Patents

Literature

34results about How to "Not affected by external forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

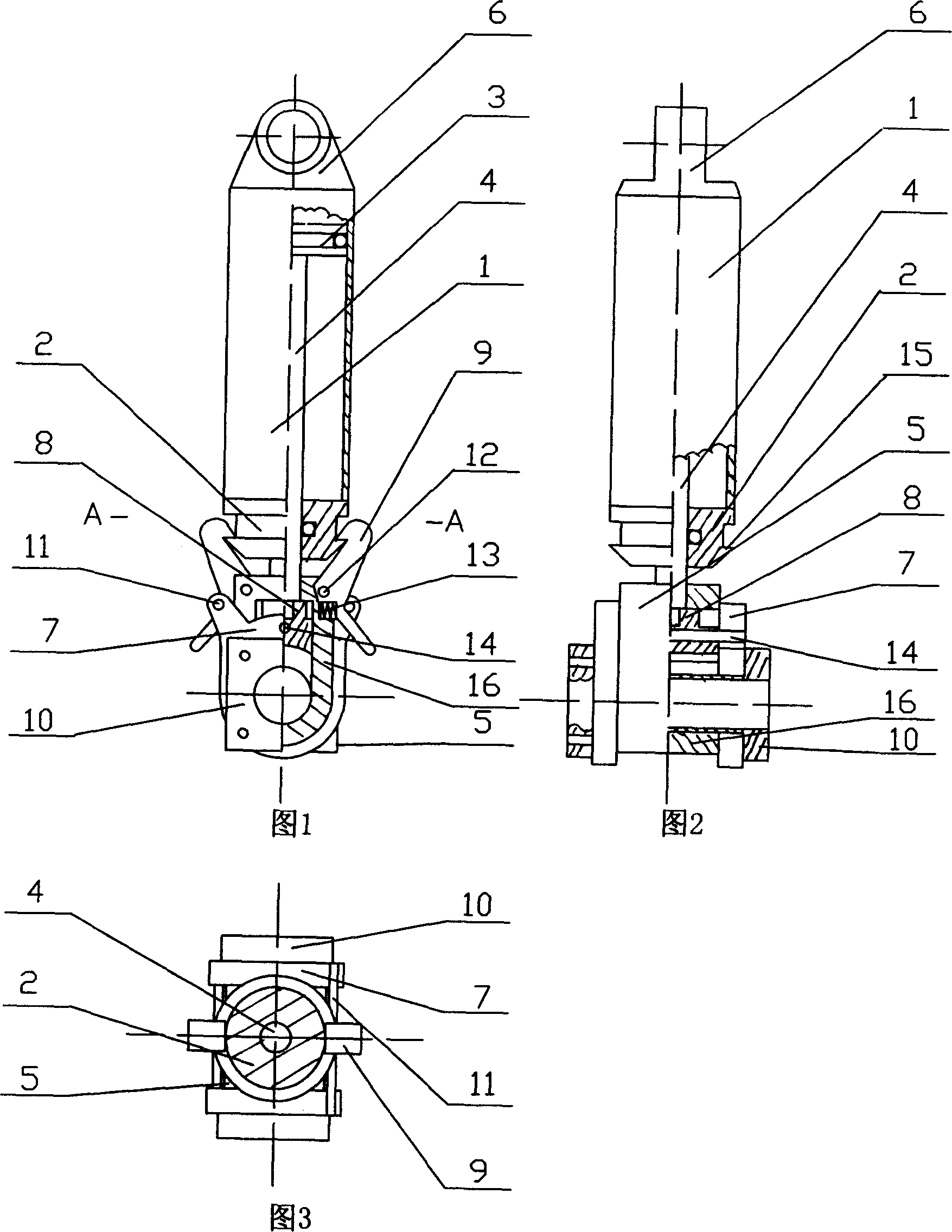

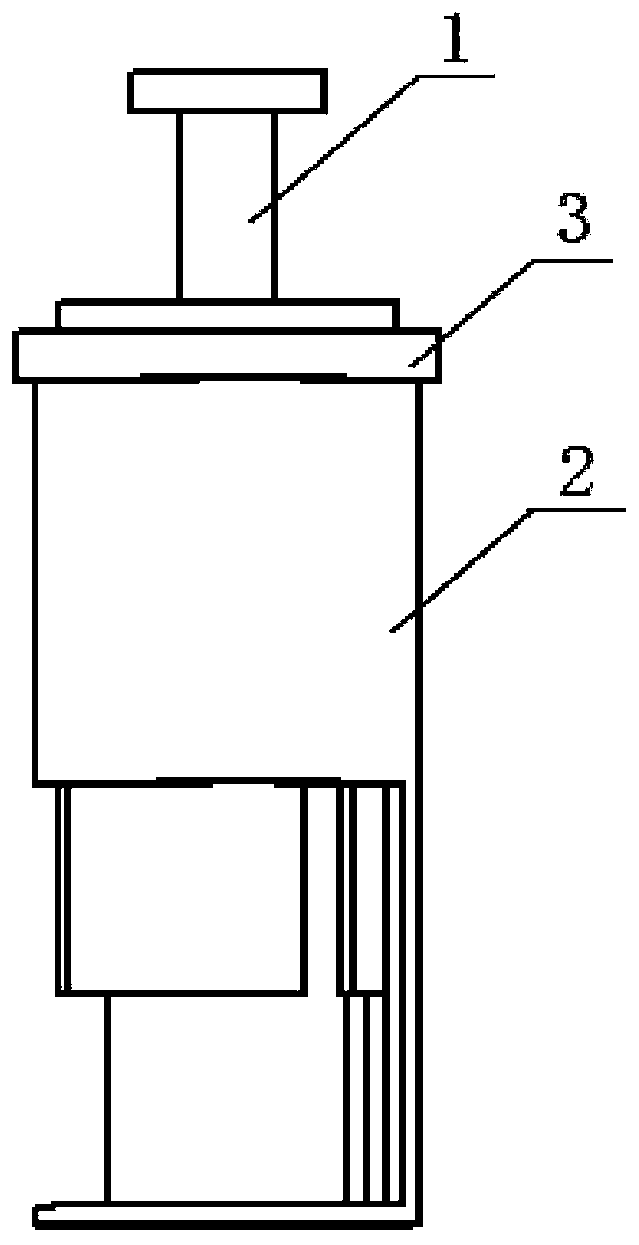

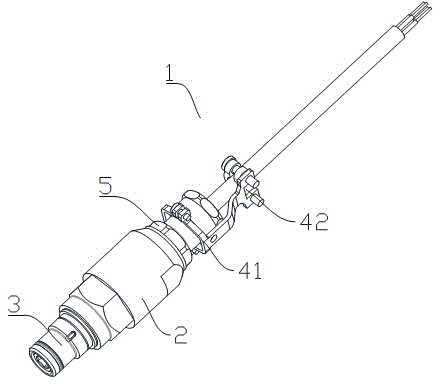

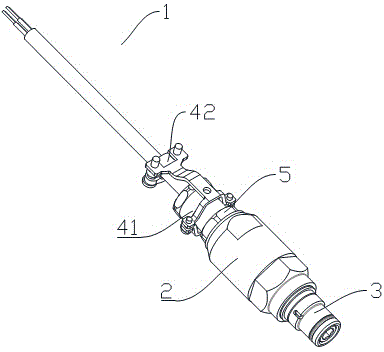

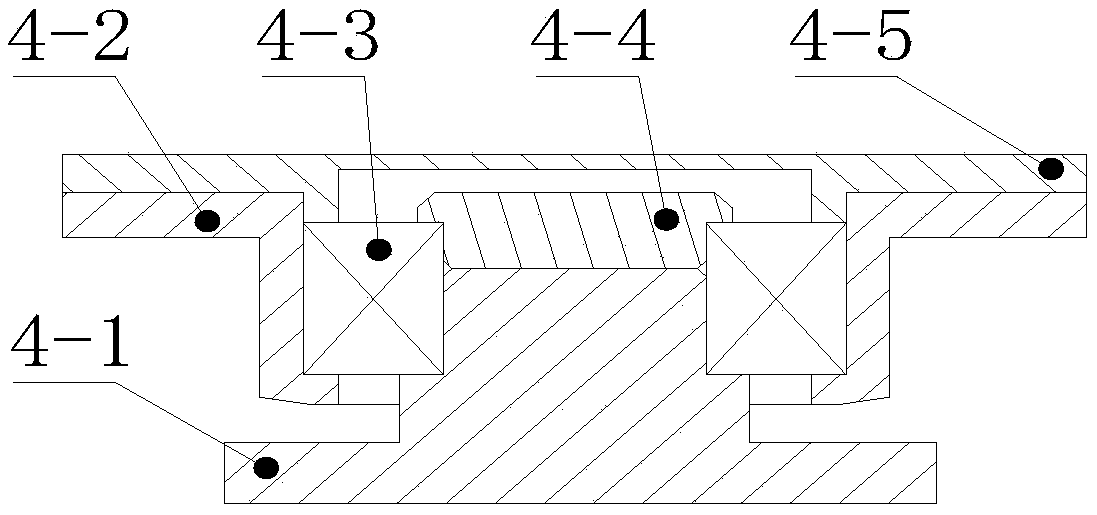

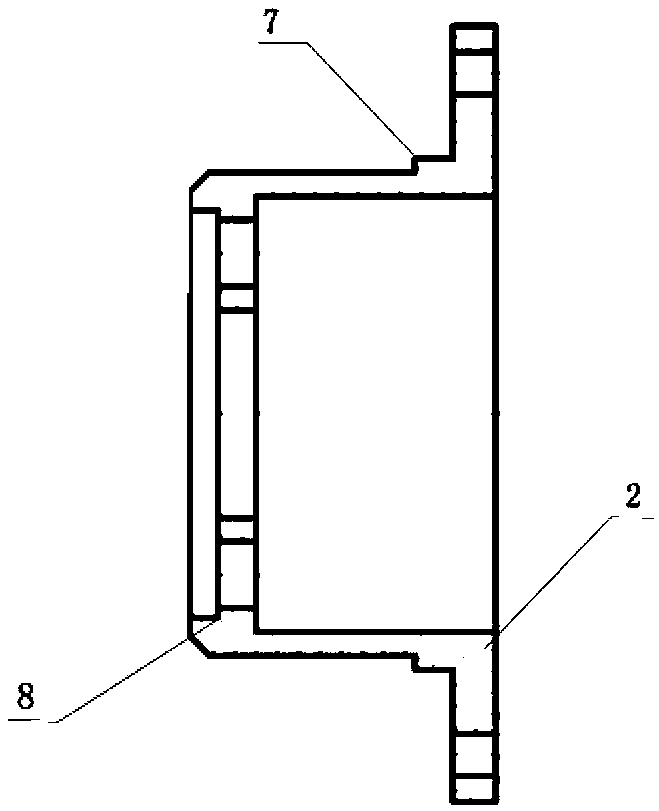

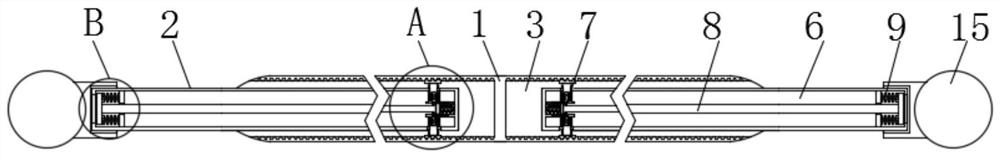

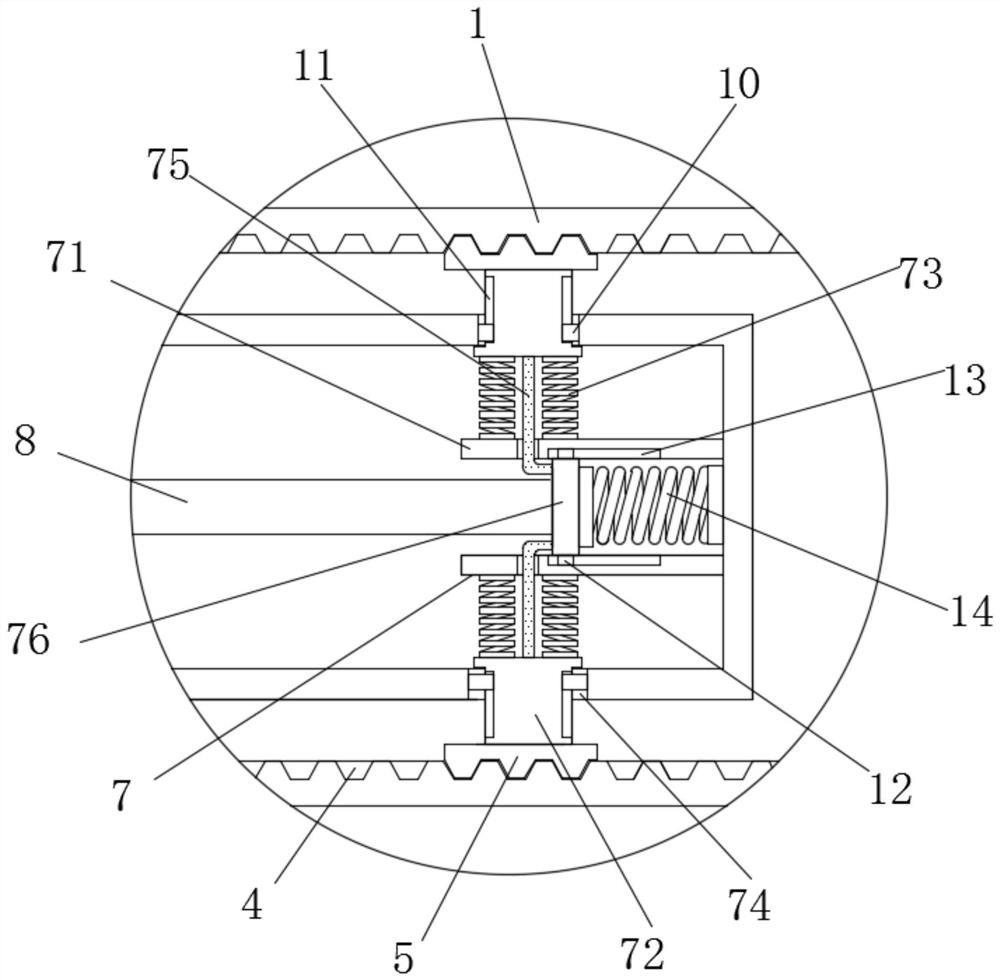

Gas cylinder or oil cylinder with self-locking device

InactiveCN101131170ANot affected by external forcesSimple structureFluid-pressure actuatorsGas cylinderSelf locking

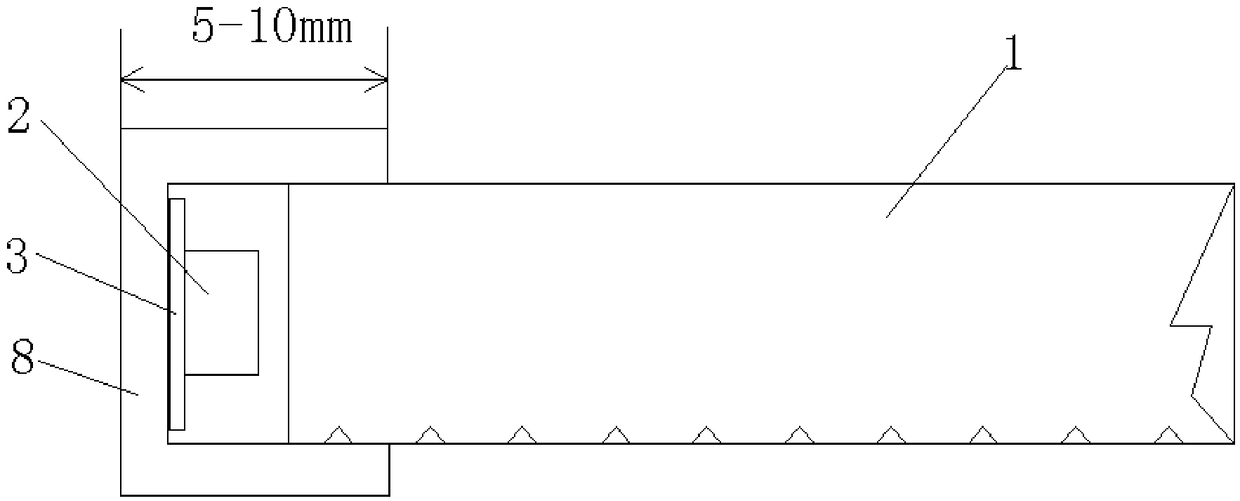

