Environment-friendly pitching stacking circular material yard

A circular stockyard, environment-friendly technology, applied in the direction of loading/unloading, conveyor, transportation and packaging, etc., can solve the problems of large size, the height of the central column cannot be reduced, and dust, so as to improve stability and avoid dust , the effect of reducing the drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

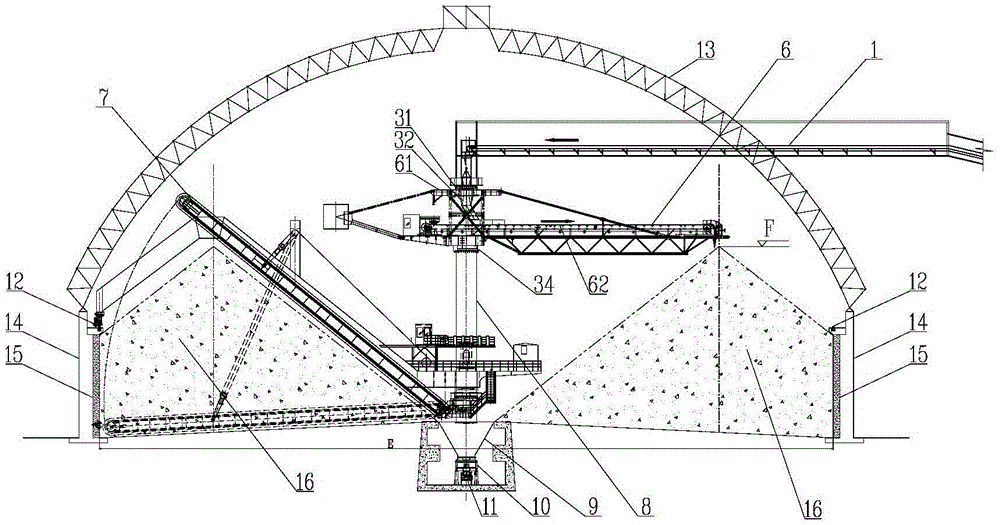

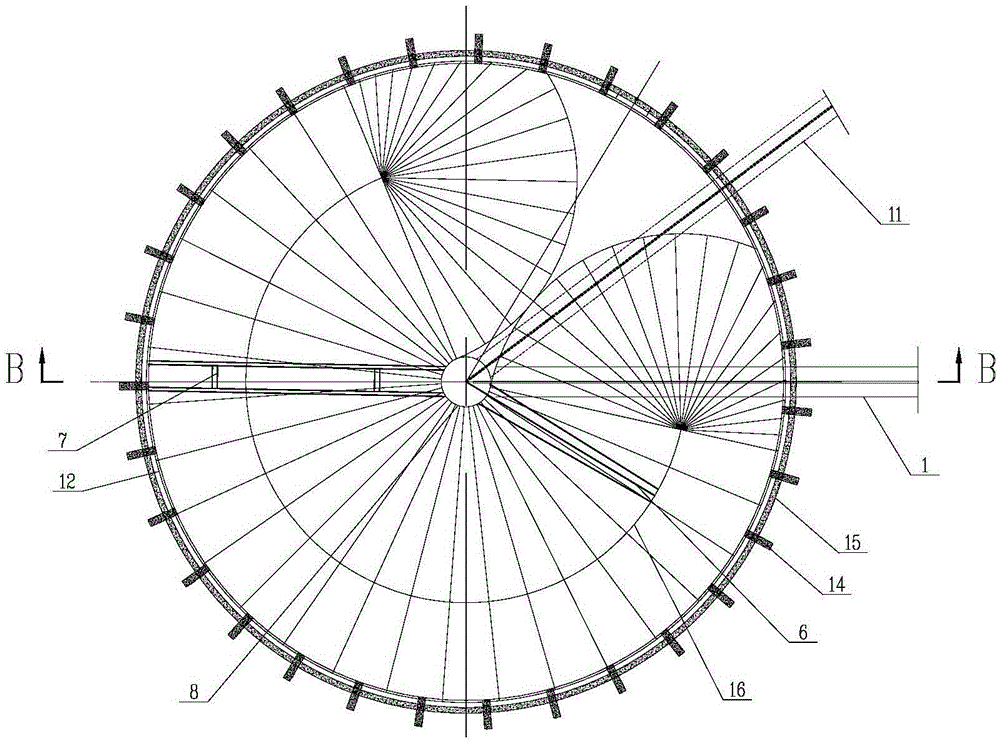

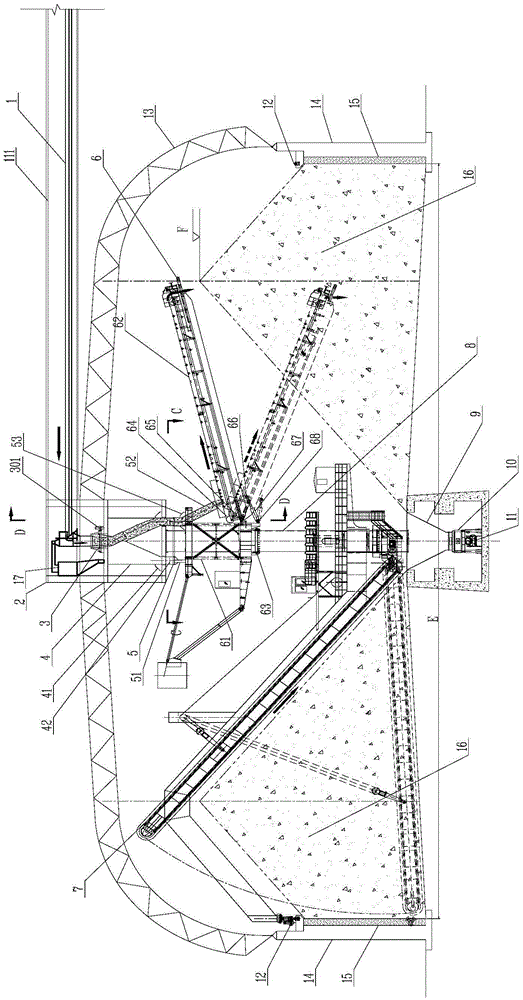

[0028] In this embodiment, the environment-friendly pitching stacking circular stockyard includes a plurality of annularly arranged pillars 14, an arc-shaped stockyard ceiling 13 is supported above the pillars 14, and an annular retaining wall 15 is arranged on the inner side of the pillars 14. The annular retaining wall 15 is sealingly connected with the annular stockyard ceiling, and the annular retaining wall 15 and the annular stockyard ceiling form a material storage space of the stockyard.

[0029] Corresponding to the center of the arc-shaped material yard ceiling 13, a central column 8 is arranged, and the upper end of the central column 8 is fixedly supported with a feeding belt conveyor 1, corresponding to the bottom of the feeding belt conveyor 1, the central column 8 is provided with a stacker 6 that rotates around the center column 8, and the bottom of the center column 8 is connected with a portal scraper reclaimer 7 that rotates around the center column 8. The gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com