Patents

Literature

52results about How to "Heat control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Evaporated fuel gas adsorbent, evaporated fuel gas trapping apparatus, active carbon and process producing the same

InactiveUS20090038477A1Heat controlMore compactGas treatmentNon-fuel substance addition to fuelActivated carbonLatent heat storage

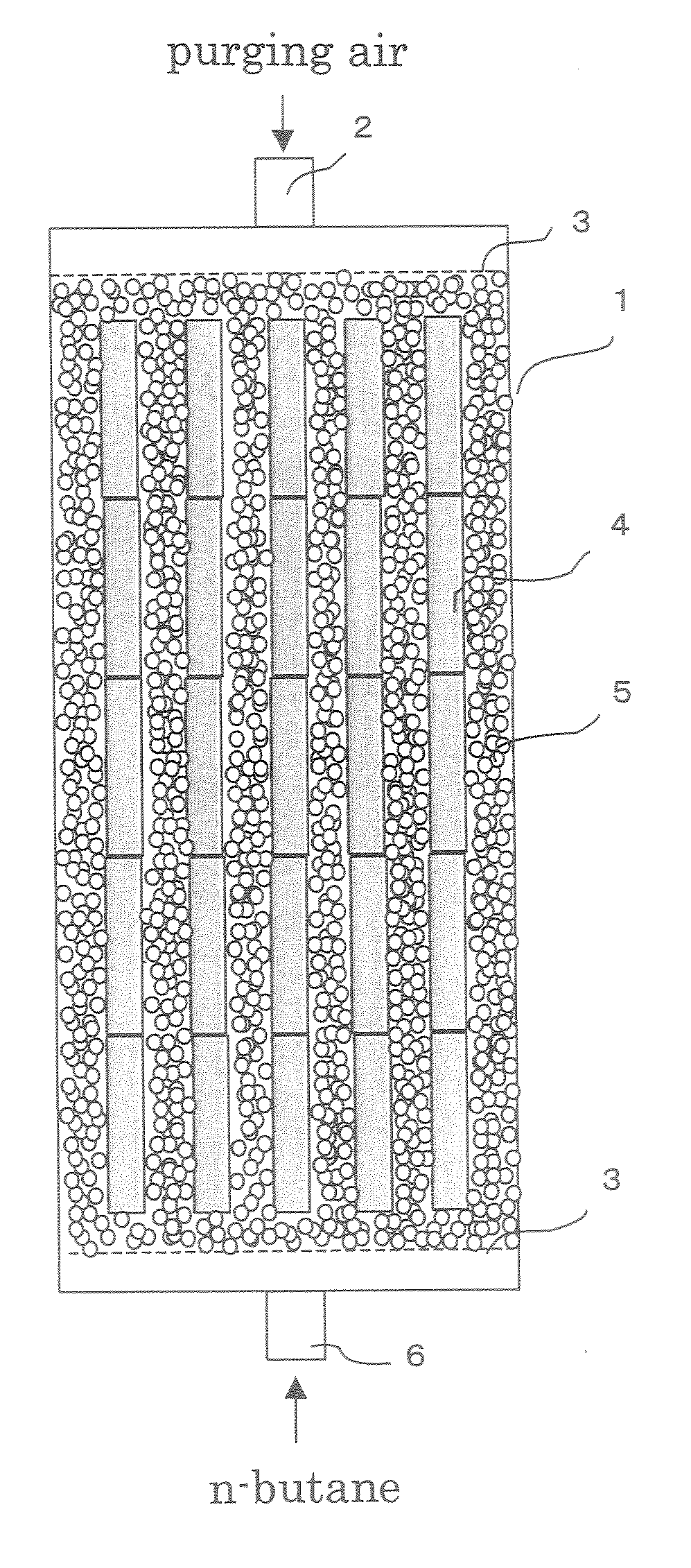

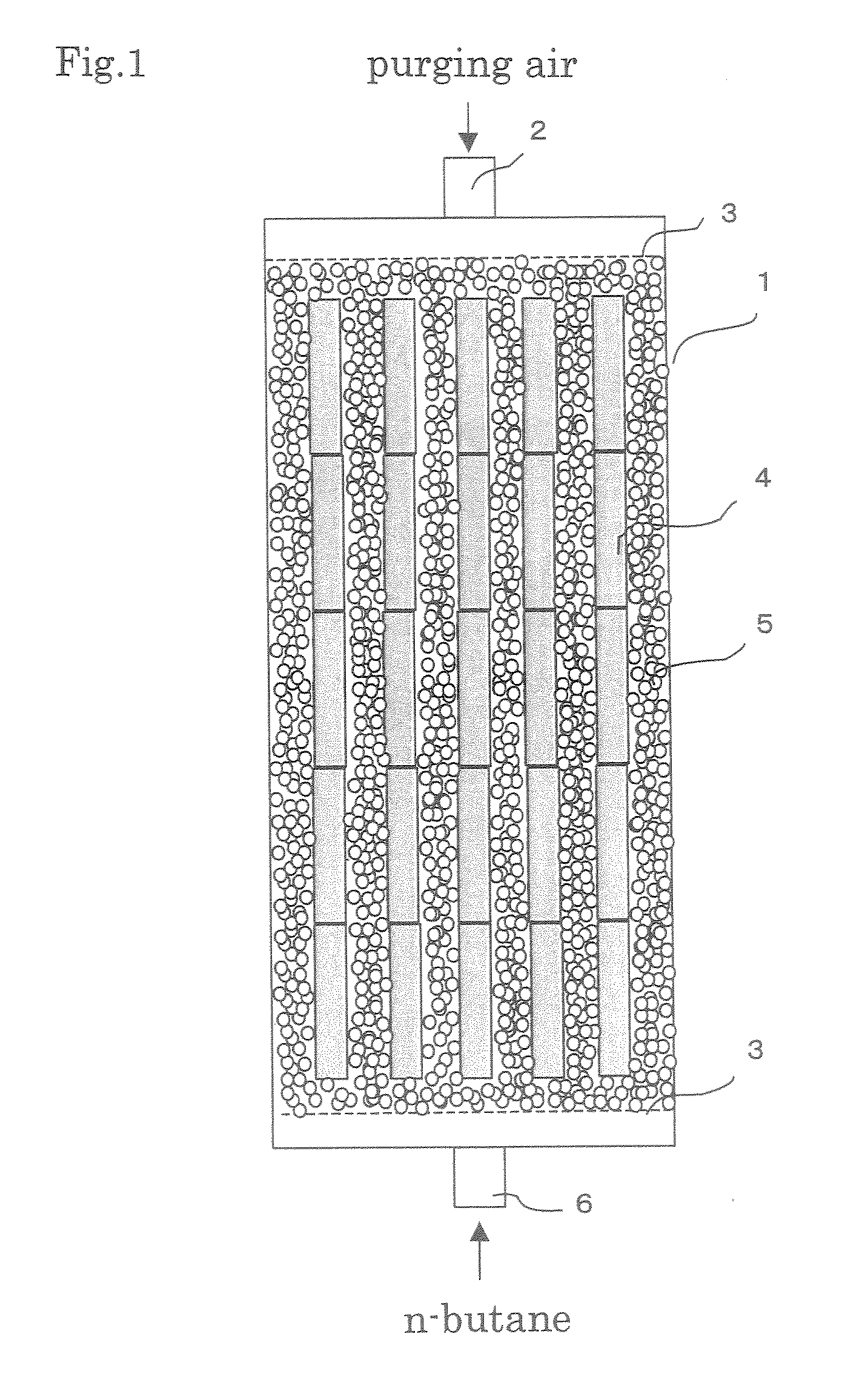

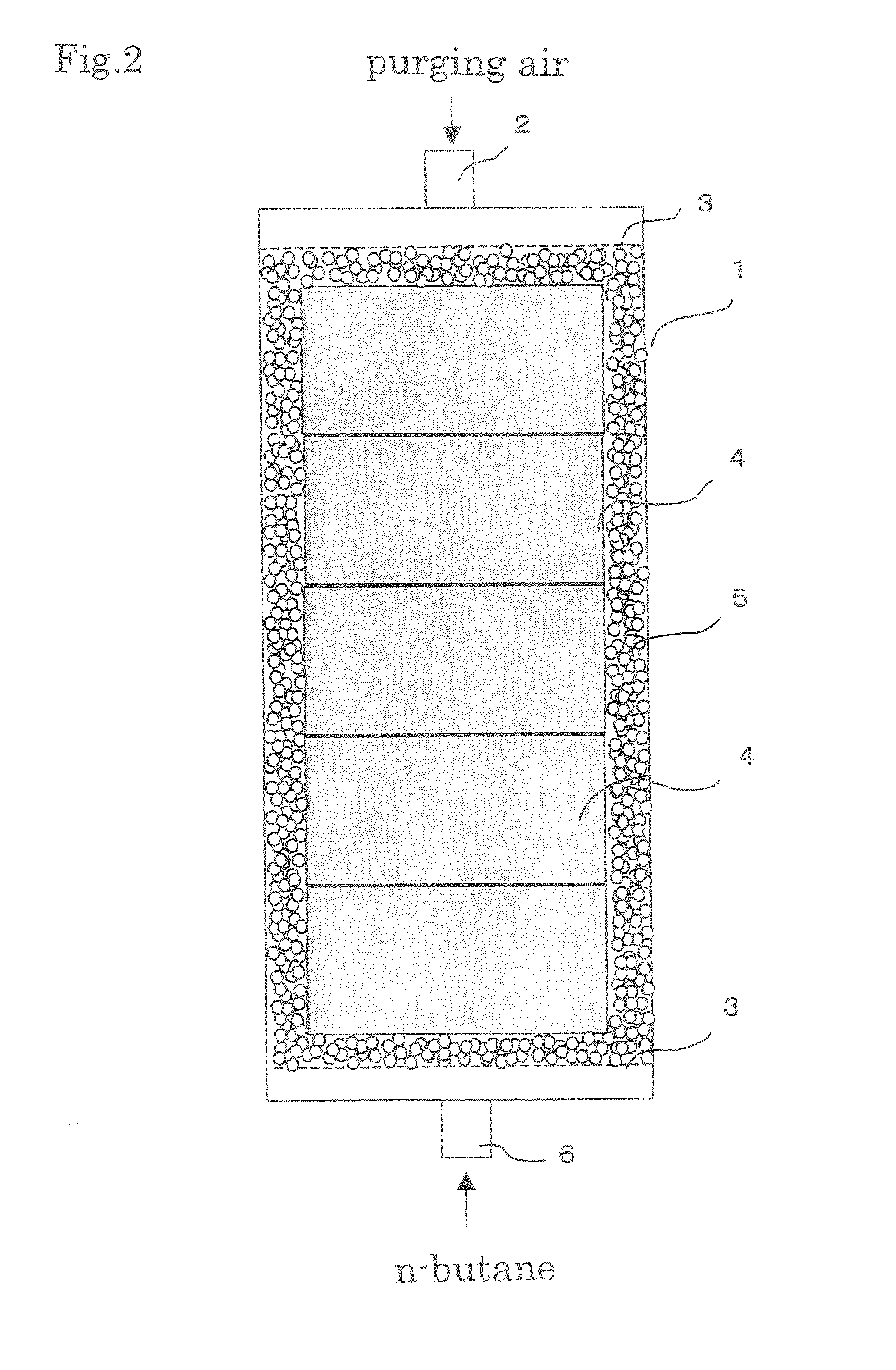

The present invention provides an evaporated fuel gas adsorbent, an evaporated fuel gas trapping apparatus that uses the adsorbent, an activated carbon, and a process for producing the activated carbon. The evaporated fuel gas adsorbent is capable of improving adsorptivity and desorptivity by reliably preventing a temperature rise and a temperature fall caused by heat generated in response to the adsorption and desorption of evaporated fuel gas, is capable of achieving a size reduction of the device, and is capable of being easily produced. The activated carbon has high mechanical strength and high abrasive resistance, has many pores suitable to adsorb an organic solvent, especially, evaporated fuel gas, and has a high packing density. The activated-carbon producing process is industrially advantageous. The evaporated fuel gas adsorbent comprises an adsorptive material and latent heat storage mediums including containers each of which is made of a flexible film and in each of which a substance that absorbs or releases heat in response to a phase change is encased. The activated carbon is characterized in that a specific surface area calculated by a BET method (multipoint method) in a nitrogen adsorption isotherm determined from a nitrogen adsorption amount at liquid nitrogen temperature is 1000 to 2500 m2 / g, in that a half-value width of a D-band peak in the neighborhood of 1360 cm−1 in Raman spectroscopic analysis is 120 cm−1 or less, and in that a half-value width of a G-band peak in the neighborhood of 1580 cm−1 in Raman spectroscopic analysis is 100 cm−1 or less.

