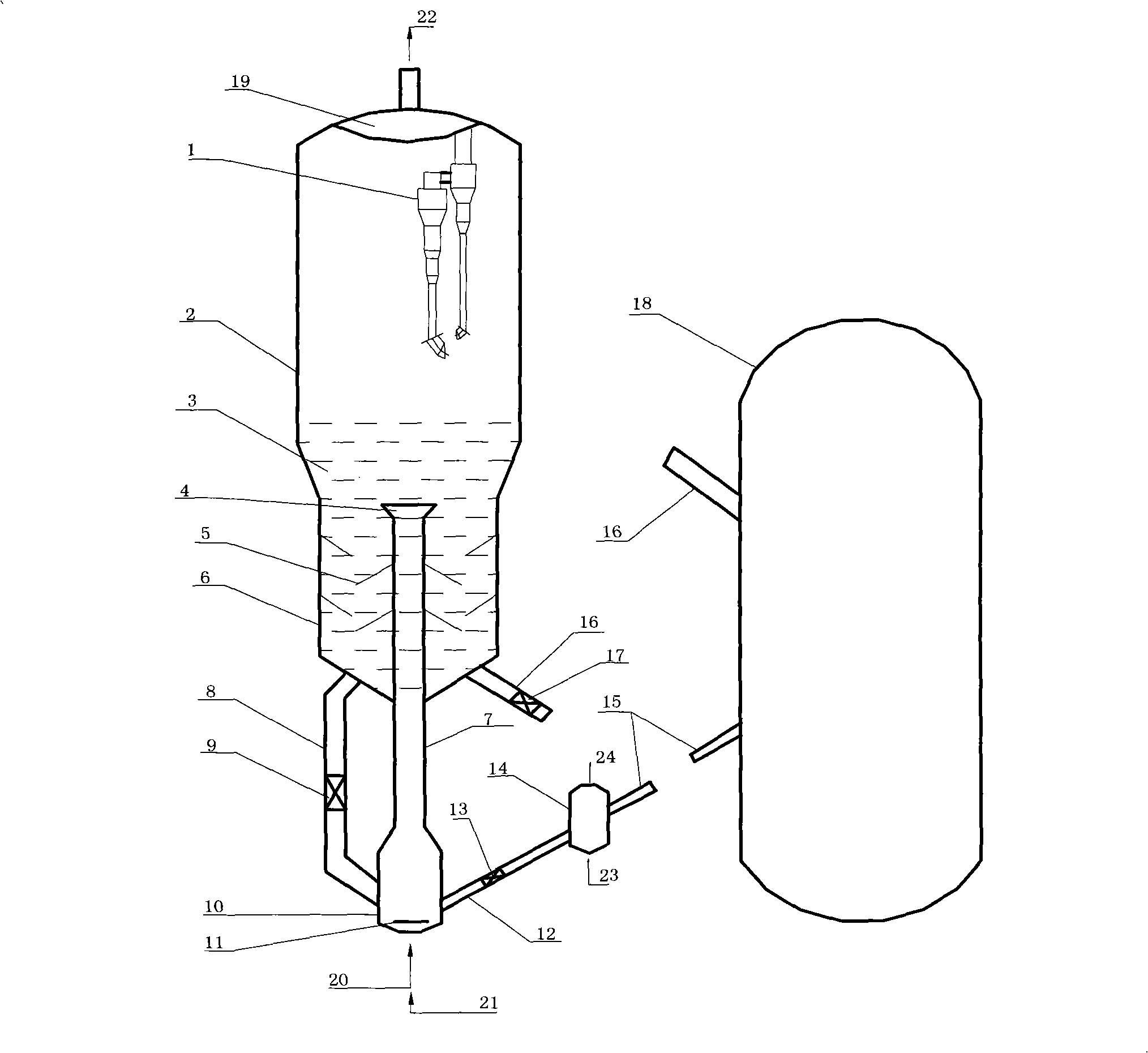

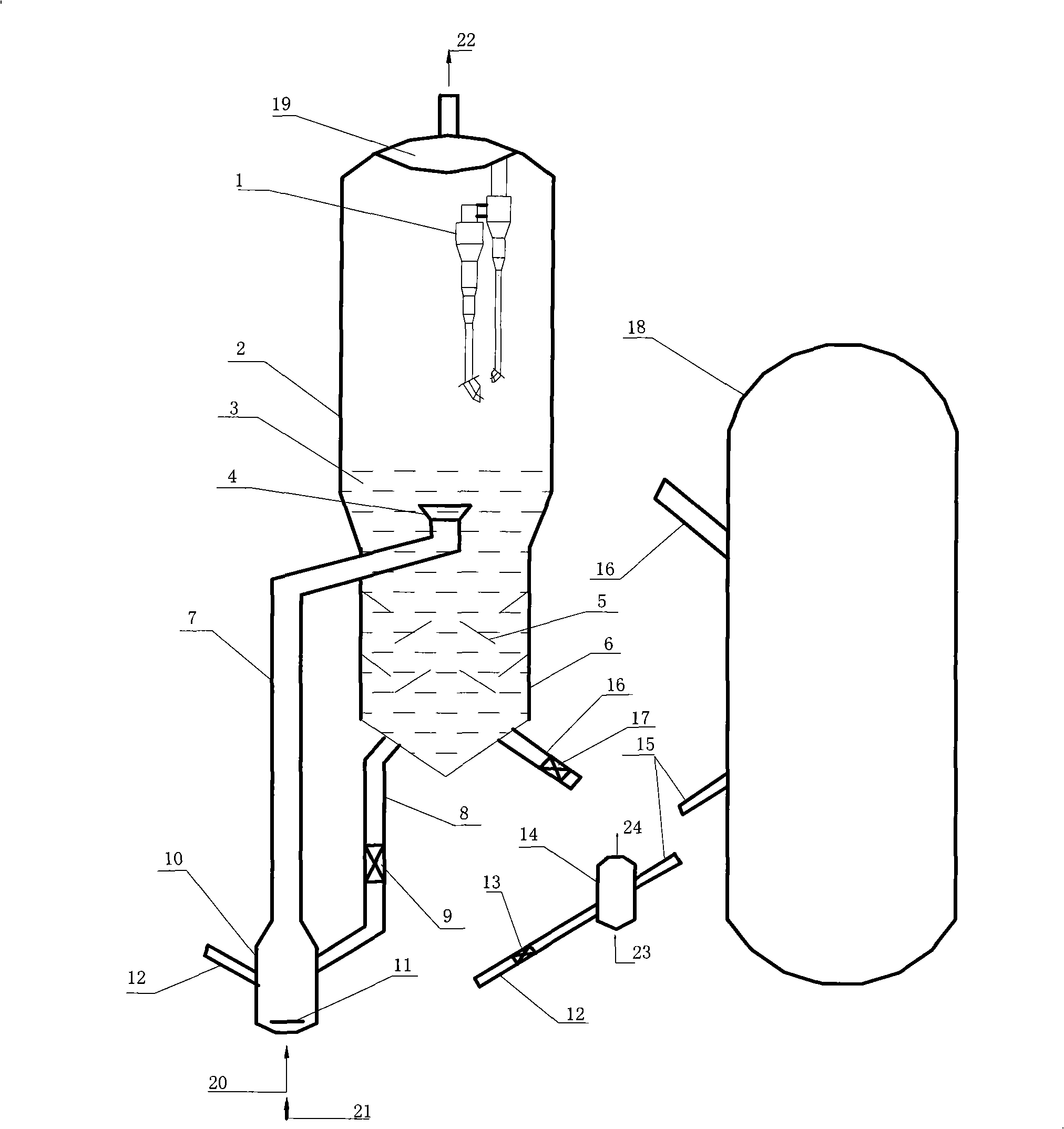

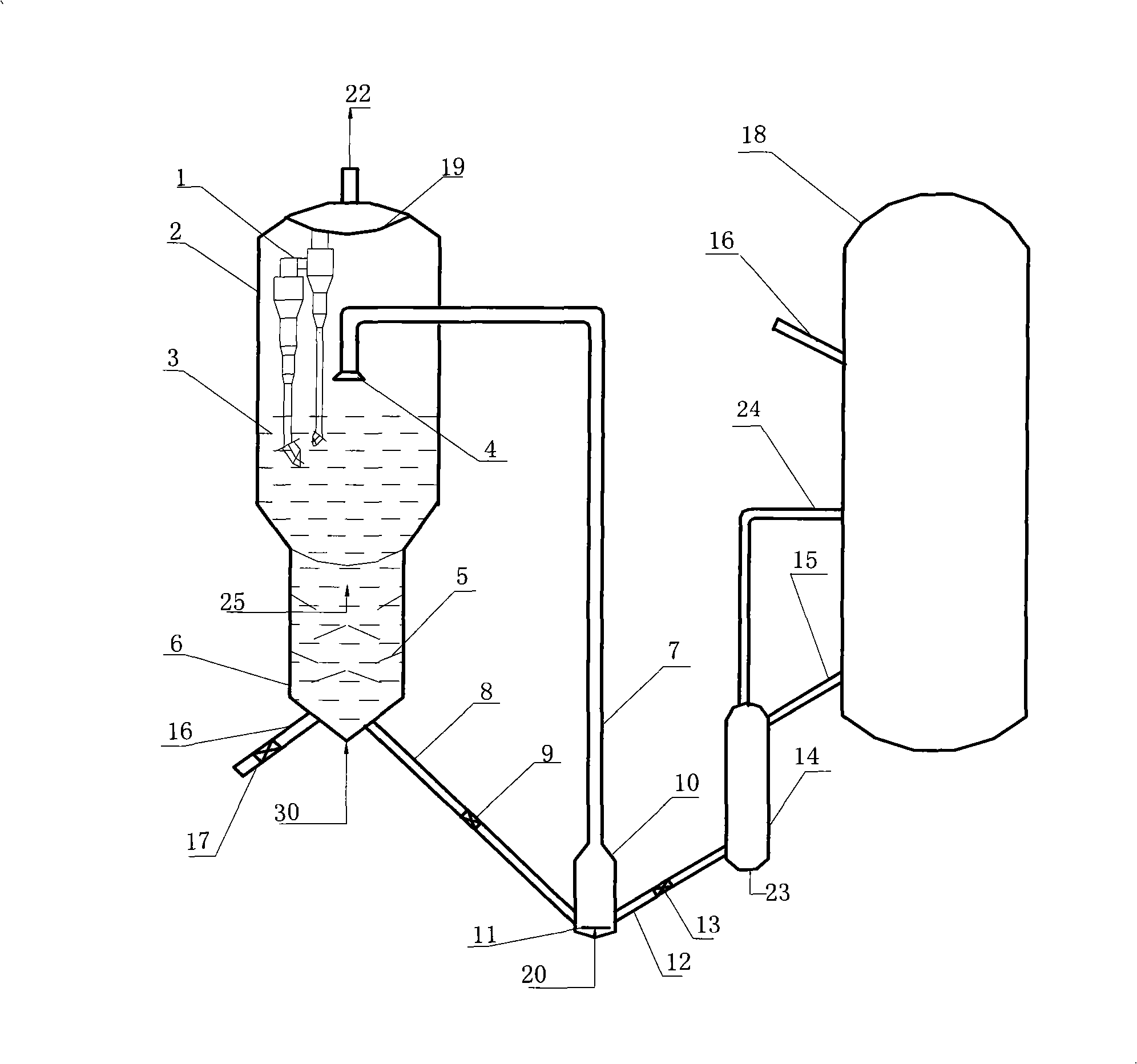

Fluidizer and fluidization method for preparing ethylene by ethanol dehydration

A technology of ethanol dehydration and fluidization device, which is applied in the field of devices for preparing hydrocarbons from non-hydrocarbon compounds, can solve the problems of lowering the purity of ethylene and increasing side reactions, and achieves the effects of improving the purity and ensuring thermal balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Relevant test among the embodiment 1 is carried out on the medium-sized device of the ethanol dehydration making ethylene (ETE) by computer real-time control, and the processing capacity of this device is 0.4t / d, and ethanol raw material is the water containing 5% (volume fraction) Ethanol, the