Crushing and recovery processing method of waste wood-plastic composite

A technology of wood-plastic composite materials and wood-plastic materials, which is applied in the field of crushing and recycling of waste wood-plastic composite materials. It can solve the problems of high energy consumption and difficulty in crushing during the recycling process, and achieve low crushing power, easy destruction, and effective crushing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

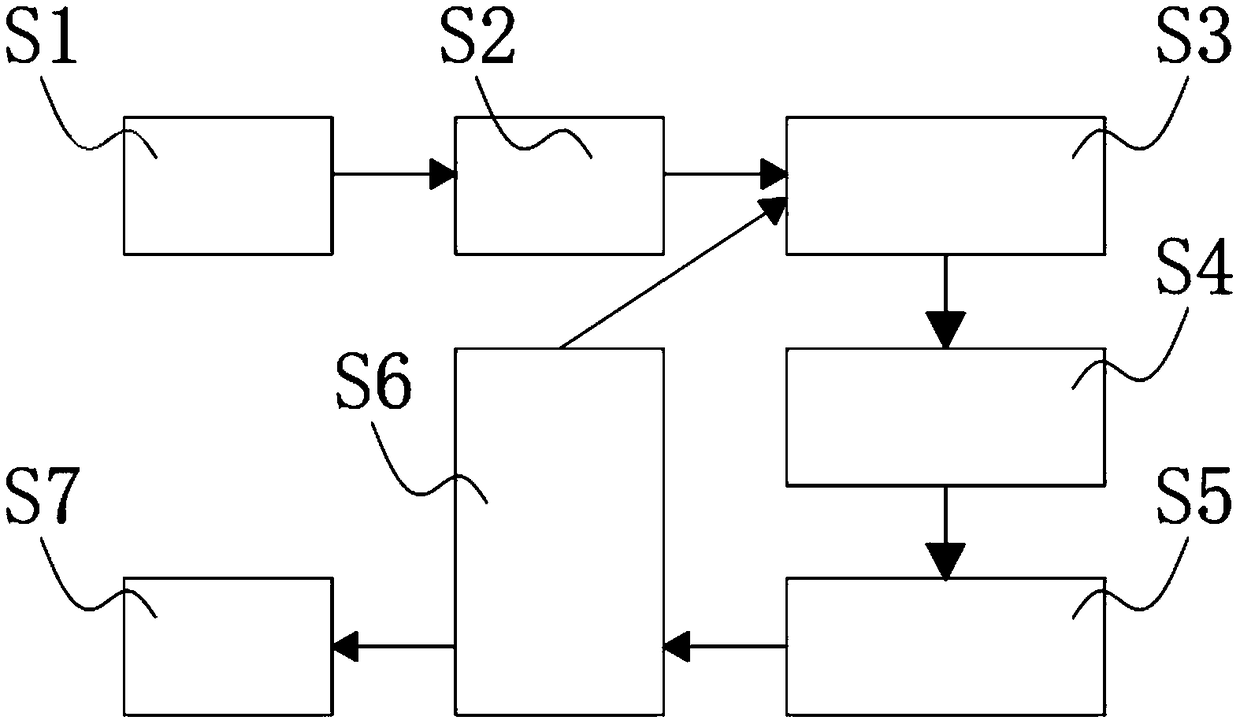

[0036] refer to figure 1 A method for crushing and recycling waste wood-plastic composite materials, comprising the following steps:

[0037] S1. Collect waste and old wood-plastic materials, and carry out preliminary cleaning on the collected waste and old wood-plastic materials. The preliminary cleaning includes preliminary segmentation and cleaning. The preliminary segmentation is to remove other materials on the waste and old wood-plastic materials by cutting machines, and clean them. Rinse with high-pressure water to cut and rinse the recovered waste wood-plastic materials, which can effectively improve the purity of waste wood-plastic materials, thereby avoiding debris remaining on waste wood-plastic materials, which is conducive to improving the efficiency and quality of processing. ;

[0038] S2. The cleaned waste wood-plastic materials are transported by clamping and feeding conveying machinery, and the clamping and feeding conveying machinery can stably transmit was...