Owner:KURARAY CO LTD

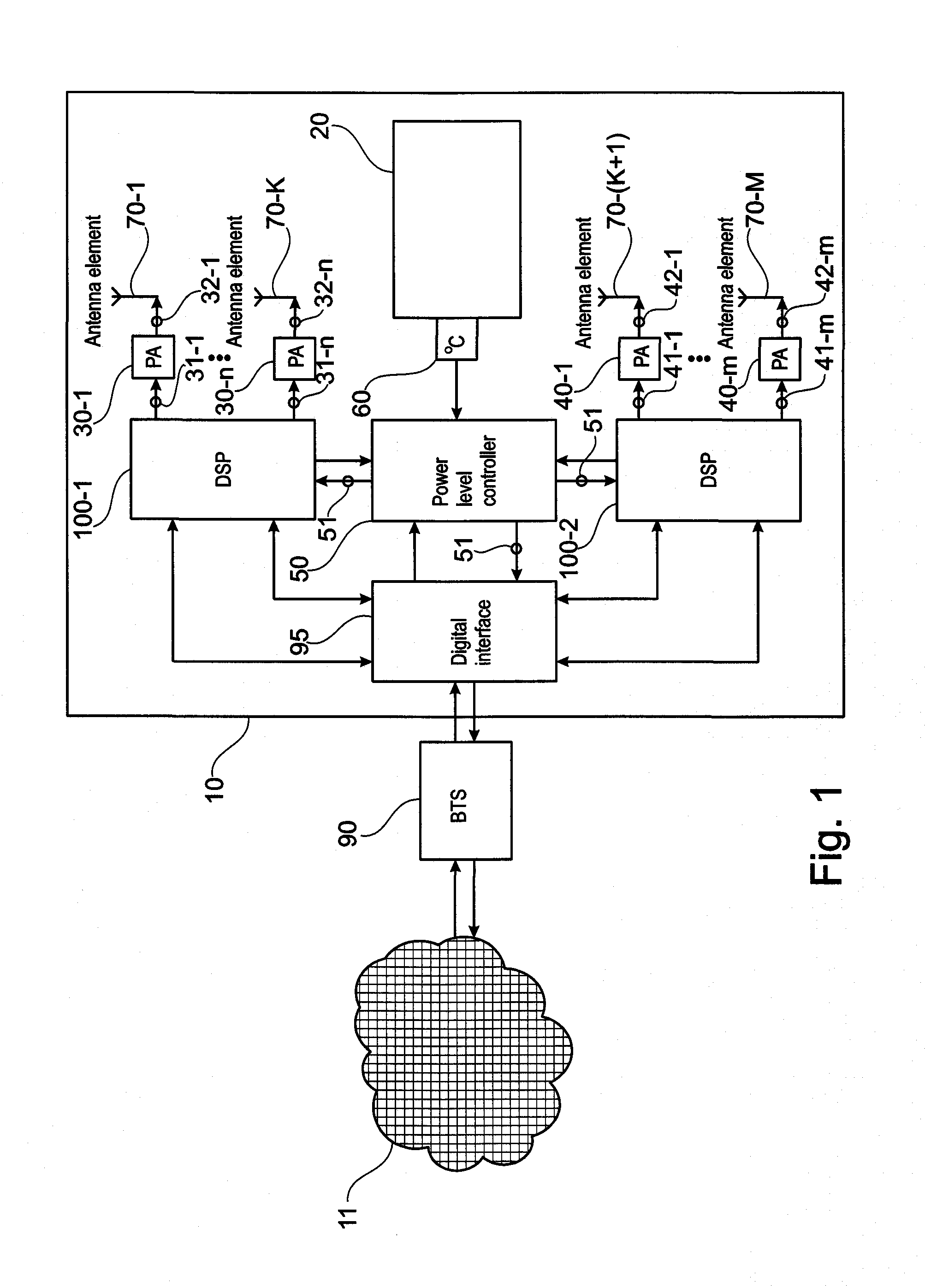

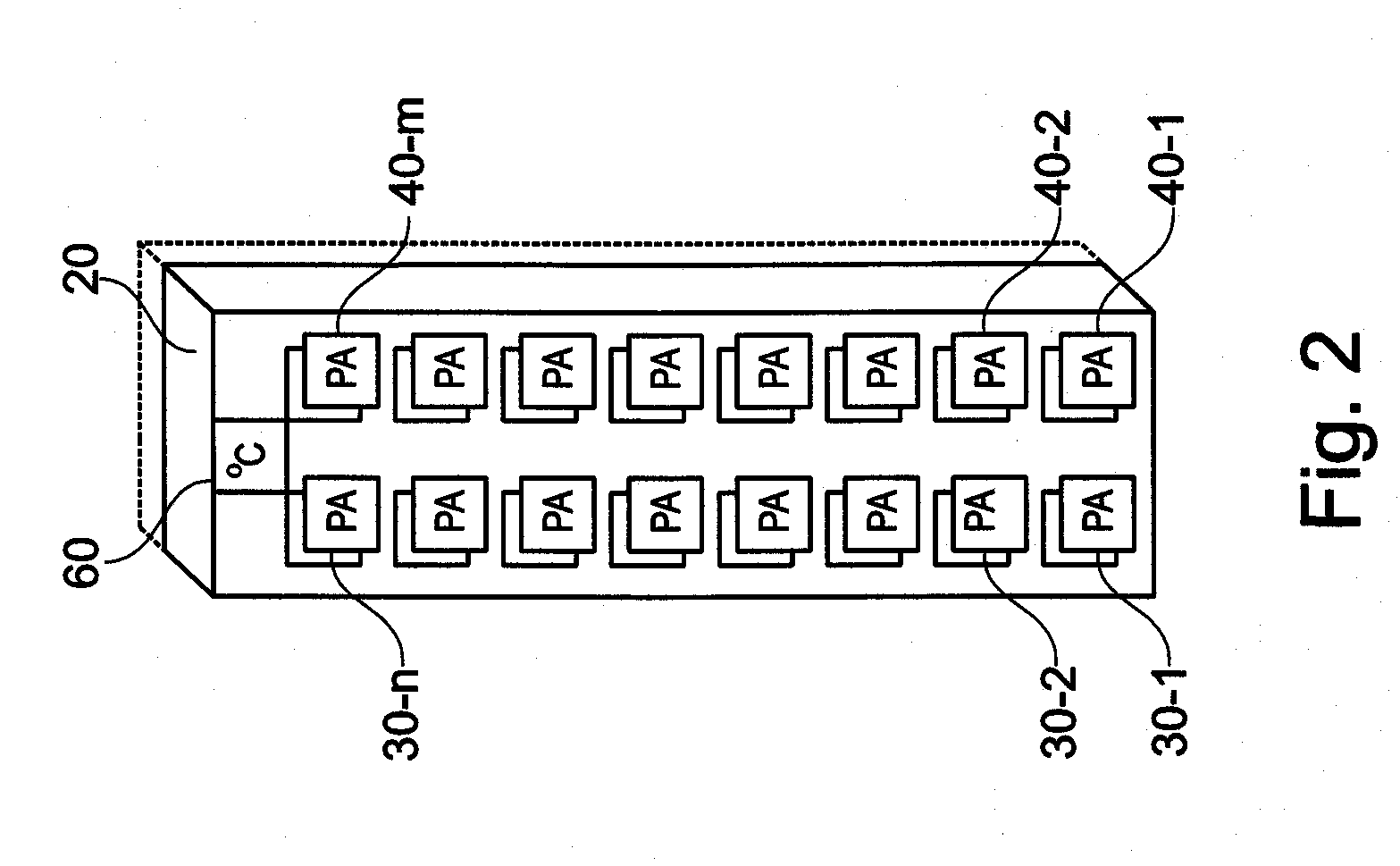

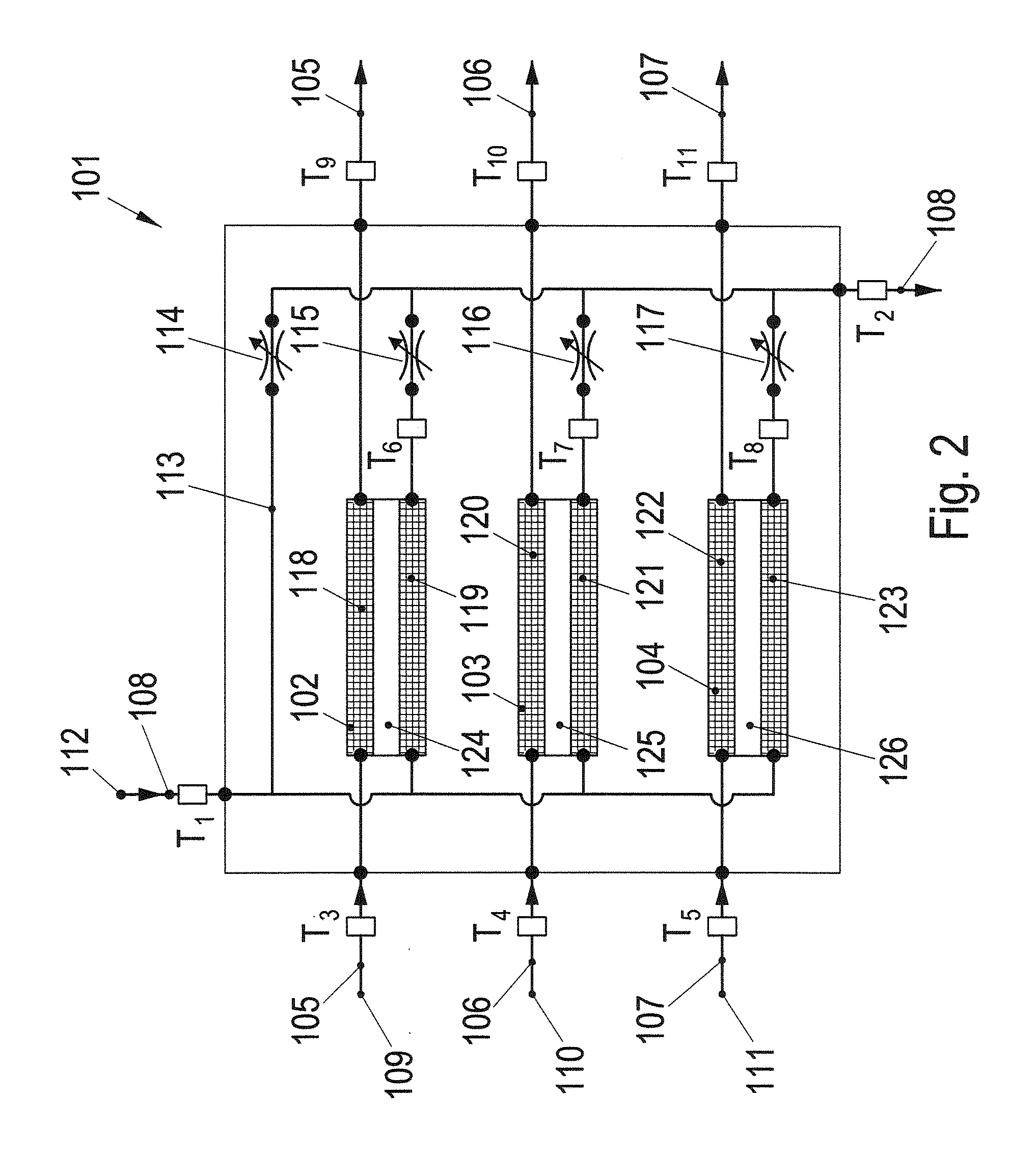

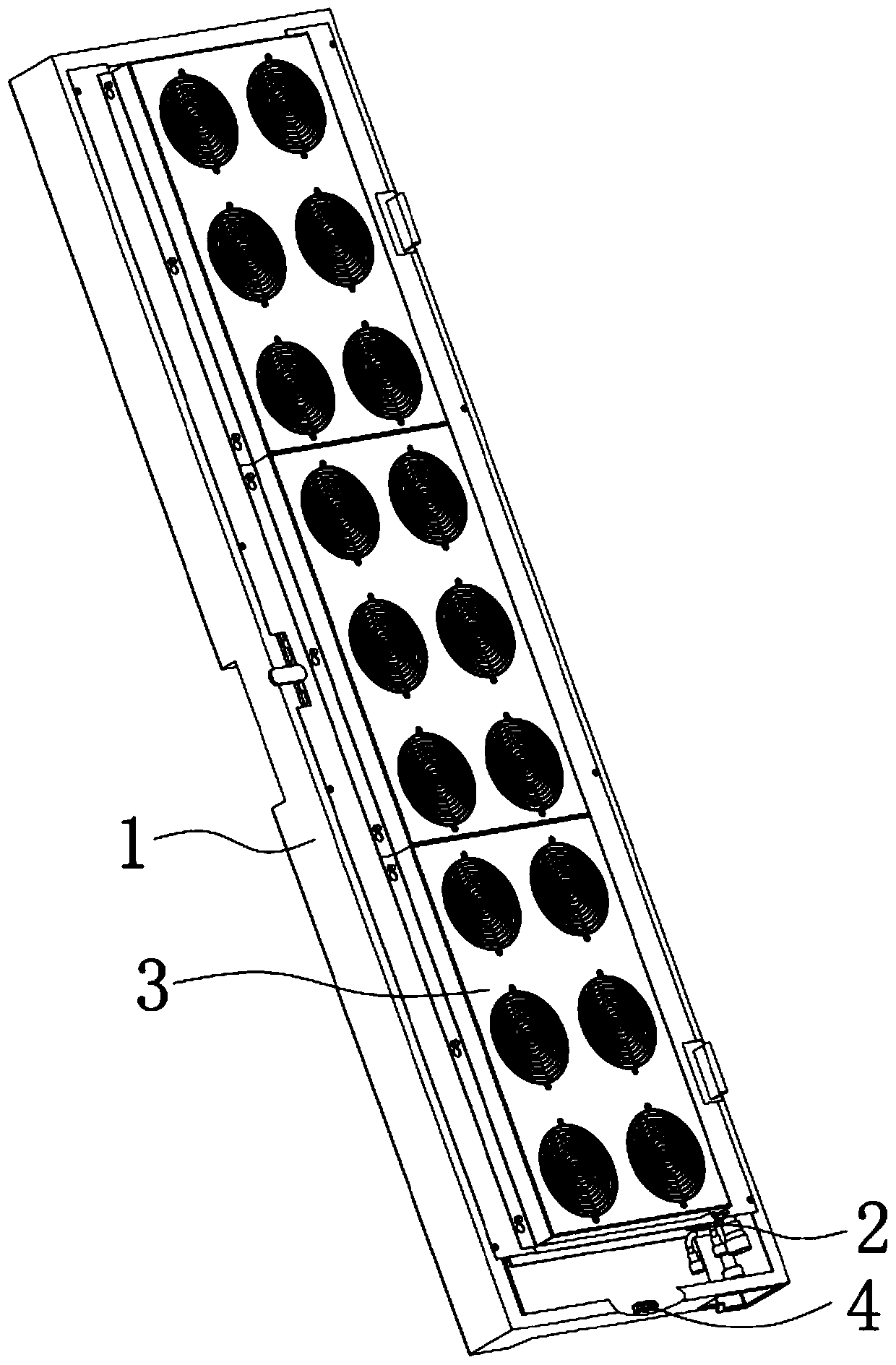

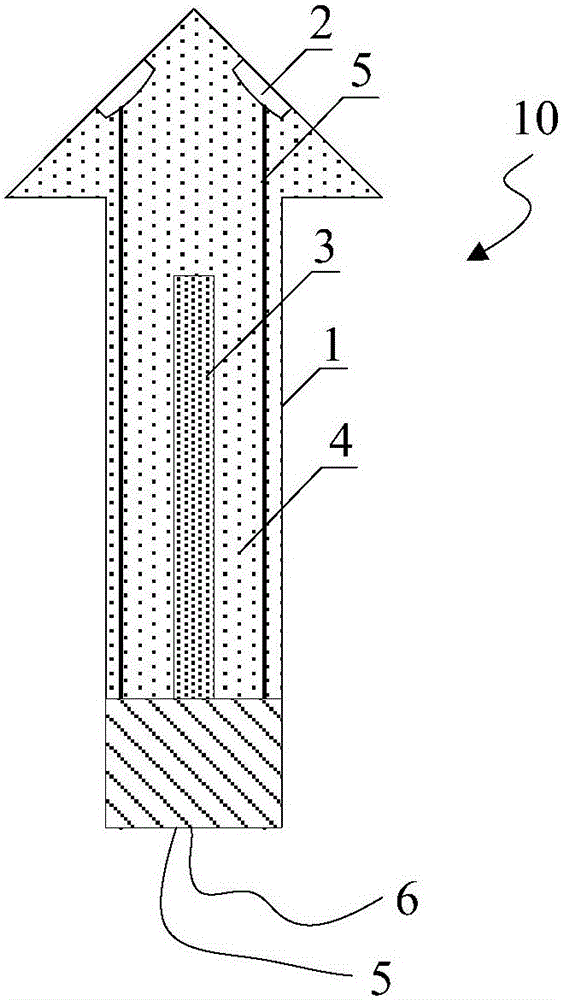

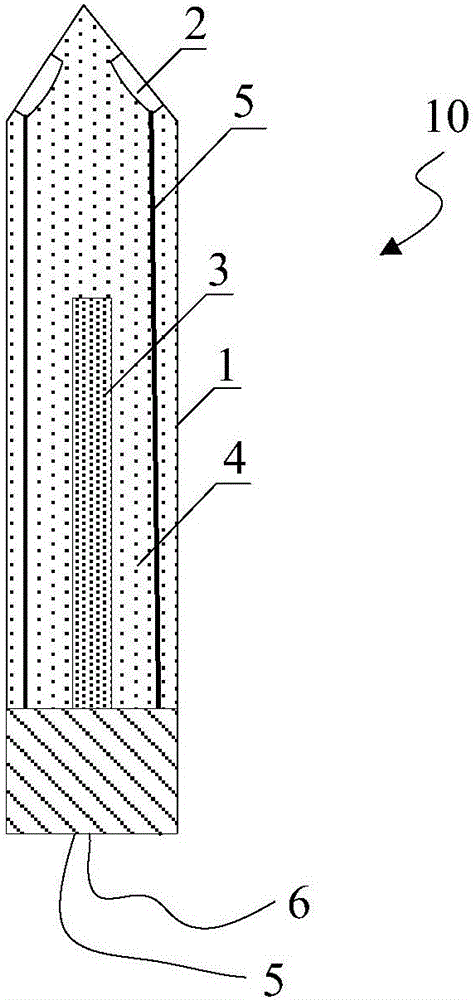

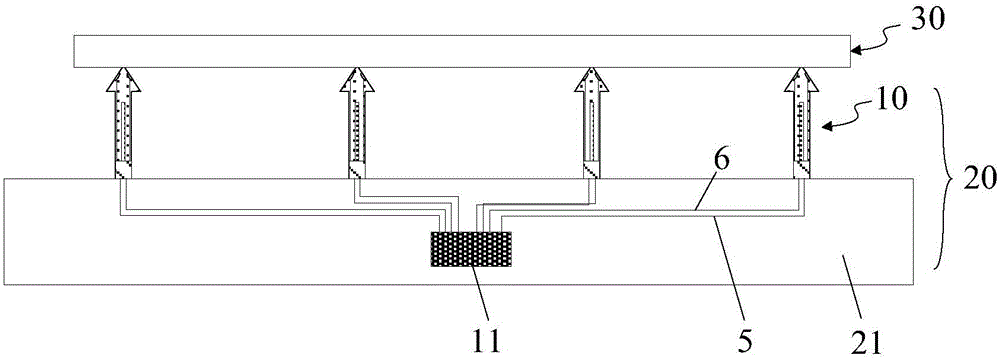

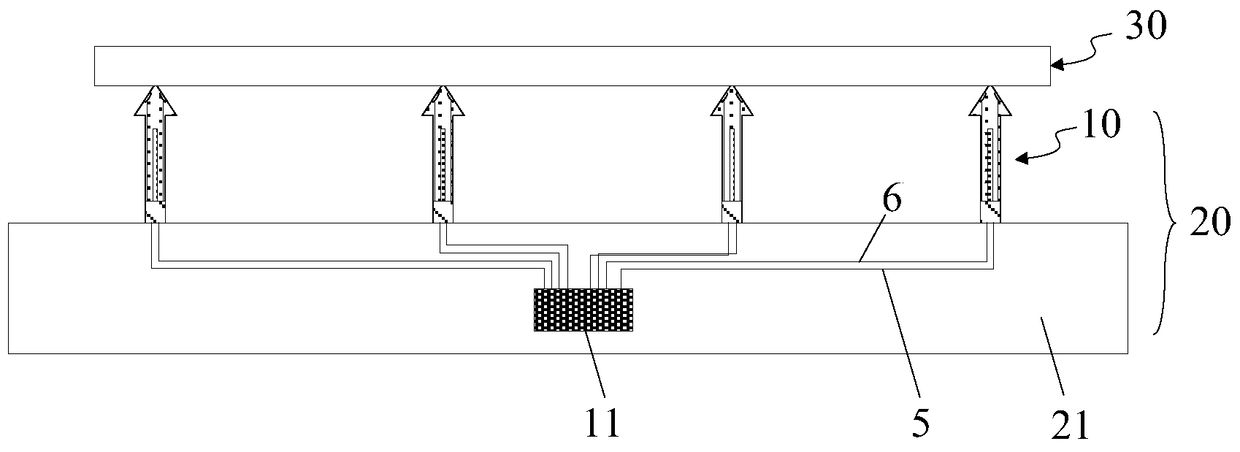

Active antenna array and method for transmitting radio signal

ActiveUS20130260702A1Heat controlResonant long antennasTransmission monitoringActive antennaRelative power

An active antenna array (10) for transmitting radio signals is disclosed. The active antenna array comprises a heat dissipating body (20), at least one first power amplifier (30) in thermal contact with the heat dissipating body (20), at least one second power amplifier (40) in thermal contact with the heat dissipating body (20) and an power level controller (50) for adjusting relative power levels of a first output signal (32) emanating from the at least one first power amplifier (30) and a second output signal (42) emanating from the at least one second power amplifier (40). A method for the transmission of radio signal is also disclosed.

Owner:TELEFON AB LM ERICSSON (PUBL)

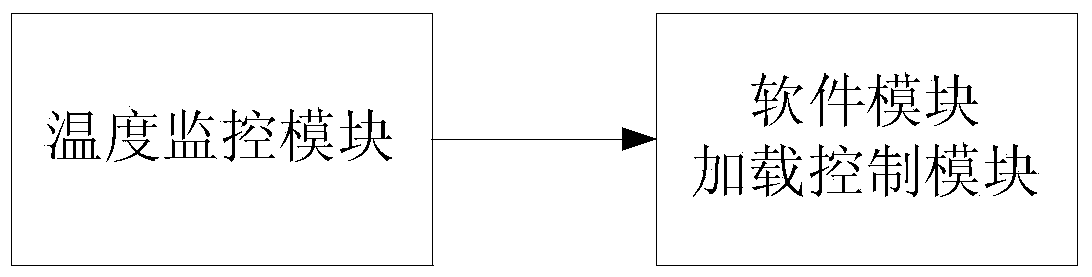

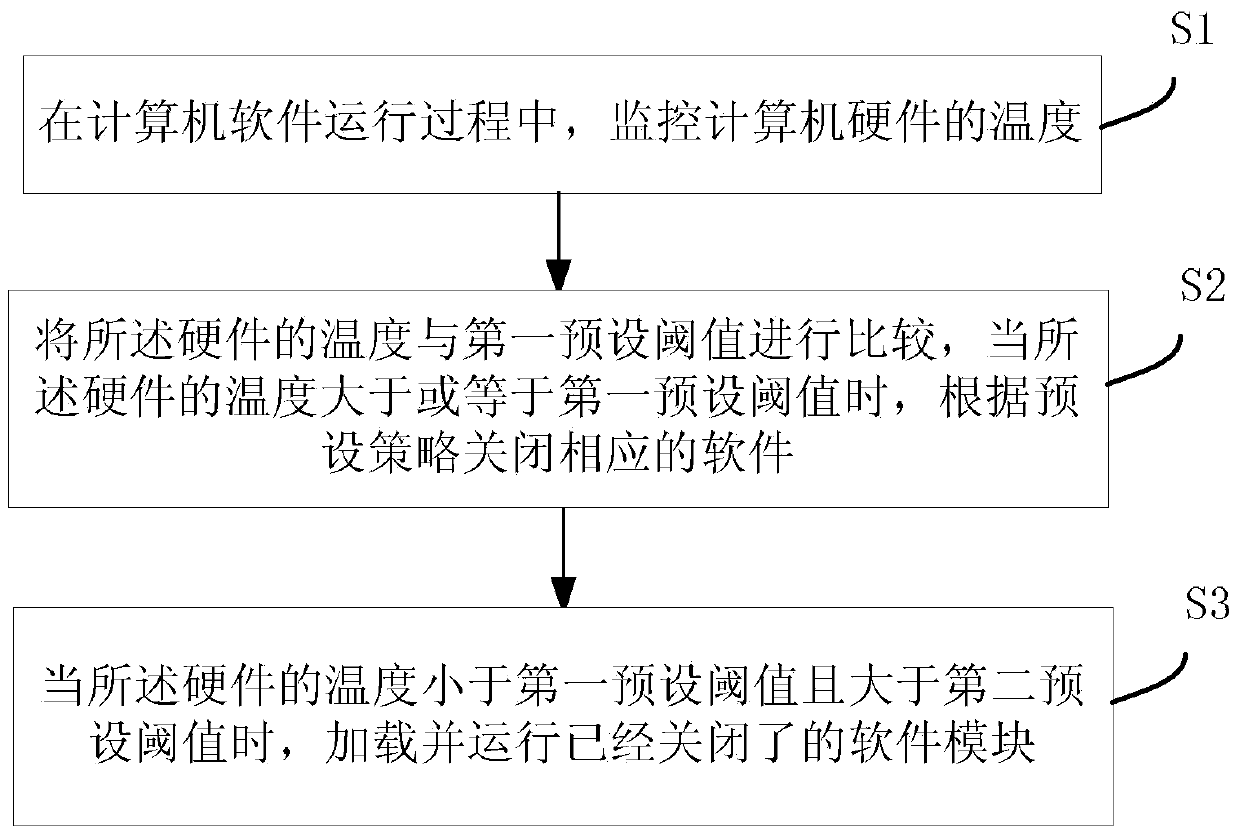

Method and device for controlling temperature of computer hardware

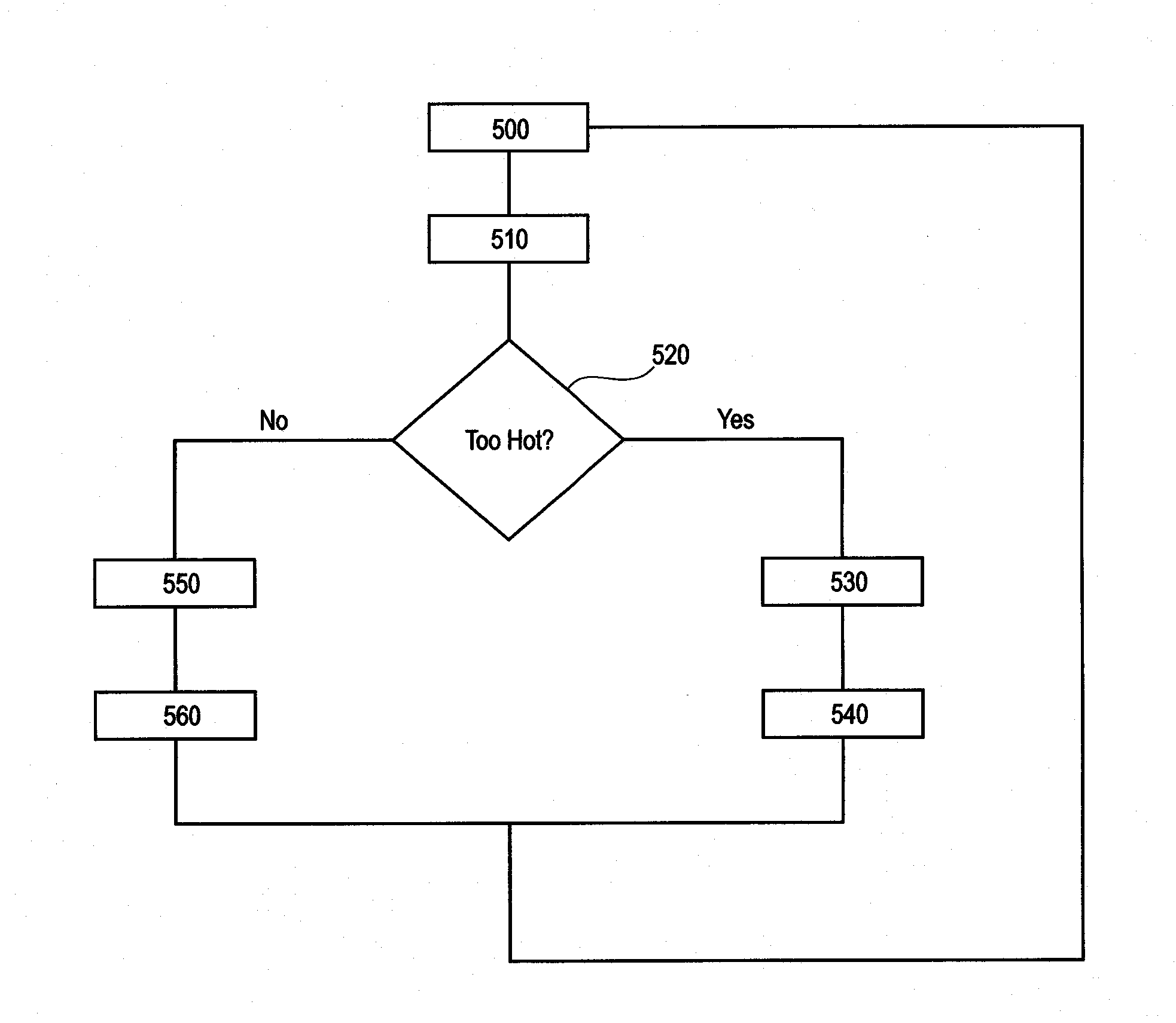

InactiveCN103699471AHeat controlHardware monitoringProgram loading/initiatingTemperature controlMonitoring temperature

The invention discloses a method and a device for controlling temperature of computer hardware. The device comprises a temperature monitoring module and a software module loading control module; the temperature monitoring module is used for monitoring temperature of computer hardware during the running process of modularized software of a computer, and transmitting the temperature of computer hardware to the software module loading control module; the software module loading control module is used for comparing the temperature of hardware with a first preset threshold, when the temperature of hardware is greater than or equal to the first preset threshold, corresponding software modules are closed according to a preset strategy. The method and the device provided by the invention, based on the modularized software run by the computer in a cloud platform, load or close the running software module according to the temperature of hardware to regulate CPU (Central Processing Unit) resource occupied by the running software, so as to control heat caused by running of software, and thus, the computer can operate in a rational temperature region, and the problems of dead halt and restart caused by over temperature are prevented.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

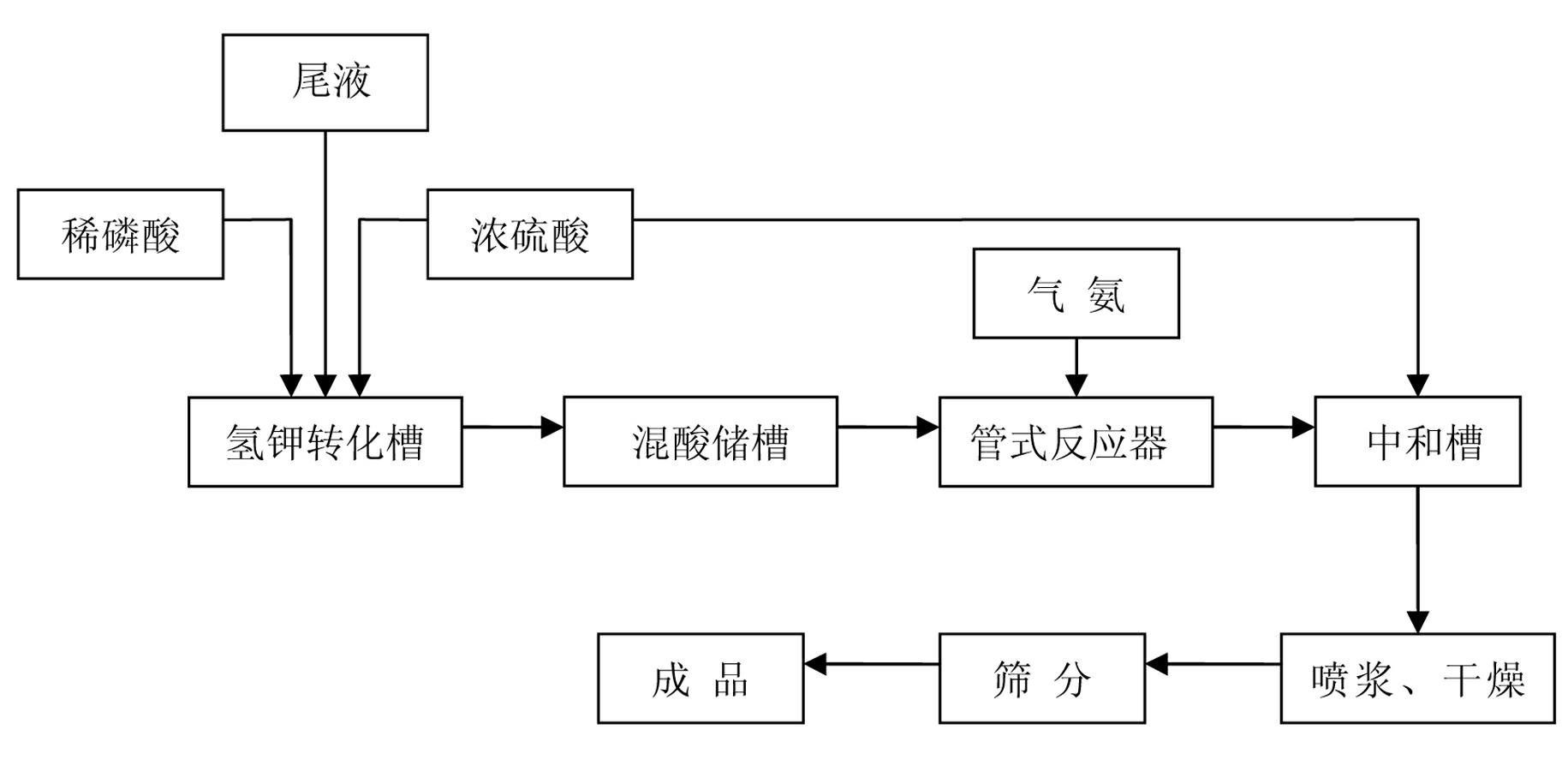

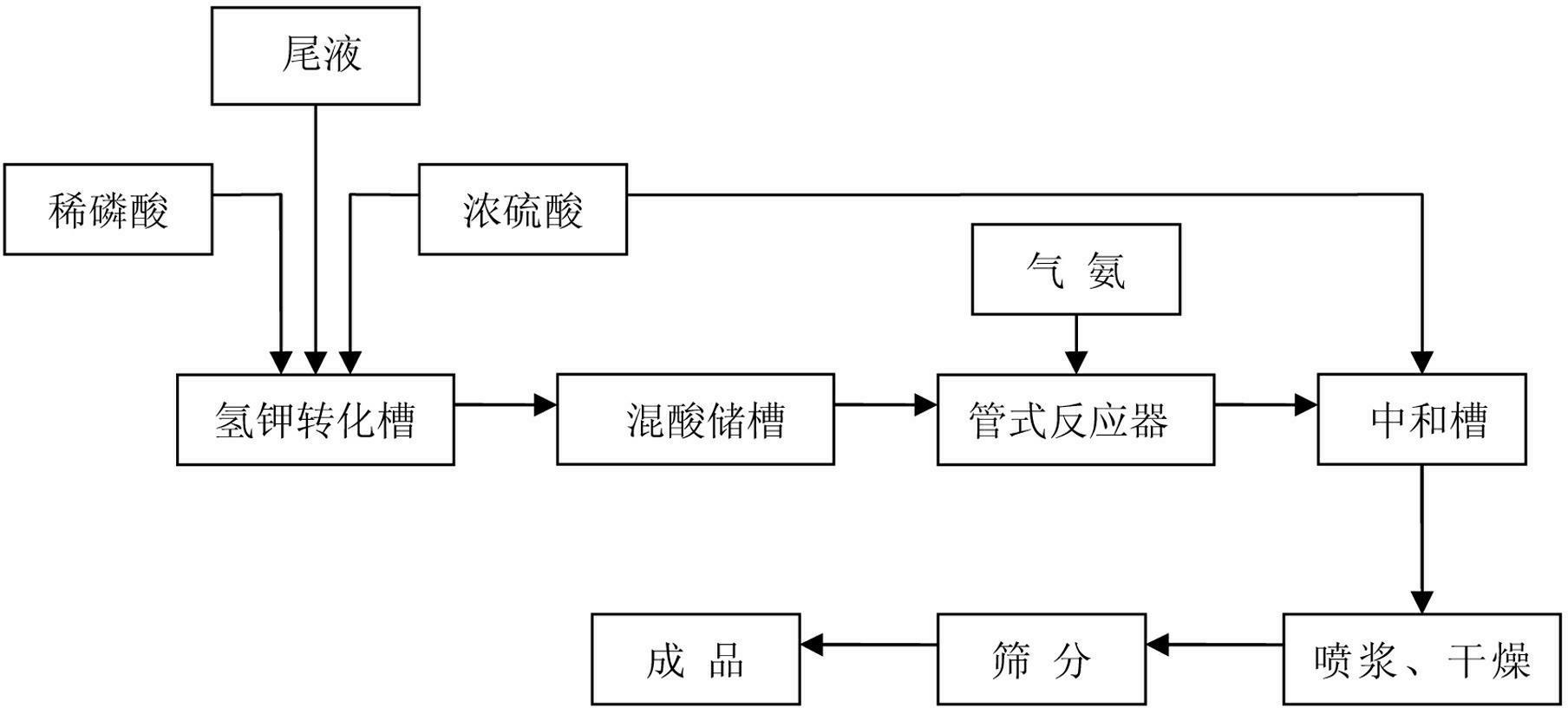

Method for producing ammonium sulfate in S-NPK device by using refined phosphoric acid byproduct tail liquid

