Patents

Literature

94results about How to "Structural fastening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

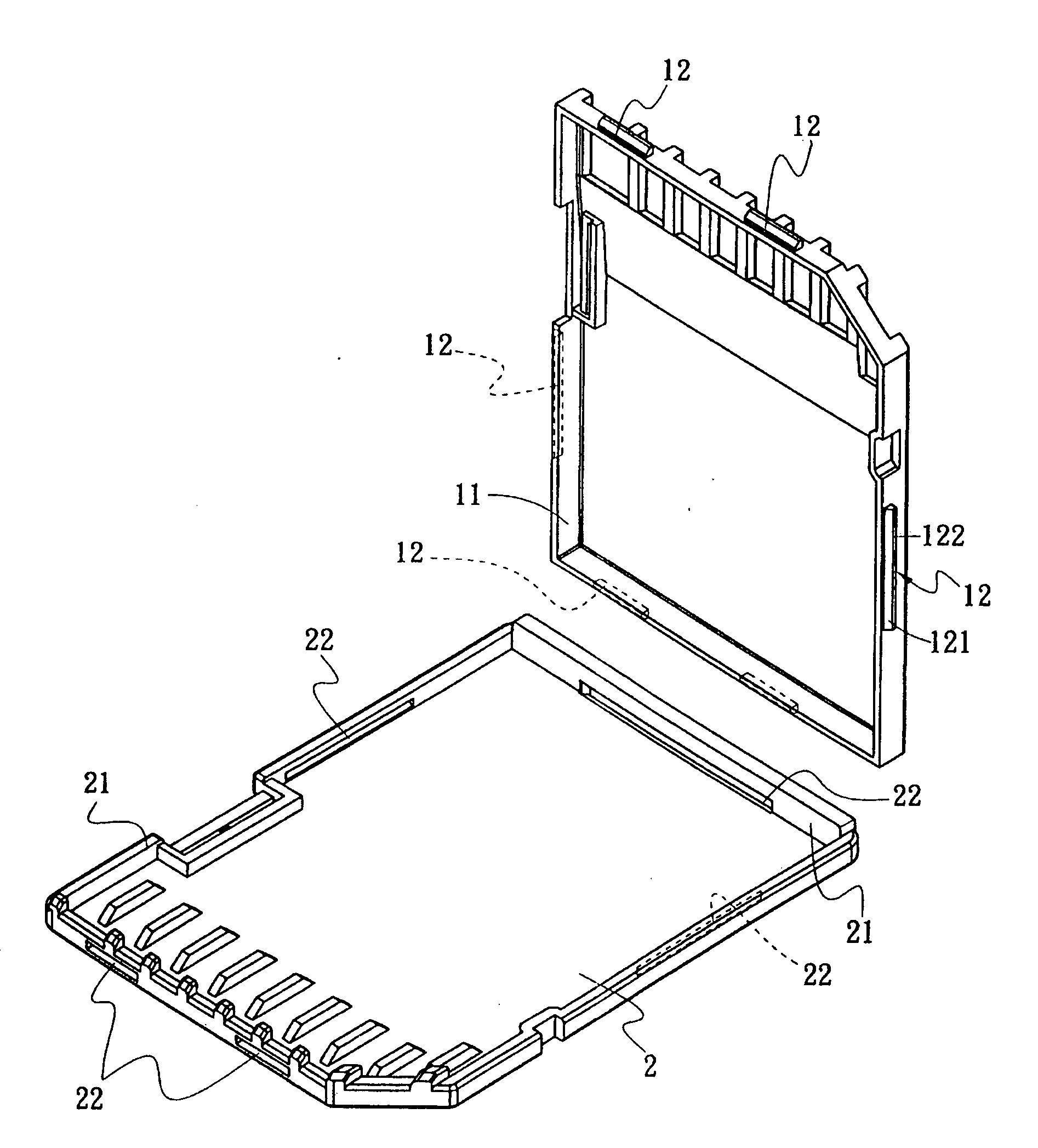

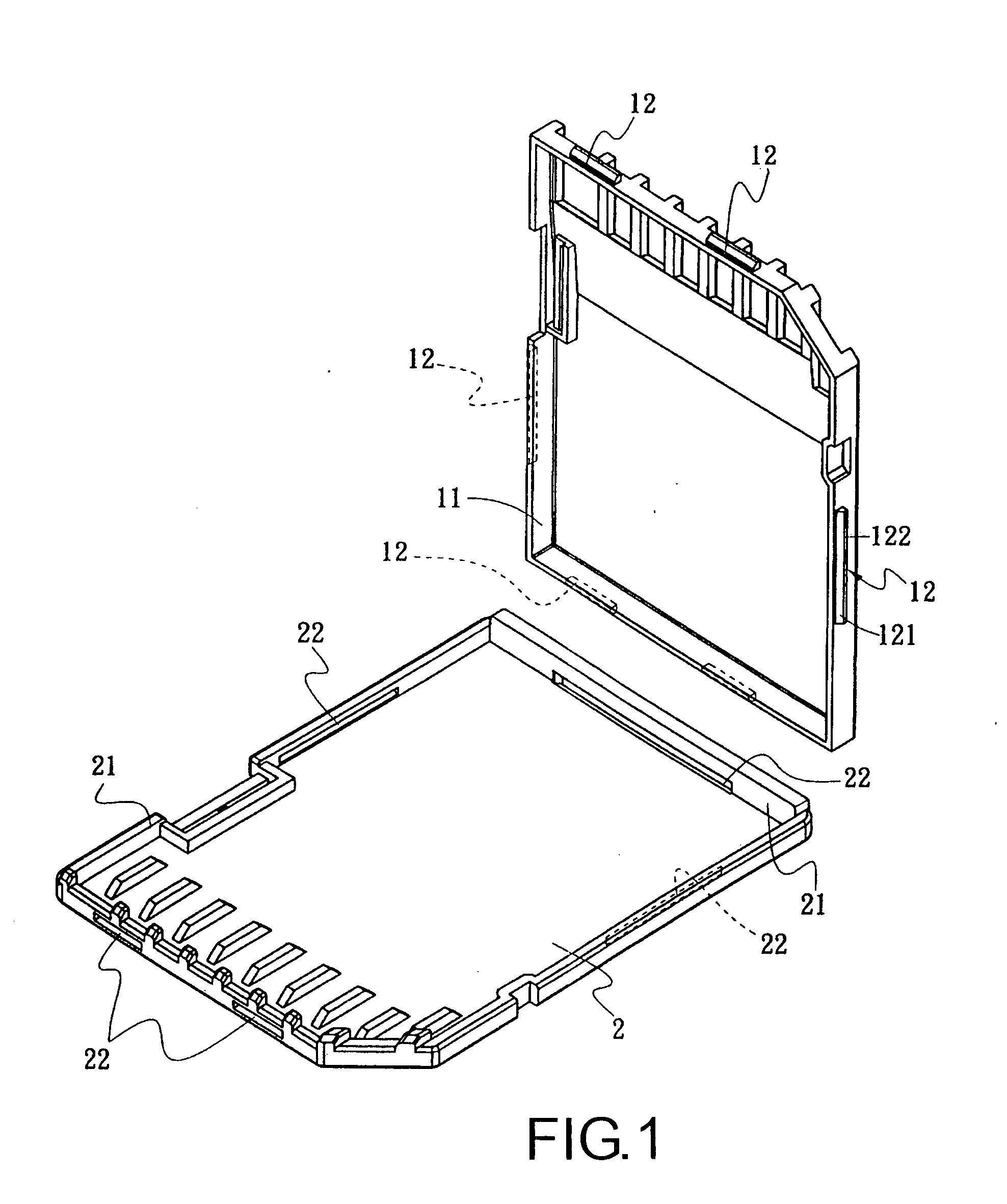

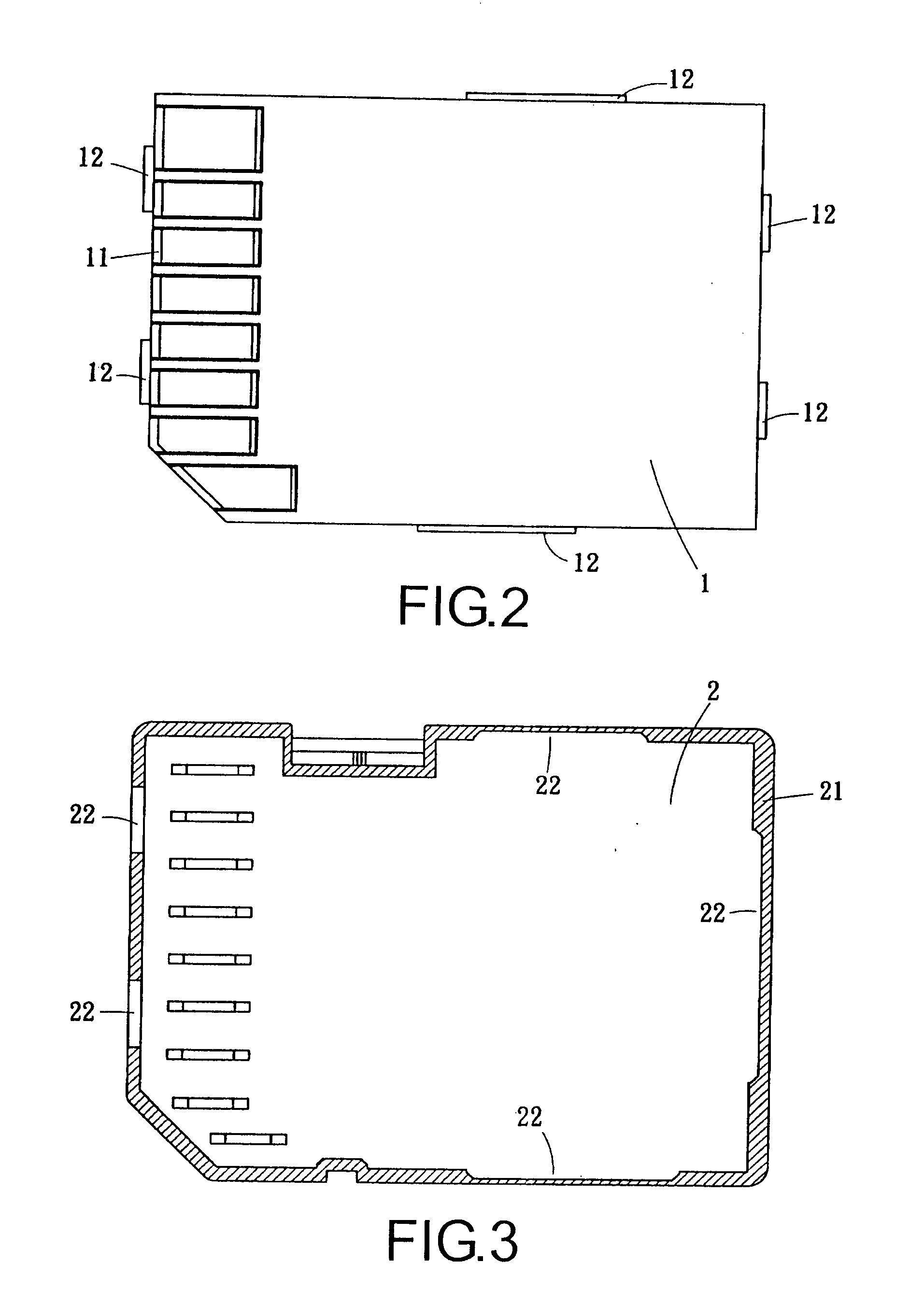

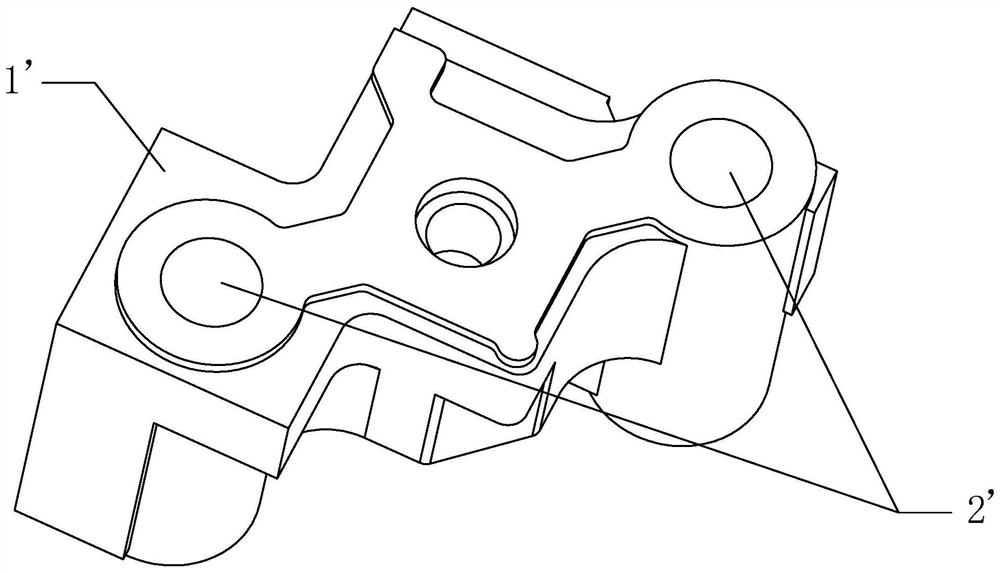

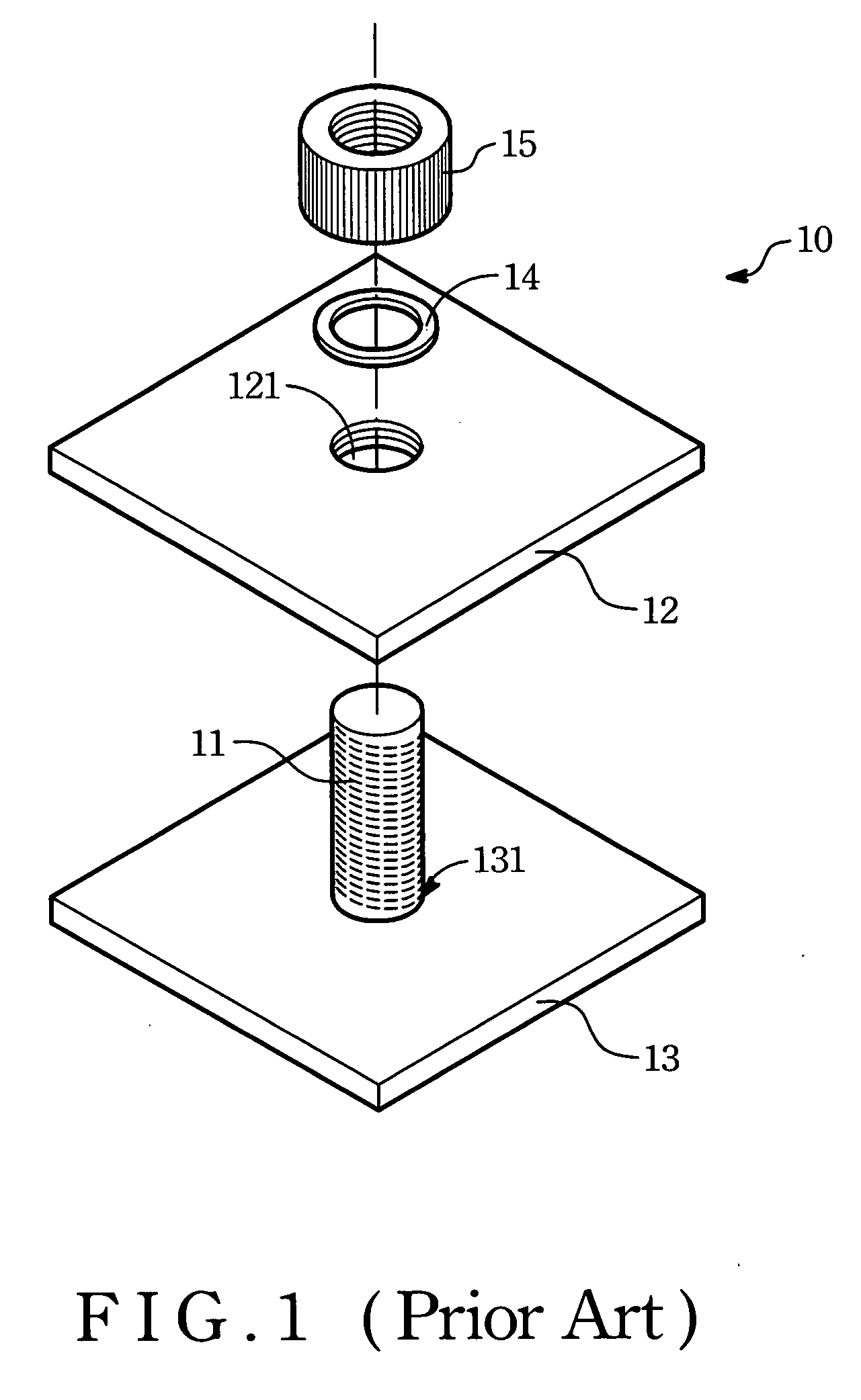

Fastening structure for memory card

InactiveUS20060003609A1Simplify the assembly processStructural fasteningPrinted circuitsRecord carriers used with machinesEngineeringMechanical engineering

