Patents

Literature

94results about How to "Guaranteed thermal balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

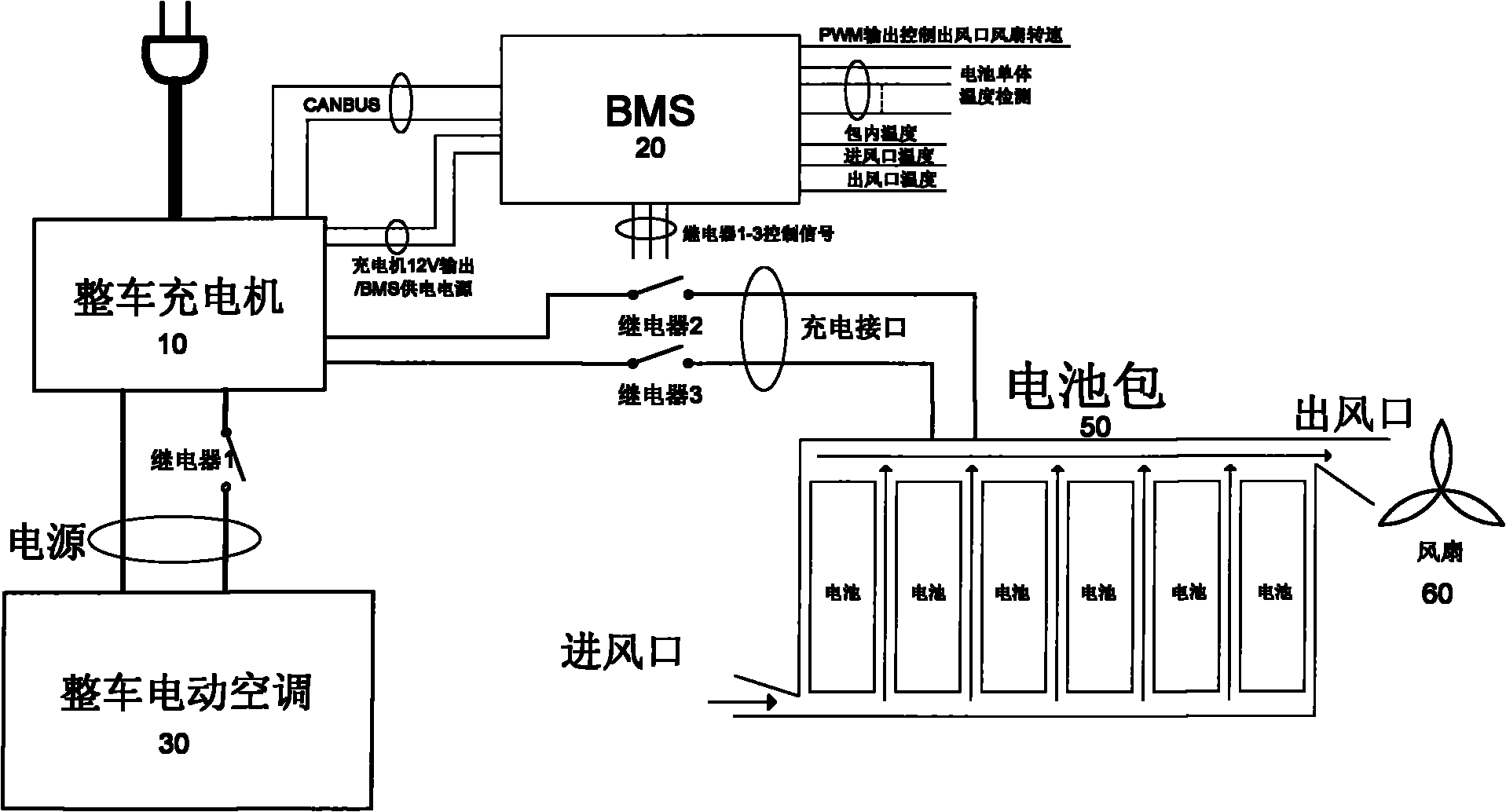

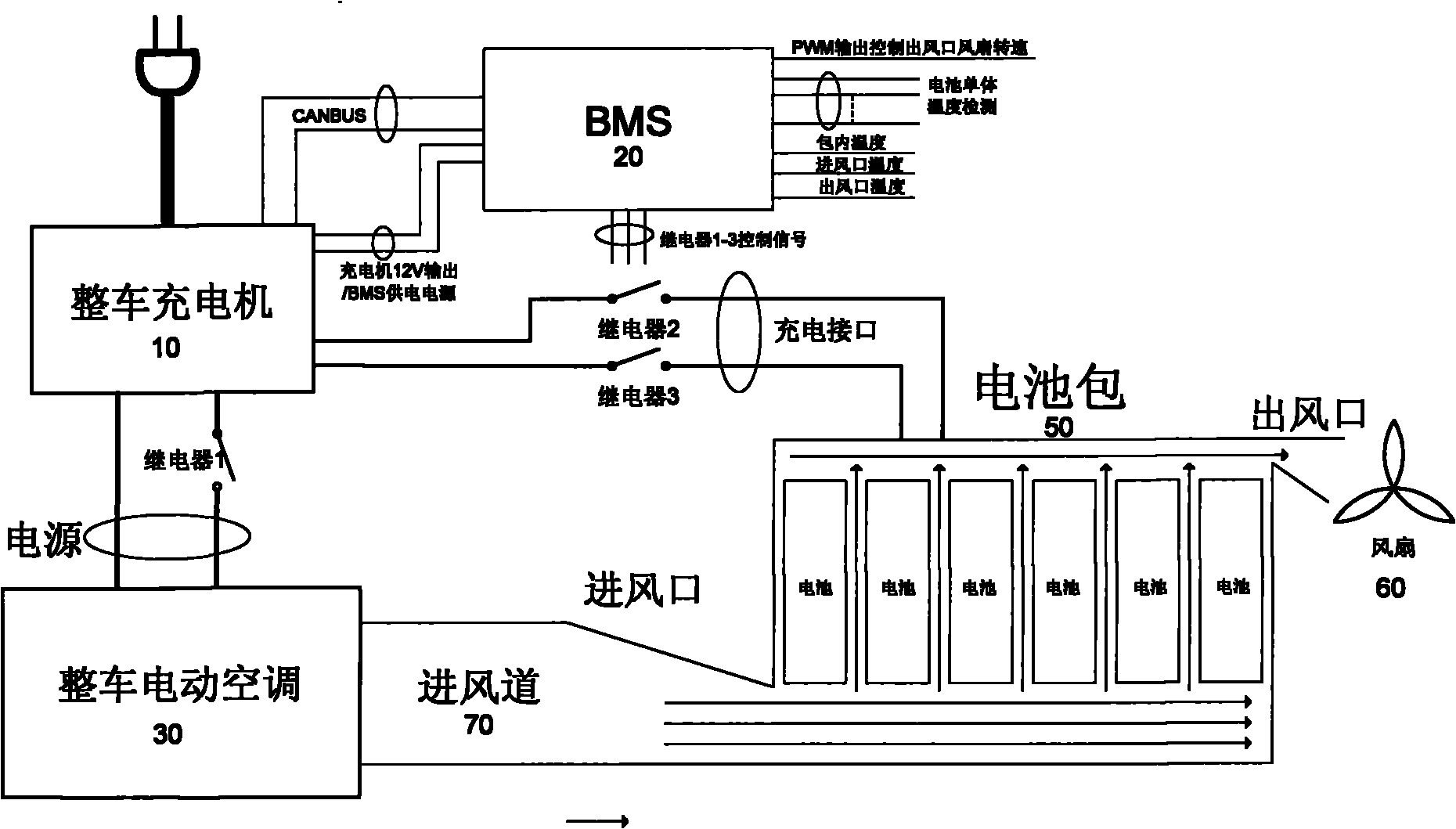

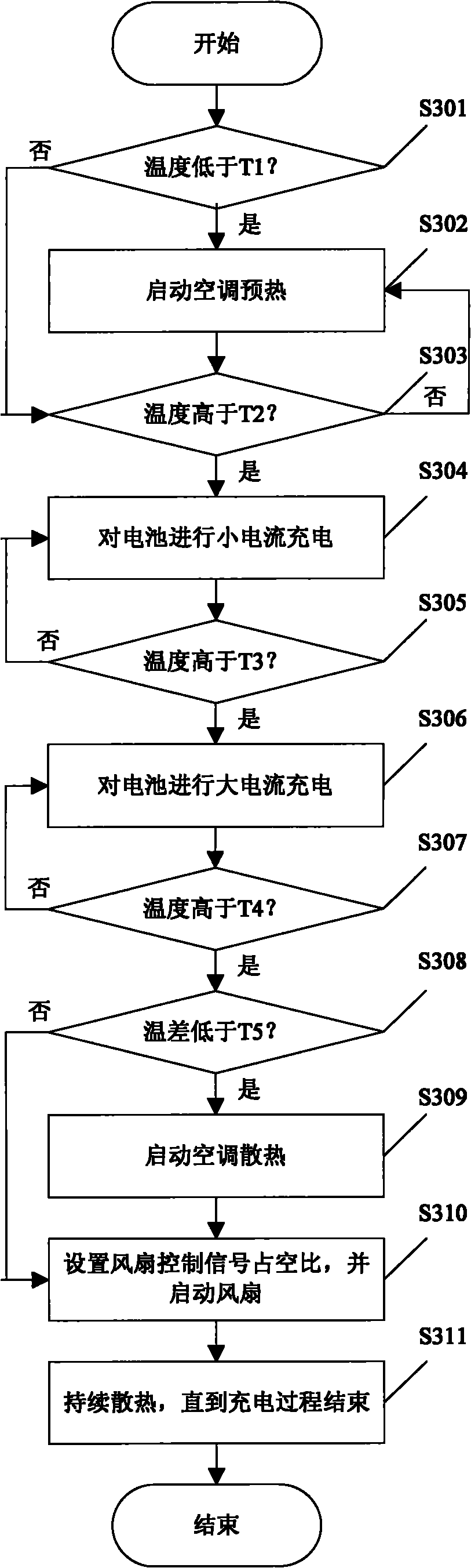

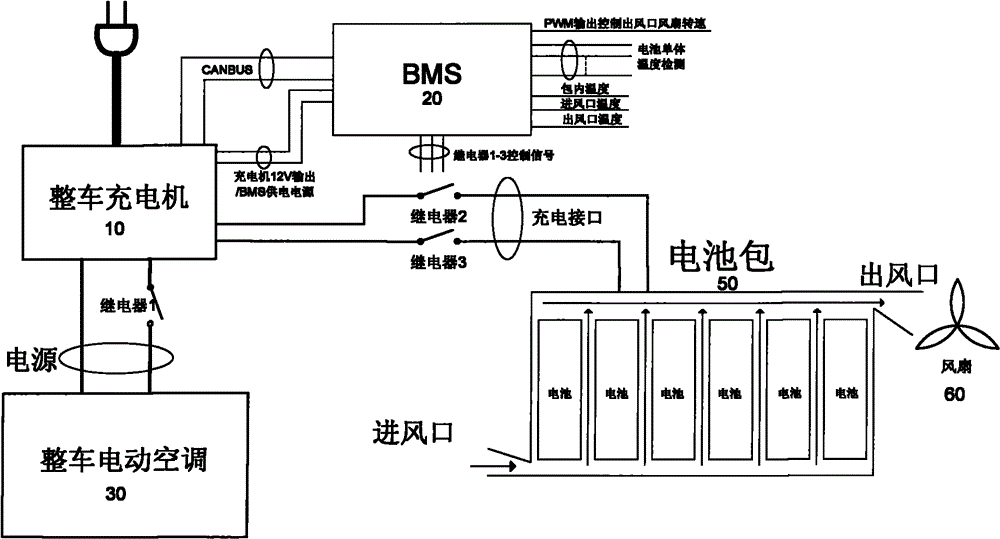

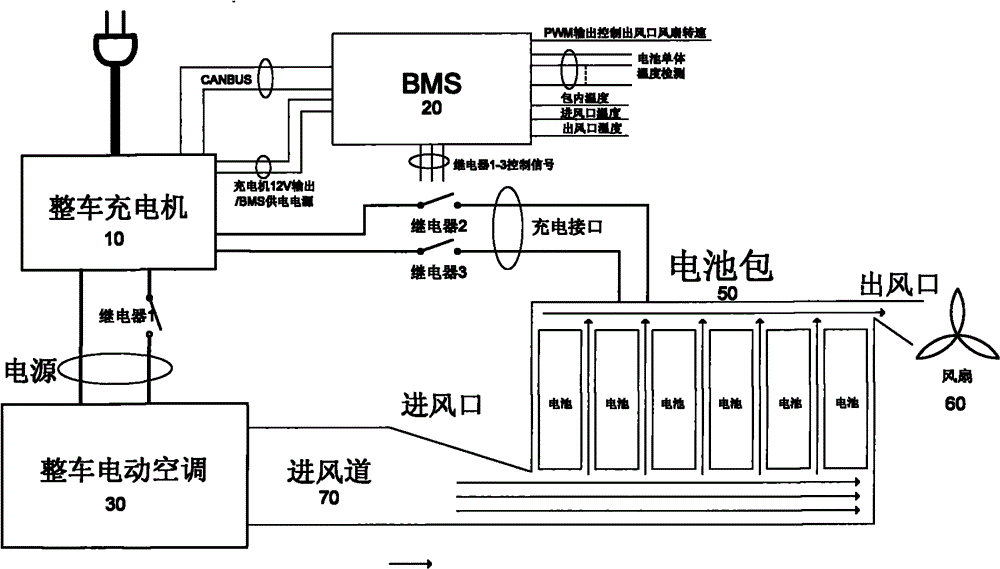

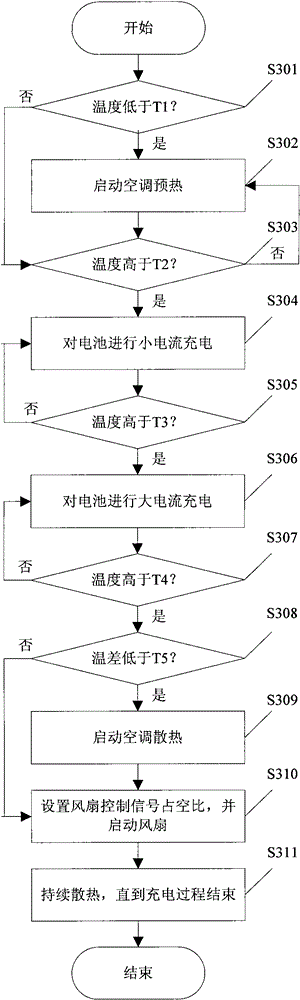

Power battery thermal management system and control method thereof

ActiveCN102139646AGuaranteed thermal balanceCell temperature controlVehicular energy storageCold airPower battery

The invention provides a power battery thermal management system which comprises a complete automobile power-driven air conditioner, a complete automobile charger, an air passage and a battery management system, wherein the air passage is connected with an air outlet of the complete automobile power-driven air conditioner and an air inlet of a battery pack and is used for leading hot air or cold air of the air conditioner into the battery pack; the battery management system is used for controlling the hot air of the air conditioner to be led into the battery pack so as to preheat the battery set in the battery pack when the lowest temperature of a battery module is lower than a first threshold value and controlling the battery set in the battery pack to be charged and discharged after preheating the battery pack; when the highest temperature of the battery module is higher than a second threshold value and the temperature difference between the ambient temperature of the air inlet of the battery pack and the temperature of the battery module is lower than a third threshold, the battery management system controls the cold air of the air conditioner to be led to the battery pack so as to dissipate heat in the battery set in the battery pack. Accordingly, the invention provides a control method of the thermal management system. The invention can lead the battery pack to be charged and discharged in the allowable temperature range and ensure the heat balance among the battery modules and prevent the battery from being overcharged and overdischarged.

Owner:CHERY AUTOMOBILE CO LTD

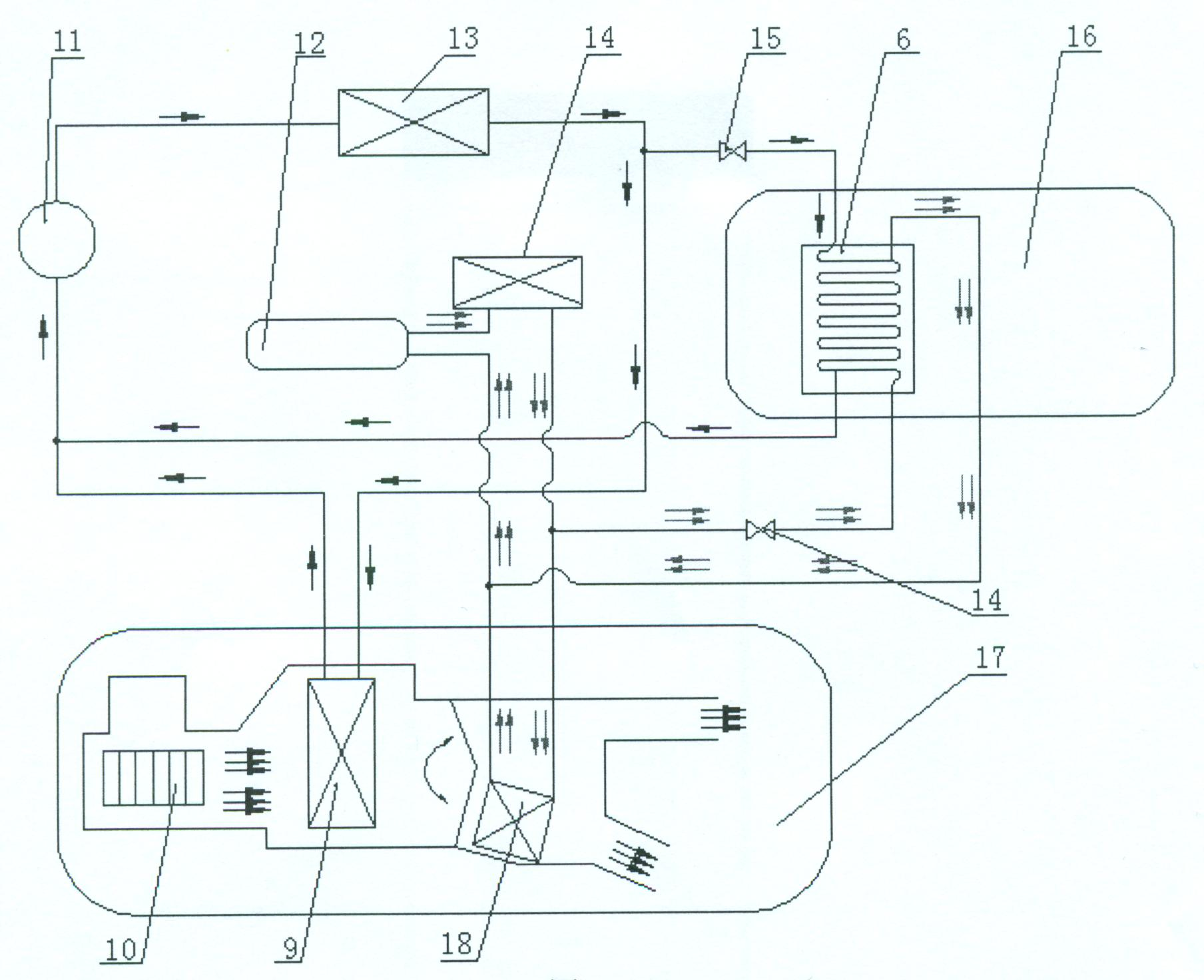

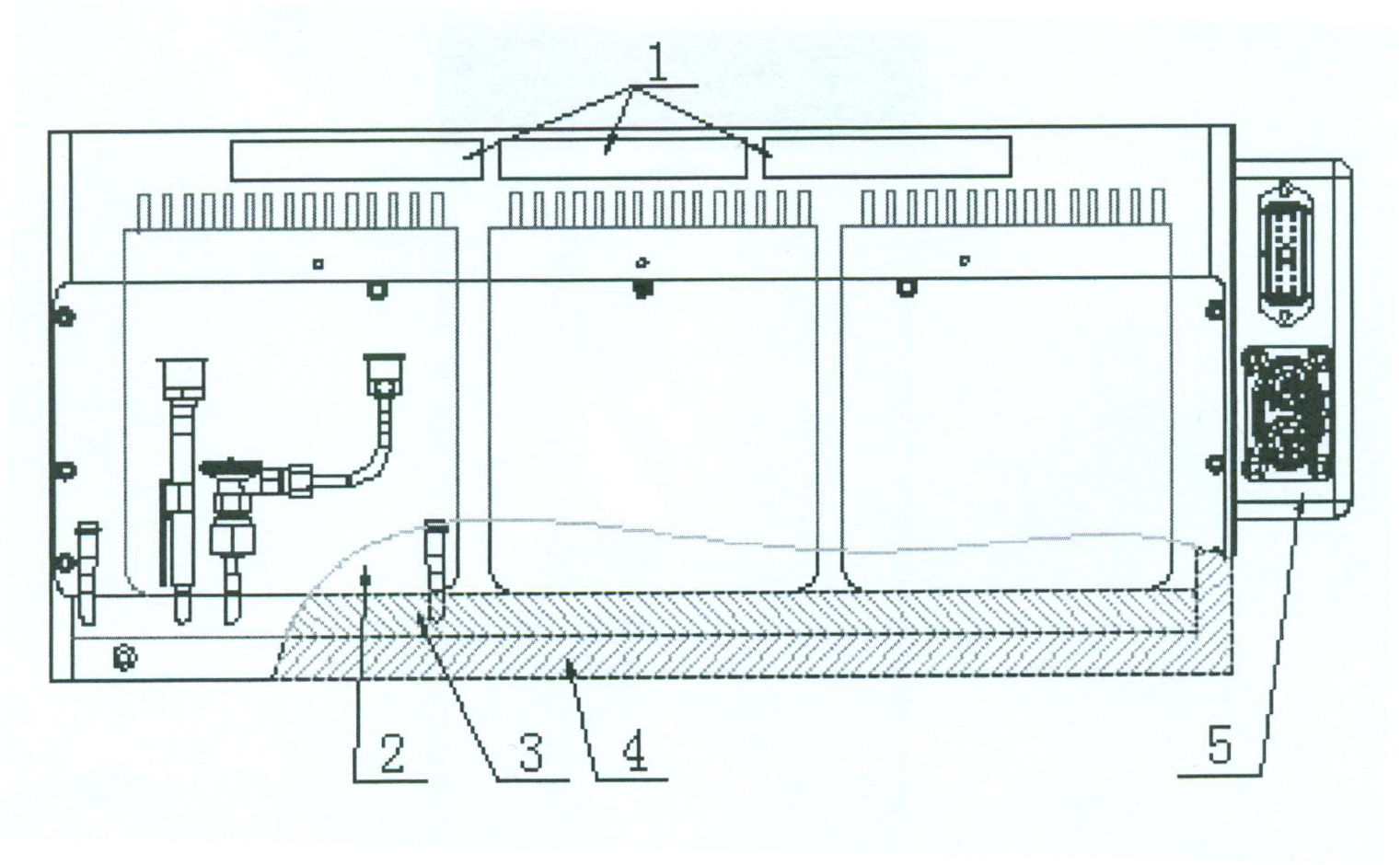

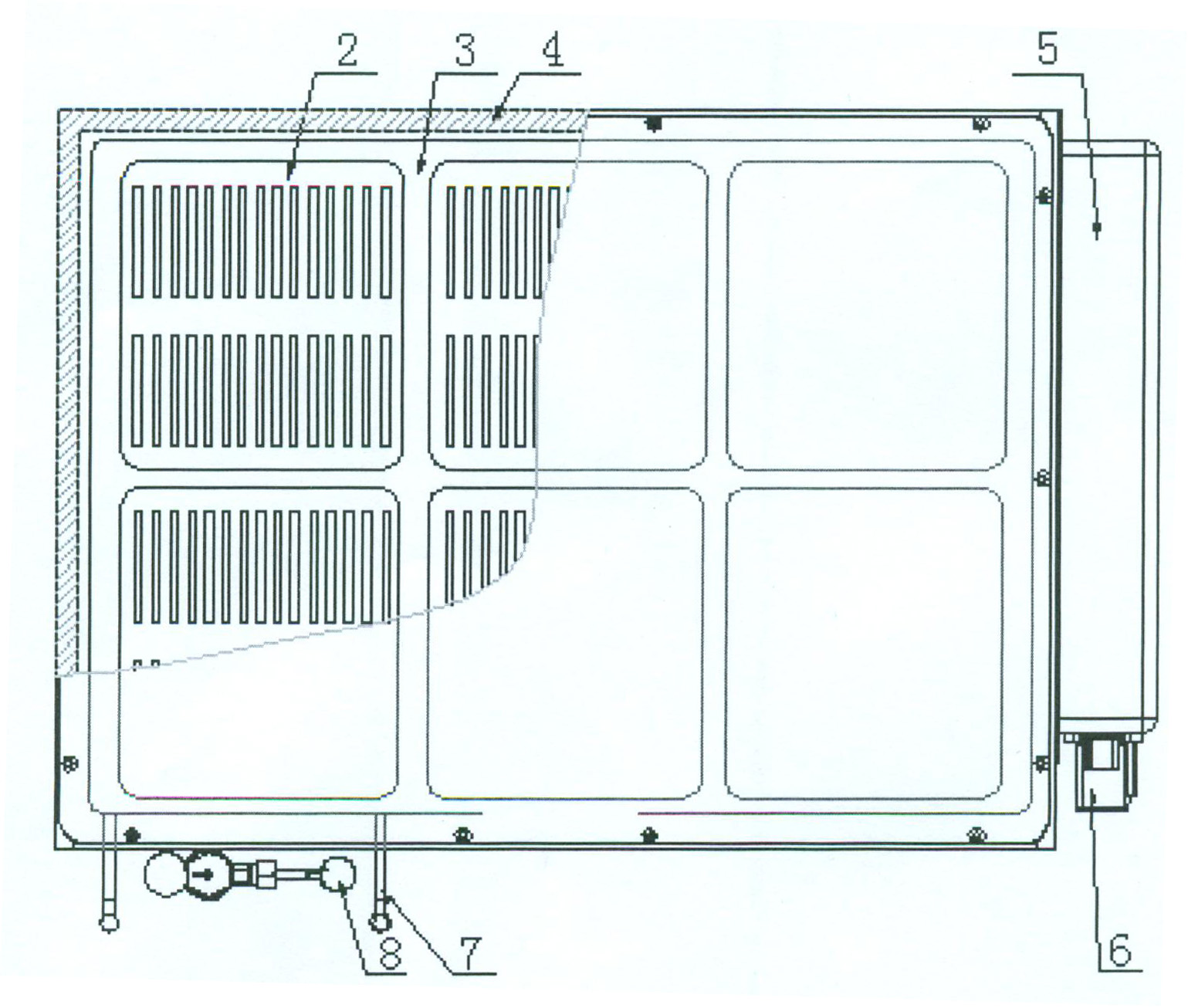

Power battery of motor vehicle provided with air conditioning system

InactiveCN102088108AGuaranteed normal startupGuaranteed normal drivingCell temperature controlLi-accumulatorsLow voltageWater storage tank

The invention discloses a power battery of a motor vehicle provided with an air conditioning system, which is technical characterized in that a heat exchanging fan is arranged on the inner surface of a top cover of a battery packaging box, a battery cell is arranged in the battery packaging box below the heat exchanging fan, a heat conducting plate is arranged at the bottom of the battery packaging box below the battery cell, a refrigerant pipe and a hot water pipe are arranged inside the heat conducting plate, a high-voltage wire connector and a low-voltage wire connector are arranged on a battery control device, an air blower is arranged at an air inlet of the vehicle body, a fan heater and an evaporator are arranged on a ventilation pipeline between the air blower and an air outlet of a passenger compartment, an electric air conditioning compressor and a condenser are connected in series and then connected in parallel with the refrigerant pipe inside the heat conducting plate on the evaporator, and a water circulation pump and a water storage tank provided with a heater are connected in series and then connected in parallel with the hot water pipe inside the heat conducting plate on the fan heater. The power battery of the motor vehicle adopts the water cooling method and air cooling method simultaneously. The air conditioner takes the heat of the battery away or heats the battery, and the fan is used for causing forced convection so as to guarantee heat balance of the battery and further guarantee the working performance and service life of the lithium battery.