weight hourly space velocity of ethanol is 1.0h -1 , fluidized bed reaction temperature 360 ° C, reaction pressure 0.2MPa (gauge pressure). The catalyst is MMC-2 catalyst (800°C, 100% steam aging for 17 hours) produced by Sinopec Qilu Catalyst Company. The preheating temperature of the ethanol feedstock is 360°C, the temperature of the recycled catalyst entering the catalyst mixing chamber is 300°C, and the temperature of the regenerated catalyst from the degassing tank of the regenerated catalyst is 700°C, and the regenerated catalyst and the recycled catalyst are mixed in the catalyst mixing chamber The temperature is 370°C. The weight ratio of the recycled spent catalyst f...

Embodiment 2

[0057] The device used in the experiment of embodiment 2, ethanol raw material and catalyst are all the same as embodiment 1.

[0058] The weight hourly space velocity of ethanol is 1.5h -1 , the fluidized bed reaction temperature is 370°C, and the reaction pressure is 0.17MPa (gauge pressure). The preheating temperature of the ethanol feedstock is 380°C, the temperature of the recycled catalyst entering the catalyst mixing chamber is 300°C, and the temperature of the regenerated catalyst from the degassing tank of the regenerated catalyst is 690°C, and the regenerated catalyst and the recycled catalyst are mixed in the catalyst mixing chamber The temperature is 390°C. The weight ratio of the recycled spent catalyst from the catalyst internal circulation pipe to the regenerated catalyst degassing tank is about 3.3:1.

[0059] The product distribution is shown in Table 1. From Table 1, it can be seen that the conversion rate of ethanol is 99.8%, and the purity of ethylene is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com