Process for preparing bamboo-based activated carbon and dedicated device therefor

A technology of activated carbon and bamboo, which is applied in the field of preparation of bamboo activated carbon, can solve the problems of difficulty in guaranteeing the uniformity and stability of product quality, no specific description of equipment, and large differences, etc. The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of bamboo activated carbon of the embodiment of the present invention may further comprise the steps:

[0051] a, crushing; the dried moso bamboo branches or branches are broken into fragments with a crusher, and the fragments with a particle size of 6 to 12mm are used for subsequent use;

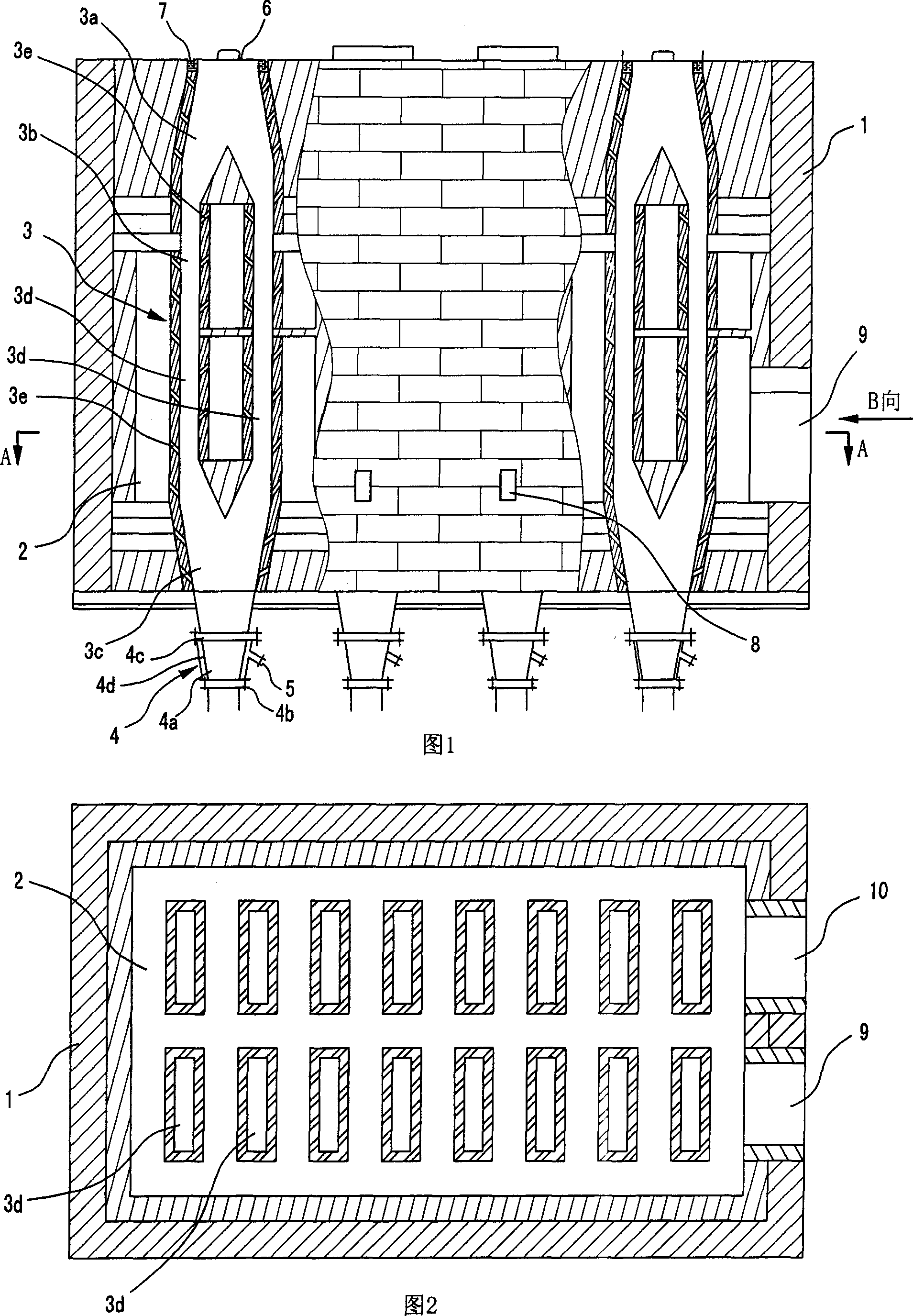

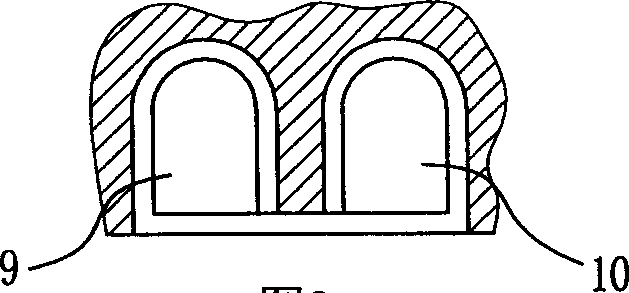

[0052] b. Carbonization: Add broken bamboo pieces into the carbonization tube from the feed port on the top of the carbonization furnace, and the broken bamboo pieces will move down from the top of the carbonization tube along the carbonization tube under the action of gravity. The amount of steam added controls the carbonization temperature, and the carbonization time is controlled by discharging the material from the discharge pipe, so that the broken bamboo pieces are carbonized in the carbonization furnace to obtain carbonized materials. The carbonization temperature is 550-750°C, and the carbonization time is 1-4 hours;

