Novel cylindrical battery stacking packing structure

A group structure, cylindrical technology, applied in the direction of battery pack components, secondary batteries, structural parts, etc., can solve the problems of large volume occupied by batteries, low energy density of batteries, and many hours of execution, so as to achieve easy installation, The effect of compact structure and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

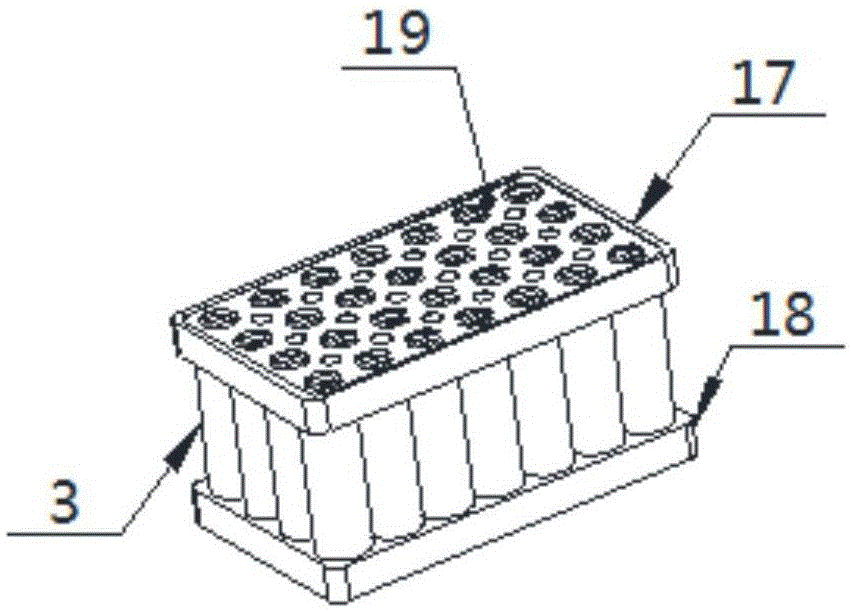

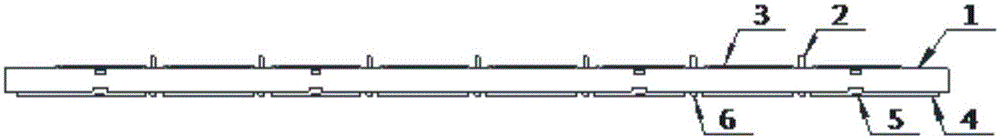

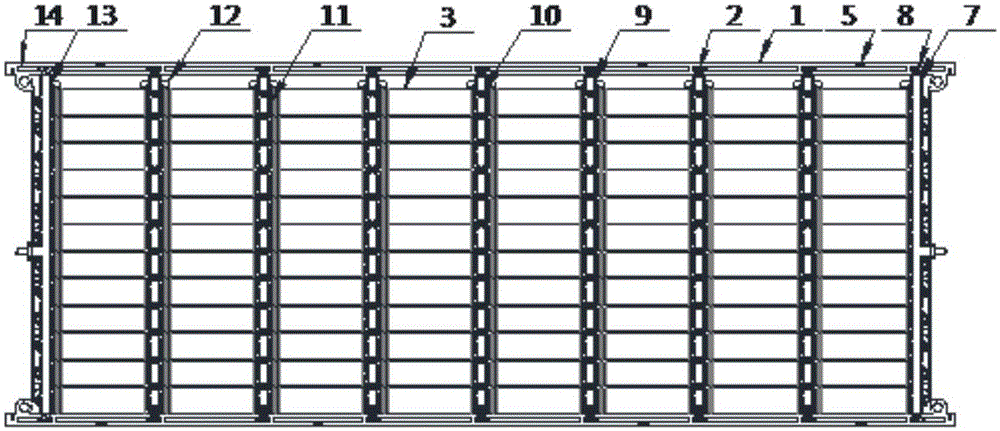

[0020] Such as figure 1 As shown, the new cylindrical battery stacking group structure includes a grouped single frame, and several battery support structures are neatly arranged on the grouped single frame, and the upper end surface of the grouped single frame is provided with upper and lower layers Parallel columns, the lower end surfaces of the frame of the grouped single frame are provided with upper and lower layer locking structures and accumulating strips, and the upper and lower end faces of the outermost frame of the grouped single frame are respectively provided with upper and lower alignment structures 1 and 2; The left and right sides of the grouped monomer frame are respectively equipped with positive and negative electrode series copper bars, and the positive and negative electrode series copper bars are respectively fixed on the grouped monomer frame by compression screws; the two ends of each battery support structure are respectively installed with conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com