InactiveCN102491297ASolving Recycling ProblemsReduce processing costsPhosphatesPhosphoric acidPotassium

The invention relates to a method for producing ammonium sulfate in an S-NPK device by using refined phosphoric acid byproduct tail liquid. The refined phosphoric acid byproduct tail liquid, concentrated sulfuric acid and diluted phosphoric acid are sufficiently mixed in a hydrogen potassium conversion tank, the mixed acid materials after being mixed enter a mixed acid storage tank and take reaction with gaseous ammonia in a tubular reactor, the obtained slurry then takes neutralization reaction with the concentrated sulfuric acid in a neutralization tank, and finally, finished ammonium sulfate products can be obtained through slurry spraying granulation, drying and sieving. The method has the advantages that the wet process phosphoric acid refined industrial phosphoric acid byproduct tail liquid, the concentrated sulfuric acid, the diluted phosphoric acid and the gaseous ammonia are directly used as raw materials, the recovery problem of the wet process phosphoric acid refined industrial phosphoric acid byproduct tail liquid is solved, the product manufacture cost is reduced, and the byproduct flow process during the phosphoric acid refining is reduced; and the S-NPK device is used for producing the ammonium sulfate, the investment cost is reduced, the device utilization rate is improved, and the economic benefits are good.

Owner:HUBEI SANNING CHEM

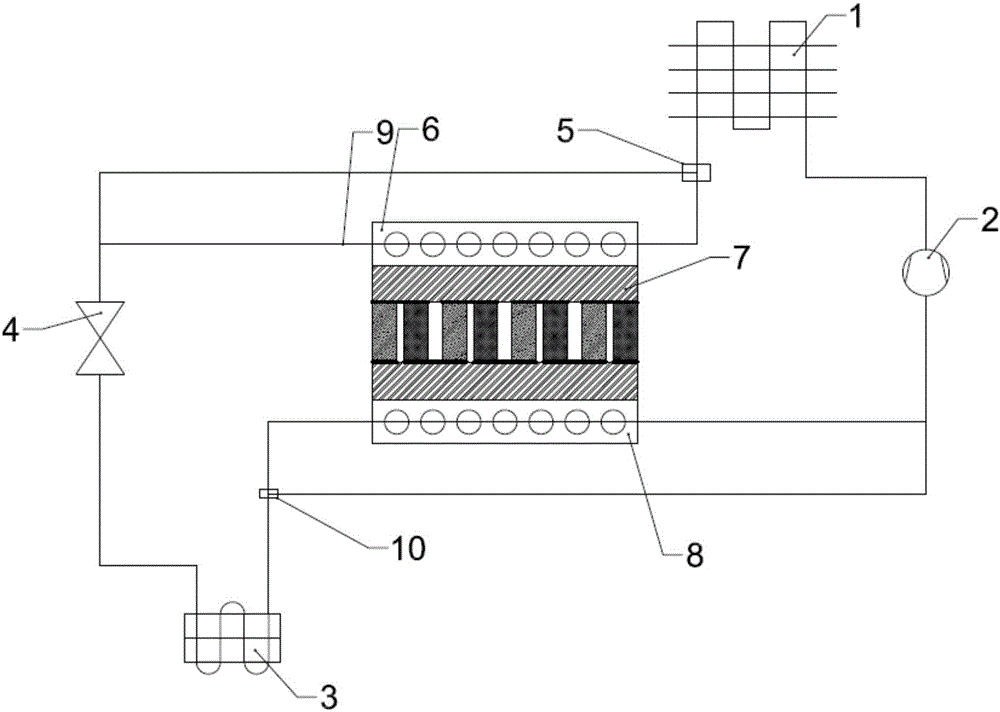

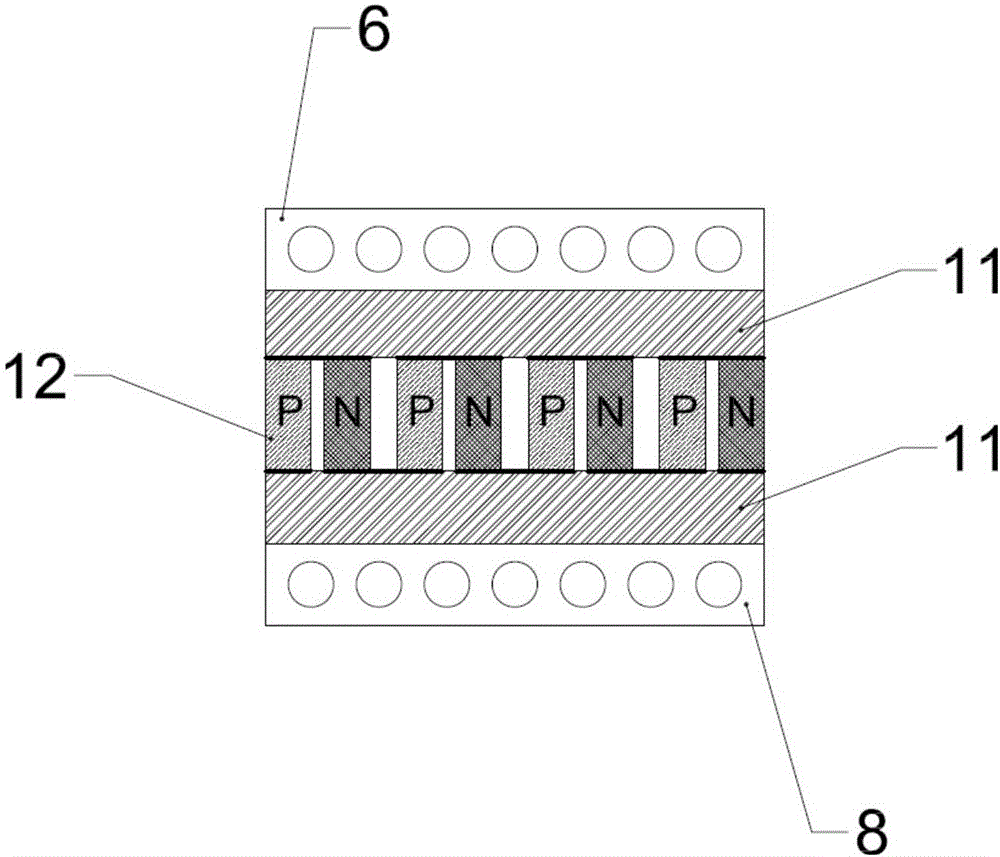

Thermoelectric heat regeneration system

ActiveCN106440432ASmall and simple structureEasy to installMechanical apparatusCompression machines with non-reversible cycleComing outEngineering

The invention discloses a thermoelectric heat regeneration system. The thermoelectric heat regeneration system comprises a refrigerating unit and a thermoelectric heat regeneration unit. The refrigerating unit comprises a compressor, an air cooling type condenser, a throttling valve, an air cooling type evaporator and circulating pipelines. The thermoelectric heat regeneration unit comprises a thermoelectric pile, heat exchangers and a bypass branch circuit controller; the hot end and the cold end of the thermoelectric pile are connected with the hot end heat exchanger and the cold end heat exchanger correspondingly; the hot end heat exchanger is connected with the circulating pipeline coming out of the evaporator, heats steam coming out of the evaporator and improves the overheating degree of a refrigerant; the cold end heat exchanger is connected with the circulating pipeline coming out of the condenser, cools liquid coming out of the condenser and improves the overcooling degree of the refrigerant; and the bypass branch circuit controller can control the flow rate of the refrigerant passing through the heat exchangers and widens the heat exchange range. Compared with a traditional heat regenerator, the thermoelectric heat regeneration system can accurately adjust and control the overcooling degree and the overheating degree of the refrigerant and has the beneficial effects of being small in size, simple in structure, easy to install, convenient to control, free of noise and environment-friendly.

Owner:HUAZHONG UNIV OF SCI & TECH

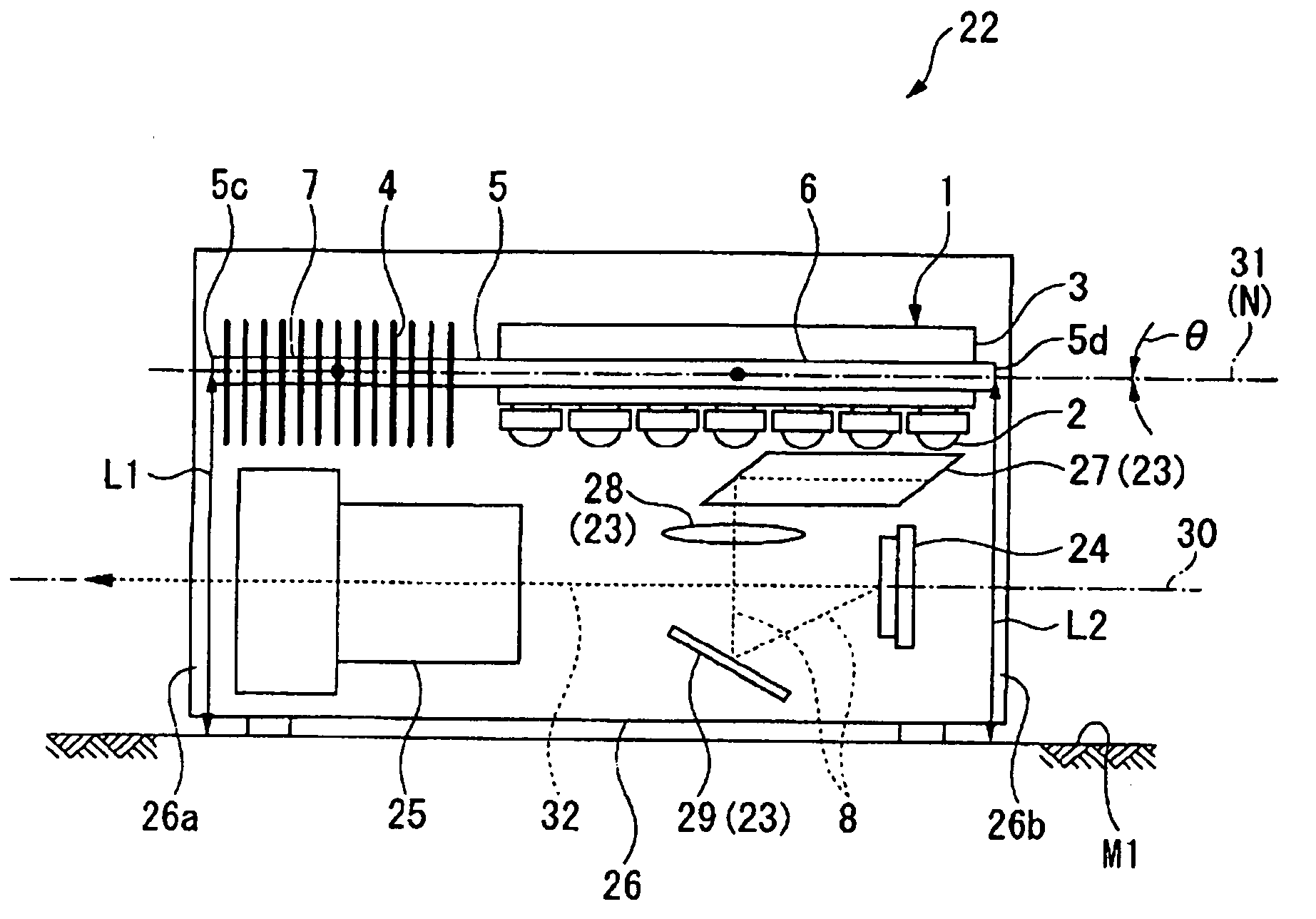

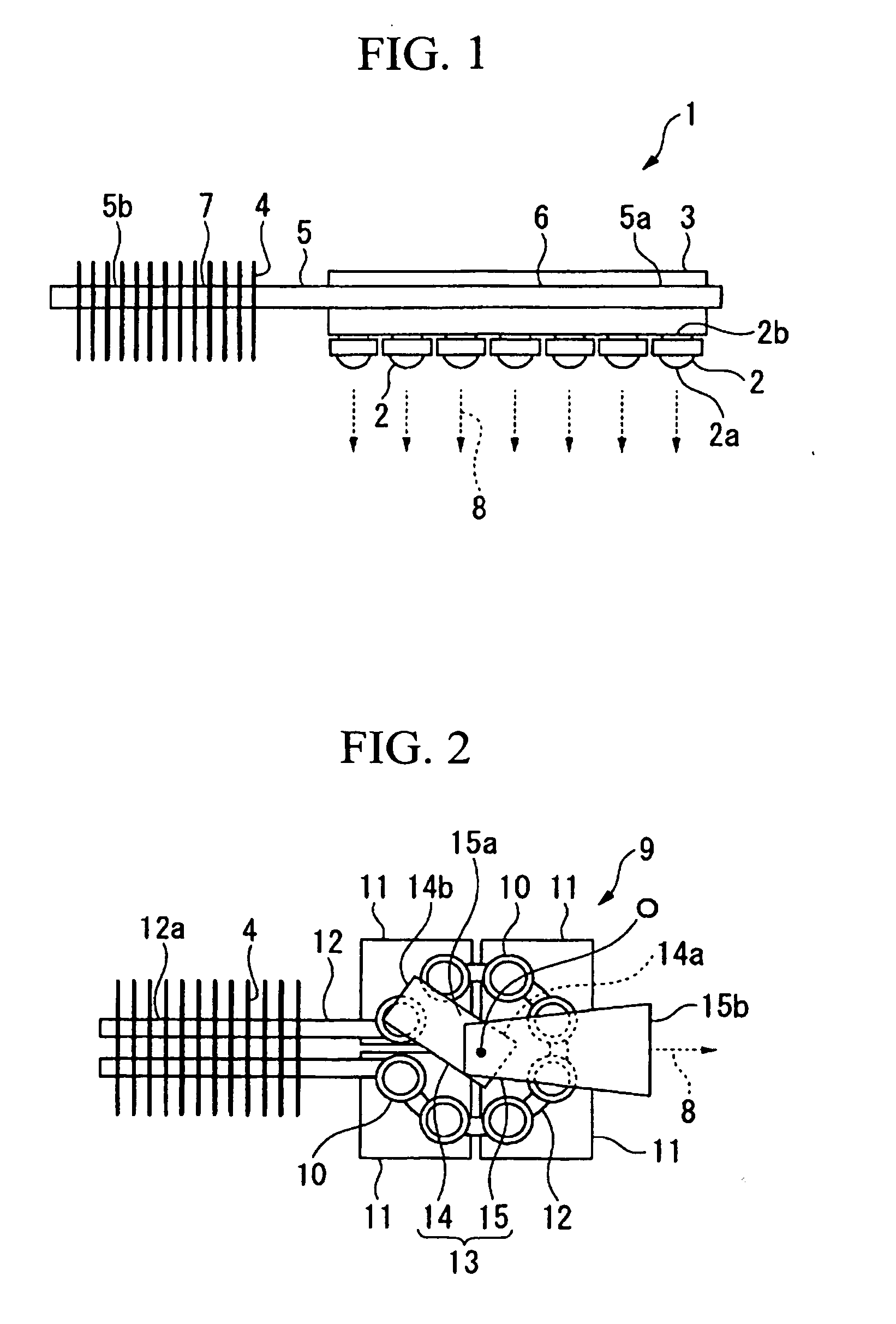

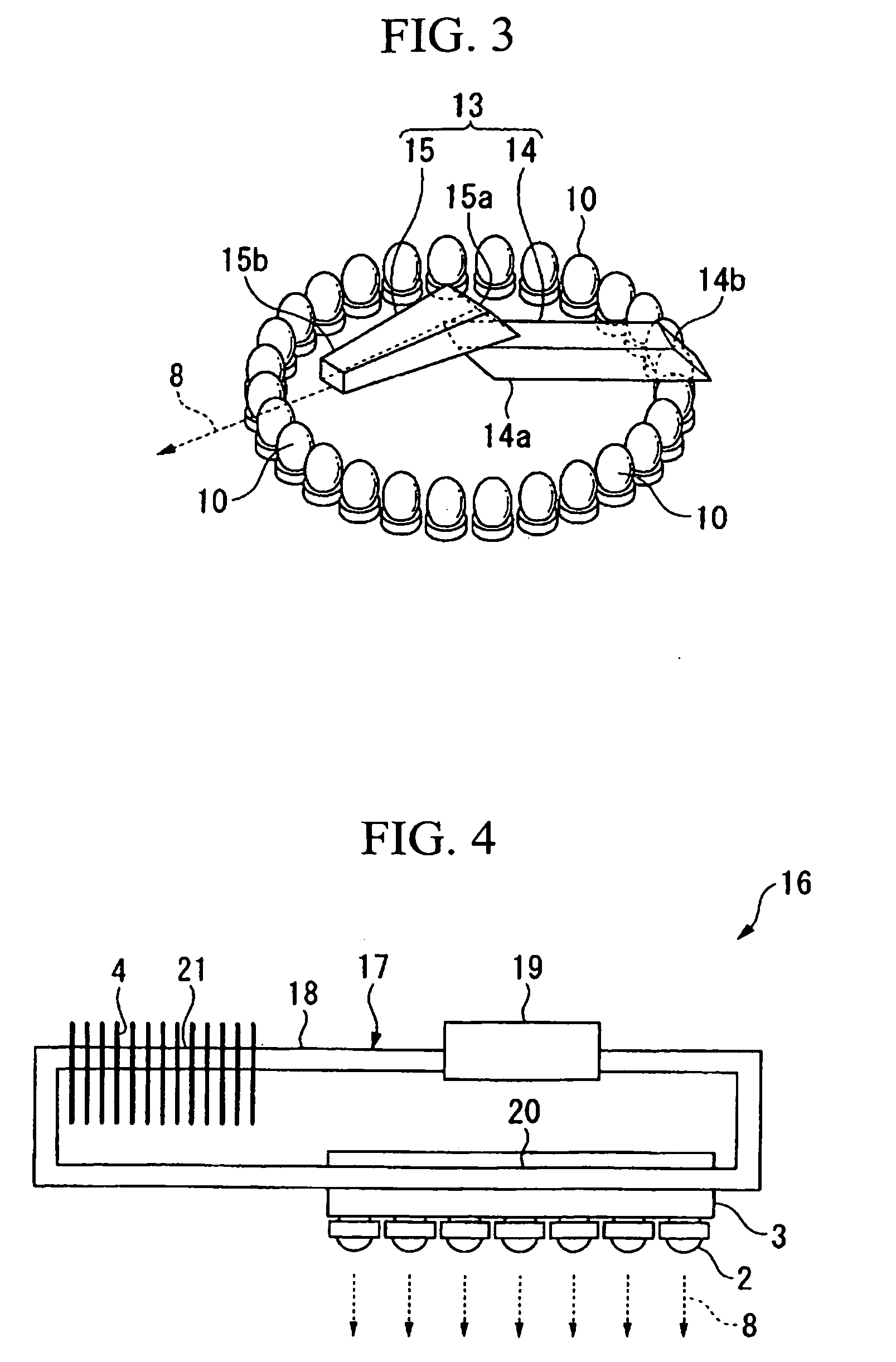

Light source apparatus and projector

InactiveUS20100073642A1Heat controlEffective and stablePoint-like light sourceLighting heating/cooling arrangementsRefrigerantOptoelectronics

Provided is a light source apparatus for illuminating an illumination area via an illumination optical part, including a plurality of light sources for emitting illumination light; one heat-absorbing member for absorbing heat which the plurality of light sources generates; a heat-radiating part for radiating the heat; and a heat-transporting part thermally connected to the heat-absorbing member and the heat-radiating part; wherein the heat-transporting part is formed of a tube member containing a refrigerant for transmitting the heat and is provided at a position shifted from an irradiation position of the illumination light.