Owner:BRILLIANCE AUTO

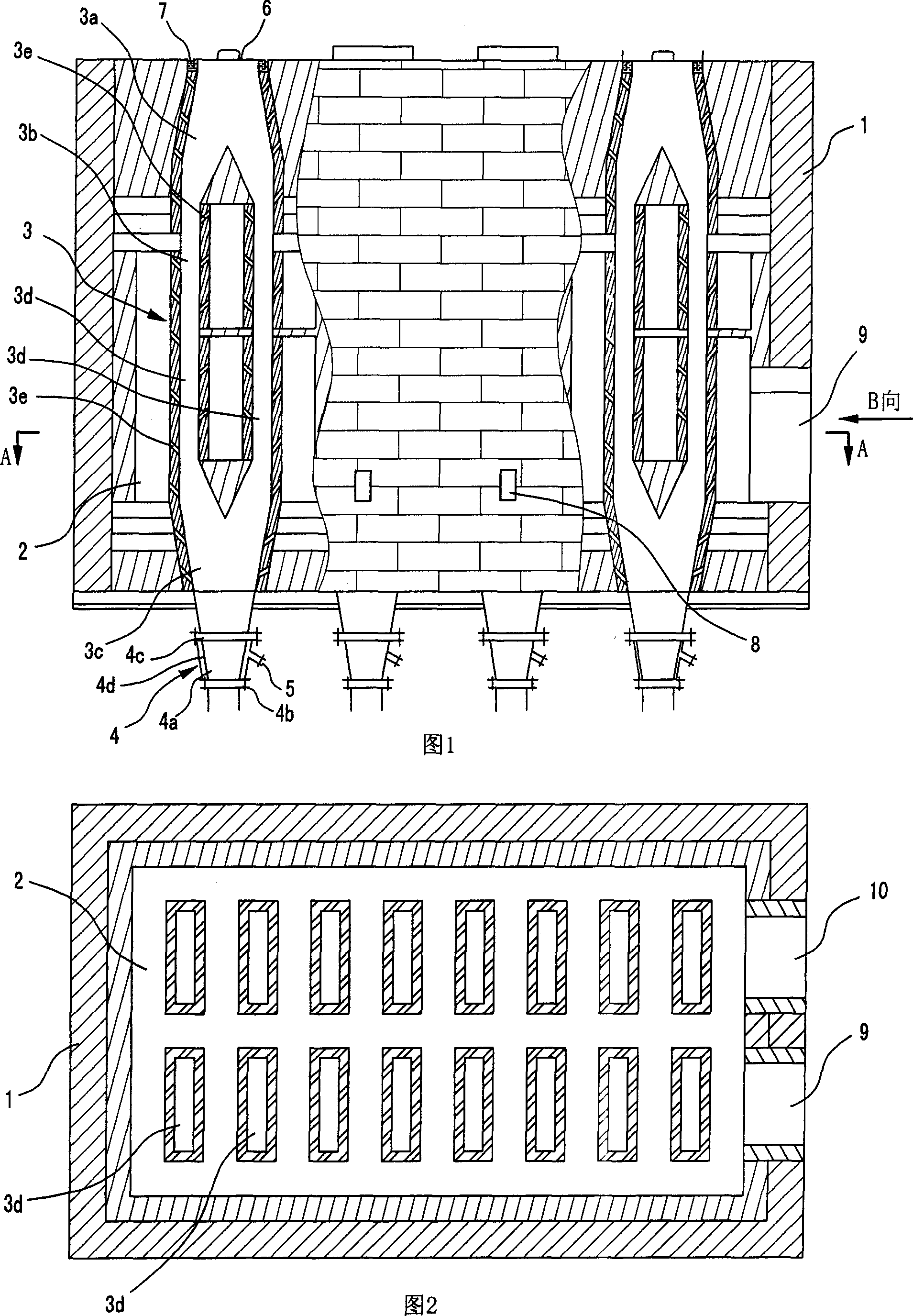

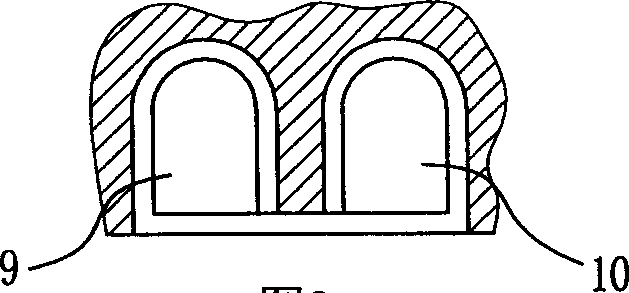

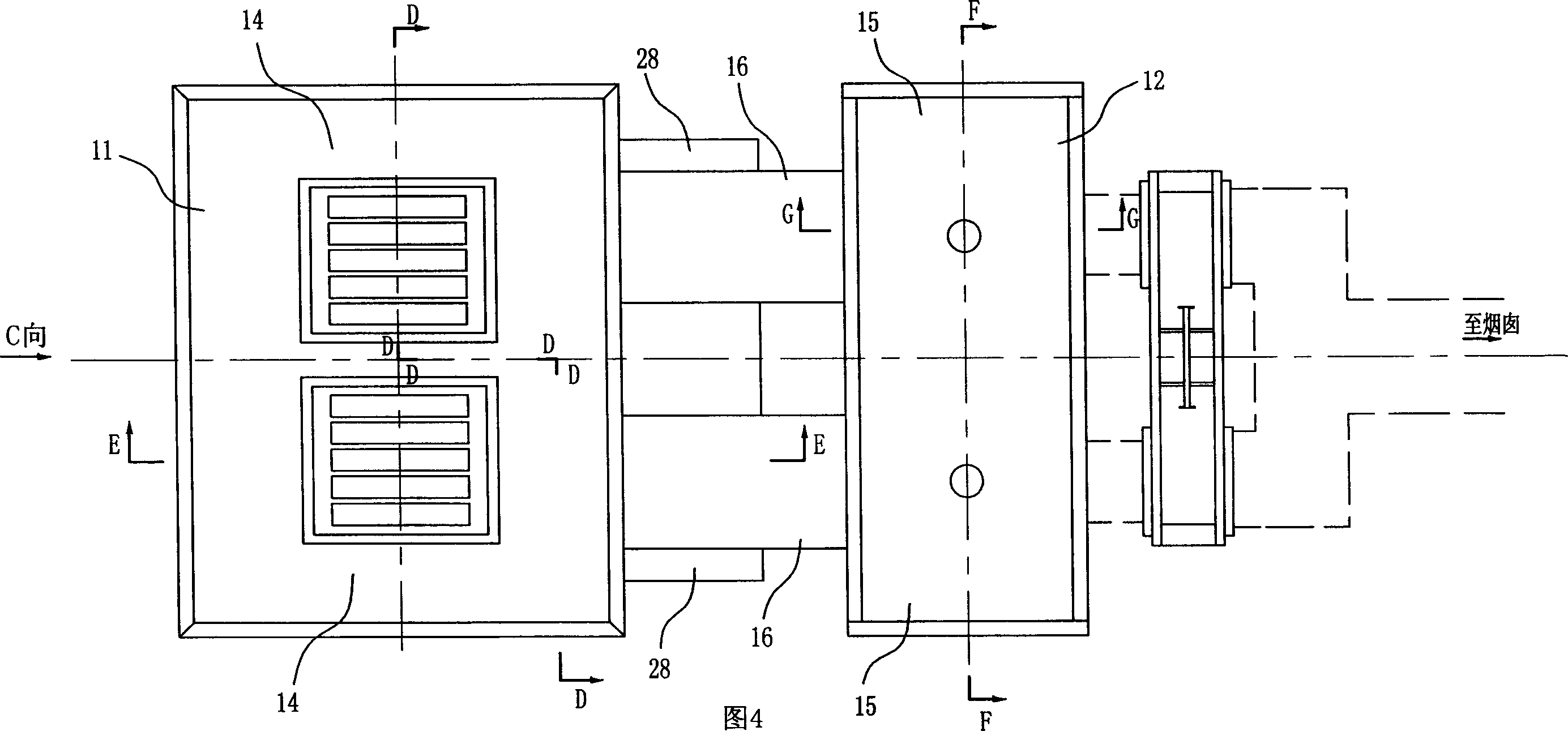

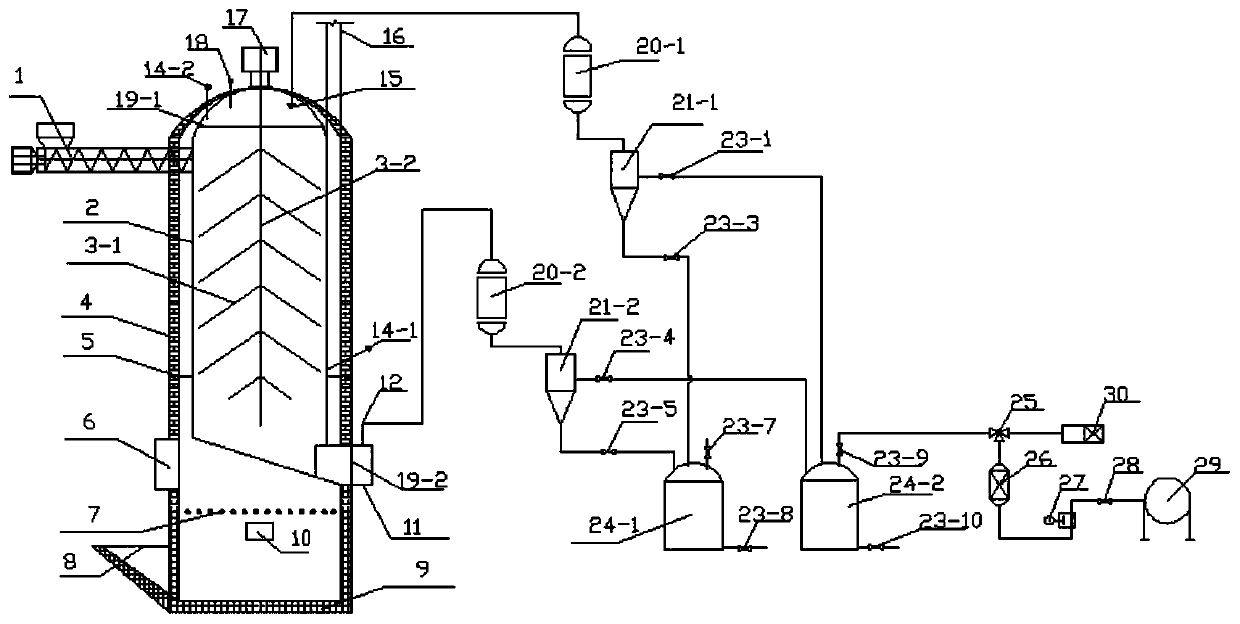

Process for preparing bamboo-based activated carbon and dedicated device therefor

The invention discloses a preparing method and specific equipment of bamboo activated-carbon, which comprises the following steps: grinding; carbonizing continuously in the multi-pipe retort at 550-750 deg.c for 1-4 h; activating continuously in the retort at 800-950 deg.c for 48-72 h; pickling; bleaching; dehydrating; drying. The retort possesses stove base, furnace, several carbonizing pipes in the furnace vertically, feeder inlet on the top of retort, discharge device on the lower end, which is divided into preheating segment, carbonizing segment and cooling segment, wherein the retorting furnace contains furnace, heat-reserving chamber, chimney with furnace and heat-reserving chamber displaying left and right symmetrical structure; the furnace is separated into left and right half-furnaces by baffle; the heat-reserving chamber is divided into left and right two heat-reserving half-chamber correspondingly; the steam injecting pipe is set on the bottom of heat-reserving half-chamber; the vertical activating band is set in the furnace with several up-to-down carbonizing material channel and transverse gas flux to connect carbonizing material channel.

Owner:浙江恒日炭业有限公司

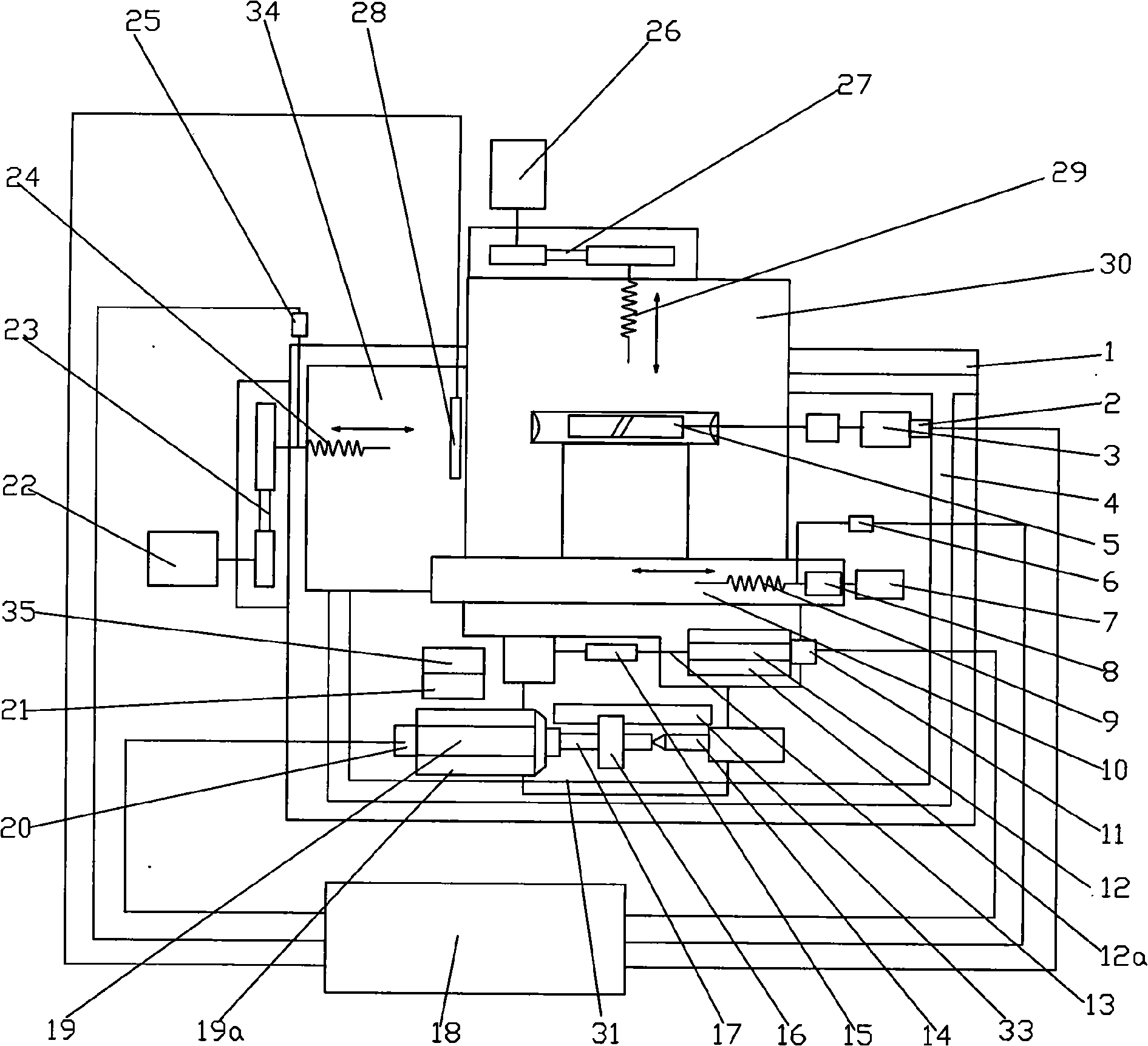

Zero-drive chain digital control gear hobbing machine

InactiveCN101298106AGuaranteed stabilityNo vibrationFeeding apparatusGear-cutting machinesHobbingGear wheel

The invention discloses a numberical control hobbing machine with zero transmission, which comprises a machine body, a main shaft system, a hobbing cutter feeding and angle adjusting system and a control system; the main shaft system comprises a functional part of a hobbing cutter main shaft and a functional part of work-piece main shaft part; the functional part of the hobbing cutter main shaft is an integration of the rotator of the servo motor I and the hobbing cutter main shaft, and the functional part of the work-piece main shaft is an integration of the rotator of the servo motor II and the work-piece main shaft. The numberical control hobbing machine of the invention can remove the manufacturing errors of transmission component of generating motion and the influence on gear process caused by space and assembly error, is able to greatly improve process accuracy and process speed of machine tool. The numberical control hobbing machine of the invention has simple structure, is able to improve overall rigidity of machine tool, solves the wearing problem caused by mechanical transmission chain, improves the retentivity of precision, causes the hobbing speed to be higher than the numberical control hobbing machine with traditional structure, shortens milling time as well as based on which, the hobbing machine is provided with the machine tool conditions required by dry type hobbing through adopting a series of matching technical measures.

Owner:CHONGQING UNIV

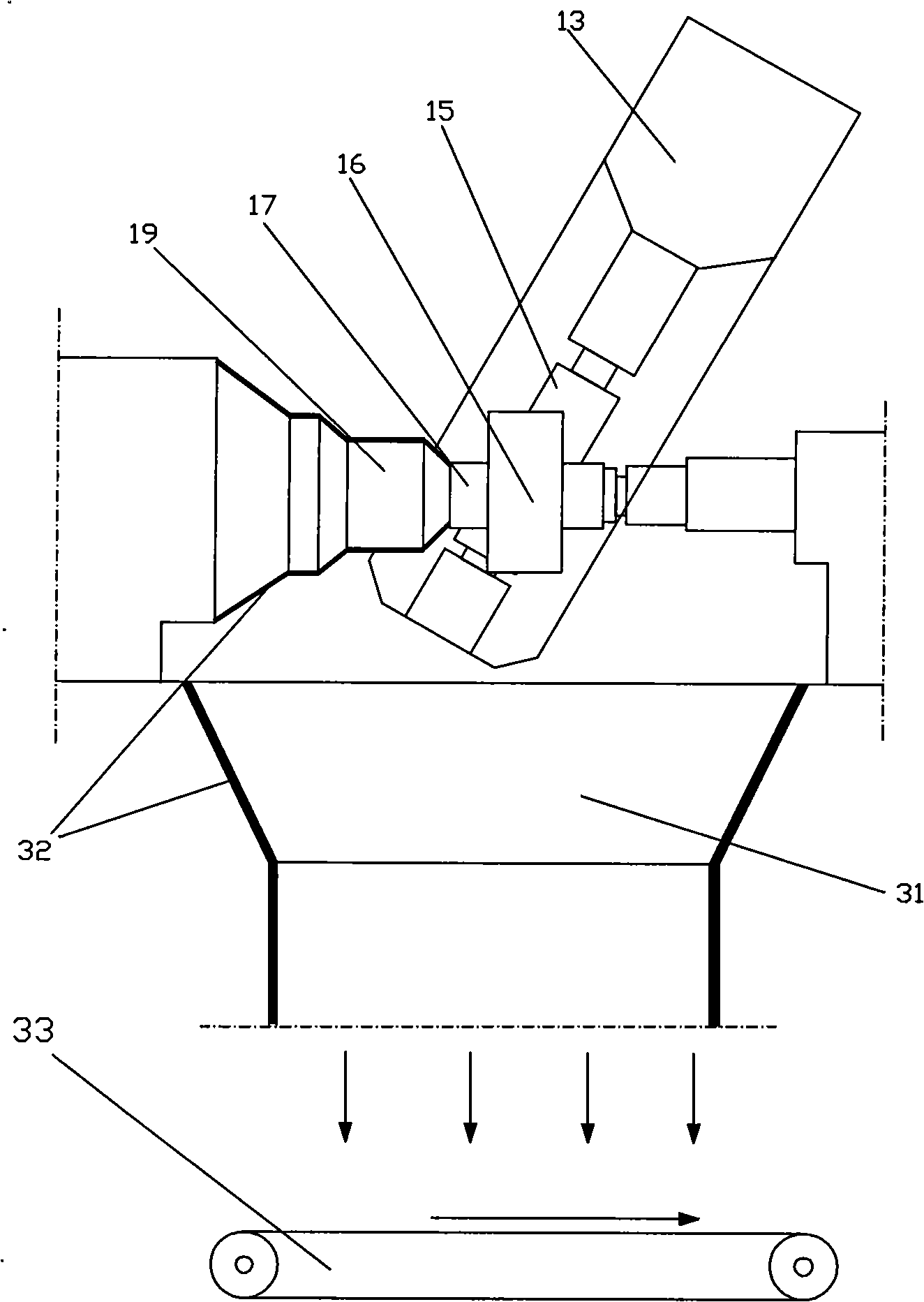

Production process for graphitized cathode

The invention discloses a graphitizing cathode process, which comprises selecting and mixing delayed petroleum coke, pitch coke, after calcinations, fragmenting and sieving, adding hard pitch binder after mixing, pugging, machining charcoal rough shape of electrobath cathode, baking to make binder pitch carbonizing, making graphitizing cathode charcoal block. The invention has good mechanical, electrical , thermal property, and costs low, is especially suitable for large scale electrolytic cell.