Owner:HWANG TIEN WAN

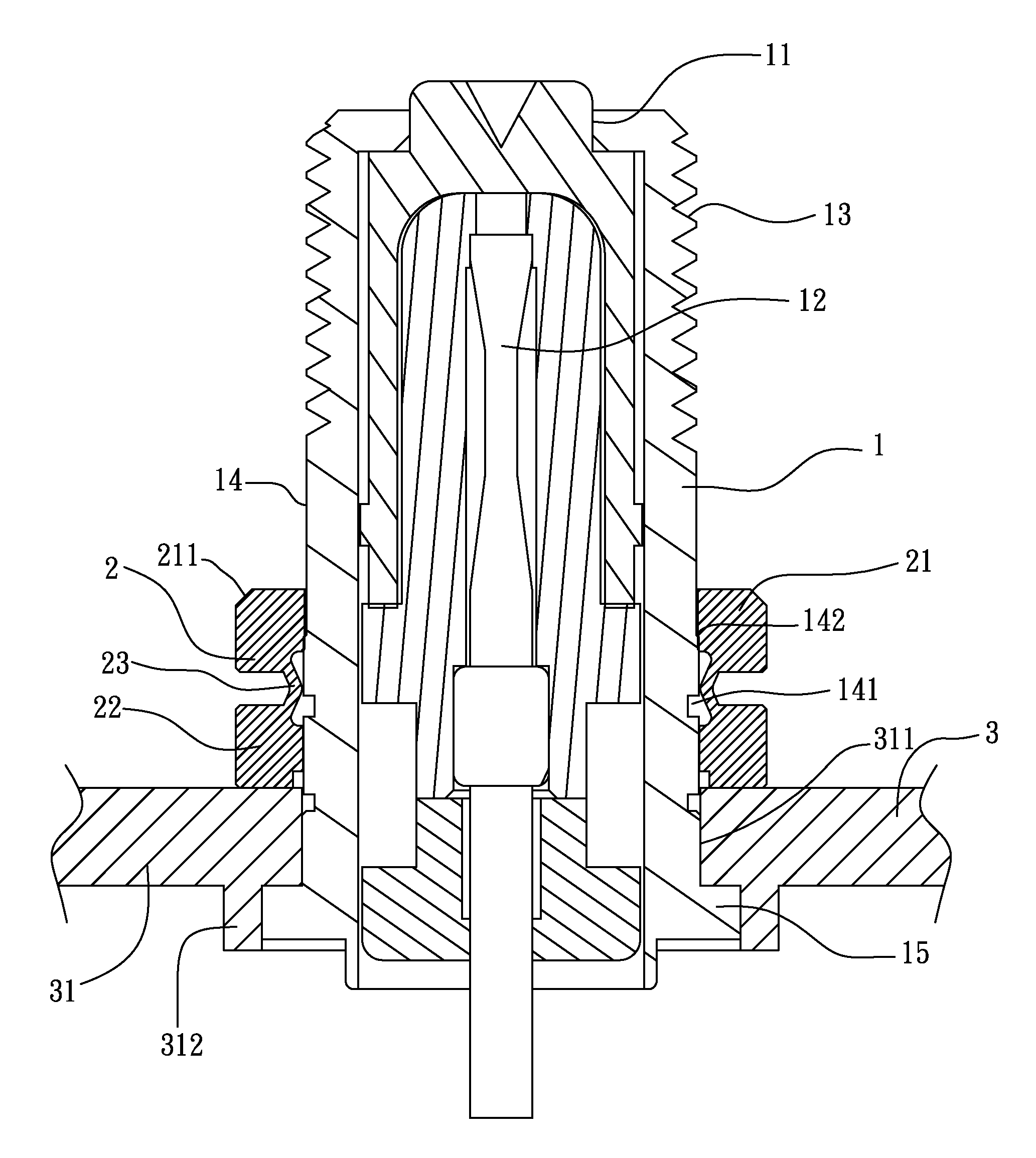

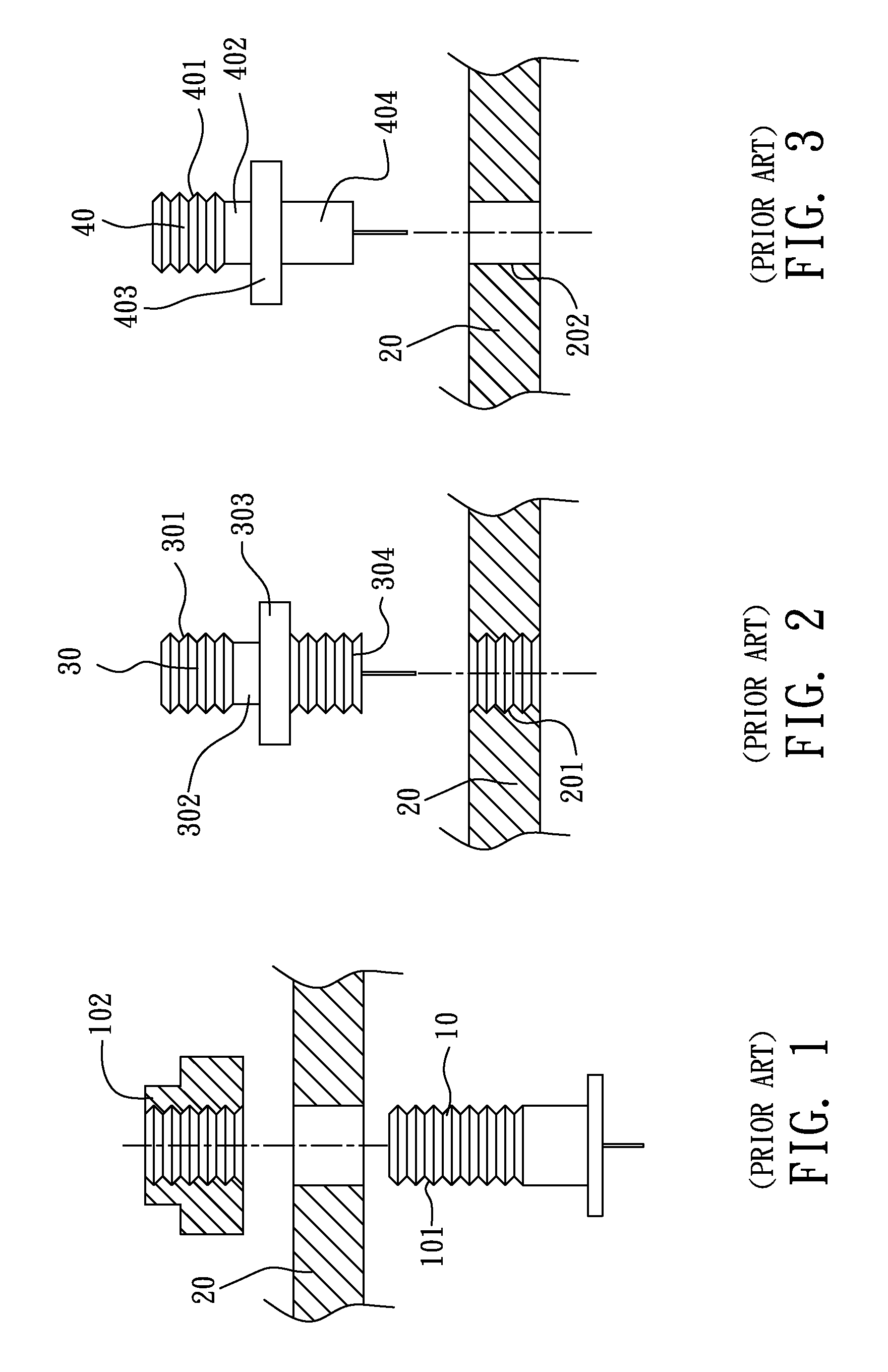

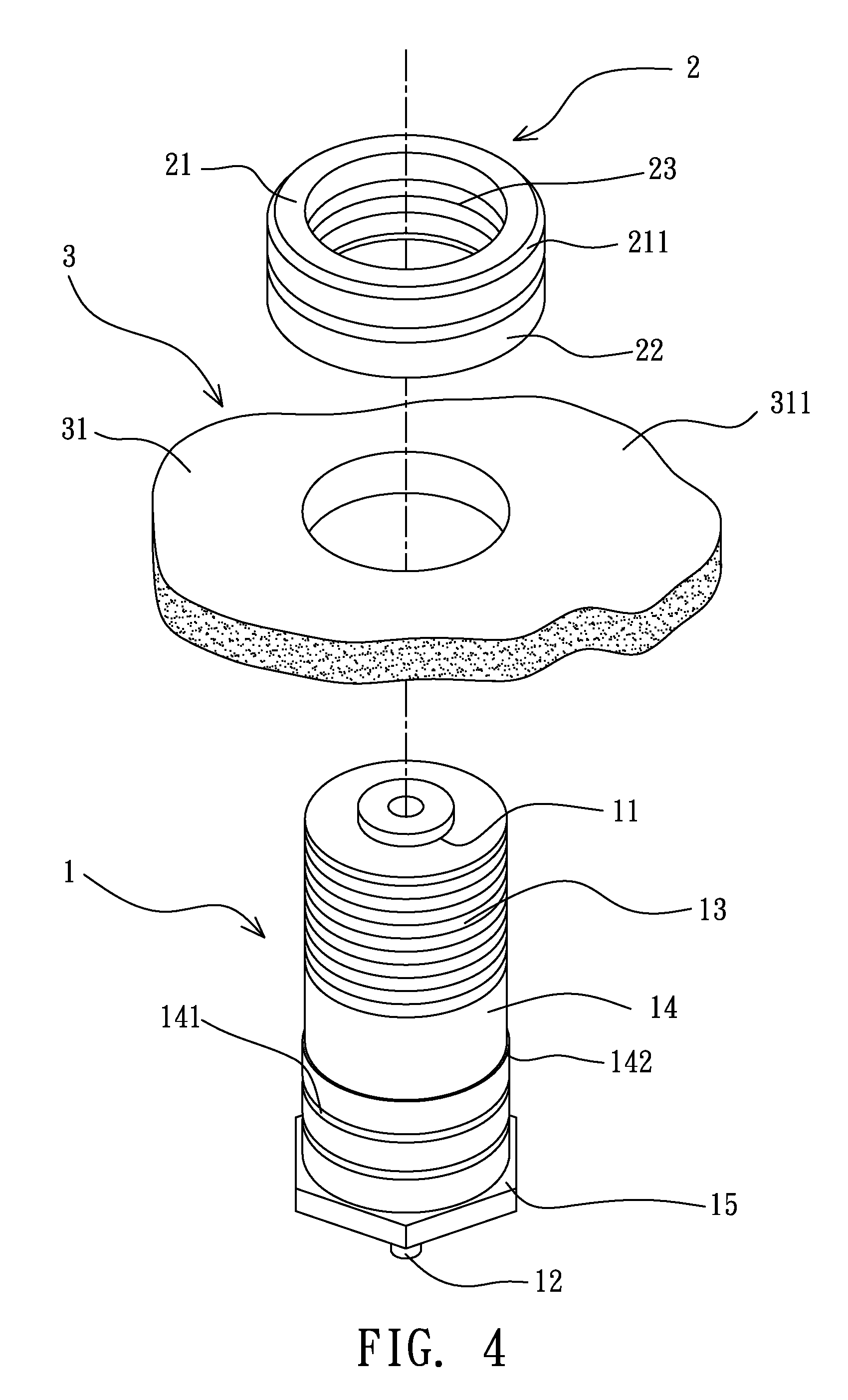

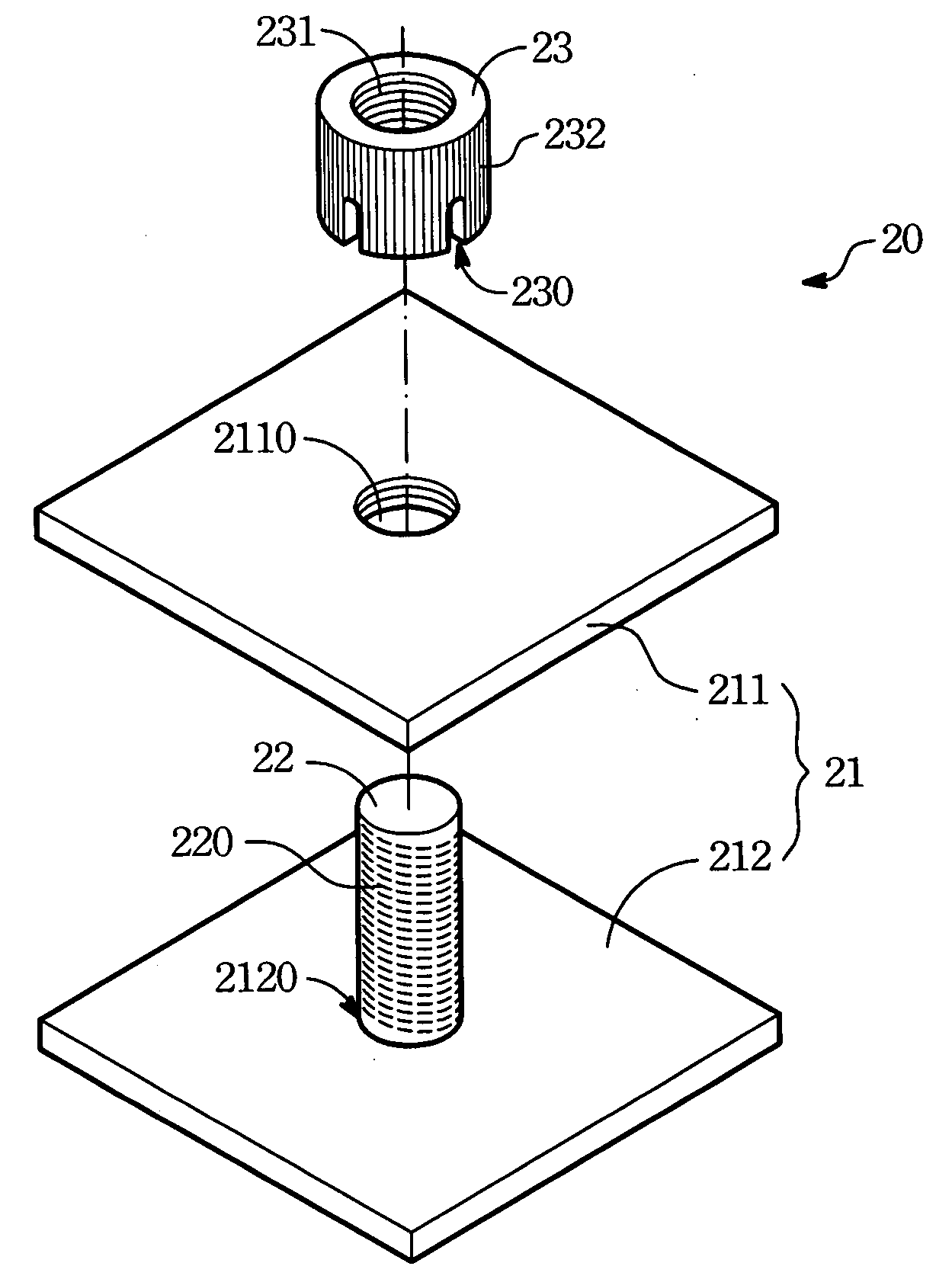

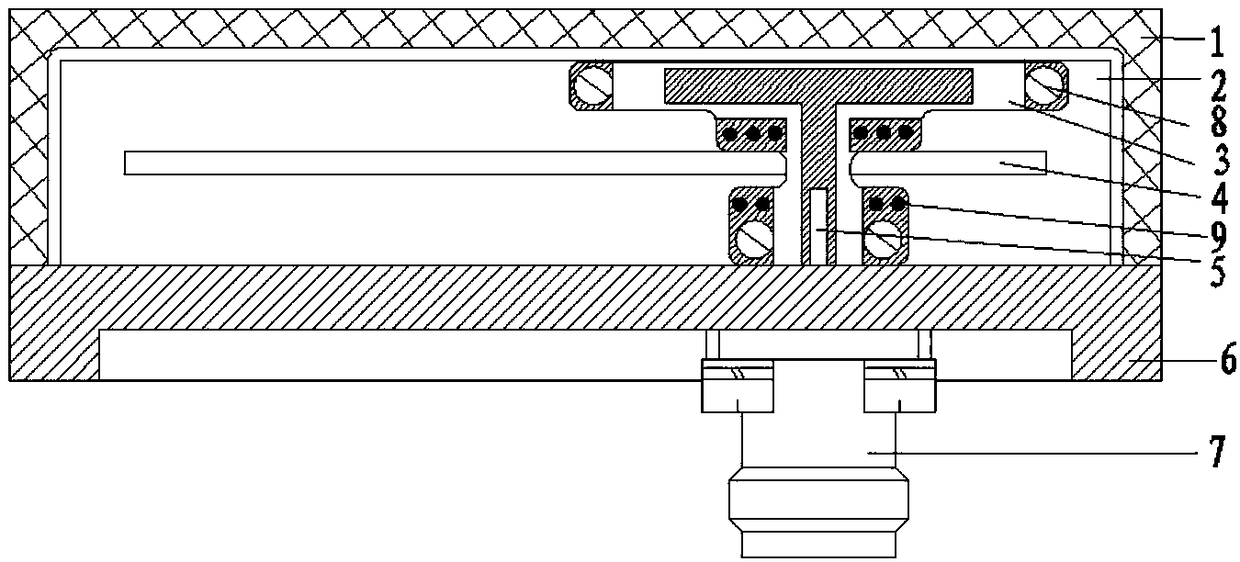

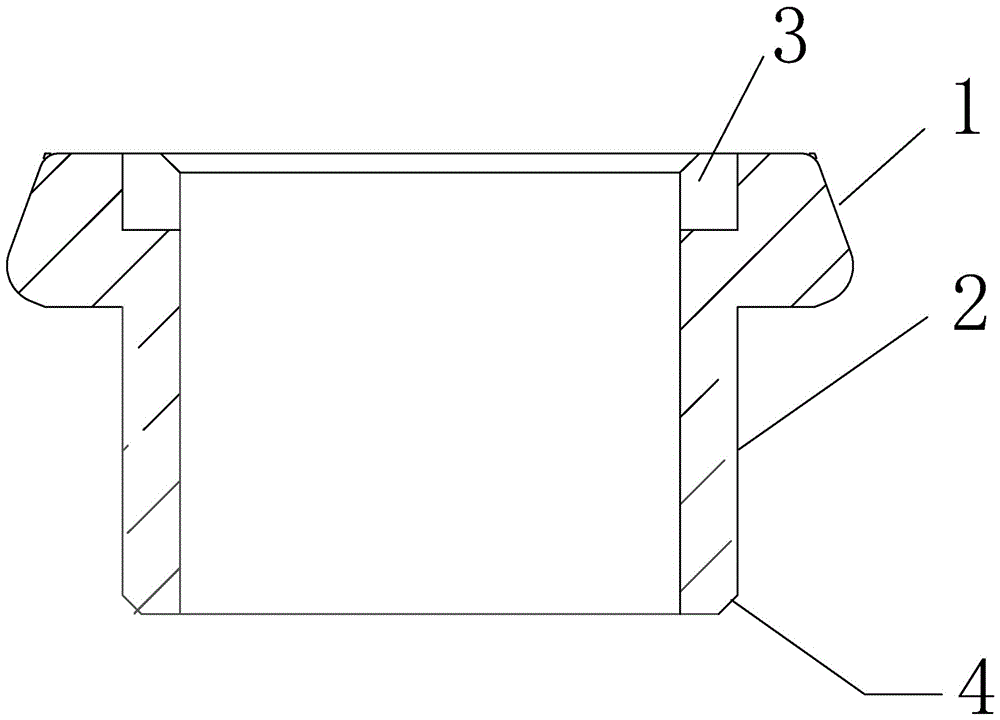

Fastening structure of signal connector

InactiveUS7682188B1Stable and tight connectionStructural fasteningSubstation/switching arrangement detailsScrewsEngineeringMechanical engineering

The present invention relates to a fastening structure of signal connector, comprises: a connector main body, which is a round-column shaped member, an insert orifice is provided on a top end of the connector main body and a signal terminal is provided in the connector main body, a middle portion of the connector main body has a combining ring-shaped surface, a positioning slot is provided on the combining ring-shaped surface, a bottom portion of the connector main body is provided with a positioning section; the connector main body is passed through a through hole preset on a base seat of an electronic equipment and the positioning section thereof is connected to a jointing section provided at a bottom end of the through hole; and a latching ring, an arched connecting sheet is provided between a top ring member and a bottom ring member for connection, and the latching ring is sleeved on the combining ring-shaped surface via the top end of the connector main body, so the bottom end of the bottom ring member is against the base seat and the connecting sheet is positioned in the positioning slot; when the top ring member is punched and downwardly moved, the connecting sheet is compressed and deformed and is latched in the positioning slot, so the connector main body is stably and tightly fastened on the base seat.

Owner:LANTEK ELECTRONICS

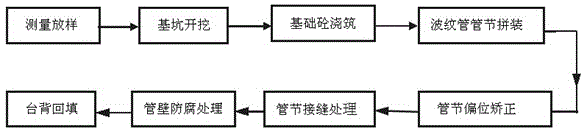

Steel corrugated pipe culvert construction method

The invention relates to a construction method, in particular to a steel corrugated pipe culvert construction method which comprises the following steps of excavation of a foundation pit, pouring of foundation concrete, assembly of corrugated pipe couplings, offset correction of the pipe couplings, and joint treatment of the pipe couplings. The assembly of corrugated pipe couplings is that in installation, middle pipe couplings are installed, positions of a water inlet and a water outlet are reserved, and the water inlet and the water outlet on two sides are installed after the middle pipe couplings are installed completely and corrected in place. By means of the steel corrugated pipe culvert construction method, the structure is firm, the construction is fast, and leakage is avoided. Practice has proved that when highway adopts a steel corrugated pipe culvert structure instead of other pipe culverts, the construction period is shortened, the manufacture cost is reduced, load-carrying capability of the structure is reasonable, load distribution is uniform, and the steel corrugated pipe culvert structure has a certain deformation resistance; slab staggering at the junction of a soft soil foundation structure and an embankment is avoided to some extent, comfort and safety of vehicle running are improved, and service and maintenance cost after construction is reduced.

Owner:THE THIRD ENG CO LTD OF CCCC SECOND HIGHWAY ENG BUREAU

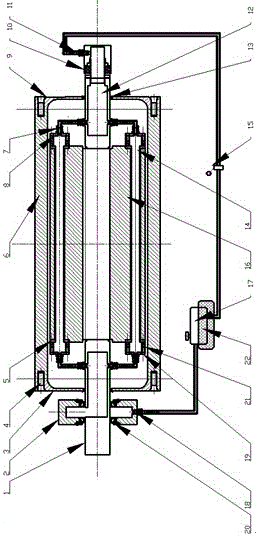

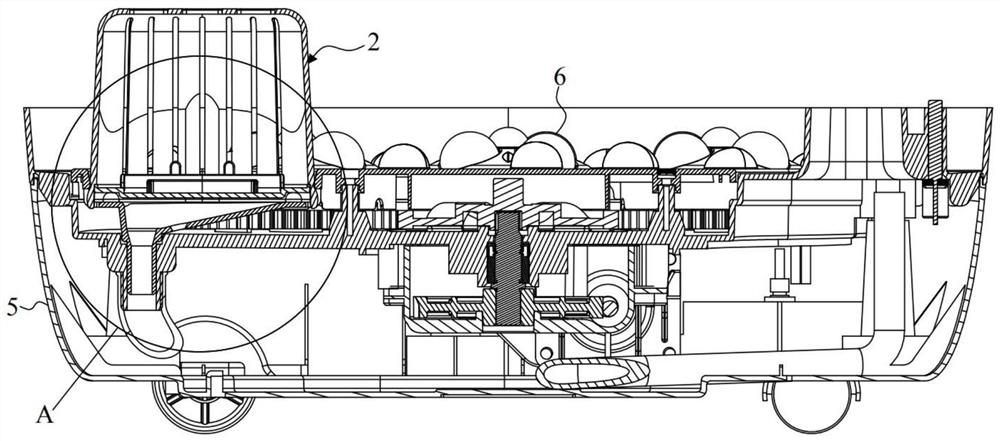

Motor rotor cooling structure

PendingCN106451863AReduce the possibility of burn-inStable mechanical propertiesMagnetic circuit rotating partsCooling/ventillation arrangementWhole bodyEngineering

The invention provides a rotor cooling structure which belongs to the field of motor cooling. A motor rotor is cooled as a whole by circulating pressed cooling oil fluid in the motor rotor. The motor rotor cooling structure comprises a high speed rotary joint, a ferrule-type pipe joint, a motor rotor body, a partially trepanned rotor shaft and the like. The high speed rotary joint comprises a bearing, a sealing ring and an external interface. The ferrule-type pipe joint comprises a ferrule, a nut, a joint body, a combined washer and the like. When aluminium casting is carried out at the corresponding position of the motor rotor body, a dummy shaft is used to cast an aluminum tube at the corresponding position of the rotor body, and a short circuit ring and the aluminum tube cast in the rotor body are cast into a whole body. A blind hole and a screw hole which fixes the ferrule-type pipe joint are arranged in the corresponding position of the partially trepanned rotor shaft. An oil collector comprises an oil collecting tank and a skeleton seal. According to the invention, the overall rotor body is cooled by the cooling oil fluid; the possibility of burning is reduced; the hidden danger of cooling fluid leakage is avoided; the vibration noise of a motor is reduced; and the service life of the motor is prolonged.