Owner:OLYMPUS CORP

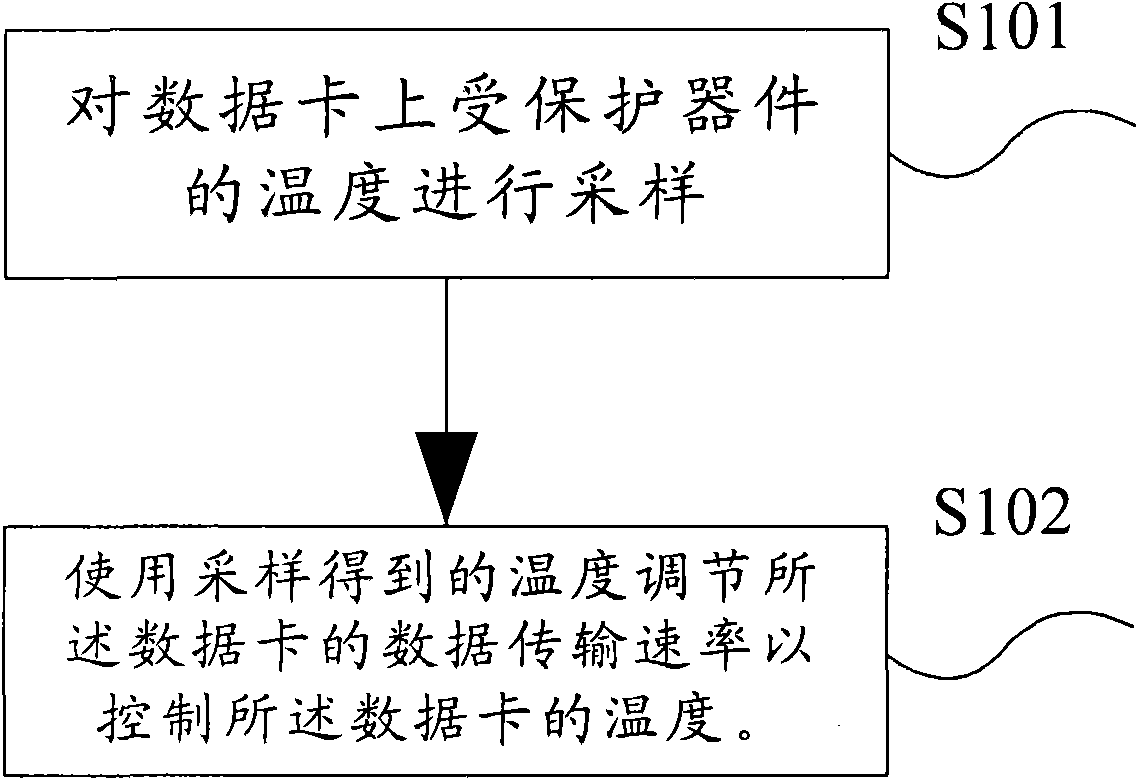

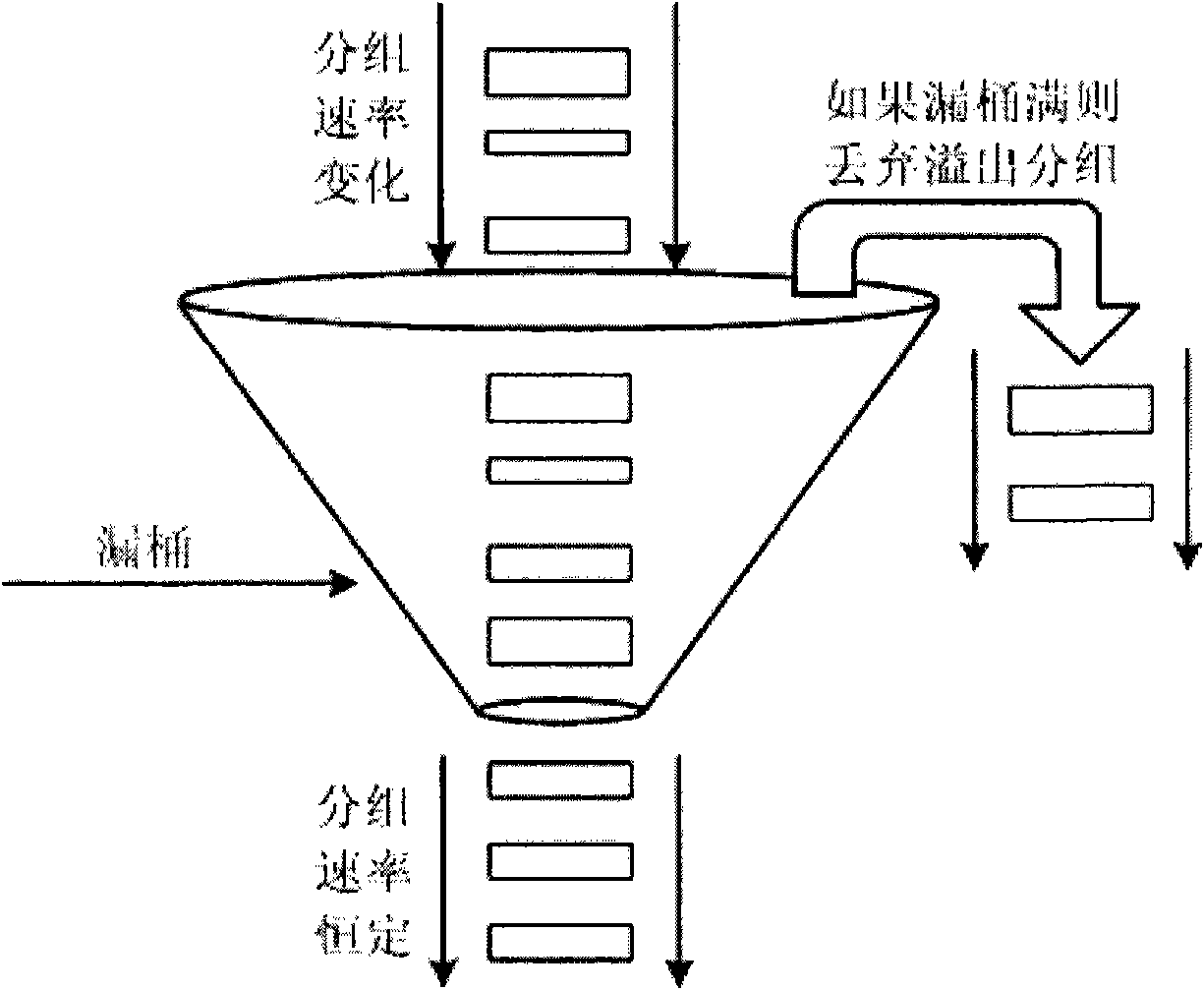

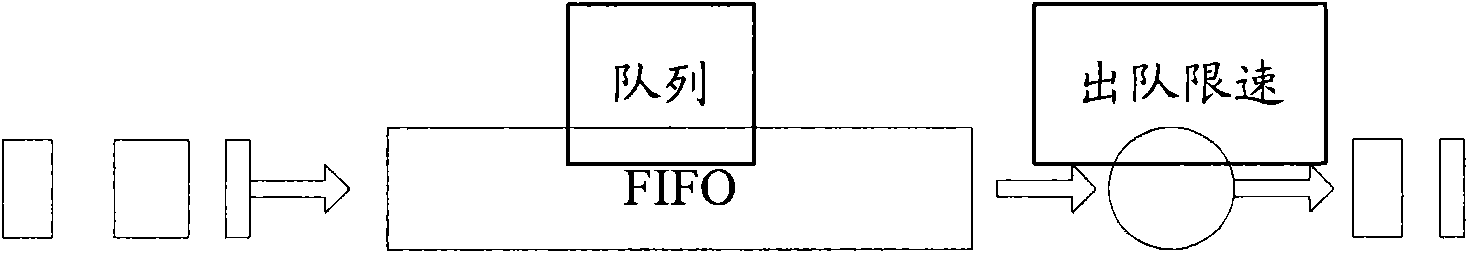

Data card temperature control method and device

InactiveCN102014201AAvoid device aging or damageHeat controlTemperature control using digital meansNetwork traffic/resource managementData transmissionWireless data

The invention discloses a data card temperature control method and device. The method comprises the following steps of: sampling the temperature of a protected device on a data card; and adjusting the data transmission rate of a temperature regulation data card according to the sampled temperature to control the temperature of the data The invention avoids the device aging or damage of a wireless data card.

Owner:ZTE CORP

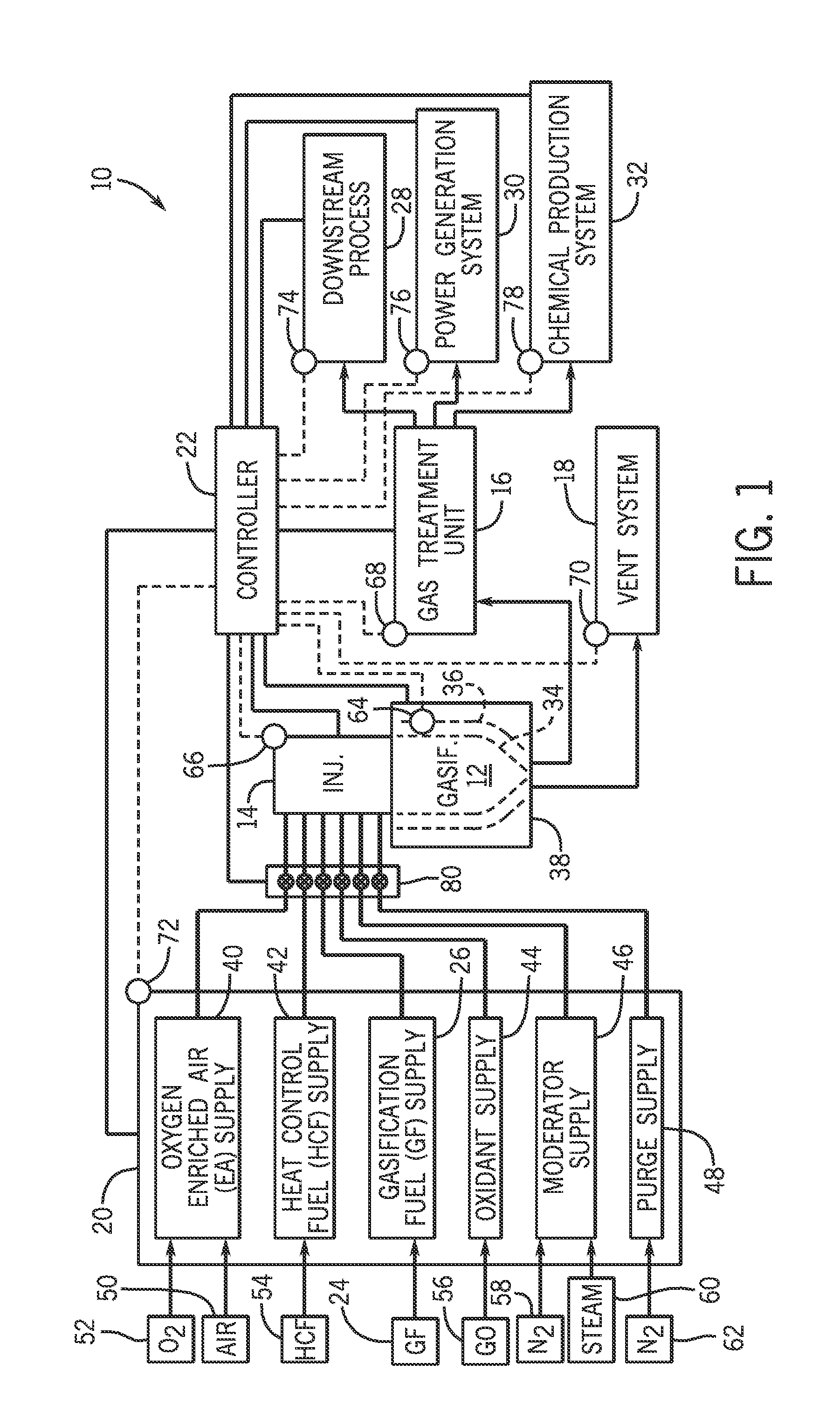

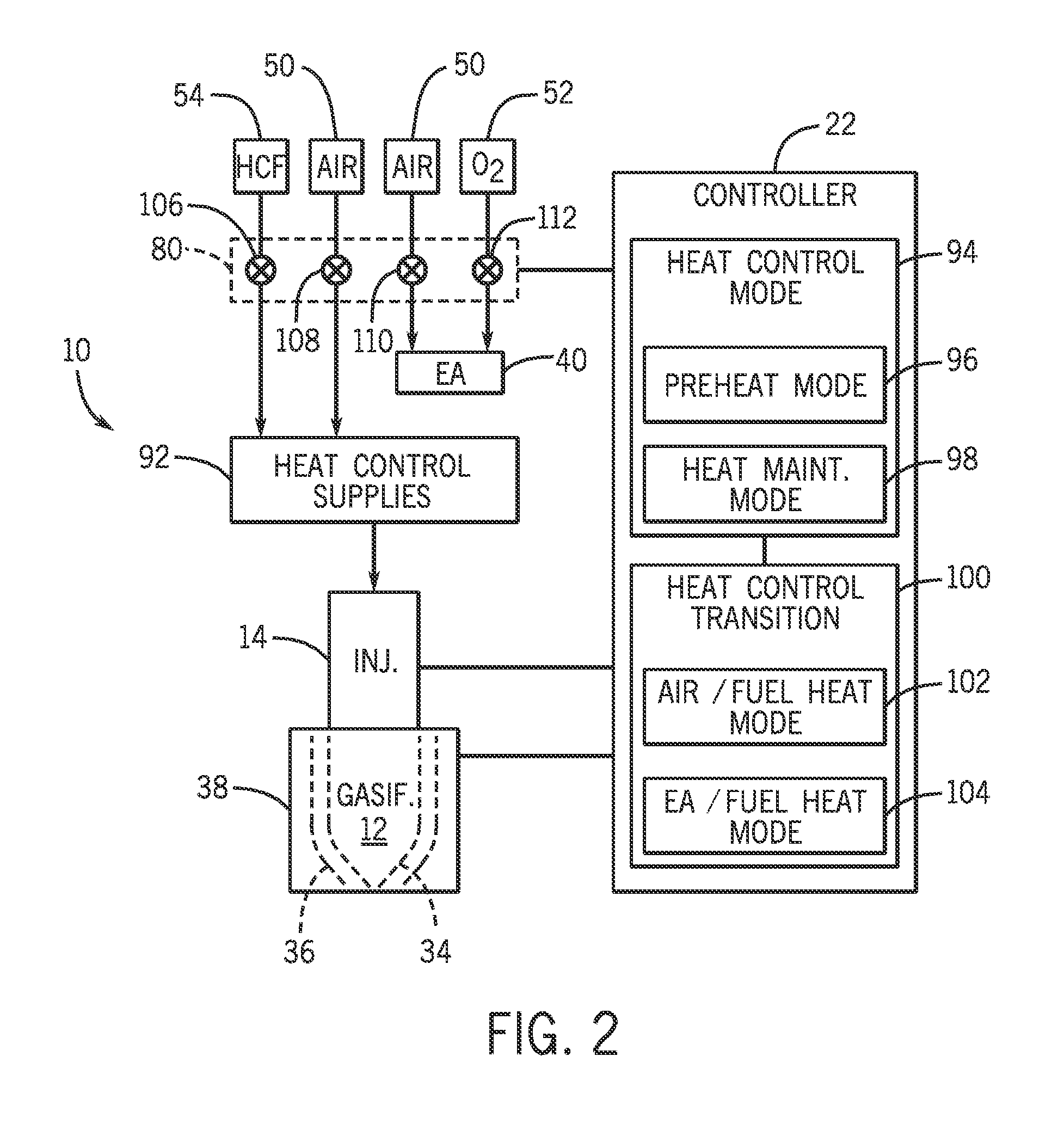

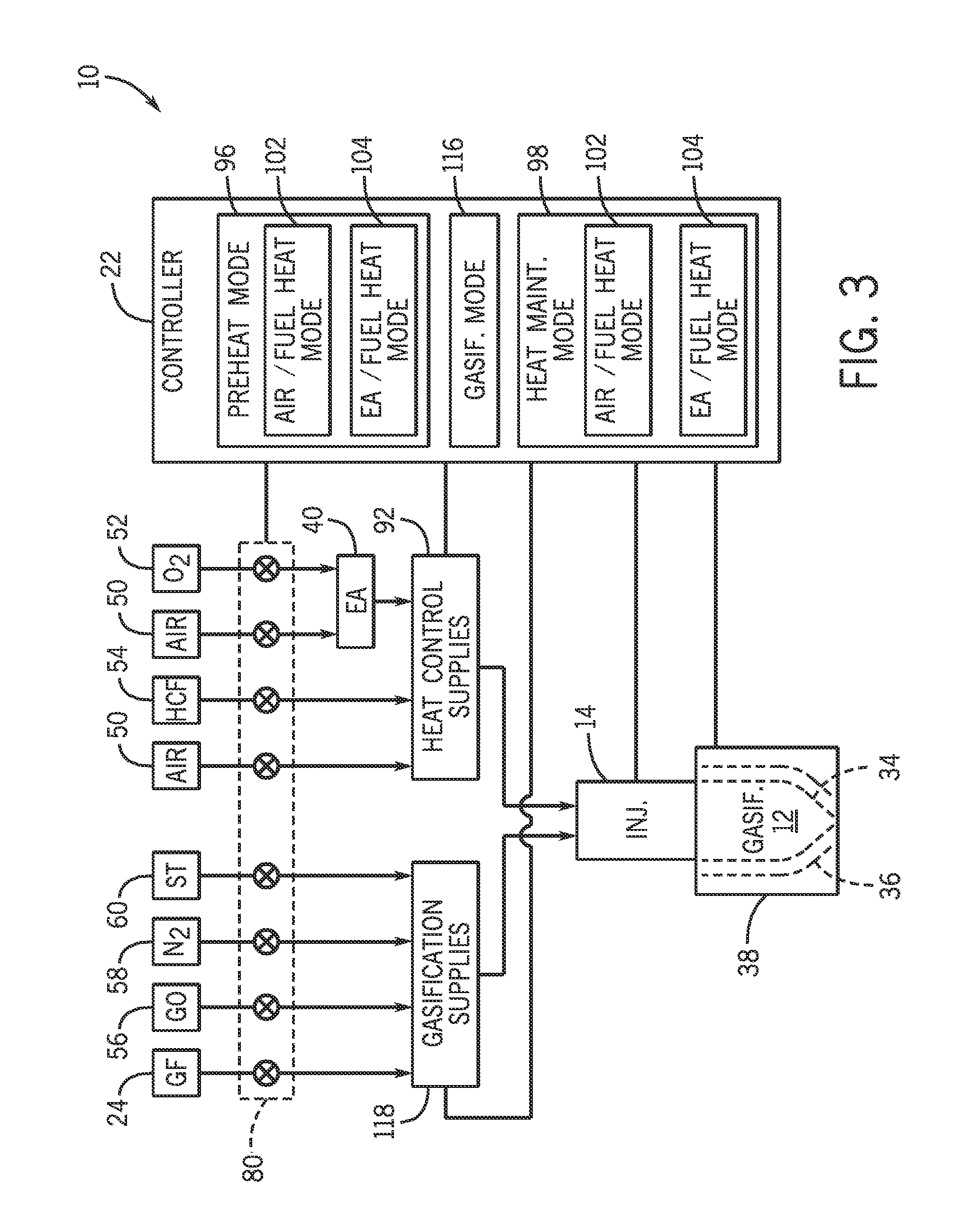

System and method for heating a gasifier

ActiveUS20130192139A1Heat controlIncrease temperatureHydrogenGasification processes detailsInjectorProcess engineering

A system includes a gasifier configured to gasify a gasification fuel during a gasification mode. The system also includes a first injector configured to inject a heat control fuel and an oxygen enriched air into the gasifier for combustion during a heat control mode. The heat control fuel is the same or different from the gasification fuel, and the oxygen enriched air includes air enriched with additional oxygen.

Owner:AIR PROD & CHEM INC

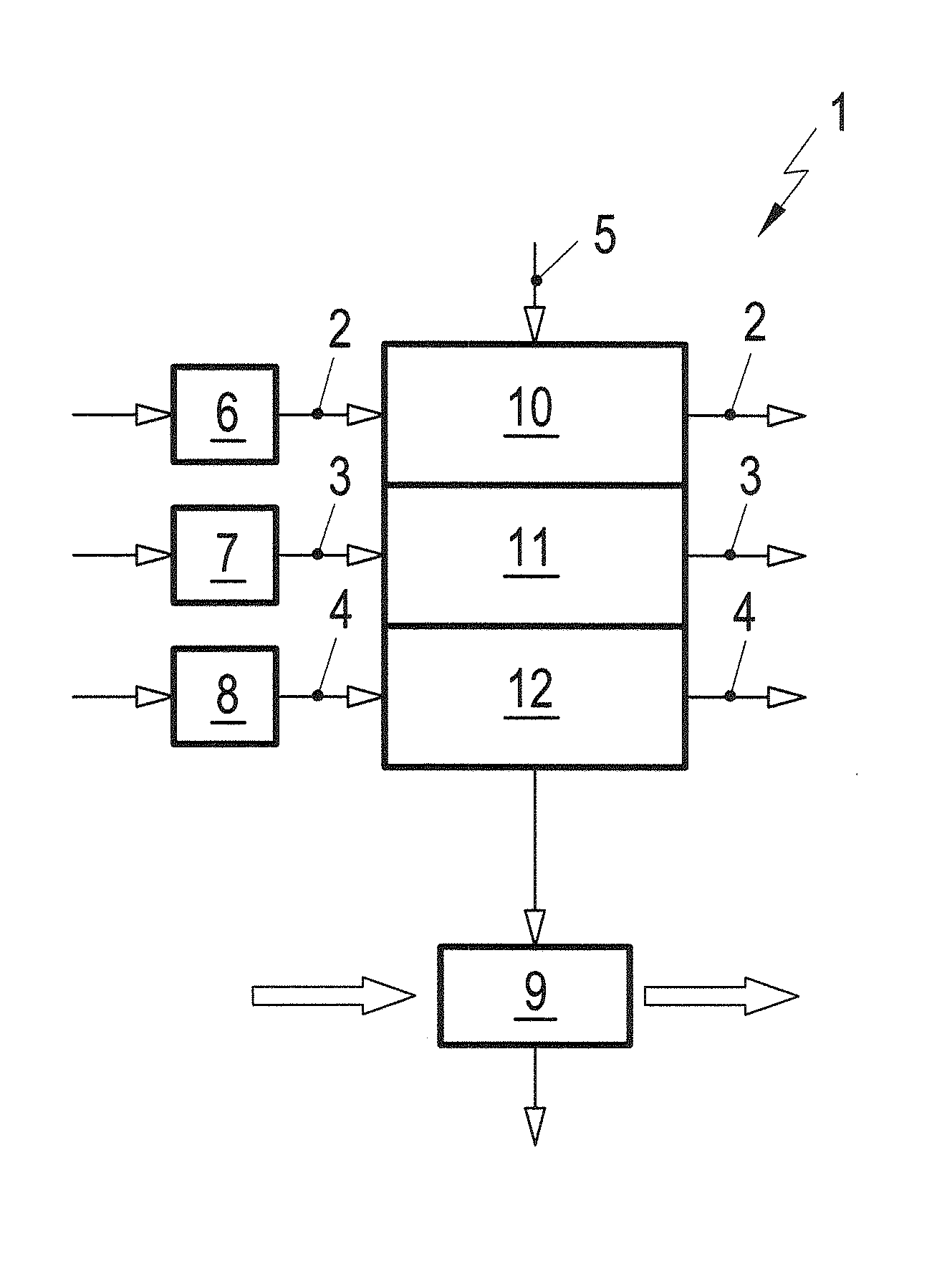

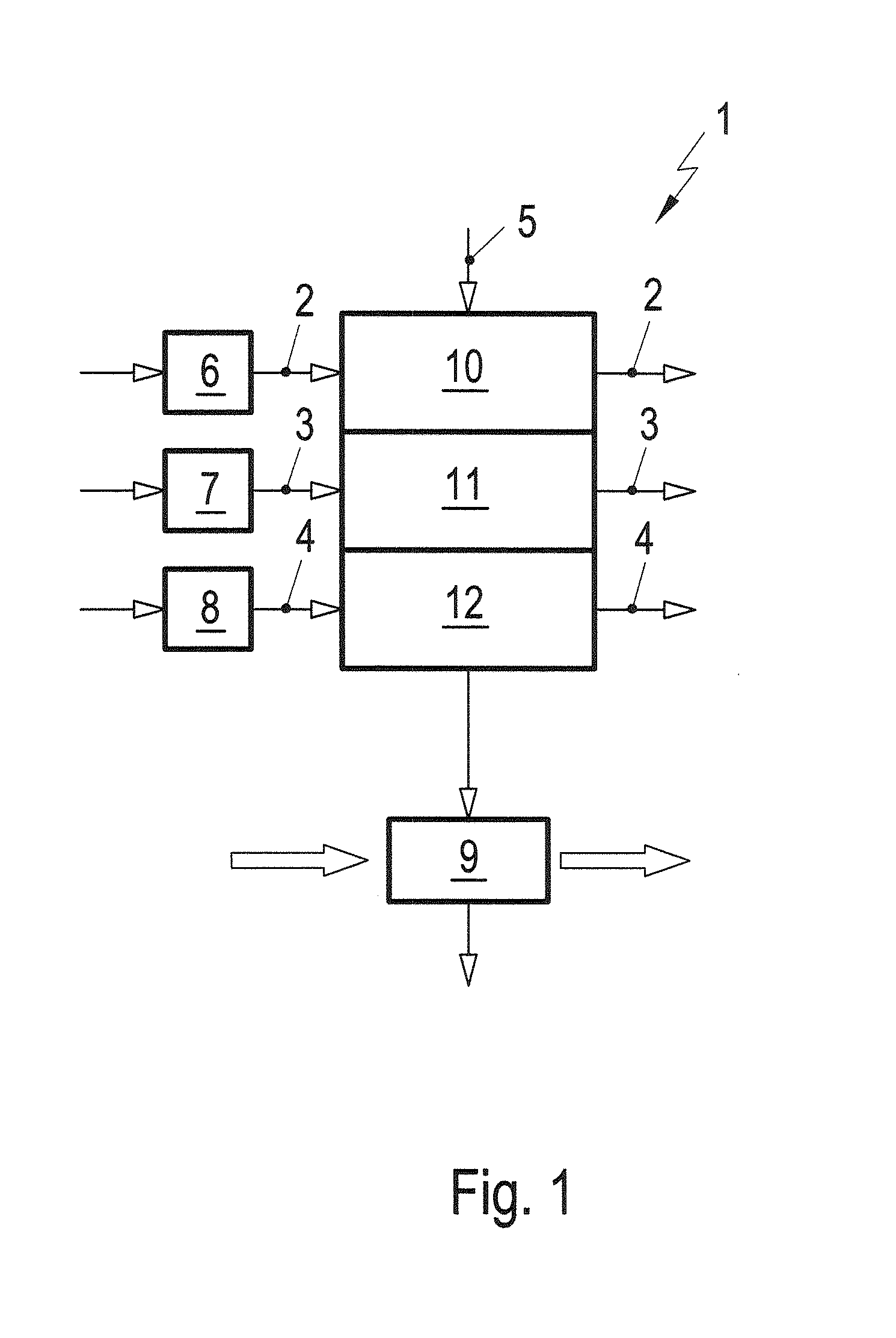

Arrangement of a thermoelectric heat pump

ActiveUS20140075962A1Heat controlExchange is limitedVehicle heating/cooling devicesMachines using electric/magnetic effectsEngineeringThermoelectric element

An arrangement of a thermoelectric heat pump in at least one first fluid circuit, one second fluid circuit and one third fluid circuit is provided for a motor vehicle. The arrangement has a first heat exchanger provided for exchange of heat between a fluid of the first fluid circuit and a fluid of a third fluid circuit, and a second heat exchanger is provided for the exchange of heat between a fluid of the second fluid circuit and the fluid of the third fluid circuit. In each case one thermoelectric element is arranged between the heat exchange regions of the first heat exchanger and between the heat exchange regions of the second heat exchanger.