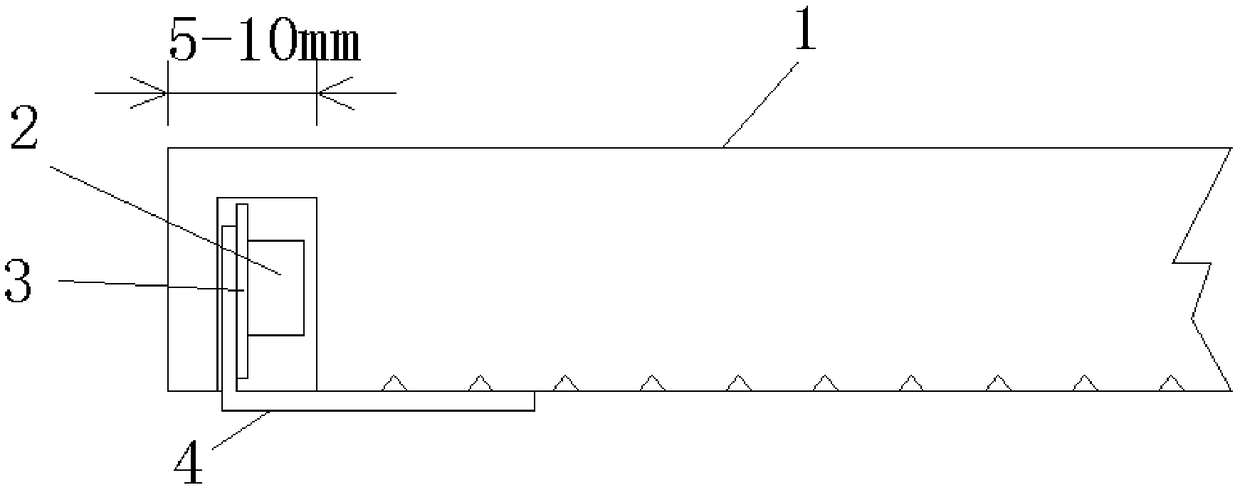

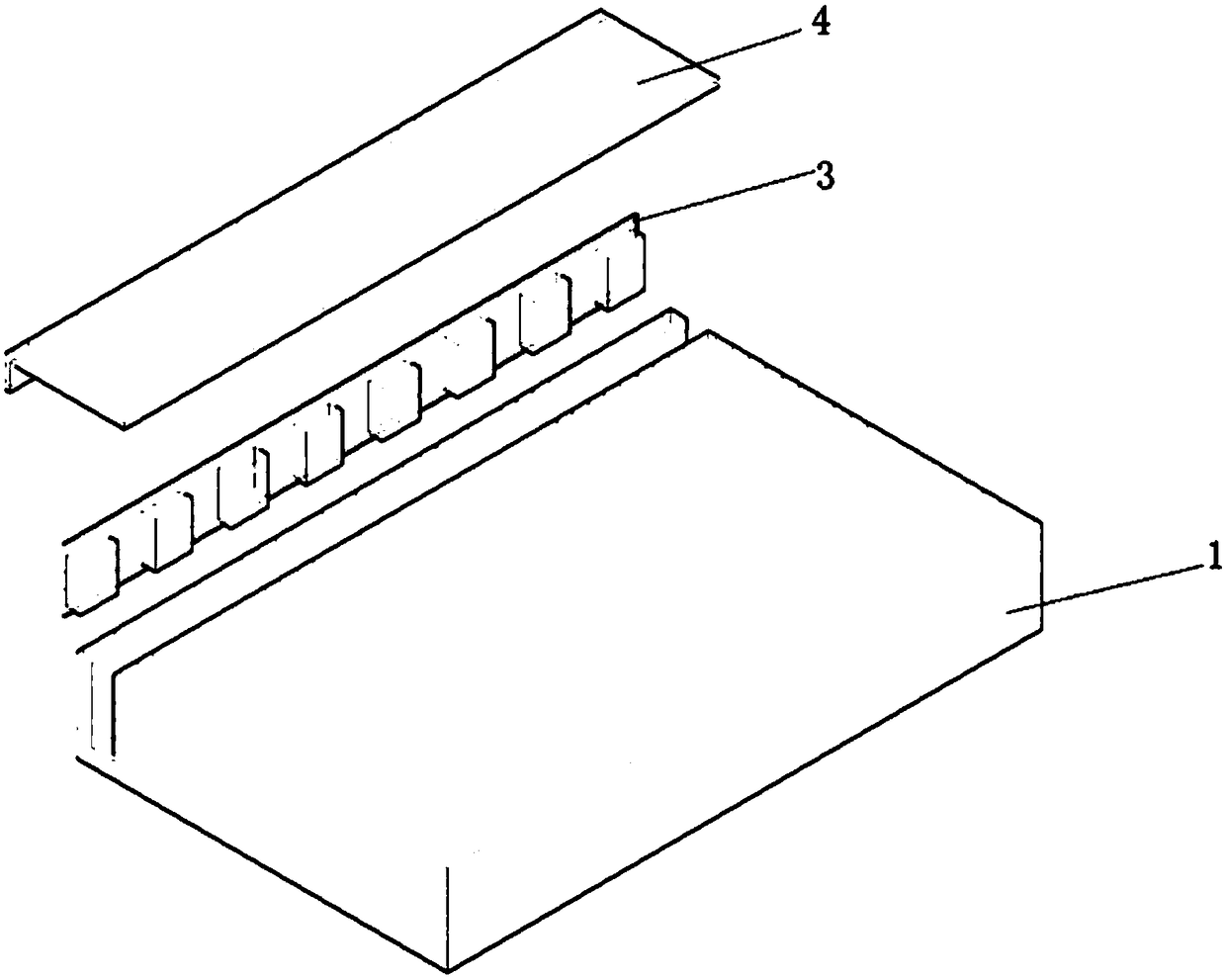

The present invention discloses one kind of air cylinder or oil cylinder with self-locking device. The air cylinder or oil cylinder includes one cylinder body, one piston rod inside the cylinder body, one cylinder cap, one piston fixed to one end of the piston rod, one lock connected to the end of the piston rod stretched beyond the cylinder cap, and one clamping slot in the outer edge of the cylinder cap. The air cylinder or oil cylinder has self-locking device in simple structure and good self-locking effect, and may be operated only in the presence of driving force caused by air or oil pressure, reaching no malfunction.