Owner:GUIYANG AL-MG DESIGN & RES INST

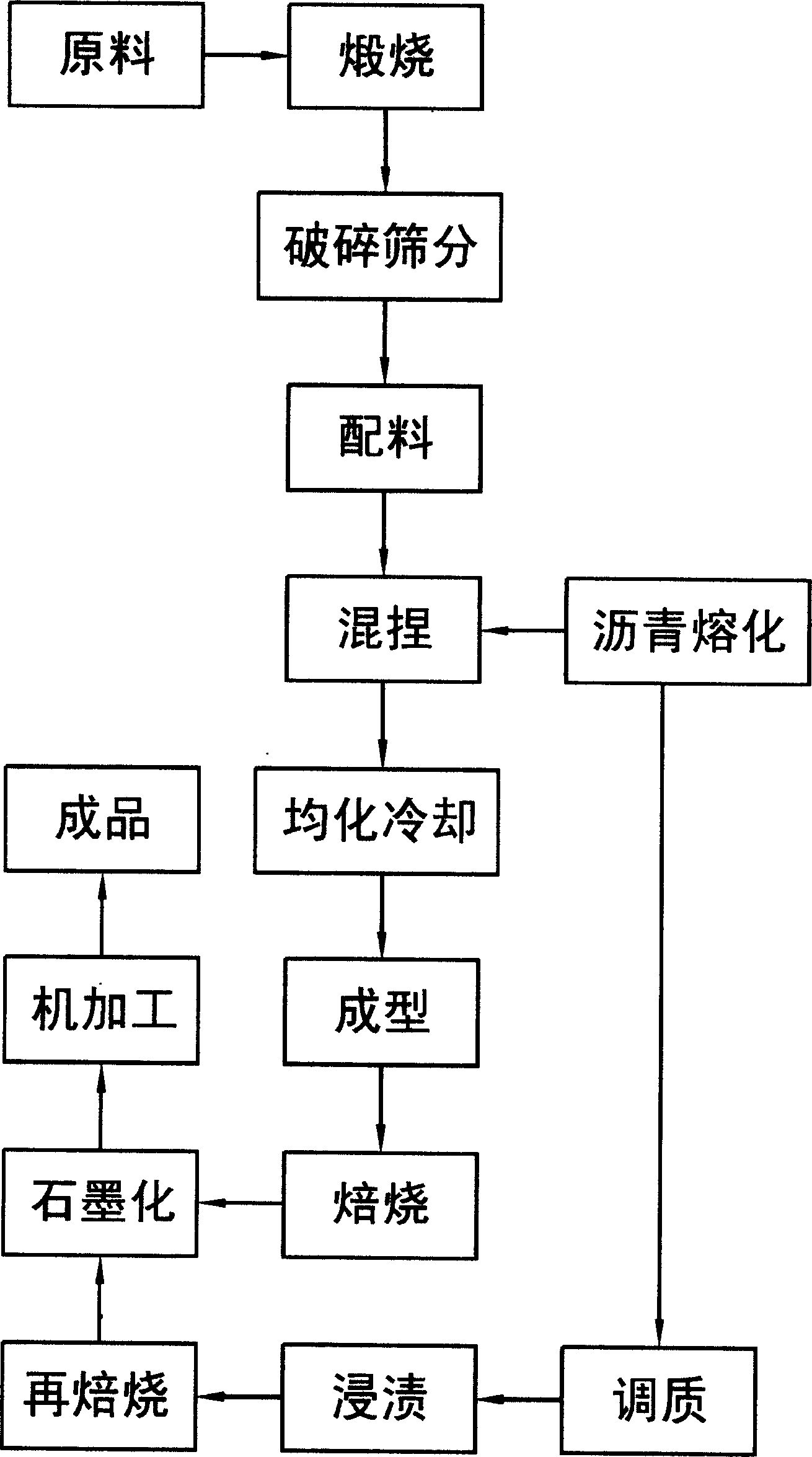

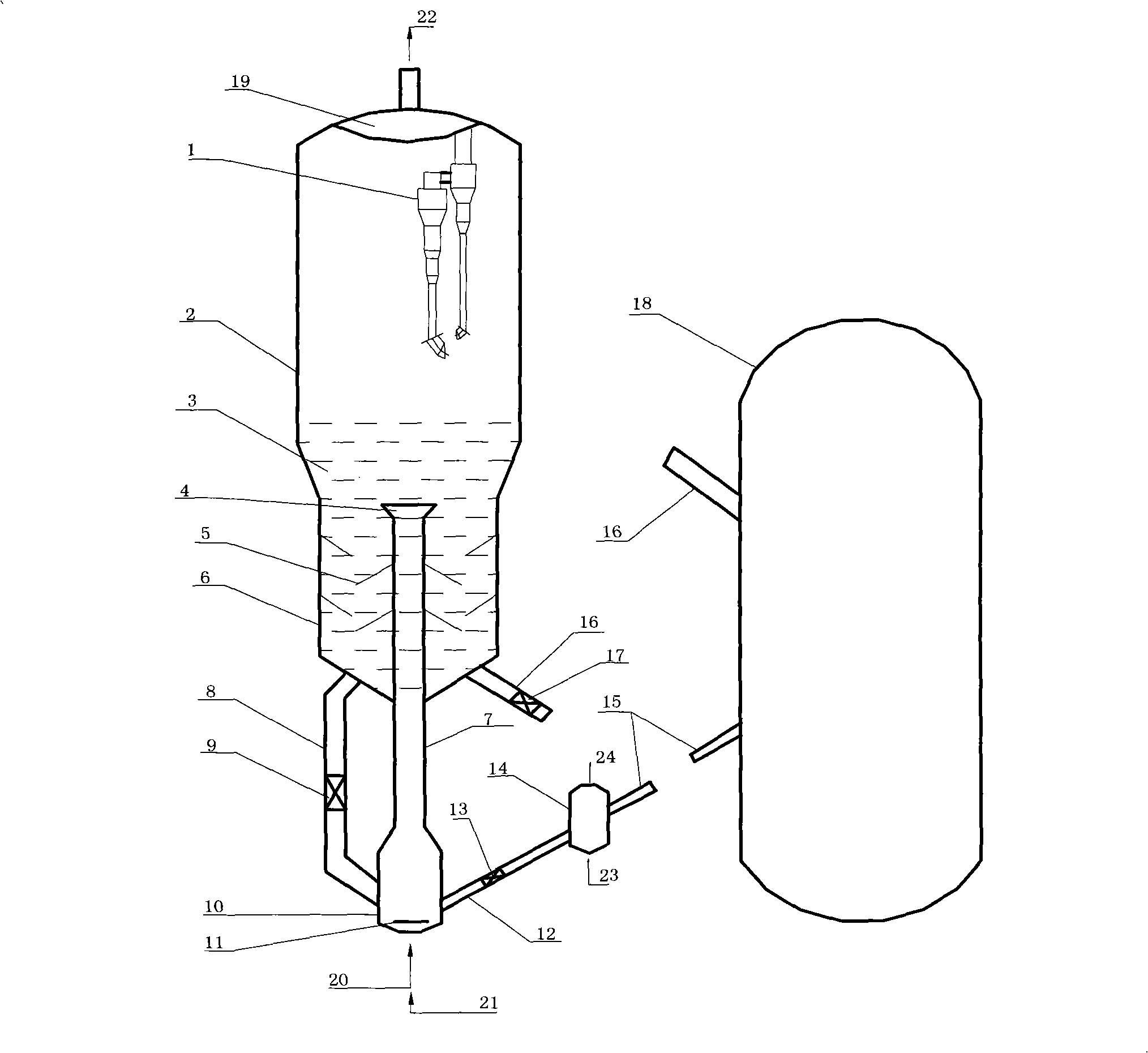

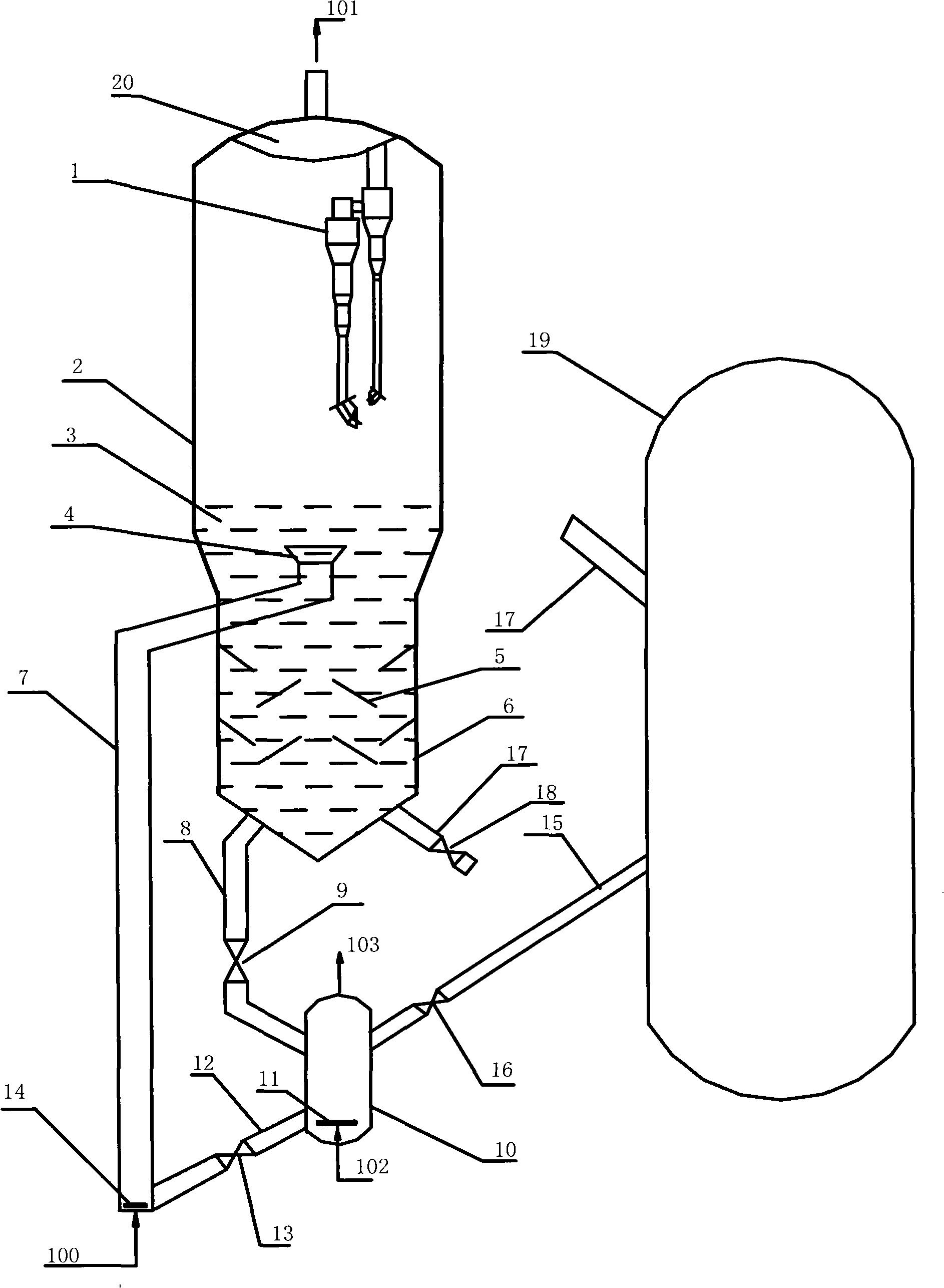

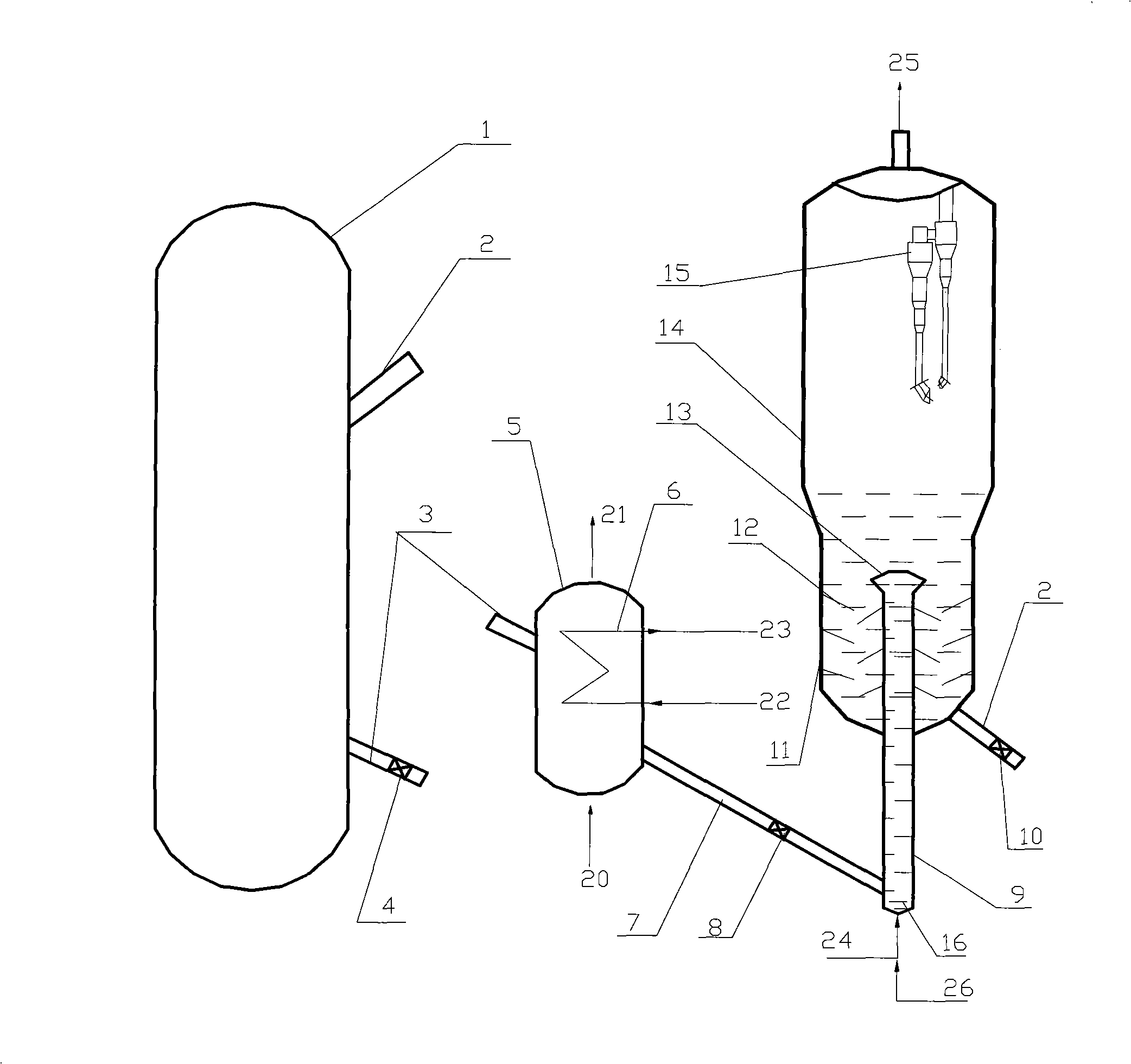

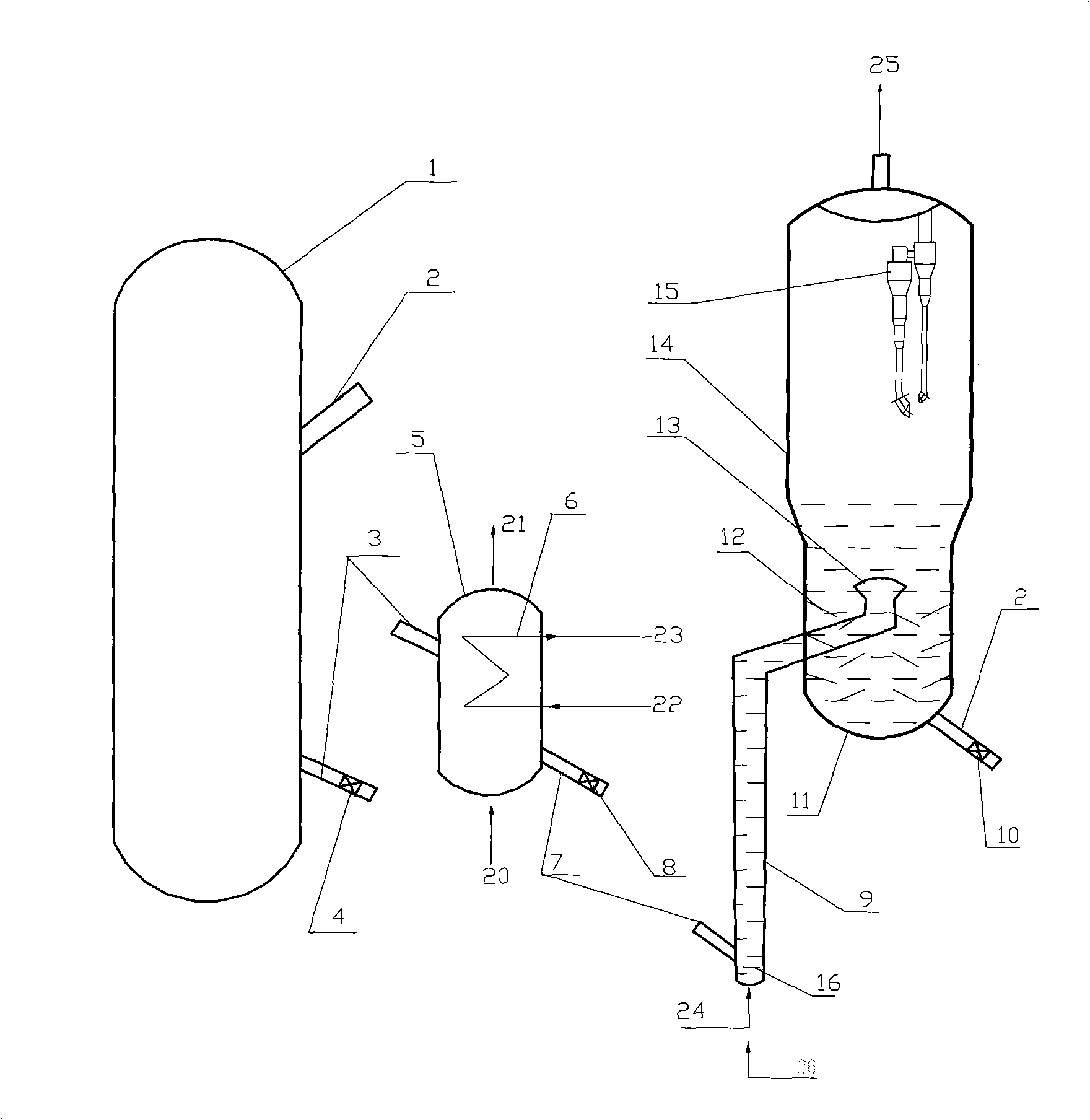

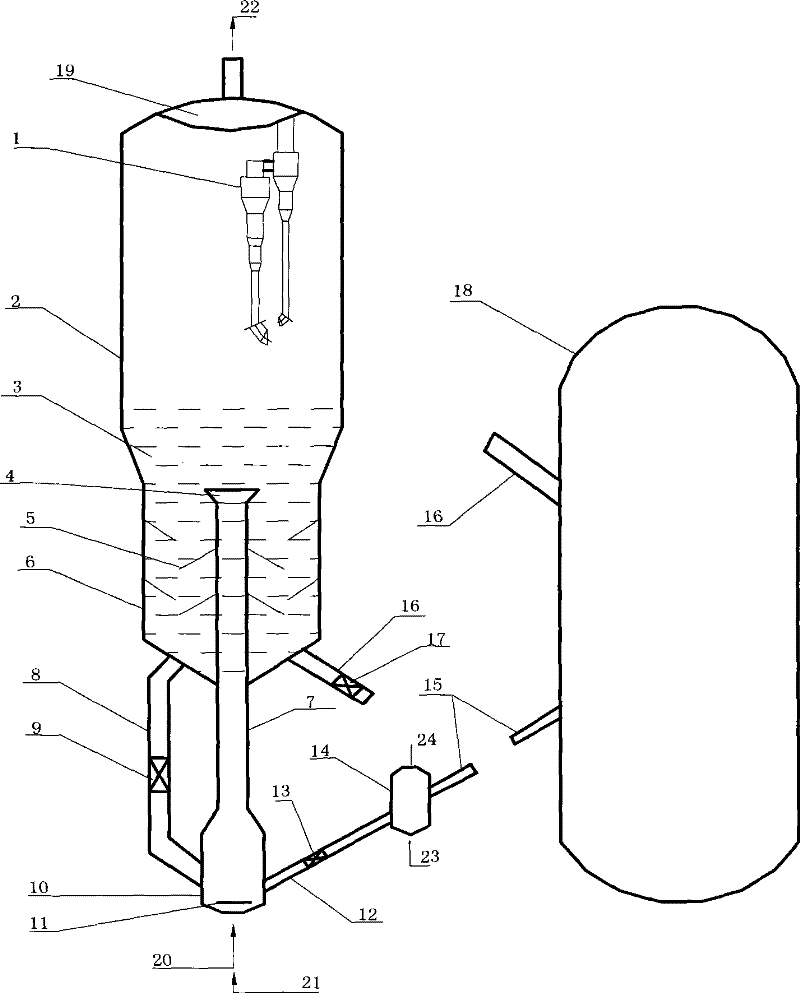

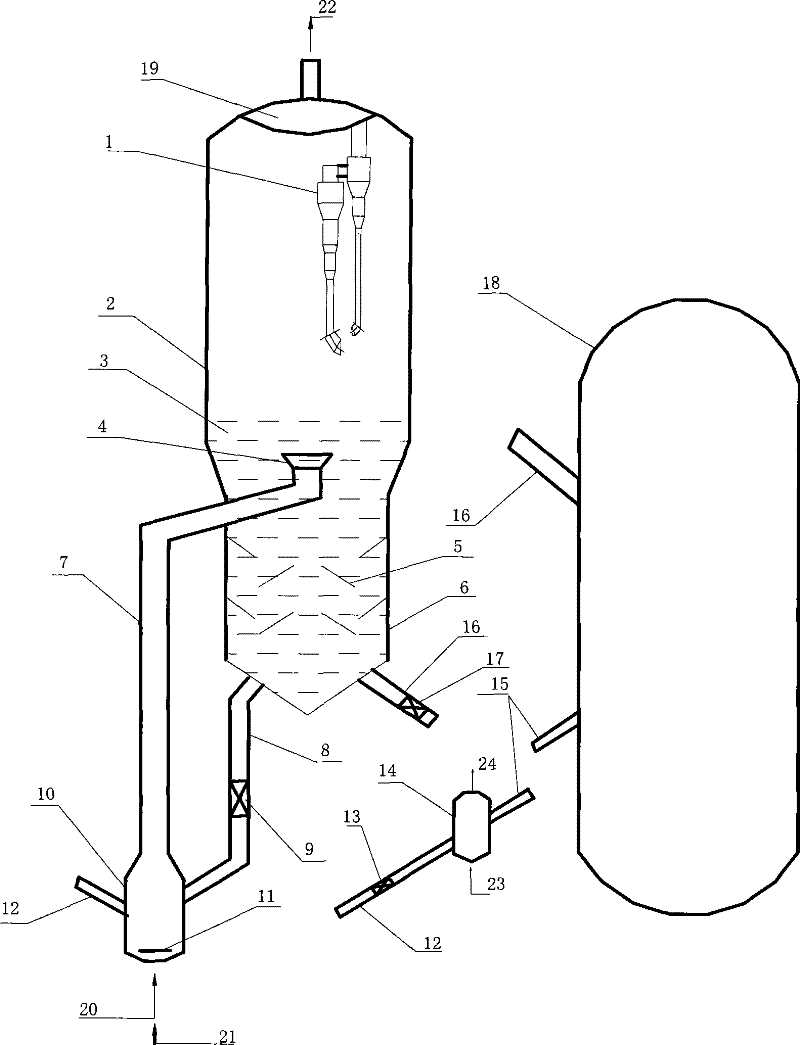

Fluidizer and fluidization method for preparing ethylene by ethanol dehydration

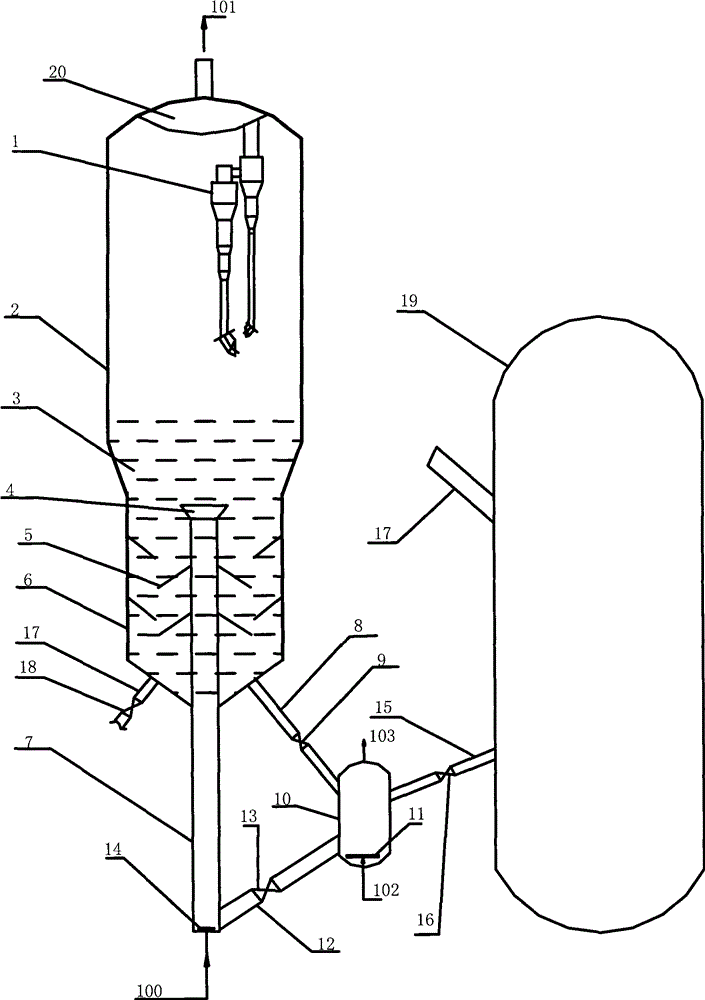

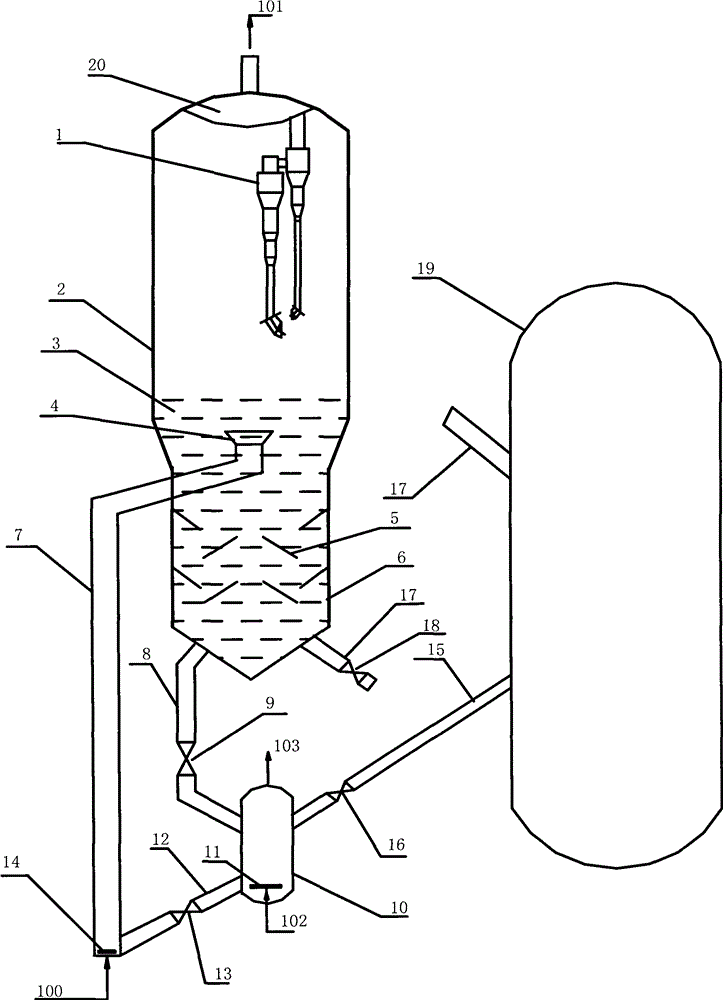

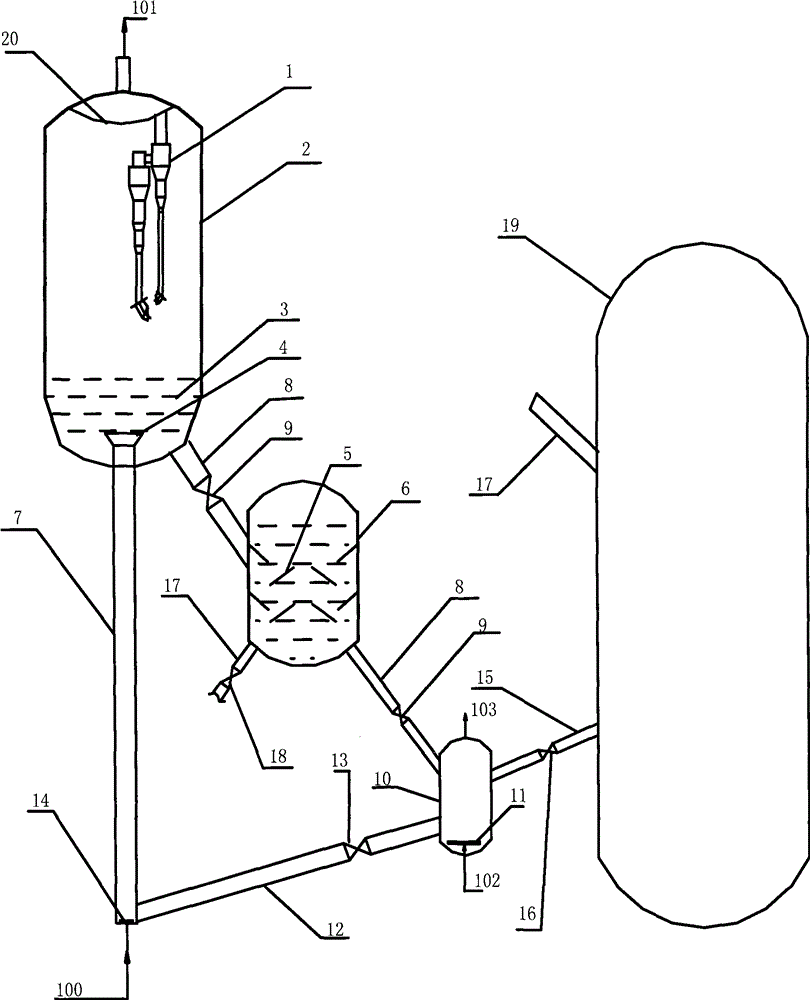

ActiveCN101274871AEfficient removalHigh purityHydrocarbon from oxygen organic compoundsChemical recyclingFlue gasPetroleum

The invention relates to a fluidized device for producing ethylene by ethanol dehydration, which comprises a fluidized bed reactor, a regenerator, a catalyst mixing chamber, a catalyst riser, a spent catalyst inner circulating pipe, a stripper and a regenerated catalyst degassing tank, wherein, the fluidized bed reactor and the regenerator are connected by spent catalyst conveying pipes, the fluidized bed reactor and the catalyst mixing chamber are connected by the catalyst riser, the stripper and the catalyst mixing chamber are connected by the catalyst inner circulating pipe, the regenerated catalyst degassing tank and the regenerator are connected by regenerated catalyst conveying pipes and the regenerated catalyst degassing tank and the catalyst mixing chamber are connected by the regenerated catalyst conveying pipes. The fluidized device, through adding the regenerated catalyst degassing tank, effectively removes flue gas taken by the regenerated catalyst and greatly improves the purity of ethylene in the product. The regenerator is arranged independently or a catalytic cracking regenerator is shared with a catalytic cracking device in the filed of petroleum refining.

Owner:CHINA PETROLEUM & CHEM CORP +1

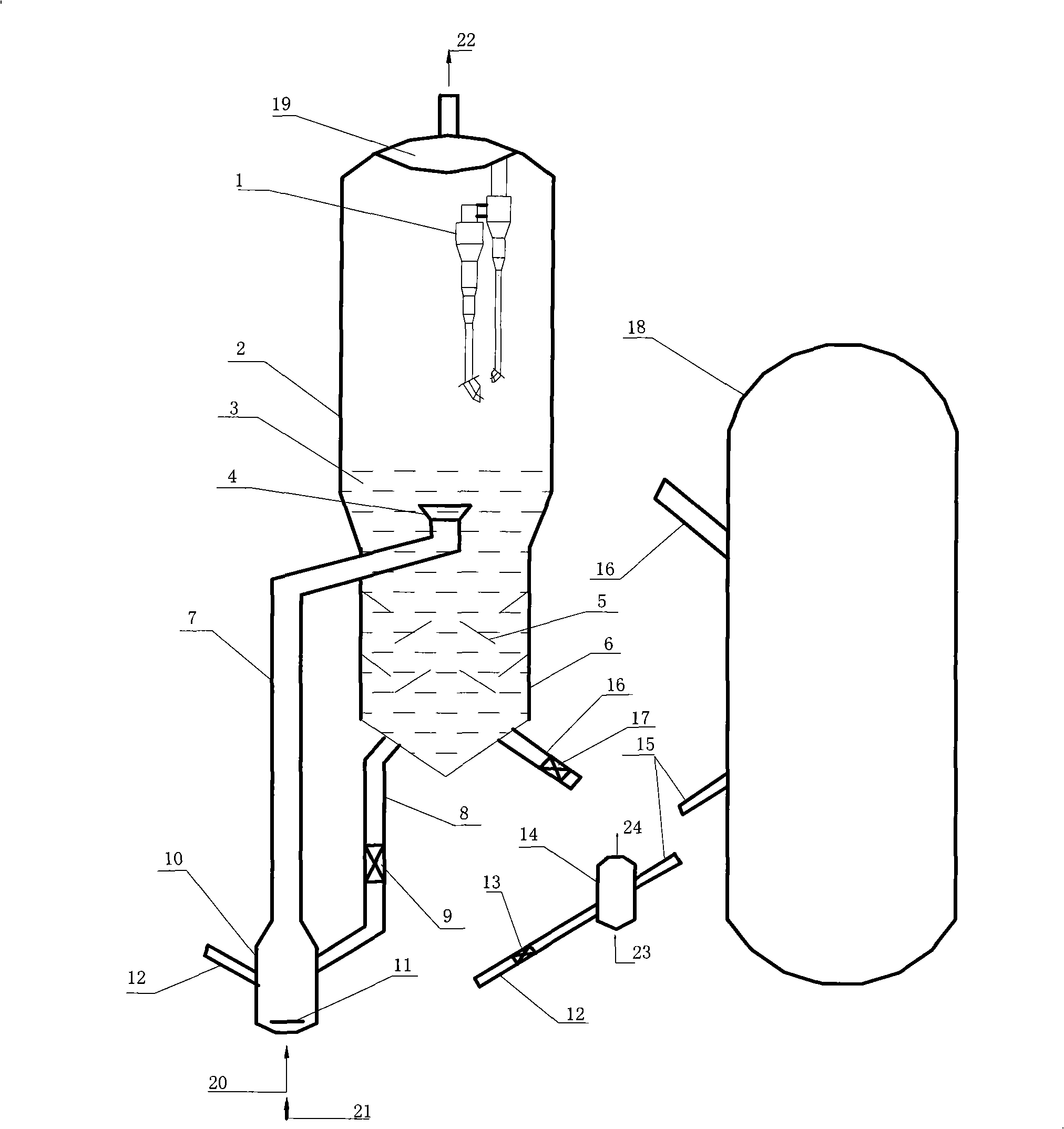

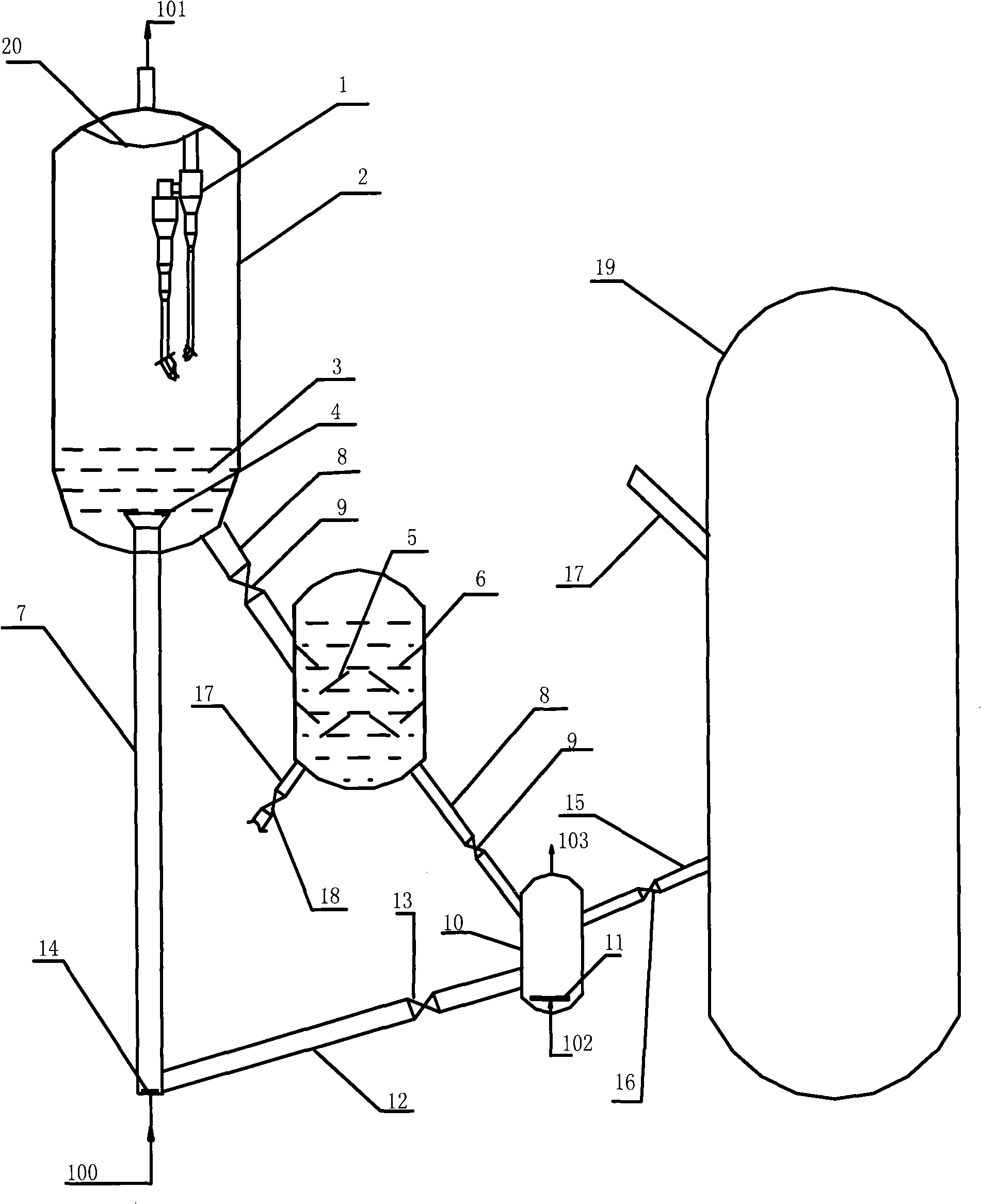

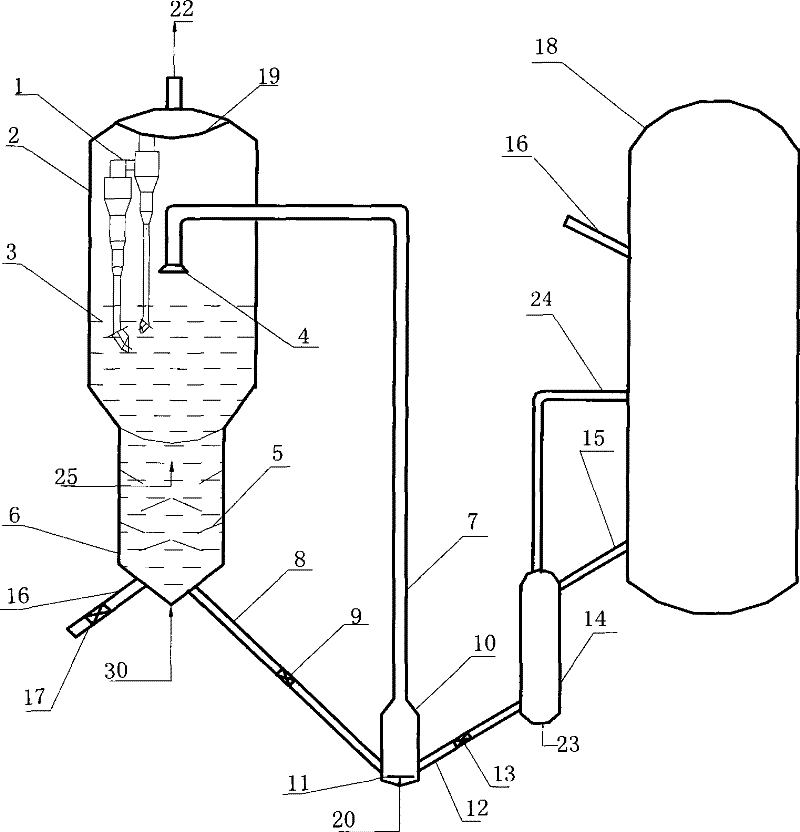

Fluidizer and method for preparing ethylene with ethanol dehydration

ActiveCN101293804AAdded degassing stepsEfficient removalHydrocarbon from oxygen organic compoundsChemical recyclingFluidized bedFlue gas

A fluidizing device for preparing ethylene by ethanol dehydration comprises a fluidized bed reactor, a regenerator, a catalyst riser, a stripper and a catalyst mixing degassing tank. The stripper and the regenerator are connected via a to-be-regenerated catalyst delivery pipeline. The fluidized bed reactor is directly connected with a catalyst riser. The catalyst mixing degassing tank and the regenerator are connected via a regenerated catalyst delivery pipeline. The catalyst mixing degassing tank and the stripper are connected via a catalyst internal recycling pipeline. By adding the catalyst mixing degassing tank, the fluidizing device can effectively remove flue gas carried by the regenerated catalyst to greatly increase the ethylene purity in the product. The regenerator can be arranged separately, or the catalytic cracking regenerator of a catalytic cracking device in a petroleum refining field can be shared.