Owner:DR ING H C F PORSCHE AG

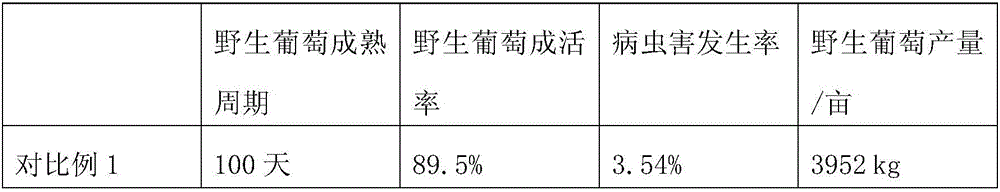

Planting method of wild grapes

InactiveCN106538342AExcellent black glossRegulating heat absorptionBiocideDead animal preservationVitis viniferaDisease

The invention discloses a planting method of wild grapes. The method comprises the following steps: (1) building a greenhouse, namely, building an arched shed, wherein the roof of the arched shed is sealed by inner and outer double-layer thin films, and the distance between the thin films is 10 to 15cm; (2) forming a seedbed; (3) implementing cutting and field planting; and (4) implementing fumigation management, namely, within 15 to 20 days after the fruiting of the wild grapes and before picking, burning fumigants to fumigate the wild grapes for 1 to 3h every 3 to 5 days. According to the planting method disclosed by the invention, the breakthrough improvement of a conventional grape greenhouse planting technology can be achieved; the light conditions of the grape growing period can be adjusted by adopting the inner and outer thin films, and thus the yield of the wild grapes can be increased, and the growth period of the grapes can be adjusted, centralized marketing can be avoided, and the sales revenue can be increased; and meanwhile, by virtue of fumigation management, the incidence of diseases and insect pests in the grape growing period can be reduced, the use amount of pesticides can be reduced, the environmental pollution to harvested grape products can be reduced, and high market values can be achieved.

Owner:广西都安密洛陀野生葡萄酒有限公司

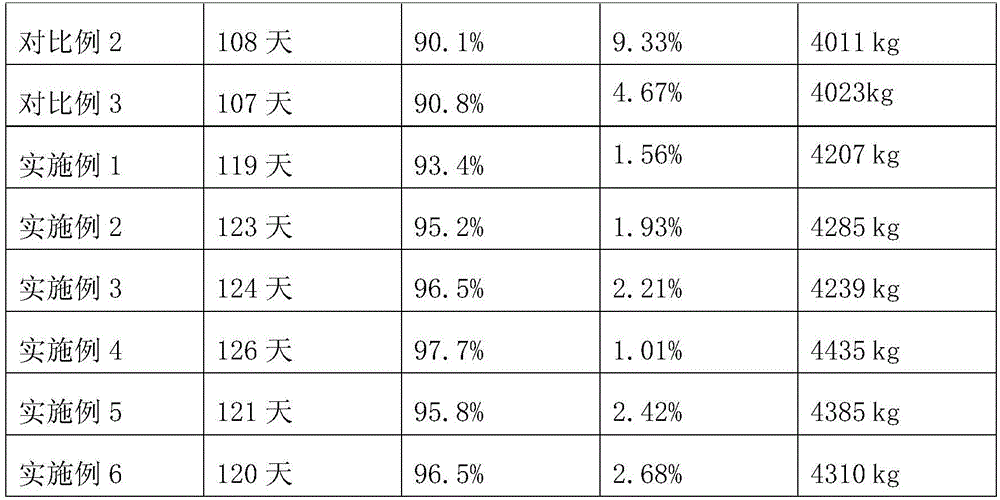

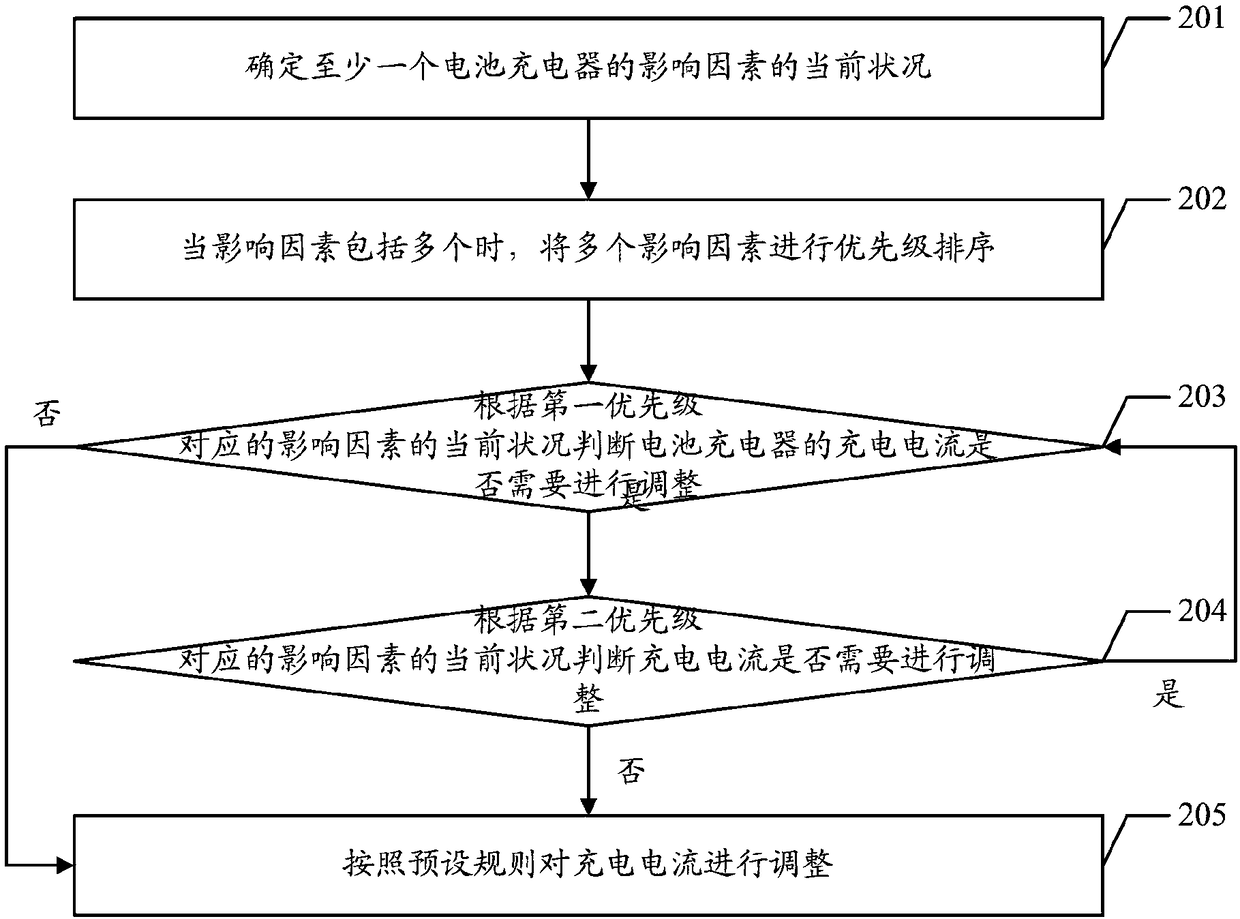

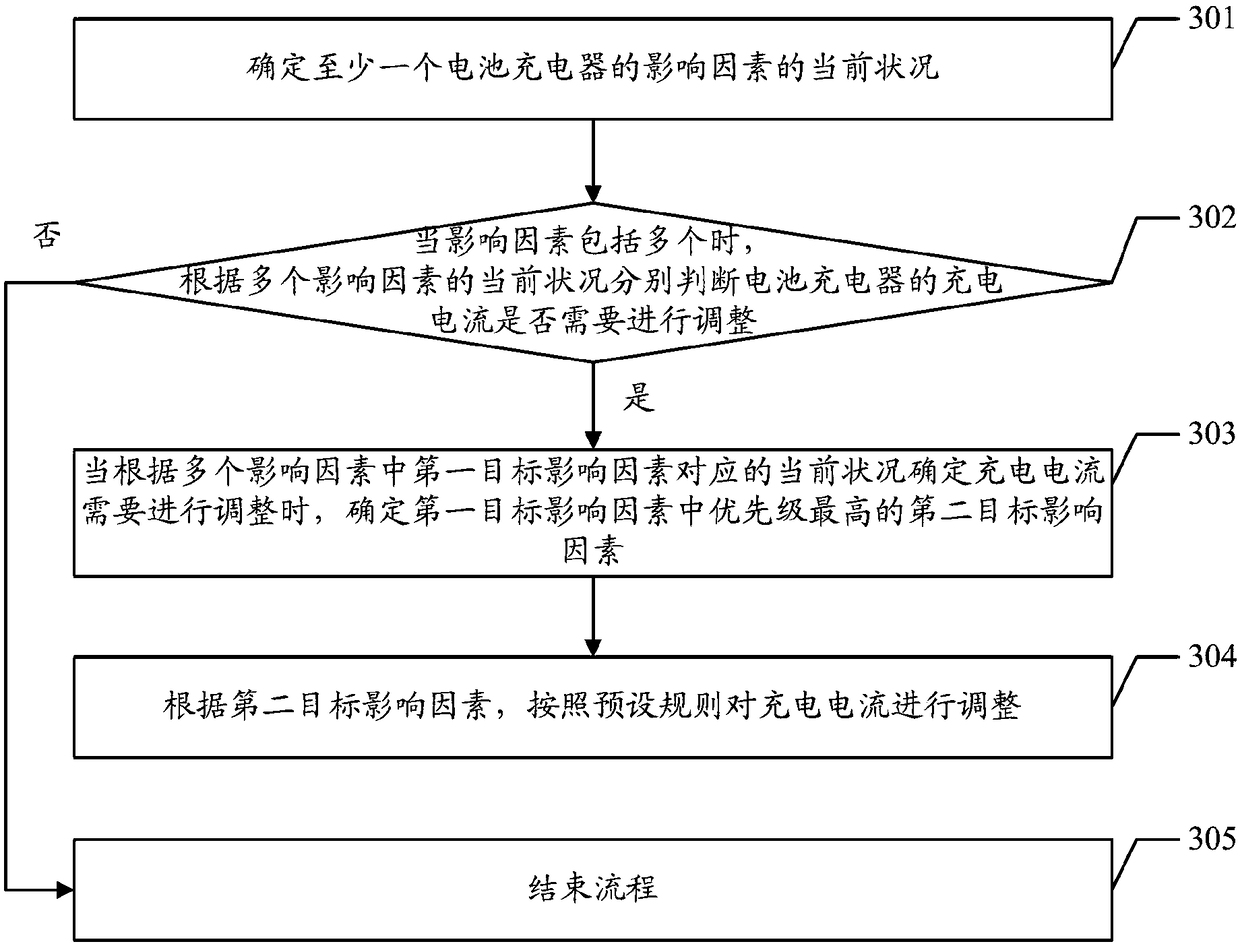

Charging current control method and apparatus, computer apparatus and readable storage medium

ActiveCN108429304AHeat controlGuaranteed thermal balanceBatteries circuit arrangementsElectric powerCharge currentPower flow

An embodiment of the invention discloses a charging current control method and apparatus, a computer apparatus and a readable storage medium that are used for adjusting a charging current of a batterycharger in real time according to different influence factors so as to maintain heat balance in an environment where the battery charger is positioned, and influence exerted on the battery charger byabnormal phenomena of the influence factors can be reduced. The method disclosed in the embodiment of the invention is applied to a UPS system, wherein the UPS system comprises at least one battery charger. The method comprises the following steps: a current condition of the influence factors of the charging current of at least one battery charger is determined, and whether the charging current needs adjustment is determined according to the current condition; if yes, the charging current is adjusted according to preset rules.

Owner:ZHANGZHOU KEHUA TECH CO LTD +1

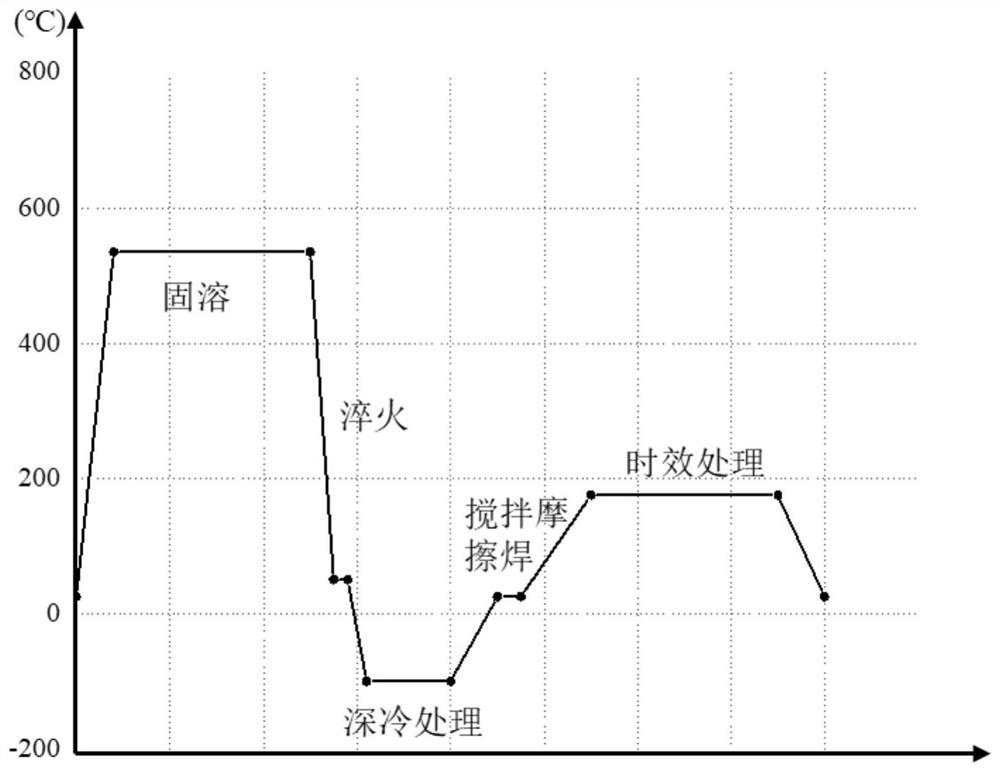

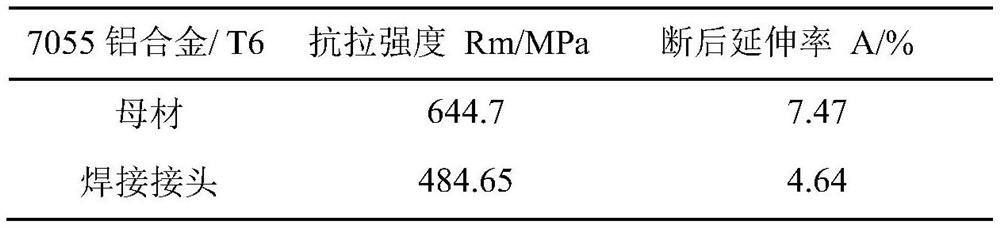

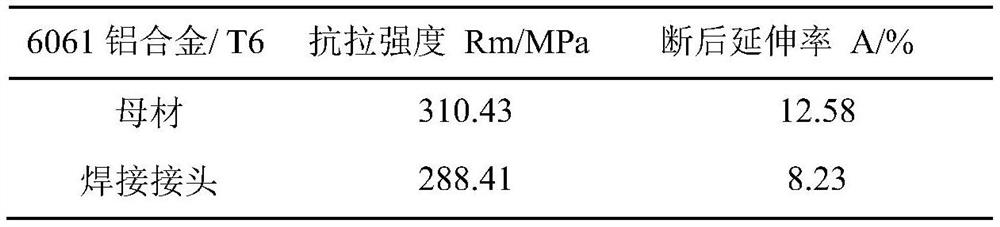

Method for improving performance of heat-treatable reinforced aluminum alloy friction stir welding joint

ActiveCN113263279AImprove mechanical propertiesImprove performanceWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingAluminium matrix

The invention discloses a method for improving the performance of a heat-treatable reinforced aluminum alloy friction stir welding joint. The method mainly comprises the following process steps that firstly, an aluminum alloy material needing to be welded is subjected to solid solution heat treatment, the solid solution temperature is (465-545) + / -5 DEG C, the heat preservation time is 4-8 hours, and after water quenching, the aluminum alloy material is placed in a low-temperature environment to be stored; friction stir welding equipment is adopted for welding the aluminum alloy, rapid cooling treatment is adopted at the welding seam position, it is guaranteed that alloy elements are subjected to solid solution in an aluminum matrix as many as possible while recrystallized grains are restrained from growing, and a supersaturated solid solution is obtained; after friction stir welding is completed, a whole welding part is subjected to peak aging heat treatment, the aging treatment temperature is (150-190) + / -5 DEG C, and the heat preservation time is 7-20 hours. According to the method, dissolution and growth of an aging precipitated phase at a welding joint part can be avoided, softening of the welding joint is inhibited, the strength and plasticity of the welding joint are improved, and finally the friction stir welding joint which is compact in structure, has the strength reaching 85% or above of the strength of base metal and is good in comprehensive performance is obtained.

