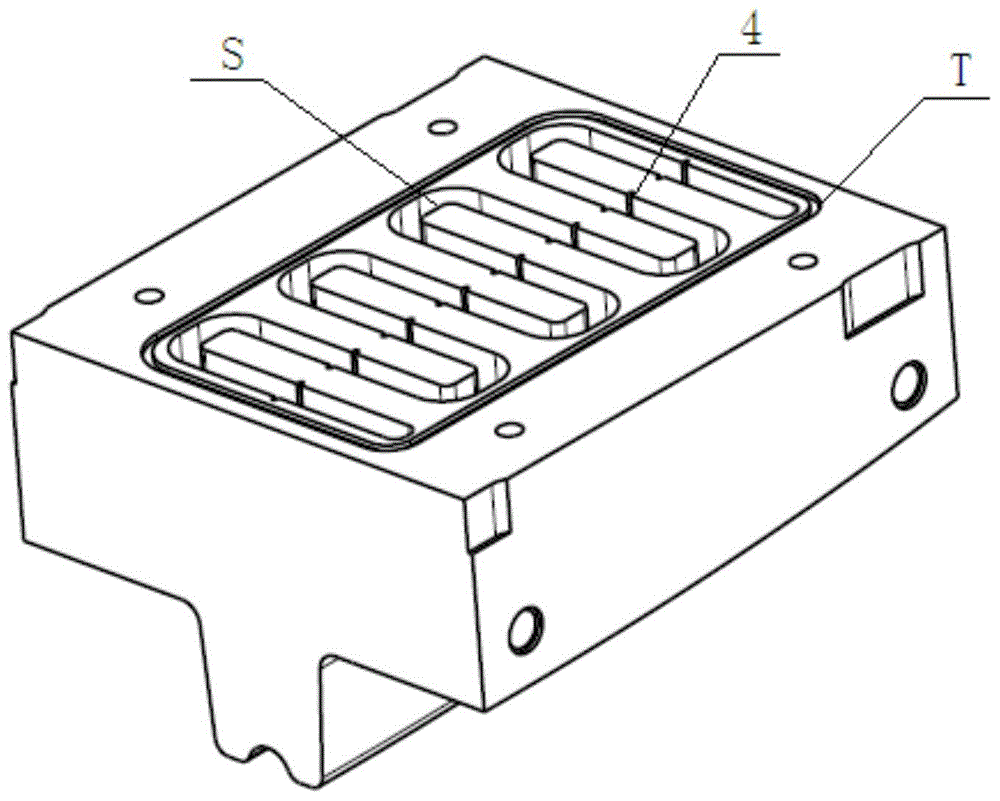

[0041] The serpentine cooling channel type hot stamping die according to the present invention will be further described below according to the specific embodiments and the accompanying drawings, but this description does not constitute an improper limitation to the technical solution of the present invention.