Owner:CHINA PETROLEUM & CHEM CORP +1

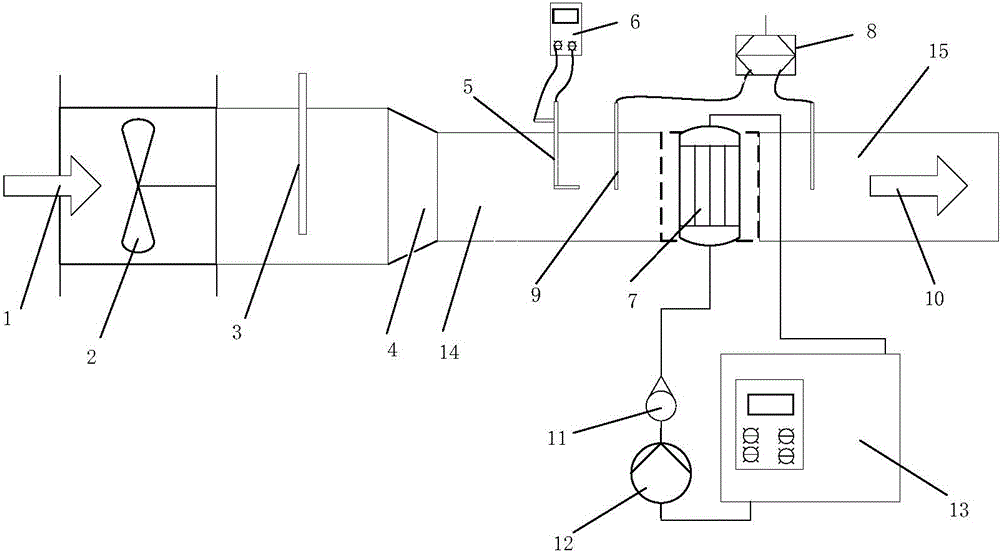

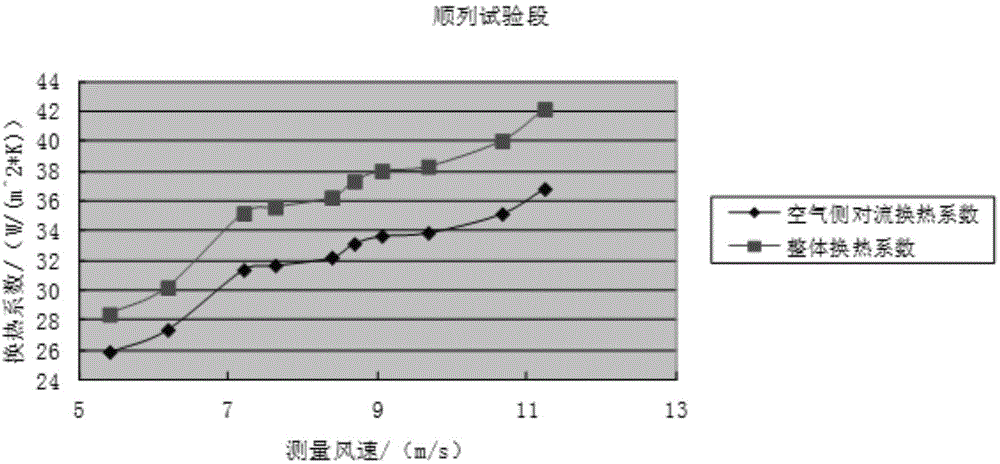

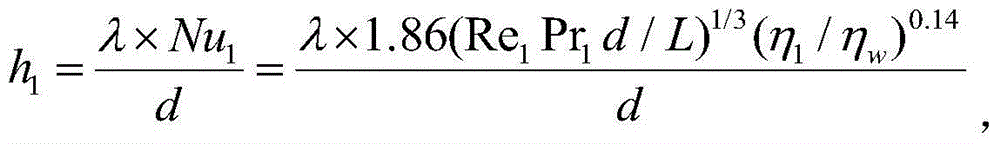

System and method for measuring heat exchange characteristics of tube bundle

InactiveCN104483349AReduce mistakesAccurate measurementMaterial heat developmentStraight tubeData acquisition

The invention discloses a system and a method for measuring heat exchange characteristics of a tube bundle. The system comprises an air inlet pipeline, wherein an air inlet is formed in the left side of the air inlet pipeline; an axial flow fan, an air flue gate and a Venturi section are sequentially arranged from left to right inside the air inlet pipeline; a first straight tube section is connected with the right side of the Venturi section; a pitot tube is arranged inside the first straight tube section; the pitot tube is connected with a micromanometer; a replaceable heat exchange tube bundle testing section is connected with the right side of the first straight tube section; a second straight tube section is connected with the right side of the heat exchange tube bundle testing section; an air outlet is formed in the right side of the second straight tube section; temperature sensors I are arranged on the left side and the right side of the heat exchange tube bundle testing section; the temperature sensors I are connected with a data acquirer I. The system has universality as only the heat exchange tube bundle testing section needs to be replaced and an air flue and water pipelines do not need to be replaced; selected testing points can meet the use requirement of the device, the measurement is precise; the heat balance is ensured, and relatively small testing result errors can be caused.

Owner:SHANDONG UNIV

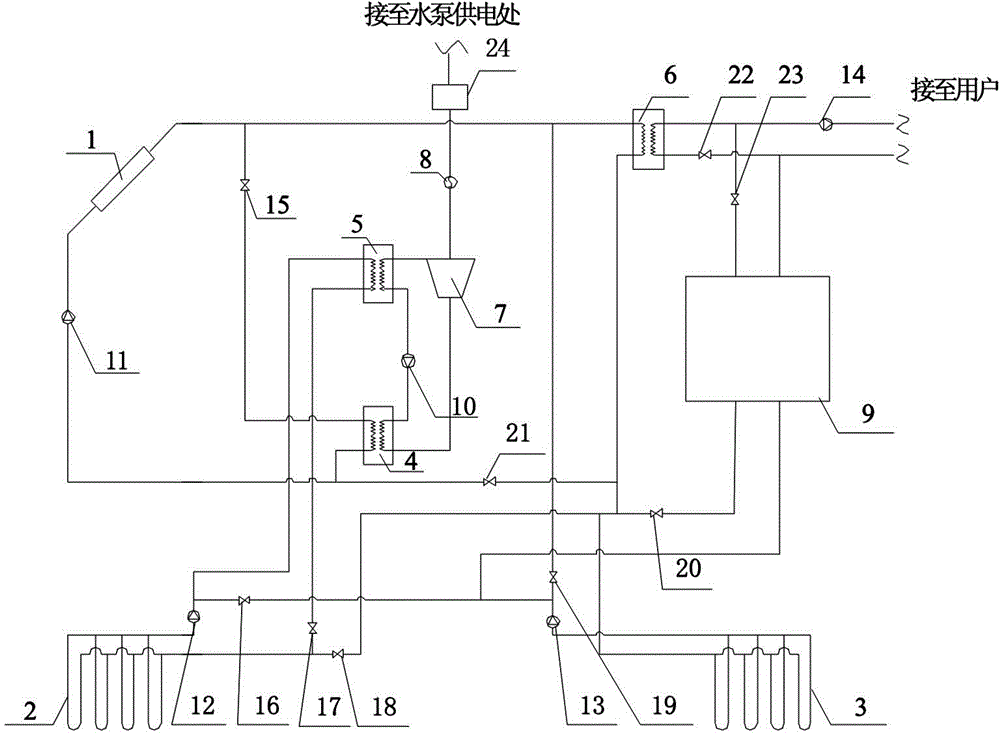

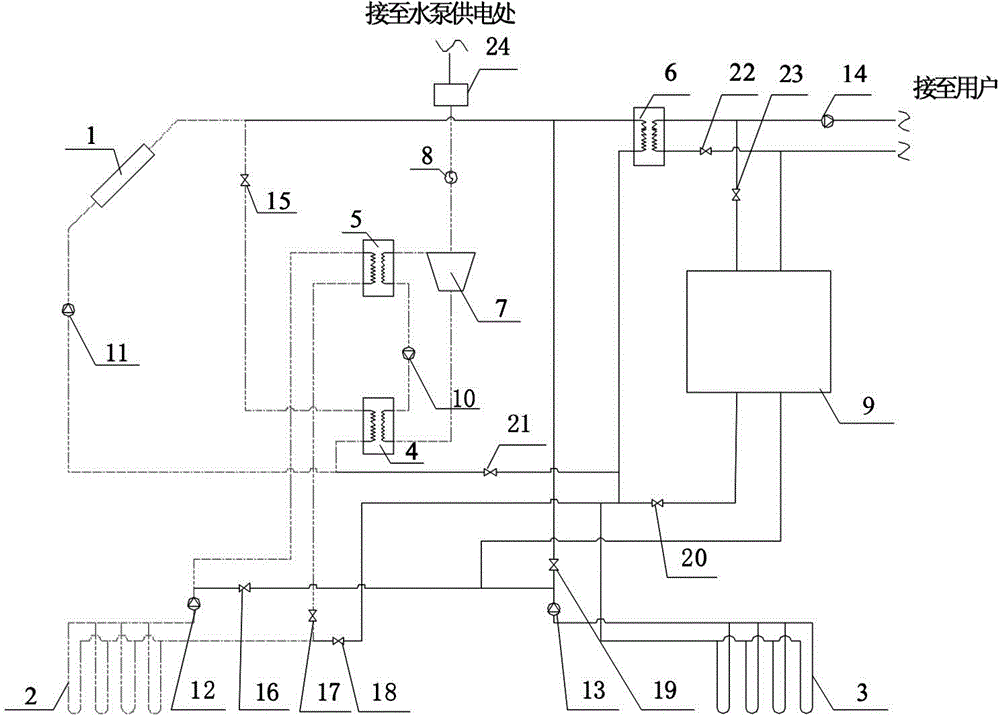

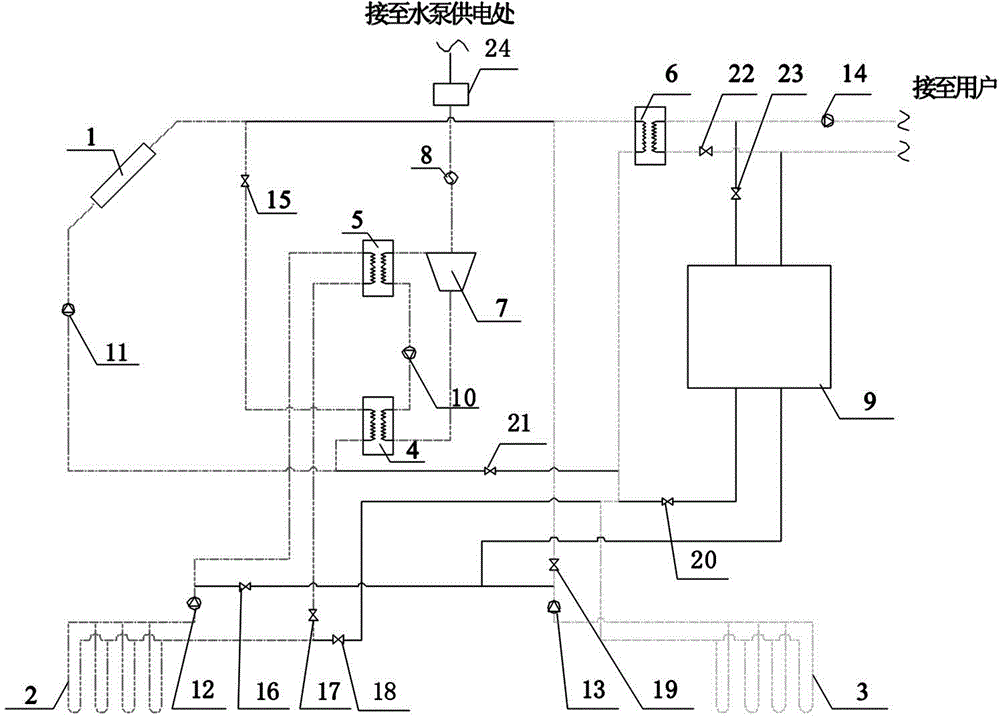

Seasonal thermal storage solar low-temperature thermal electricity generation composite ground-source heat pump system

ActiveCN104061717AReduce dependenceGood energy saving effectHeat pumpsFrom solar energyOrganic Rankine cycleEngineering

The invention discloses a seasonal thermal storage solar low-temperature thermal electricity generation composite ground-source heat pump system. The system consists of a solar thermal collector, a ground heat exchanger, a first heat exchanger, a second heat exchanger, a third heat exchanger, a booster pump, an expansion machine, a generator, a ground-source heat pump cold and hot water unit, an electrical storage device and the like, wherein the first heat exchanger, the second heat exchanger, the booster pump, the expansion machine and the generator form an organic Rankine cycle low-temperature thermal electricity generation device; the solar thermal collector collects solar energy all the year round, in a non-heat supply period, the collected solar heat is used as a heat source of the low-temperature thermal electricity generation device by the first heat exchanger, cold is obtained from soil by a thermal storage series soil heat exchanger and is used as a cold source of the low-temperature thermal electricity generation device by the second heat exchanger, and the heat of condensation is stored in the soil. The system is applicable to civil architectures and office buildings in a severe cold area, and is particularly applicable to regions, which are far away from a centralized heating heat pipeline, are strict in atmospheric environment requirements and have frequent outage, of the severe cold area.

Owner:新疆品源太阳能科技开发有限责任公司

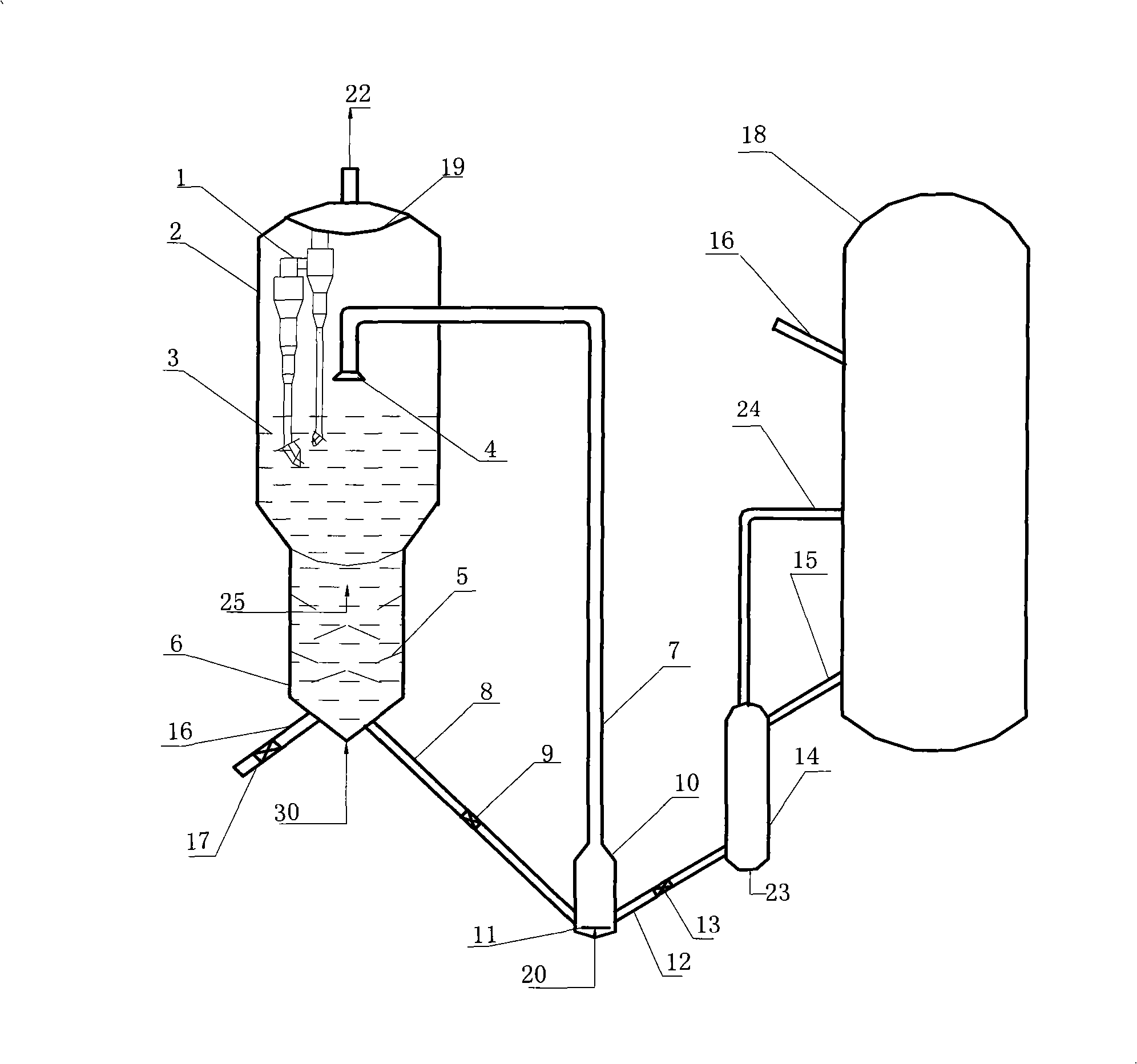

Fluidizer and technique for preparing ethylene by ethanol dehydration

ActiveCN101274872AEfficient removalHigh purityHydrocarbon from oxygen organic compoundsChemical recyclingFluidized bedFlue gas

The invention relates to a fluidized device for producing ethylene by ethanol dehydration, which comprises a fluidized bed reactor, a regenerator, a catalyst riser, a stripper and a regenerated catalyst degassing tank, wherein, the stripper and the regenerator are connected by spent catalyst conveying pipes, the fluidized bed reactor and the catalyst riser are connected directly, the regenerated catalyst degassing tank and the regenerator are connected by regenerated catalyst conveying pipes, the regenerated catalyst degassing tank and the catalyst riser are connected by the regenerated catalyst conveying pipes and an external heat collector is positioned in the regenerated catalyst degassing tank. The fluidized device, through adding the regenerated catalyst degassing tank, effectively removes flue gas taken by the regenerated catalyst and greatly improves the purity of ethylene in the product. The regenerator is arranged independently or a catalytic cracking regenerator is shared with a catalytic cracking device in the field of petroleum refining.

Owner:CHINA PETROLEUM & CHEM CORP +1

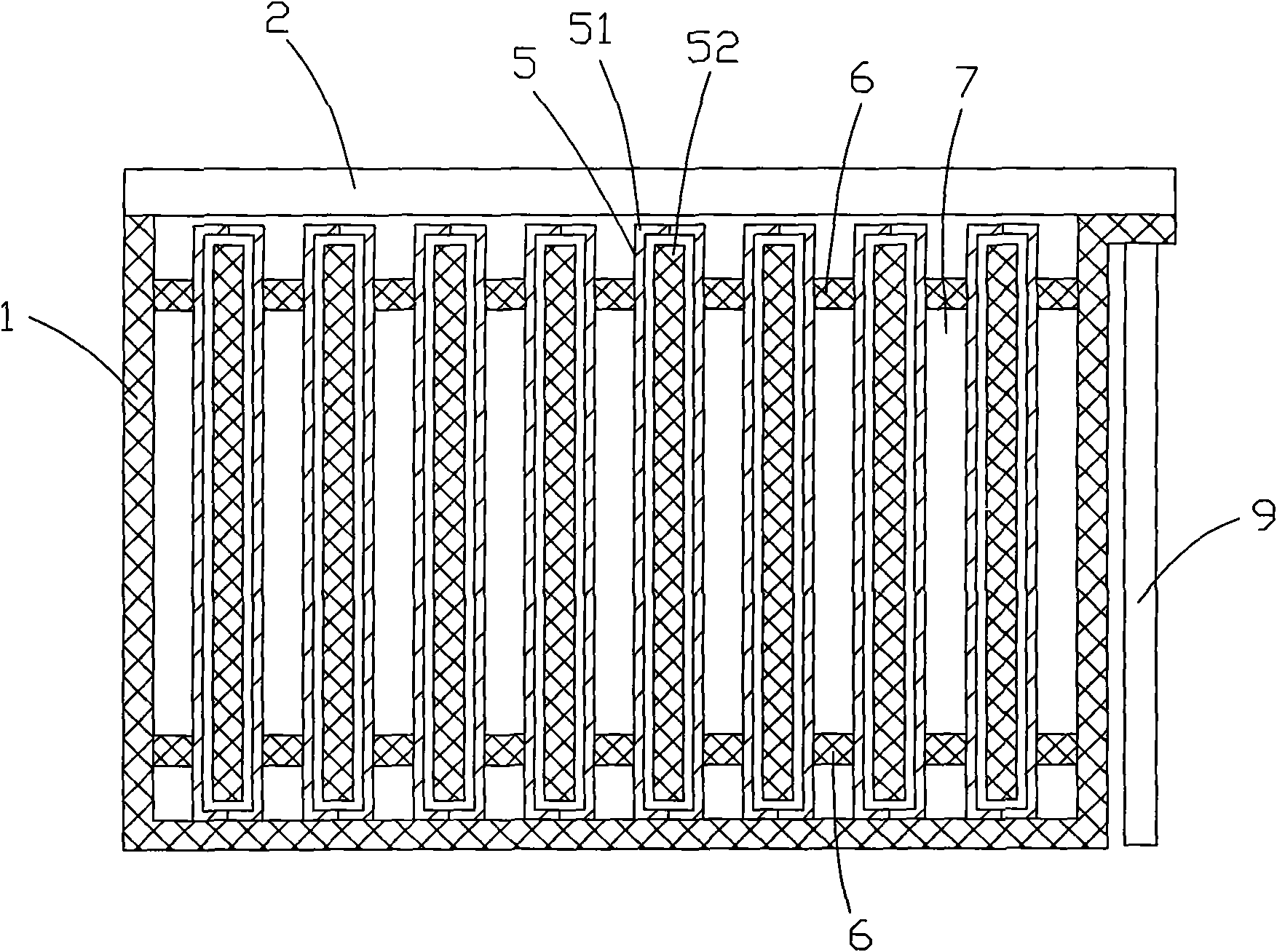

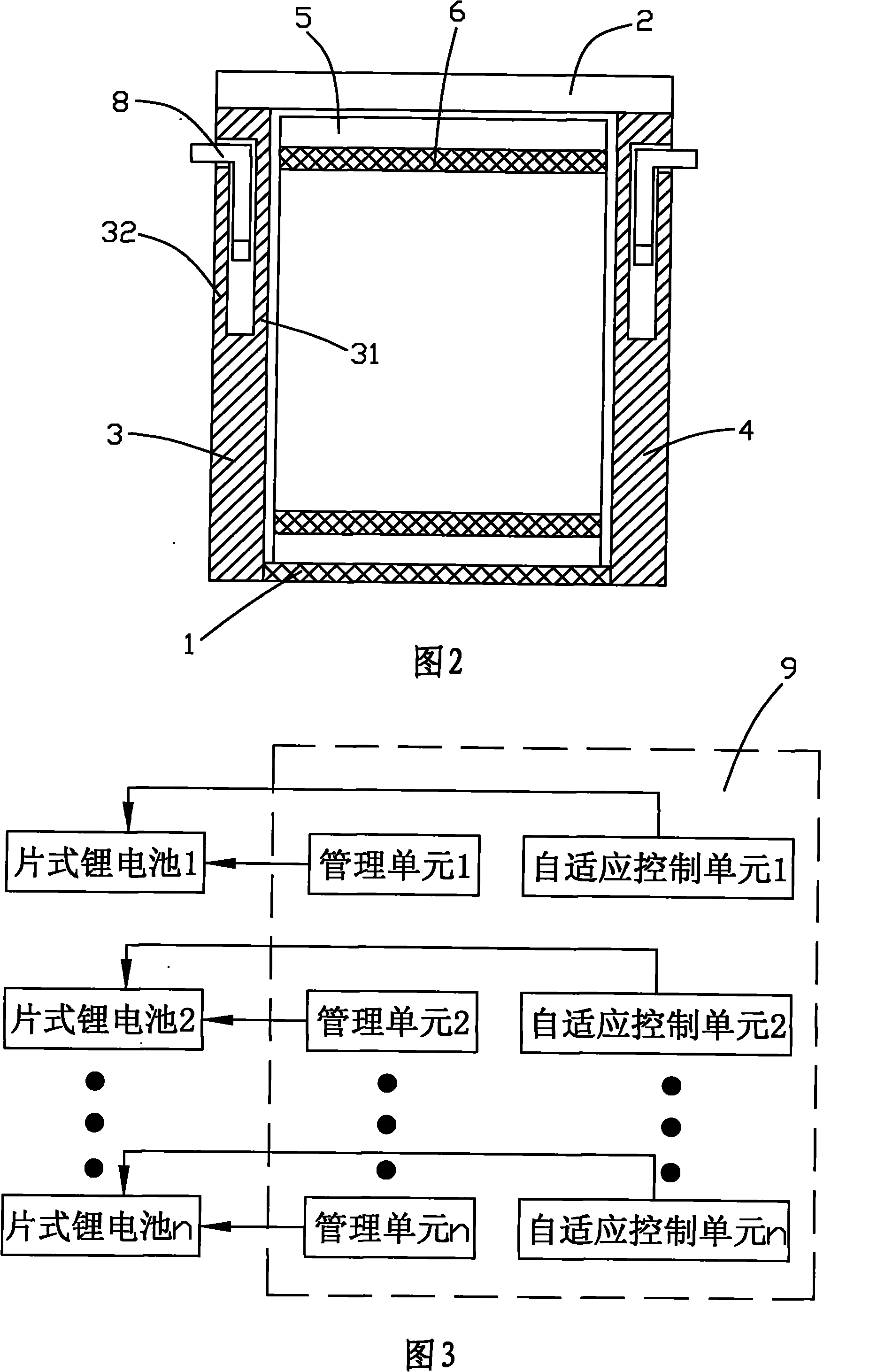

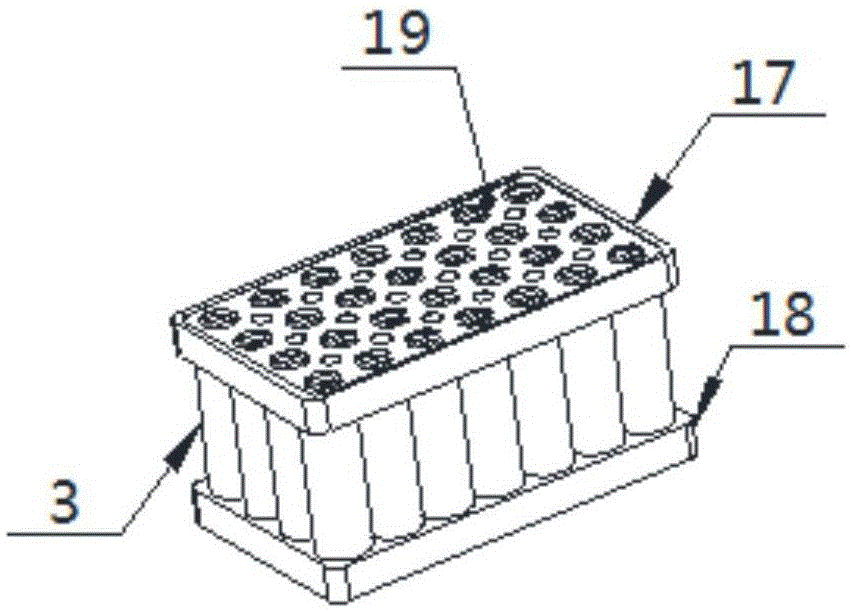

Common module for lithium ion batteries

InactiveCN102055027AAvoid mutual interferenceEffective isolationCell component detailsSecondary cells servicing/maintenanceCombustionEngineering

The invention discloses a common module for lithium ion batteries, which belongs to the field of electric-vehicle-mounted batteries, and comprises a shell and a lithium battery pack, wherein the shell consists of a U-shaped box body, a top cover, a front radiation plate and a rear radiation plate; the lithium battery pack consists of a plurality of chip type batteries which are connected in series, parallel or both series and parallel; the chip type batteries are arranged in space defined by the U-shaped box in parallel; and each two adjacent chip type lithium batteries are fixed by foam glue, so that a lithium battery expansion gas is formed between the two adjacent chip type lithium batteries. In the invention, an expandable and strong isolating layer is arranged between each two adjacent lithium batteries, so that failed lithium batteries can be isolated effectively to prevent accidents such as combustion, explosion and the like and battery cell grade impact-proof protection can be realized.

