Cooling equipment for electric vehicle parts

A cooling equipment and electric vehicle technology, applied in the field of electric vehicle accessories, can solve problems such as uneven cooling, long cooling time, affecting casting quality and use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

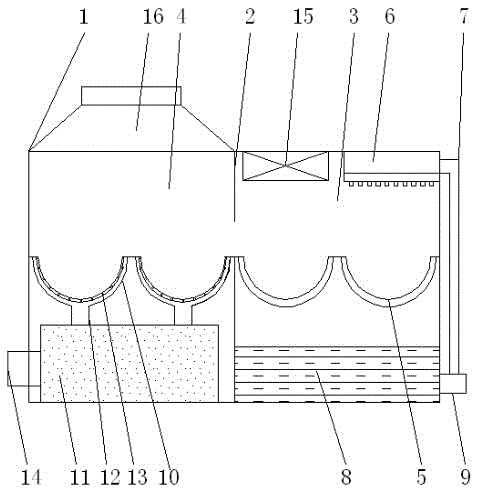

[0019] Such as figure 1 As shown, a cooling device for electric vehicle accessories of the present invention includes a cooling outer casing 1, and the inside of the cooling outer casing 1 is divided into a first cooling chamber 3 and a second cooling chamber 4 by a partition 2, and the first cooling chamber The interior of the chamber 3 is provided with a first storage tank 5, and the top of the interior of the first cooling chamber 3 is provided with a spraying device. The spraying device includes a nozzle assembly 6 and a drainage channel 7. The nozzle assembly 6 is connected to the water collection tank 8 through the drainage channel 7. The first The bottom of the cooling chamber 3 is provided with a water collection tank 8, and one side of the water collection tank 8 is provided with a water outlet 9. The second cooling chamber 4 is provided with a second placement tank 10 and a steam device. The steam device includes a steam collection tank 11 and The steam channel 12, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com