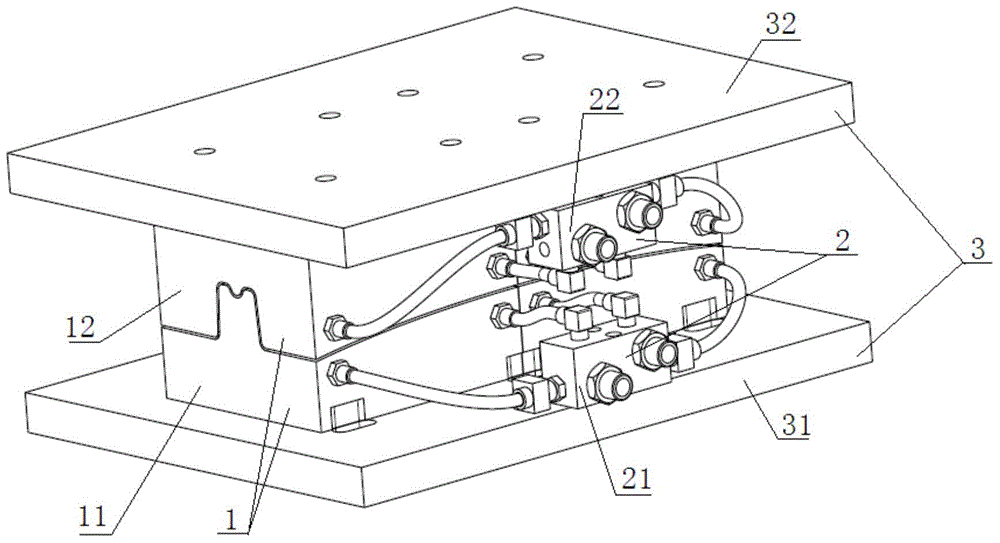

[0042] figure 1 It shows the three-dimensional assembly structure of the serpentine cooling channel type hot stamping die in one embodiment of the present invention.

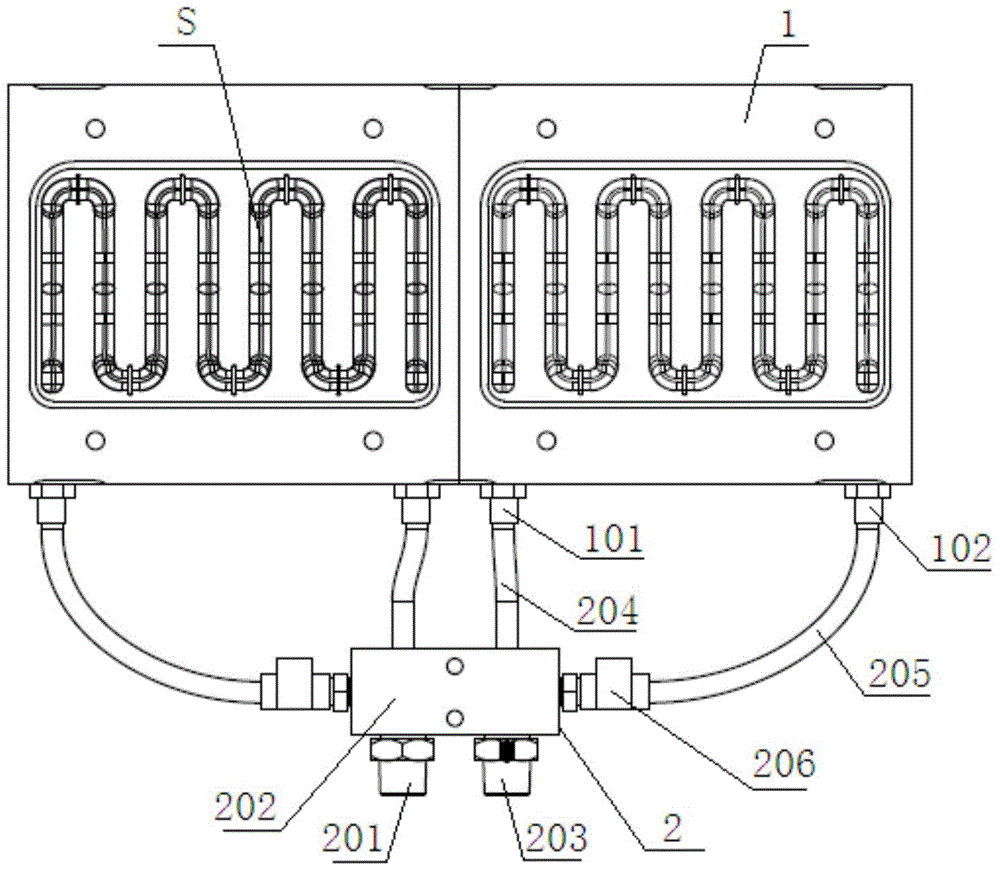

[0043] Such as figure 1 As shown, the serpentine cooling channel type hot stamping die in this embodiment includes an insert 1 (including a pair of punch inserts 11 and a die insert 12), a water flow distribution controller 2 (including a punch insert Water flow distribution controller 21 and die insert water flow distribution controller 22), template 3 (including first template 31 and second template 32); The distribution controller 21 is connected to the water flow distribution controller 22 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com