Owner:UNIV OF SCI & TECH BEIJING

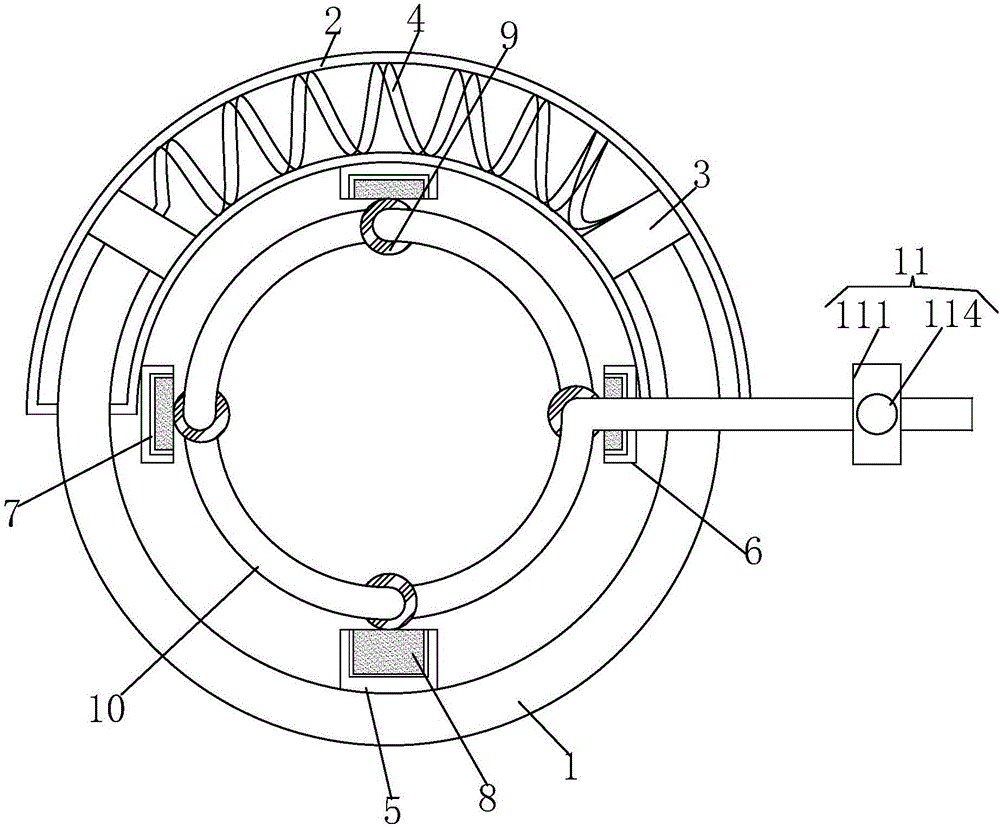

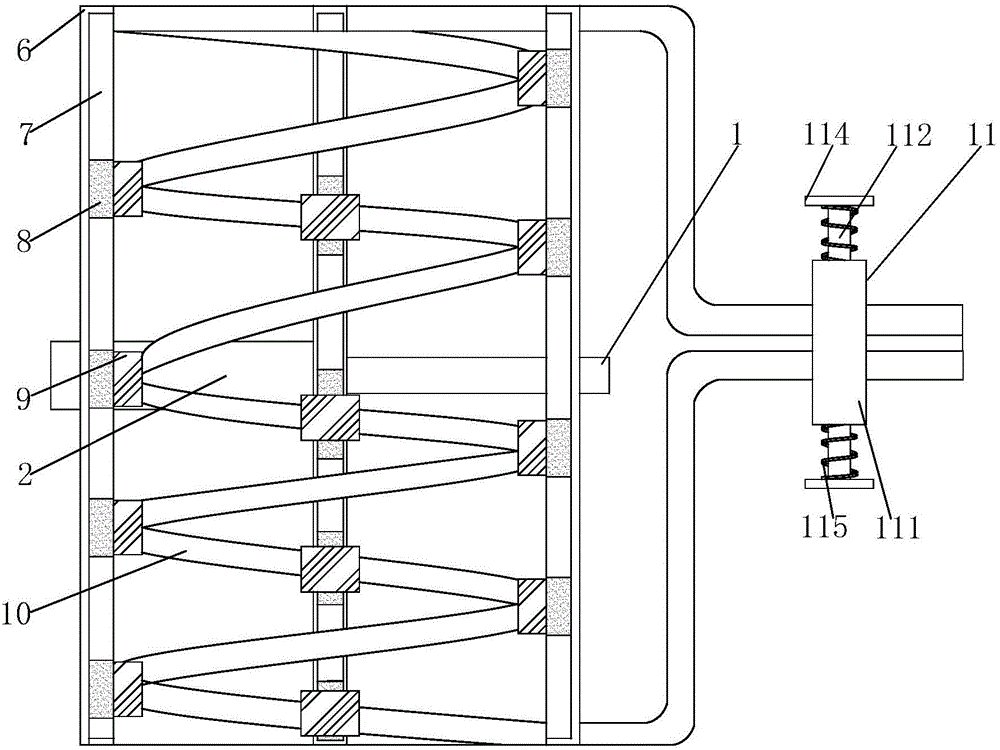

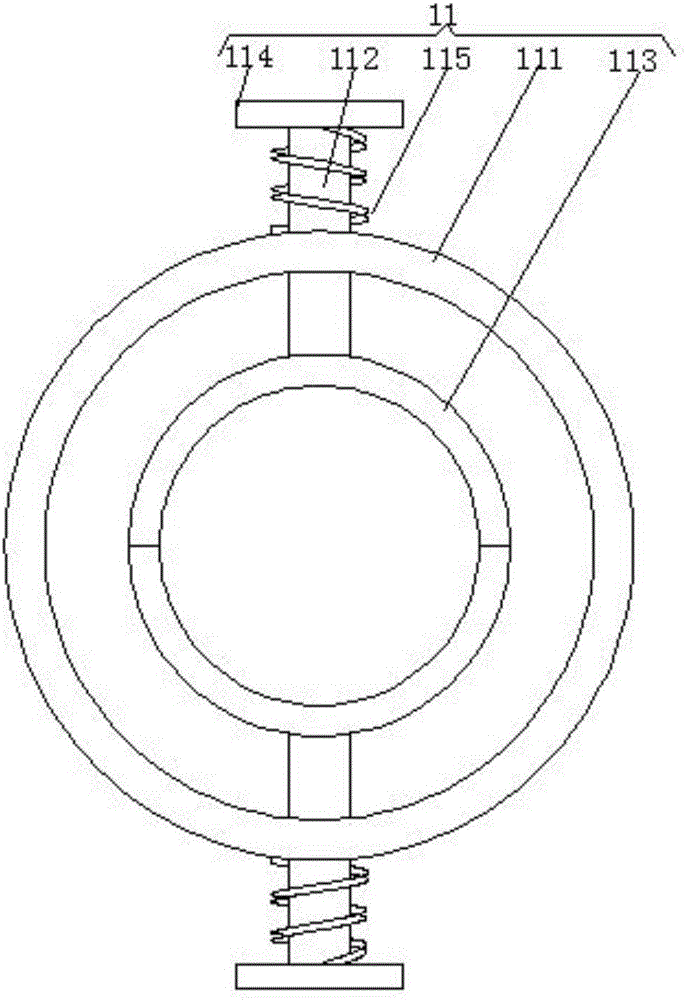

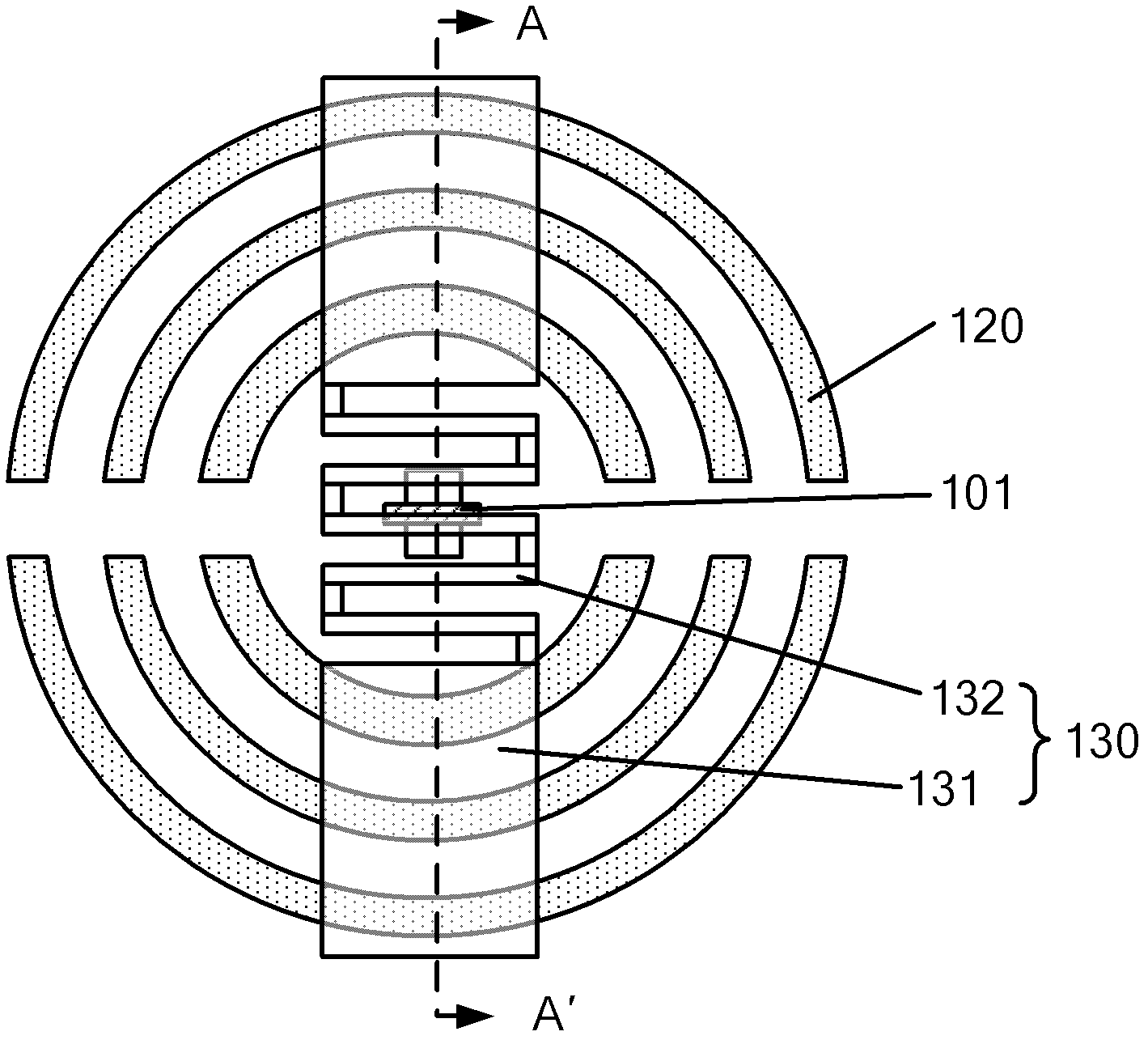

Size-adjustable induction coil

ActiveCN106783108AChange diameterChange distanceTransformersTransformers/inductances coils/windings/connectionsEngineeringPiston

The invention discloses a size-adjustable induction coil, comprising an arc-shaped soft rod; the two ends of the arc-shaped soft rod pass through an arc-shaped sleeve and are fixedly connected with the sides, back on to each other, of two pistons in the arc-shaped sleeve, and the opposite sides of the two pistons are movably connected with each other by a first spring; the inner side wall of the arc-shaped soft rod is fixedly connected with a first vertical plate; the inner side wall of the arc-shaped soft rod is fixedly connected with three second vertical plates at equal intervals; the sides, back on to the arc-shaped soft rod and the arc-shaped sleeve, of the first vertical plate and the second vertical plates are respectively provided with a sliding rail in an embedding way, and sliding blocks are respectively connected into the sliding rail in a sliding way. According to the size-adjustable induction coil, by improving the arc-shaped soft rod and the arc-shaped sleeve, the diameter between the arc-shaped soft rod and the arc-shaped sleeve can be changed, so that the sizes of coils formed by winding an induction line between the first vertical plate and the three vertical plates can be changed; by improving the sliding rails and the sliding blocks, the induction line can contract in a circular sleeve, so that the distances between the coils formed by winding the induction line can be changed.

Owner:JIANGSU HENGKANG ELECTRICAL

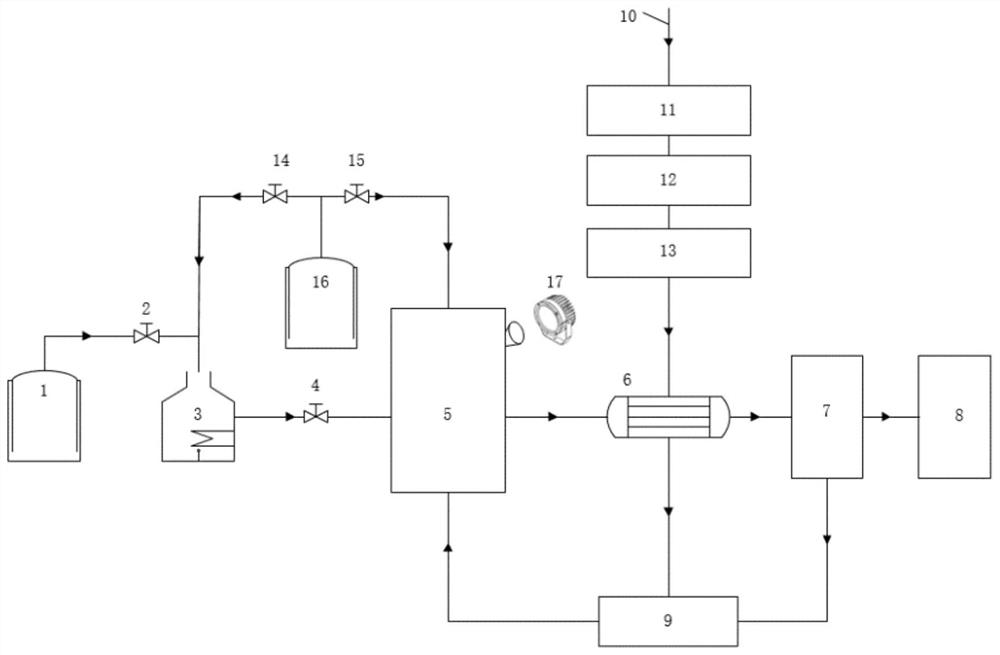

Heat-emitting graphite material comprising amorphous carbon particles and a production method therefor

InactiveCN102575144AContribute to thinningImprove economySemiconductor/solid-state device detailsSolid-state devicesHeat managementThermal management system

The present invention relates to a heat management system in the context of the emission of heat generated in electronic equipment. More specifically, the present invention relates to: an effective heat-emitting material which can dramatically improve not only heat diffusion in the horizontal direction but also heat conductivity in the vertical direction by using amorphous carbon particles to fill the voids which exist in peeled graphite sheets; and a production method therefor. Amorphous carbon particles are thermally isotropic and structurally constitute microcrystals of graphite and diamond, and their size is prererably from 10 to 110 nm.

Owner:崔锡洪 +1

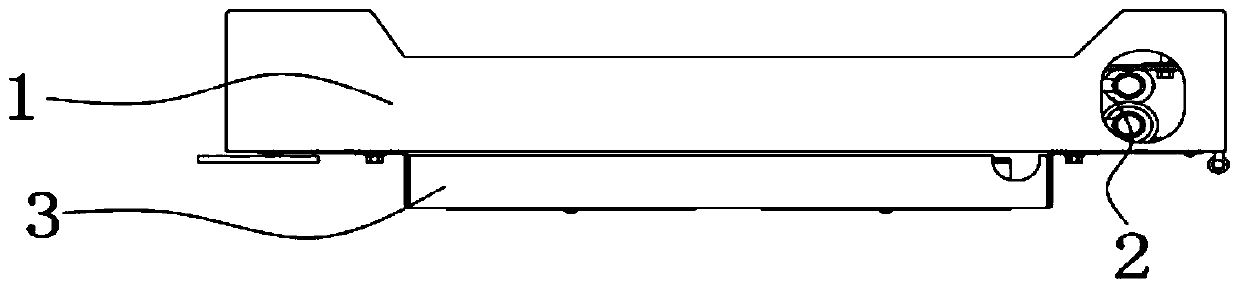

Traditional Chinese medicinal material drying machine

InactiveCN105157378AIncrease heating powerGuaranteed qualityDrying gas arrangementsDrying machines with non-progressive movementsMedicinal herbsSolenoid valve

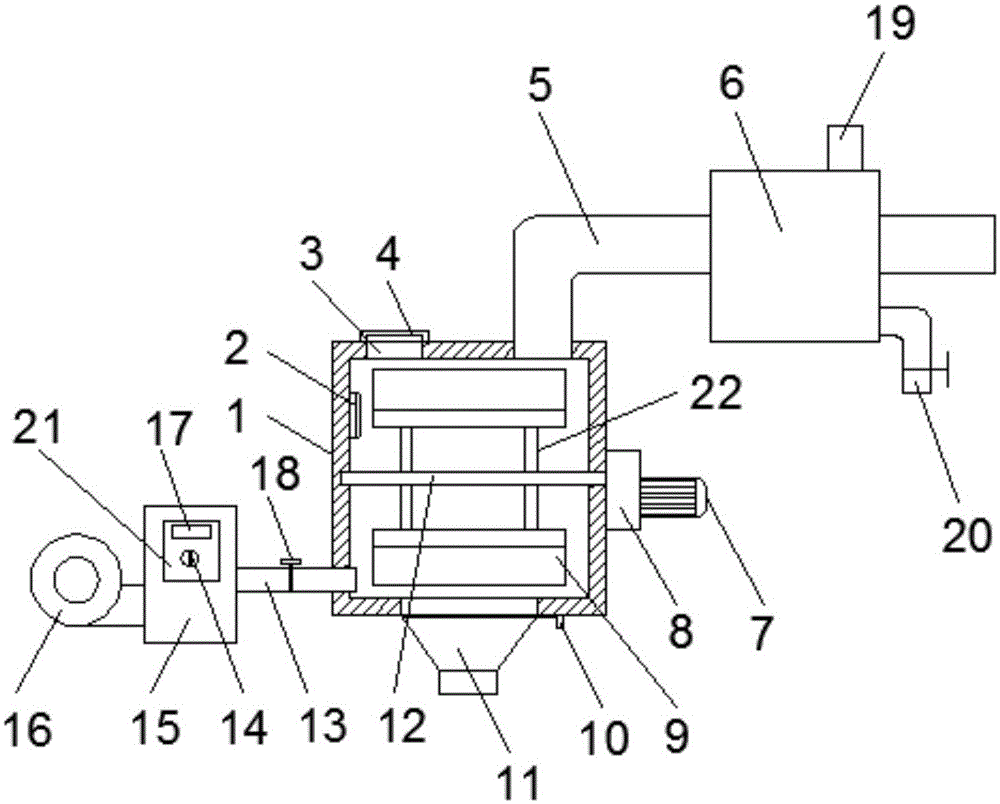

The invention relates to a traditional Chinese medicinal material drying machine which comprises a drying box, wherein the right part of the upper side surface of the drying box is provided with an air outlet; the air outlet is communicated with an exhaust pipe; the exhaust pipe is provided with a heat exchanger; the left part of the upper side surface of the drying box is provided with a feed port; the feed port is provided with a cover plate; the middle part of the drying box is connected with a rotating shaft; the right end of the rotating shaft protrudes out of the drying box; the outer wall of the rotating shaft arranged in the drying box is provided with a bracket; the bracket is connected with a frying board; the right end of the rotating shaft is connected with a motor through a speed reducer; the motor is a change speed motor; a temperature sensor is arranged in the drying box; the left side end of the lower part of the drying box is connected with an air inlet pipe; the air inlet pipe is provided with a solenoid valve; the other end of the air inlet pipe is connected with a heating box; the heating box is connected with a fan; and the outer wall of the heating box is provided with a controller. The traditional Chinese medicinal material drying machine has the advantages of simple and reasonable structure and low operating cost, has the self-control drying temperature, and greatly lowers the energy consumption.

Owner:成都米戈科技有限公司

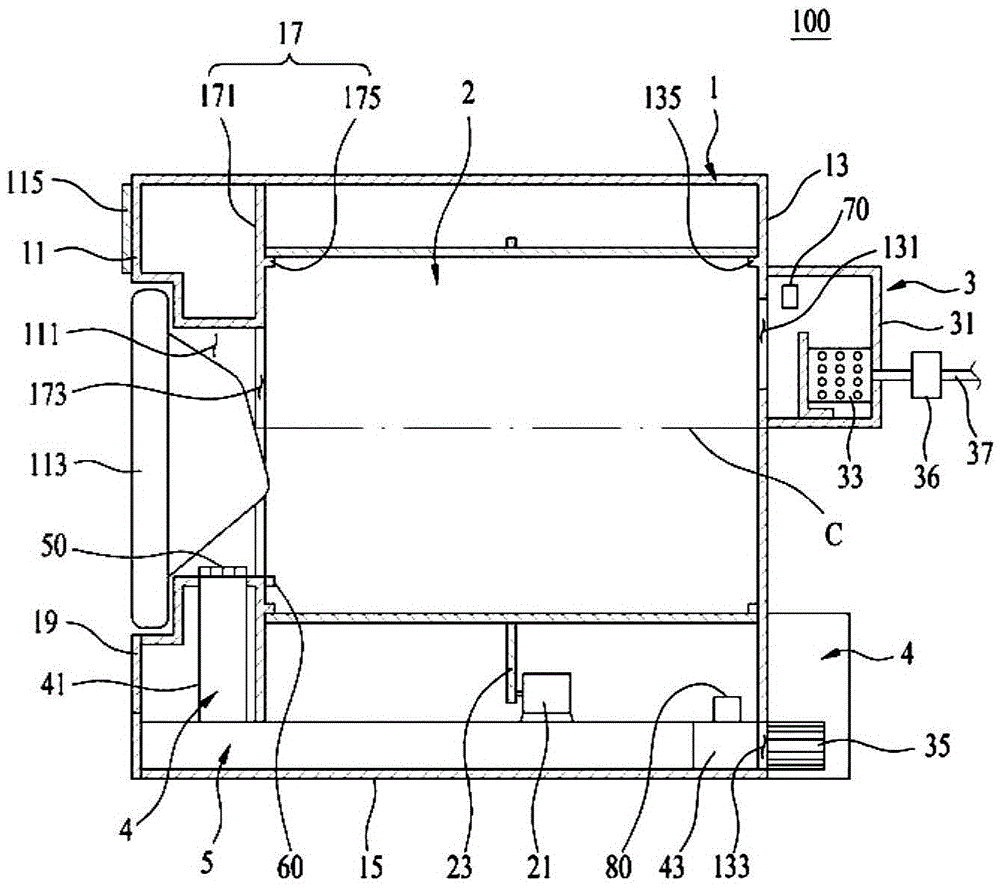

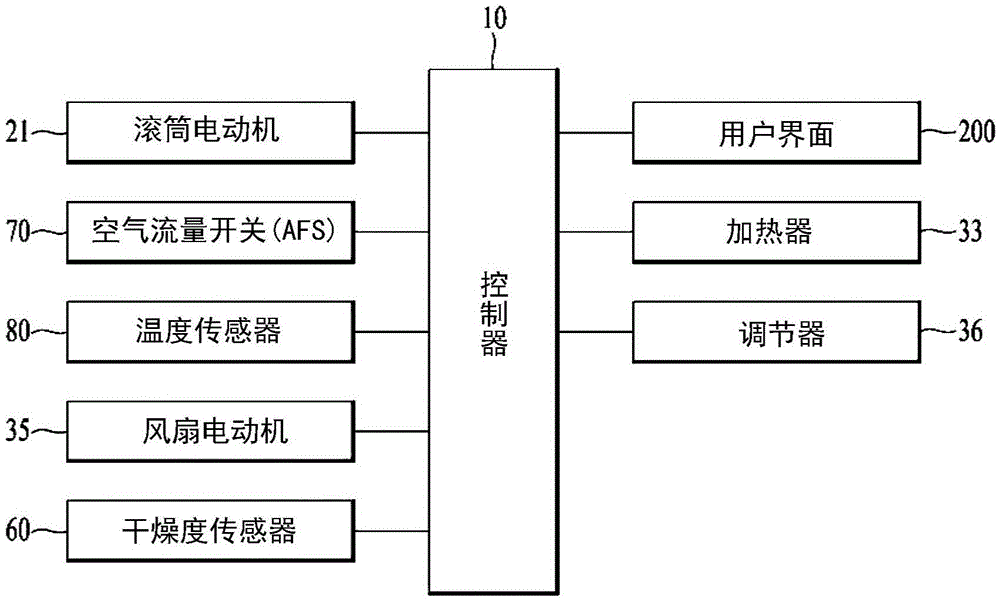

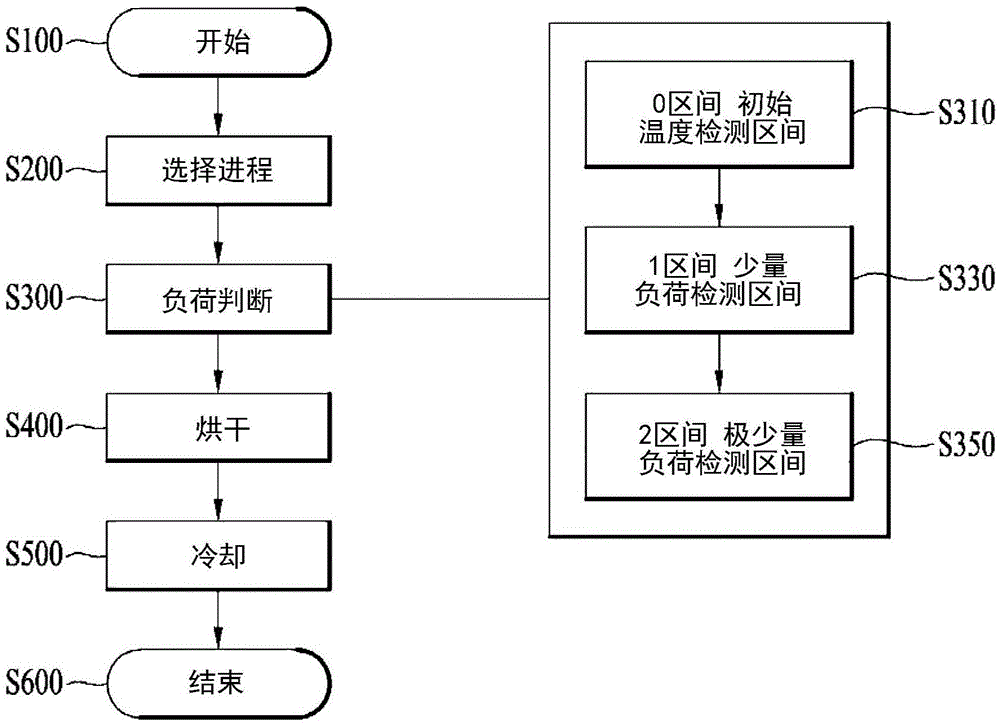

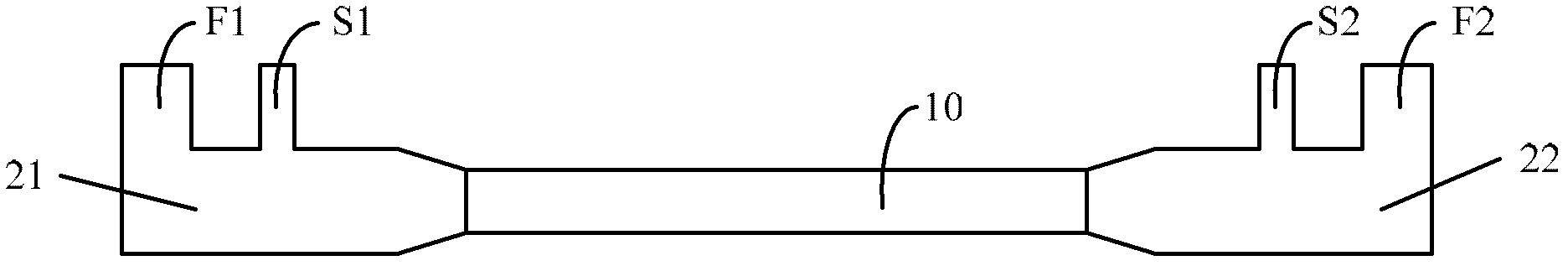

Drying machine

ActiveCN105951405AThe effect of bias is minimizedEasy to controlTextiles and paperLaundry driersEngineeringElectric motor

A method of controlling a drying machine includes a first load decision step for supplying hot air to the inside of a drum by driving a heater and a fan motor together with drive of the drum and determining, based on variation in a temperature of air discharged from the drum, whether a load applied to clothes accommodated in the drum is a temporary small load or a medium and large load, wherein the variation in temperature of air is sensed by a temperature sensor; a second load decision step which is performed selectively after the first load decision step is performed and the load is judged as the temporary small load in the first load decision step, and in which the hot air supply is interrupted, the drum is driven and whether the load is a small load or an extremely small load is judged by using a dryness sensor of the drum; a drying step based on the load determined in the first load decision step or the second decision step.

