Power battery thermal management system and control method thereof

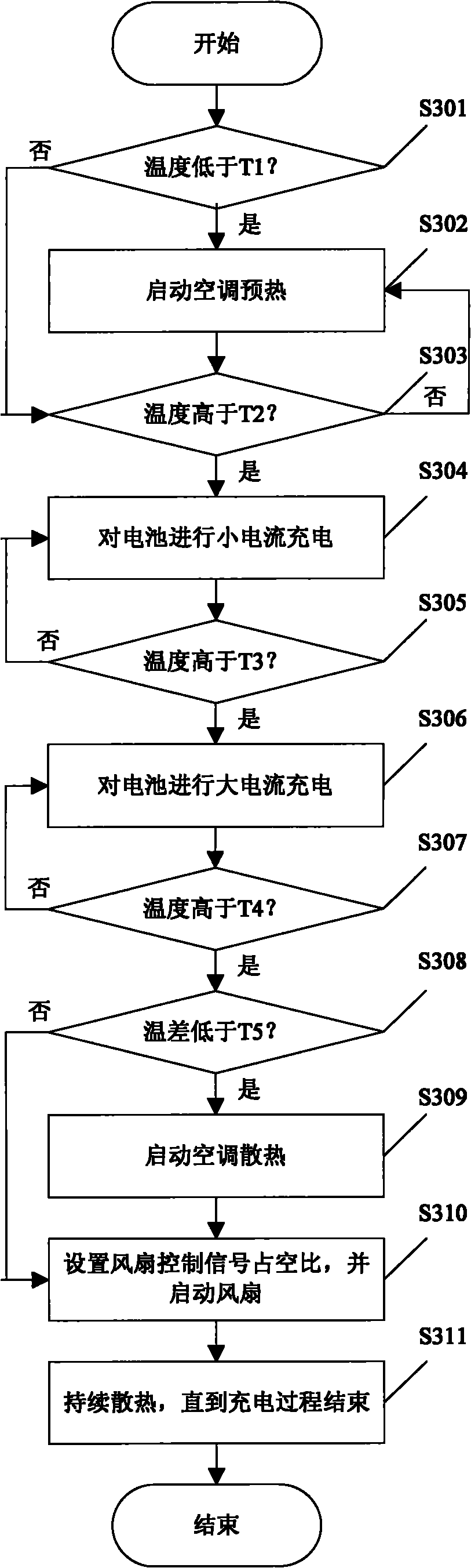

A thermal management system and power battery technology, applied in battery temperature control, secondary batteries, power devices, etc., can solve the problem of lack of battery preheating or heat dissipation, to ensure thermal balance, prevent overcharging and overdischarging and the effects of overcharge and overdischarge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be described with reference to the drawings and examples.