Owner:CHANGCHUN UNIV OF TECH

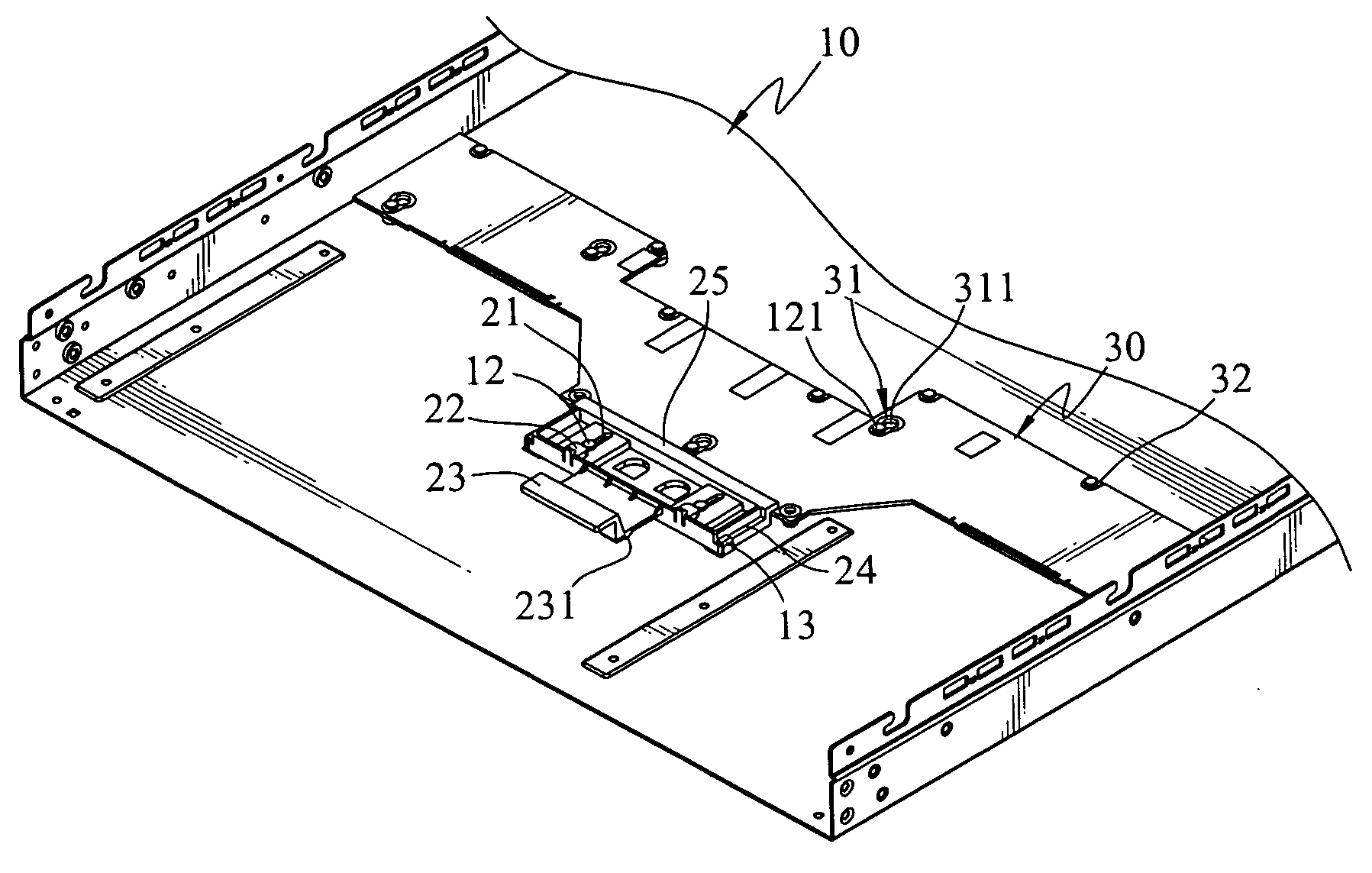

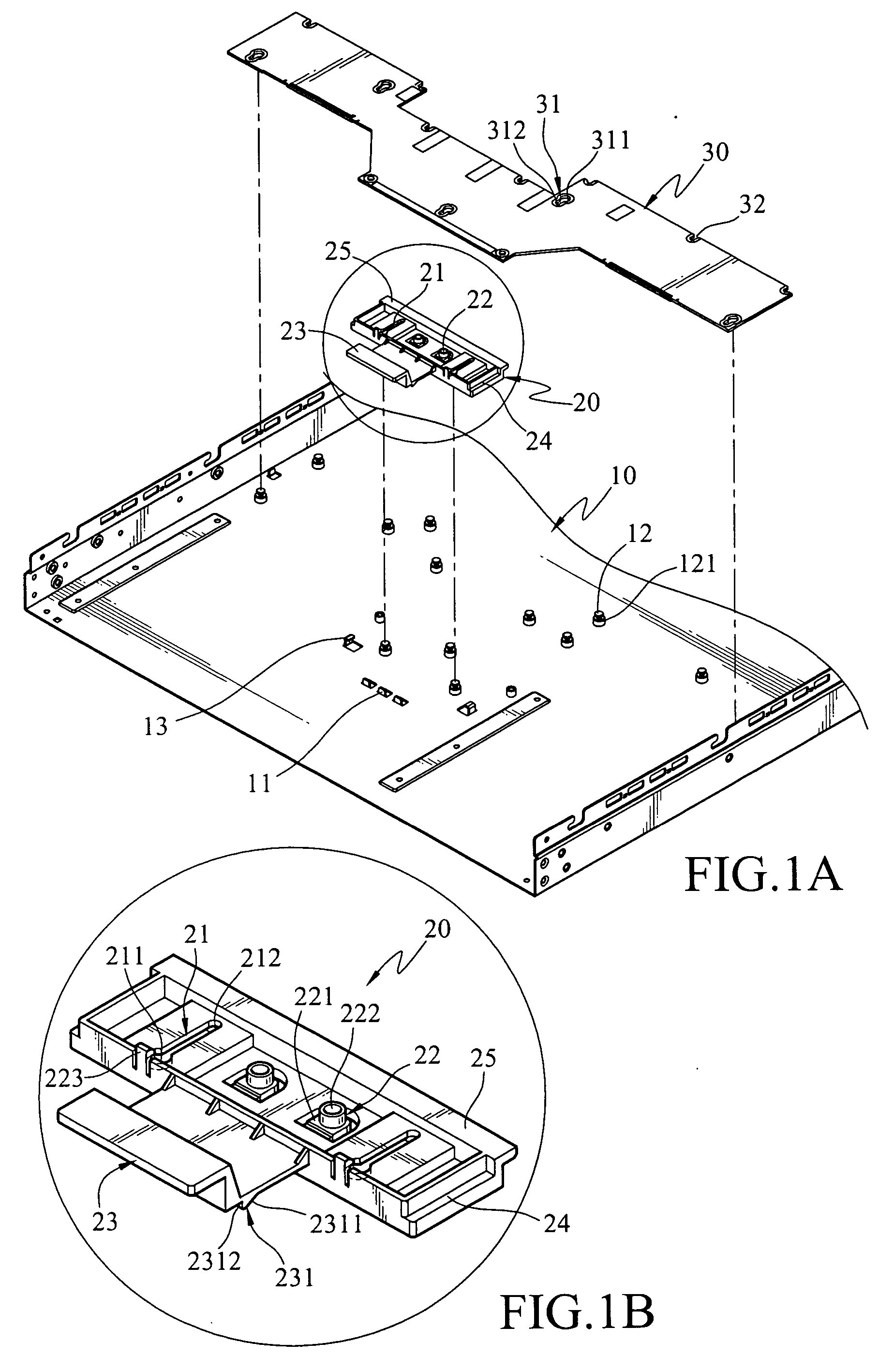

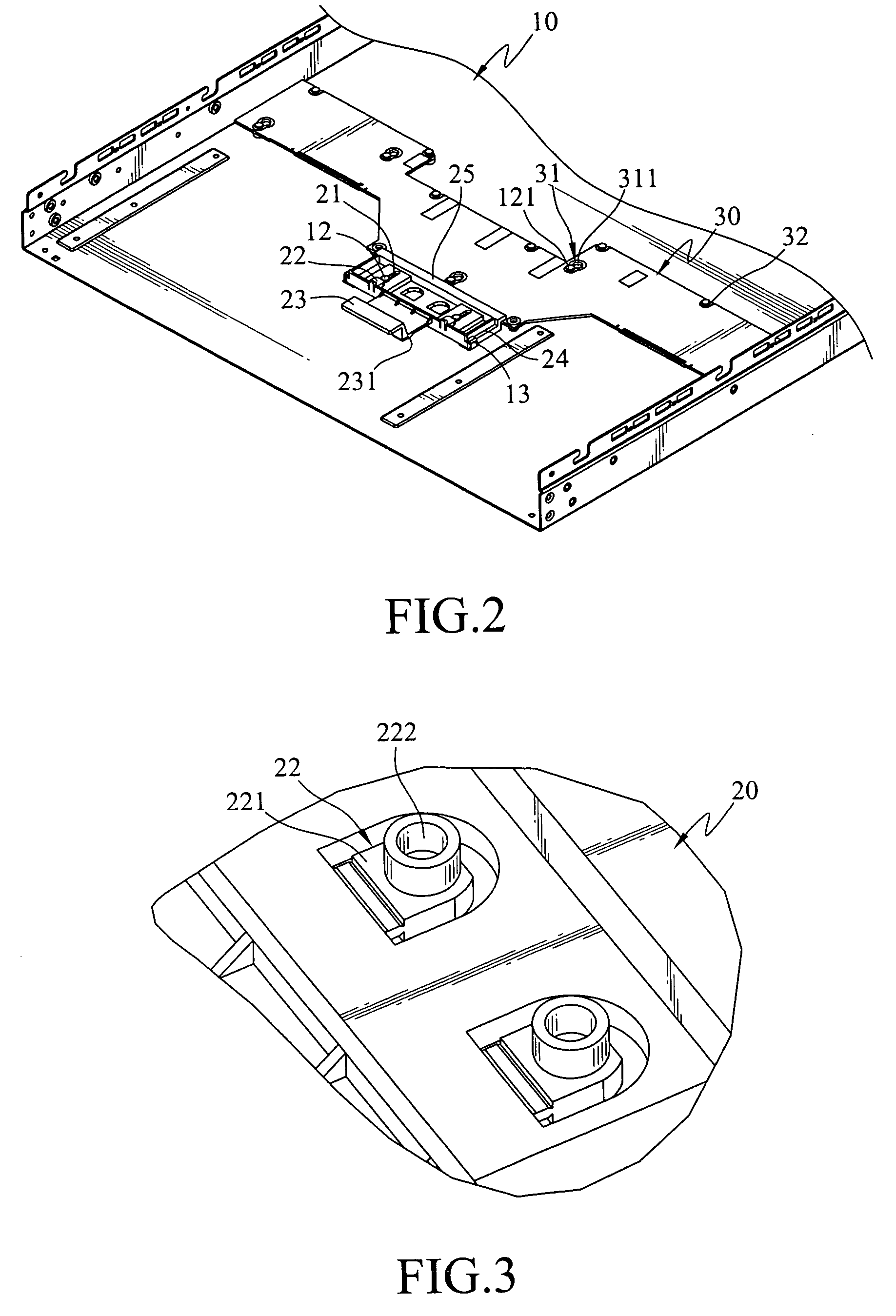

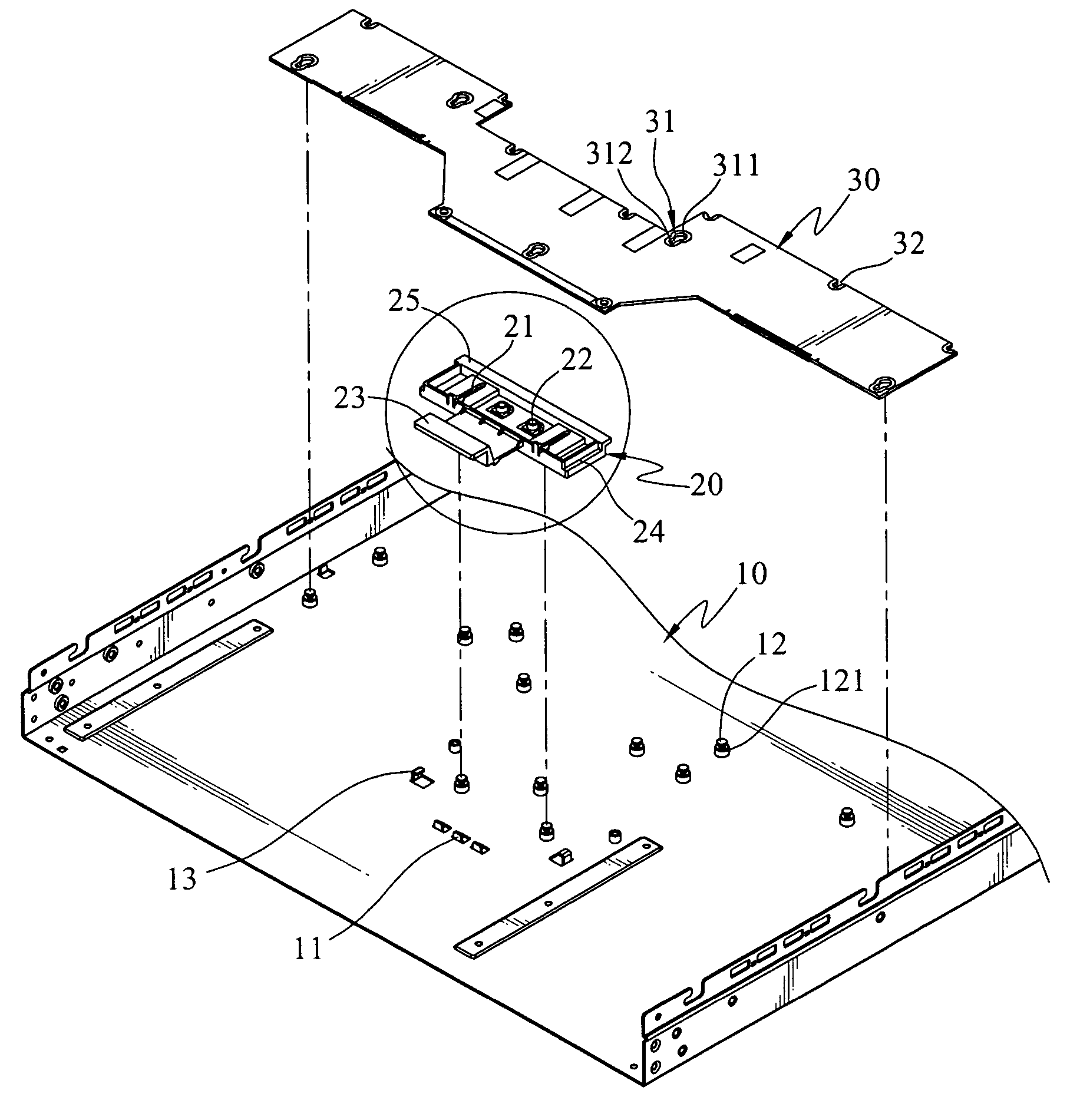

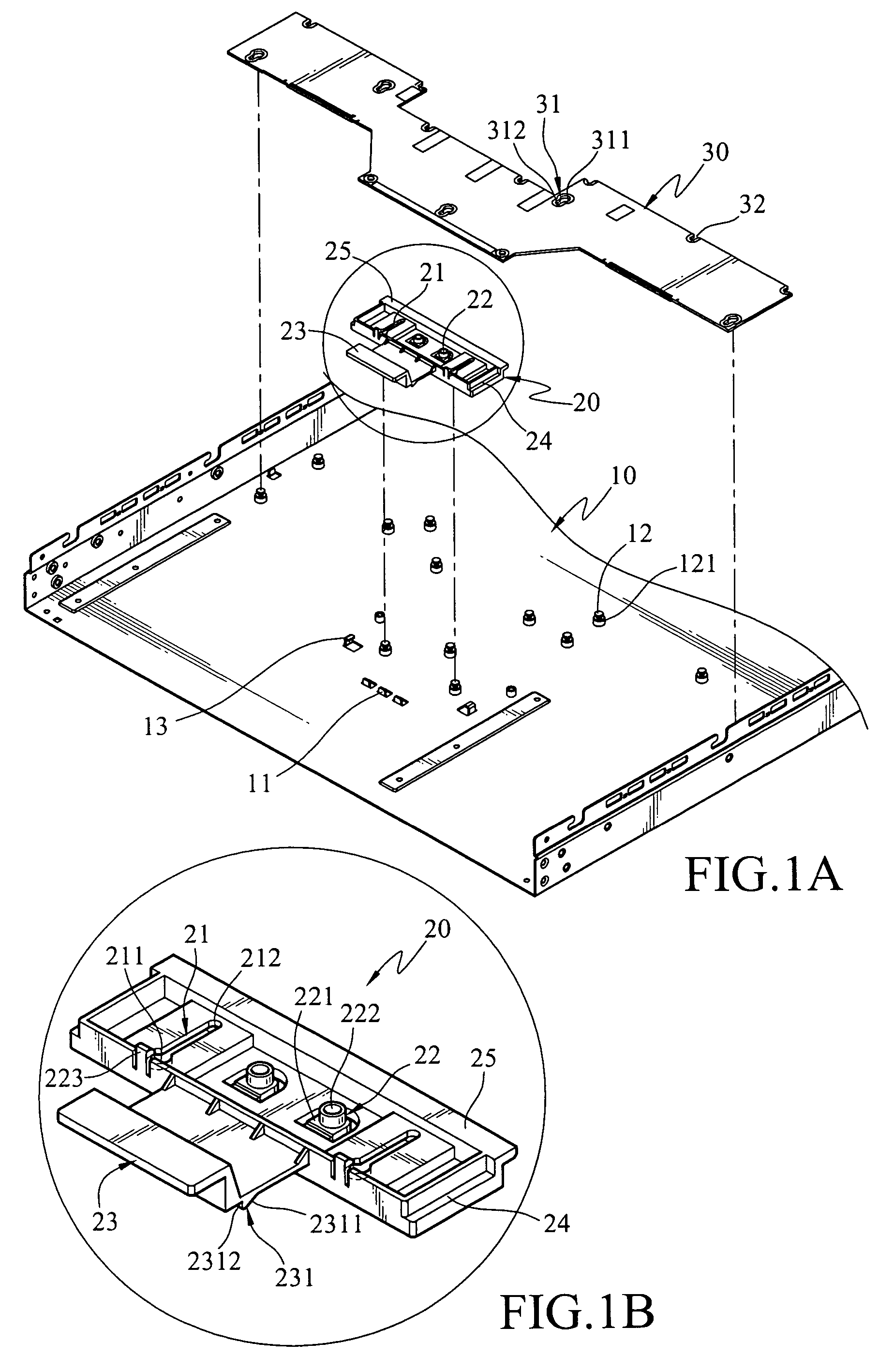

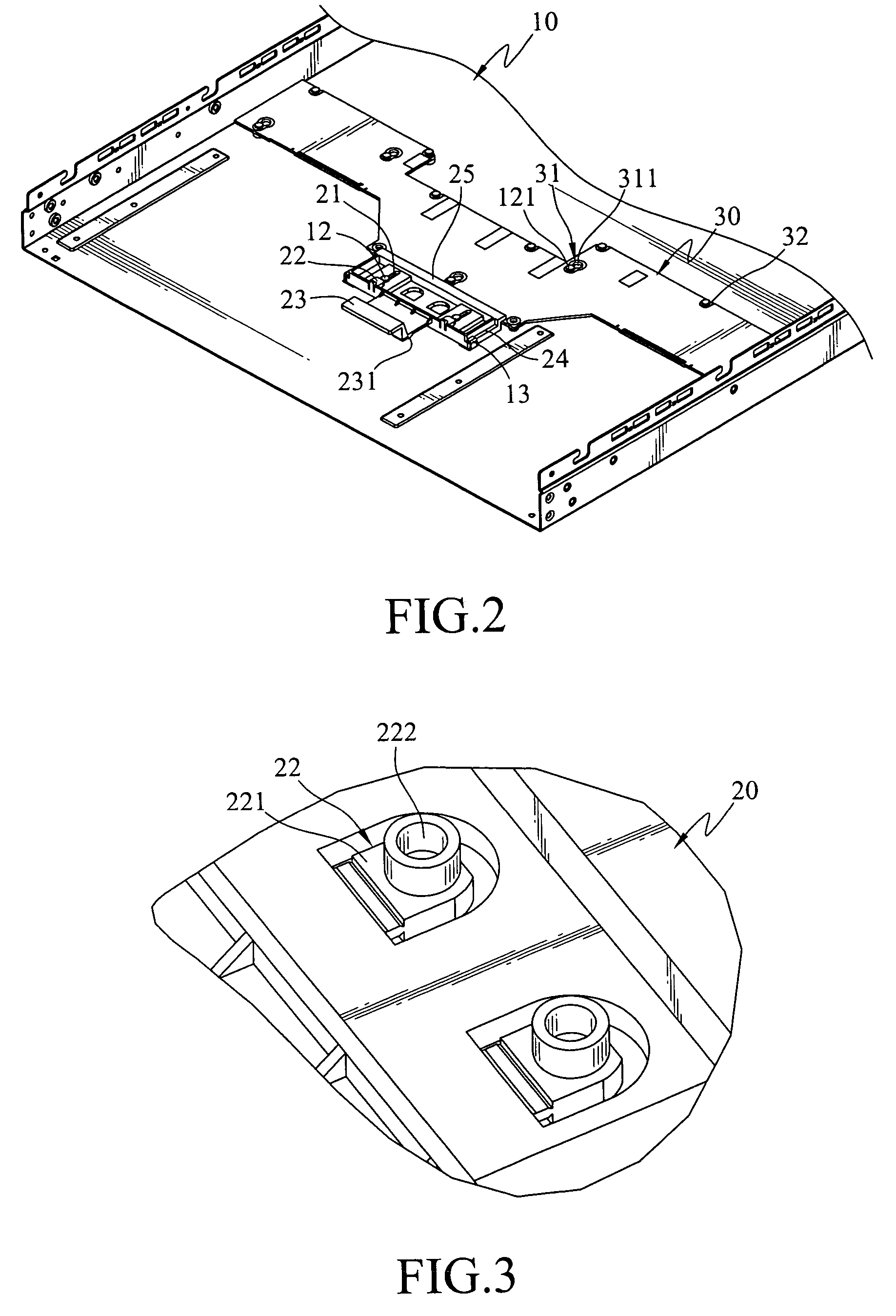

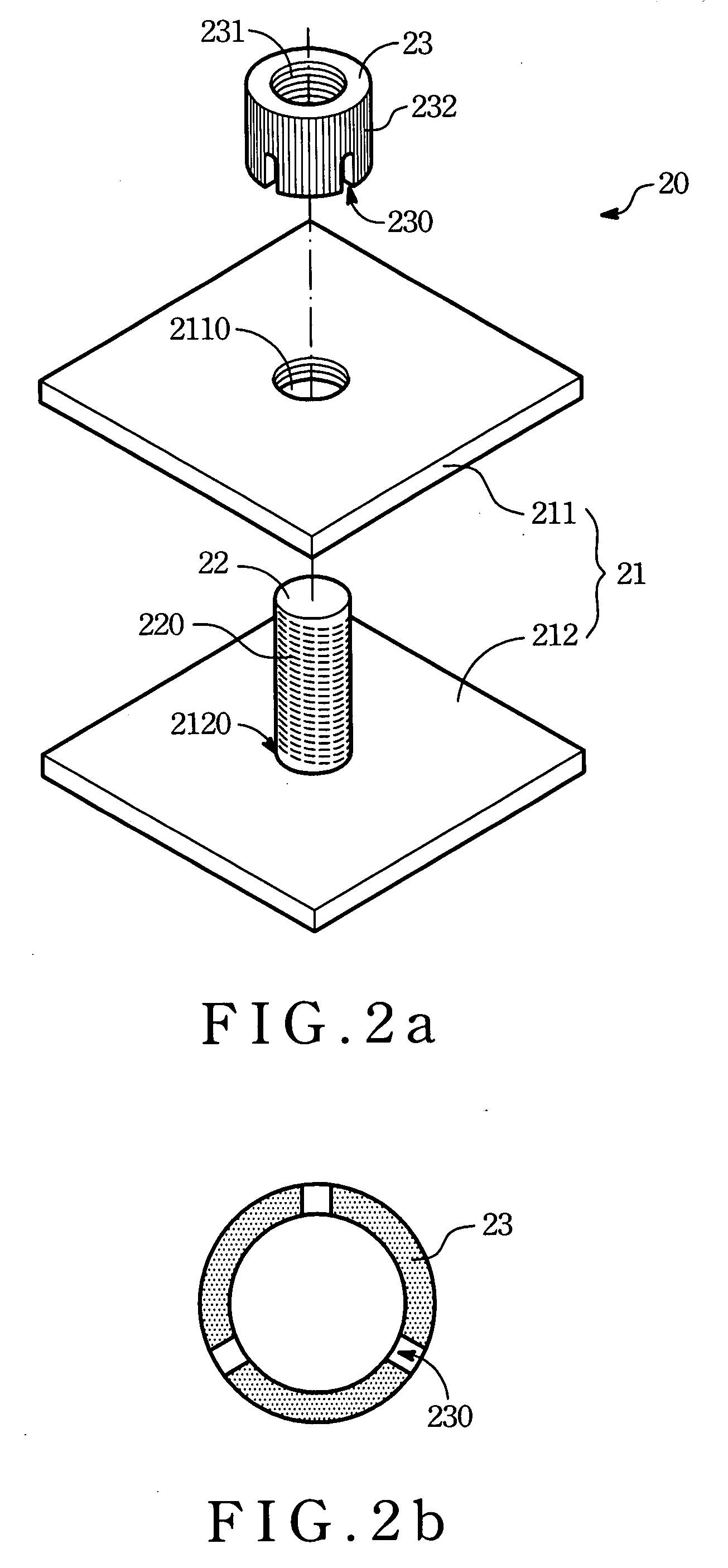

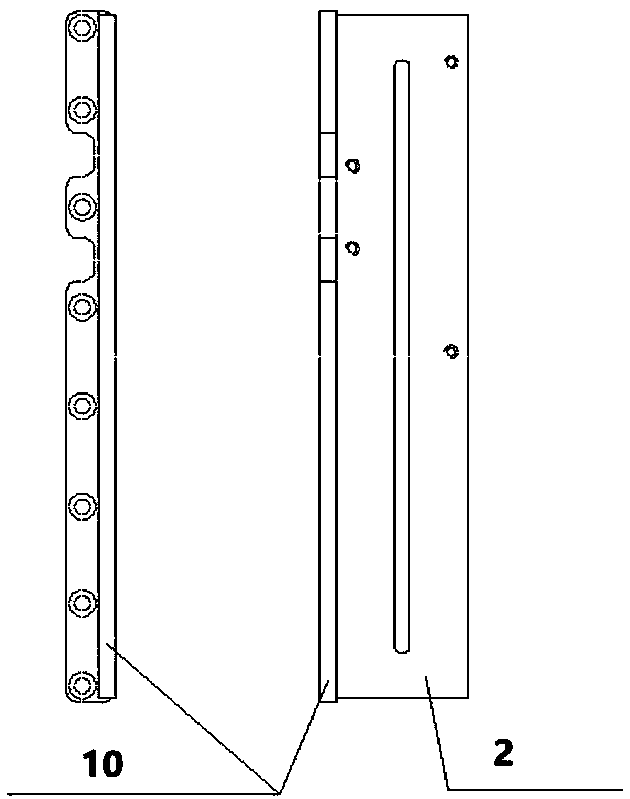

Circuit board fastening structure

ActiveUS20060171134A1Without usingStructural fasteningDigital data processing detailsCircuit arrangements on conductive chasisDetentElectrical and Electronics engineering

A circuit board fastening structure includes a seat, a fastening plate movably mounted onto the seat, and a circuit board. Anchoring members are provided to confine the circuit board. The seat has a detent wall to anchor a detent member located on the fastening plate so that the fastening plate and the circuit board may be coupled and anchored securely.

Owner:MITAC INT CORP

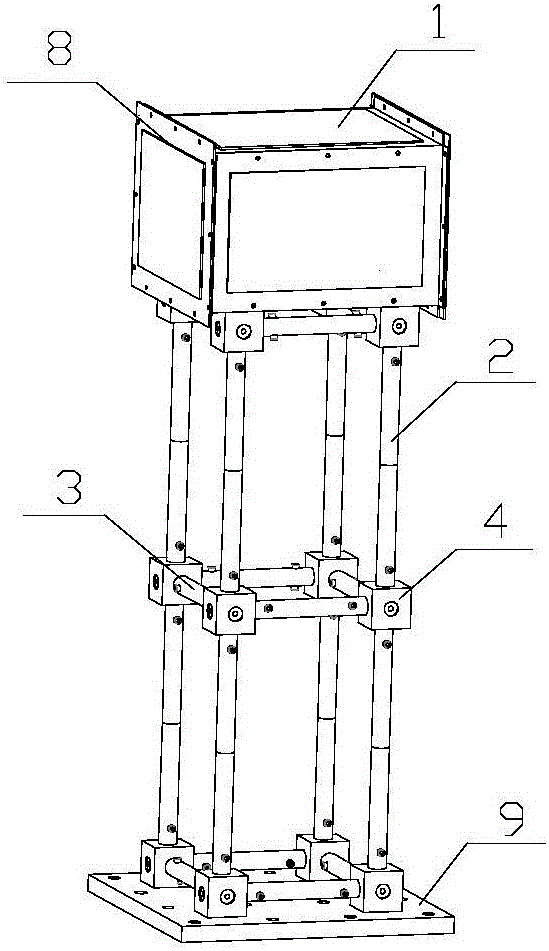

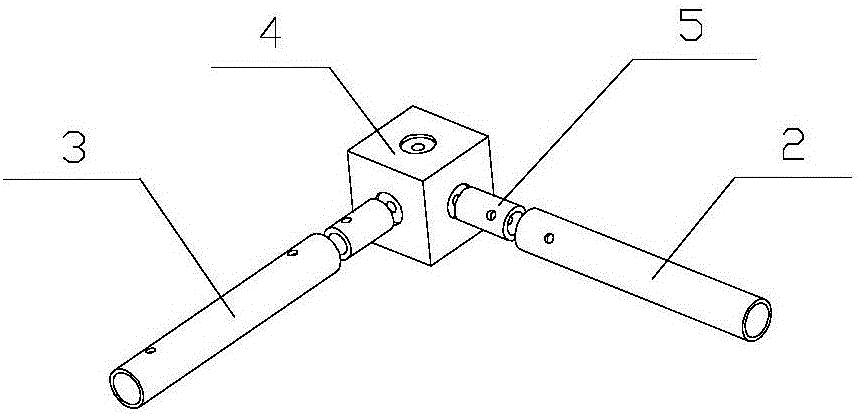

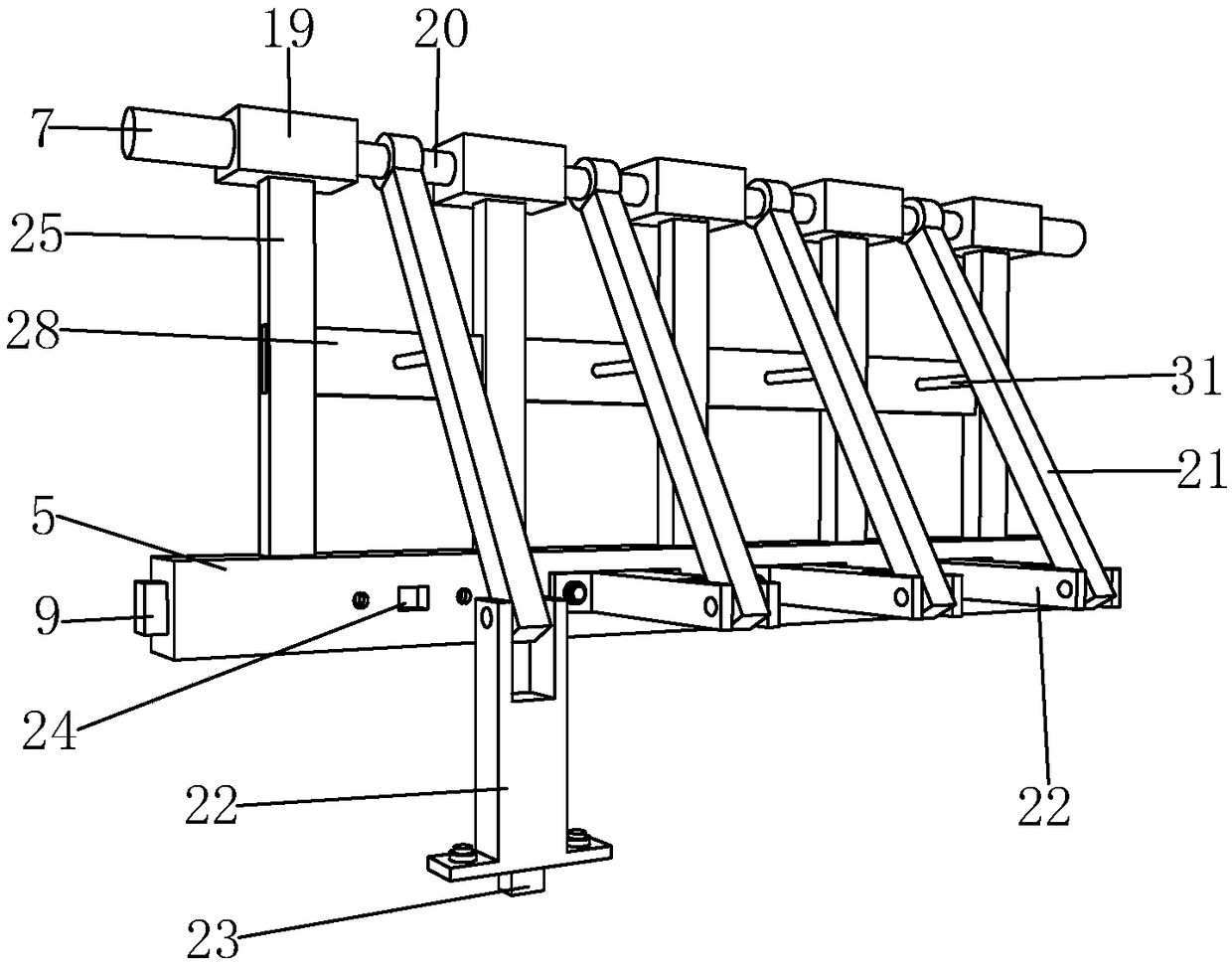

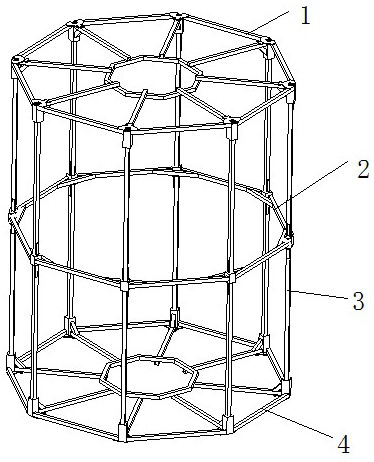

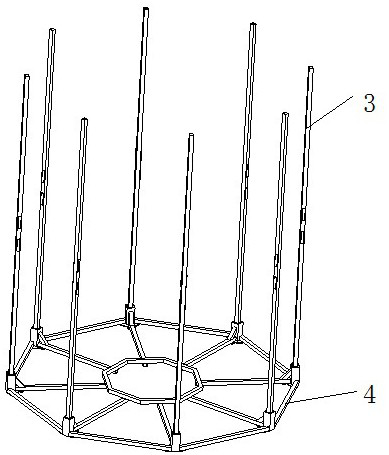

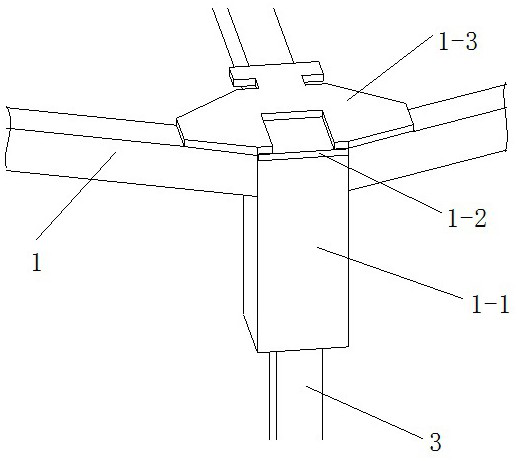

Space truss and spaceflight loading structure for space operation

InactiveCN106763468ASave spaceEasy to assembleNon-rotating vibration suppressionViscoelastic dampingEngineering