Owner:夏培根

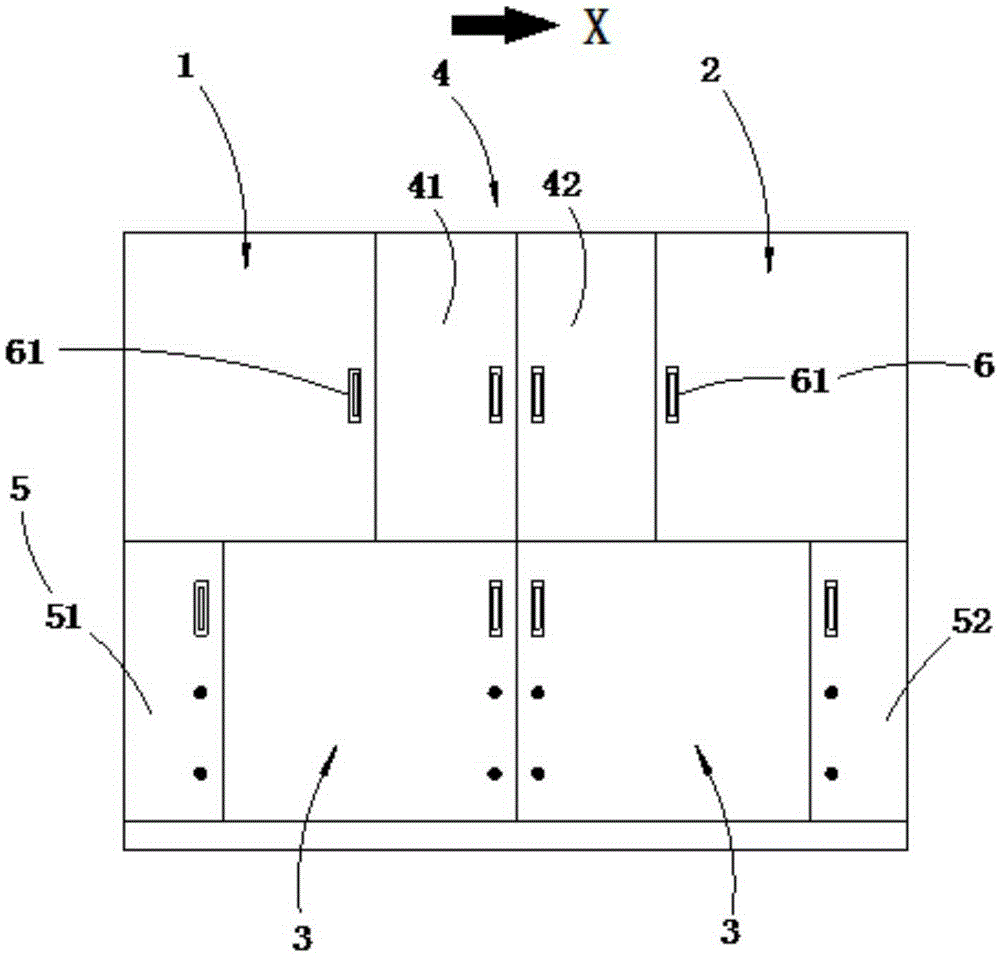

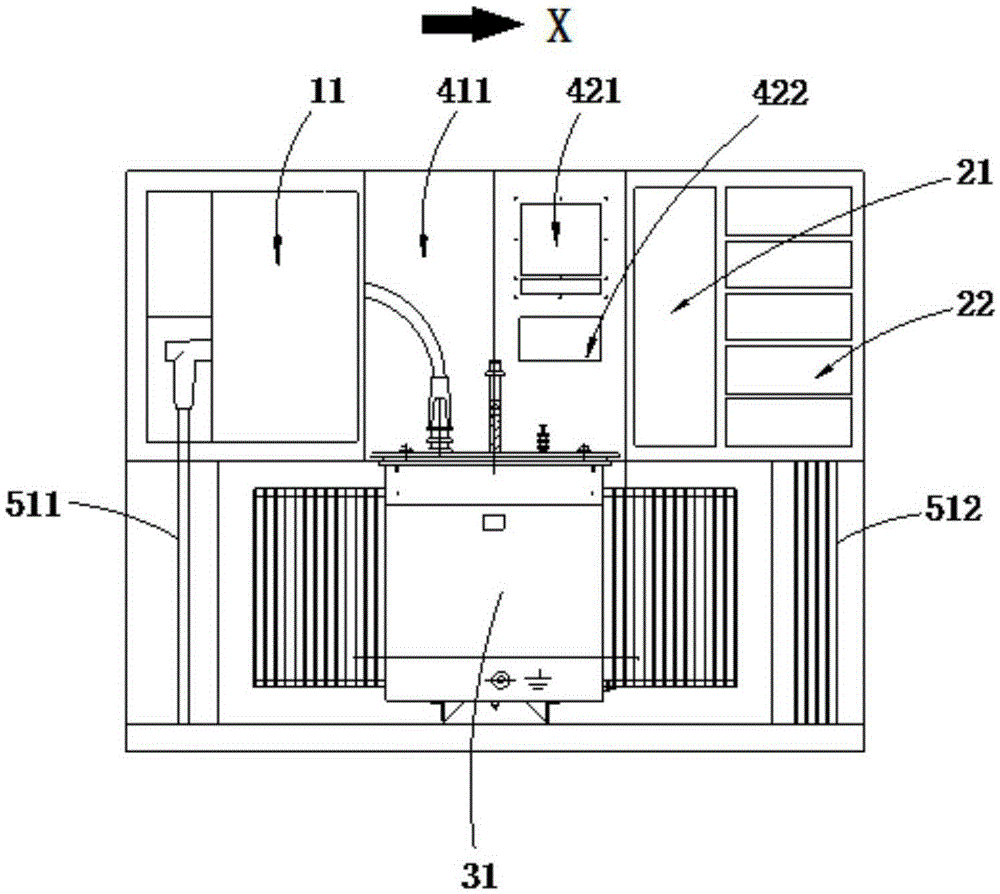

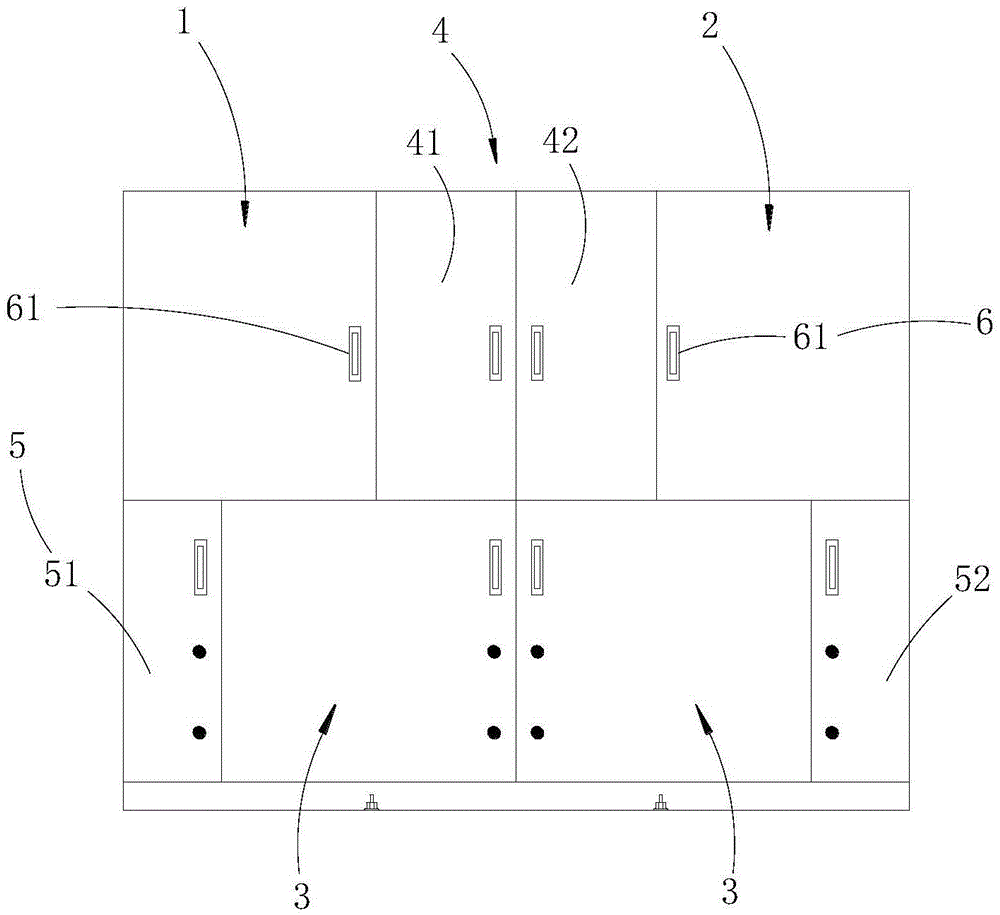

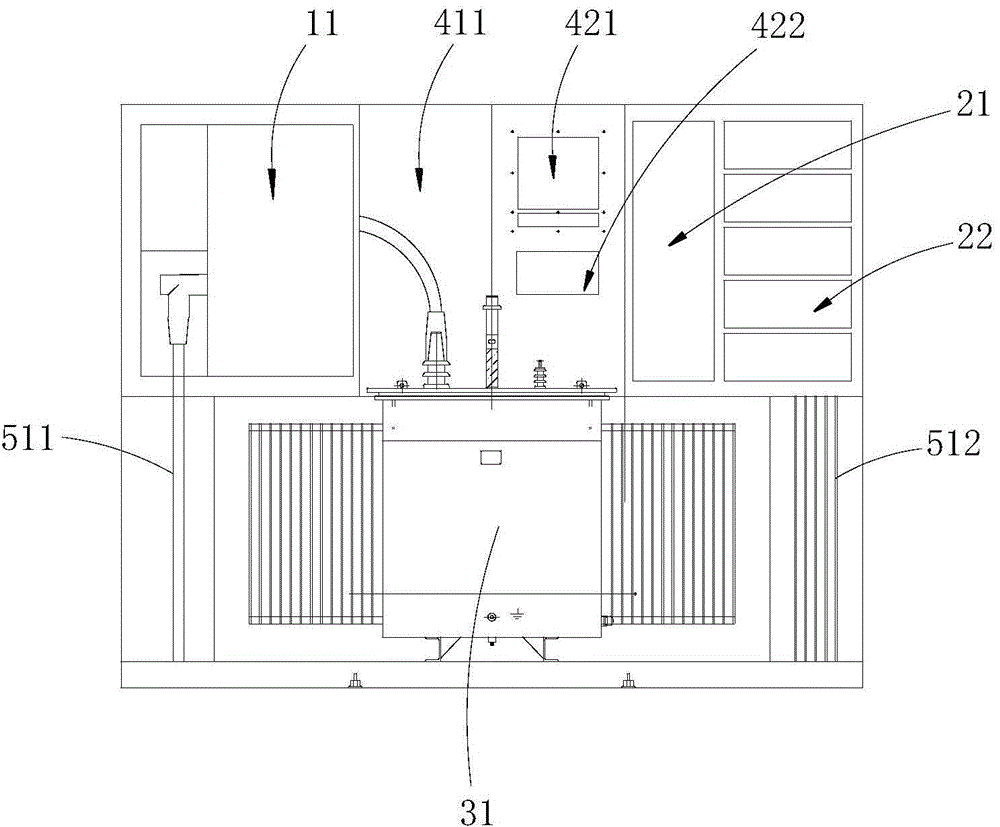

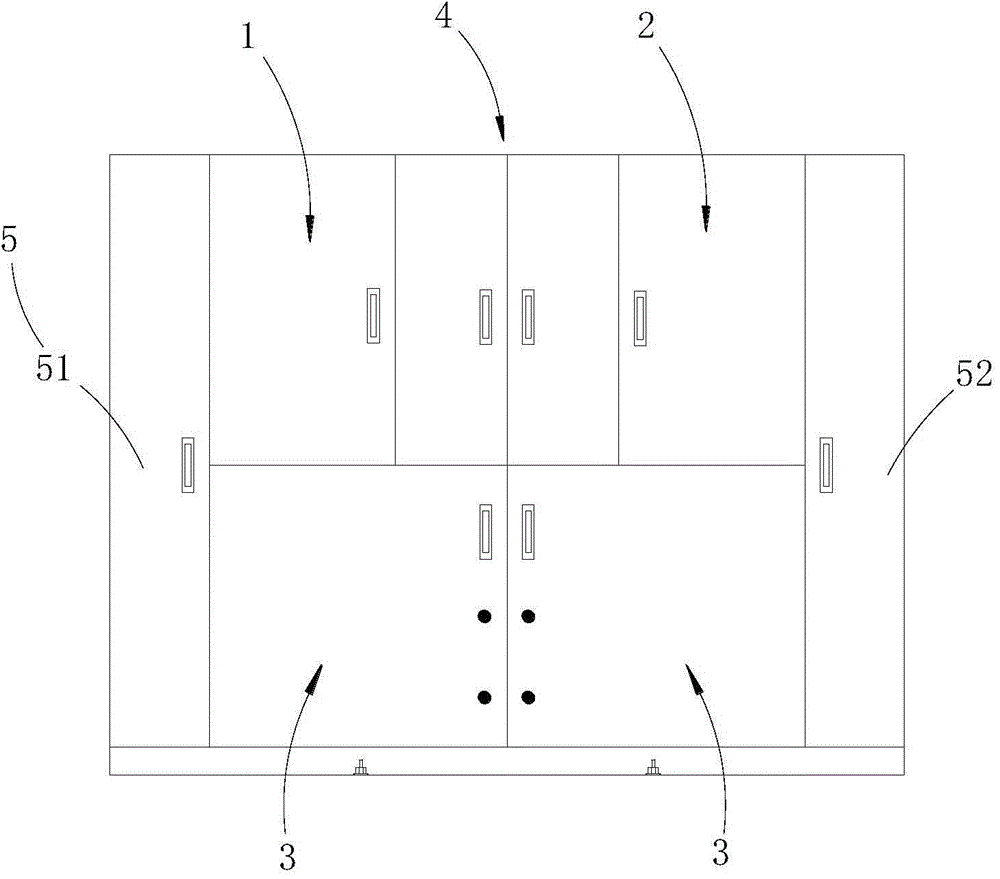

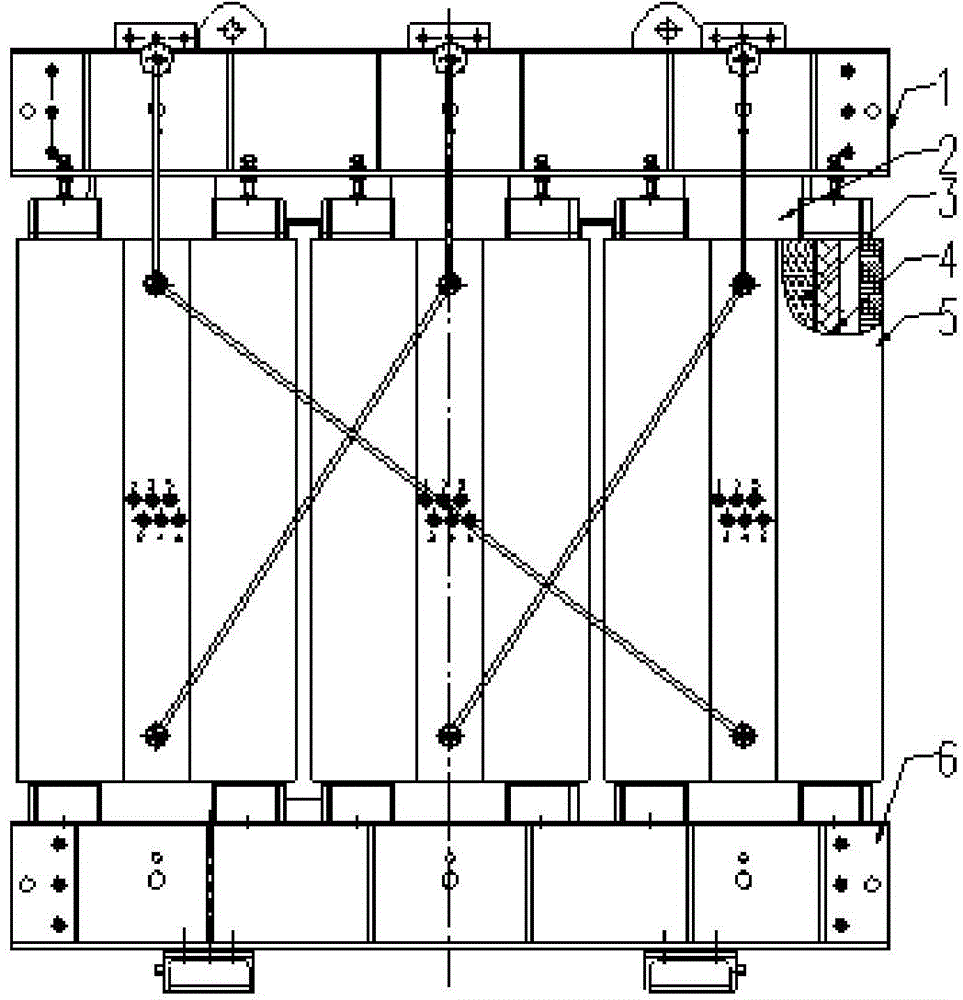

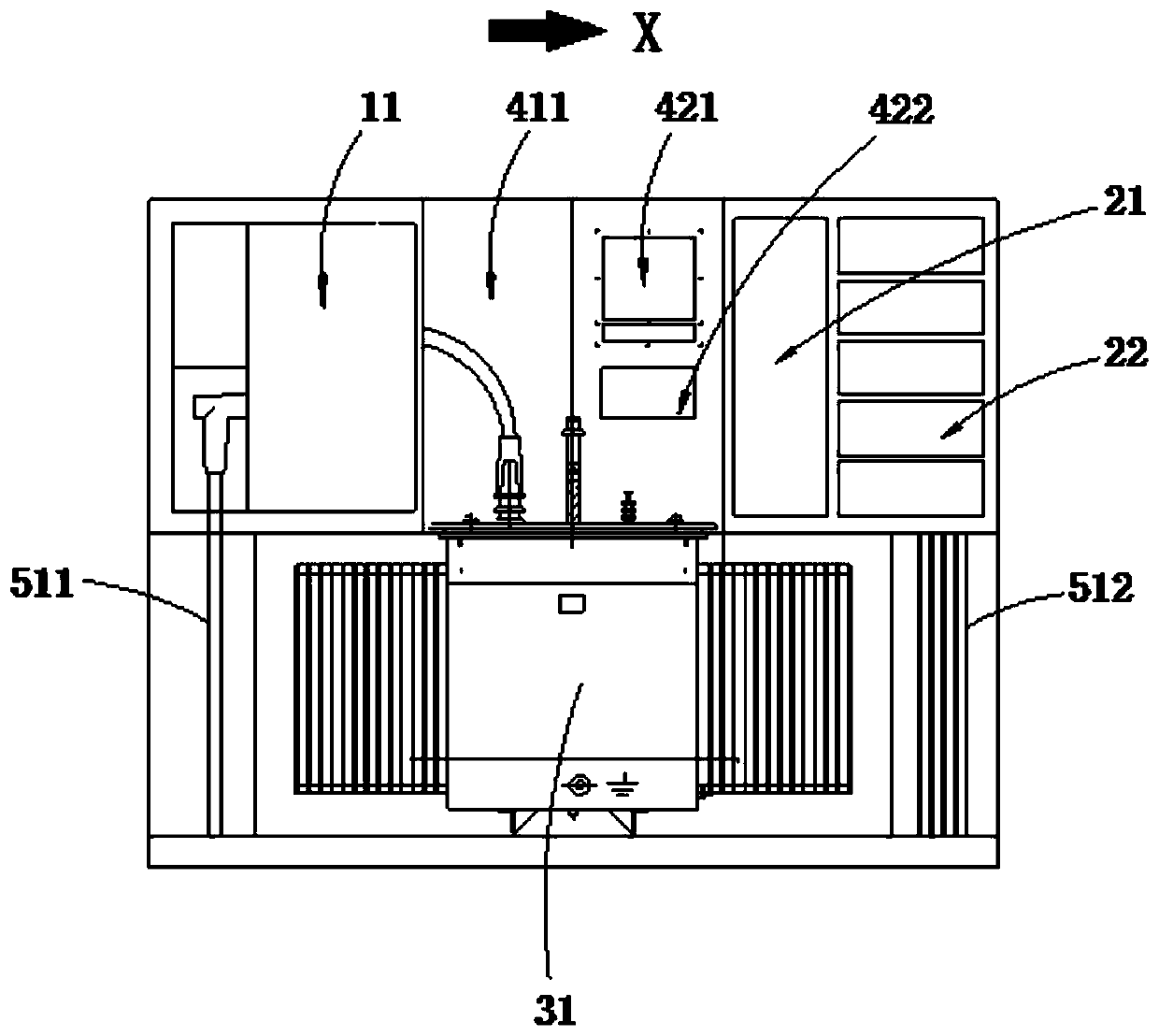

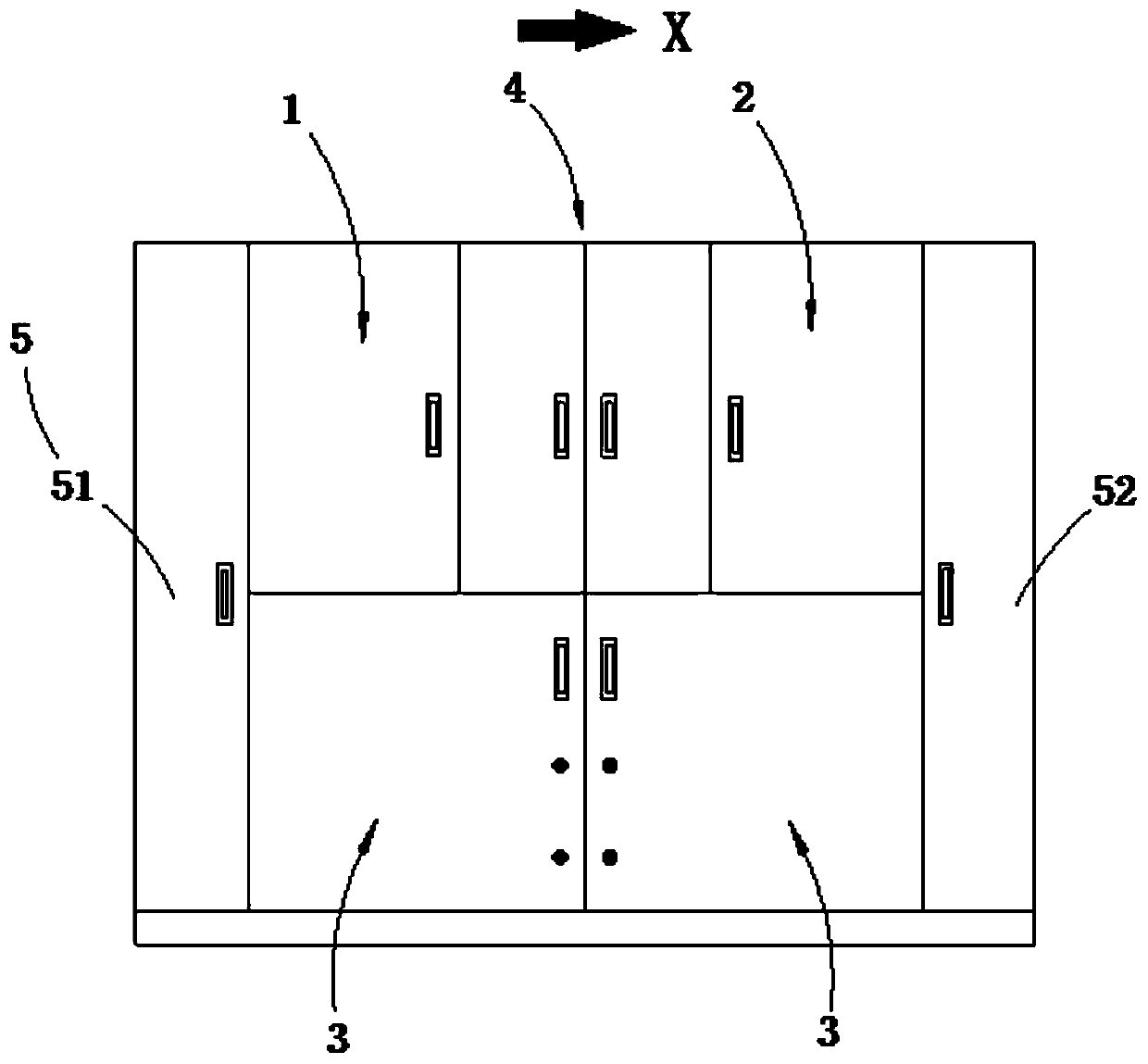

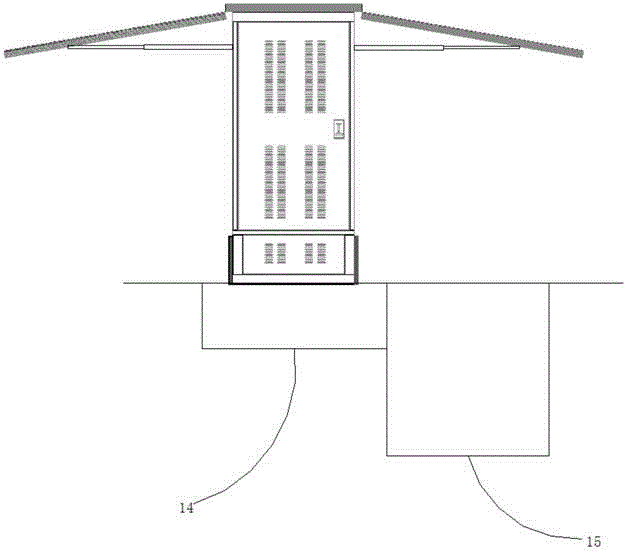

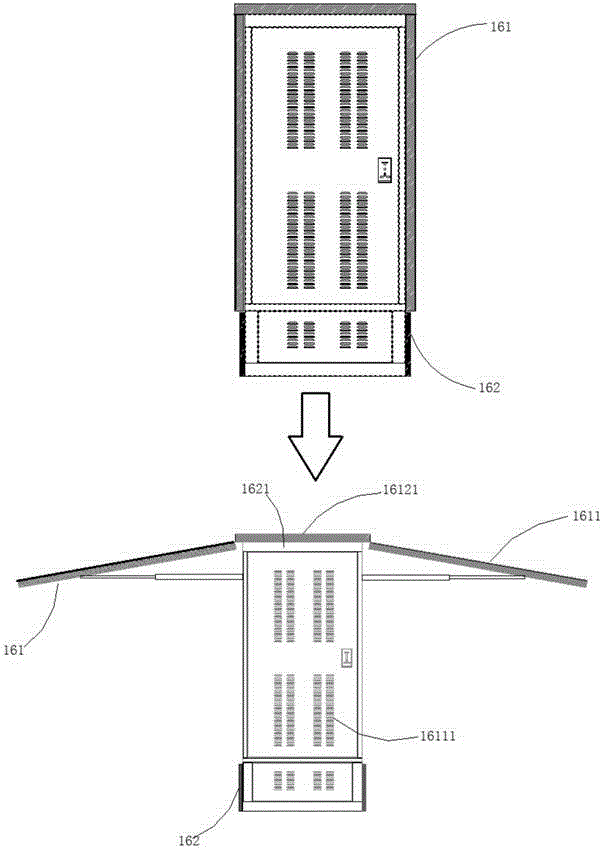

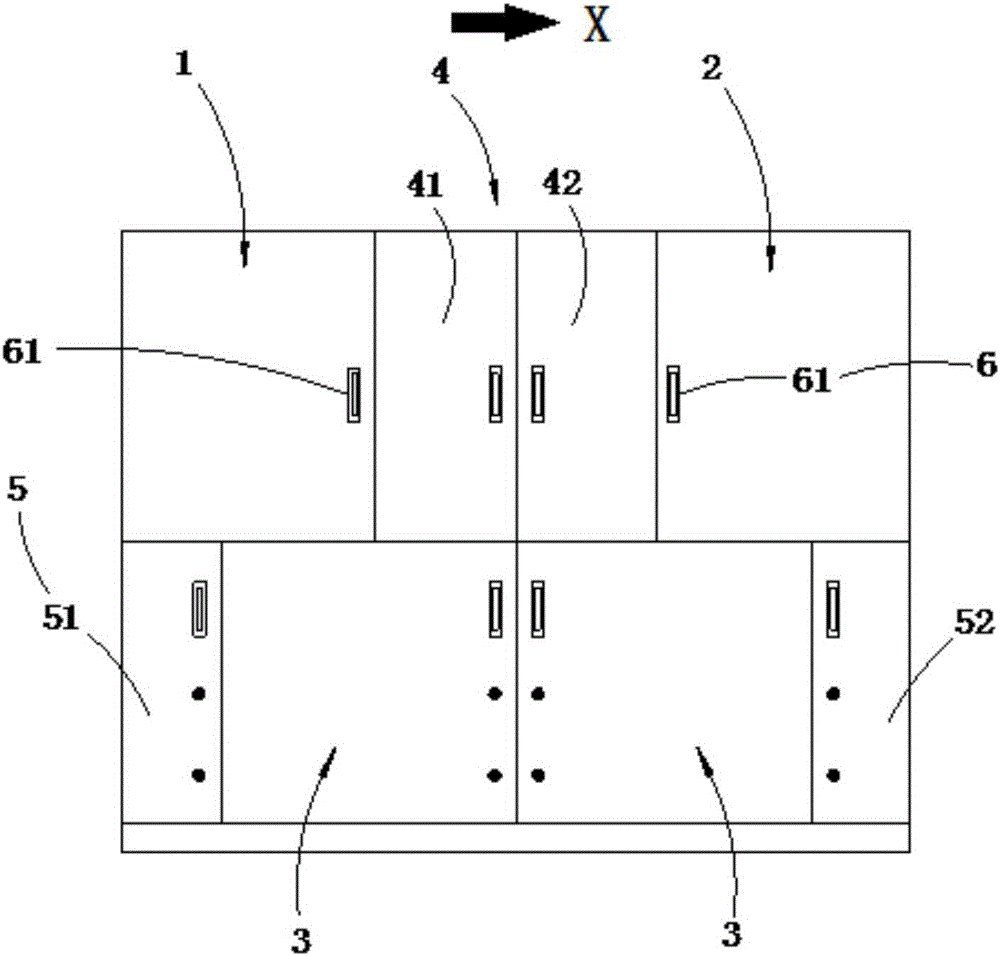

Novel box type transformer station

ActiveCN105762693AReduce difficultySpeed up heat dissipationTransformers/inductances coolingSubstation/switching arrangement cooling/ventilationTransformerLow voltage

The invention discloses a novel box type transformer station. The novel box type transformer station at least comprises a high-voltage switch chamber, a low-voltage switch chamber and a transformer chamber, wherein the high-voltage switch chamber, the low-voltage switch chamber and the transformer chamber are in echelonment distribution, and equipment lines in the high-voltage switch chamber, the low-voltage switch chamber and the transformer chamber are M-shaped, U-shaped or V-shaped. Different from the prior art, the novel box-type transformer station enables the volume of the box type transformer station to be reduced by 1 to 3 times compared to a conventional transformer station through innovative adoption of an upper-lower multilayer distribution structure, reduces the area of occupied land, facilitates transportation and decreases the transport cost; and a downward pedestal of the conventional box type transformer station does not have to be manufactured, such that the difficulty of a construction project is reduced, the cost is decreased, and unfavorable influences brought by moisture in the half-embedded pedestal to each device in the box type transformer station can be better avoided.