Owner:陈香玲

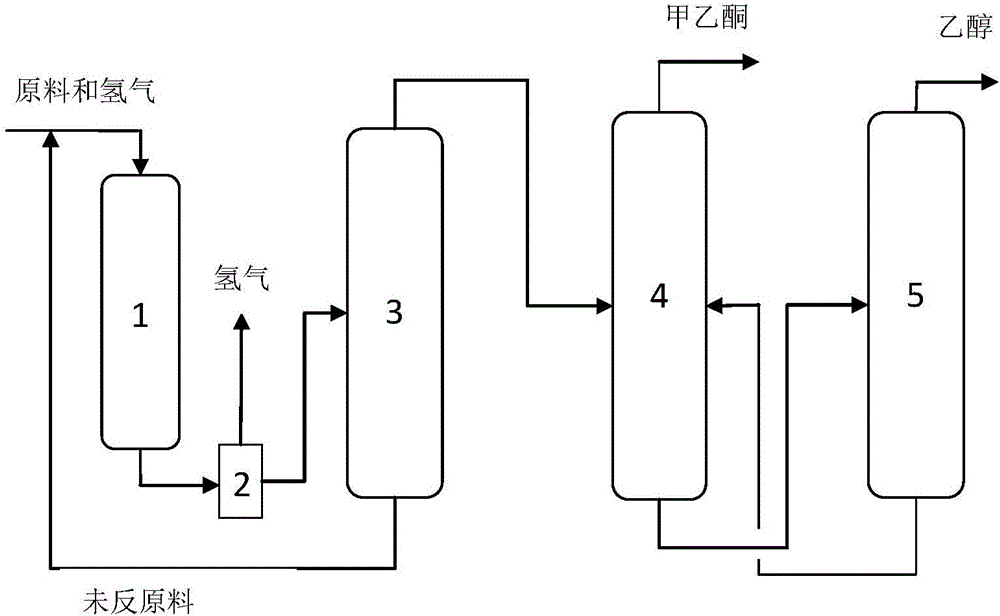

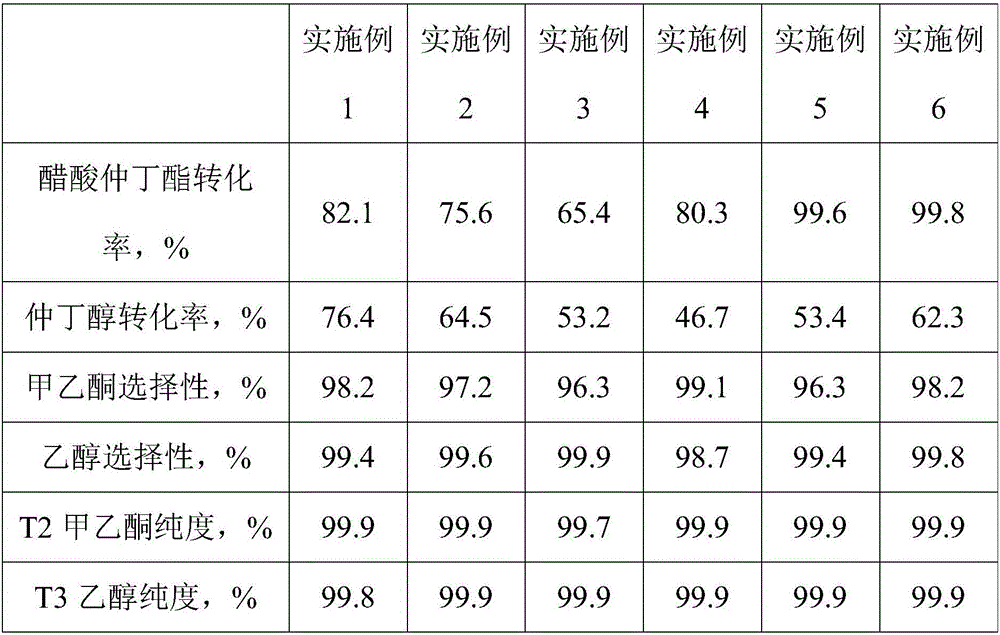

Technological method for transferring hydrogenation for sec-butyl acetate by secondary butyl alcohol and simultaneously producing methyl ethyl ketone

ActiveCN106117025AImprove conversion rateReduce operating severityOrganic compound preparationPreparation by dehydrogenationLiquid productHydrogen

The invention relates to a technological method for transferring hydrogenation for sec-butyl acetate by sec-butyl alcohol and simultaneously producing methyl ethyl ketone. According to the method, the composition of sec-butyl alcohol and sec-butyl acetate is taken as a raw material, the transferring hydrogenation for sec-butyl acetate by sec-butyl alcohol is realized under the effect of a hydrogenation catalyst, and the sec-butyl alcohol is dehydrogenized, so that the methyl ethyl ketone is obtained, the sec-butyl acetate is subjected to transferring hydrogenation, so as to produce the sec-butyl alcohol and ethyl alcohol; the produced sec-butyl alcohol is dehydrogenized, so that the methyl ethyl ketone is obtained. A product is subjected to gas-liquid separation, high-purity hydrogen is obtained, and a liquid product is subjected to distillation separation firstly, so that the composition of ethyl alcohol and methyl ethyl ketone is obtained, and the sec-butyl alcohol or the composition of the sec-butyl alcohol and the sec-butyl acetate in a column reactor returns a transferring hydrogenation reactor, so as to be reacted continuously; the composition of ethyl alcohol and the methyl ethyl ketone is subjected to extractive distillation firstly, so that a high-purity methyl ethyl ketone product is obtained, an extraction agent containing ethyl alcohol in the column reactor is rectified again, a high-purity ethyl alcohol product is obtained, and the extraction agent in the column reactor returns an extractive distillation column to be recycled. The method solves the problems that the sec-butyl acetate and the sec-butyl alcohol are azeotropic and high-purity sec-butyl alcohol and methyl ethyl ketone cannot be obtained.

Owner:九江齐鑫化工有限公司 +2

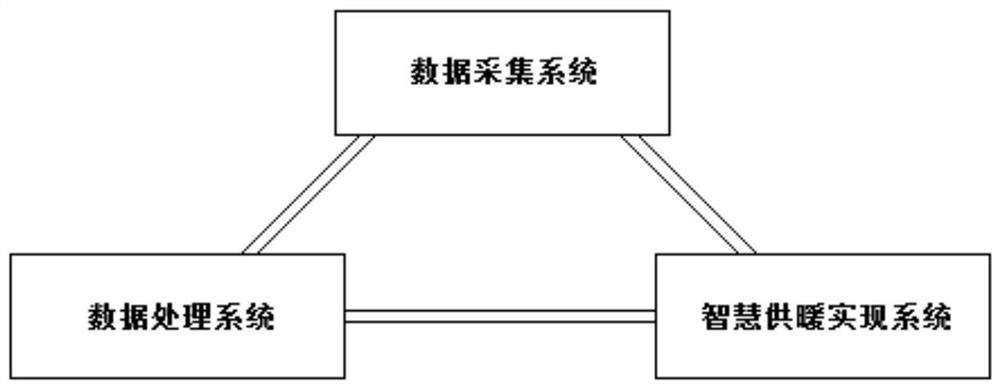

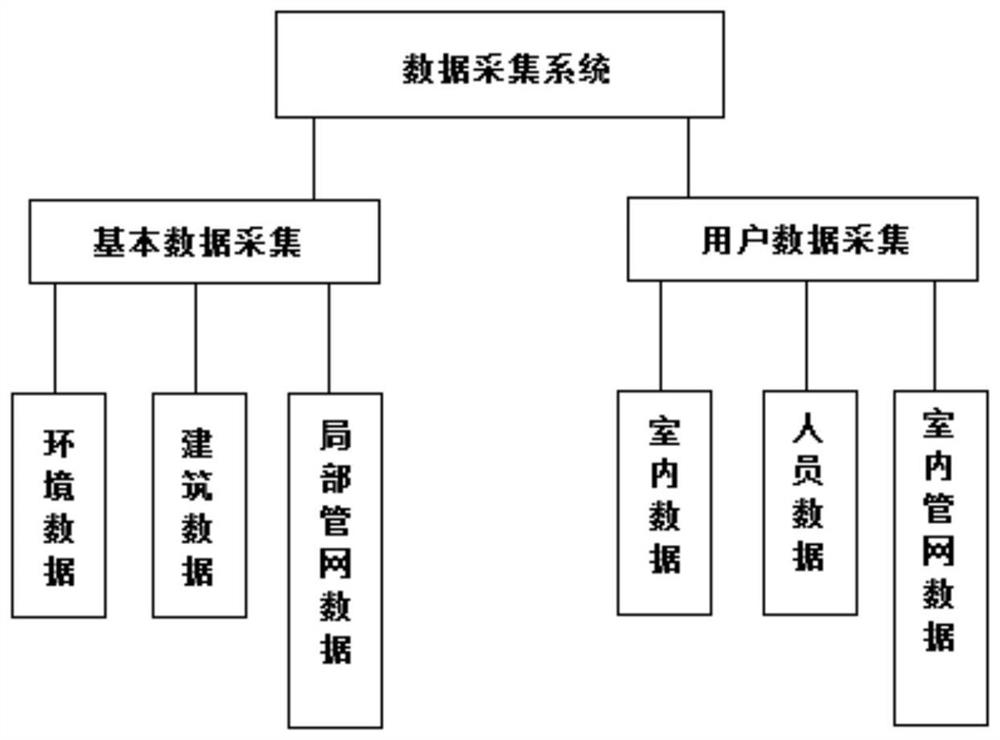

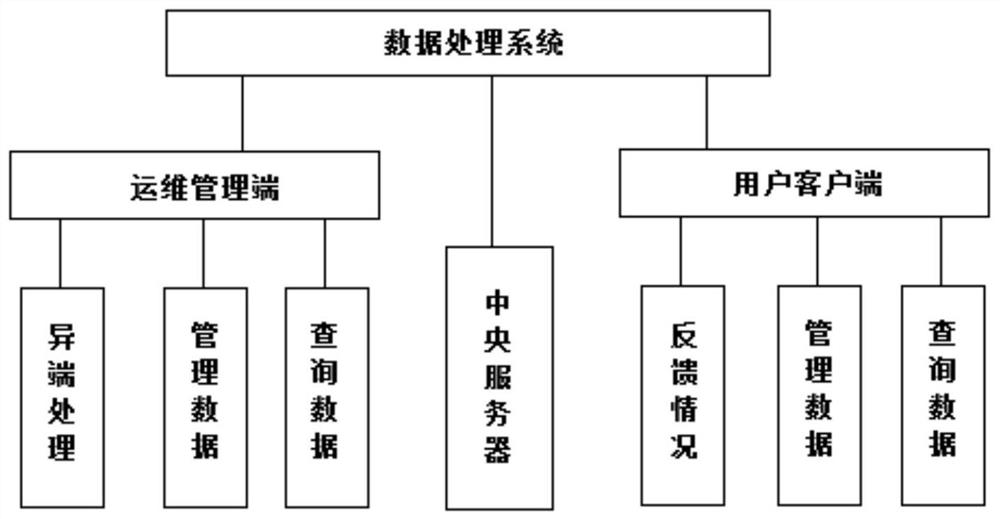

Novel indoor smart heating system and method

InactiveCN111795426AGuaranteed thermal balanceSuitable room temperatureLighting and heating apparatusSpace heating and ventilation detailsHeating systemHeating time

The invention provides a novel indoor smart system and method, and belongs to the field of smart home and smart heating. The novel indoor smart system and method aim to solve the problems that an existing scheme cannot provide personalized heating for individual households, cannot realize the fact that a user can independently set an indoor temperature and cannot realize the fact that the user canset heating time. According to the technical scheme, the three parts of the system is realized through a data acquisition system, a data processing system and an intelligent heating system, remote system control and personalized management are achieved, and personalized heating service capable of saving energy is provided through the joint participation of the operation and maintenance party andthe user in heating adjusting.

Owner:哈电发电设备国家工程研究中心有限公司

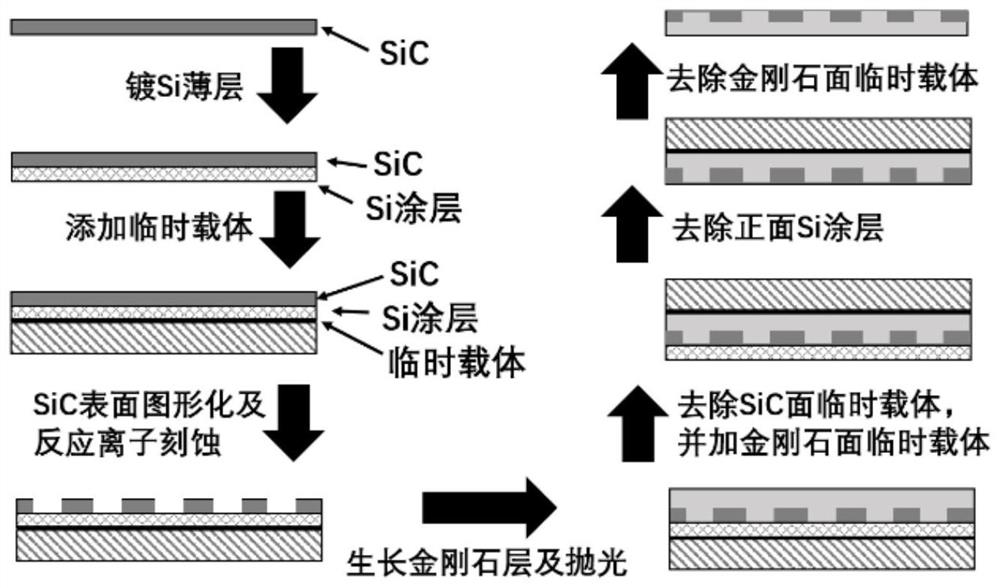

Preparation method of embedded diamond-based silicon carbide composite substrate

ActiveCN113151898AHigh thermal conductivitySolve heat concentrationPolycrystalline material growthFrom chemically reactive gasesSic substrateComposite substrate

The invention relates to a preparation method of an embedded diamond-based silicon carbide composite substrate, and belongs to the field of semiconductor material preparation. The method comprises the following steps: firstly, adhering a temporary carrier to a silicon carbide (SiC) substrate plated with a Si coating, and then carrying out surface patterning and reactive ion etching on SiC to form a SiC layer with a pattern structure; and then depositing a layer of diamond on the surface to cover SiC, and grinding and polishing the surface of the diamond layer. Then, after the temporary carrier of the SiC substrate is removed, adhering the temporary carrier to the diamond side. After the original Si coating is removed through reactive ion etching, the temporary carrier on the diamond side is removed, and finally the embedded diamond-based SiC composite substrate is obtained. Heat can be quickly dissipated under the conditions of high power and high integration, meanwhile, the excellent performance of SiC and diamond serving as wide bandgap semiconductors can be fully played, and a preparation basis for the structural design of a wide bandgap semiconductor heterogeneous material is provided.