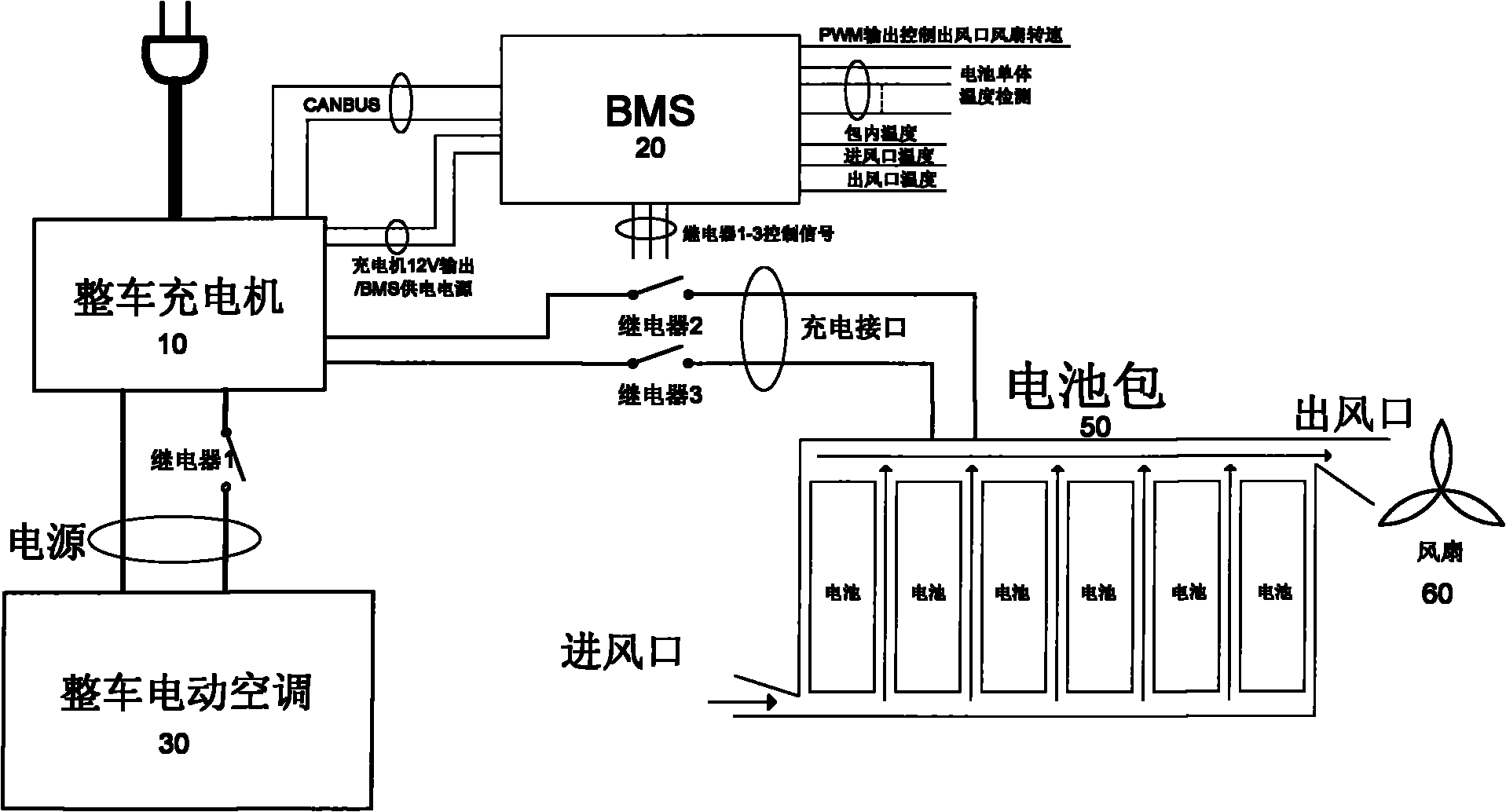

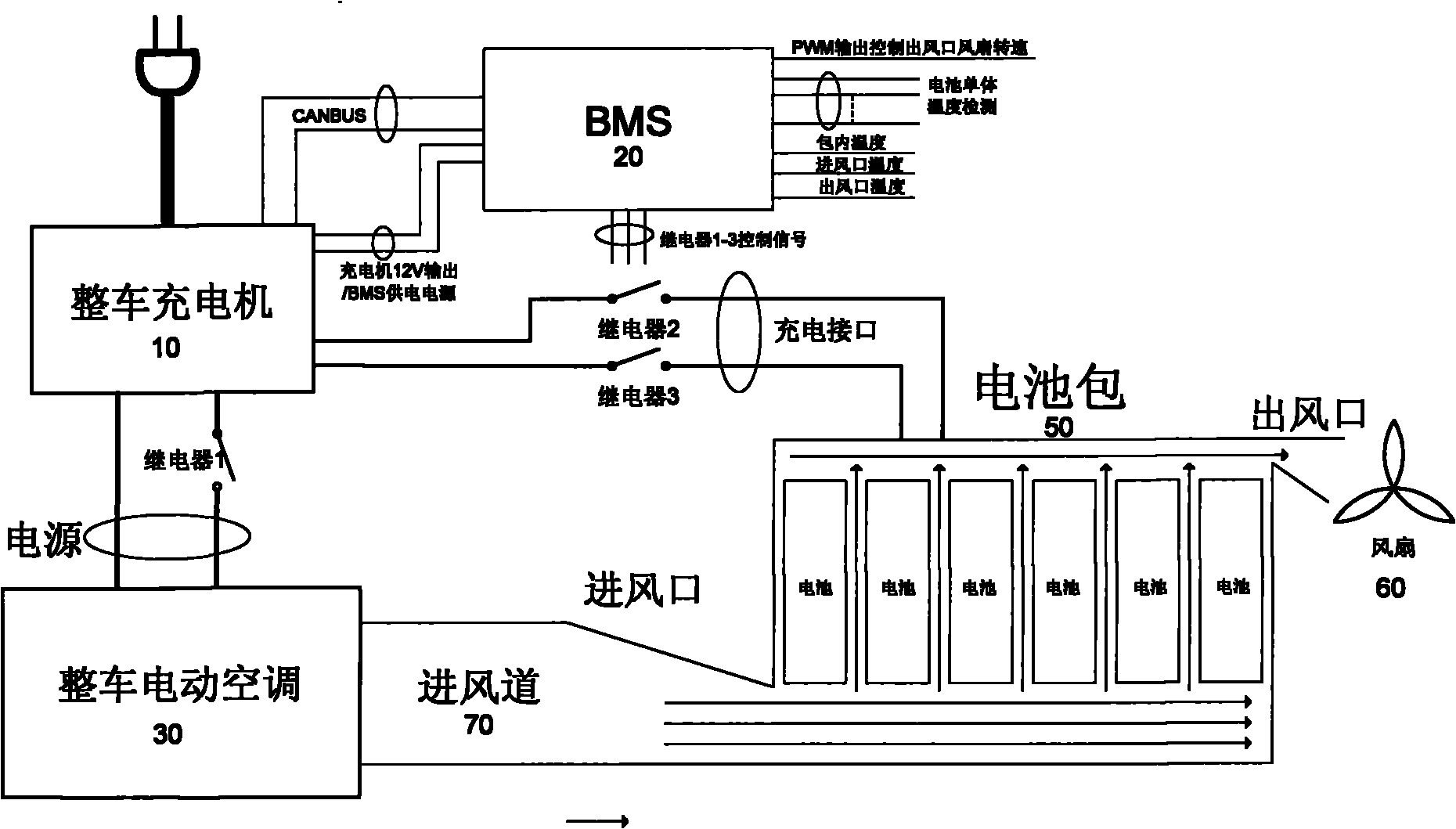

[0022] figure 1 It is a structural schematic diagram of an existing electric vehicle system. Such as figure 1 As shown, the existing electric vehicle system includes a vehicle charger 10 , a battery management system (BMS) 20 , a vehicle electric air conditioner 30 , relays 1 - 3 , a battery pack 50 and a fan 60 . Wherein, the vehicle charger 10 is connected to household 220V alternating current, and is used for charging the BMS 20 , the vehicle electric air conditioner 30 and the battery pack in the battery pack 50 . The relay 1 is a power switch of the vehicle electric air conditioner 30 and is used to control the power supply of the vehicle charger 10 to the vehicle electric air conditioner 30 . The relays 2 and 3 are power switches of the battery pack 50 and are used to control the power supply of the battery pack 50 by the vehicle charger 10 . The BMS 20 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com