Owner:袁茂银

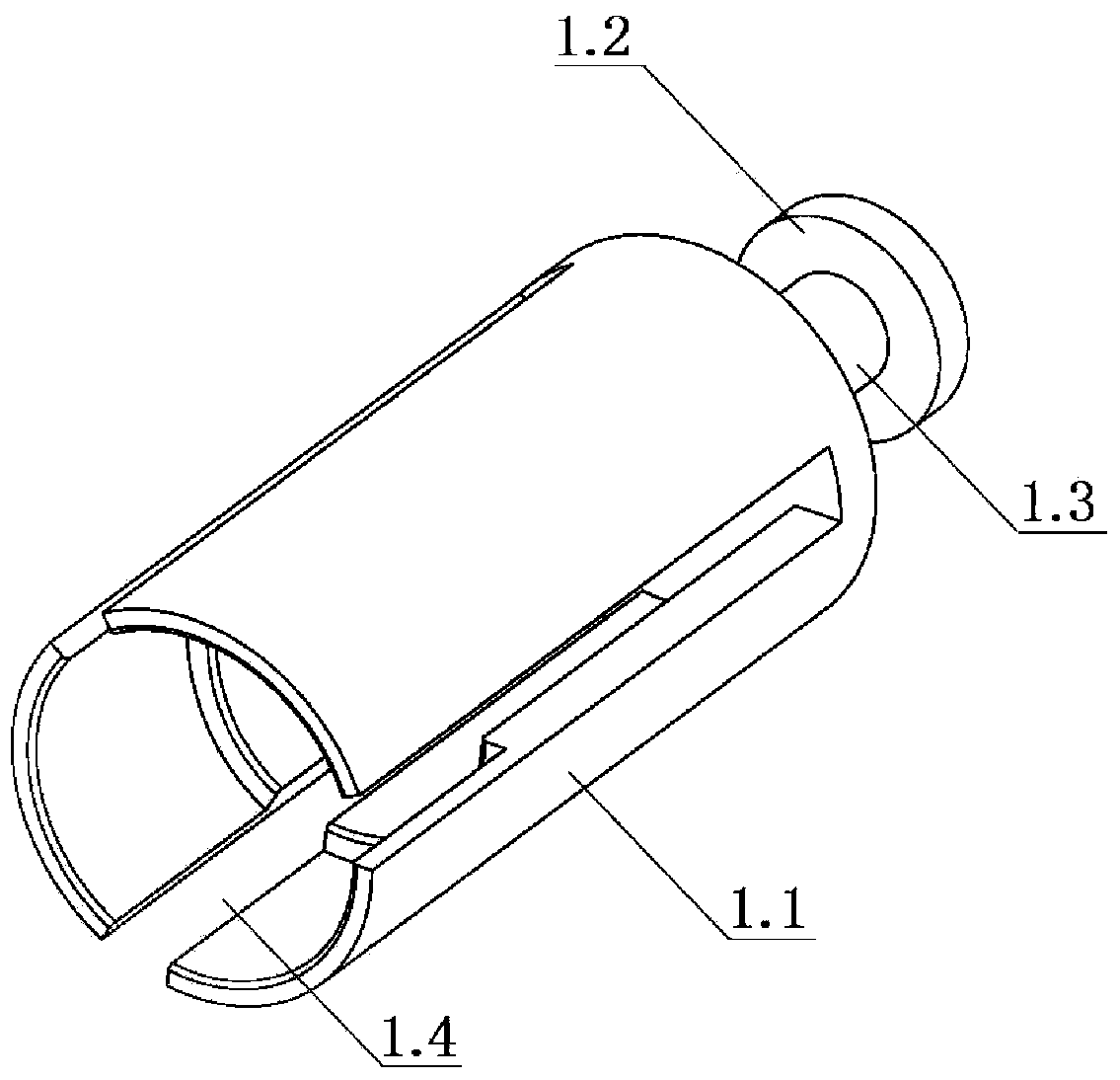

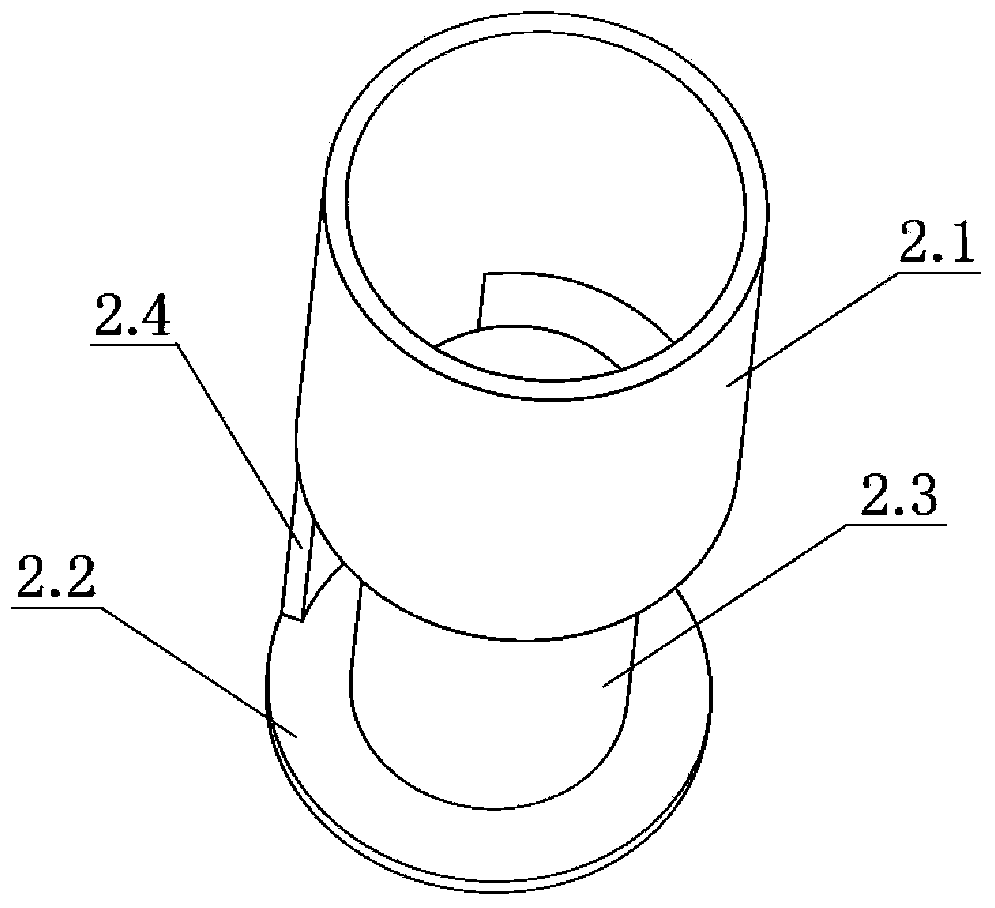

Piston type sampler

ActiveCN103969081ANot affected by external forcesWithdrawing sample devicesTriaxial shear testEngineering

The invention relates to a piston type sampler for a geotechnical engineering triaxial test soil sample. The piston type sampler mainly comprises a piston and a piston cylinder, wherein the piston is sleeved with the piston cylinder; the main body of the piston is a hollow cylindrical three-section casing; the upper part of the piston cylinder is a cylinder; the bottom of the piston cylinder is a base; a solid cylinder is erected in the center of the base of the piston cylinder; the three-section casing is formed in the way that three axial strip-shaped openings are formed in the cylindrical casing at equal intervals to equivalently divide the casing into three sections; the inner diameter of the cylinder at the upper part of the piston cylinder is slightly larger than the outer diameter of the piston; the piston is slidably inserted into the piston cylinder; a piston cover is arranged at the top end of the piston cylinder; three mutually spaced arc-shaped hollowed parts are formed at the top of the piston cover; the three arc-shaped hollowed parts are matched with the three sections of the piston three-section casing in size. The piston type sampler provided by the invention ensures that during the whole process of taking out the soil sample, the top part and the bottom part of the soil sample are not influenced by external force, external thrust is uniformly exerted on a saturator, an integral supporting and protecting system is provided for the taking-out process of the saturator, and the soil sample cannot be broken by external force to be incomplete.

Owner:BEIJING JIAOTONG UNIV

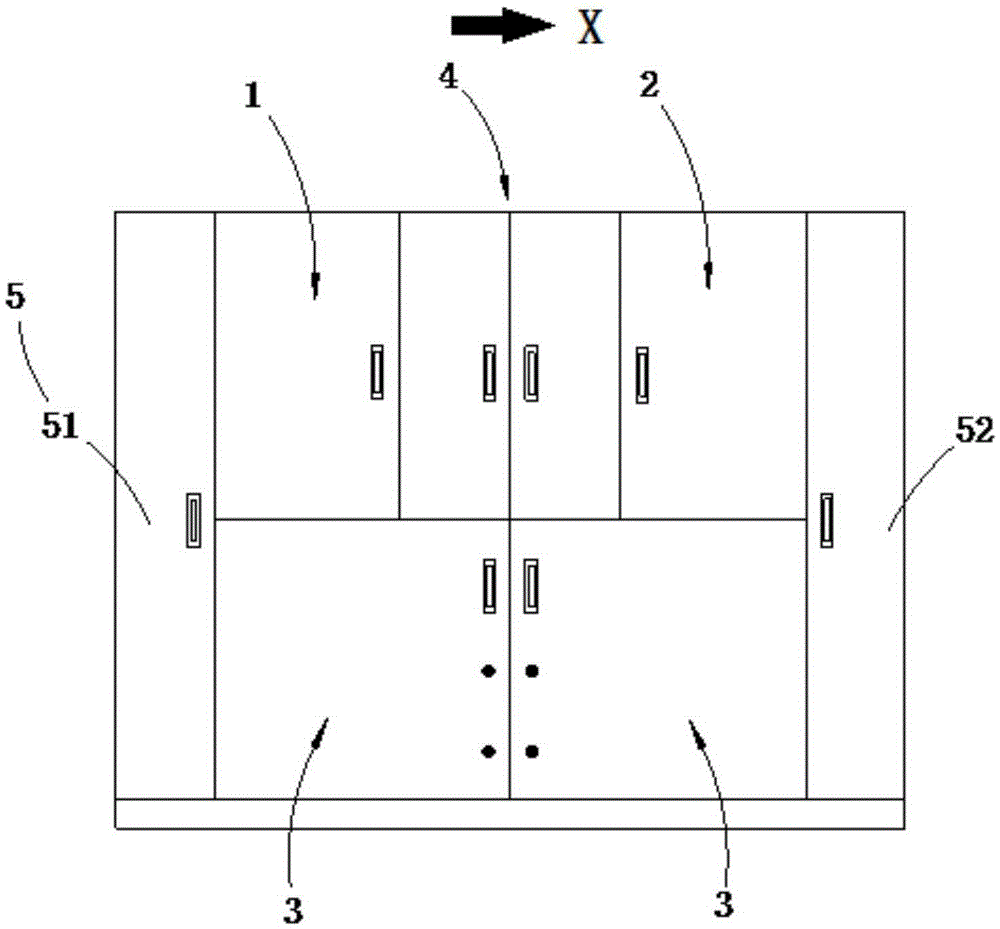

Box-type substation

InactiveCN104638555AReduce volumeReduce difficultyBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationTransformerLow voltage

The invention discloses a box-type substation. The box-type substation at least comprises a high-voltage switchgear chamber, a low-voltage switchgear chamber and a transformer chamber, which are distributed in the shape of steps, wherein equipment circuits in the high-voltage switchgear chamber, the low-voltage switchgear chamber and the transformer chamber are M-shaped, U-shaped or V-shaped. The box-type substation is different from the prior art on the aspect that a structure that a plurality of layers are distributed up and down is creatively adopted, so that the size of the box-type substation is 1 to 3 times smaller than that of the traditional substation, the occupation area is reduced, the box-type substation is convenient to transport, and the transportation cost is reduced; a downward foundation of the traditional box-type substation is not required to be manufactured, the difficulty for constructing a project is reduced, the cost is reduced, and adverse influence to each piece of equipment in the box-type substation by humidity in the semi-buried foundation can be better avoided.

