Motor suitable for electric toothbrush and implementation method thereof

An electric toothbrush and the technology of the realization method are applied in the direction of dentistry, electrical components, electromechanical devices, etc., which can solve the problems of easy damage and difficult repair, and achieve the effects of high magnetic field utilization rate, increased life, and improved motor life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

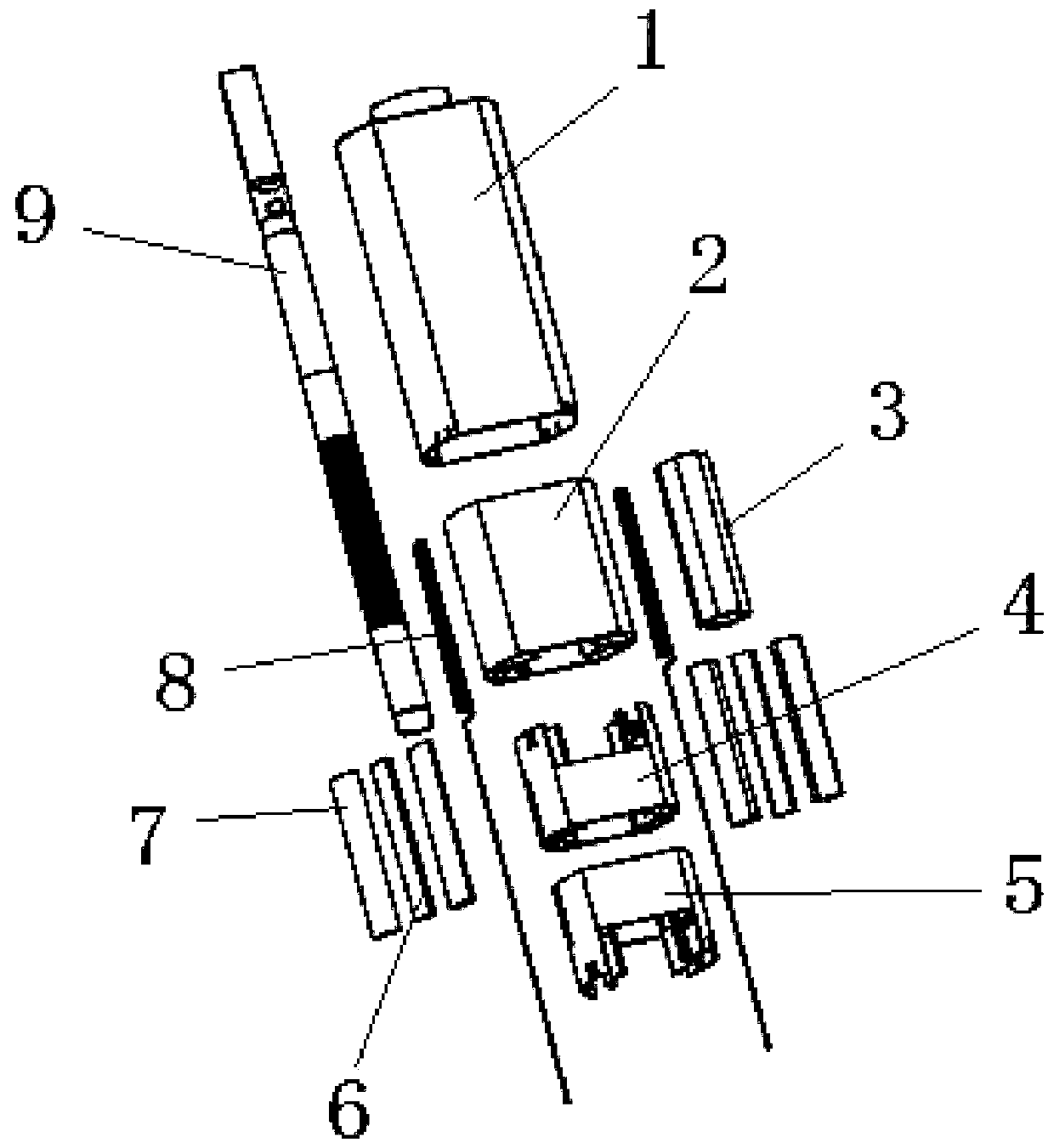

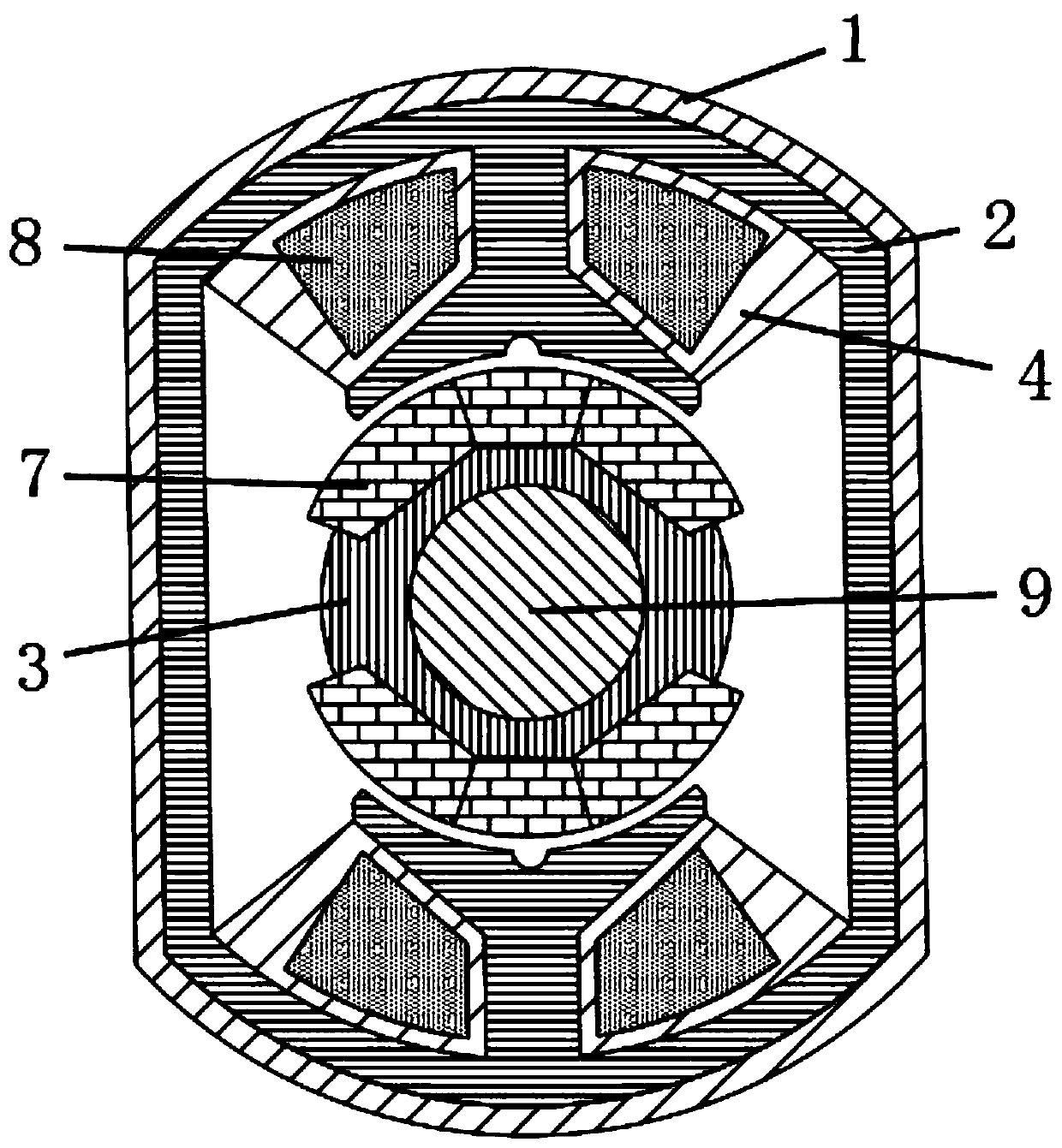

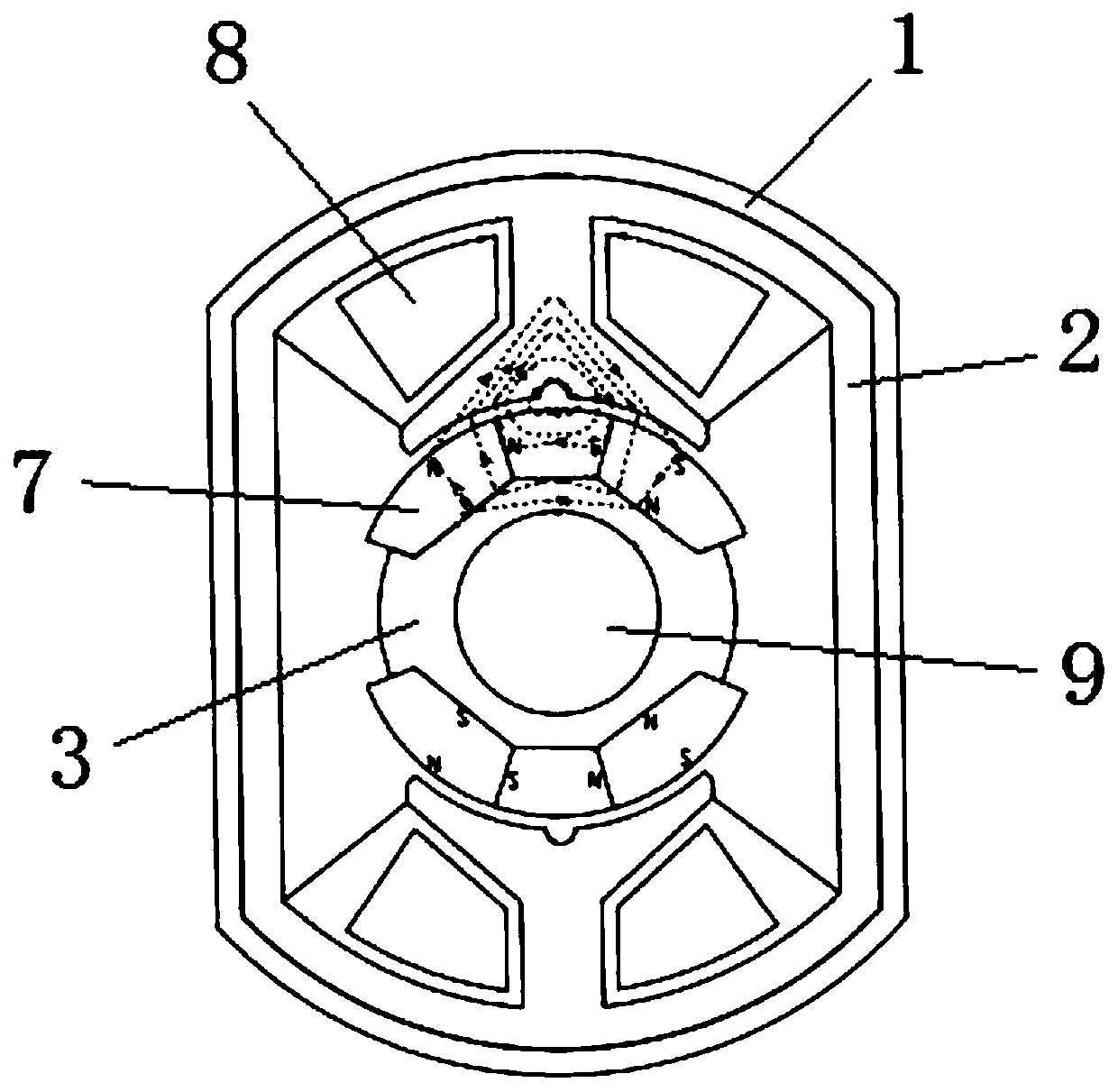

[0030] see Figure 1-3 , the present invention provides the following technical solutions: a motor suitable for electric toothbrushes, including a casing 1, a stator assembly is connected to the inner wall of the casing 1, a rotor assembly is provided inside the stator assembly, and the