Three-column pull plate type dry amorphous alloy transformer

A technology of amorphous alloy and transformer, which is applied in the field of three-column pull-plate type dry-type amorphous alloy transformer, can solve the problem that star connection cannot be used to connect group power grid systems, star connection power grid systems cannot be applied, and the scope of application And regional restrictions and other issues, to achieve the effect of low noise, small footprint and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

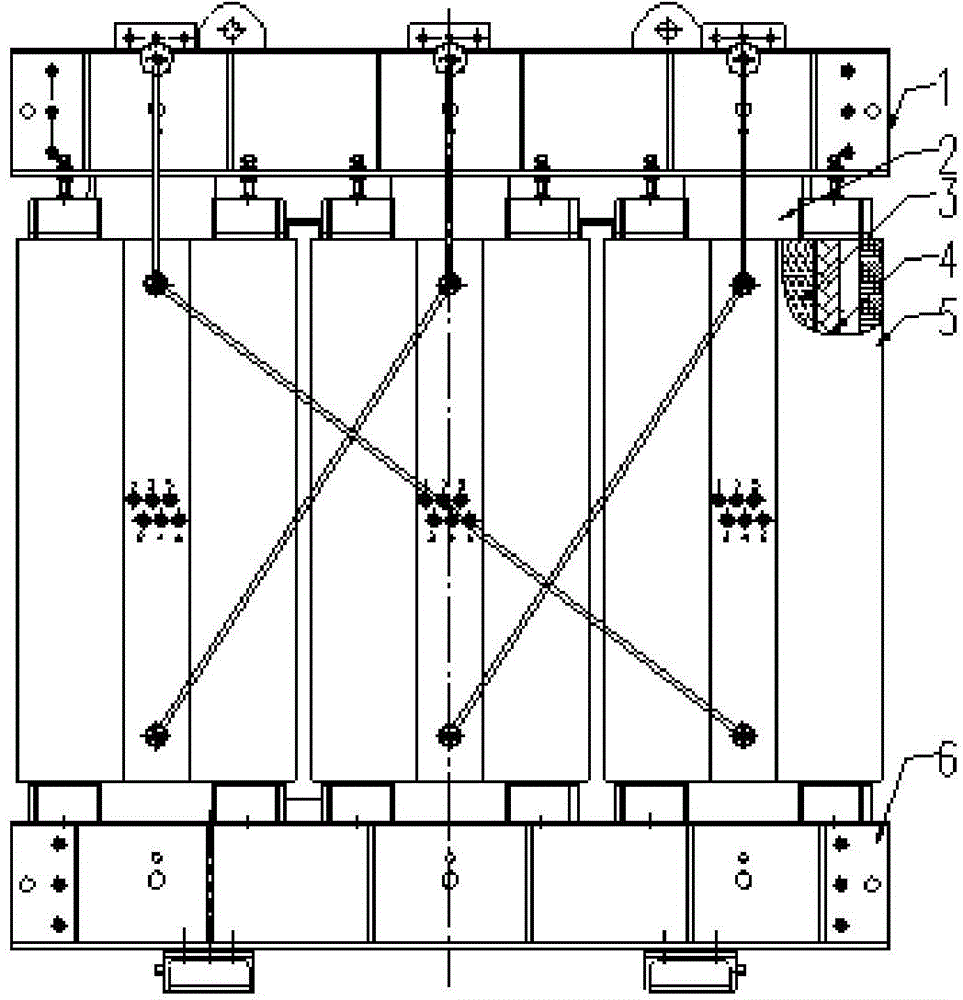

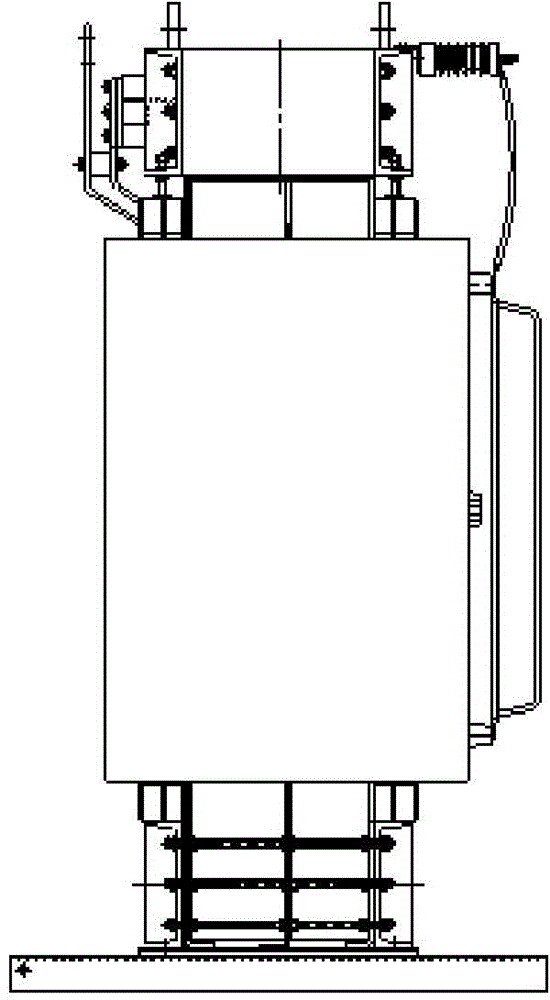

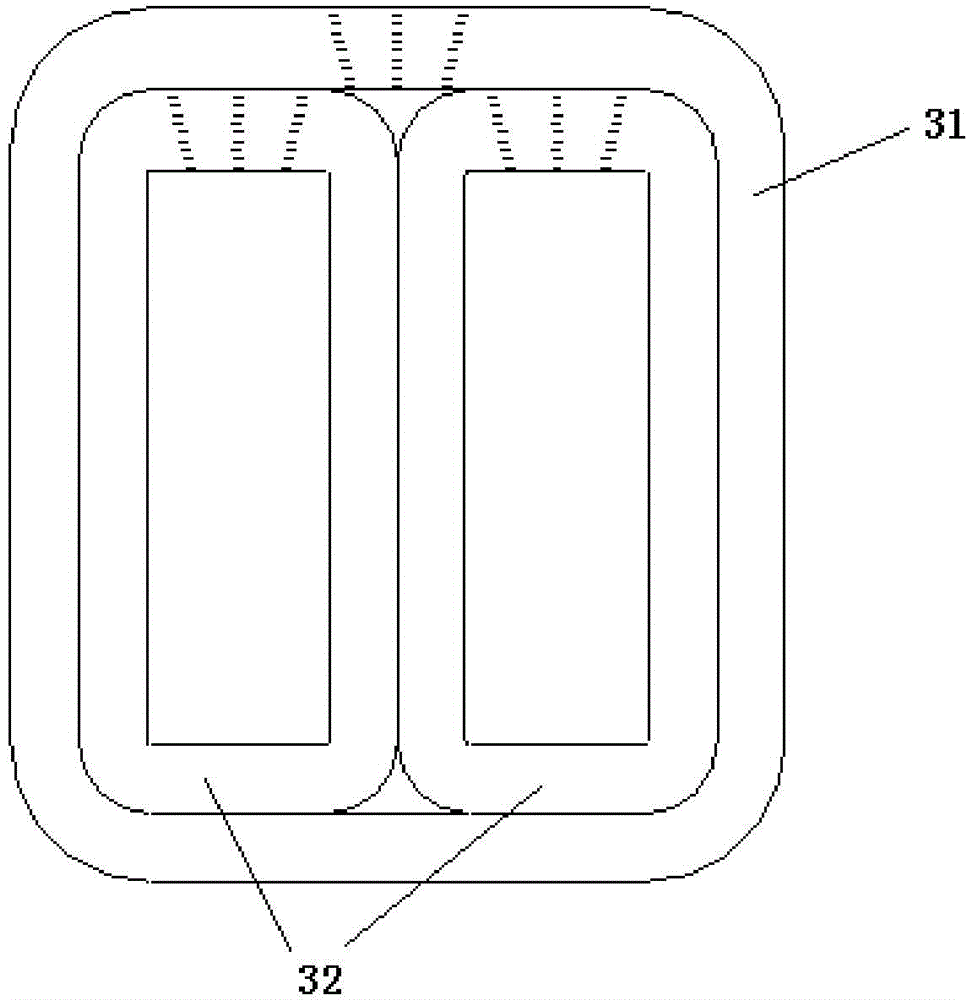

[0028] Such as figure 1 and 2 As shown, a three-column pull-plate type dry-type amorphous alloy transformer is used in a delta or star connection group grid system. The transformer includes an upper clamp 1, a pull plate 2 and a lower clamp connected sequentially from top to bottom The clip 6 and the iron core 3 fixedly connected with the pull plate 2, the iron core 3 is an amorphous alloy iron core, and adopts a three-phase three-column structure, and the iron core 3 includes an outer frame iron core 31 and two inner frame iron cores Core 32 , the two inner frame iron cores 32 are arranged inside the outer frame iron core 31 , and the end surfaces of the outer frame iron core 31 and inner frame iron core 32 are coated with epoxy resin.

[0029] Such as Figure 4 and 5 As shown, the pull plate 2 is formed by a steel plate according to the size of the iron core. There are many small holes on the pull plate 2. The pull plate and the iron core 3 are fully bonded to form a whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com