The invention relates to space truss and spaceflight loading structures, in particular to a space truss and spaceflight loading structure for space operation. The space truss and spaceflight loading structure comprises a box body structure and a space truss body. One end of the space truss body is fixedly connected with the bottom of the box body structure. The other end of the space truss body is connected with a tool. A restricted damping layer is arranged on the outer wall of the box body structure. The space truss body comprises long pipe assemblies, short pipes and square connecting blocks, wherein the multiple long pipe assemblies are connected through the square connecting blocks so that a multi-section square or triangular frame can be formed, and every two adjacent squaer connecting blocks are connected through the corresponding short pipe perpendicular to the long pipe assemblies. The space truss and spaceflight loading structure has great damping performance, the optimal damping effect can be achieved by changing the thickness, the material, the laying position and the laying area of the viscoelastic damping layer, and a precise photoelectric instrument is installed in the box body structure for astronauts to perform space operation.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

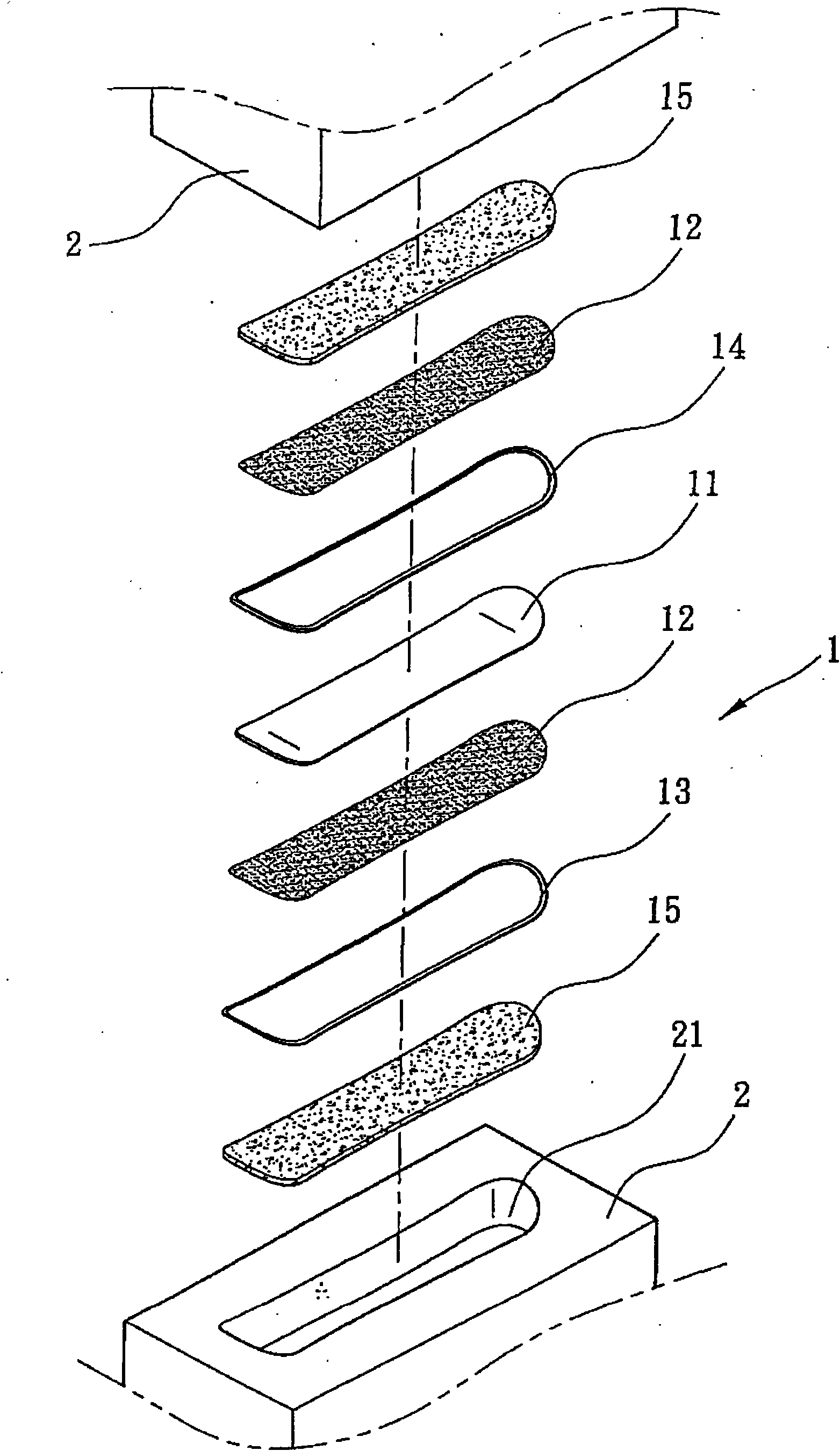

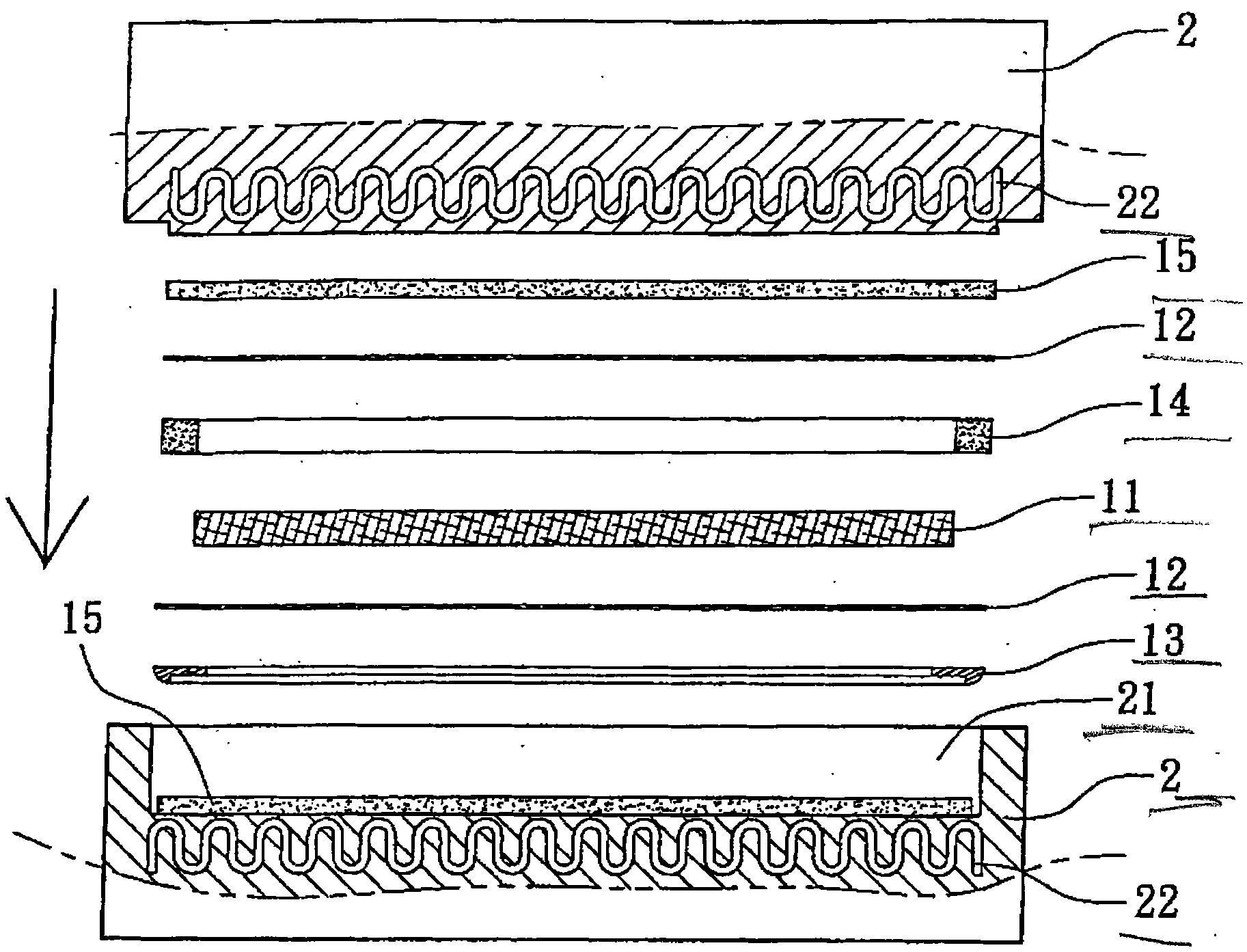

Method for producing recoverable environmentally-friendly ski

The invention discloses a method for producing a recoverable environmentally-friendly ski, which comprises the following steps of: melting thermoplastic material or resin and glass fiber cloth (sheet) together in a first heating die by using the heat generated by a heating element to form a thermoplastic bonding material; and embedding a steel edge ring, a middle main board, a plastic edge ring encircling the middle main board and upper and lower plastic boards into a die cavity of a second heating die according to an accurate position, then embedding the thermoplastic bonding material at the upper and lower positions of the middle main board, clamping and pressing upper and lower dies of the second heating die, thermally melting the thermoplastic bonding material by the heat generated by a heating element in the second heating die to bond the upper and lower plastic boards, the plastic edge ring, the steel edge ring and the middle main board together, and cooling the whole to form a ski finished product. The ski produced by the method can be reclaimed, the waste ski can be reclaimed through equipment such as an incinerator and the like, and the purpose of environmental friendliness is fulfilled.

Owner:张家口京禧体育器材有限公司

Circuit board fastening structure

ActiveUS7414861B2Structural fasteningWithout usingDigital data processing detailsCircuit arrangements on conductive chasisDetentEngineering

Owner:MITAC INT CORP

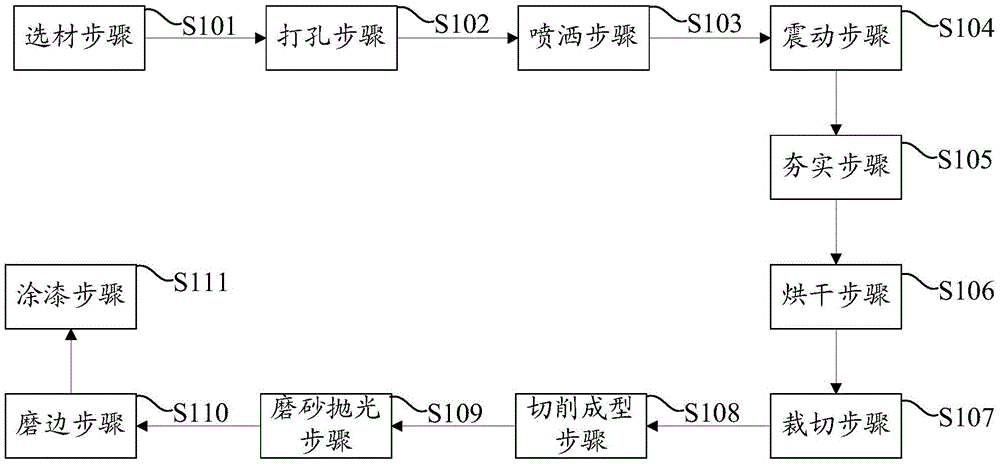

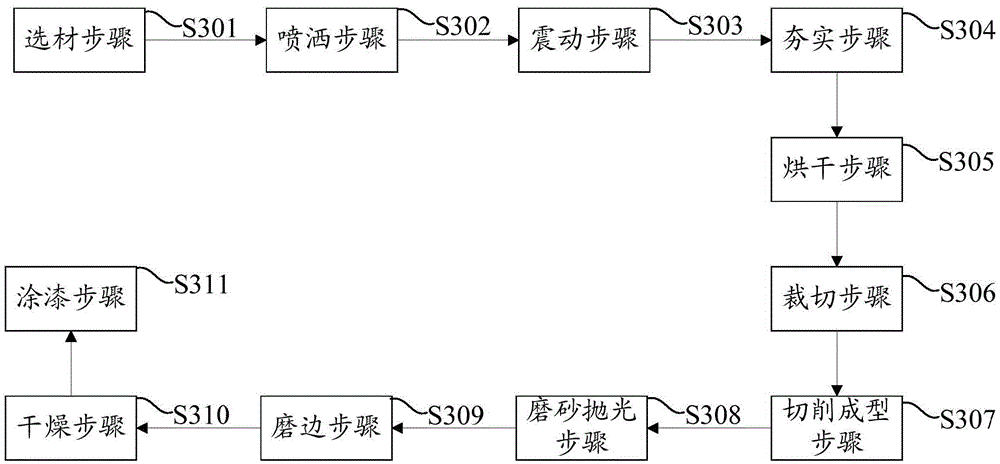

Mobile phone shell manufacturing technology

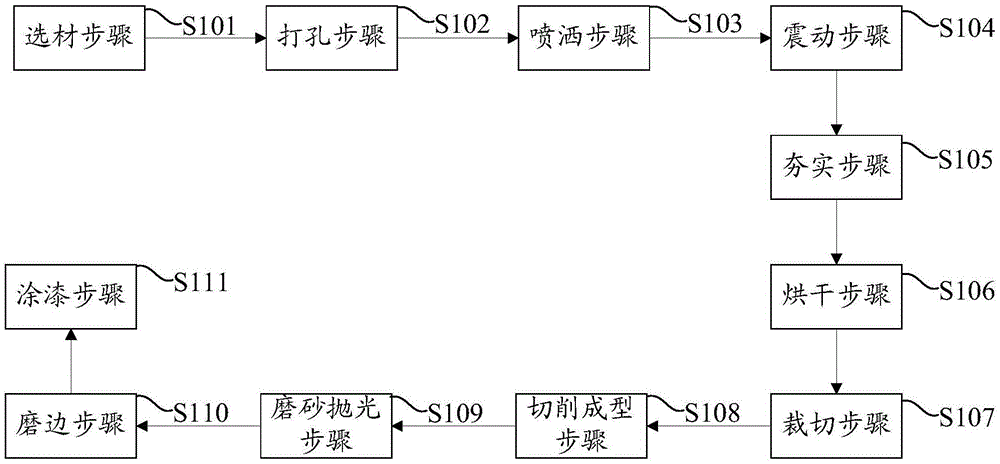

ActiveCN105599093AHigh hardnessImprove wear resistanceWood working apparatusTelephone set constructionsManufacturing technologyPunching

The invention relates to a mobile phone shell manufacturing technology. The technology comprises the steps of material selecting, punching, spraying, vibrating, tamping, drying, cutting, cutting molding, grinding and polishing, edge grinding and paint coating. According to the mobile phone shell manufacturing technology, by selecting superior basswood and thoroughly wetting, tamping and drying the basswood, the structure of the basswood is more compact, therefore, a manufactured mobile phone shell is higher in hardness and has the better abrasive resistance, and the service life of the mobile phone shell is prolonged.

Owner:东莞市林泽通讯器材有限公司

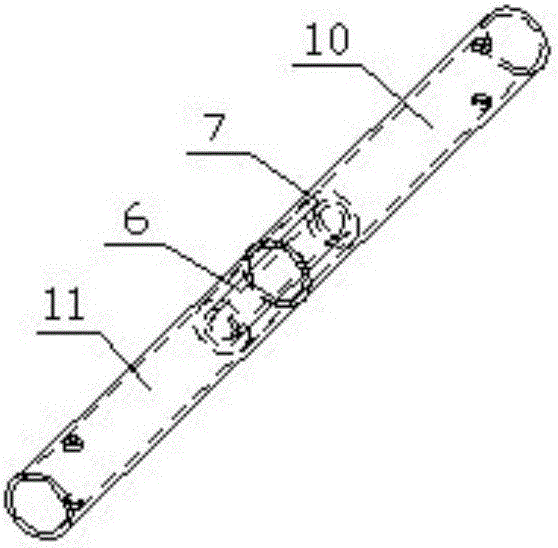

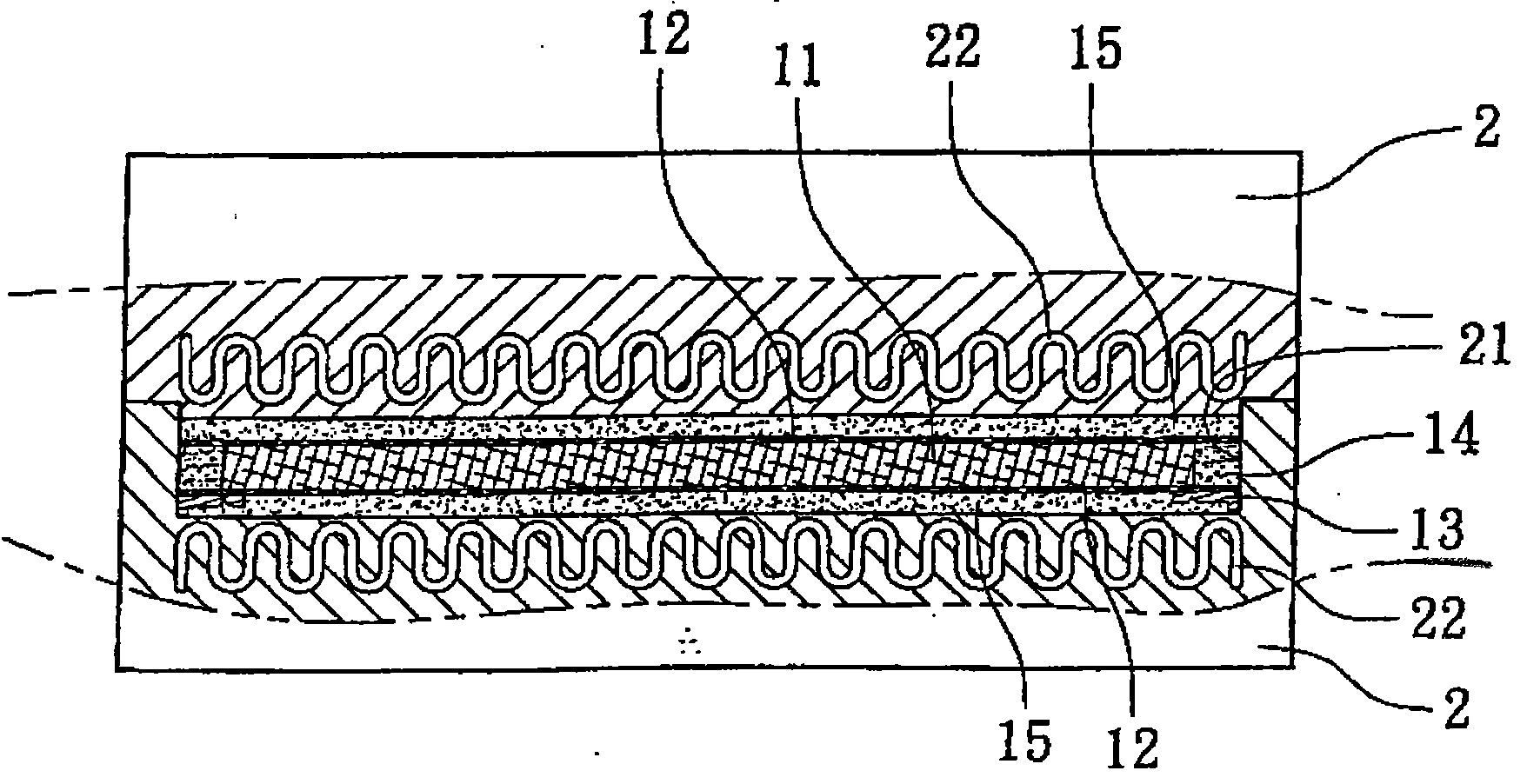

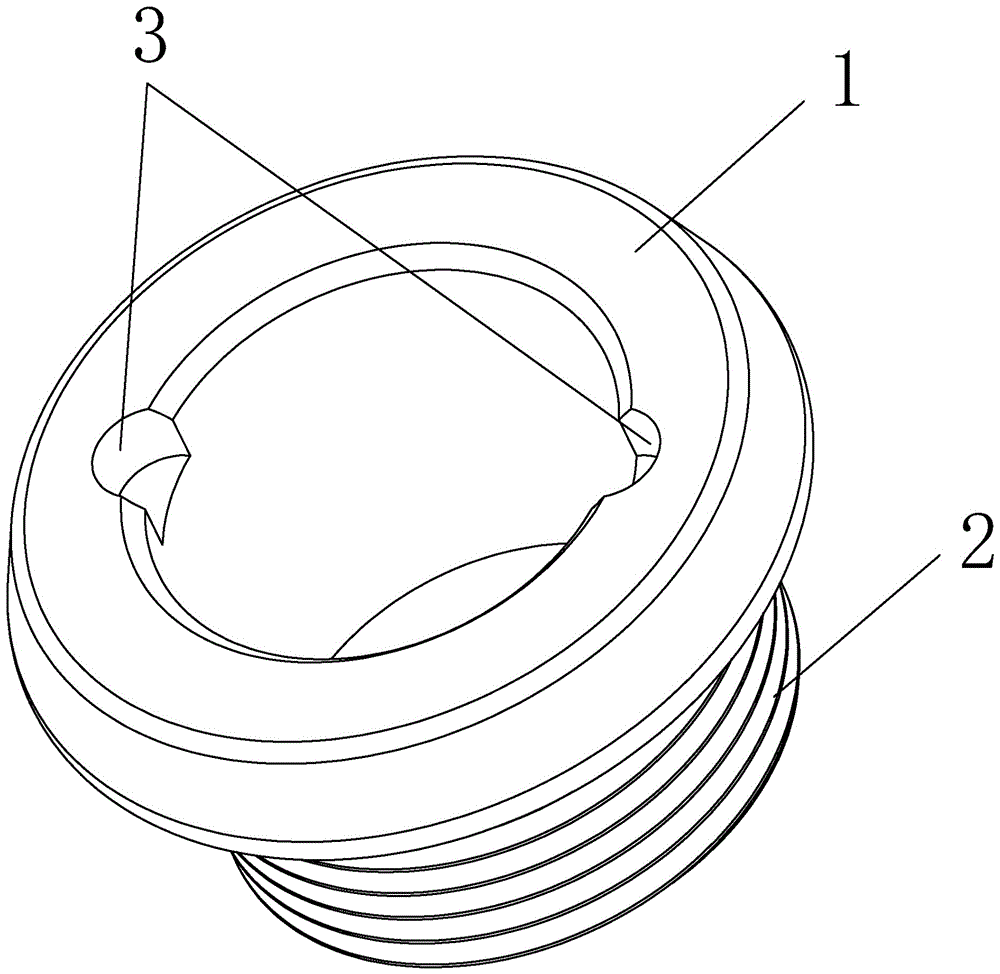

Winding pipe

The invention relates to a winding pipe which comprises a plastic layer and a stiffening rib coated in the plastic layer. The winding pipe is characterized in that the plastic layer is formed by spirally winding a plastic sheet; every two adjacent rings of plastic sheet are mutually overlapped and fused at the edges, so that a spiral overlapping region is formed on the plastic layer; and the stiffening rib is in the shape of a spiral spring matched with the overlapping region and is embedded in the overlapping region. The winding pipe is simple in overall structure, and is formed by winding only one plastic sheet and one stiffening rib, so that the prepared pipe body has smooth inner wall; and thus, dust, foreign bodies and the like can not be easily accumulated in the use process. The stiffening rib is just positioned in the overlapping region of the plastic sheet, and the inner layer plastic sheet and outer layer plastic sheet in the high temperature state are completely fused, so that the winding pipe has the advantages of firm overall structure and longer service life. According to the winding pipe, the adhesive layer does not need to be previously coated on the periphery of the stiffening rib, and the spring formed by the stiffening rib has favorable elasticity, so that the pipe body has high strength and favorable pressure bearing capacity.