Owner:袁茂银

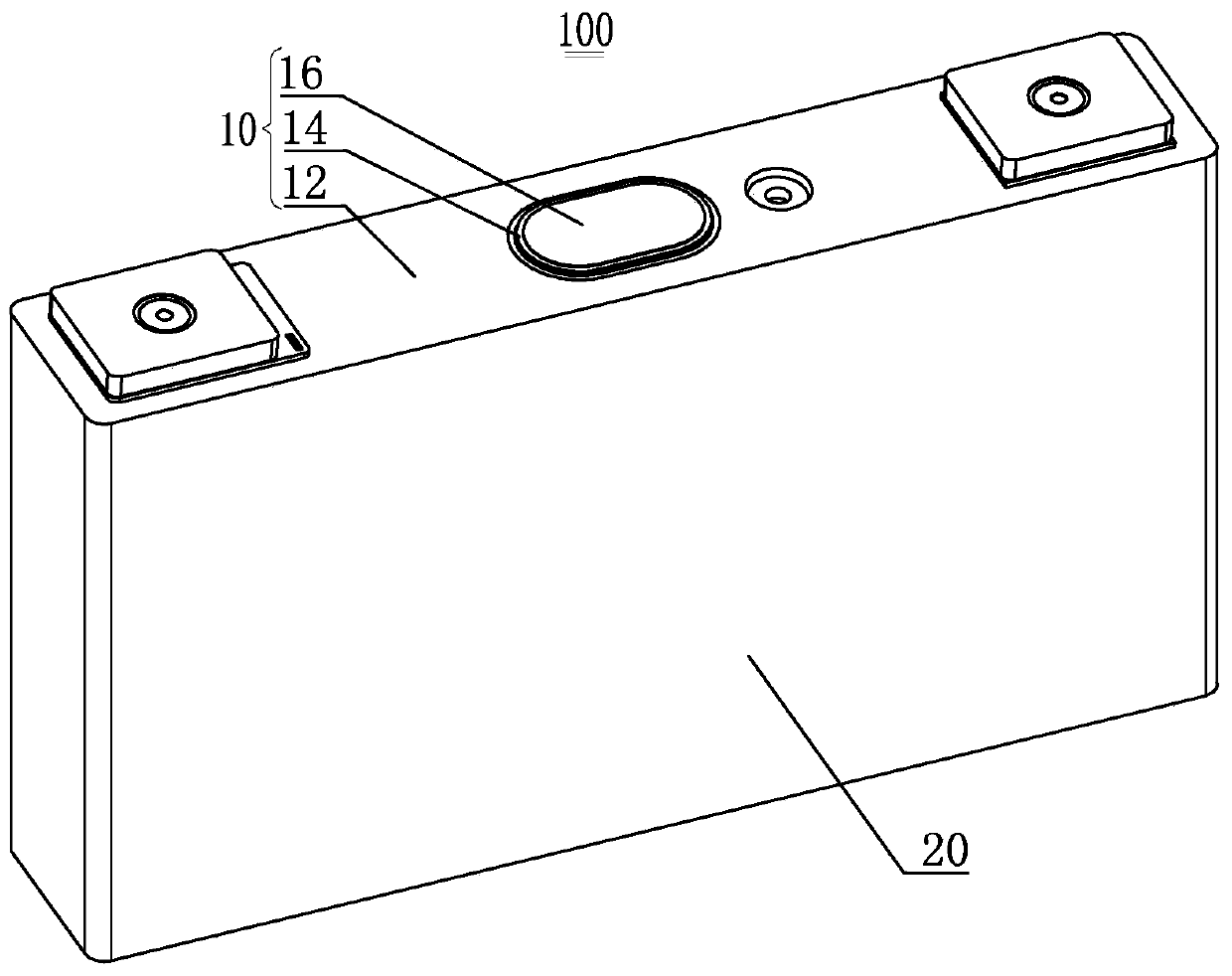

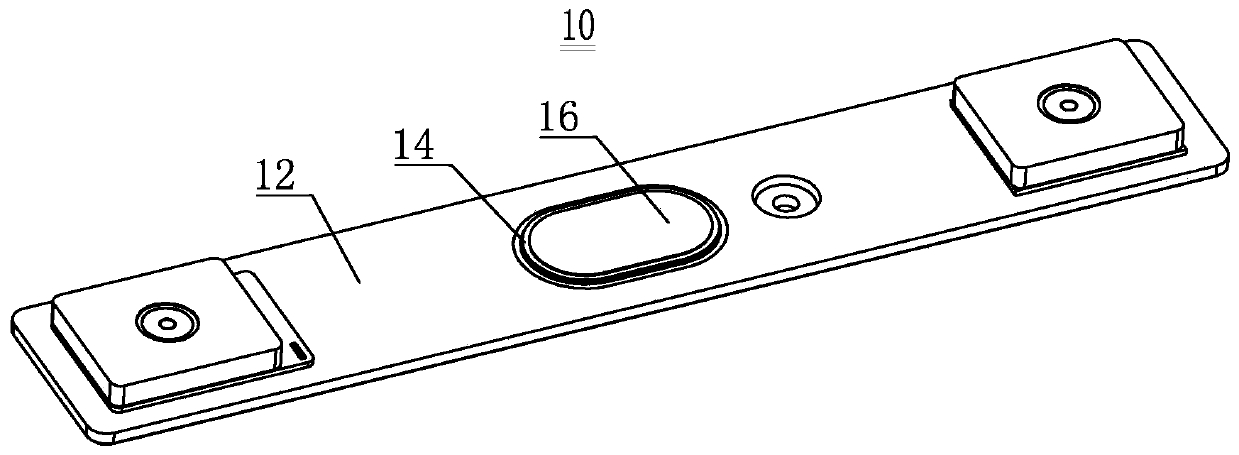

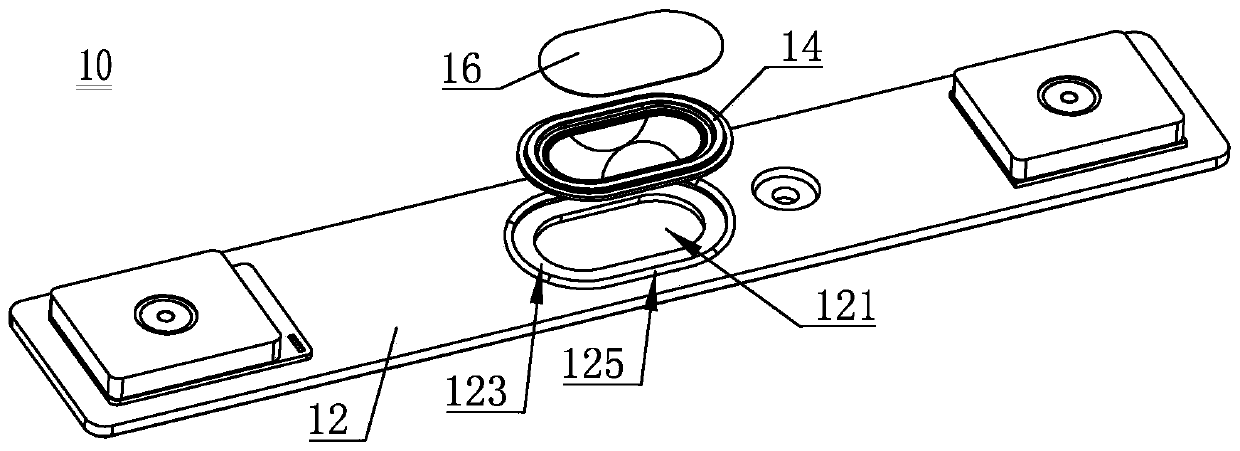

Battery top cover assembly and single battery

PendingCN111446388AAllow outflowImprove mechanical propertiesVent arrangementsCell lids/coversStructural engineeringBattery cell

The invention discloses a battery top cover assembly and a single battery. The battery top cover assembly comprises a top cover and an explosion-proof valve. The top cover is provided with an explosion-proof hole, and the top cover is used for sealing a shell; and the explosion-proof valve comprises a reinforcing boss and an anti-explosion piece, the reinforcing boss is arranged around the anti-explosion piece, the thickness of the reinforcing boss is larger than that of the anti-explosion piece, the reinforcing boss is connected with the top cover, and the anti-explosion piece covers and seals the anti-explosion hole. According to the battery top cover assembly, deformation resistance of the explosion-proof valve is improved, the influence of top cover deformation on the explosion-proof valve can be effectively reduced, and reliability of the explosion-proof valve is improved.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

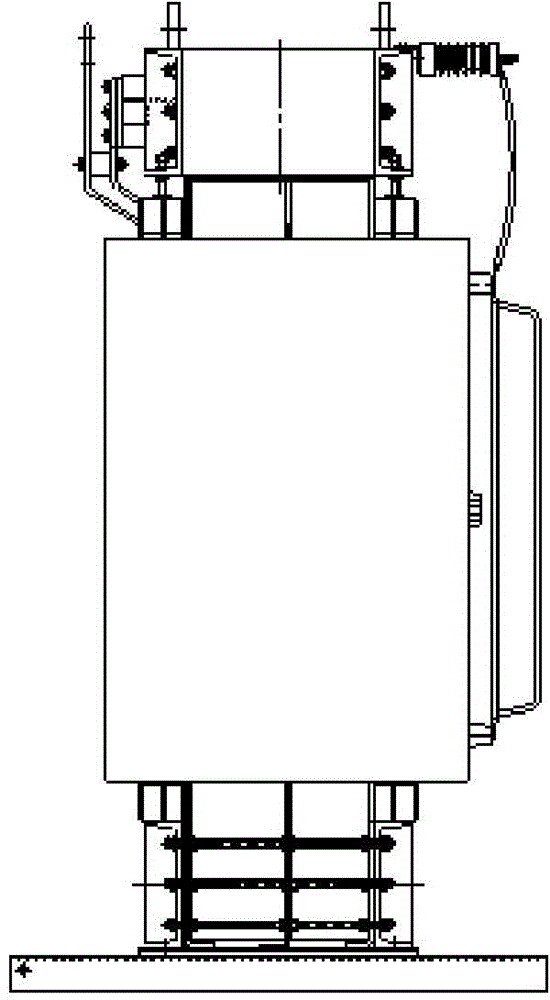

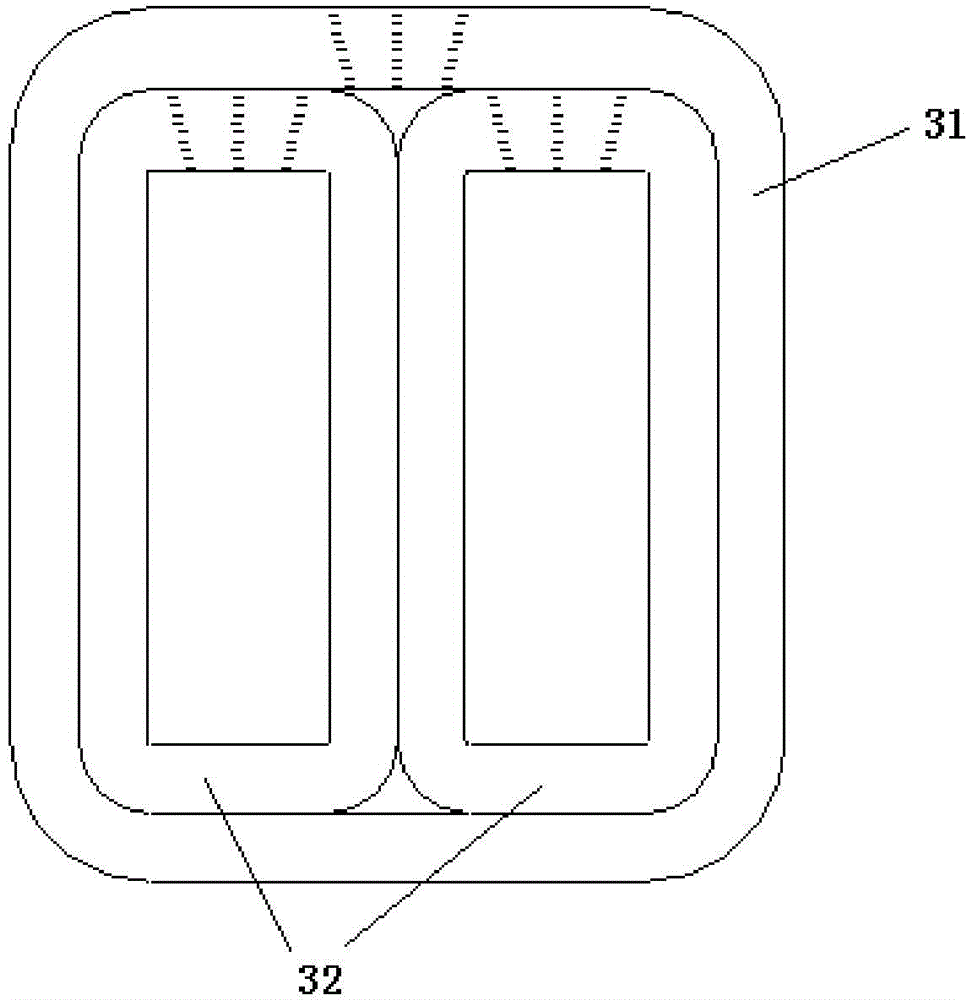

Three-column pull plate type dry amorphous alloy transformer

InactiveCN106158281AUniform magnetic circuitSmall capacitance to groundTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLow voltageAlloy

The invention relates to a three-column pull plate type dry amorphous alloy transformer which is used for being connected with a group grid system through a triangular or star connection method, the transformer comprises an upper clamping piece, a pull plate, a lower clamping piece and an iron core, the upper clamping piece, the pull plate and the lower clamping piece are sequentially connected from top to bottom, and the iron core is fixedly connected with the pull plate. The iron core is an amorphous alloy iron core, a three-phase three-column type structure is adopted, and the iron core is sequentially sleeved with a low-voltage coil and a high-voltage coil. Compared with the prior art, the three-column pull plate type dry amorphous alloy transformer has the advantages that the three-phase three-column structure is achieved, the transformer is suitable for the triangular connection method and the star connection method, the loss and noise are low, and the structure is firm.