Owner:UNIV OF SCI & TECH BEIJING +1

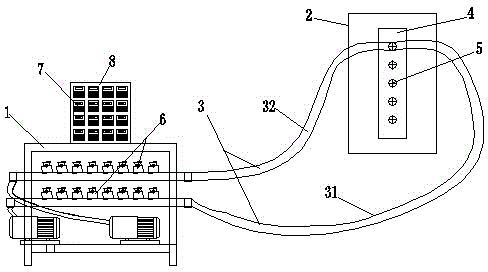

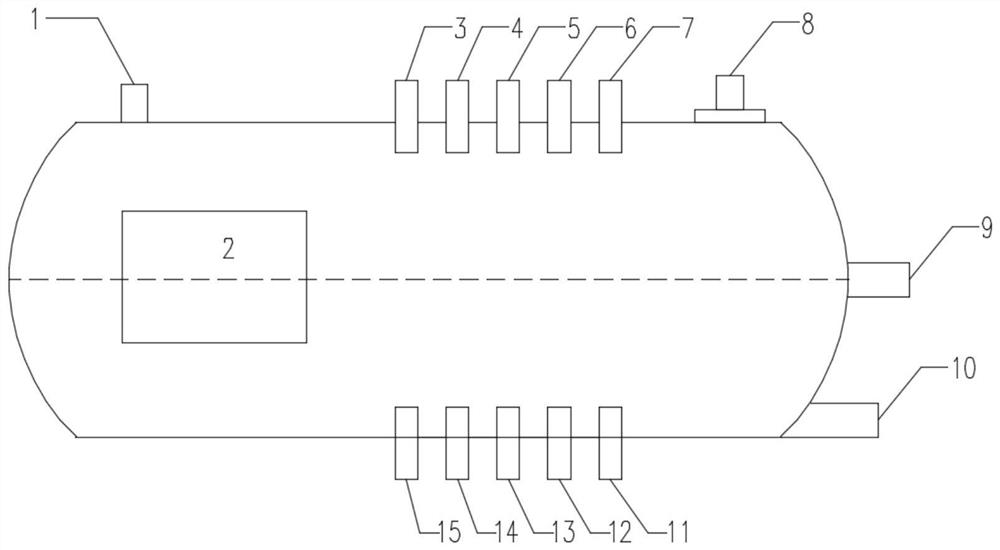

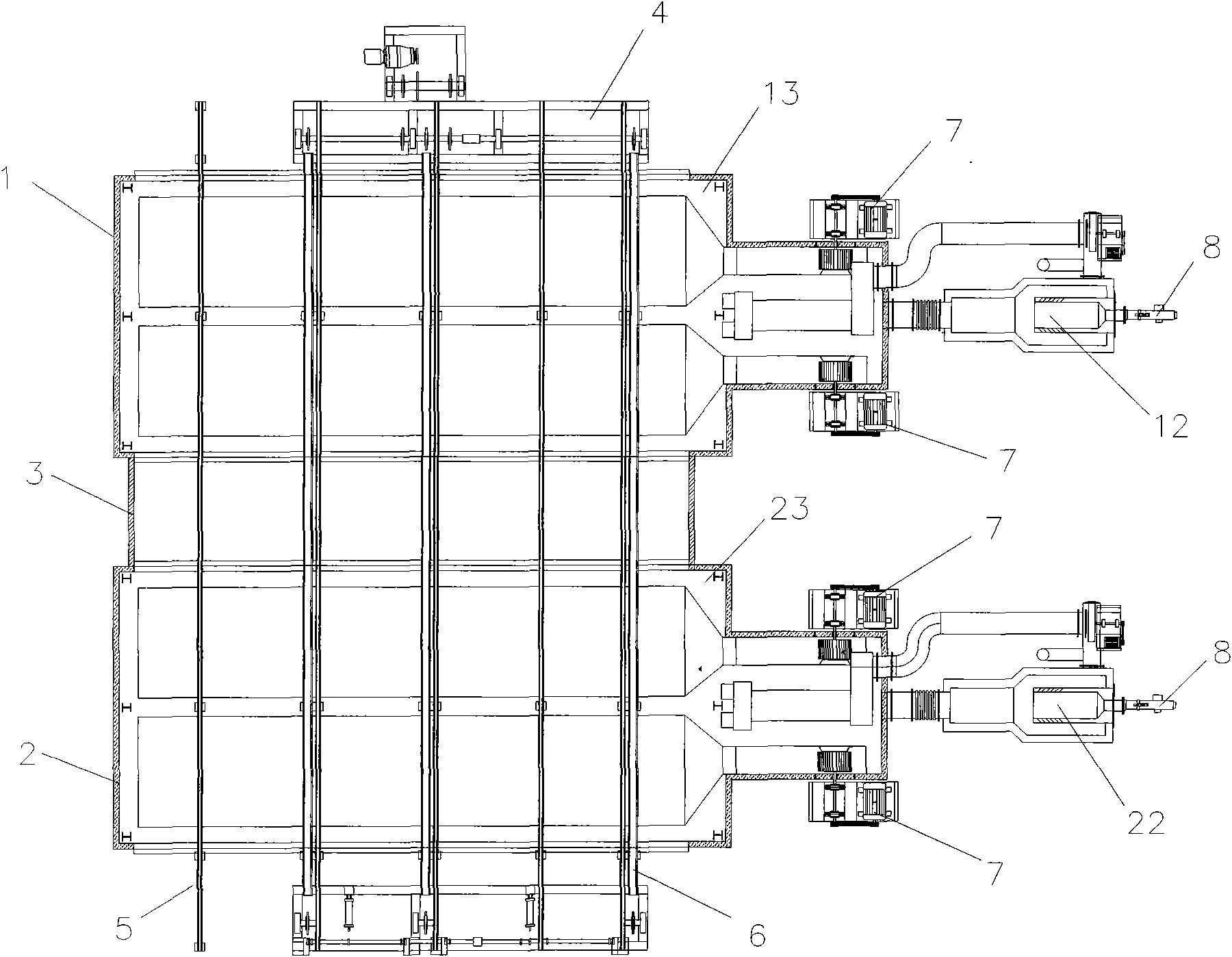

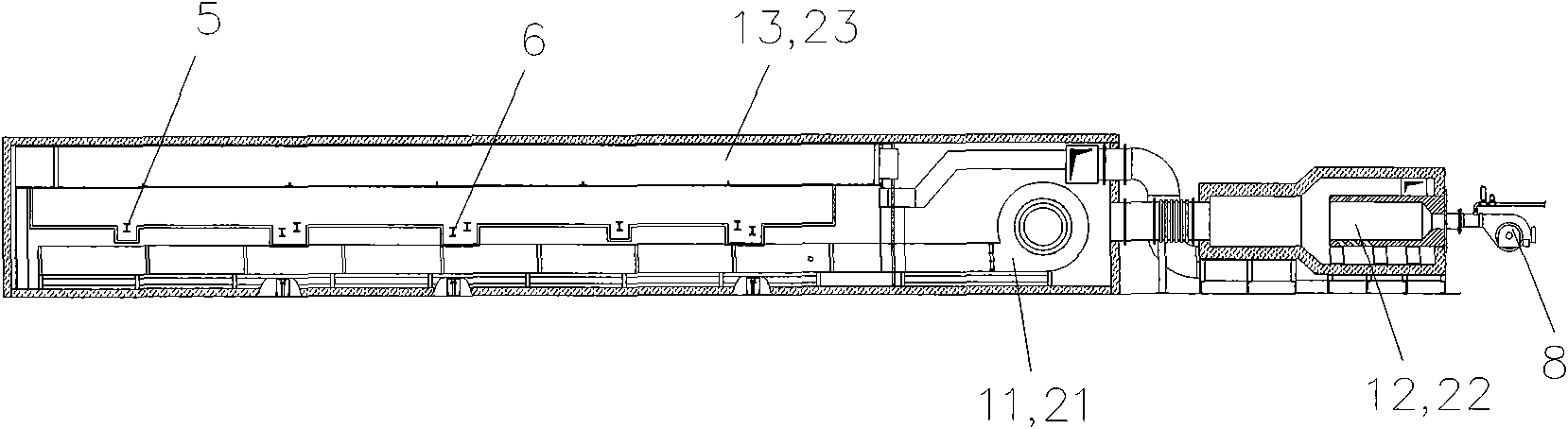

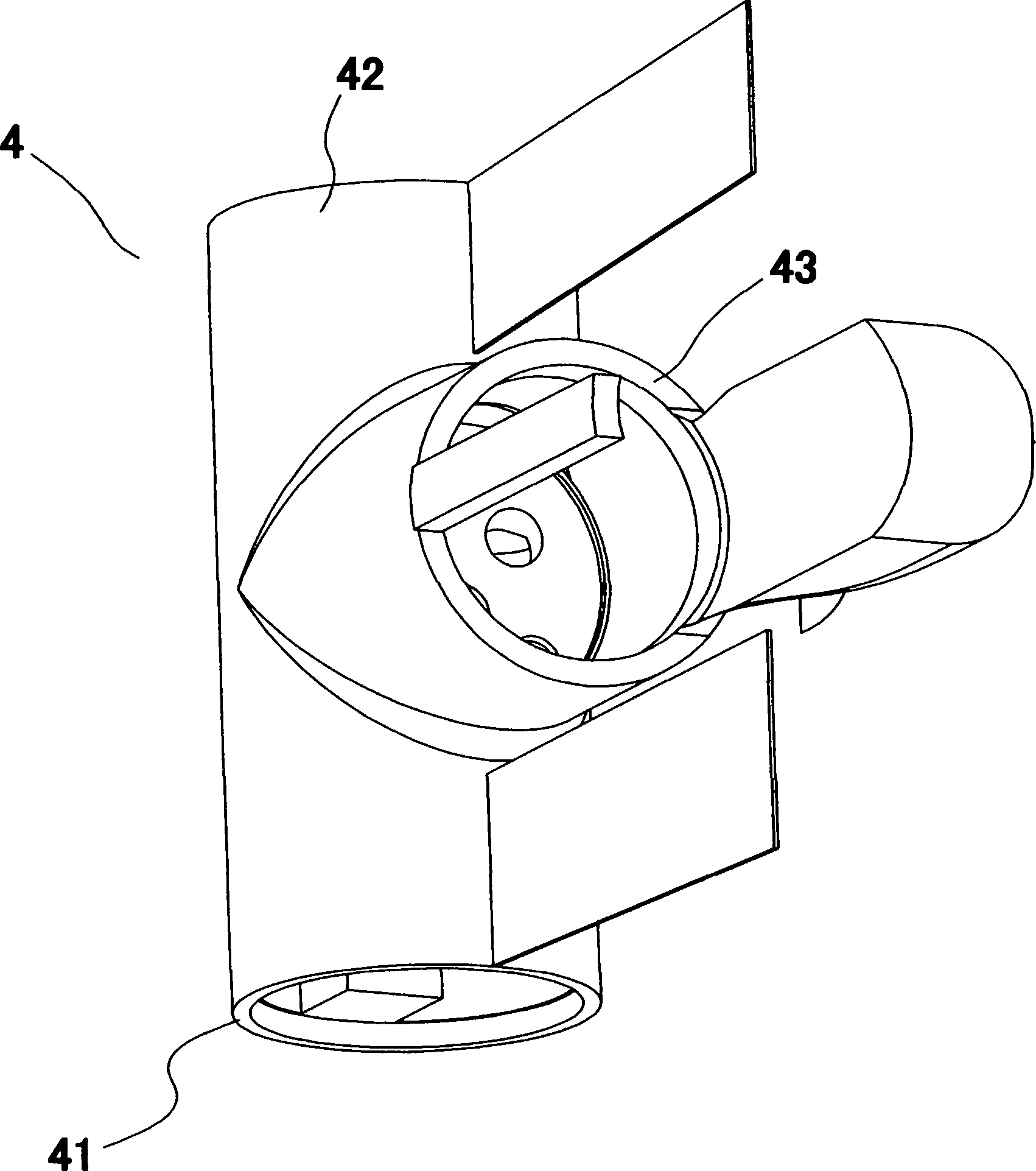

Intermittent cooling water supplying system for die casting mold

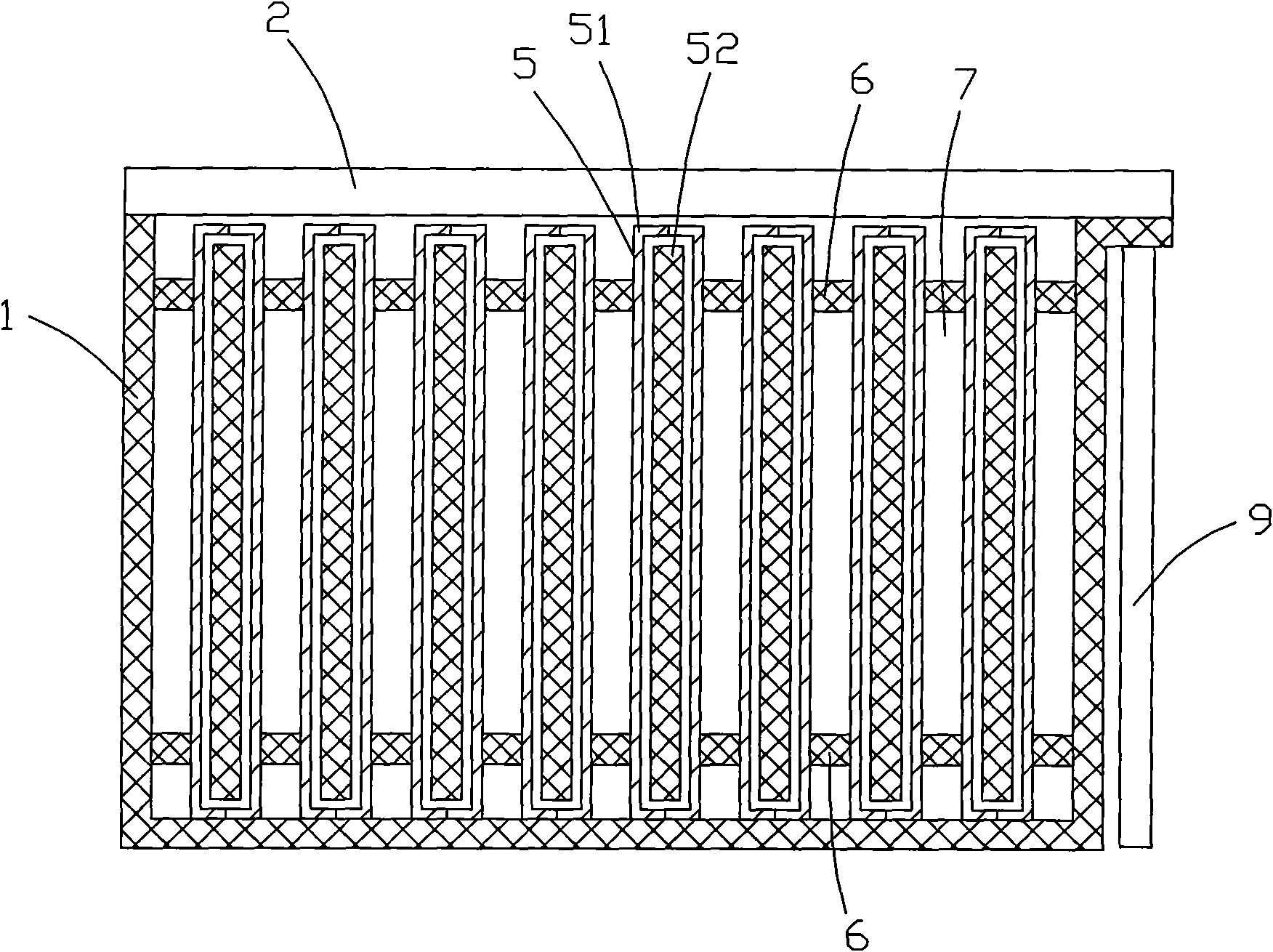

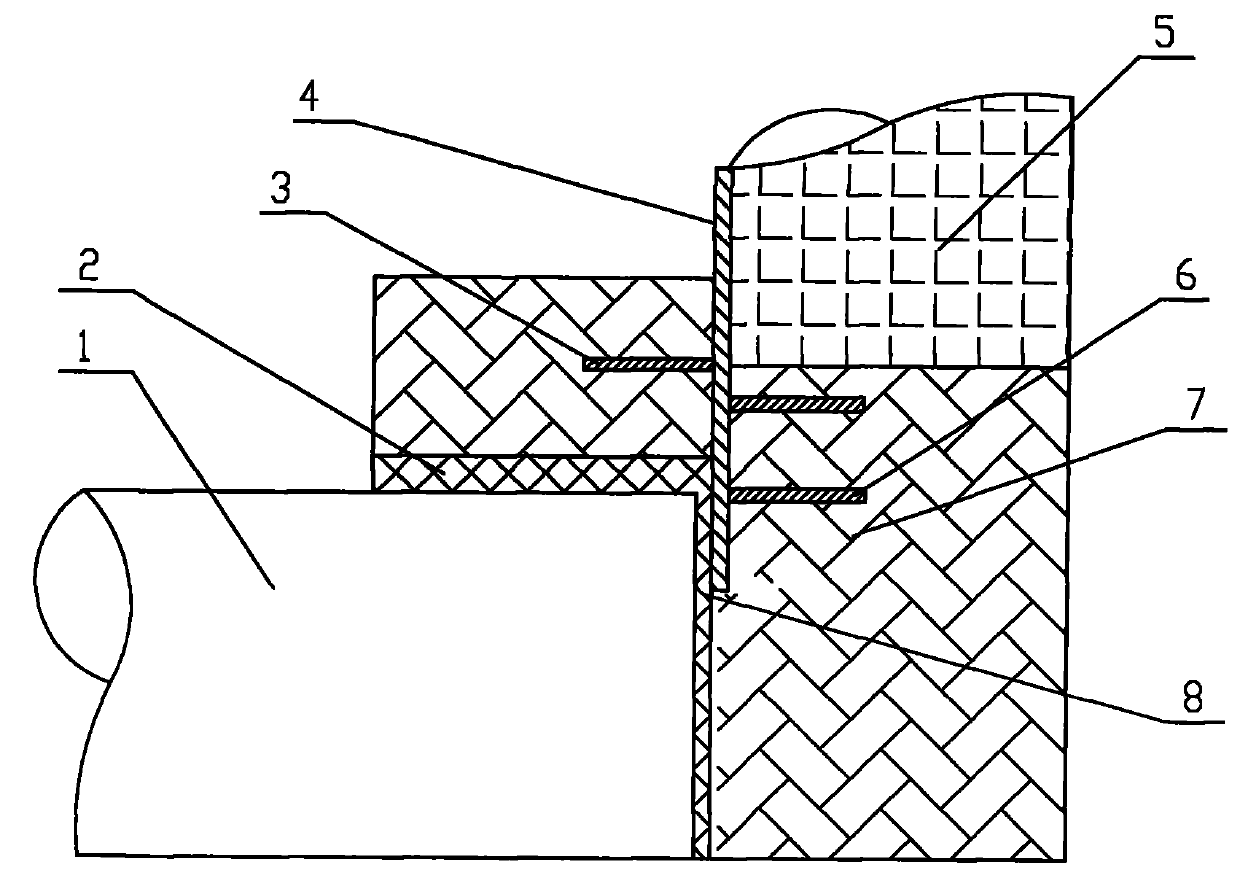

The invention relates to an intermittent cooling water supplying system for a die casting mold. The intermittent cooling water supplying system for the die casting mold comprises a machine body (1), and a cooling pipe (3) connected to a mold (2) is arranged on the machine body (1). The mold (2) is provided with a cooling connecting block (4) corresponding to the cooling pipe (3), and the cooling connecting block (4) is provided with a plurality of cooling connectors (5) corresponding to the cooling pipe (3). The cooling pipe (3) is provided with valves (6), and time relays (7) and a control box (8) are further arranged to control the valves (6) to act. According to the intermittent cooling water supplying system for the die casting mold, the time relays are arranged, water is intermittently supplied to the mold by controlling the water supplying time of the cooling water, and thus the heat balance of the mold is guaranteed.

Owner:YANGZHOU RONGTAI IND DEV

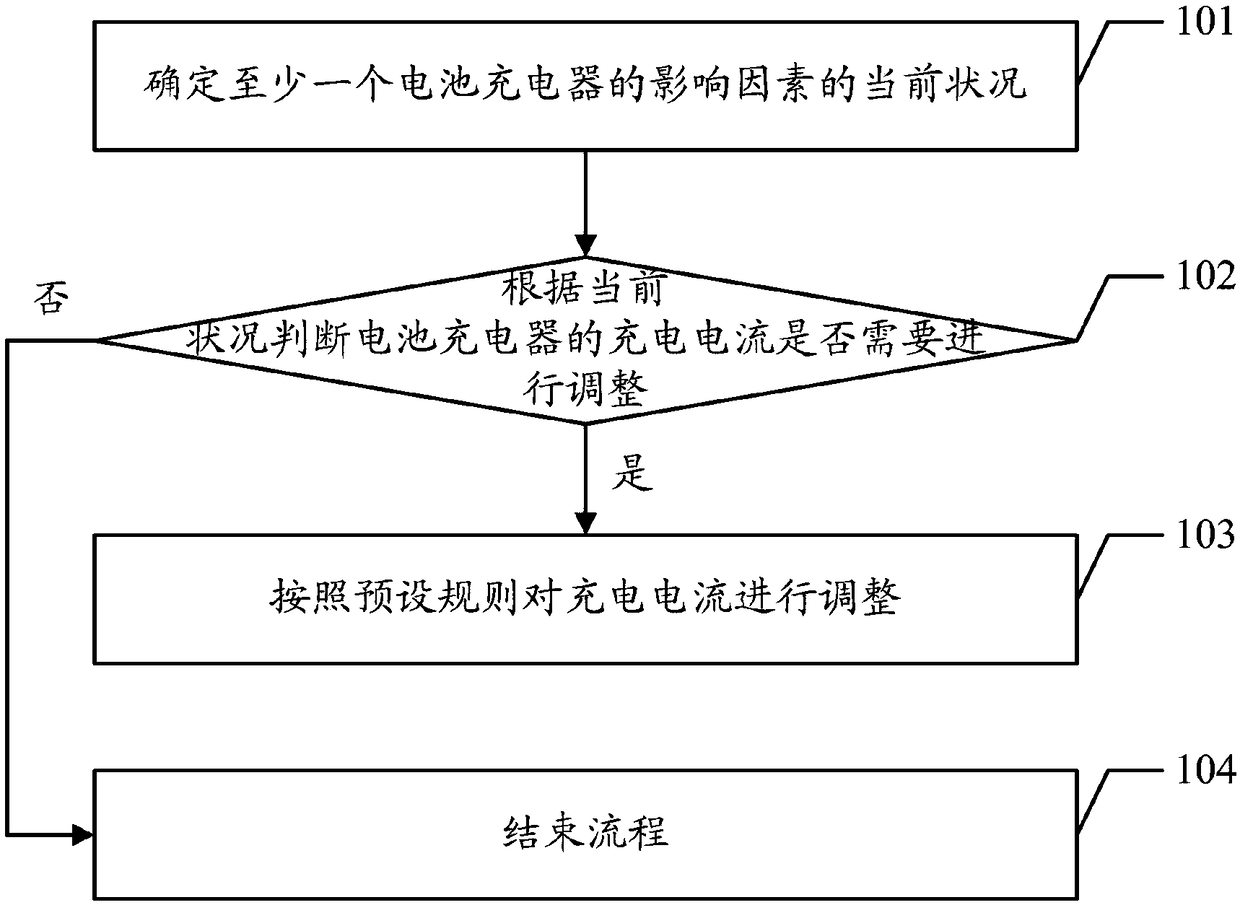

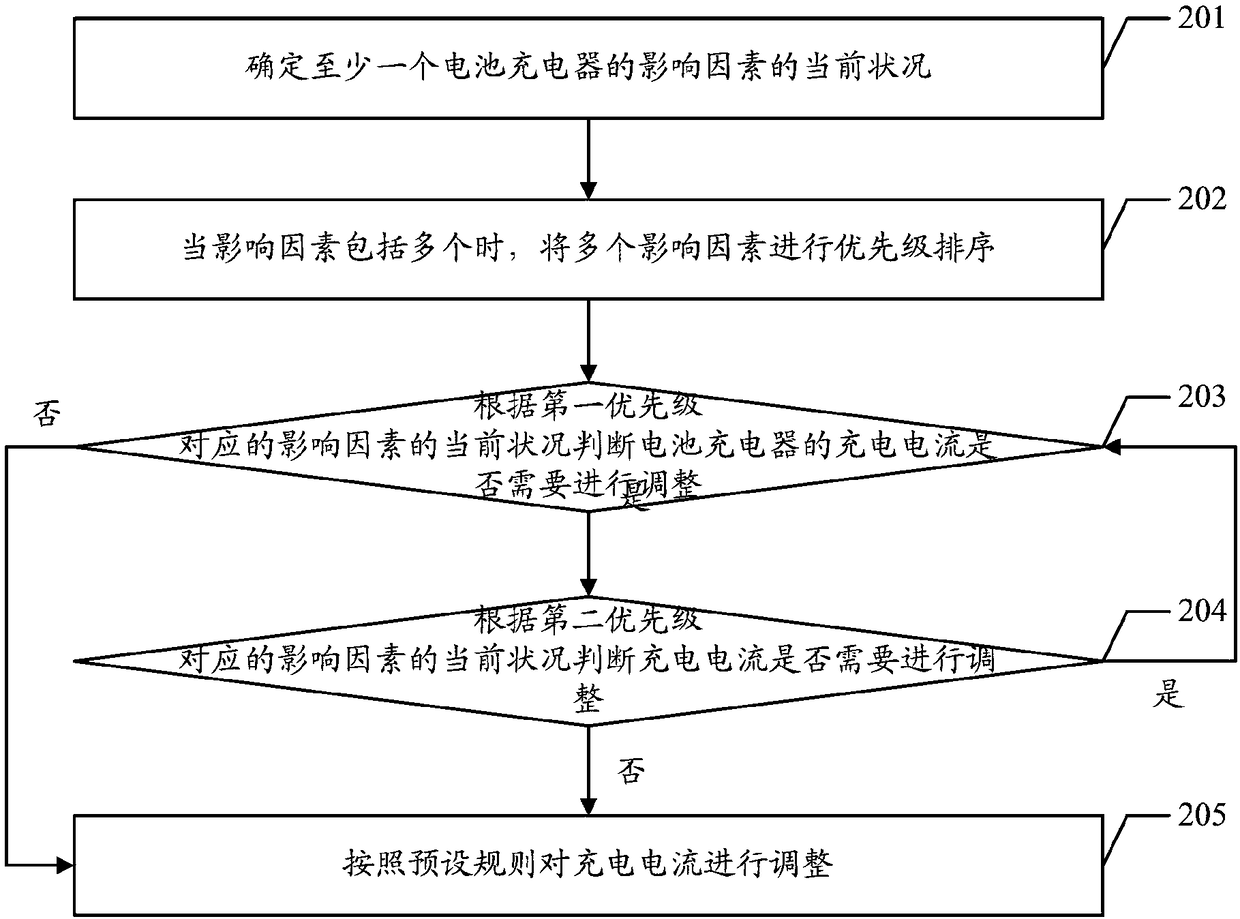

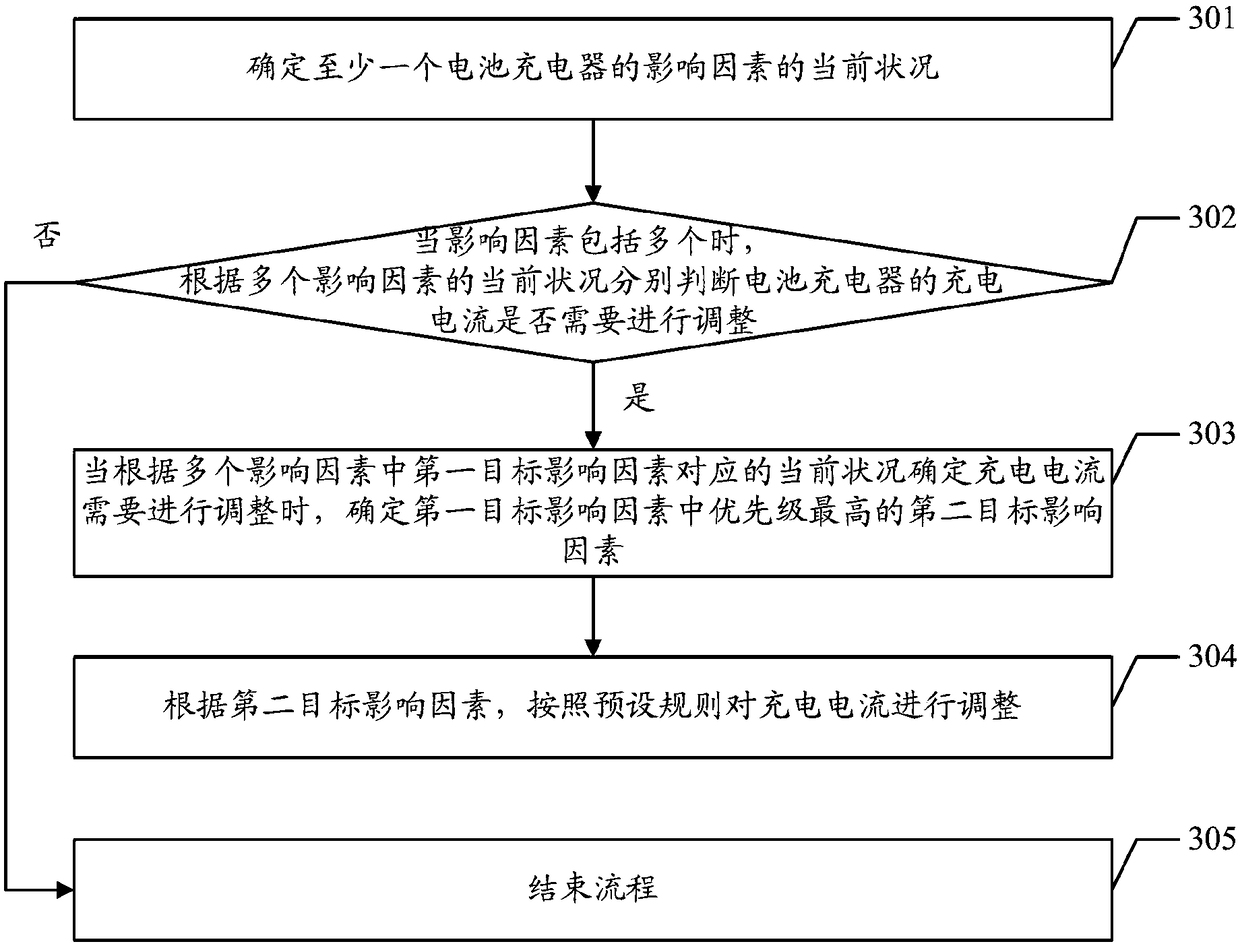

Charging current control method and apparatus, computer apparatus and readable storage medium

ActiveCN108429304AHeat controlGuaranteed thermal balanceBatteries circuit arrangementsElectric powerCharge currentPower flow

An embodiment of the invention discloses a charging current control method and apparatus, a computer apparatus and a readable storage medium that are used for adjusting a charging current of a batterycharger in real time according to different influence factors so as to maintain heat balance in an environment where the battery charger is positioned, and influence exerted on the battery charger byabnormal phenomena of the influence factors can be reduced. The method disclosed in the embodiment of the invention is applied to a UPS system, wherein the UPS system comprises at least one battery charger. The method comprises the following steps: a current condition of the influence factors of the charging current of at least one battery charger is determined, and whether the charging current needs adjustment is determined according to the current condition; if yes, the charging current is adjusted according to preset rules.

Owner:ZHANGZHOU KEHUA TECH CO LTD +1

Comprehensive utilization method for bottom-top composite blowing smelting reduction of high-iron red mud

ActiveCN113174456ARealize continuous recoveryTake advantage ofExhaust gas handlingCement productionFiberTempering

The invention discloses a comprehensive utilization method for bottom-top composite blowing smelting reduction of high-iron red mud. The comprehensive utilization method mainly comprises the following steps: the high-iron red mud is mixed with a reducing agent, a slag former and fluorite; the mixed raw materials are added into a reduction furnace molten pool for a reduction reaction, oxygen-enriched air and fuel gas are blown to the top in the reduction process, and mixed gas of reducing gas and oxygen is blown to the bottom in the reduction process; and low-sulfur and low-phosphorus pig iron and reducing slag are obtained through bottom-top composite blowing smelting reduction, and rock wool products are prepared through tempering, centrifuging and wire drawing and fiber forming of the thermal-state reducing slag. By means of bottom-top composite blowing smelting reduction, continuous reduction of the high-iron red mud can be achieved, a low-residue high-quality pig iron product is directly obtained, the reduction rate of iron reaches 95% or above, and meanwhile the recovery rate of sodium oxide reaches 70% or above.

Owner:NORTHEASTERN UNIV +1

Power battery thermal management system and control method thereof

ActiveCN102139646BGuaranteed thermal balanceCell temperature controlVehicular energy storageCold airPower battery

The invention provides a power battery thermal management system which comprises a complete automobile power-driven air conditioner, a complete automobile charger, an air passage and a battery management system, wherein the air passage is connected with an air outlet of the complete automobile power-driven air conditioner and an air inlet of a battery pack and is used for leading hot air or cold air of the air conditioner into the battery pack; the battery management system is used for controlling the hot air of the air conditioner to be led into the battery pack so as to preheat the battery set in the battery pack when the lowest temperature of a battery module is lower than a first threshold value and controlling the battery set in the battery pack to be charged and discharged after preheating the battery pack; when the highest temperature of the battery module is higher than a second threshold value and the temperature difference between the ambient temperature of the air inlet of the battery pack and the temperature of the battery module is lower than a third threshold, the battery management system controls the cold air of the air conditioner to be led to the battery pack so as to dissipate heat in the battery set in the battery pack. Accordingly, the invention provides a control method of the thermal management system. The invention can lead the battery pack to be charged and discharged in the allowable temperature range and ensure the heat balance among the battery modules and prevent the battery from being overcharged and overdischarged.

Owner:CHERY AUTOMOBILE CO LTD

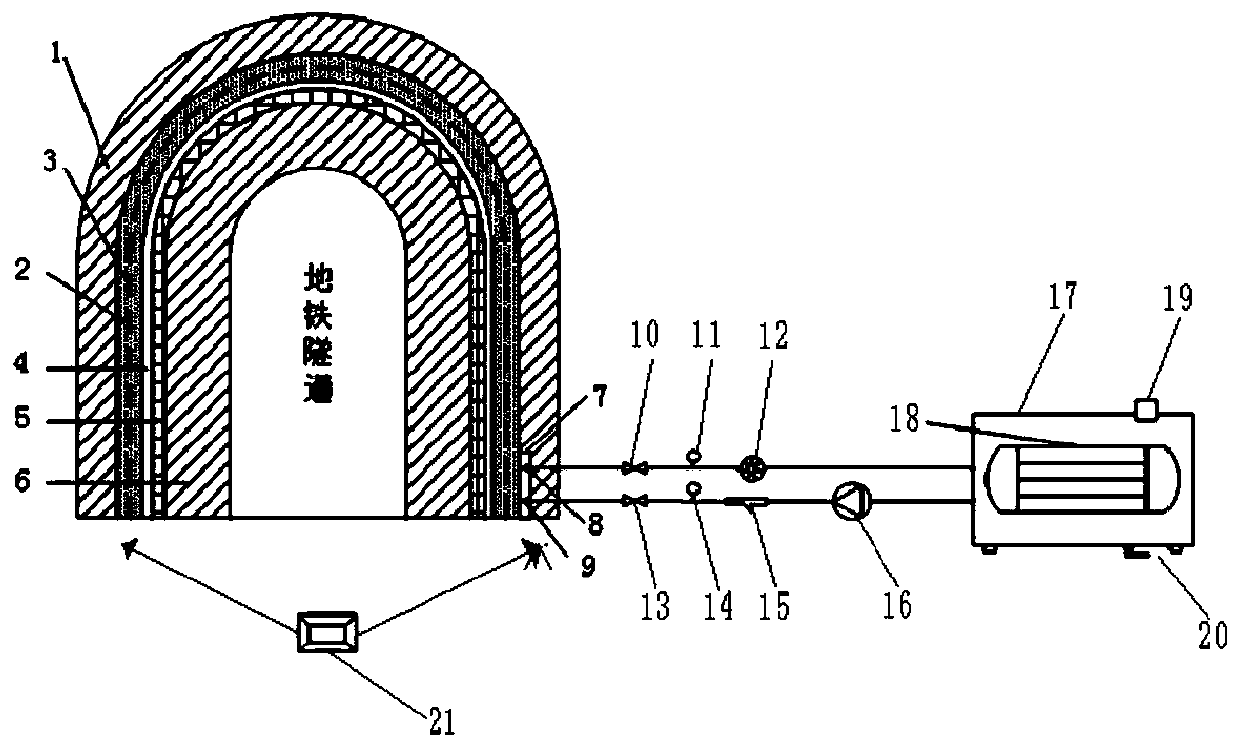

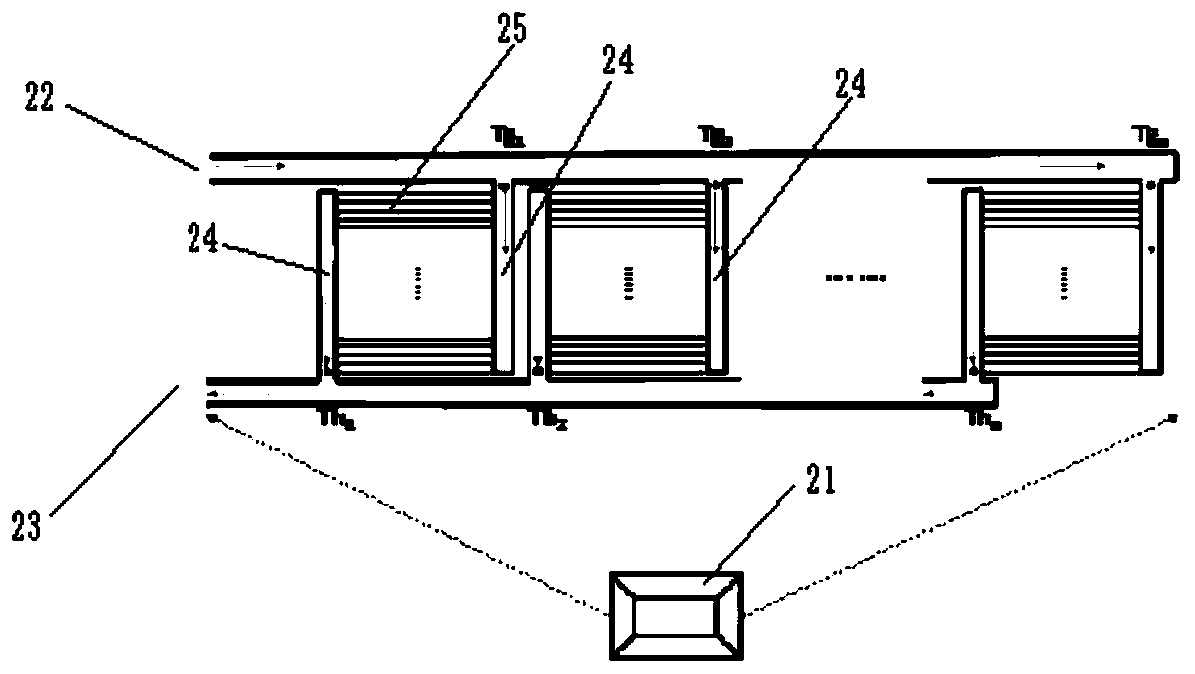

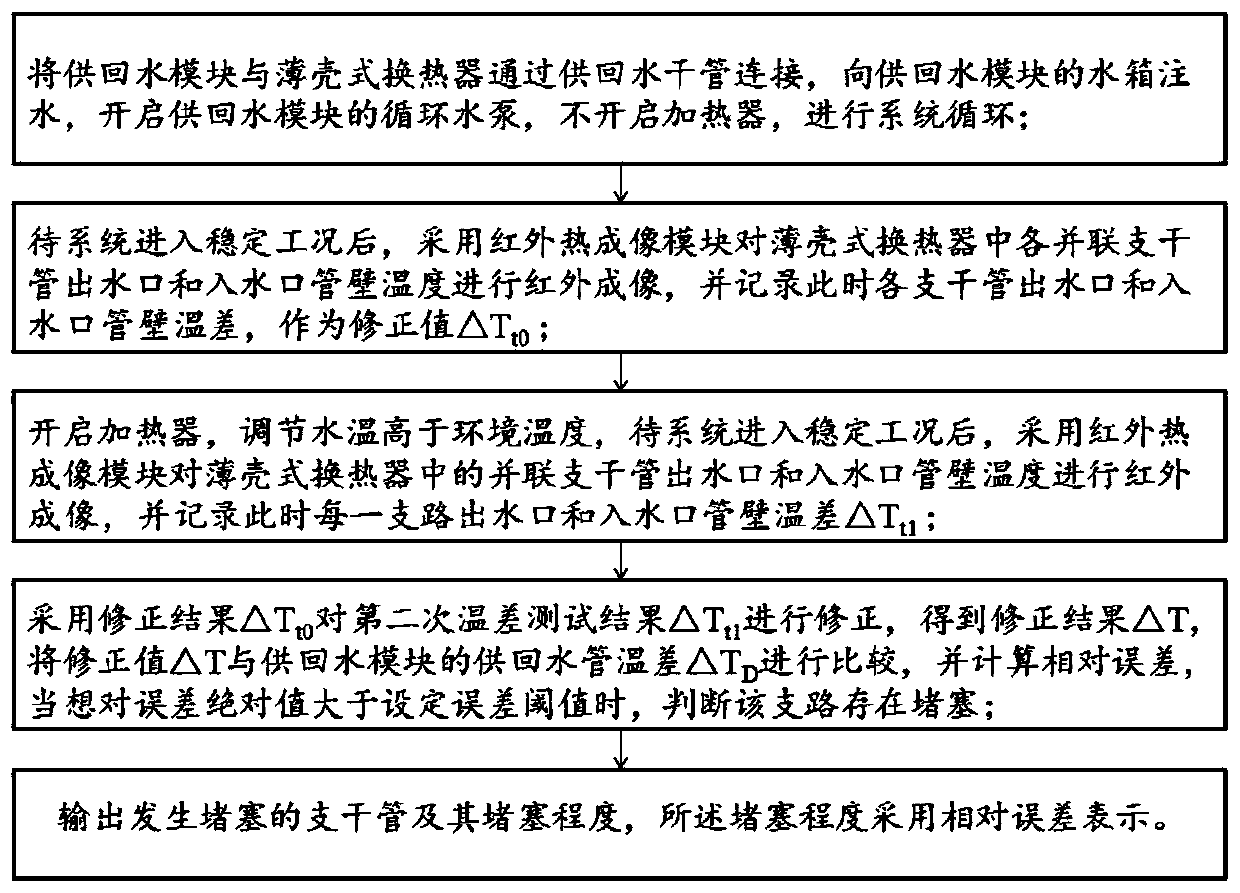

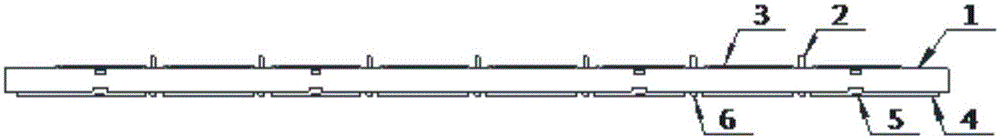

System and method for detecting blockage of thin shell type heat exchanger for tunnel

PendingCN110220546AEasy to operateReliable methodMeasurement devicesLighting and heating apparatusThin shellsEngineering

