Constant temperature control device of combined type fan electronic control system

An electronic control system, constant temperature control technology, applied in the control device, measuring device, coolant flow control and other directions of the cooling device, can solve the problem that the engine cannot effectively solve the problem of low temperature temperature rise and high temperature heat dissipation of the engine, large water and gas temperature deviation, and engine Low thermal efficiency and other problems, to achieve the effect of preventing backflow turbulence, stabilizing the deviation of water and gas temperature, and solving low temperature heating and high temperature heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

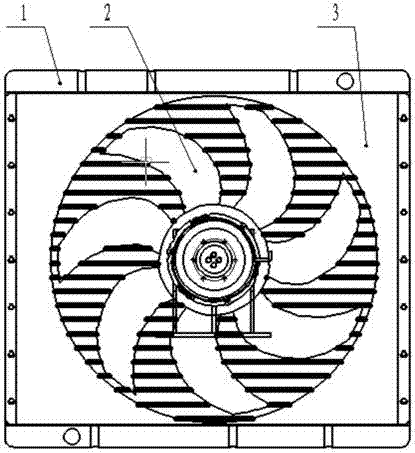

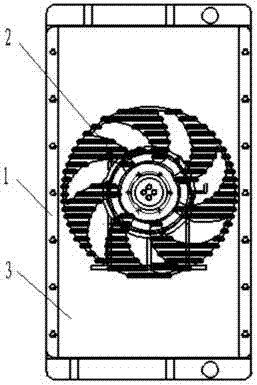

[0064] Example 1, such as Figure 1-3 and 15 as shown:

[0065] The first speed of the two-speed clutch is flexible drive, the clutch output speed is 40%-60% of the input speed, the second speed is rigid drive, the output speed is equal to the input speed. The electronic fan is driven to rotate by the electric energy of the whole vehicle, and at the same time, the number of its work is controlled by the control system.

[0066] The electronic fan and the mechanical fan 2 are respectively arranged before and after the water tank 1, and the mechanical fan 2 is for blowing when the electronic fan is for suction. When the electronic fan is blowing, the mechanical fan 2 is sucking.

[0067] Warming control strategy:

[0068] Assume that the electronic fans 1, 2, 3, and 4 work as ON, and do not work as OFF.

[0069] 1. When the temperature of the engine coolant is very low and does not reach the operating temperature t1 set by the system, the clutch rotates at one speed. Electr...

Embodiment 2

[0075] Example 2, such as Figure 1-3 and 15 as shown:

[0076] Embodiment 2 is improved on the basis of Embodiment 1, and the two-speed clutch is changed to a three-speed clutch.

[0077] Three-speed clutch (the first speed does not transmit working torque, the second speed is flexible drive, the clutch output speed is 40%-60% of the input speed, the third speed is rigid drive, the output speed is equal to the input speed).

[0078] Warming control strategy:

[0079] Assume that the electronic fan is ON when it is working, and OFF when it is not working.

[0080] 1. When the temperature of the engine coolant is very low and does not reach the operating temperature t1 set by the system, the clutch rotates at one speed. Electronic fans are all OFF. At this time, the engine water temperature rises rapidly, and the system basically does not consume engine power.

[0081] 2. When the coolant temperature reaches the working temperature t1 set by the system and does not reach t...

Embodiment 3

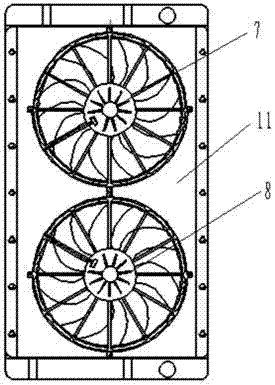

[0091] Example 3, such as Figure 4-6 and 15 as shown:

[0092] The first speed of the two-speed clutch is flexible drive, the clutch output speed is 40%-60% of the input speed, the second speed is rigid drive, the output speed is equal to the input speed.

[0093] The structure of the electronic fan windshield and the mechanical fan windshield is the same as that of Embodiment 1. The sealing method is also the same.

[0094] Warming control strategy:

[0095] Assume that the first and second electronic fans are ON when they are working, and OFF when they are not working.

[0096] 1. When the temperature of the engine coolant is very low and does not reach the operating temperature t1 set by the system, the clutch rotates at one speed. Electronic fans are all OFF. At this time, the engine water temperature rises rapidly, and the system basically does not consume engine power.

[0097] 2. When the coolant temperature reaches the working temperature t1 set by the system an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com