Owner:NINGBO YINZHOU QIUAI JIELI PLASTIC FACTORY

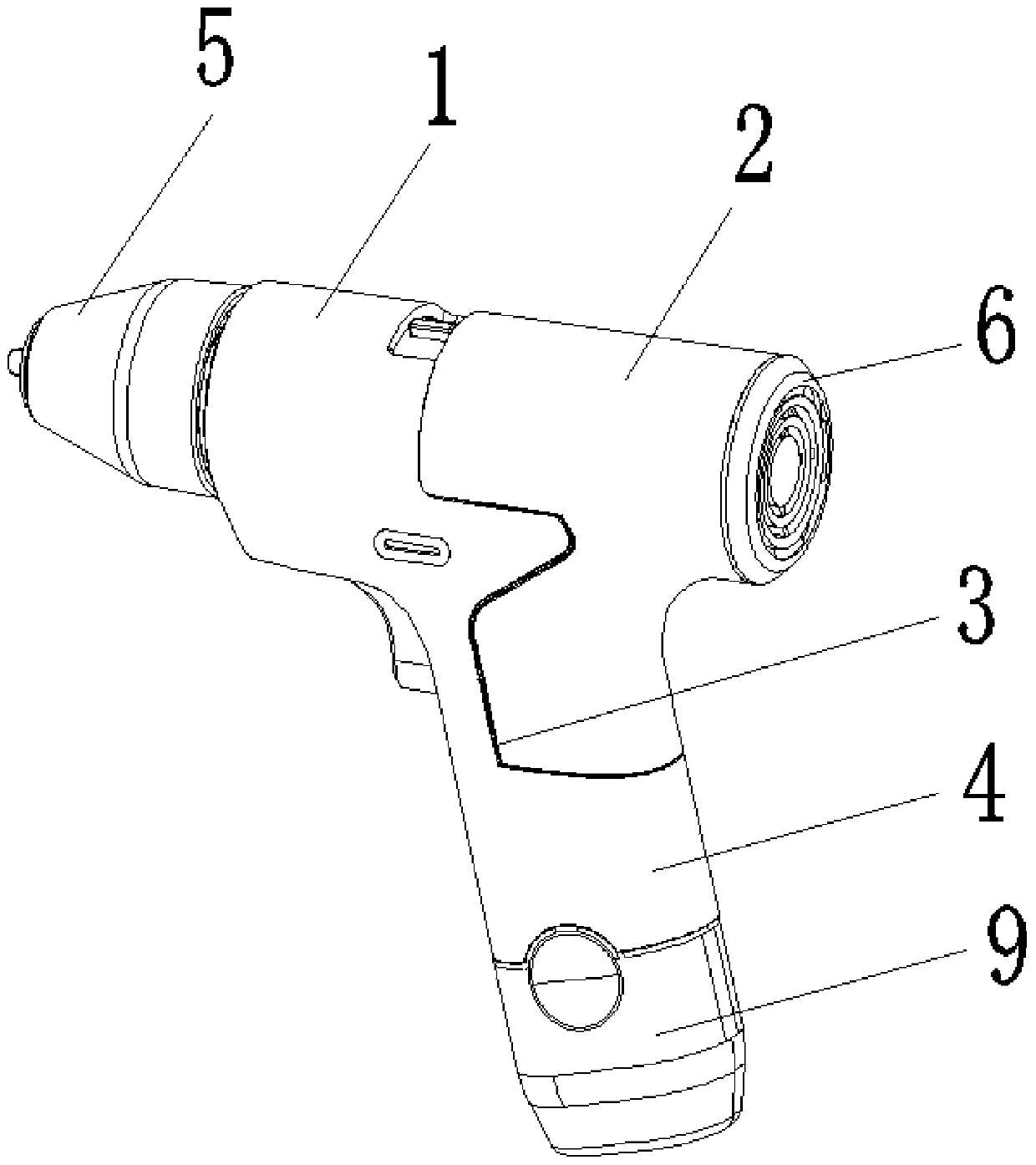

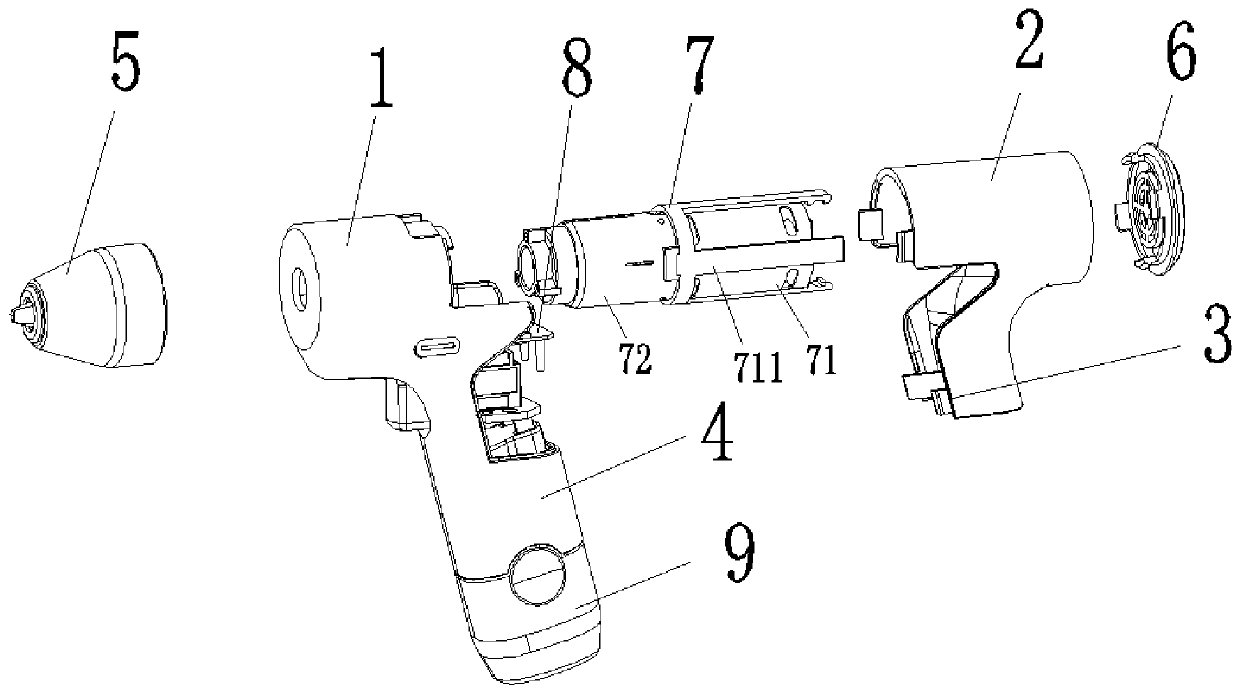

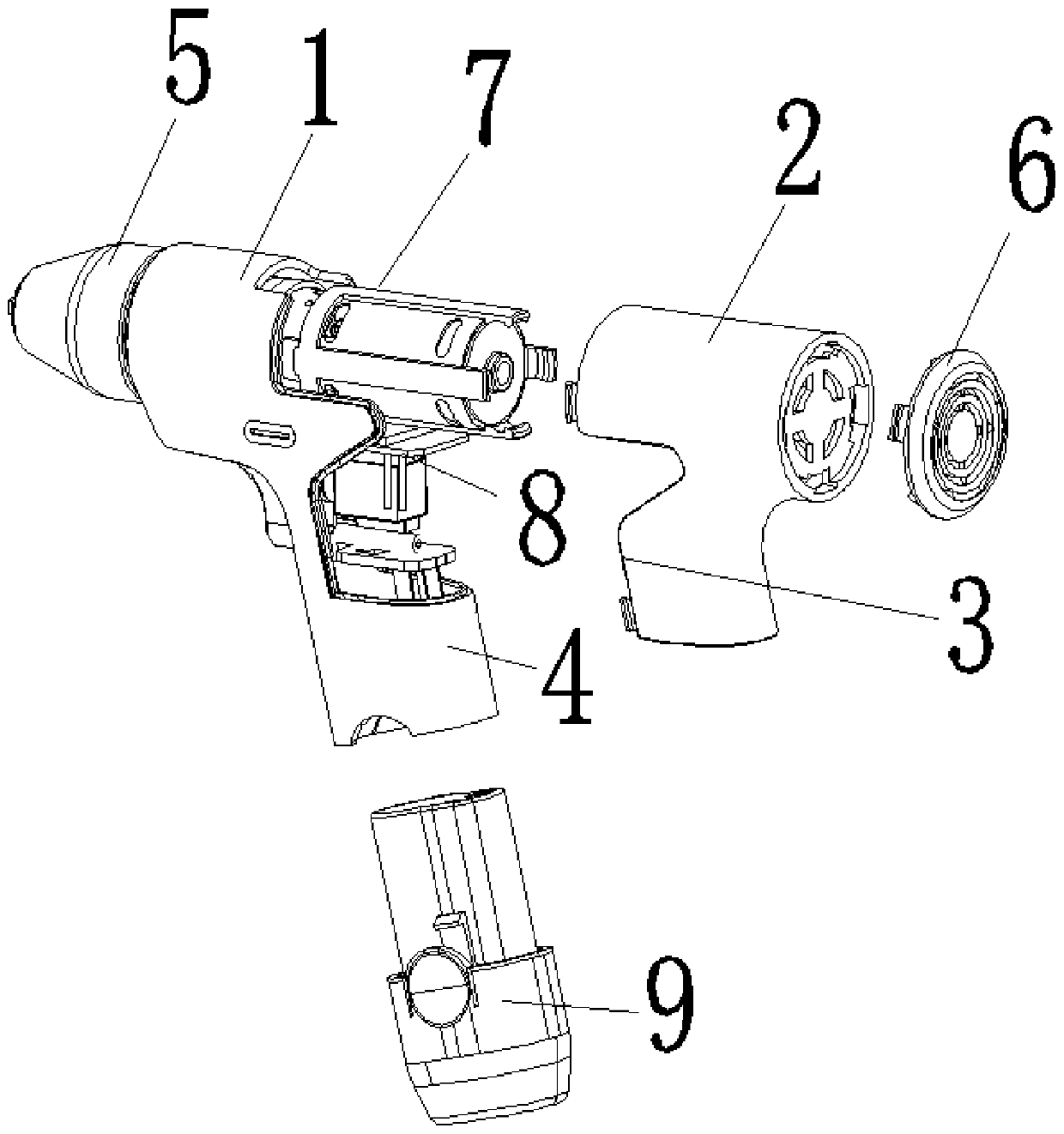

Electric tool shell and electric tool

InactiveCN111546295AReduce usageAvoid influencePortable power-driven toolsCell component detailsEngineeringContact line

The invention discloses an electric tool shell and an electric tool. The electric tool shell comprises at least one first shell element and at least one second shell element. The first shell elementsand the second shell elements are connected together along at least one contact line and / or contact face. The first shell elements and the second shell elements are connected without screws. Modularized assembling structures are adopted inside the electric tool, including at least one drive system unit module, at least one controller unit and at least one battery unit module which are all fixedlyconnected with the electric tool shell, wherein a locking structure is arranged on the drive system unit module. The electric tool is compact in structure and smaller in size, no screws are adopted for connection of the shell, and the surface of the shell is provided with visual holes as few as possible.

Owner:ZHEJIANG LERA NEW ENERGY POWER TECH CO LTD

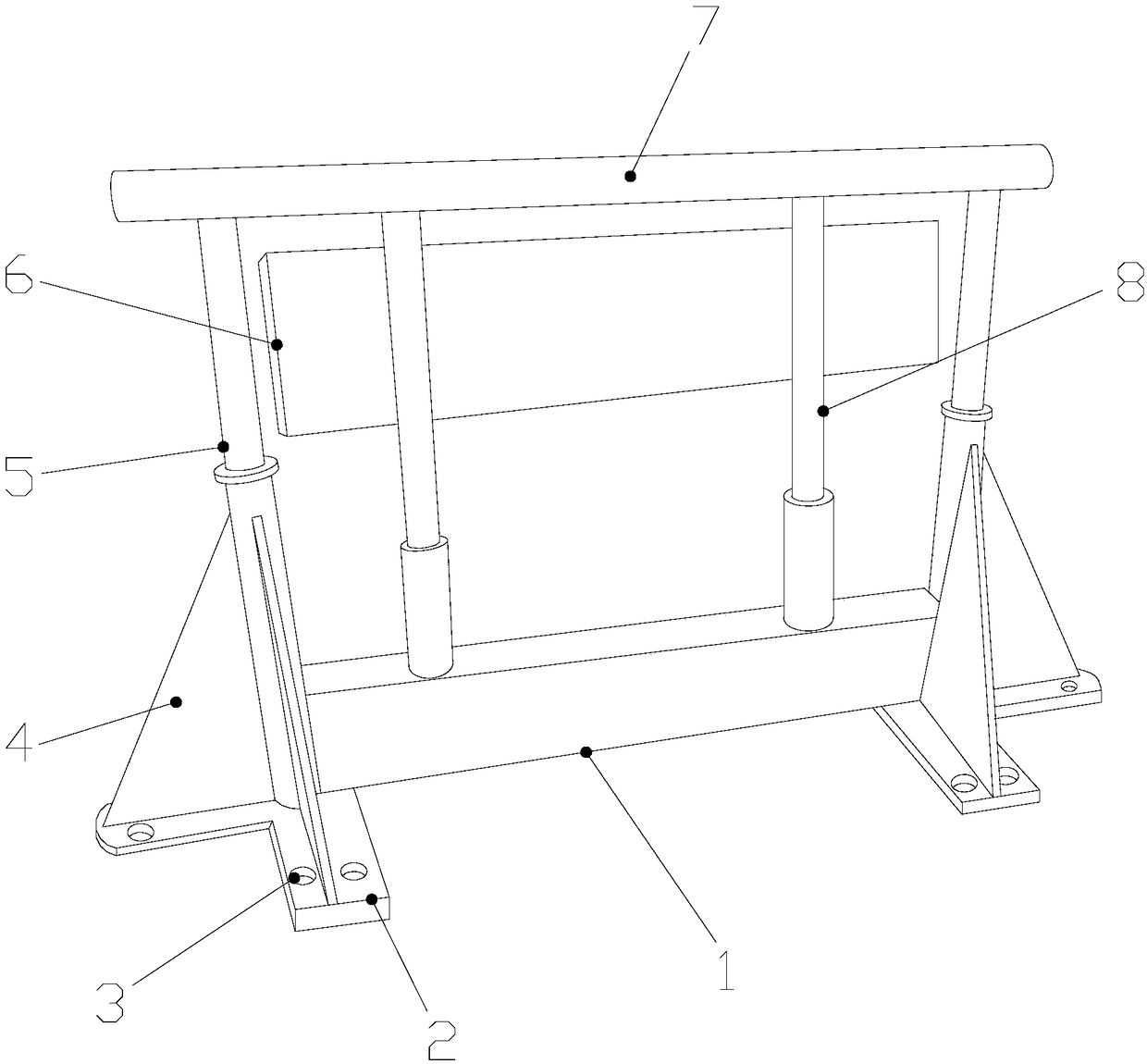

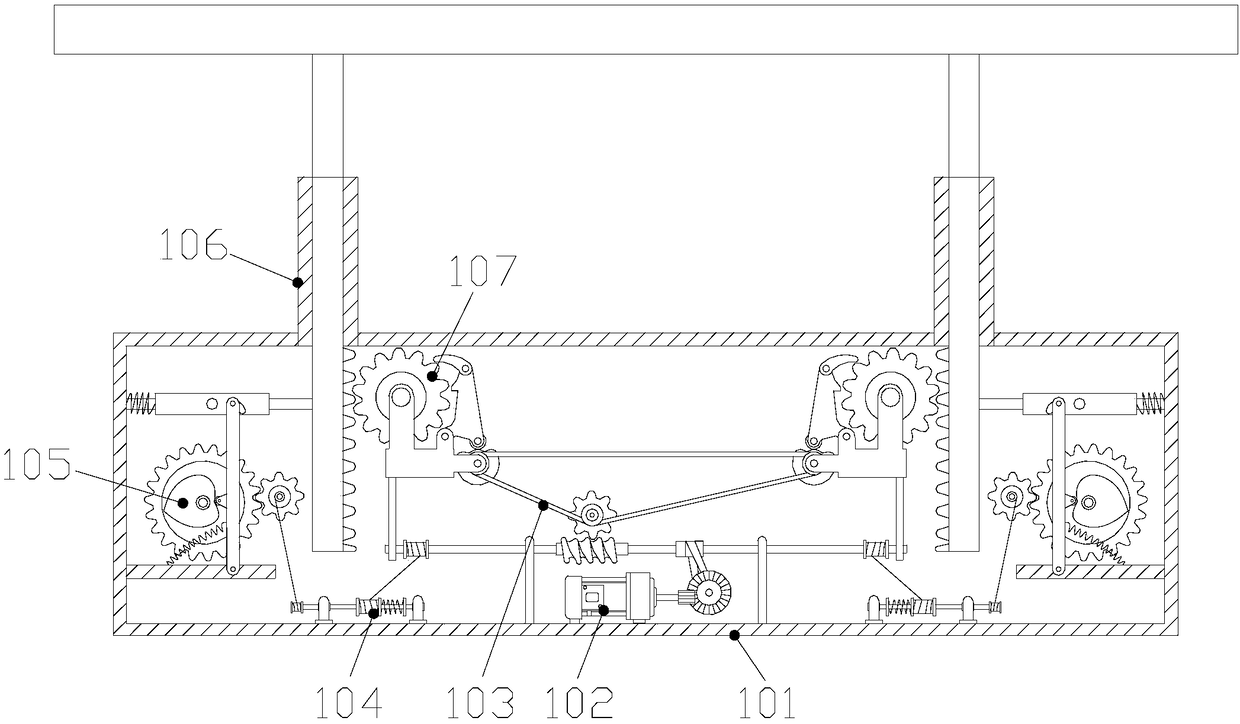

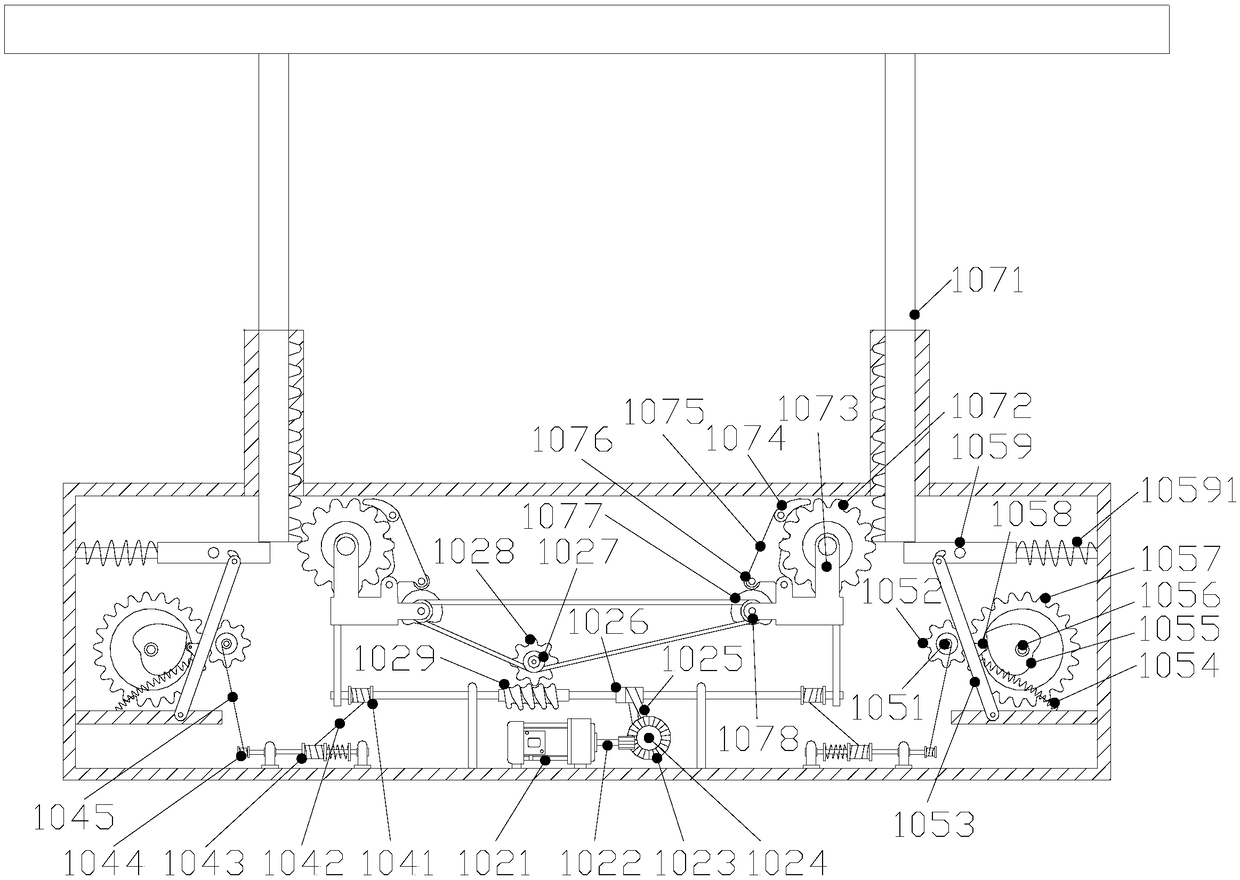

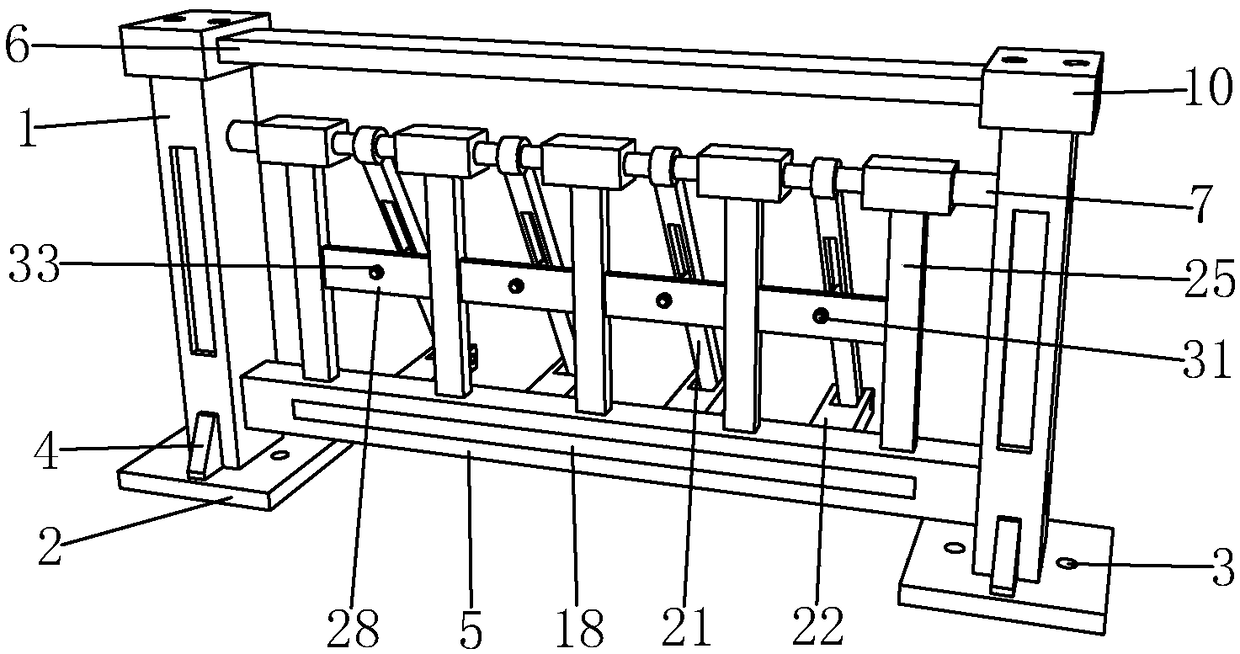

Electric power construction device with security fence

The invention discloses an electric power construction device with a security fence, which comprises an electric power device, a support, a mounting hole, a reinforcing plate, a driven expansion fence, a anti-collision plate, a protective hand railing and a driving telescopic fence; according to the invention, a driving mechanism drives a lifting mechanism to rotate, the driving telescopic fence is lifted upwards through a lifting rack, so that the security fence can automatically stretch and the storage is facilitated, and the driving telescopic fence is provided with the anti-collision plate, which can avoid collision and damage of the security fence and improve the practicability. The support mechanism can strengthen the driving telescopic fence to drive the protective hand railing to rise, so that automatic decline does not appear, the security fence is small in size, can be stretched when in use, and is compact and tight instruction, the protection effect is obvious.

