Method for preparing gas, liquid and carbon products by biomass pyrolysis

A technology of biomass pyrolysis and biomass charcoal, applied in the direction of biofuel, indirect heating carbonization, special form of carbonization, etc., to achieve the effect of improving selectivity, improving availability, increasing yield and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

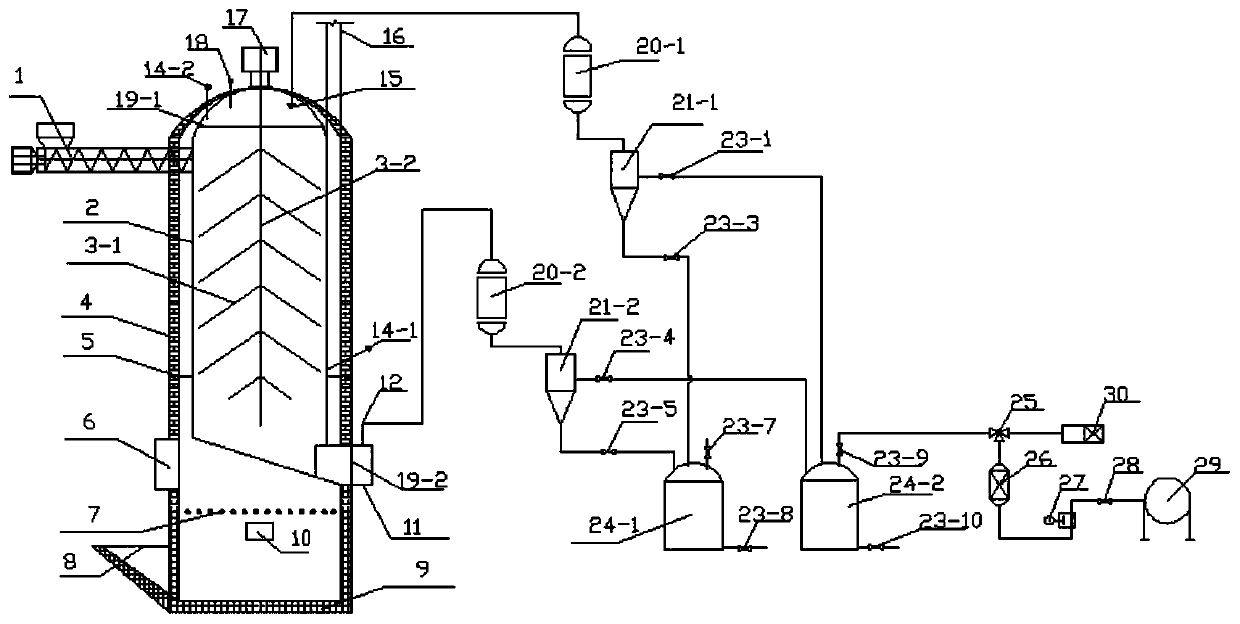

Image

Examples

Embodiment 1

[0038] A method for preparing gas, liquid, and charcoal products by pyrolysis of biomass, characterized in that: after mixing biomass raw materials with water, under normal pressure, insulated from air, and programmed temperature cracking to obtain gas, acetic acid, furfural, and biomass charcoal , including the following steps:

[0039] (1) Impurity removal and crushing: remove impurities such as soil and stones mixed into the raw materials of chestnut bracts, and crush them into 2-60 mesh particles;

[0040] (2) Stirring and mixing: add a certain amount of water to the pulverized raw materials, and stir evenly to make the moisture content of the raw materials reach 25%;

[0041] (3) Loading and deoxygenation: put the above-mentioned water-containing biomass raw materials into the cracking furnace, and pass inert gas or vacuum to remove the air in the cracking device before cracking;

[0042] (4) Heating cracking: use external heating, gradually increase the temperature for ...

Embodiment 2

[0047] A method for preparing gas, liquid, and charcoal products by pyrolysis of biomass, characterized in that: after mixing chestnut bract raw materials with water, under normal pressure, air is isolated, and the temperature is programmed to be cracked to obtain gas, acetic acid, furfural, and biomass charcoal , including the following steps:

[0048] (1) Impurity removal and crushing: remove impurities such as soil and stones mixed into the raw materials of chestnut bracts, and crush them into 2-60 mesh particles;

[0049] (2) Stirring and mixing: add a certain amount of water to the crushed raw materials, and stir evenly to make the moisture content of the raw materials reach 33%;

[0050] (3) Loading and deoxygenation: put the above-mentioned water-containing biomass raw materials into the cracking furnace, and pass inert gas or vacuum to remove the air in the cracking device before cracking;

[0051] (4) Heating cracking: use external heating, gradually increase the tem...

Embodiment 3

[0056] A method for preparing gas, liquid, and charcoal products by pyrolysis of biomass, characterized in that: after mixing camellia oleifera shell raw material with water, under normal pressure, air is isolated, and the temperature is programmed to be cracked to obtain gas, acetic acid, furfural, and biomass charcoal , including the following steps:

[0057] (1) Impurity removal and crushing: remove impurities such as soil and stones mixed into the camellia oleifera shell raw material, and crush it into 2-60 mesh particles;

[0058] (2) Stirring and mixing: add phosphoric acid aqueous solution with a concentration of 0.5 times the mass of dry raw materials and 10% concentration, add it to the crushed raw materials, and stir evenly;

[0059] (3) Loading and deoxygenation: put the above-mentioned water-containing biomass raw materials into the cracking furnace, and pass inert gas or vacuum to remove the air in the cracking device before cracking;

[0060] (4) Heating and pyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com