Owner:LG ELECTRONICS INC

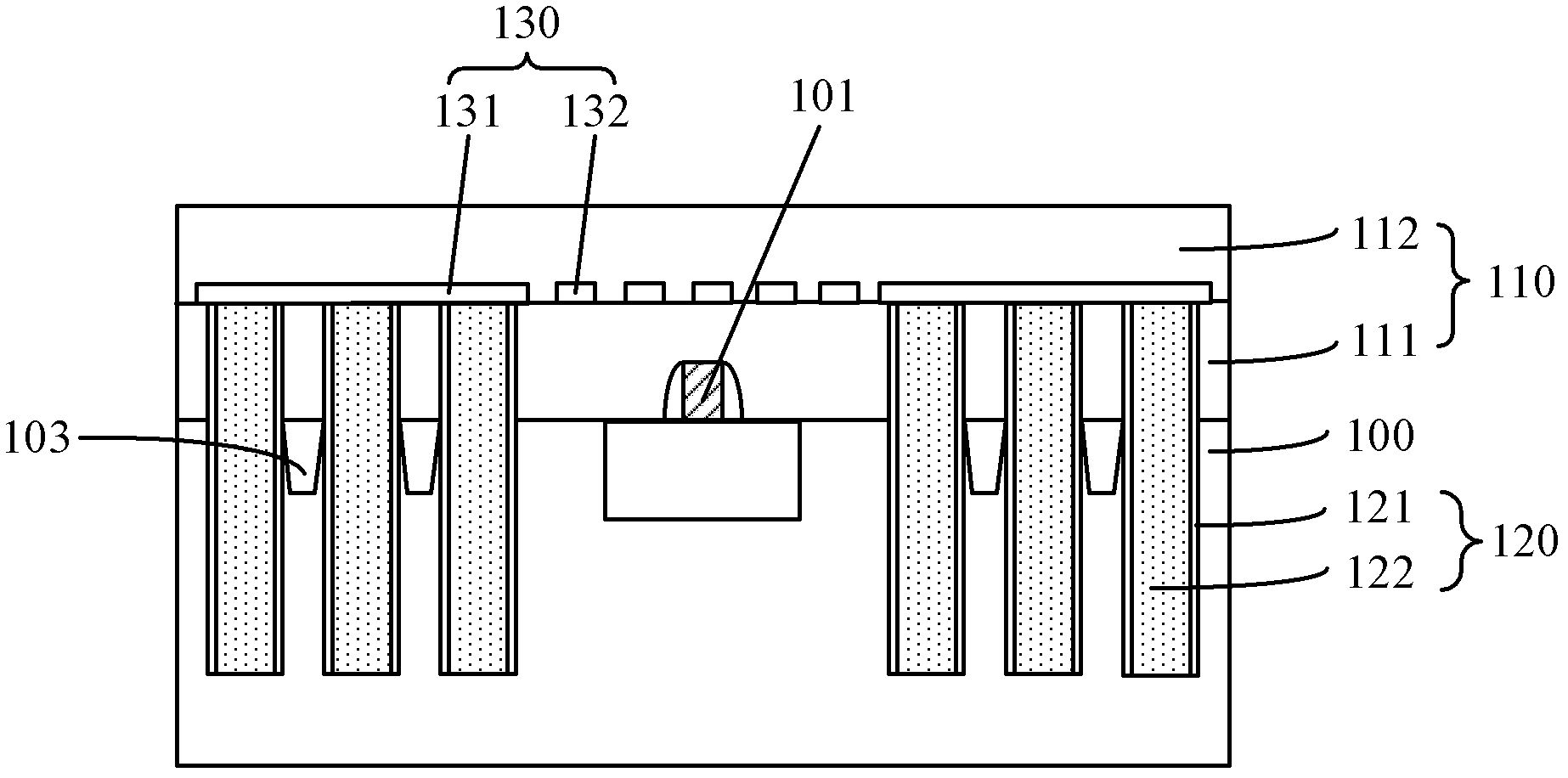

Micro heating device

ActiveCN103187397AHeat controlEvenly heatedSemiconductor/solid-state device detailsSolid-state devicesDielectric layerSemiconductor

The invention discloses a micro heating device which comprises a semiconductor substrate, a device to be detected that is located on the semiconductor substrate, an interlayer dielectric layer located on the surface of the semiconductor substrate, heat conduction grooves located in the semiconductor substrate and the interlayer dielectric layer, and heating structures located in the interlayer dielectric layer, wherein the heat conduction grooves surround the device to be detected; the heating structures are connected with the heat conduction grooves, and generate heat and conduct the heat into the heat conduction grooves; and the heat conduction grooves are utilized to heat the device to be detected. The heat conduction grooves surround the device to be detected, so that the device to be detected is heated uniformly, and temperature of the device to be detected is controlled by changing the heat generated by the heating structures and controlling the heat generated by the heat conduction grooves.

Owner:SEMICON MFG INT (SHANGHAI) CORP

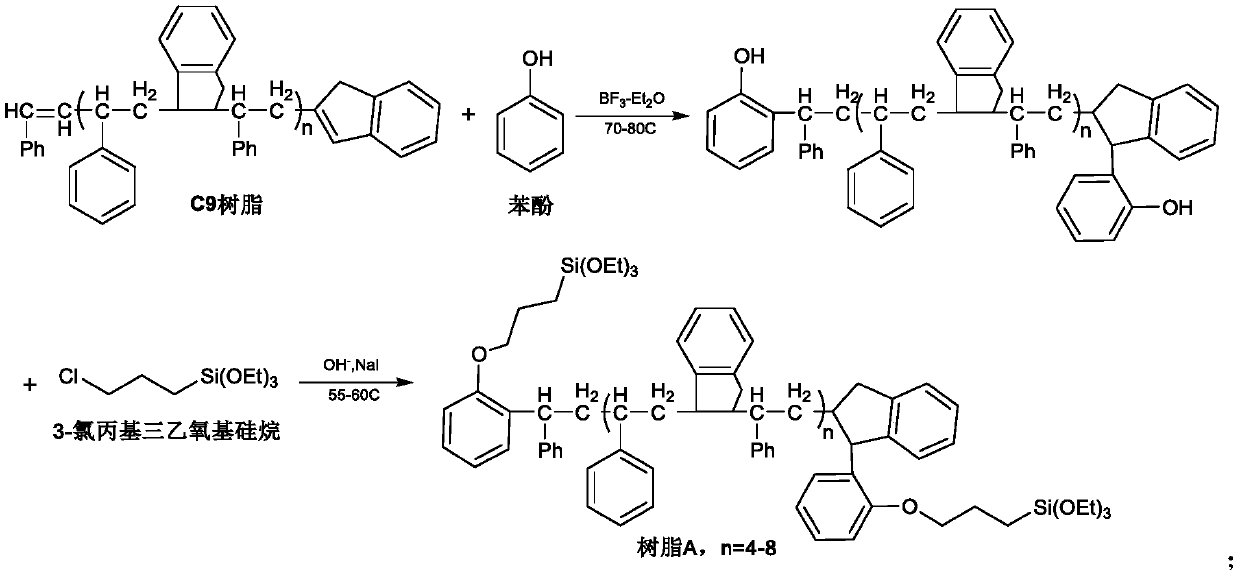

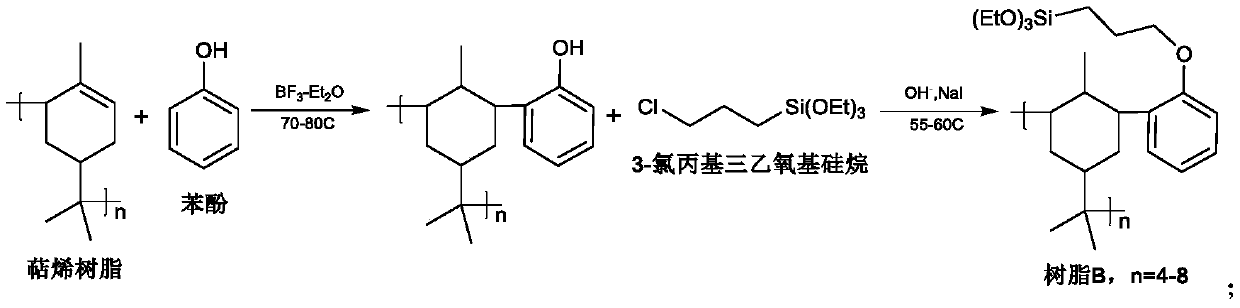

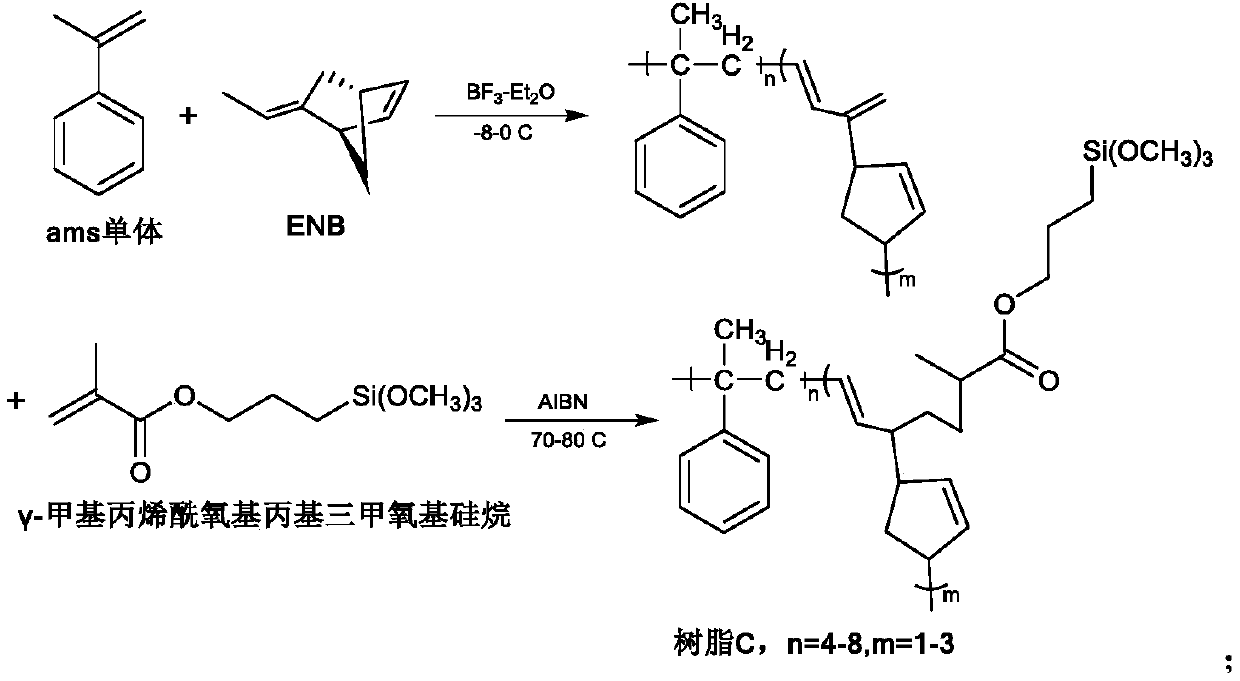

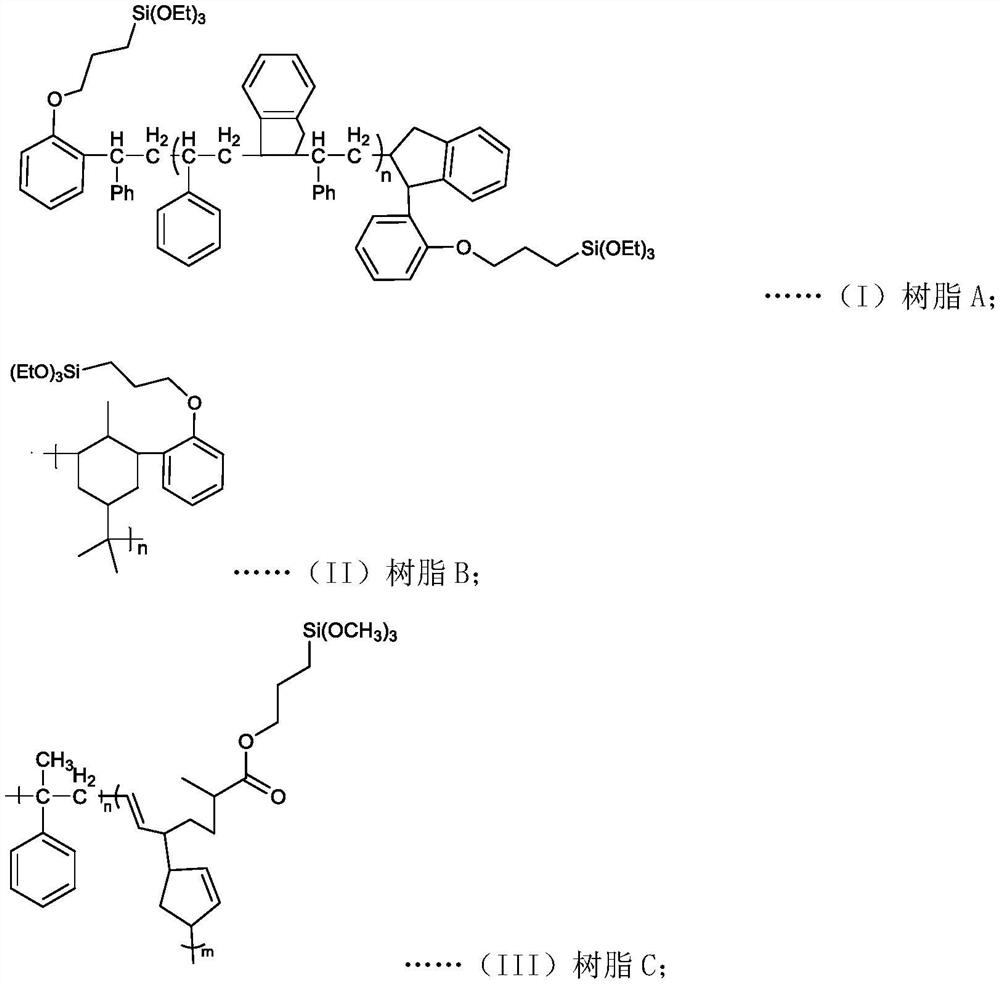

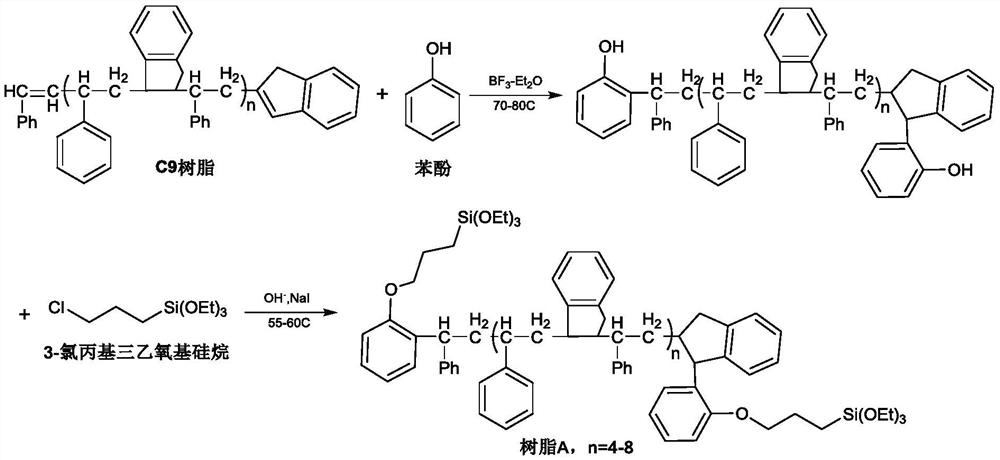

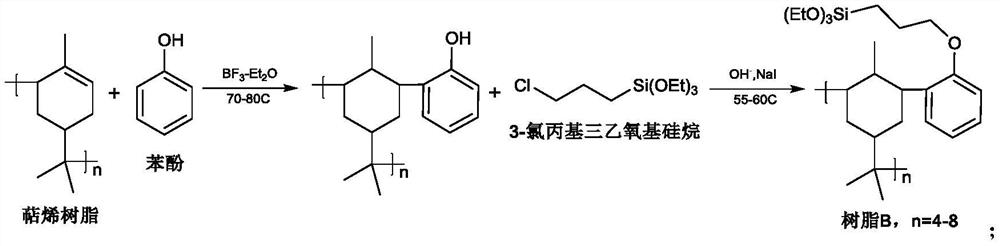

Preparation method for resin for improving wet skid resistance of rubber and application of resin

The invention discloses a preparation method for resin for improving wet skid resistance of rubber. The preparation method comprises the steps: (1) subjecting resin R and a functional group compound Bto a reaction, so as to obtain resin R-B and improve degree of polymerization of the resin R, wherein the resin R is selected from petroleum resin C9, petroleum resin C5, alpha-methylstyrene homopolymerized resin, resin DCPD, terpene resin, pinene resin and copolymerized resin based on alpha-methylstyrene as a principal chain, and the functional group compound B is selected from phenol, cardanol,ethylidene norbornene, rosin, hexa methoxy melamine resin (HMMM) and divinylbenzene; and (2) subjecting the resin R-B to a reaction with silane S, thereby obtaining resin R-B-S. The resin prepared bythe method is used for being added into the rubber, can be effectively dispersed inside the rubber and is distributed in tire treads during vulcanization, and thus, the wet skid resistance of the rubber is remarkably improved.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

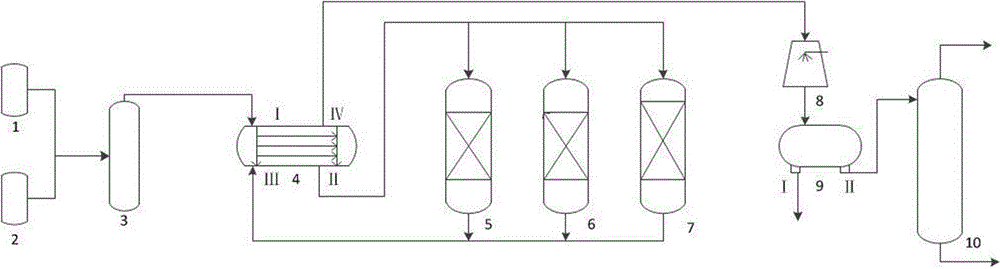

Method for preparing gasoline by using naphtha and methanol

ActiveCN106833730AIncrease profitReduce carbon deposition rateLiquid hydrocarbon mixture productionBio-feedstockAlkanePtru catalyst

The invention relates to the technical field of oil product processing, and particularly relates to a method for preparing gasoline by using naphtha and methanol. According to the method, naphtha and methanol serving as raw materials in a weight ratio of (4-5):1 react with a molecular sieve catalyst at the temperature of 200-500 DEG C, the pressure of 0.1-5.0MPa and a raw material weight space velocity of 0.1-10h<-1>. By adopting the preparation method, circulating air is not adopted for temperature control in a reaction system, and the reaction equipment is simple; saturated alkane, especially straight-chain paraffin, is the ingredient of naphtha, can perform alkylation reaction with methanol under the reaction condition of the method, so that the carbon chain is prolonged, and heavy petroleum ether is realized to become a qualified gasoline component.

Owner:邯郸市飞耀新能源科技有限公司

Perming agent, application of perming agent and perming method

InactiveCN107510207AFully heat stableStructural fasteningCosmetic preparationsHair cosmeticsHeating timeComputer science

The invention discloses a perming agent, application of the perming agent and a perming method, and relates to the technical field of perming. The purpose is to improve the technical problems that by means of an existing perming agent, standard perming conditions cannot be provided focusing on different hair qualities and damage to hair is likely to occur. The perming agent contains a perming medium prepared from water and an acid-base balancing agent in a mass ratio of 10 to 1-10 to 8; in the conditions of the same perming temperature, perming tension and hair piece size, the perming heating time is positively correlated with the use amount of the perming medium. The perming agent provides a premise and a guarantee for datamation of the perming technology. The perming method comprises the following steps that after the use amount of the perming medium, the perming heating time and the diameter of a perming rod are determined, the perming medium is applied on softened hair, and perming is conducted on the determined hair piece according to the determined perming heating time; after a paste preparation is applied, the hair is combed. According to the method, through calculation of the use amount of the perming medium and the perming time, accurate technical guidance and theoretical data can be provided for perming, and the method is beneficial to achieving standardized perming.

Owner:河南省居艺红人工智能科技有限责任公司

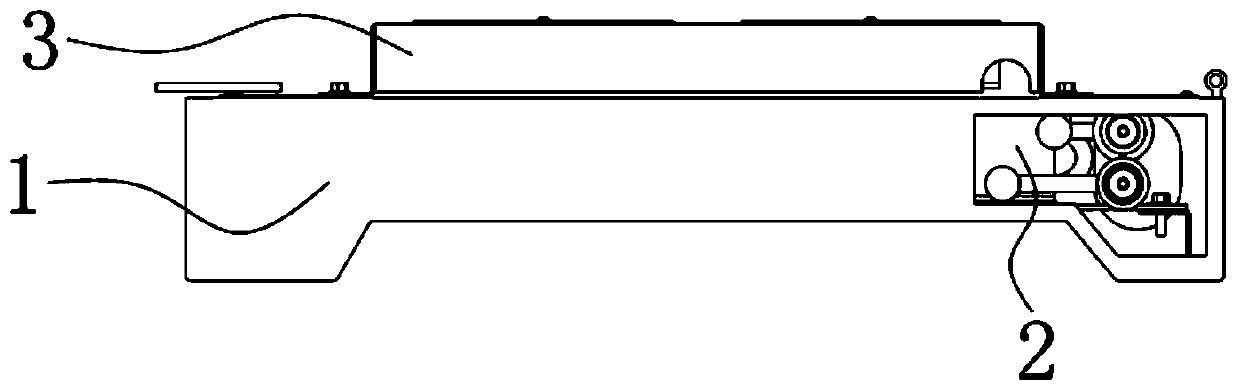

Liquid cooling cabinet door

ActiveCN104994707BReduce energy consumptionAvoid downtimeCooling/ventilation/heating modificationsHigh densityEnergy consumption

Owner:BEIJING XINGDA TECH DEV

Support element for supporting substrate and support device

InactiveCN105097632AAvoid the Mura PhenomenonShow uniformSemiconductor/solid-state device manufacturingElectricityLiquid-crystal display

The invention discloses a support element for supporting a substrate and a support device, and aims at solving the problem that when the support element and the substrate, which are different in temperature, contact with each other, Mura is generated at the contact part, so that a finished liquid crystal display is uneven in display. The support element for supporting the substrate comprises a body with a hollow structure, a temperature sensor, a heating component, a heat-conducting liquid, a first lead and a second lead, wherein the temperature sensor, the heating component and the heat-conducting liquid are arranged in the hollow structure of the body; the first lead is connected to the temperature sensor; the second lead is connected to the heating component; the temperature sensor is attached to the inner wall of the body and is used for sensing the temperature data of the body; the heating component is used for providing heat energy for the heat-conducting liquid; the heating component and the heat-conducting liquid are insulated with each other; the heat-conducting liquid is used for transferring the heat energy provided by the heating component to the body; the first lead and the second lead extend outside the body from the hollow structure of the body; the first lead is used for transmitting the temperature data sensed by the temperature sensor; and the second lead is used for supplying electricity to the heating component.