Owner:黄婷婷

Guardrail for a wooden gallery bridge and a construction method thereof

ActiveCN109267480ARapid positioningEasy to fix with nailsBridge structural detailsBridge erection/assemblyArchitectural engineeringBuilding construction

The invention discloses a guardrail for a wooden gallery bridge and a construction method thereof. Theguardrail includes piles;a cross bar, a support bar and a mounting rod are respectively arranged between the piles, a support block and a fixing support bar are respectively arranged on that mounting bar, a support rod is movably connecting with that fixed support rod, a support bar is movably connecting with a positioning bar, one end of that positioning bar is fix on the cross bar, a receiving groove is arranged on the support bar, a threaded bar is movably connected in the receiving groove, a railing is arranged between the support block and the cross bar, a reinforcing plate is arranged between the railings, a positioning hole is arranged on the reinforcing plate, the threaded bar passes through the positioning hole, and one end of the threaded bar is connected with a locking cap; the construction method comprises the following steps: (a) railing installation; (b) adjustment; (c)that column pile is in place; (d) Gradual installation. The invention has the advantages of stable structure, simple assembly, time-saving and labor-saving, convenient maintenance in the later period, easy operation and gradual orderly adjustment of the construction method, which is favorable for controlling the construction progress and ensuring the construction quality.

Owner:金华市广和古建筑技术研发有限公司

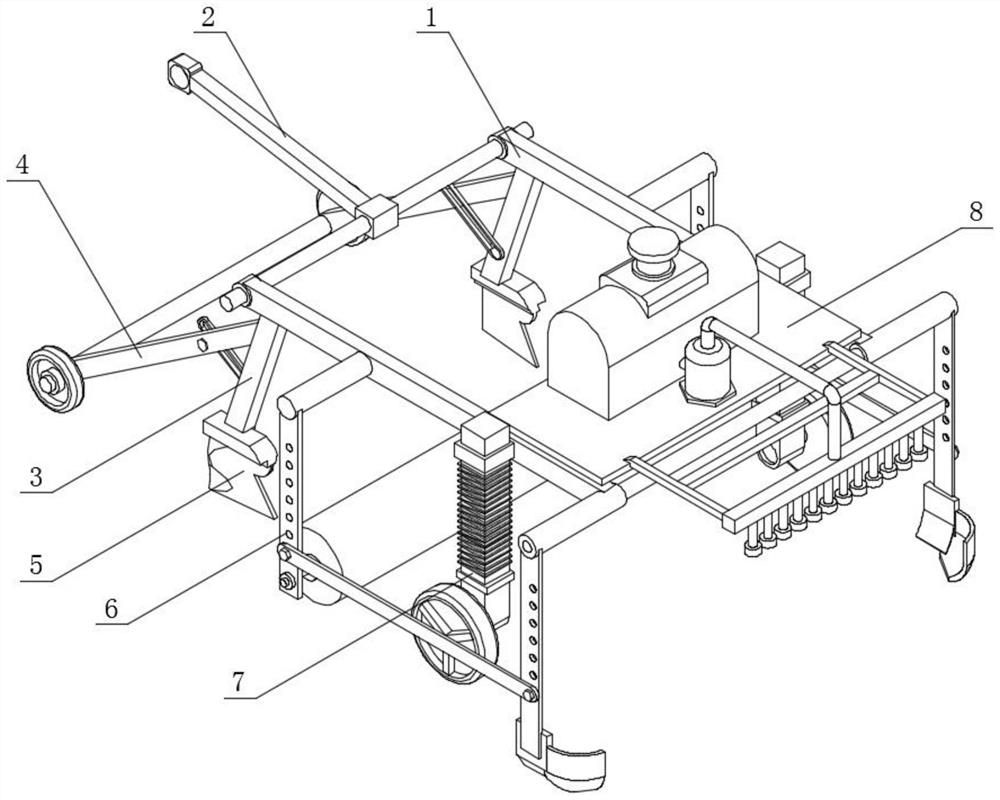

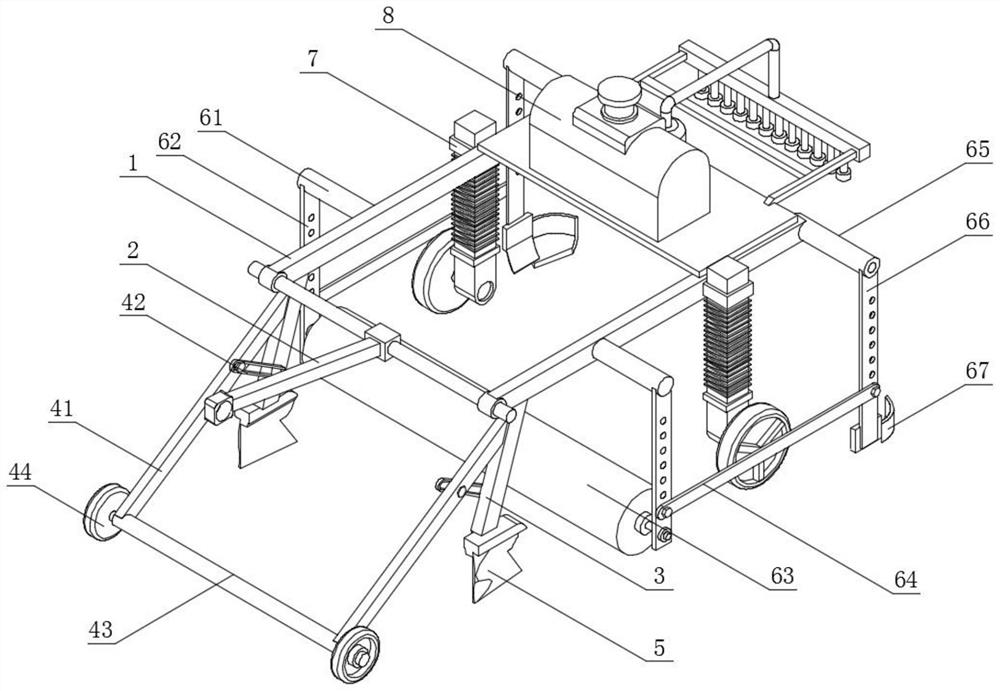

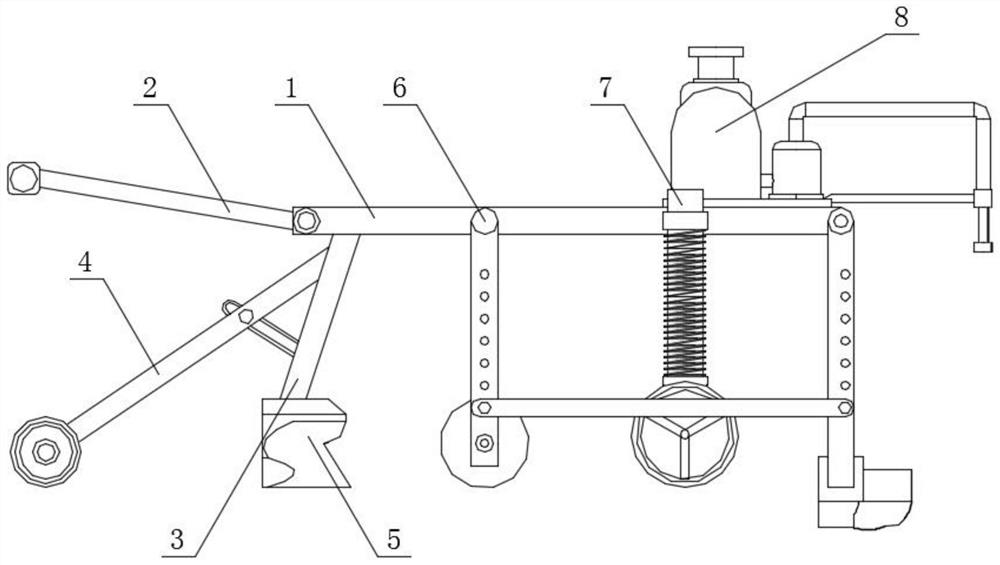

Agricultural planting film mulching device

InactiveCN112154837ASimple structureEasy to installLiquid spraying apparatusPlant protective coveringsAgricultural engineeringAgriculture

The invention discloses an agricultural planting film mulching device which comprises a rack, a traction frame, ditching vertical arms, traction assemblies, ditching coulters, a film laying assembly,film pressing assemblies and a spraying assembly. The traction frame is fixedly installed in the center of the end face of one side of the rack through bolts, and the ditching vertical arms are fixedly installed at the two sides of the bottom of one end of the rack through welding; and the ditching coulters are fixedly installed on the bottom end faces of the ditching vertical arms through bolts,the traction assemblies are arranged at one sides of the exteriors of the ditching vertical arms, the film laying assembly is arranged at the outer side of the end face of the rack, the film pressingassemblies are arranged at the two sides of the interior of the end face of the rack, and the spraying assembly is arranged above the top end face of the rack. When the agricultural planting film mulching device is used, the labor intensity can be effectively reduced, the film mulching quality can be effectively improved, the labor time is saved, and the film mulching efficiency is improved; and meanwhile, the bonding tightness of covering soil and the surface of a film can be improved, and the situation that the covering film falls off can be avoided.

Owner:胡金锁

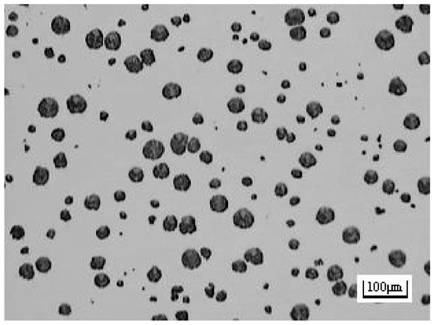

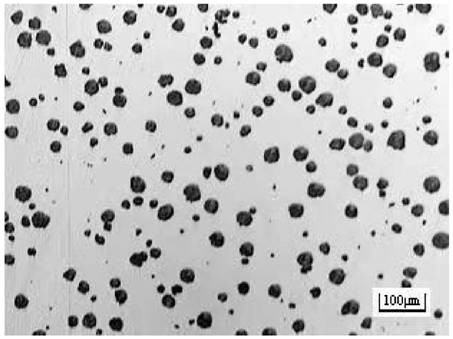

Casting method of oil pressure casting

ActiveCN113070447AImprove mechanical propertiesReduce sizeFoundry mouldsFoundry coresCasting defectDuctile iron

The invention discloses a casting method of an oil pressure casting. The casting method of the oil pressure casting comprises the steps that sand mold manufacturing is conducted, iron liquid preparation is conducted, specifically, raw materials including, by mass, 45%-50% of pig iron, 30%-35% of scrap steel and 15%-25% of foundry returns are weighed; then a carburant which accounts for 0.7%-1.1% of the total amount of the pig iron, the scrap steel and the foundry returns is added; spheroidizing and inoculating are conducted, spheroidized iron liquid is slagged off and stood, and the iron liquid is poured into a casting system of the oil pressure casting in the step (1) when the temperature is reduced to 1370 DEG C-1400 DEG C so as to form a casting; metal-stream inoculation is carried out by using inoculation powder while pouring is carried out, and the addition amount of the inoculation powder is 0.08%-0.10% of the total mass of the raw iron liquid; and after the casting is cooled, the nodular cast iron oil pressure casting is obtained. The casting method of the oil pressure casting has the advantages that the structure is firm, the strength is high, the defects of sand falling, slag inclusion, air holes and the like are not prone to occurring, the oil pressure working face structure of the obtained casting is smooth and free of casting defects and white openings, and the method can be used under the high-pressure condition and is free of oil leakage and oil seepage.

Owner:宁波拓铁机械有限公司

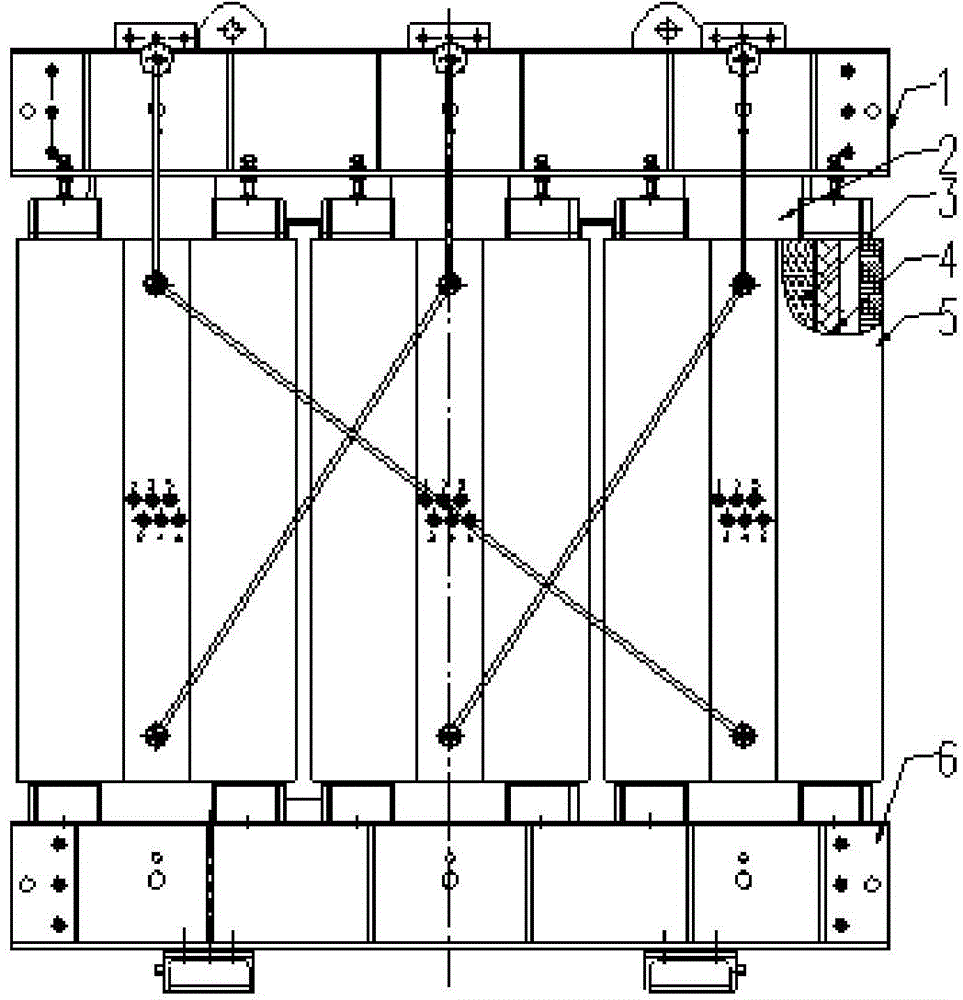

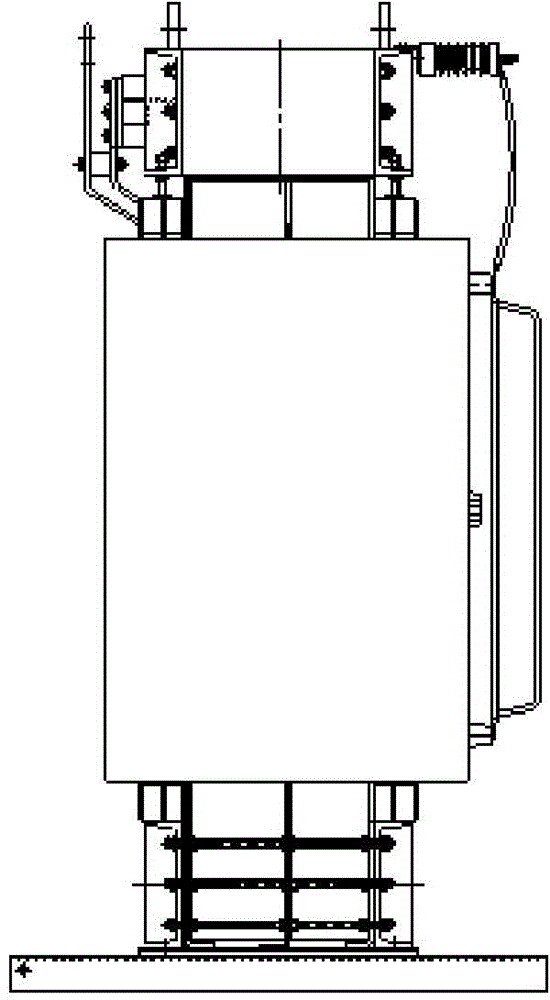

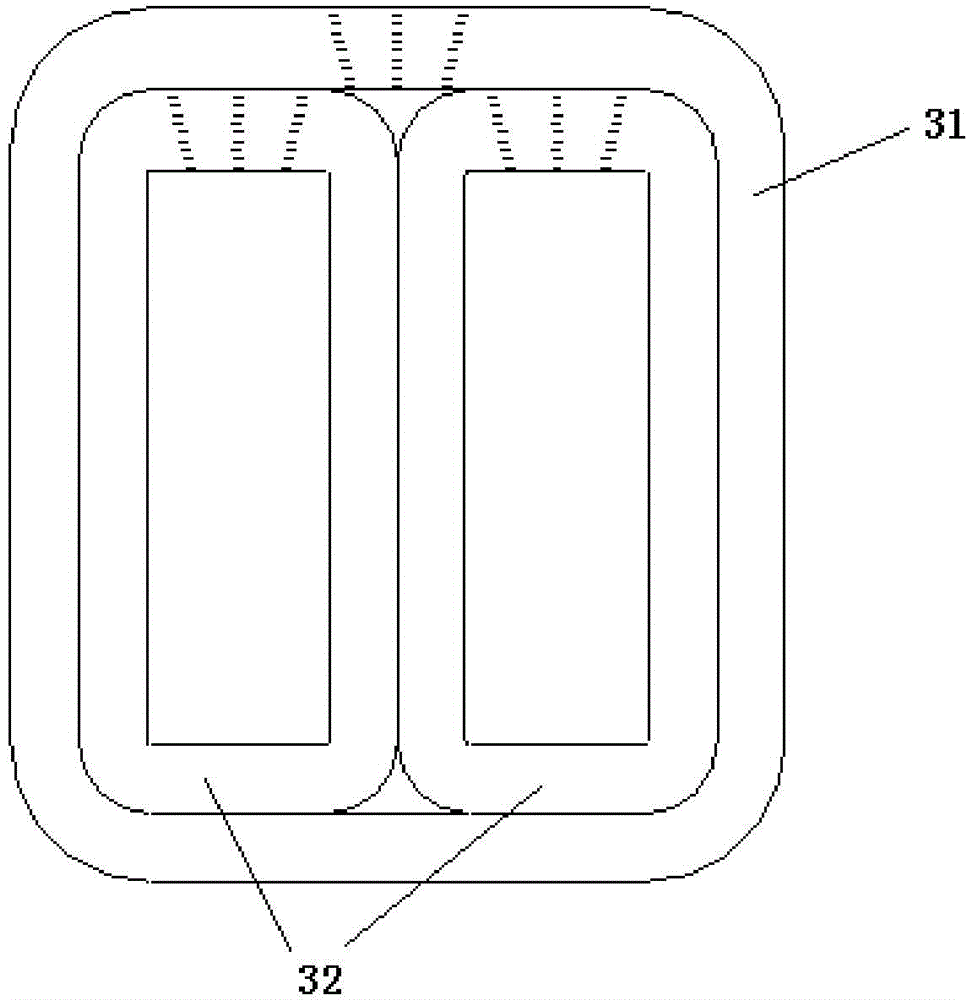

Three-column pull plate type dry amorphous alloy transformer

InactiveCN106158281AUniform magnetic circuitSmall capacitance to groundTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLow voltageAlloy

The invention relates to a three-column pull plate type dry amorphous alloy transformer which is used for being connected with a group grid system through a triangular or star connection method, the transformer comprises an upper clamping piece, a pull plate, a lower clamping piece and an iron core, the upper clamping piece, the pull plate and the lower clamping piece are sequentially connected from top to bottom, and the iron core is fixedly connected with the pull plate. The iron core is an amorphous alloy iron core, a three-phase three-column type structure is adopted, and the iron core is sequentially sleeved with a low-voltage coil and a high-voltage coil. Compared with the prior art, the three-column pull plate type dry amorphous alloy transformer has the advantages that the three-phase three-column structure is achieved, the transformer is suitable for the triangular connection method and the star connection method, the loss and noise are low, and the structure is firm.

Owner:SHANGHAI FLYING KING ELECTRIC

Perming agent, application of perming agent and perming method

InactiveCN107510207AFully heat stableStructural fasteningCosmetic preparationsHair cosmeticsHeating timeComputer science

The invention discloses a perming agent, application of the perming agent and a perming method, and relates to the technical field of perming. The purpose is to improve the technical problems that by means of an existing perming agent, standard perming conditions cannot be provided focusing on different hair qualities and damage to hair is likely to occur. The perming agent contains a perming medium prepared from water and an acid-base balancing agent in a mass ratio of 10 to 1-10 to 8; in the conditions of the same perming temperature, perming tension and hair piece size, the perming heating time is positively correlated with the use amount of the perming medium. The perming agent provides a premise and a guarantee for datamation of the perming technology. The perming method comprises the following steps that after the use amount of the perming medium, the perming heating time and the diameter of a perming rod are determined, the perming medium is applied on softened hair, and perming is conducted on the determined hair piece according to the determined perming heating time; after a paste preparation is applied, the hair is combed. According to the method, through calculation of the use amount of the perming medium and the perming time, accurate technical guidance and theoretical data can be provided for perming, and the method is beneficial to achieving standardized perming.

Owner:河南省居艺红人工智能科技有限责任公司

Two-dimensional combined type packaging frame and express packaging bag adopting same

ActiveCN111874401AHigh mechanical strengthPrevent sideways bendingFlexible container closureContainers to prevent mechanical damageStructural engineeringMechanical engineering

The invention discloses a two-dimensional combined type packaging frame and an express packaging bag adopting the same. An upper frame, a lower frame and stand columns of the packaging frame are of aninserting-mounting structure, are fixed through inserting plates at the same time, and are used for placing objects on the inner side of the packaging frame in the transportation and storage processes; and the objects are fixed to the inner side of the packaging frame through filler or in a hanging mode, extrusion is prevented, the upper frame and the lower frame are of an integrated structure, thus the mechanical strength is higher, and the packaging frame is suitable for packaging and transporting the large-size objects. As for the composition mode of the express packaging bag, an inner packaging bag is hung on the inner side of the packaging frame, an outer packaging bag is mounted on the outer side of the packaging frame in a sleeving mode, the inner packaging bag is used for packaging the objects, collision and extrusion of the objects are avoided in the transportation and storage process in a hanging mode, the outer packaging bag forms outer-layer protection, and a seal is arranged in a matched mode, so that the privacy of the objects is ensured; and the key point is that the packaging frame and the express packaging bag can be recycled, the logistics cost is reduced, paperpackaging boxes are gradually eliminated, and resources are saved.

Owner:重庆科林包装制品有限公司

Nut having cutting and fastening structure thereof

InactiveUS20070292232A1Increase surface frictionStructural fasteningNutsBoltsScrew threadEngineering

A nut having a cutting and fastening structure thereof applied to fasten at least a board with a hole are disclosed. The nut has at least a cutting through itself. The fastening structure includes a bolt and a nut. When the nut is threaded on the bolt, the cutting of the nut and threads of the bolt touch each other for increasing the friction.