The invention provides a system and a method for detecting blockage of a thin shell type heat exchanger for a tunnel. The system comprises the thin shell type heat exchanger, a water supply and returnmodule and an infrared temperature measurement module, wherein the thin shell type heat exchanger comprises a plurality of branch main pipes and is used for heating and releasing heat in surroundingrocks of the tunnel; the water supply and return module is connected with the thin shell type heat exchanger through a water supply and return pipeline and is used for supplying water to the thin shell type heat exchanger; and the infrared temperature measurement module is used for testing the temperature of a water outlet and a water inlet of each branch main pipe. According to the system of theinvention, the infrared temperature measurement module is used for detecting the temperature of the water outlet and the water inlet of the branch main pipe, thus the technical problem that the blockage problem of the thin shell type heat exchanger at the front end of a subway ground source heat pump cannot be quickly detected at present is solved, the operation is simple, the method is quick andreliable, a blocked branch of the thin shell type heat exchanger can be quickly detected, and the blockage degree of the branch can be evaluated.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

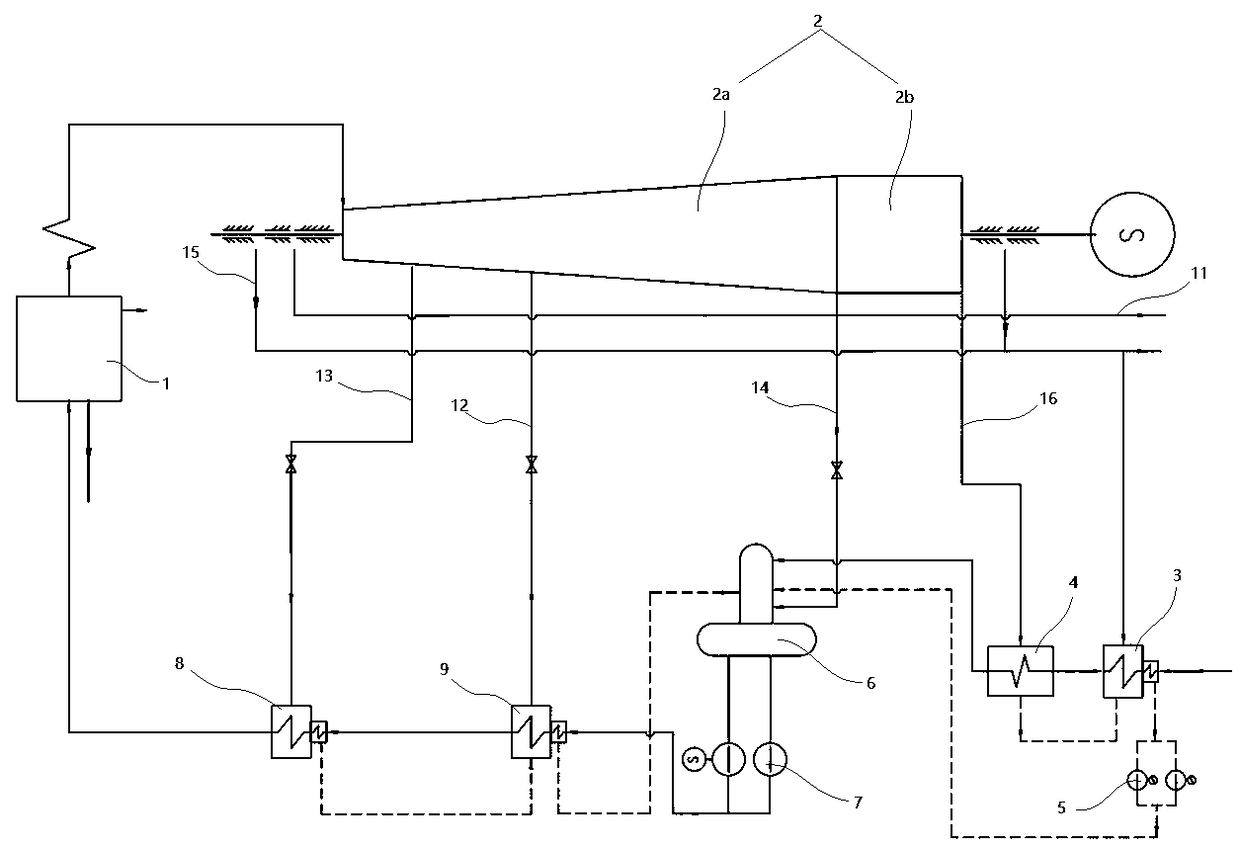

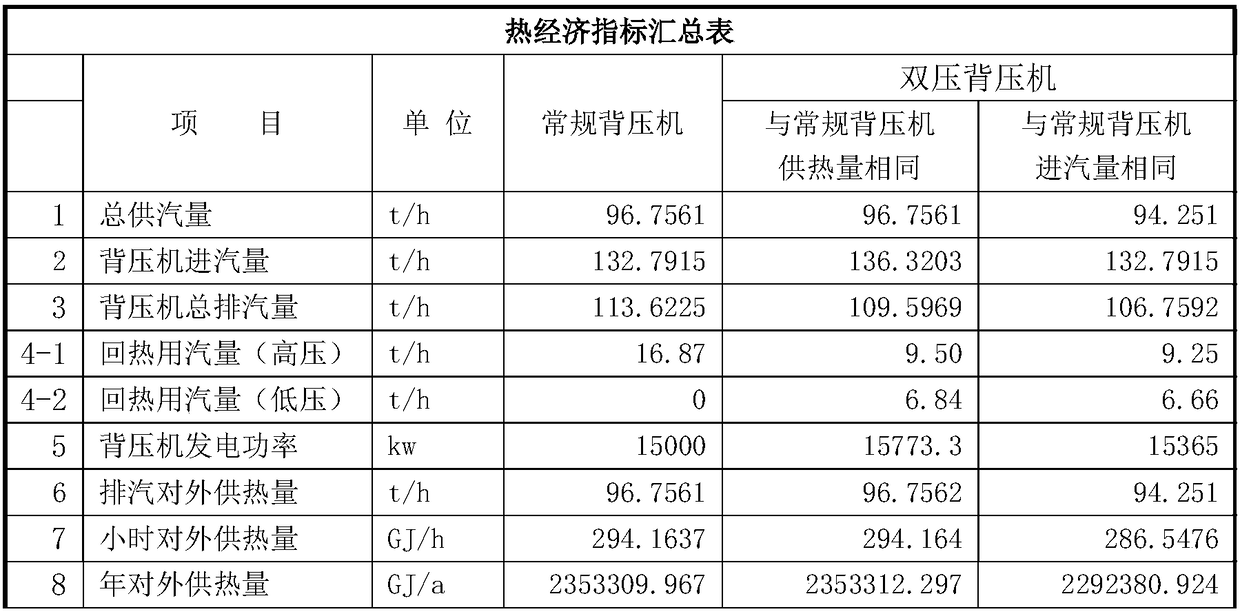

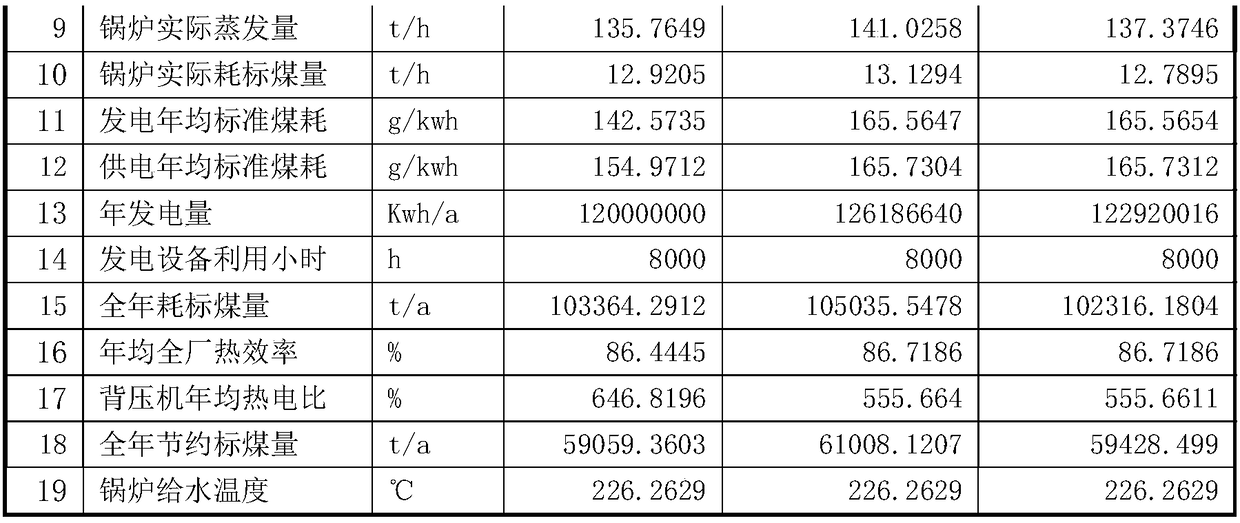

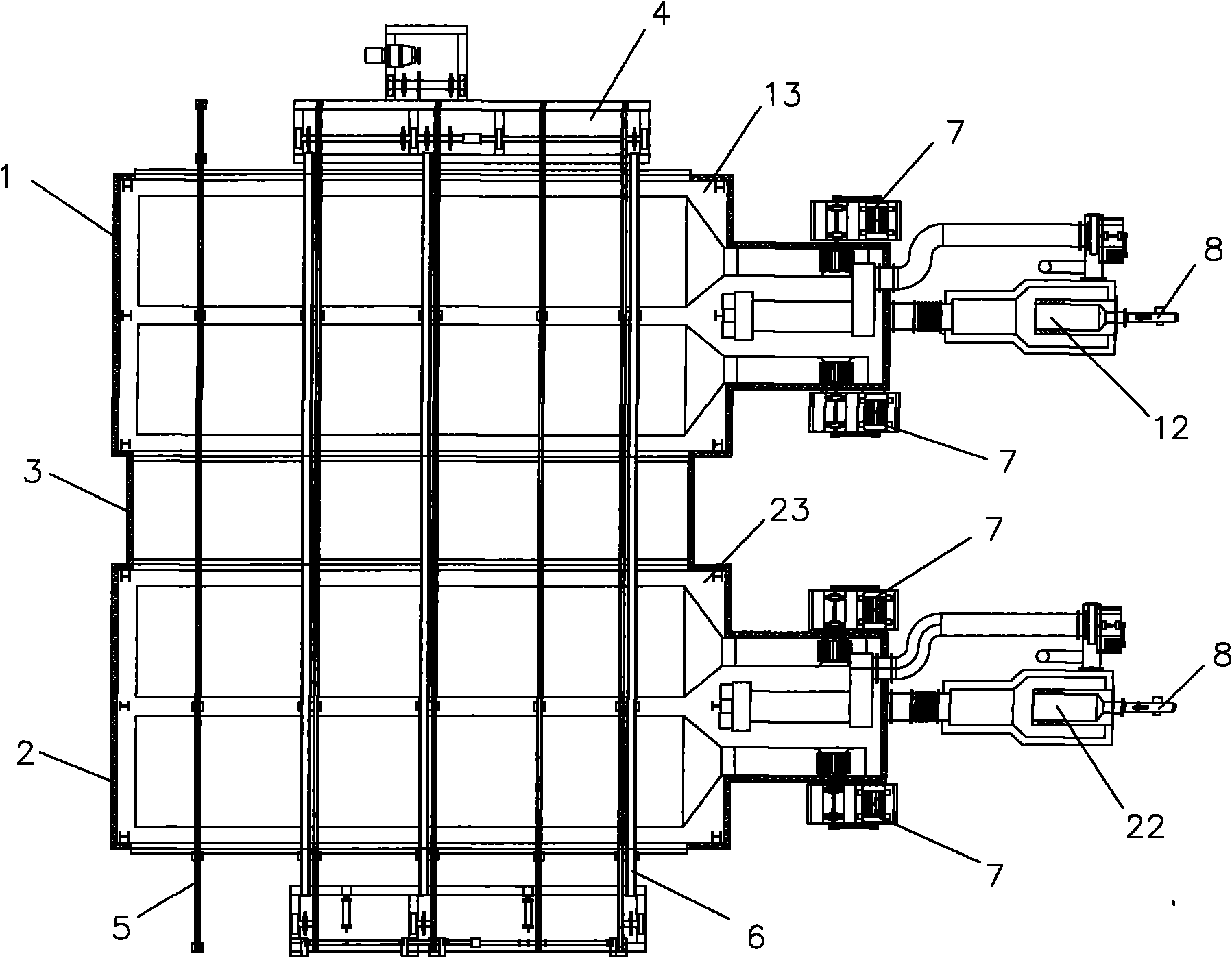

Dual-pressure back-pressure turbine heat supply system

PendingCN108915808AGuaranteed thermal balanceIncrease power generationSteam useGenerating capacityEngineering

The invention discloses a dual-pressure back-pressure turbine heat supply system. The dual-pressure back-pressure turbine heat supply system comprises a boiler, a dual-pressure back-pressure turbine,a shaft sealing heater, a drainage pump, a low-pressure heater, a deaerator, an electric water feeding pump, a first high-pressure heater and a second high-pressure heater; the dual-pressure back-pressure turbine comprises a high-pressure back-pressure turbine portion and a low-pressure back-pressure turbine portion which are connected in series, high-pressure exhausted steam is used for being conveyed to the deaerator from a pipeline after external heat supply, and low-pressure exhausted steam is connected to the low-pressure heater and used for heating demineralized water conveyed by the shaft sealing heater; condensation water of the low-pressure heater flows to the shaft sealing heater, and condensation water of the shaft sealing heater is pumped to the deaerator through the drainage pump; and shaft sealing leaked gas of the dual-pressure back-pressure turbine is connected to the shaft sealing heater through a pipeline and used for heating demineralized water for water replenishing, and the demineralized water heated by the low-pressure heater is connected to the deaerator. According to the system, no cold source loss is generated, part of the steam which is originally used forheating the demineralized water continues to doing work in the low-pressure back-pressure turbine portion, gradient utilization of energy is fully achieved, and the generating capacity of the back-pressure turbine is increased.

Owner:SOUTHEAST UNIV

Converter high-iron-ratio smelting process

InactiveCN111876549AGuaranteed uptimeRun fastManufacturing convertersMaterials preparationSmelting process

The invention discloses a converter high-iron-ratio smelting process. The process comprises the following steps that firstly, scrap steel material preparation is performed, specifically, steel-iron materials are prepared according to the molten iron ratio of 89%-91% and the scrap steel ratio of 9%-11%; secondly, charging is performed, all scrap steel materials in scrap steel are added into a converter firstly, then 90% of total limestone and 20% of total dolomite are added from a high-level bin, and then molten iron is added for blowing; thirdly, converter blowing is performed; fourthly, normal smelting to tapping is performed according to the prior art; and fifthly, slag remains in the converter. The converter high-iron-ratio smelting process is technically optimized from the aspects of aloading system, an oxygen supply system, a slag-making system, slag remaining operation, furnace type control and the like, so that thermal balance is ensured, stable operation of the converter undera high-iron-ratio production mode is achieved, economic and technical indexes such as steel-iron material consumption and slag-making material consumption are optimized and improved, stable operationof the furnace condition is achieved, the cost is lowered, and the smelting efficiency is improved.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

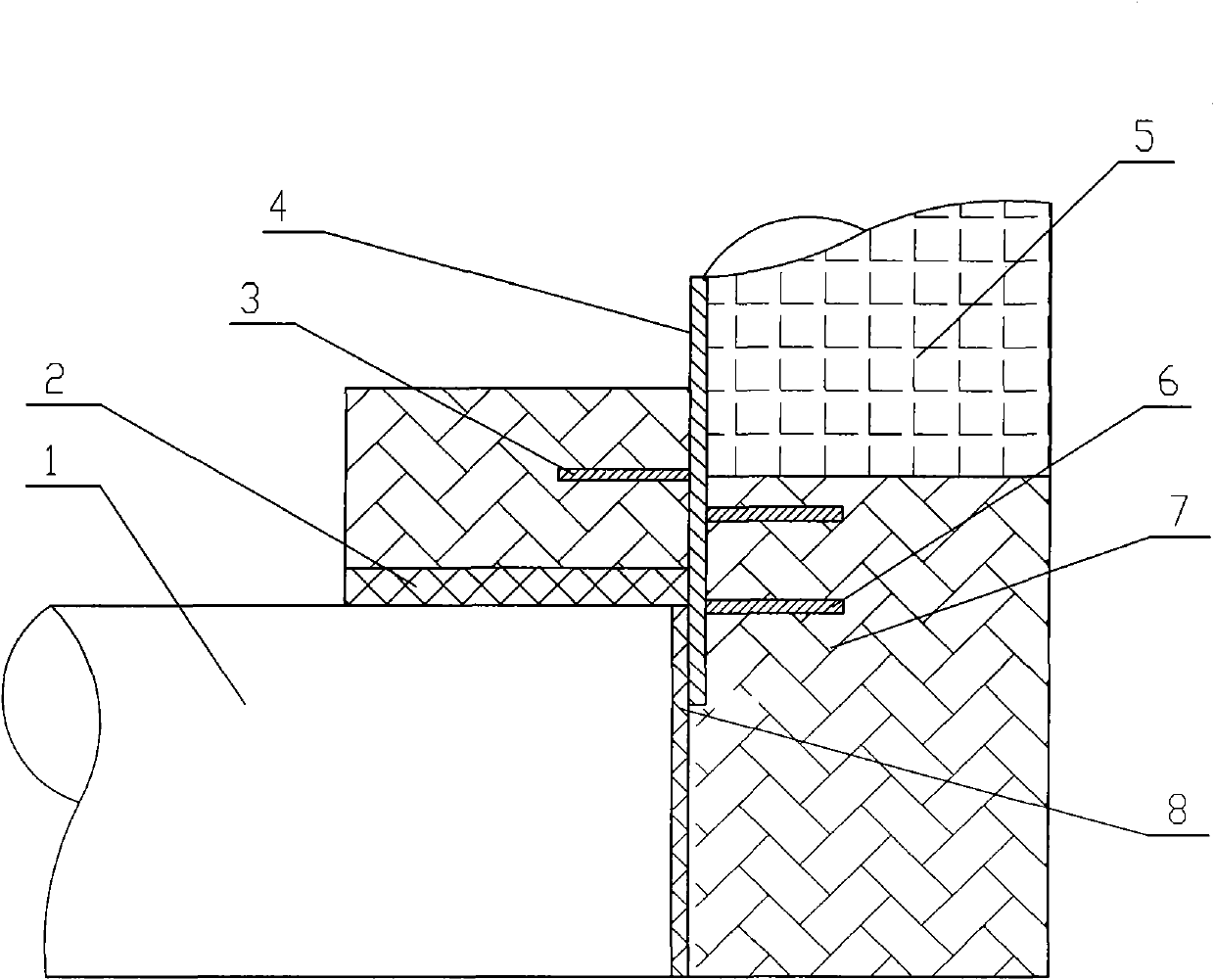

Device for baking and curing inner anti-corrosion layer of pipe

InactiveCN101992182AAvoid coolingEfficient ConcentrationPretreated surfacesCoatingsEngineeringHeat balance

The invention provides a device for baking and curing an inner anti-corrosion layer of a pipe, which comprises a baking oven, a curing oven, a heat insulation chamber and a chain conveying mechanism, wherein the heat insulation chamber is arranged between the baking oven and the curing oven and is mutually communicated with the baking oven and the curing oven, and the chain conveying mechanism sequentially passes through the baking oven, the heat insulation chamber and the curing oven to form a circulation loop. The pipe is directly conveyed from the baking oven to the curing oven by the device through the chain conveying mechanism, the cooling of the pipe baked by the baking oven can be effectively prevented through the heat insulation chamber, therefore, the energy can be saved, and the consumption can be reduced; the heat energy can be effectively collected through a worm case arranged in the oven, the stability and the uniformity of the circulated air supply can be ensured, the heat balance in a hearth can be ensured, meanwhile, the heat energy is prevented from being spread out, and the energy consumption can be saved.

Owner:SHANGHAI TUBE COTE PETROLEUM PIPE COATING

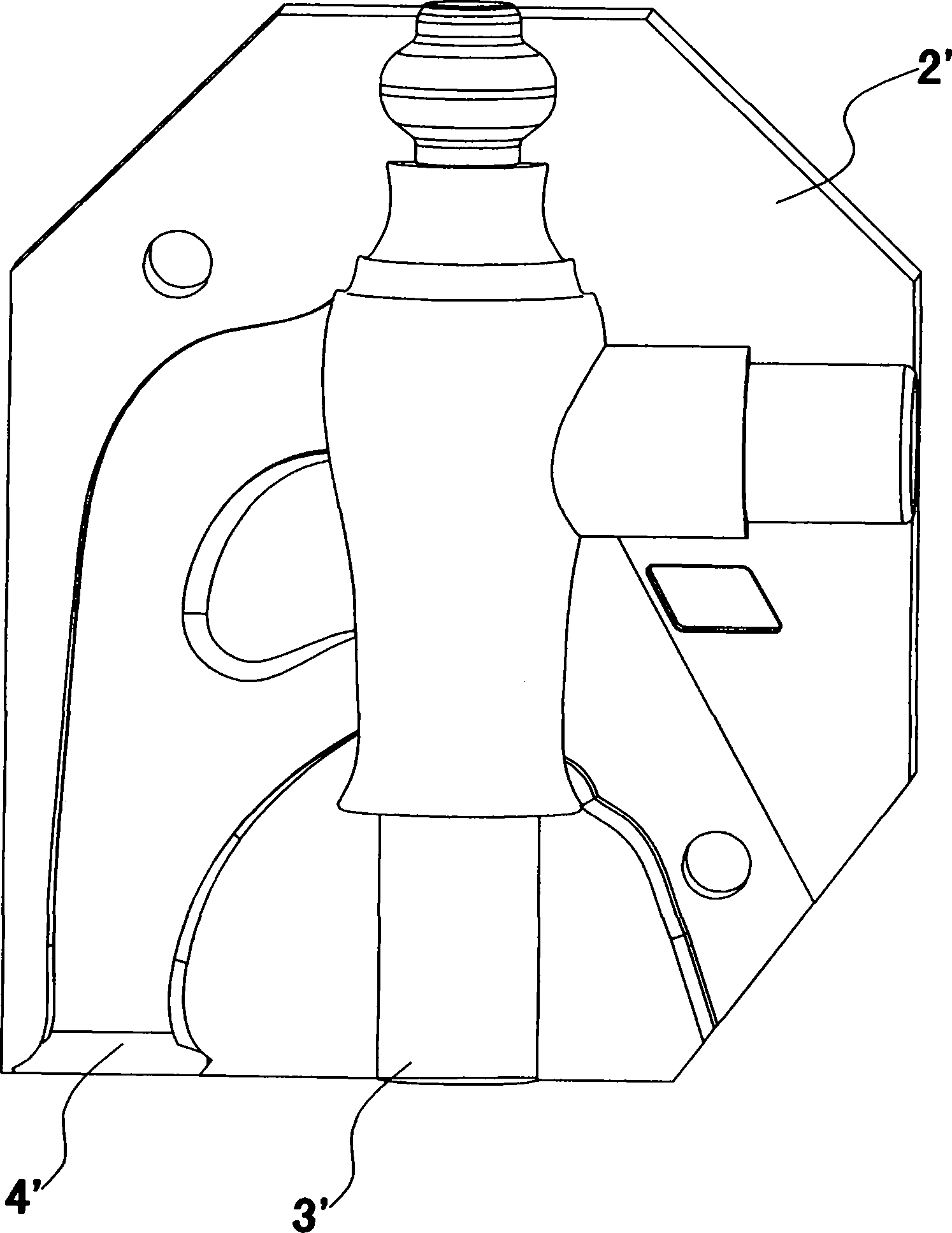

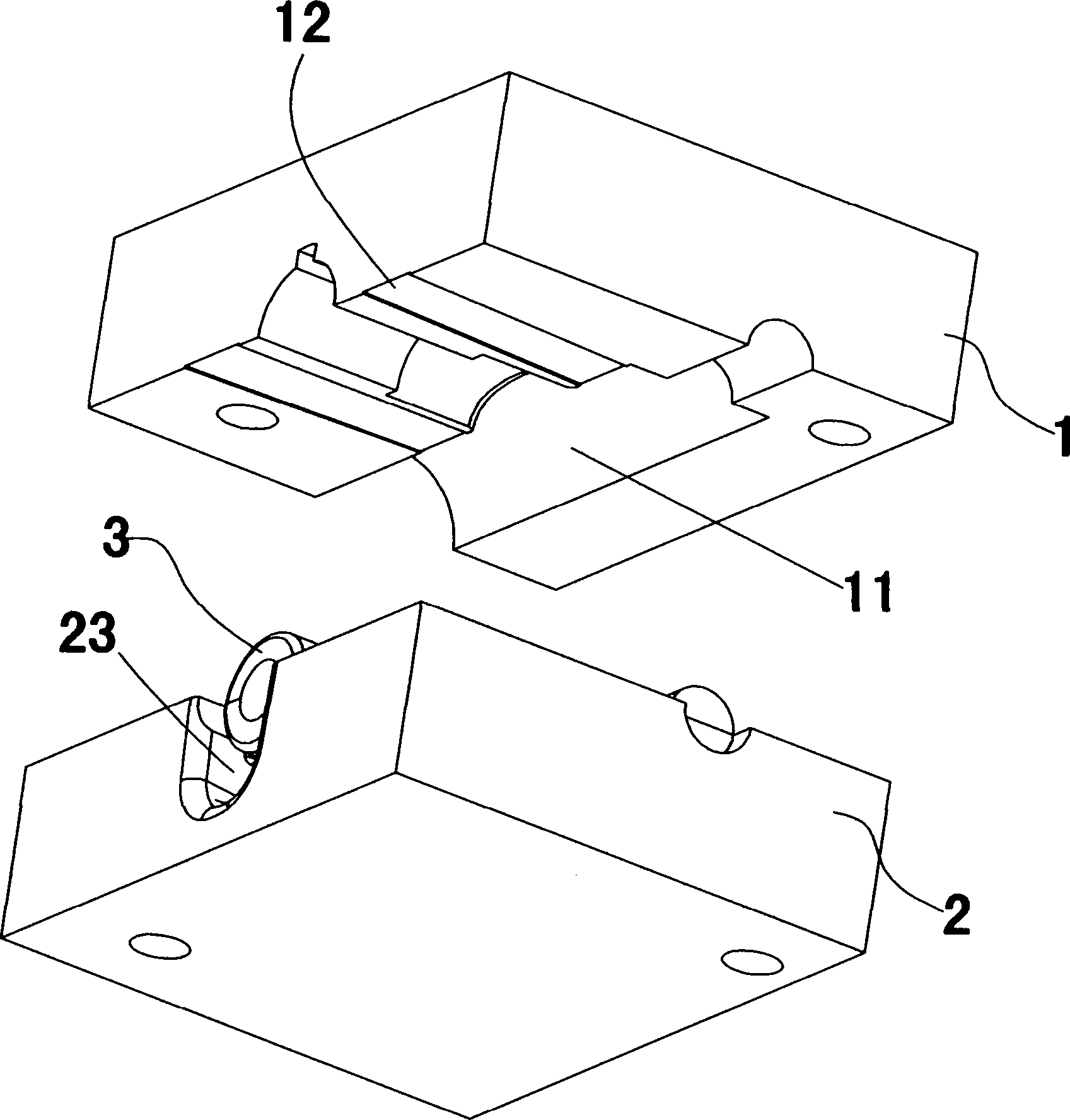

Casting technology for lead-free brass tap

ActiveCN104259393AGuaranteed thermal balanceSimple structureFoundry mouldsFoundry coresHeat balanceMaterials science

The invention provides a casting technology for a lead-free brass tap, which the advantages that the flowing distance of products in the pouring process is short, simultaneous solidification is realized, and hot cracks are reduced; the die has excellent heat balance effect, is favorable to the heat balance of the products and reduces stress micro-cracks during cooling. The casting technology comprises the step of casting-molding lead-free brass fluid through a gravity casting device, wherein the gravity casting device comprises an upper half die, a lower half die and a sand core, die cavities fitted with the shape of a tap body are respectively correspondingly arranged between the upper half die and the lower half die, the sand core is arranged in the die cavities between the upper half die and the lower half die, the shape of the sand core is matched with the shape of a water-in part, a water-out part and an inner cavity of a valve core mounting part of the tap body, pouring cavities are formed between the sand core and the die cavities, a gate for allowing lead-free melt copper to be poured is further formed in the upper half die or the lower half die, the gate is connected with the pouring cavities, the gate is provided with an inner gate and an outer gate, and the inner gate is correspondingly arranged at the pouring cavity part for molding the valve core mounting part of the tap body.

Owner:GUANGDONG WEIXIANG SANITARY WARE

Method for constructing refractory materials at pellet rotary kiln bellow port

ActiveCN102087074AExtended service lifeImprove sealingLinings repairRotary drum furnacesRefractoryEngineering

The present invention, belonging to the technical field of pellet rotary kiln bellow port, particularly relates to a method for constructing refractory materials at pellet rotary kiln bellow port, and the method comprises the steps as follows: a row of U-shaped nails are welded on the bellow steel plate at one side of a prefabricated component of the rotary kiln top at the bellow port, two rows of U-shaped nails are welded on the other side of the bellow steel plate, wherein the two rows of the U-shaped nails are equidistantly arranged above and below the previously-mentioned row of U-shaped nails; the transverse spacings between the U type nails are 90mm to 150mm, and the vertical spacings between the U-shaped nails are 60mm to 120mm; asbestos felts are arranged between the prefabricated component of the top of the rotary kiln and the bellow steel plate and on the partial surface of the prefabricated component of the top of the rotary kiln adjacent with the bellow steel plate, and refractory materials are cast at the position where the two rows of U-shaped nails are welded. The lengths of the U-shaped nails are 40m to 80m, and the layer thicknesses of the cast refractory material are 90m to 160m. The method for constructing refractory materials at pellet rotary kiln bellow port provided by the invention prolongs the service life of the refractory materials made at the pellet rotary kiln bellow port, satisfies the requirement of production, decreases the maintenance loads, and reduces the production cost.

