Loading and unloading machine of annular furnace

A discharge machine and annular furnace technology, applied in the field of charging and discharging machines, can solve the problems of lack of multi-stage synchronous expansion and contraction production function, poor equipment operation stability, difficulty in meeting production needs, etc., to reduce temperature, Small footprint and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

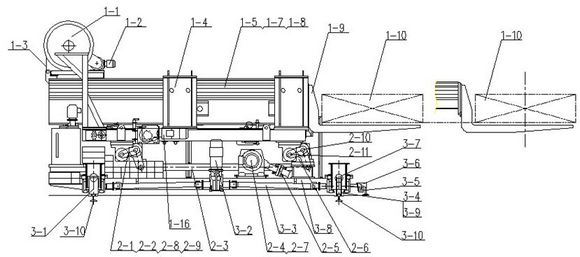

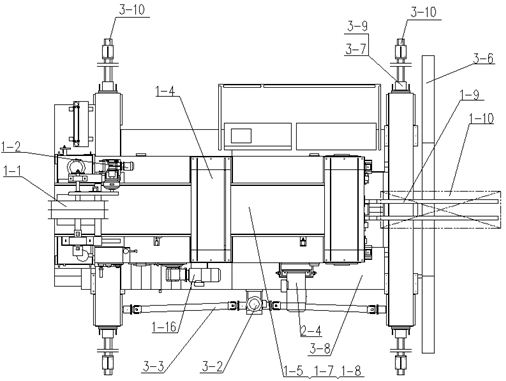

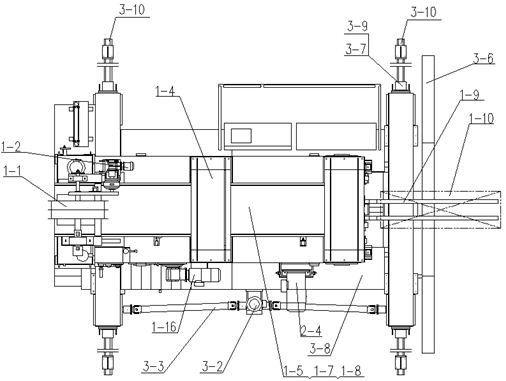

[0021] Such as Figure 1-Figure 4 As shown, a ring furnace charging and discharging machine is composed of a walking device, a lifting device and a telescopic device connected;

[0022] The telescopic device includes a reel set 1-1, a reel drive mechanism 1-2, a cooling hose 1-3, a bracket 1-4, a third-stage telescopic arm 1-5, a support guide wheel set 1-6, a first Secondary telescopic arm 1-7, first stage telescopic arm 1-8, material fork 1-9, transmission tensioning mechanism 1-11, first stage transmission mechanism 1-12, second stage transmission mechanism 1-13, rubber Buffer mechanism 1-14, third stage transmission mechanism 1-15, main drive mechanism 1-16, manual drive mechanism 1-17 and frame 1-18; described frame 1-18 is arranged horizontally, frame 1-18 The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com