Owner:ASUSTEK COMPUTER INC

Broadband slot dipole antenna

ActiveCN108879076ARealize coupled feedStructural fasteningRadiating elements structural formsRadiating element housingsElevation angleElectrical conductor

The invention discloses a broadband slot dipole antenna. The structure of the antenna is jointly formed by an antenna housing, a mounting plate, a slot dipole, a feeder panel and a radio-frequency connector. By arranging a rectangular metal conductor slot dipole structure which is slotted in a central symmetry mode, the slot dipole and the mounting plate are perpendicularly fastened; the feeder panel is a composite substrate, wherein a special-shaped metal printed circuit is photo-etched on one face of the composite substrate, and the light panel face of the feeder panel is orthogonal and attached to the slot dipole at the biasing position; and the radio-frequency connector is fastened to the back face of the mounting plate, and a probe of the radio-frequency connector penetrates through the mounting plate to be connected with one end of the printed circuit of the feeder panel. The antenna can effectively overcome the defects of pattern interference, narrow bandwidth, low elevation angle and low gain of an existing telemetry system antenna, has the good structure strength and is particularly suitable for a telemetry system on an aircraft.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

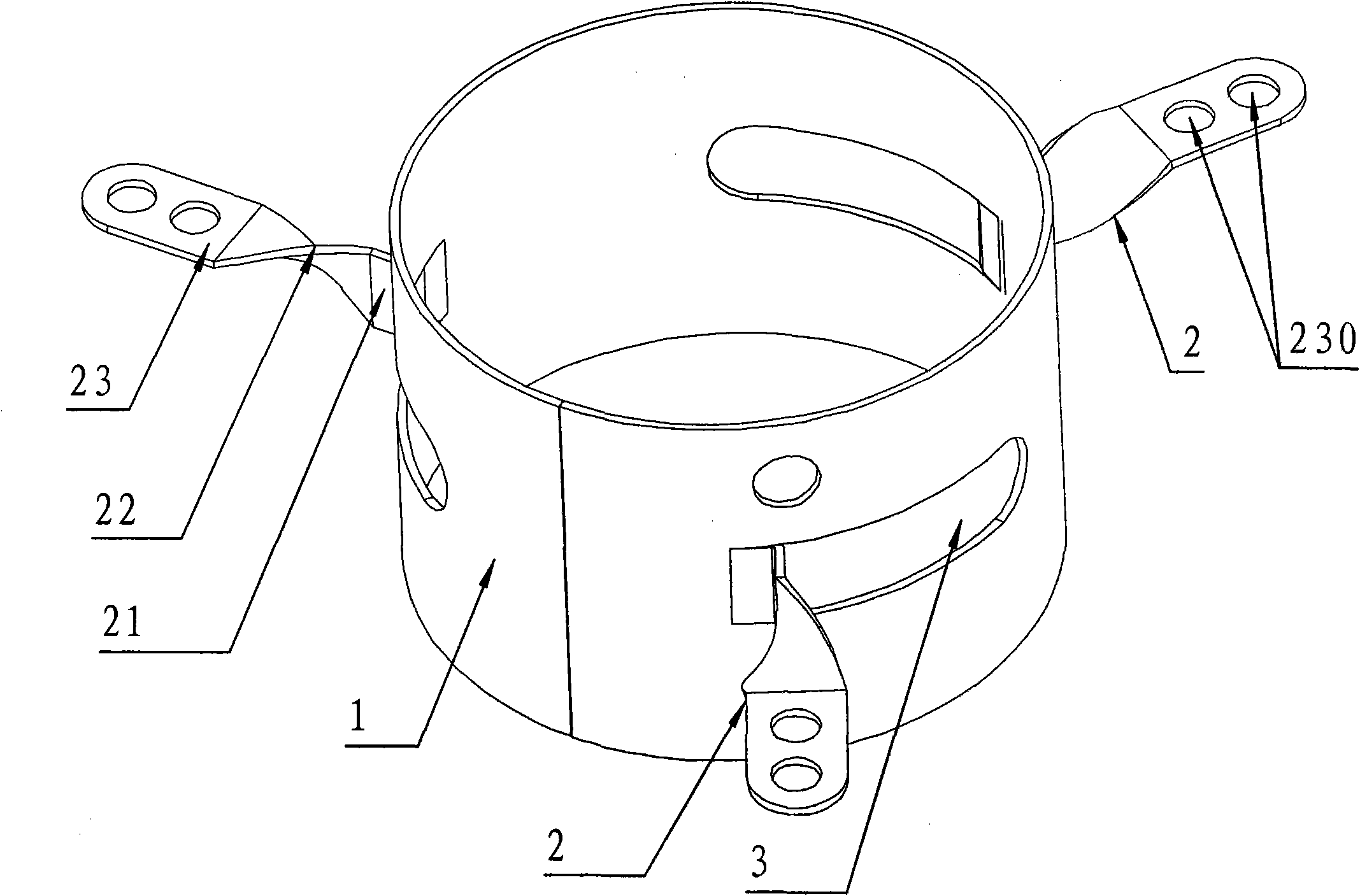

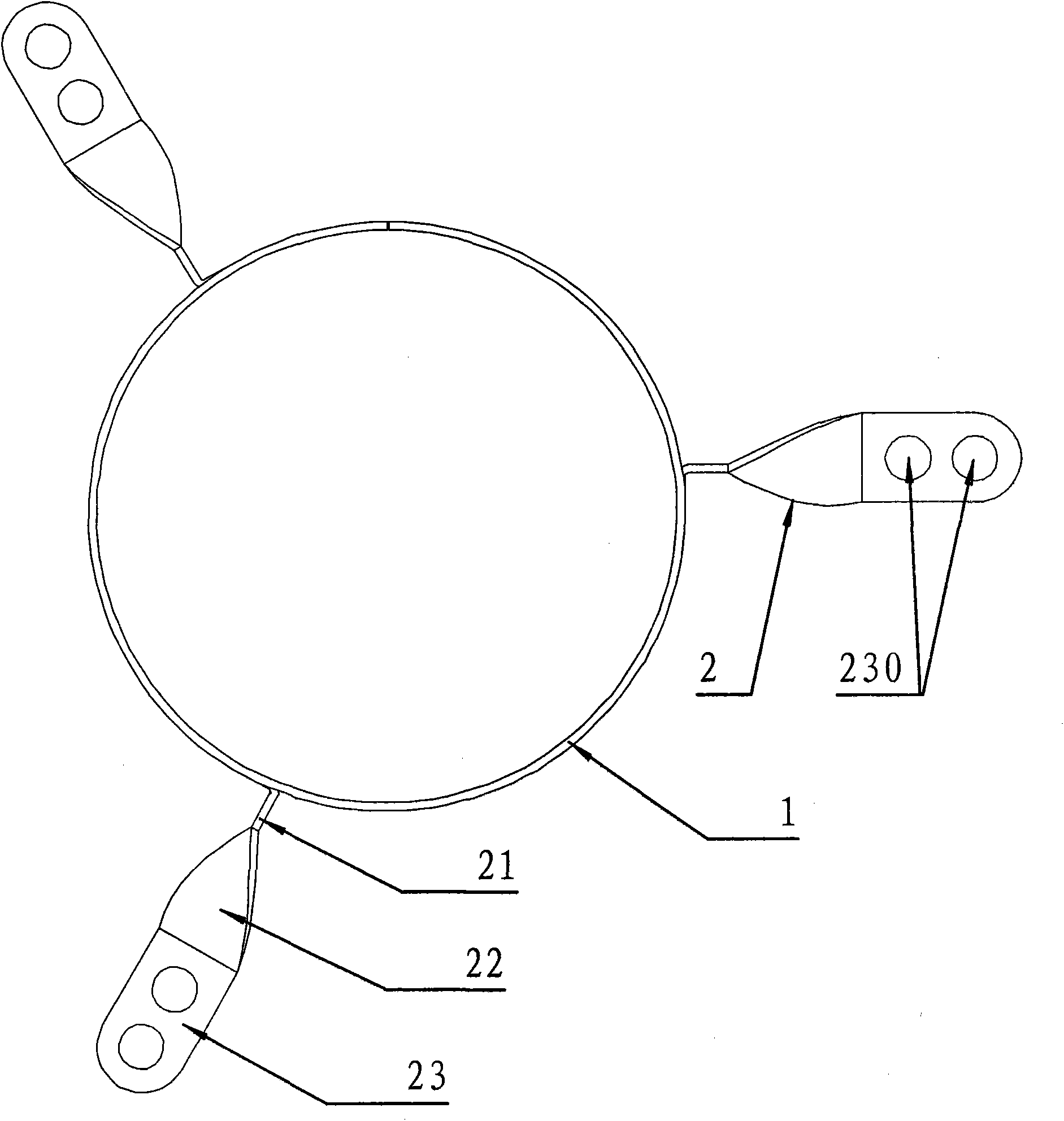

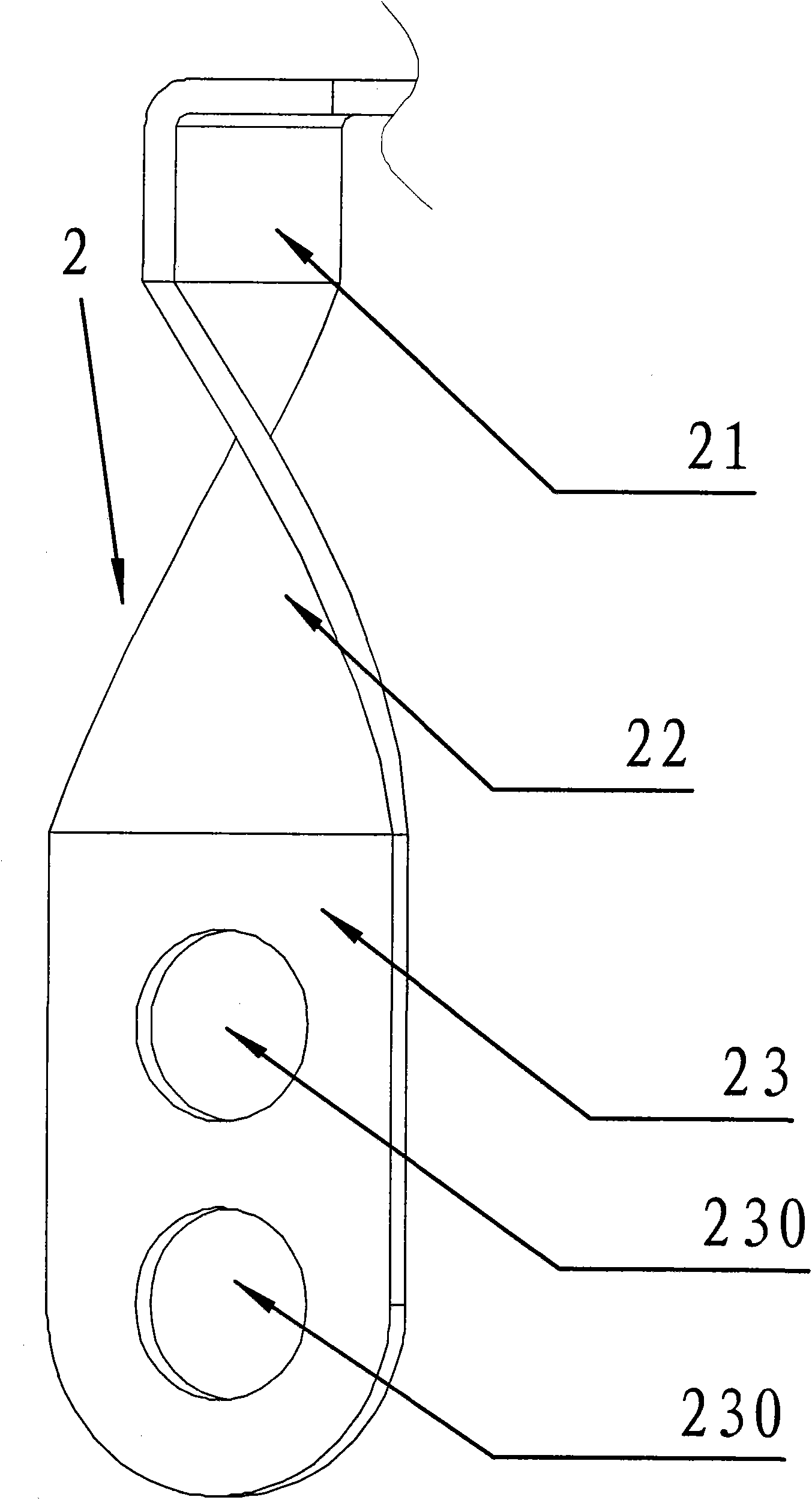

Motor case

The invention discloses a motor case, comprising a hollow motor shell (1), wherein a plurality of supports (2) are punched on the wall surface of the hollow motor shell, a groove (3) is formed beside the supports (2) and on the wall surface of the motor shell (1), one end of each support (2) is connected onto the wall surface of the shell (1), partial material of the motor shell is fully utilized, maximization on material utilization is realized, a welding or riveting process is reduced, potential safety hazard caused by secondary connection is reduced, and material cost and production cost are greatly reduced.

Owner:ZHONGSHAN BROAD OCEAN

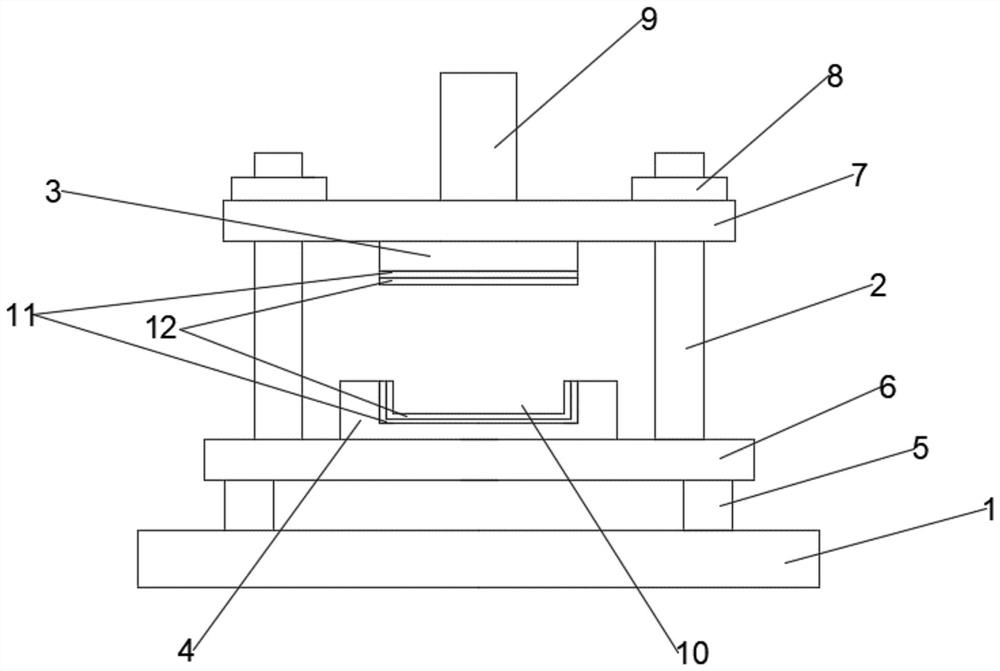

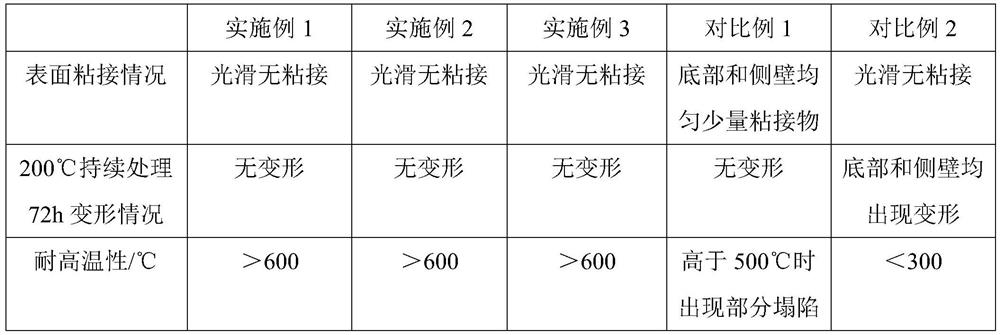

Machining equipment for injection mold casting

The invention relates to machining equipment for injection mold casting. The equipment comprises a fixed bottom plate, guide columns, an upper mold and a lower mold, a plurality of fixed columns are fixedly arranged on the upper surface of the fixed bottom plate, and a supporting plate is arranged at the upper ends of the fixed columns; the lower mold is correspondingly arranged below the upper mold, the lower mold is fixedly arranged above the supporting plate, and a cavity of a concave structure is formed in the upper surface of the lower mold; and the lower surface of the upper mold and the surface of the cavity are each provided with an easy-to-demold layer, and each easy-to-demold layer comprises a reinforcing layer and an anti-adhesion layer which are sequentially arranged from inside to outside. According to the machining equipment for injection mold casting, the machining equipment for injection mold casting is arranged to be of an integrated structure of the fixed bottom plate, the guide columns, the upper mold and the lower mold, the fixed bottom plate and the guide columns play a supporting and fixing role, so that normal operation of the upper mold and the lower mold is guaranteed, the overall structure is firmer through the connection relation of the guide columns, the supporting plate and a connecting plate, the connecting strength is high, and collapse and falling are not prone to occurring in the using process.

Owner:广州盈在科技有限公司

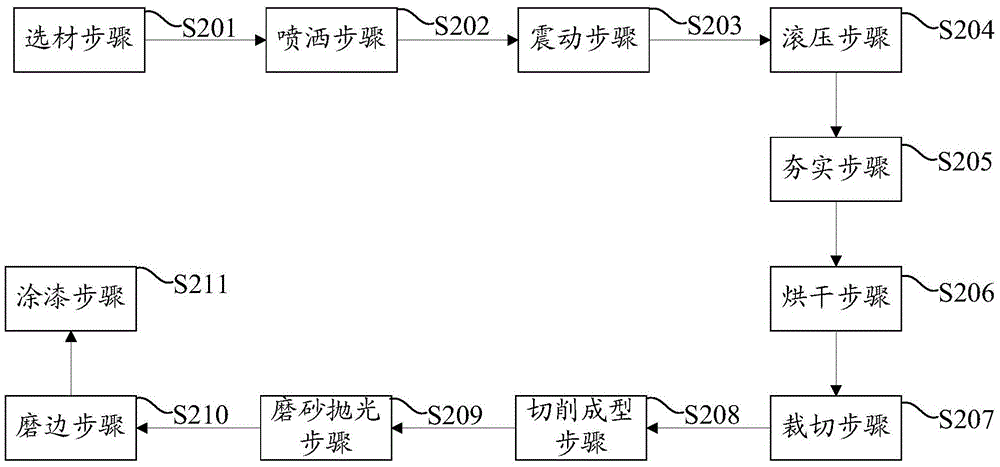

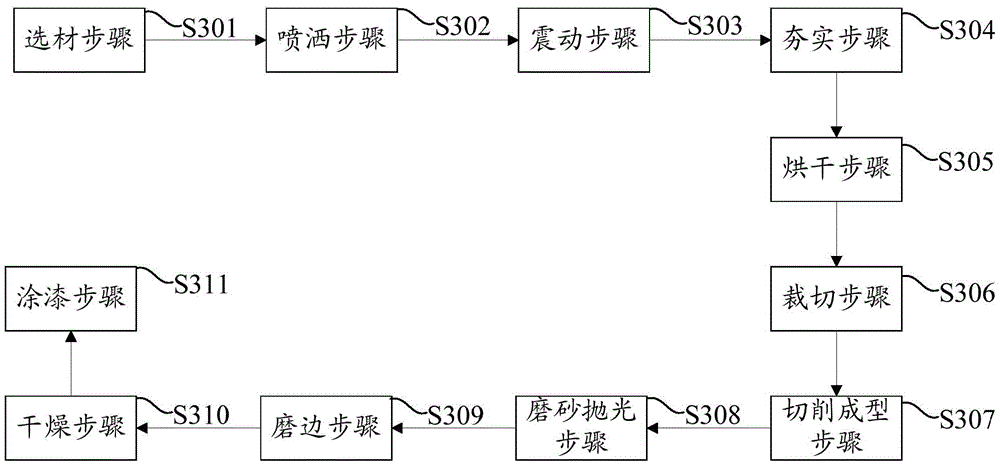

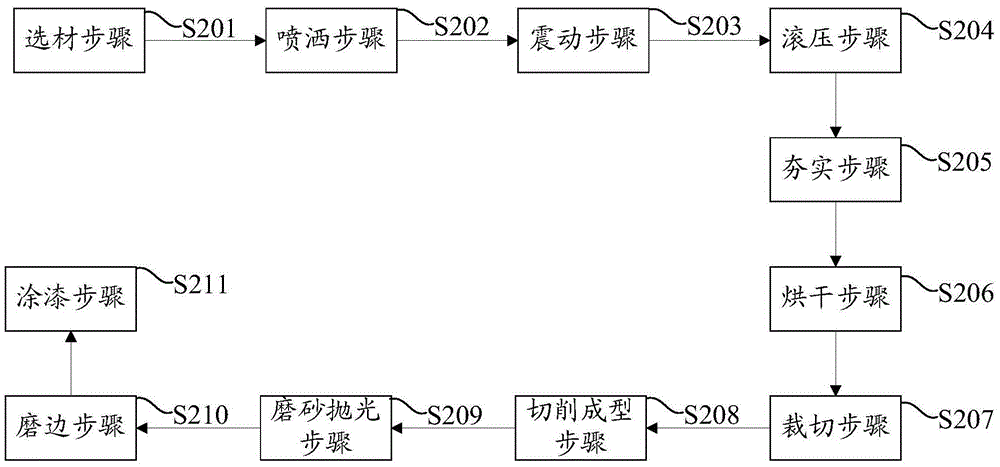

Basswood shell manufacturing process

ActiveCN105563594AStructural fasteningImprove wear resistanceWood working apparatusWear resistanceMaterials science

The invention relates to a basswood shell manufacturing process. The basswood shell manufacturing process comprises the following steps: material selecting, spraying, vibrating, rolling, tamping, drying, cutting, cutting molding, polishing, edge grinding and painting. According to the basswood shell manufacturing process, superior basswood is selected, after being wetted thoroughly, the basswood is tamped and then dried, so that the structure of the basswood is fastened, a manufactured mobile phone shell is high in hardness and has good wear resistance, and the service life of the mobile phone shell is prolonged.

Owner:浙江泰星儿童玩具有限公司

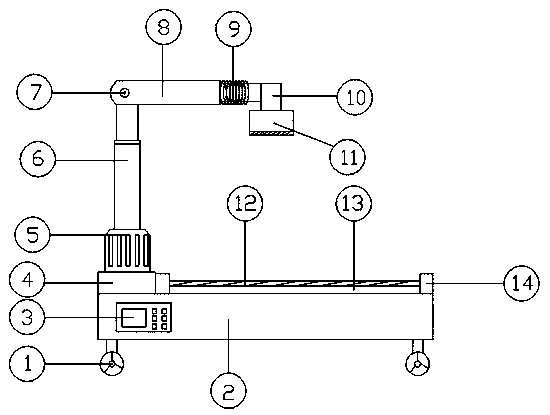

Movable printing device

InactiveCN109334229AAvoid affecting the printing effectReduce manpower consumptionRotary pressesPrinting press partsEngineeringPressure - action

The invention discloses a movable printing device comprising sliding wheels, a base, a control panel, a fixing seat, a motor, a lifting air cylinder, fixing bolt, a telescopic mechanical arm, a resetspring, a connection block, a print head, an electromagnetic attracting plate, a face plate and limiting blocks. The movable printing device is characterized in that the sliding wheels are arranged onthe lowest portion of the whole structure, the telescopic mechanical arm is arranged at the top end of the lifting air cylinder, and the left end and the right end of the panel are each provided withone limiting block. According to the movable printing device, the device is controlled to move through the sliding wheels, so that manpower consumption is reduced; a product is firmly attracted to the face plate through the electromagnetic attracting plate, so that the fixation function is achieved; the lifting air cylinder moves up and down through the pressure action, so that the height position of the print head can be adjusted according to products of different sizes; the print head can be driven by the telescopic mechanical arm to move in the horizontal direction, so that more complete printing can be conducted on the product, and the printing precision is improved. The movable printing device further has the features of being low in manufacturing cost, firm and durable and achievingflexible connection of all components.

Owner:滁州千字文印务有限公司

Water pipe joint and water pipe mounting structure

InactiveCN106764142AInhibit sheddingStructural fasteningScrew threaded jointsEngineeringScrew thread

The invention discloses a water pipe joint and a water pipe mounting structure. The water pipe joint comprises a stud and a screw head, wherein the center of the stud and the center of the screw head are hollow tubular structures; and outer thread teeth are arranged on the outer surface of the stud. The water pipe joint is simple in production process, is relatively good in sealing property, can be quickly mounted on the spot, and is very practical.

Owner:SHENZHEN VMAX POWER

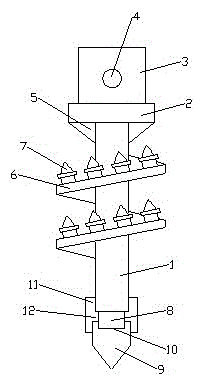

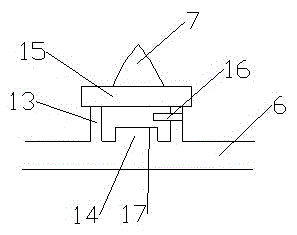

Reinforced concrete rotary drill bit

The invention belongs to the drill bit technical field, and especially relates to a reinforced concrete rotary drill bit comprising a drill spindle; the top of the drill spindle is provided with a connecting ring having a connecting pole; a connecting hole is arranged in the connecting pole; the bottom face of the connecting ring is provided with a reinforcement plate; the other side of the reinforcement plate is fixed on the drill spindle; the outer wall of the drill spindle is provided with a spiral slice having annular limit platforms; picks are arranged in the limit platforms; the spiral slice is also provided with limit bosses arranged in middles of the limit platforms; the bottom face of the pick is provided with a limit groove matched with the limit boss; the outer wall of the pick is provided with a limit ring arranged on the top of the limit platform; the pick is connected with the limit platform through a bolt.

