Cement clinker cooling system and method

A cement clinker and cooling section technology, which is applied in the field of cement production, can solve the problems of troublesome equipment maintenance, large civil construction investment, and large floor area, and achieve the effects of long service life, low operating cost, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

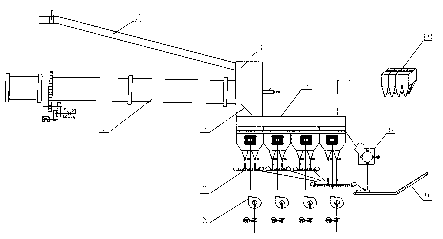

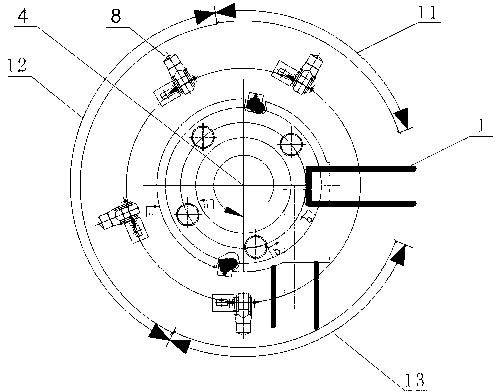

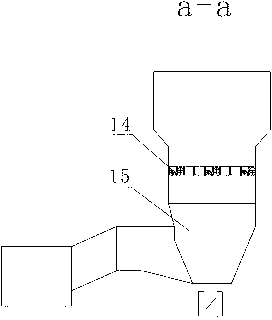

[0020] combine Figure 1-Figure 4 , a cooling system for cement clinker, comprising a rotary kiln 1, a kiln head cover 3, an annular cooler 4, a bag filter 10, a zipper machine 7, a crusher 6 and a chain bucket conveyor 9, the rotary kiln 1 and the annular cooling The machines 4 are connected through the kiln head cover 3, and the feeding end of the annular cooler 4 is provided with a distribution pan 5 located in the kiln head cover 3, and the distribution pan 5 is located below the discharge port of the rotary kiln 1; 4 There are first cooling section 11, second cooling section 12 and third cooling section 13 according to its circumferential length, the lengths of the first, second and third cooling sections account for 15% to 30% and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com