Owner:ANSTEEL GRP MINING CO LTD

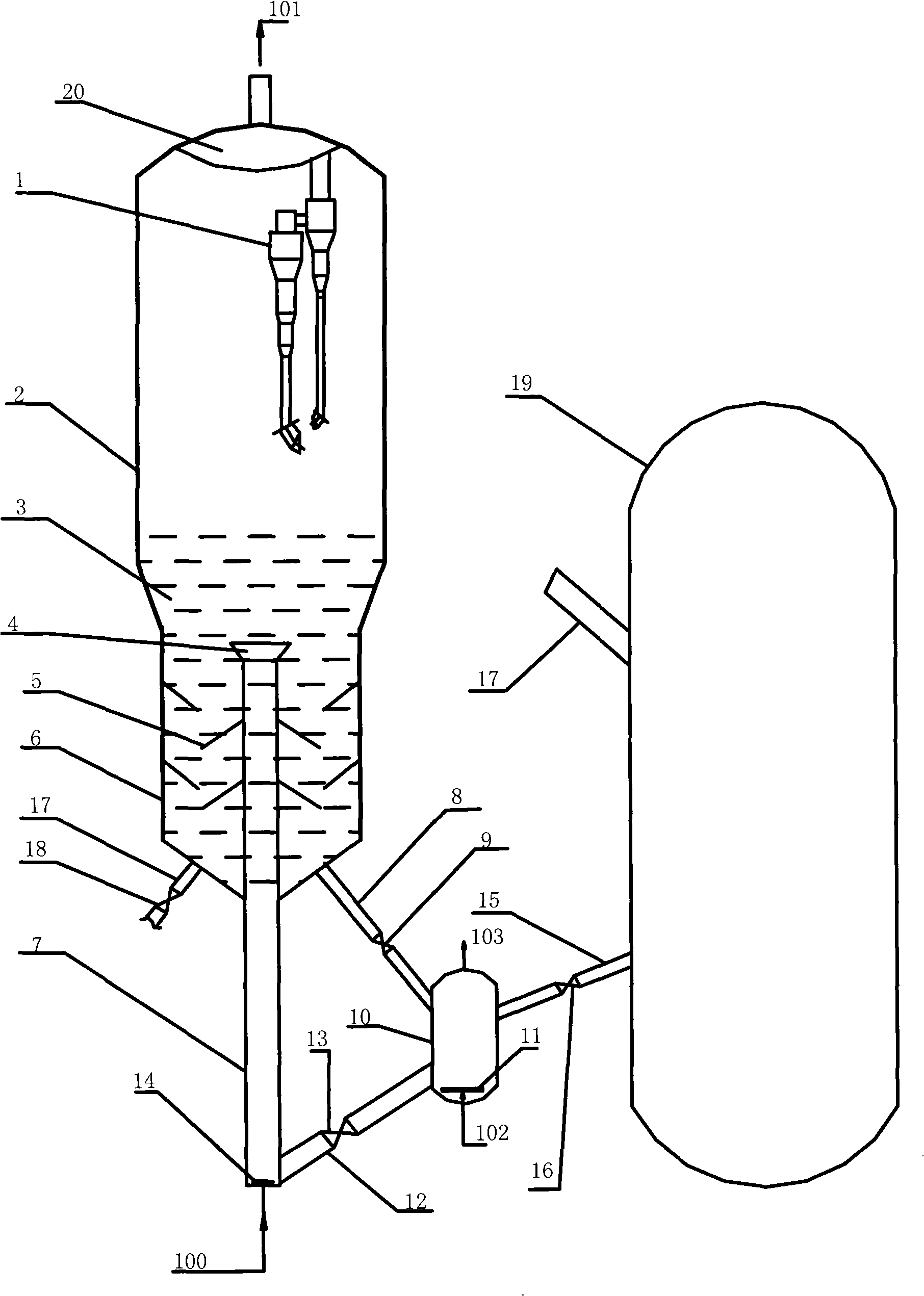

Fluidizer and method for preparing ethylene with ethanol dehydration

ActiveCN101293804BAdded degassing stepsEfficient removalHydrocarbon from oxygen organic compoundsChemical recyclingFluidized bedFlue gas

Owner:CHINA PETROLEUM & CHEM CORP +1

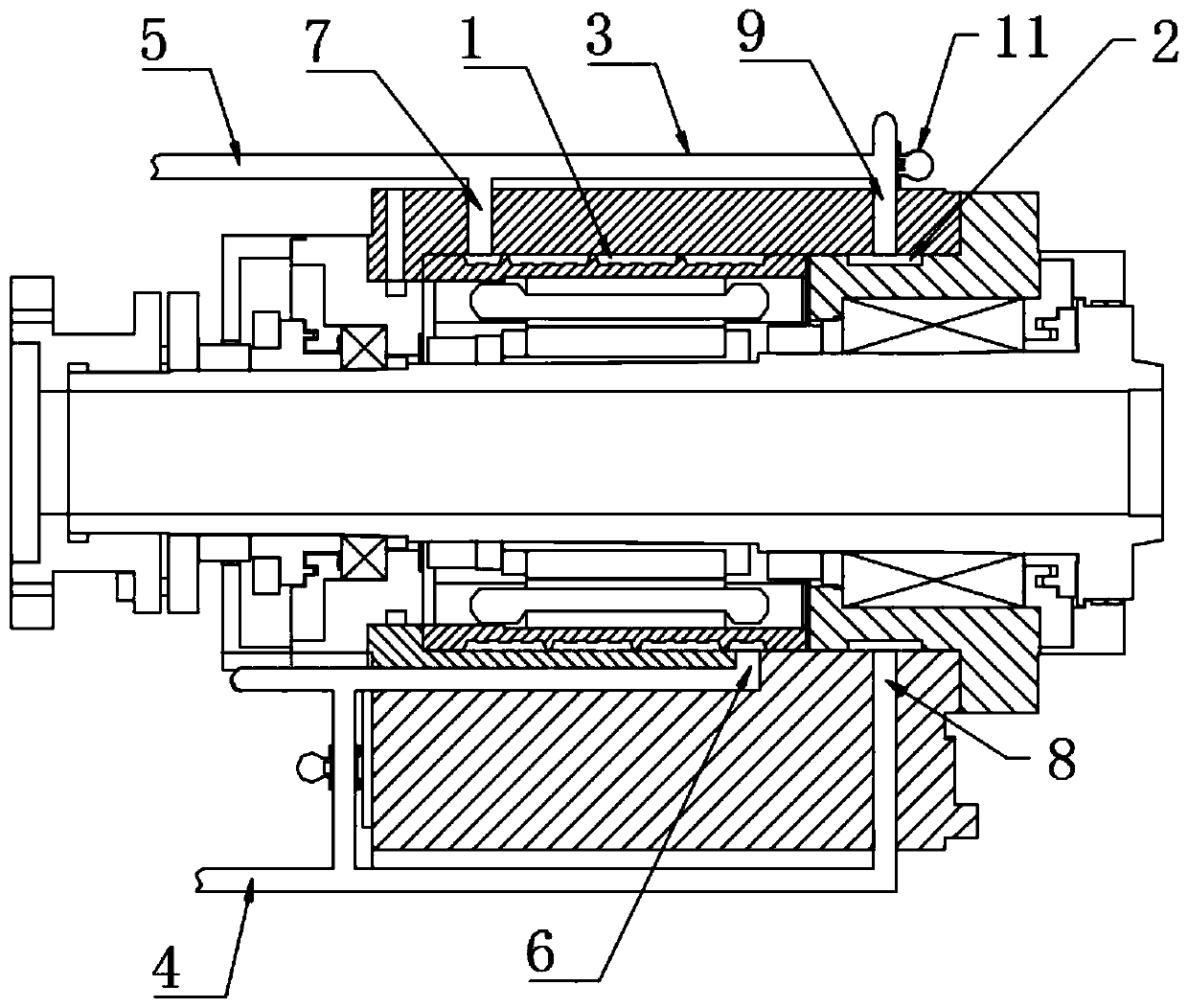

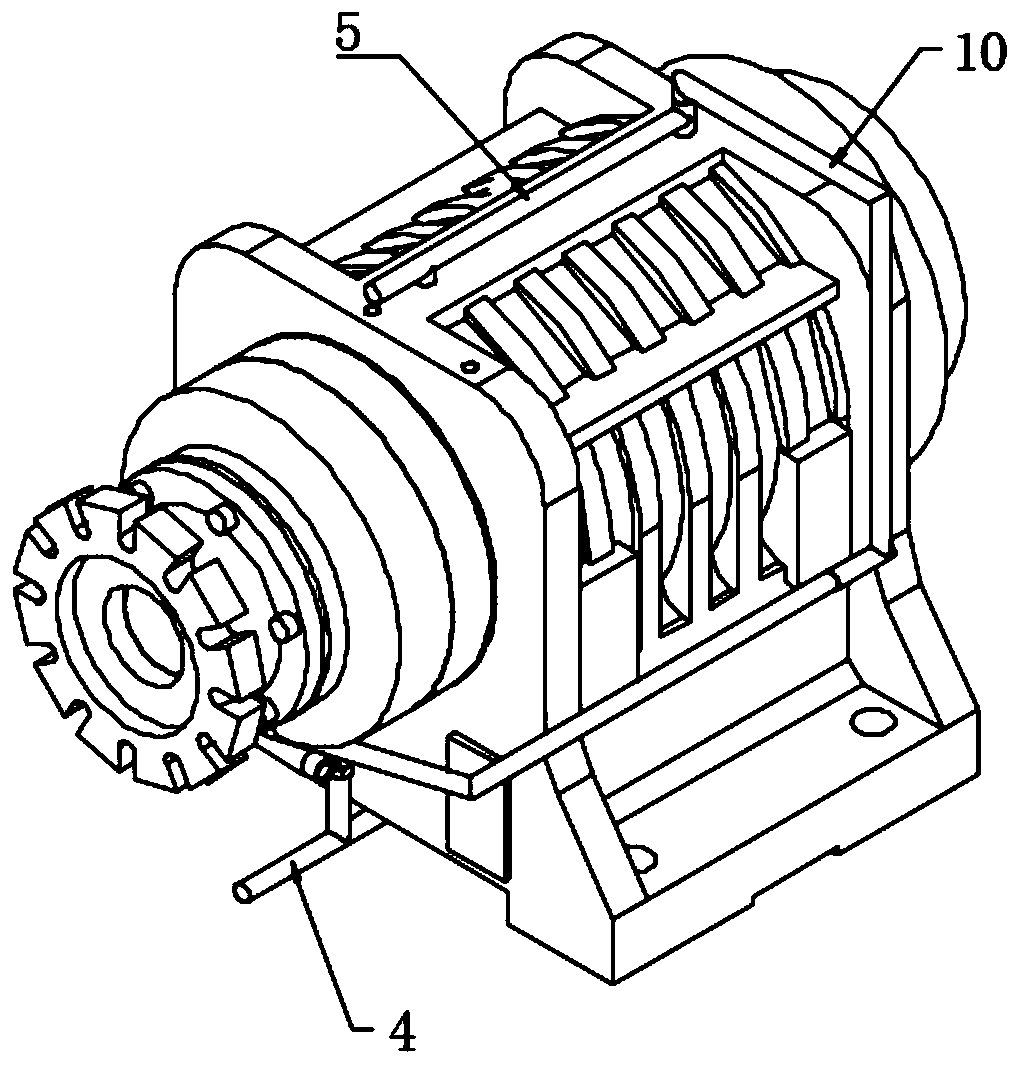

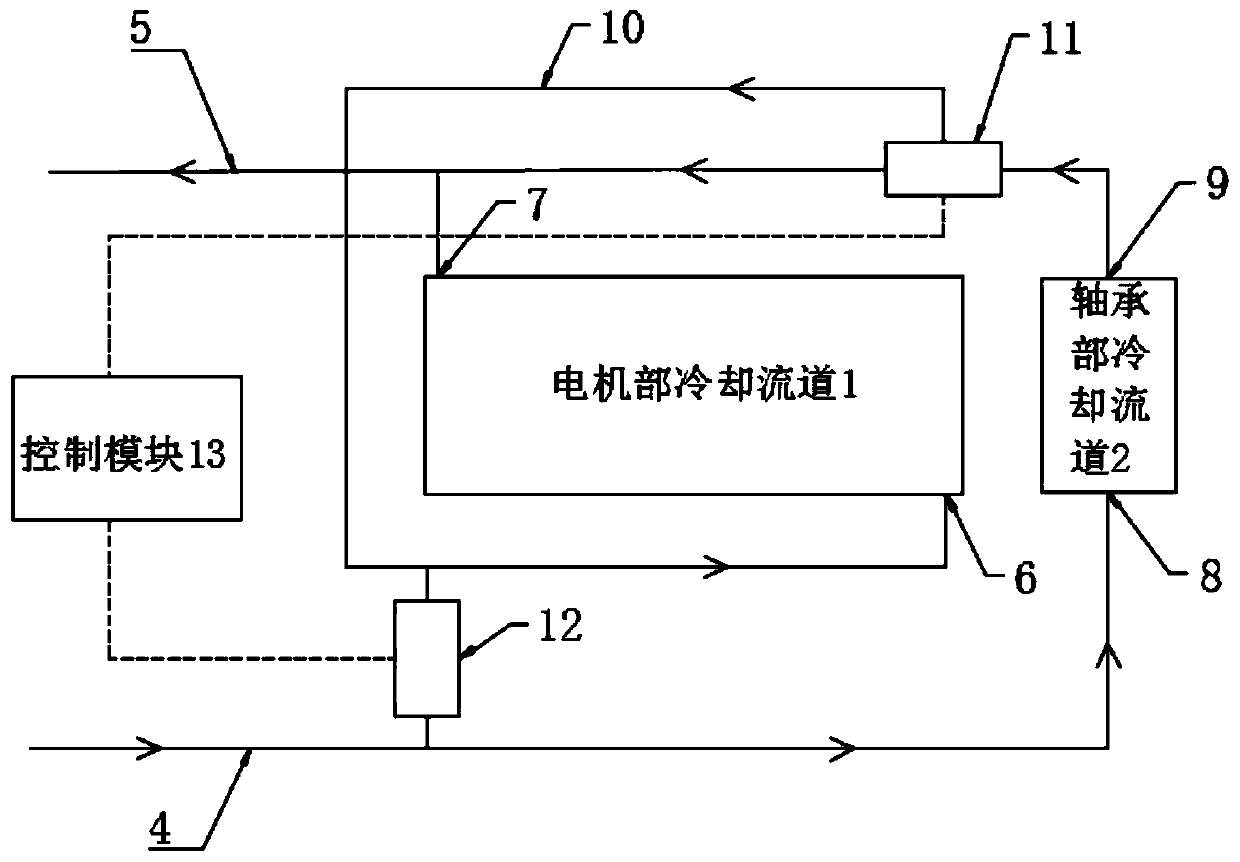

Cooling system, electric spindle and numerical control machine tool

ActiveCN111113143AEasy to reach thermal equilibriumGuaranteed thermal balanceLarge fixed membersMaintainance and safety accessoriesNumerical controlThermodynamics

The invention provides a cooling system, an electric spindle and a numerical control machine tool. The cooling system comprises a motor part cooling flow channel and a bearing part cooling flow channel; a valve pipe assembly is communicated with the motor part cooling flow channel and the bearing part cooling flow channel, and cooling liquid is introduced into the motor part cooling flow channel and the bearing part cooling flow channel by the valve pipe assembly; the valve pipe assembly can control and switch a parallel cooling mode and a series cooling mode; in the parallel cooling mode, cooling liquid flows through the motor part cooling flow channel and the bearing part cooling flow channel at the same time; and in the series cooling mode, the cooling liquid flows through any one of the motor part cooling flow channel and the bearing part cooling flow channel and then flows through the other one. According to the cooling system, the parallel connection mode and the series connection mode are rapidly switched for cooling under the working conditions of different rotating speeds of the electric spindle, the heat productivity is small at a low speed, and heat balance is achieved more rapidly and more easily through the parallel connection mode; and the heat productivity is large at a high speed, the series connection mode with large single-channel flow is adopted, so that theheat balance of a heat source part of the spindle is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

Fluidizer and fluidization method for preparing ethylene by ethanol dehydration

ActiveCN101274871BEfficient removalHigh purityHydrocarbon from oxygen organic compoundsChemical recyclingFlue gasPetroleum

The invention relates to a fluidized device for producing ethylene by ethanol dehydration, which comprises a fluidized bed reactor, a regenerator, a catalyst mixing chamber, a catalyst riser, a spent catalyst inner circulating pipe, a stripper and a regenerated catalyst degassing tank, wherein, the fluidized bed reactor and the regenerator are connected by spent catalyst conveying pipes, the fluidized bed reactor and the catalyst mixing chamber are connected by the catalyst riser, the stripper and the catalyst mixing chamber are connected by the catalyst inner circulating pipe, the regenerated catalyst degassing tank and the regenerator are connected by regenerated catalyst conveying pipes and the regenerated catalyst degassing tank and the catalyst mixing chamber are connected by the regenerated catalyst conveying pipes. The fluidized device, through adding the regenerated catalyst degassing tank, effectively removes flue gas taken by the regenerated catalyst and greatly improves thepurity of ethylene in the product. The regenerator is arranged independently or a catalytic cracking regenerator is shared with a catalytic cracking device in the filed of petroleum refining.

Owner:CHINA PETROLEUM & CHEM CORP +1

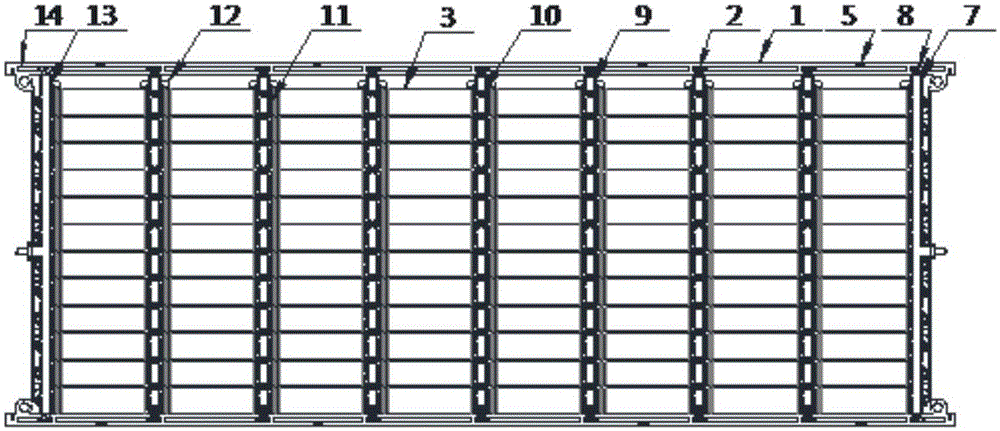

Novel cylindrical battery stacking packing structure

InactiveCN105024025AGuaranteed thermal balanceEasy to installSecondary cells charging/dischargingCell component detailsHigh energyEngineering

The invention discloses a novel cylindrical battery stacking packing structure. The novel cylindrical battery stacking packing structure comprises a monomer packing framework and battery support structures, wherein upper-lower layer parallel posts are arranged on the upper end face of the border of the monomer packing framework; upper-lower layer locking structures and current accumulation bar press bars are arranged on the lower end face of the border of the monomer packing framework; a positive electrode serial-connection copper bar and a negative electrode serial connection copper bar are arranged on the left and right sides of the monomer packing framework respectively; the positive electrode serial-connection copper bar and the negative electrode serial-connection copper bar are fixed to the monomer packing framework through compression screws; conductive domes are arranged at the two ends of each battery support structure respectively; current accumulation PCB (Printed Circuit Board) bars are arranged between columns of the battery support structures; each current accumulation PCB bar is in compression joint with the current-conducting elastic sheet in the same column; and the upper-lower layer parallel posts of the upper layer monomer packing framework are pressed against the current accumulation PCB bars of the lower layer monomer packing framework. Batteries are directly snapped into on the monomer packing framework and connected in series and in parallel without welding, so that the novel cylindrical battery stacking packing structure has the advantages of convenience in installation, high assembly efficiency, small unit battery duty ratio and high energy density.

Owner:何健舟

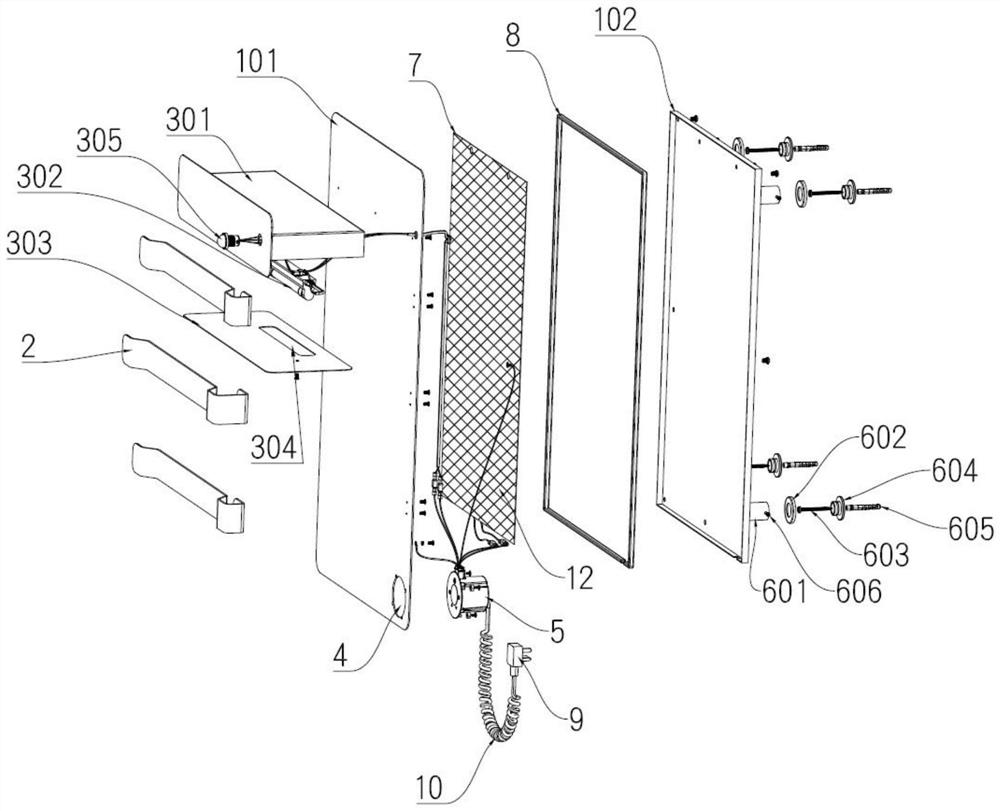

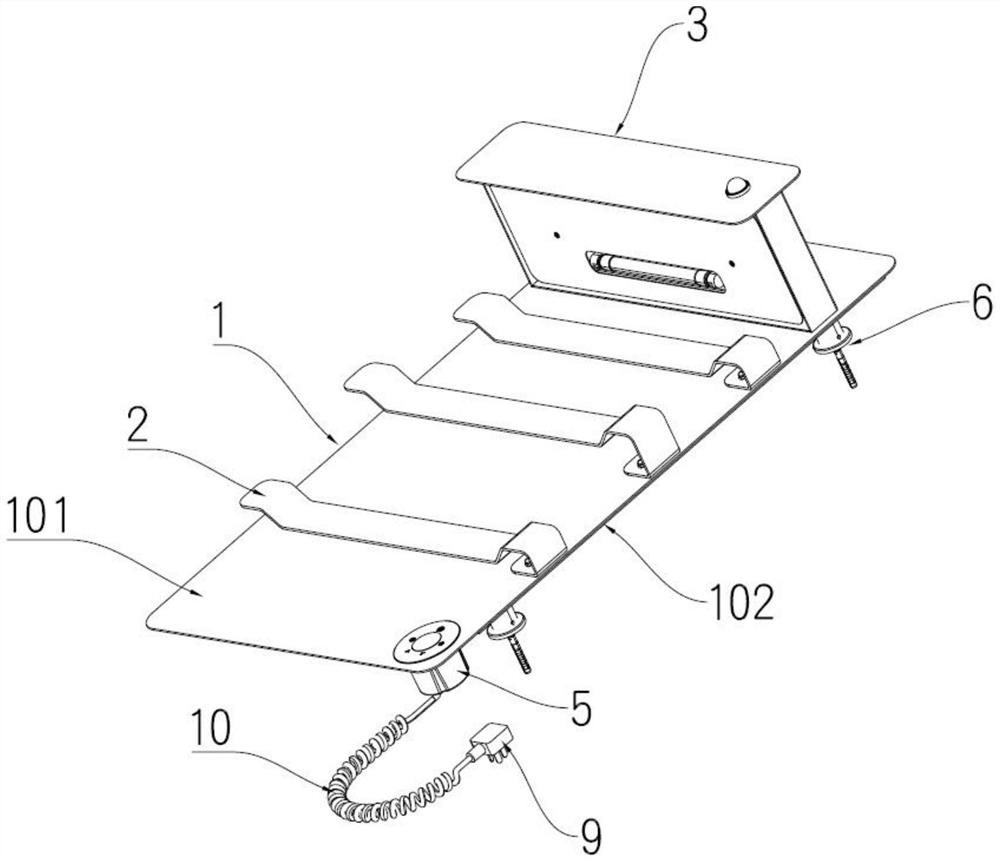

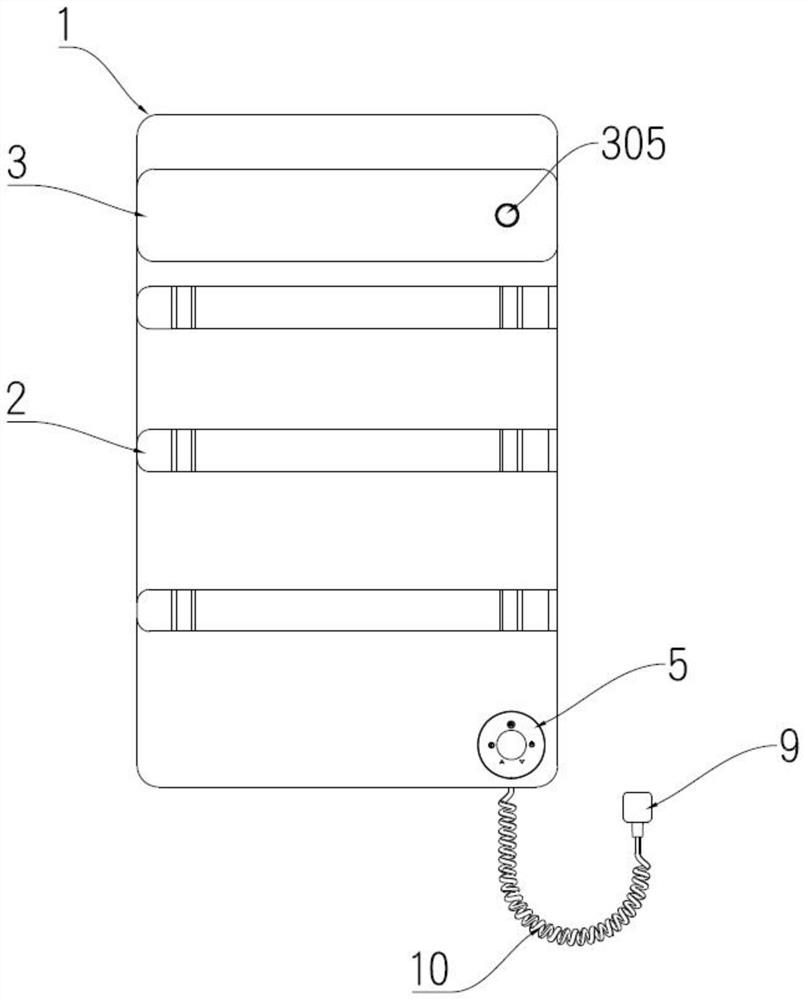

Sterilization type graphene electric heating towel rack

The invention relates to the technical field of towel racks and particularly relates to a sterilization type graphene electric heating towel rack. The towel rack comprises a mounting plate, a plurality of transverse plates, a temperature controller and a socket, wherein the mounting plate comprises a panel and a back plate fixedly arranged on one side of the panel, and a graphene heating film plate is further fixedly arranged between the panel and the back plate; one end of each transverse plate is fixedly arranged on the panel, and the other end of each transverse plate is a movable end; the temperature controller is fixedly arranged on the panel through a through hole, and an input end of the temperature controller is electrically connected with a temperature sensor through a connecting wire; the temperature sensor is fixedly arranged on a graphene heating film plate; a plug is electrically connected to the temperature controller through a telescopic connecting wire, and a panel is also fixedly provided with a sterilization mechanism for sterilization. The towel rack is advantaged in that the towel rack is simple in structure, convenient to use, fast in heating, stable in performance, uniform in heating, good in heat conversion effect and high in safety.

Owner:JIANGXI AVONFLOW HVAC TECH CO LTD

Method for preparing gas, liquid and carbon products by biomass pyrolysis

ActiveCN109762583ALow selectivityHigh selectivityBiofuelsIndirect heating destructive distillationFuranPhosphoric acid

The invention discloses a method for preparing gas, liquid and carbon products by biomass pyrolysis. The method comprises the steps that firstly biomass raw materials such as residues of branches andleaves after extracting essential oil from wood chips, bamboo chips, chestnut shells, oil tea shells and natural spices are mixed with water, the moisture content of the raw materials is controlled tobe 25-80%, and then the raw materials are charged into a cracking furnace; inert gas is introduced before cracking to pump out air in the system; temperature programming and cracking are performed, and the temperature is maintained at 150 DEG C, 200 DEG C, 300 DEG C and 400 DEG C in the temperature rising period, and the final temperature is 500 DEG C; liquid obtained by cracking is mainly an aqueous solution of acetic acid, furan and phenol derivative organic compounds, uncondensed combustible gas is mainly H2, CO, methane, ethane, propane, and solid is biomass charcoal; and acid, such as phosphoric acid, sulfuric acid and hydrochloric acid, of 0.1-20% of the mass of the biomass raw materials is added, and the selectivity of furfural can be increased.

Owner:GUANGXI FORESTRY RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com