Owner:天津市八方工程机械设备有限公司

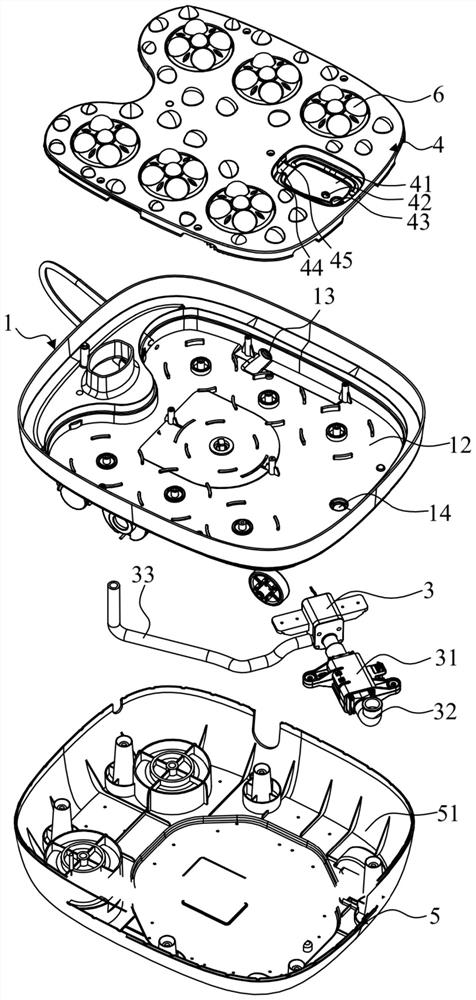

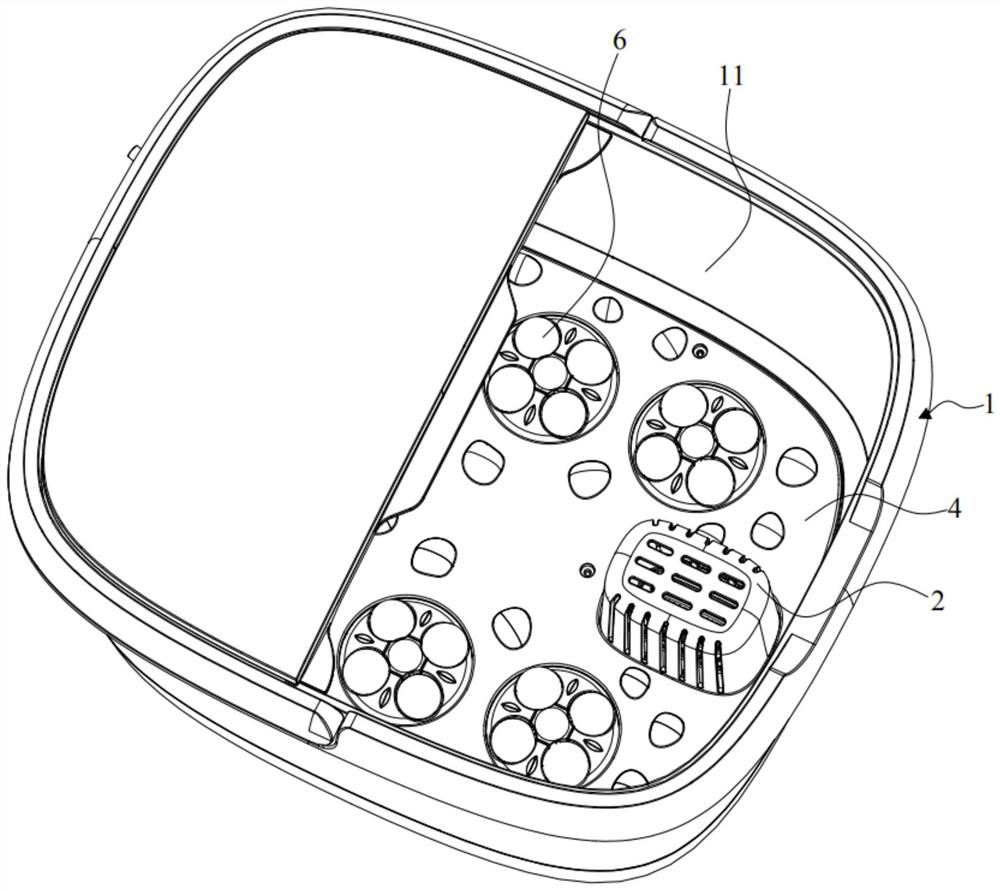

Filtering mechanism and foot bath device

PendingCN111870160ASolve the real problemStructural fasteningMechanical apparatusBathsMedicineWater leak

The invention provides a filtering mechanism and a foot bath device, the filtering mechanism relates to a shell and comprises a filtering box and a circulating water pump, a chassis cover is arrangedin the shell and divides an inner cavity of the shell into an upper cavity and a lower cavity, a mounting groove is formed in the top of the chassis cover, and a medicine box is arranged in the mounting groove. When the filtering mechanism is applied to the foot bath device, the upper cavity can serve as a foot bath cavity, Chinese herbal medicine and the like are placed in the medicine box to besoaked, the circulating water pump is started, and therefore water in the upper cavity passes through the medicine box, then enters the mounting groove and returns to the upper cavity, and the medicine box is flushed through the rapidly-circulating water; the medicine effect can rapidly permeate out, and the exertion of the medicine effect is improved; when the foot bath device is not used, residual water in the upper cavity and the mounting groove can enter the lower cavity through the water leakage holes, and the residual water in the upper cavity and the mounting groove is avoided.

Owner:WUHU BEICI ELECTRICAL APPLIANCE CO LTD

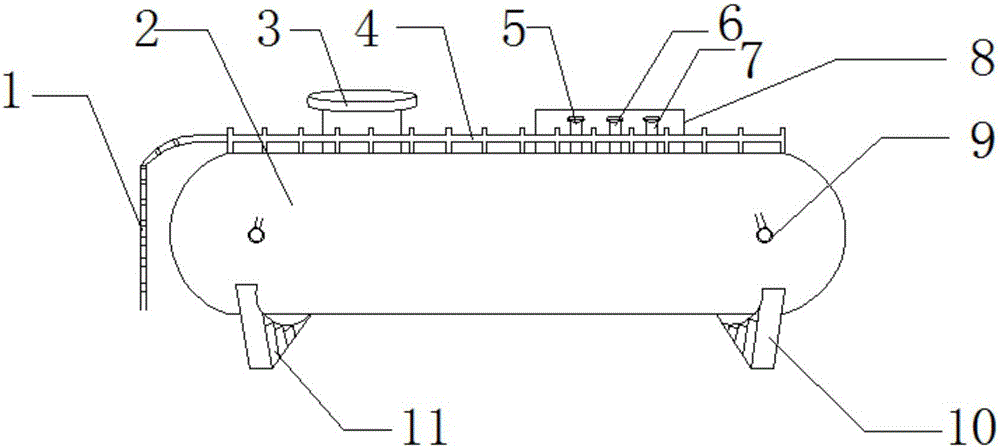

Novel oil storage tank for oil storage and transportation

InactiveCN106185088AEasy to transportEasy to insertLarge containersTank wagonsBreatherThermal insulation

The invention discloses a novel oil storage tank for oil storage and transportation. The novel oil storage tank comprises an escalator, an oil storage tank body, a liquid inlet, a railing rack, a breather valve, an oil inlet hole, an oil outlet hole, a thermal insulation box, a plurality of hanging rings, pedestals and bearing bases. According to the novel oil storage tank, structural connection is firm, the hanging rings are arranged on the surface of the oil storage tank body, the oil storage tank can be lifted through the hanging rings, and thus transportation of the oil storage tank can be facilitated. The breather valve, the oil outlet hole and the oil inlet hole are arranged in the thermal insulation box, a certain temperature of the inside of the thermal insulation box is guaranteed, mobility of oil products can be improved by raising the temperature of the oil products, and therefore the oil products can be output smoothly from the inside of the oil storage tank, and practicability is ensured. The escalator and the railing rack are arranged at the tail and the top of the oil storage tank body correspondingly, and accordingly a worker can climb upon the top of the oil storage tank to insert a pipeline into the oil inlet hole and the oil outlet hole conveniently. The liquid inlet is formed in the top of the oil storage tank, maintenance personnel can enter the oil storage tank for maintenance and overhaul conveniently. The novel oil storage tank is simple in overall structure, high in applicability and capable of being applied and popularized.

Owner:四川启昌管道工程有限责任公司

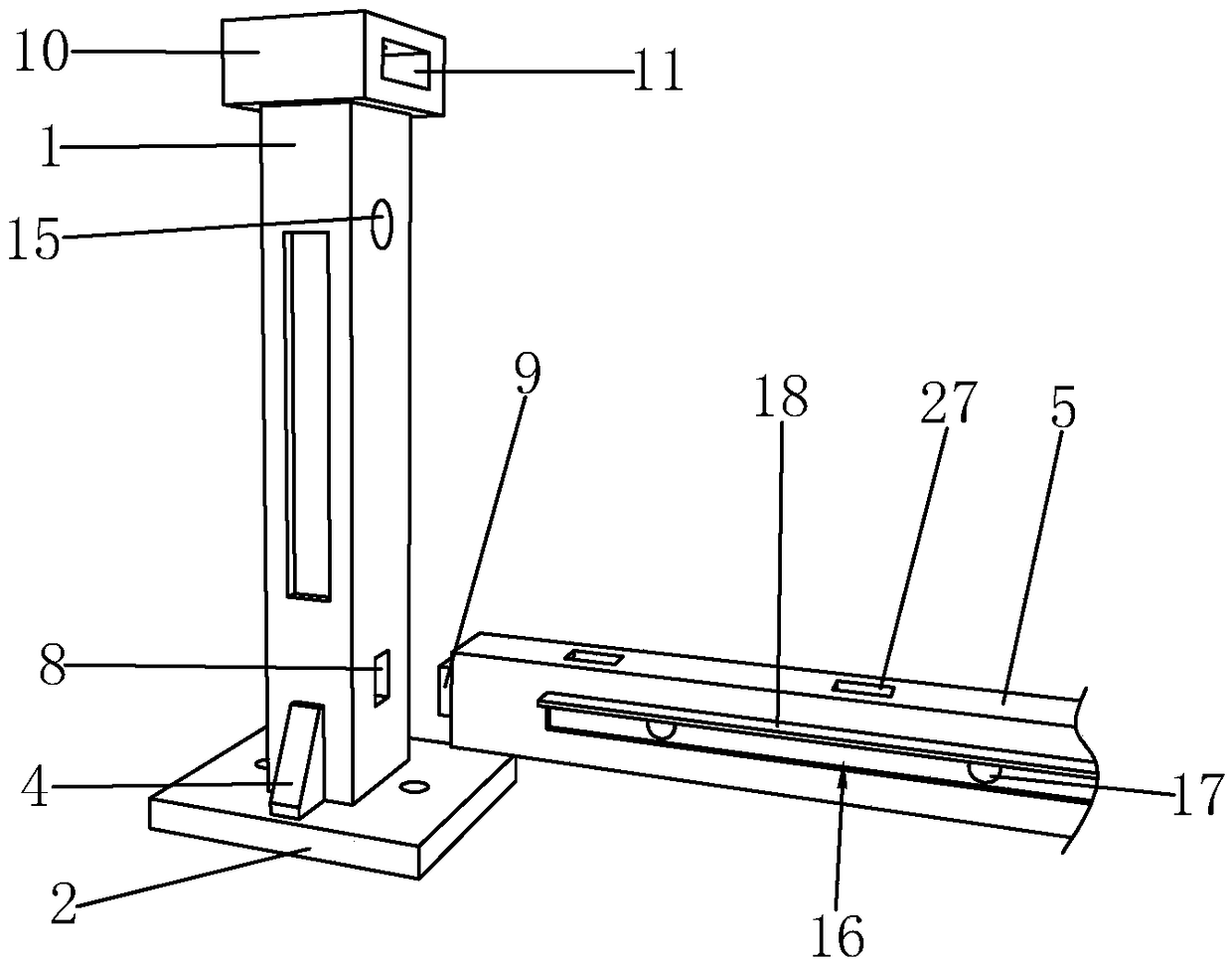

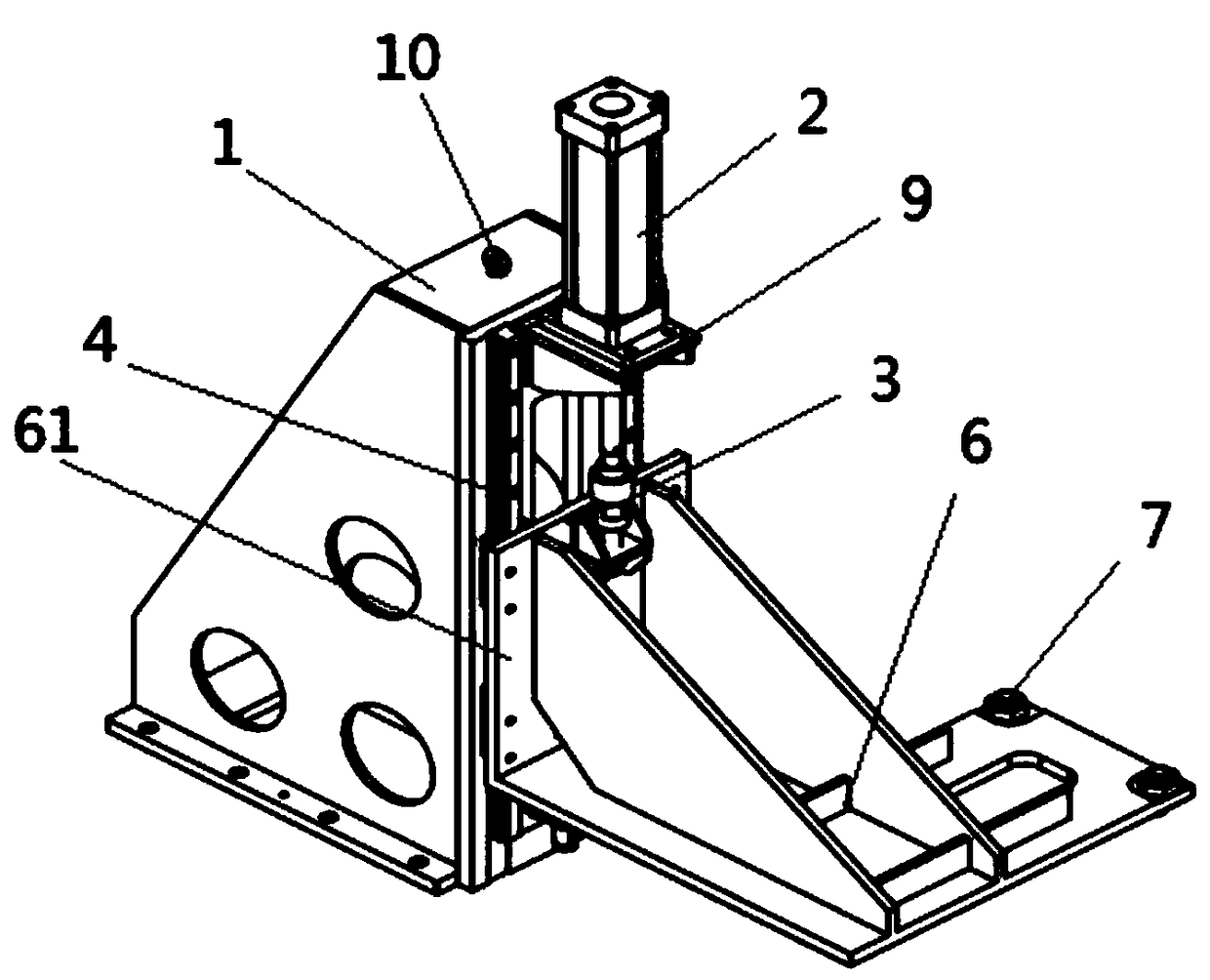

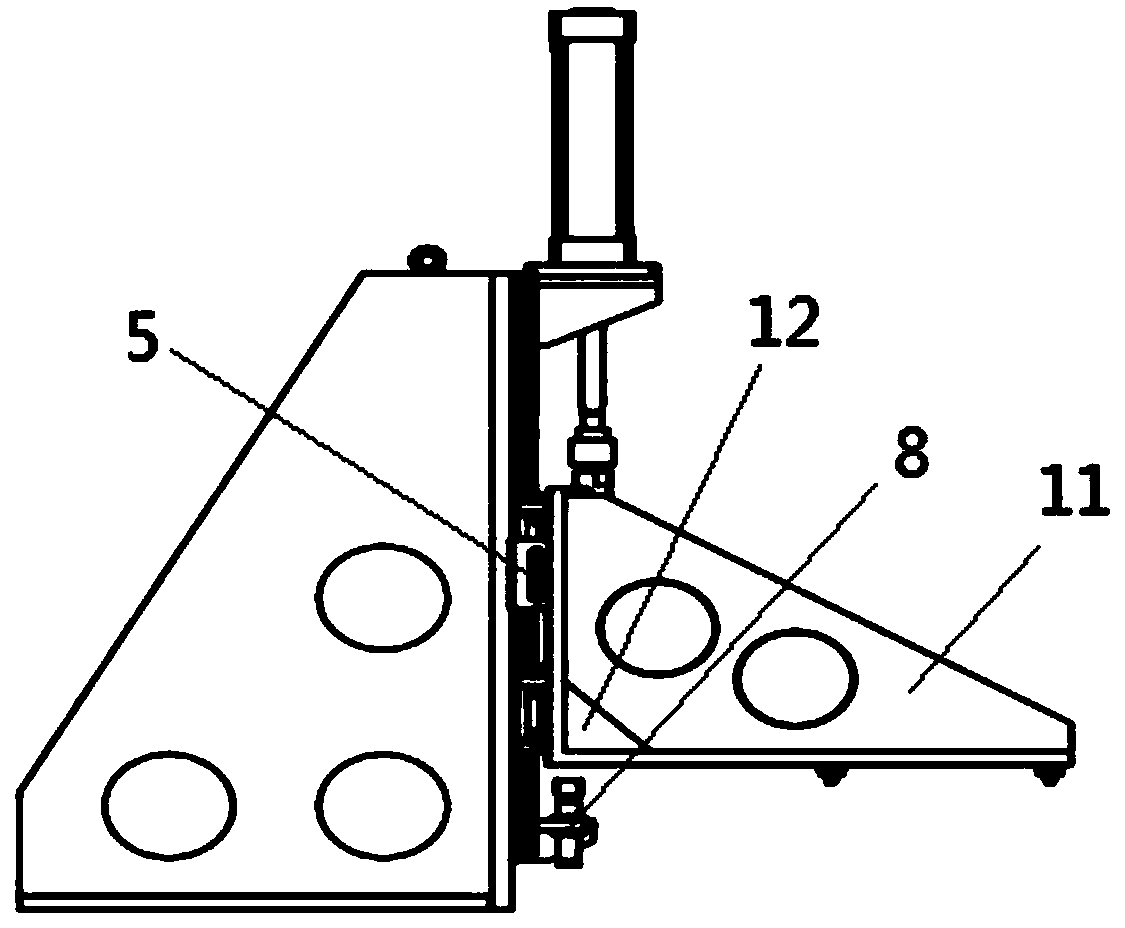

Engine cylinder body compressing device

The invention discloses an engine cylinder body compressing device which comprises a fixing frame, an air cylinder, a slide rail, sliders, a pressing plate and a positioning pin. An air cylinder supporting frame is arranged on the upper portion of the fixing frame and provided with a penetrating hole. The slide rails are fixed to the fixing frame and arranged on two sides of the supporting frame correspondingly in a vertically downward mode. The air cylinder is fixed to the supporting frame, and a guide rod of the air cylinder penetrates out of the penetrating hole of the supporting frame andis vertically downward. The pressing plate is composed of an L-shaped plate and a connecting plate, the connecting plate is perpendicularly fixed to the rear end of the L-shaped plate, and the plate surface of the connecting plate is slidably arranged on the slide rails through the sliders. The positioning pin is fixed to the front end of the L-shaped plate. The lower end of the guide rod of the air cylinder is connected with the upper portion of the connecting plate. The engine cylinder body compressing device has the advantages that the structure is simple, work is reliable, the compressingeffect on the plane of an engine is good, and interference with assembly accessories is avoided.

Owner:GUANGXI YUCHAI MASCH CO LTD

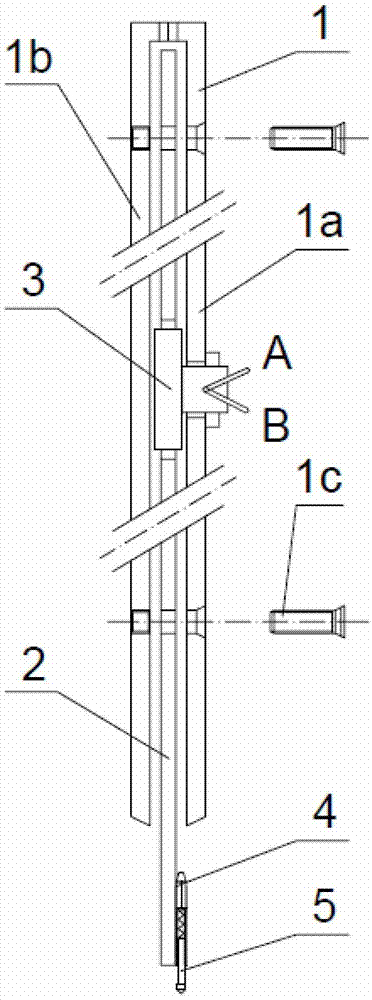

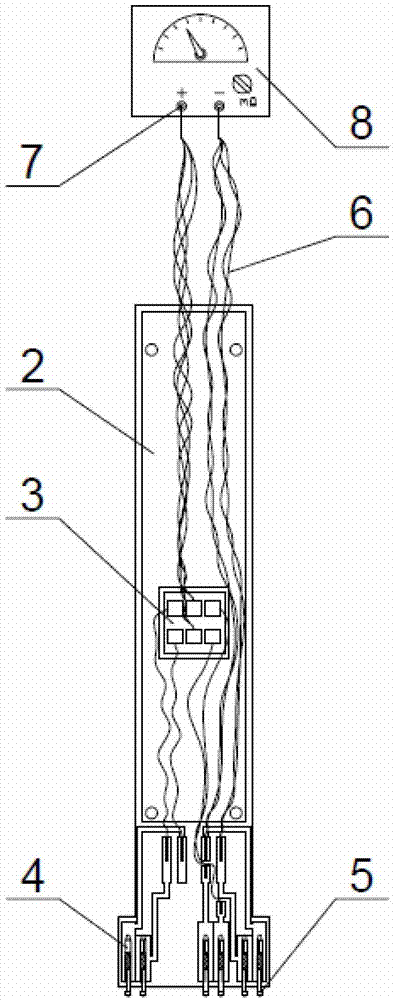

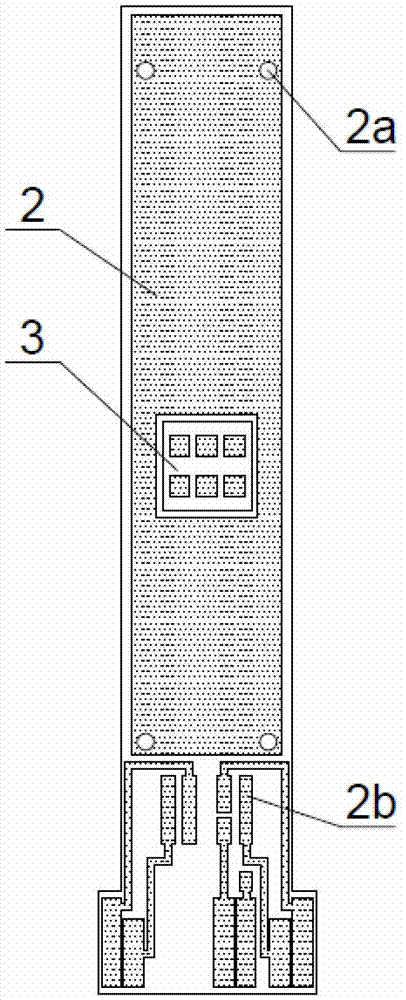

Method for testing micro-resistance library sheet resistance value of printed wiring board

InactiveCN102967762AStructural fasteningEasy to cleanResistance/reactance/impedenceEnvironmental resistanceTest efficiency

The invention discloses a method for testing a micro-resistance library sheet resistance value of a printed wiring board. The method is characterized by comprising the following steps of processing the printed wiring board before appearance milling, performing milling processing to a resistance value test library and testing micro-resistance. A micro-resistance testing device consists of a testing probe, a lead and a plug special for a micro-resistance tester, wherein the testing probe consists of a casing, a printed board, a double-pole double-throw switch, a spring testing needle sleeve and a spring testing needle. The casing of the micro-resistance testing device is made of a plastic material, and an upper casing and a lower casing are fixed through a screw and are fastened in structure, convenient to dismantle, clean and maintain, economic and environment-friendly. The micro-resistance testing device can be held by one hand and respectively performs resistance value testing to through hole micro-resistance and laser hole micro-resistance, and the test efficiency is improved.

Owner:DALIAN PACIFIC ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com