Embodiment 2

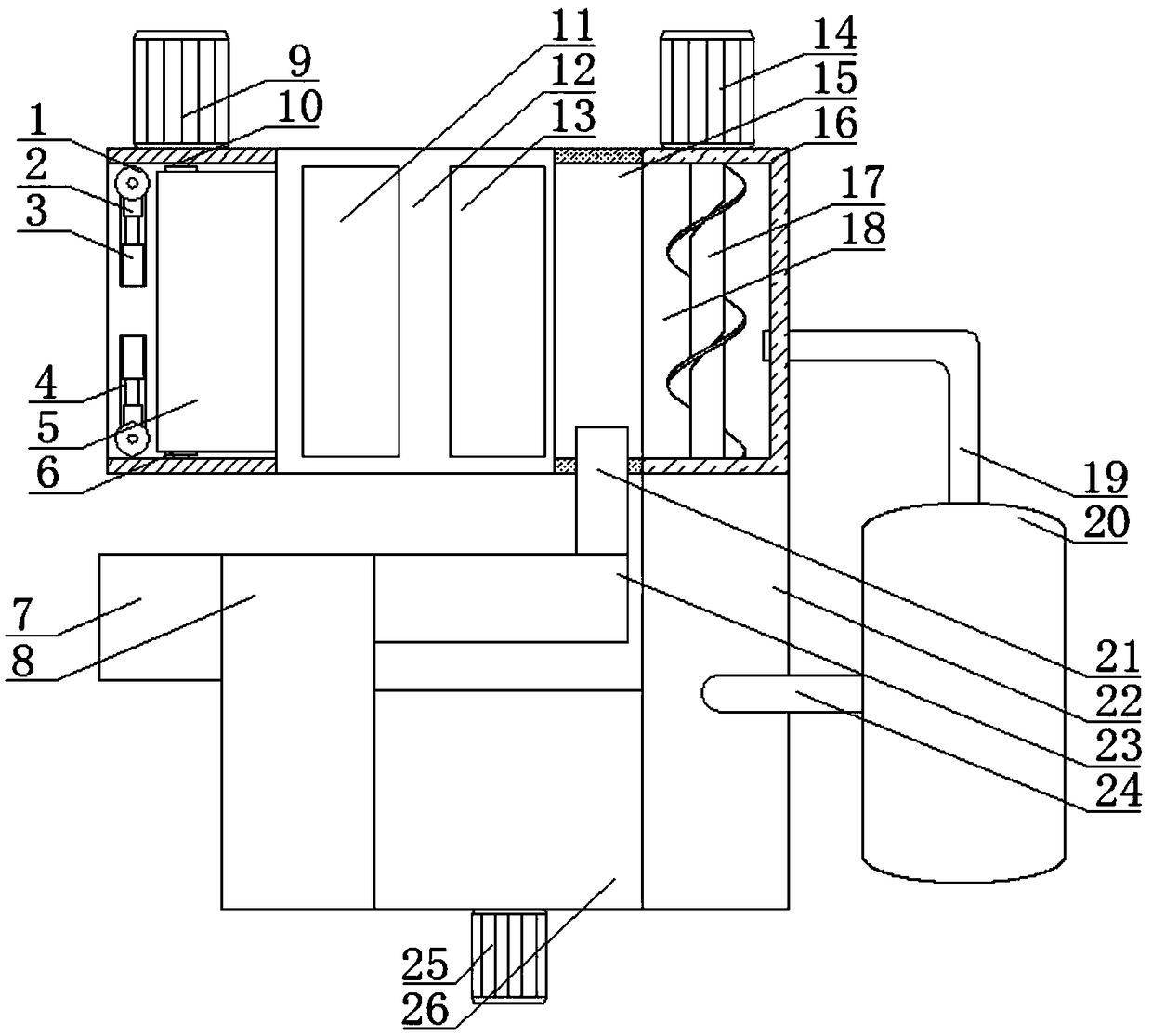

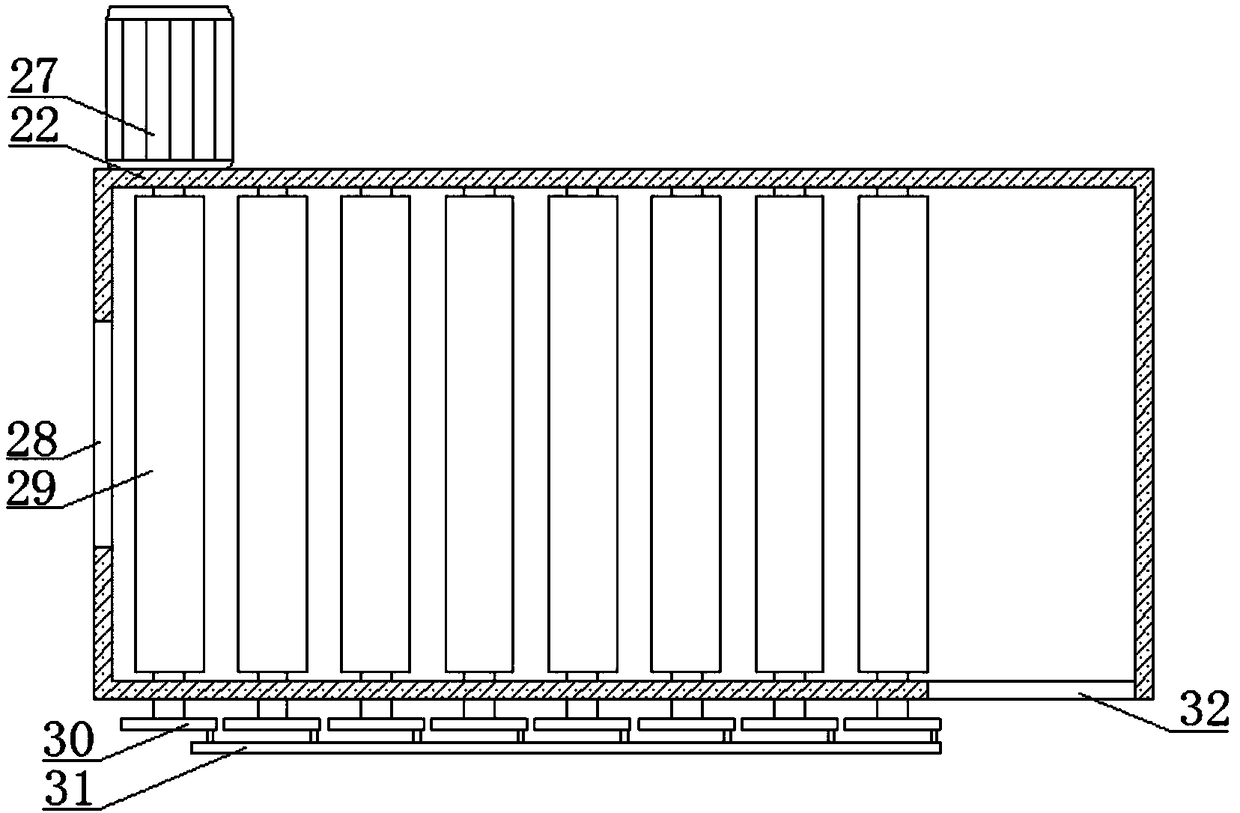

[0046] refer to Figure 2-8 , the crushing and recycling processing method of waste wood-plastic composite materials, using a low-temperature impact crushing device for waste wood-plastic materials, the low-temperature impact crushing device for waste wood-plastic materials has a liquid nitrogen processing bin 22, and the upper end of the liquid nitrogen processing bin 22 runs through A second connecting pipe 24 is provided, the lower end of the second connecting pipe 24 is connected with a spray plate 33, and one end of the second connecting pipe 24 is connected with a liquid nitrogen storage tank 20, so that the liquid nitrogen in the liquid nitrogen storage tank 20 can pass through the second The connecting pipe 24 and the spray plate 33 enter the liquid nitrogen storage tank 20, thereby facilitating cooling of the material, increasing the brittleness of the material, and facilitating crushing;

[0047] One side of the liquid nitrogen storage tank 20 is provided with a pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com