stator assembly includes a stator 2 and a coil 8 , wherein the coil 8 is fixed on both sides inside the stator 2, the rotor assembly includes the rotor 3, the second magnetic steel 7 and the magnetic steel assembly, wherein the rotor 3 is sleeved on the outside of the rotating shaft 9, and the outer side of the rotor 3 is connected with two The magnetic steel components are symmetrical to each other, and the outer wall of the magnetic steel component is an arc-shaped structure.

[0031] Further, the magnet assembly includes two second magnets 7 and a first magnet 6 , wherein the first magnet 6 is connected between the two second magnets 7 .

[0032] By adopting the above technical solution, tw...

Embodiment 2

[0036] This embodiment differs from Embodiment 1 in that: further, the stator 2 is connected with an insulating frame, and the coil 8 is connected inside the insulating frame.

[0037] Further, the insulating frame includes a first insulating frame 4 and a second insulating frame 5, wherein the first insulating frame 4 is located above the second insulating frame 5, and the coil 8 is connected between the first insulating frame 4 and the second insulating frame 5. internal.

[0038] By adopting the above technical solution, the winding and installation of the coil 8 are facilitated.

[0039] Further, the implementation method of the motor suitable for electric toothbrush according to the present invention includes the following steps:

[0040] (1), the coil 8 is connected to the inside of the first insulating frame 4 and the second insulating frame 5, the first insulating frame 4 and the second insulating frame 5 are respectively bonded to the inside of the stator 2 by glue, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com