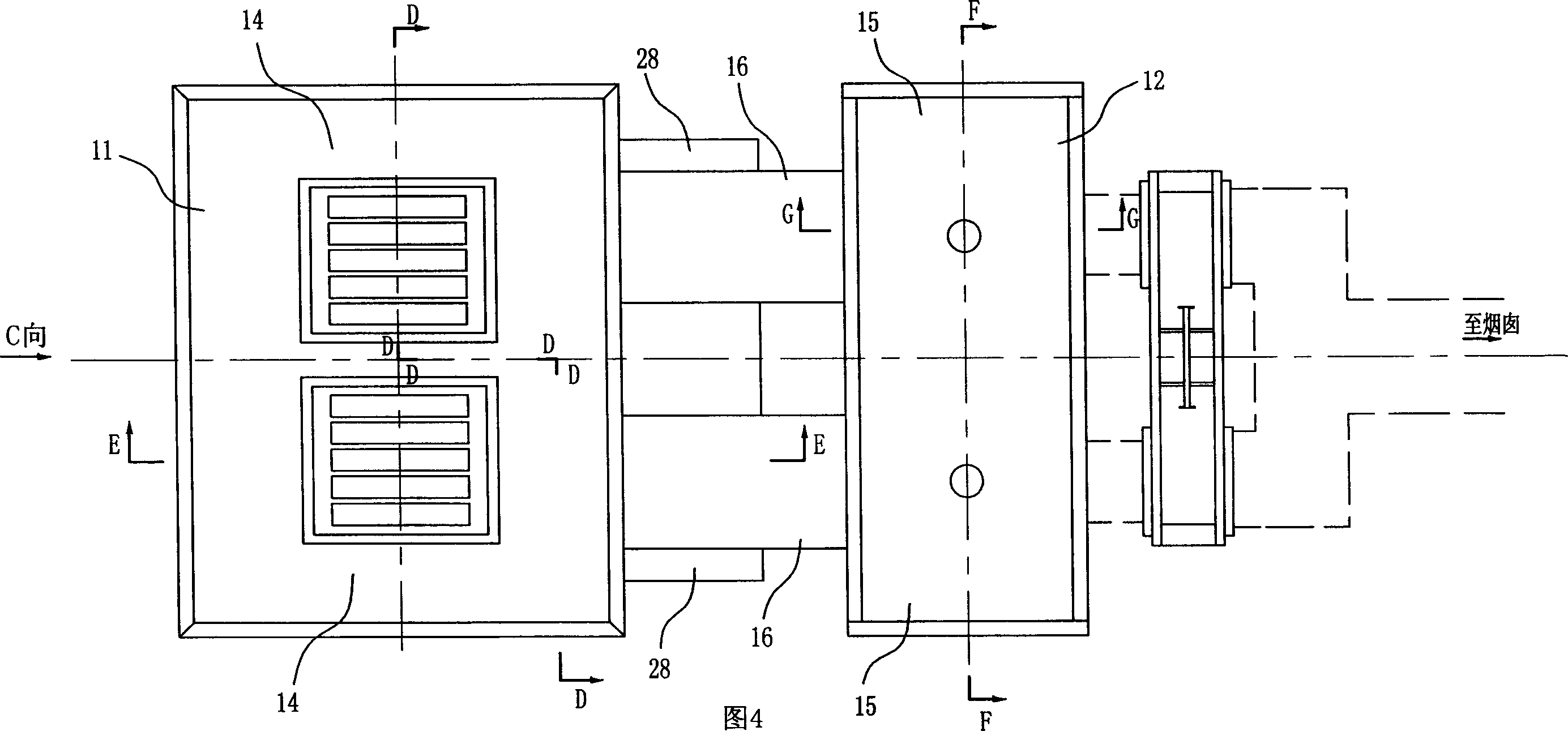

[0053] c. Activation: Add the carb...

preparation example 1

[0057] a, the dried moso bamboo is broken into 6mm fragments with a crusher, and screened for subsequent use; b, the above-mentioned crushed material is carbonized in a multi-tube carbonization furnace, the carbonization temperature is 550 ° C, and the carbonization time is 4 hours; c, the above-mentioned The carbonization material is activated in the activation furnace, the activation temperature is 850°C, and the activation time is 72 hours. d. Soak the above-mentioned activation material in the pickling tank with a concentration of 3-5wt% hydrochloric acid solution for 1-3 hours, fully stir, and then Rinse with tap water for 3 to 5 times, then dehydrate, dry, screen and pack to obtain the finished activated carbon.

preparation example 2

[0059] a, the moso bamboo after drying is broken into 12mm fragments with a crusher, and screened for subsequent use; b, the above-mentioned crushed material is carbonized in a multi-tube carbonization furnace, the carbonization temperature is 750 ° C, and the carbonization time is 1 hour; c, the above-mentioned The carbonized material is activated in the activation furnace, the activation temperature is 950°C, and the activation time is 48 hours. d. The above-mentioned activation material is soaked in a pickling tank with a concentration of 3-5% hydrochloric acid solution for 1-3 hours, fully stirred, Then rinse with tap water for 3 to 5 times, then dehydrate, dry, screen and pack to obtain the finished activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com