Owner:BOE TECH GRP CO LTD +1

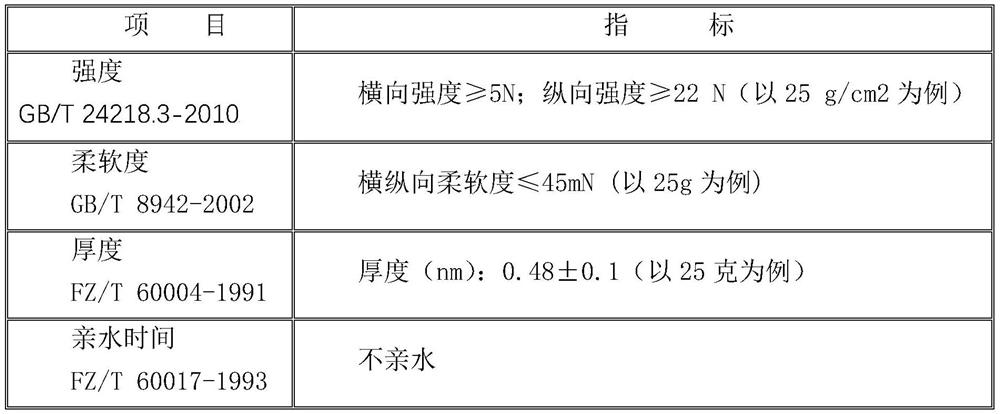

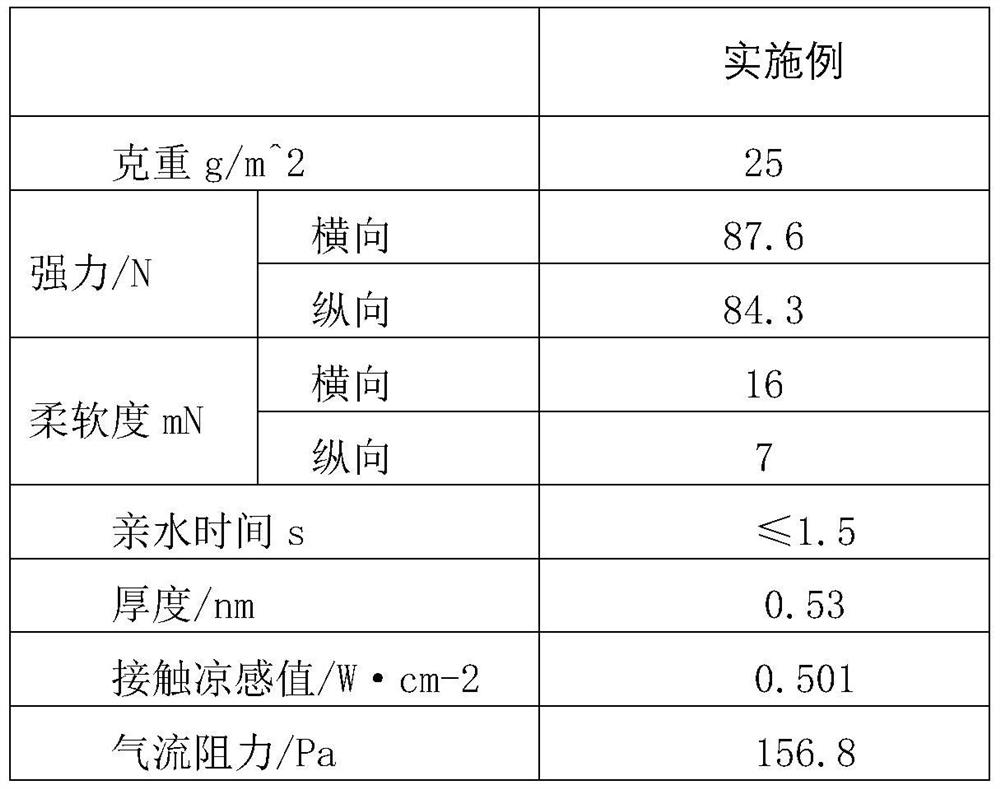

Special hot air nonwoven fabric for face masks and manufacturing method of special hot air nonwoven fabric for face masks

InactiveCN111663244AReasonable formulaReduce voidsHeating/cooling textile fabricsNon-woven fabricsPolymer scienceNonwoven fabric

The invention provides a special hot air nonwoven fabric for face masks and a manufacturing method of the special hot air nonwoven fabric for face masks. The hot air nonwoven fabric is made of PE / PETsheath-core composite fiber of a concentric structure, wherein a sheath layer material of the PE / PET sheath-core composite fiber is PE; a core layer material is PET; the PE / PET sheath-core composite fiber comprises a first ingredient and a second ingredient; the first ingredient is PE / PET composite fiber with the thickness of 2 D, the length of 38 mm and the sheath-core ratio of 40 / 60; the secondingredient is PE / PET composite fiber with the thickness of 1.5 D, the length of 38 mm and the sheath-core ratio of 50 / 50; and the mass ratio of the first ingredient to the second ingredient is 2:8. The special hot air nonwoven fabric for face masks and the manufacturing method of the special hot air nonwoven fabric for face masks provided by the invention have the advantages that the prepared hotair nonwoven fabric has the good fluffy effect and good air permeability; when the special hot air nonwoven fabric is applied to face mask products, the wearing comfortable feeling is improved; the cooling feeling effect at the inner side of the face mask is also realized; the problems of sultry and damp feelings, allergy and the like generated when the weather is hot or the face masks are worn for a long time are solved; the manufacturing method is simple; the flexibility is high; and good development prospects are realized.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

Tandem type heat compensation and heat regeneration combined photo-thermal coupling methane/carbon dioxide dry reforming system and method based on same

PendingCN113683055AIncrease production capacityEmission reductionHydrogenCarbon compoundsHeat regenerationGas blending

The invention discloses a tandem type heat compensation and heat regeneration combined photo-thermal coupling methane / carbon dioxide dry reforming system and a method based on the same, and belongs to the field of synthesis gas preparation through carbon dioxide / methane dry reforming. The system mainly comprises a photo-thermal dry reforming unit, a product separation unit, a flue gas purification unit, a heat exchanger and a gas mixing device. The flue gas purification unit is used for purifying the tail gas of a power plant, carbon dioxide and methane in the tail gas are recycled, purified gas enters a heat exchanger to be preheated and then is fully mixed in the gas mixing device, then the photo-thermal dry reforming unit is used for preparing synthesis gas, emission of carbon dioxide can be reduced, and unreacted carbon dioxide and methane are separated out through the product separation unit, and are input into a photo-thermal coupler for continuous reaction, so that the energy utilization rate is improved. Meanwhile, the photo-thermal coupling reactor can reduce the reaction temperature, and process gas regenerative heat is utilized to preheat raw materials after the reaction is completed. The dual effects of carbon emission reduction and energy consumption reduction can be effectively realized.

Owner:XI AN JIAOTONG UNIV

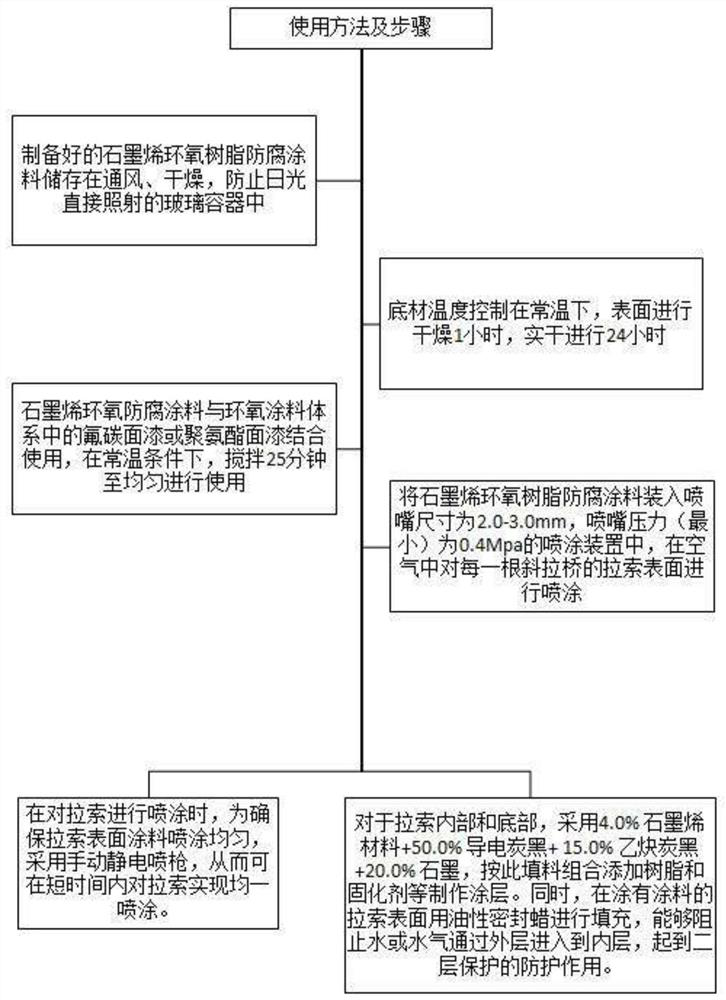

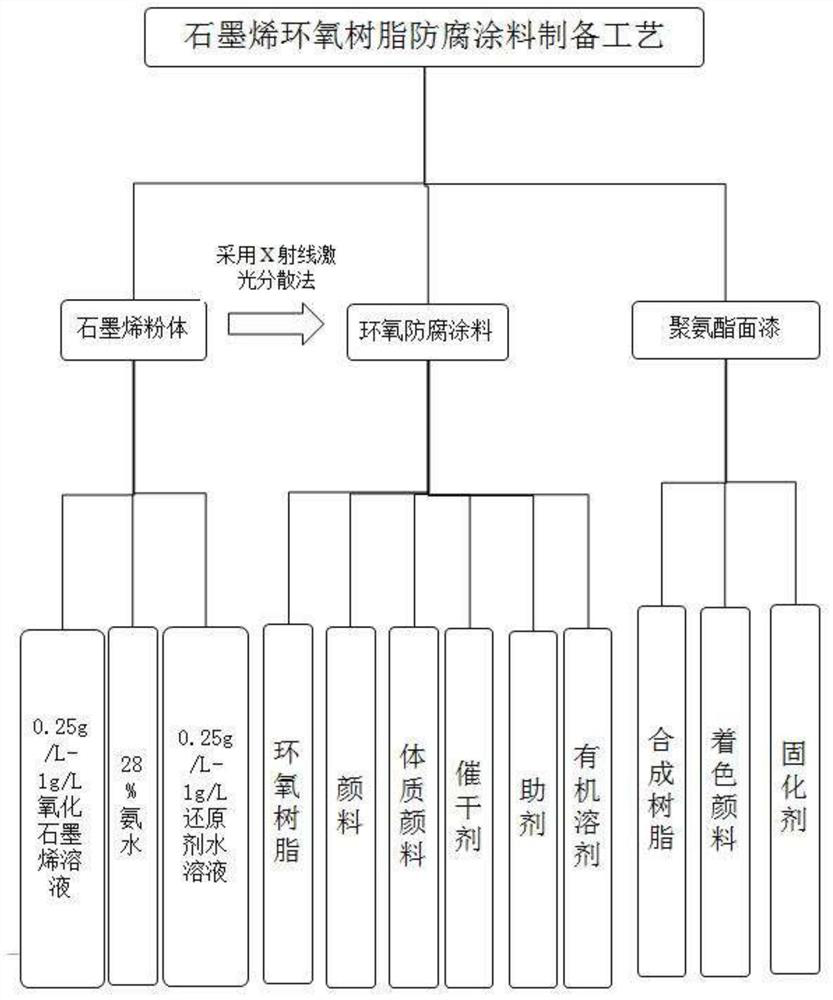

Preparation method and application method of composite anticorrosive coating for stay cable of cable-stayed bridge

InactiveCN113308172AImprove liquidityReduce thicknessAntifouling/underwater paintsPaints with biocidesEpoxyCoating system

The invention discloses a preparation method and an application method of a composite anticorrosive coating for a stay cable of a cable-stayed bridge. According to the invention, a graphene epoxy resin anticorrosive coating is prepared by dispersing graphene in an ammonia water solvent by adopting an X-ray laser dispersion method so as to prepare a graphene dispersion liquid, adding an anti-precipitating agent, and subjecting a formed mixture and waterborne epoxy resin to magnetic stirring and mixing, wherein the graphene dispersed in the coating is used as an anti-corrosion barrier so as to improve the corrosion resistance of the composite coating. The composite anticorrosive coating can endow traditional epoxy anticorrosive coatings with a part of special functions, including ultraviolet resistance, wear resistance, antibacterial property and the like, which are not possessed by the traditional epoxy anticorrosive coatings. Meanwhile, the X-ray laser dispersion method is adopted, so the graphene can be dispersed more effectively, and the corrosion resistance of the coating is greatly improved; and the coating can be used in combination with fluorocarbon finish paint or polyurethane finish paint in an epoxy coating system, color changing is conducted on a primer paint film through the finish paint so as to adjust the film forming color of the coating, and therefore, the corrosion resistance and the attractive appearance of the stay cable of the cable-stayed bridge are greatly improved.

Owner:NANJING INST OF TECH

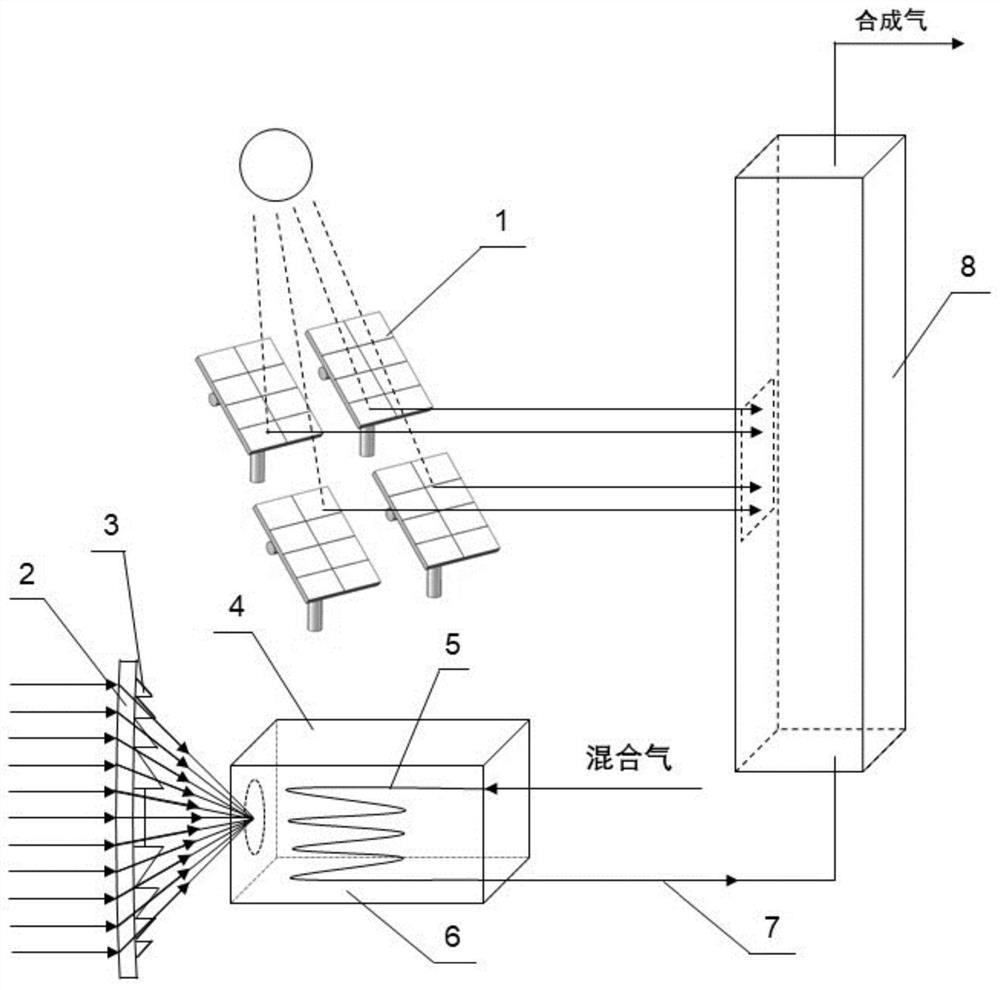

Solar photo-thermal coupling utilization system suitable for methane dry reforming reaction and method thereof

PendingCN113620243ARealization of light and heat coupling utilizationEffective use of photothermal couplingSolar heating energyHydrogenPtru catalystThermodynamics

The invention discloses a solar photo-thermal coupling utilization system suitable for a methane dry reforming reaction, and belongs to the technical field of photo-thermal utilization of solar energy in methane dry reforming production of synthesis gas. The system is composed of a heliostat, a curved surface optical filter, a curved surface Fresnel transmission type condenser, a heat storage box, a coiled pipe, liquid metal, a heat preservation pipeline and a methane dry reforming reactor. Sunlight is converted into parallel light through the heliostat at the upper end of the system, and the parallel light enters a photo-thermal catalyst in the methane dry reforming reactor through glass; parallel light at the lower end is subjected to light condensation and heat collection through a curved-surface light filter and a curved-surface Fresnel transmission-type condenser to be supplied to liquid metal in the heat storage box, the liquid metal exchanges heat with mixed gas in a coiled pipe through the coiled pipe, and the preheated mixed gas leaves the heat storage box and then flows into the methane dry reforming reactor through the heat preservation pipeline; and under the action of the photo-thermal catalyst, synthesis gas is generated through reaction, so that photo-thermal coupling utilization of solar energy in the methane dry reforming reaction is realized.

Owner:XI AN JIAOTONG UNIV

A kind of preparation method and application of resin for improving wet skid resistance of rubber

Provided is a preparation method for resin for improving wet skid resistance of rubber, the first step: subjecting R resin and B functional group compound to a reaction, to obtain R-B resin and improve degree of polymerization of R resin; wherein R resin is selected from C9 petroleum resin, C5 petroleum resin, α-methylstyrene homopolymer resin, DCPD resin, terpene resin, pinene resin or copolymerized resin based on α-methylstyrene as a principal chain, B functional group compound is selected from phenol, cardanol, ethylidene norbornene (ENB), rosin, hexa methoxy melamine resin (HMMM) or divinylbenzene; the second step: subjecting R-B resin to a reaction with S silane, to obtain R-B-S resin. The prepared resin is used for being added into the rubber, can be effectively dispersed inside the rubber and is distributed in tire tread during vulcanization, which remarkably improves the wet skid resistance of the rubber.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

A support and a support device for supporting a substrate

InactiveCN105097632BAvoid the Mura PhenomenonImprove yieldSemiconductor/solid-state device manufacturingElectricityLiquid-crystal display

The invention discloses a support element for supporting a substrate and a support device, and aims at solving the problem that when the support element and the substrate, which are different in temperature, contact with each other, Mura is generated at the contact part, so that a finished liquid crystal display is uneven in display. The support element for supporting the substrate comprises a body with a hollow structure, a temperature sensor, a heating component, a heat-conducting liquid, a first lead and a second lead, wherein the temperature sensor, the heating component and the heat-conducting liquid are arranged in the hollow structure of the body; the first lead is connected to the temperature sensor; the second lead is connected to the heating component; the temperature sensor is attached to the inner wall of the body and is used for sensing the temperature data of the body; the heating component is used for providing heat energy for the heat-conducting liquid; the heating component and the heat-conducting liquid are insulated with each other; the heat-conducting liquid is used for transferring the heat energy provided by the heating component to the body; the first lead and the second lead extend outside the body from the hollow structure of the body; the first lead is used for transmitting the temperature data sensed by the temperature sensor; and the second lead is used for supplying electricity to the heating component.

Owner:BOE TECH GRP CO LTD +1

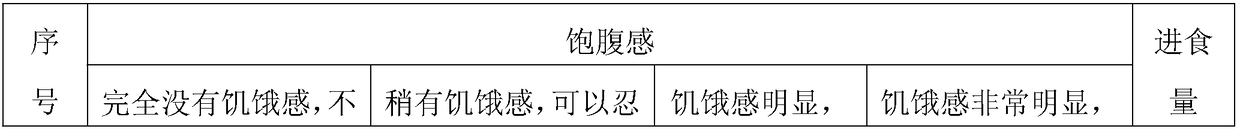

High-energy meal replacement composition capable of reducing weight, and preparation method and application of high-energy meal replacement composition capable of reducing weight

The invention relates to the technical field of functional health-care products, in particular to a high-energy meal replacement composition capable of reducing weight, and a preparation method and application of the high-energy meal replacement composition capable of reducing weight. According to the high-energy meal replacement composition capable of reducing weight, a camellia oil extract and fresh ginger essential oil are used as effective components, and the high-energy meal replacement composition capable of reducing weight is rich in unsaturated fatty acids, vitamin A, vitamin B, vitamin C, vitamin E, calcium, iron, zinc, carotene, and various trace elements beneficial to human bodies, so that during daily drinking, balanced nutrition is guaranteed; besides, the high-energy meal replacement composition capable of reducing weight has good oxygen enrichment capacity, can resist hypoxia and resist weariness, provides enough energy for the human bodies, and has the characteristics of being low in calorie and capable of generating continuous satiety; few high-energy meal replacement composition capable of reducing weight is eaten, but the high-energy meal replacement compositioncapable of reducing weight is nutritive and high in value, and the appetite and the calorie can be strictly and accurately controlled; and besides, the high-energy meal replacement composition capableof reducing weight is convenient to eat and contributes to health and reducing weight.

Owner:袁浩卿

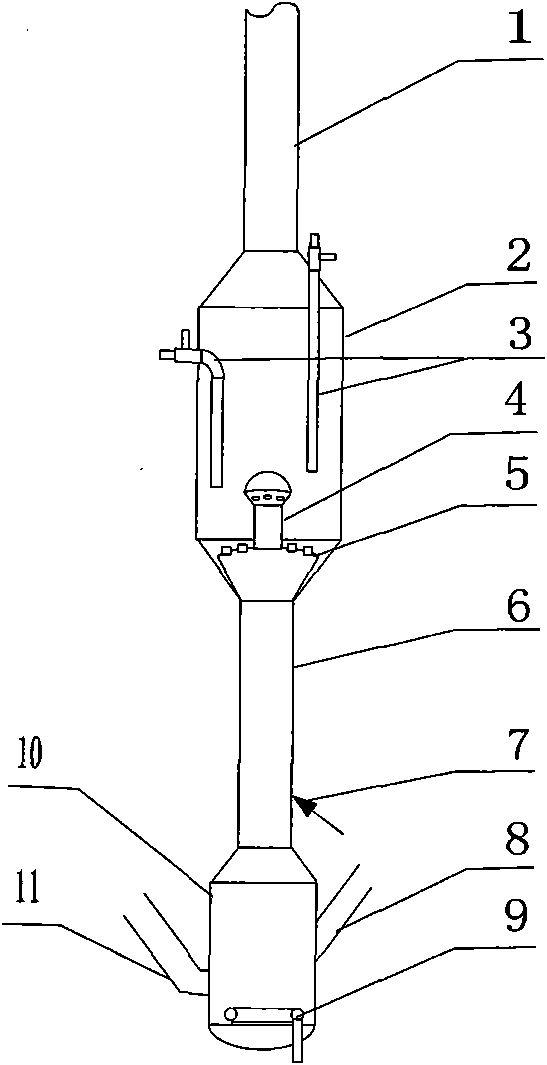

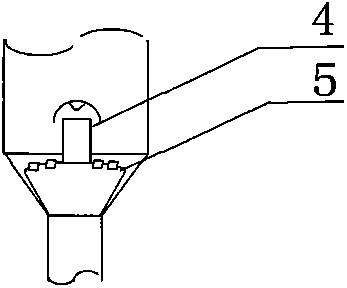

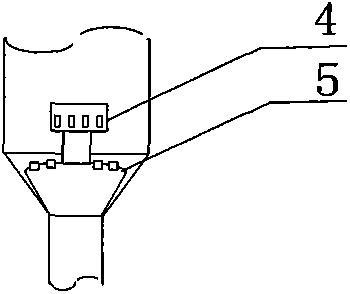

Heavy oil catalytic cracking method and heavy oil catalytic cracking equipment

InactiveCN104277861AHigh activityRaise feed mixing temperatureCatalytic crackingHydrocarbon oils treatmentFuel oilPetrochemical

The invention relates to a heavy oil catalytic cracking method and belongs to the technical field of petrochemical engineering, and the heavy oil catalytic cracking method is used for solving the coking problem of a heavy oil catalytic cracking riser and a settler as well as reducing the coke generating ratio of the device, improving the product yield and improving the product quality. The method comprises the following steps: feeding a catalyst; feeding heavy raw material oil; vaporizing the raw material oil; carrying out gas-solid contact; carrying out a catalytic cracking reaction; and carrying out a gas-solid separation process. The method is characterized by improving the catalyst / oil ratio, the mixing temperature of a feeding section, the catalyst activity in the catalytic cracking process and the vaporization rate of the fed heavy oil by virtue of heat taking in the middle of a riser reactor. The method has the advantages of improving the catalyst activity in the catalytic cracking process as well as the vaporization rate of the fed heavy oil, reducing the non-vaporized oil, preventing the riser and the settler from coking, reducing the coke yield, improving the product yield and improving the product quality. The invention further provides a combined distributor and middle heat taking equipment of the riser for realizing the method. The invention relates to a catalytic cracking device for processing heavy oil.

Owner:刘英聚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com