Owner:SHANGHAI FLYING KING ELECTRIC

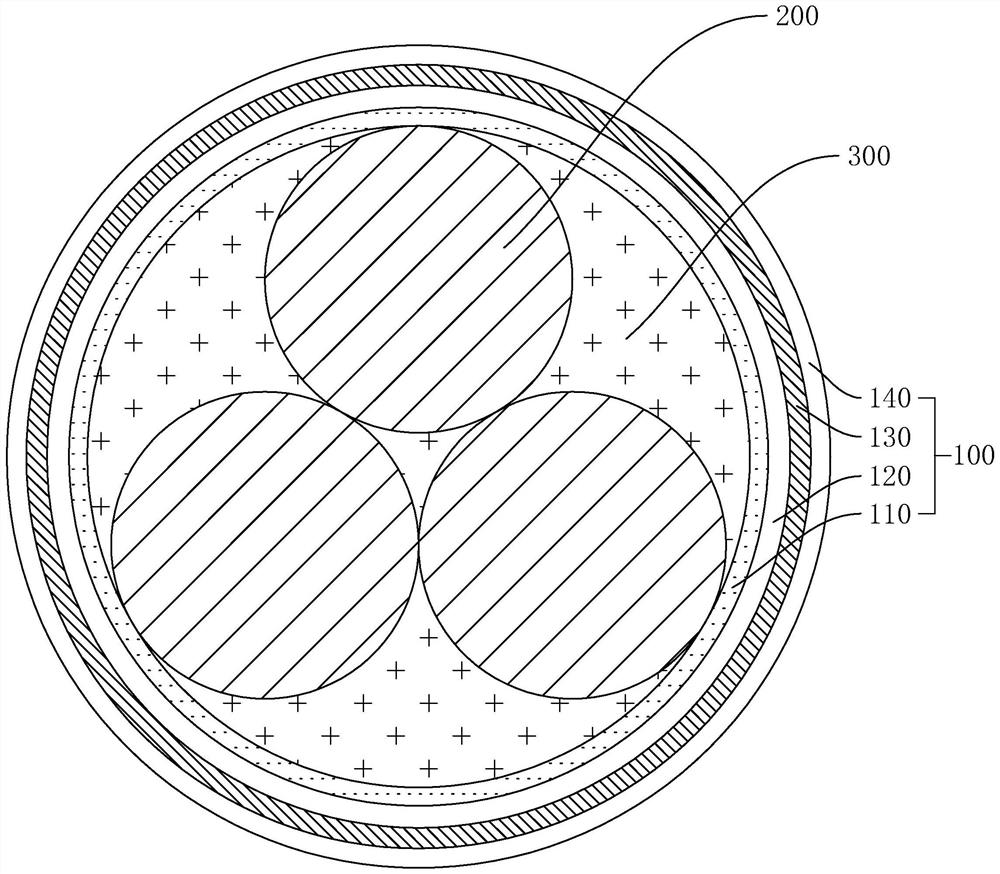

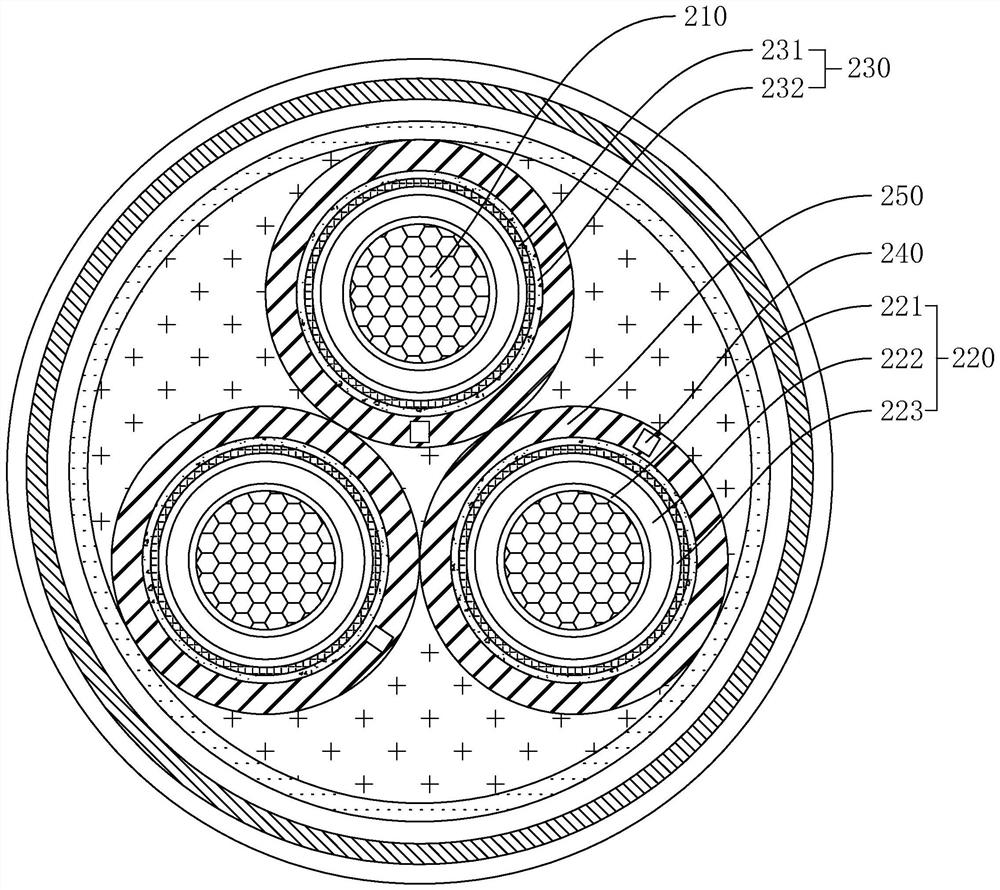

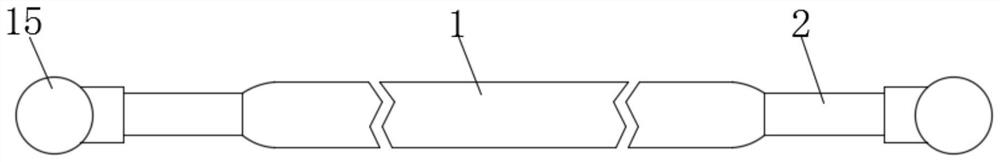

Medium-high voltage cable for smart power grid and preparation method of medium-high voltage cable

PendingCN111933335AGood physical and mechanical propertiesFast laying workPlastic/resin/waxes insulatorsPower cables with screens/conductive layersGraphene coatingElectrically conductive

The invention discloses a medium-high voltage cable for a smart power grid and a preparation method of the medium-high voltage cable, and relates to the technical field of power cables. In the structure of a composite shielding layer, an annealed soft copper strip can be effectively grounded to protect the long-term normal operation of a wire core; a graphene coating semi-conductive band has an excellent discharge effect under the condition of assisting in shielding heat energy and can achieve secondary protection of the wire core; miniature collectors are installed within a fixed distance outside the graphene coating semi-conductive band; after failure of the cable, the two miniature collectors at the head and tail of the fault section can instantly emit high-frequency electromagnetic waves, and a fault point can be quickly and accurately positioned through partial discharge equipment, so that maintenance is conducted in time; an inner lining layer, an armor layer and an outer sheathlayer are combined to form a whole which has excellent physical and mechanical properties, the whole cable is not easy to scratch and damage when being directly buried in soil and gravel in the open air and field and other severe environments, and rapid laying work and later maintenance work can be realized.

Owner:YUANCHENG CABLE CO LTD

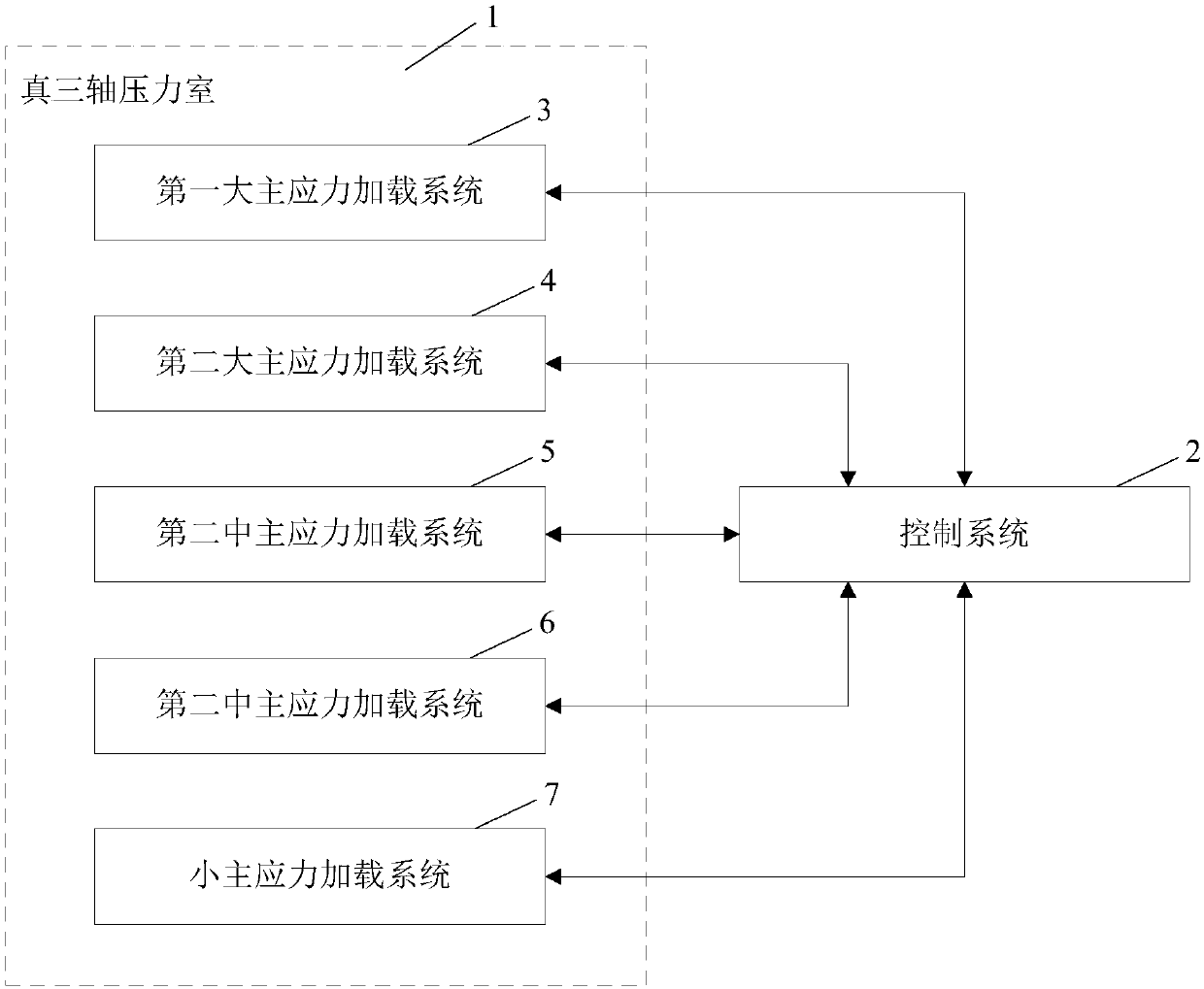

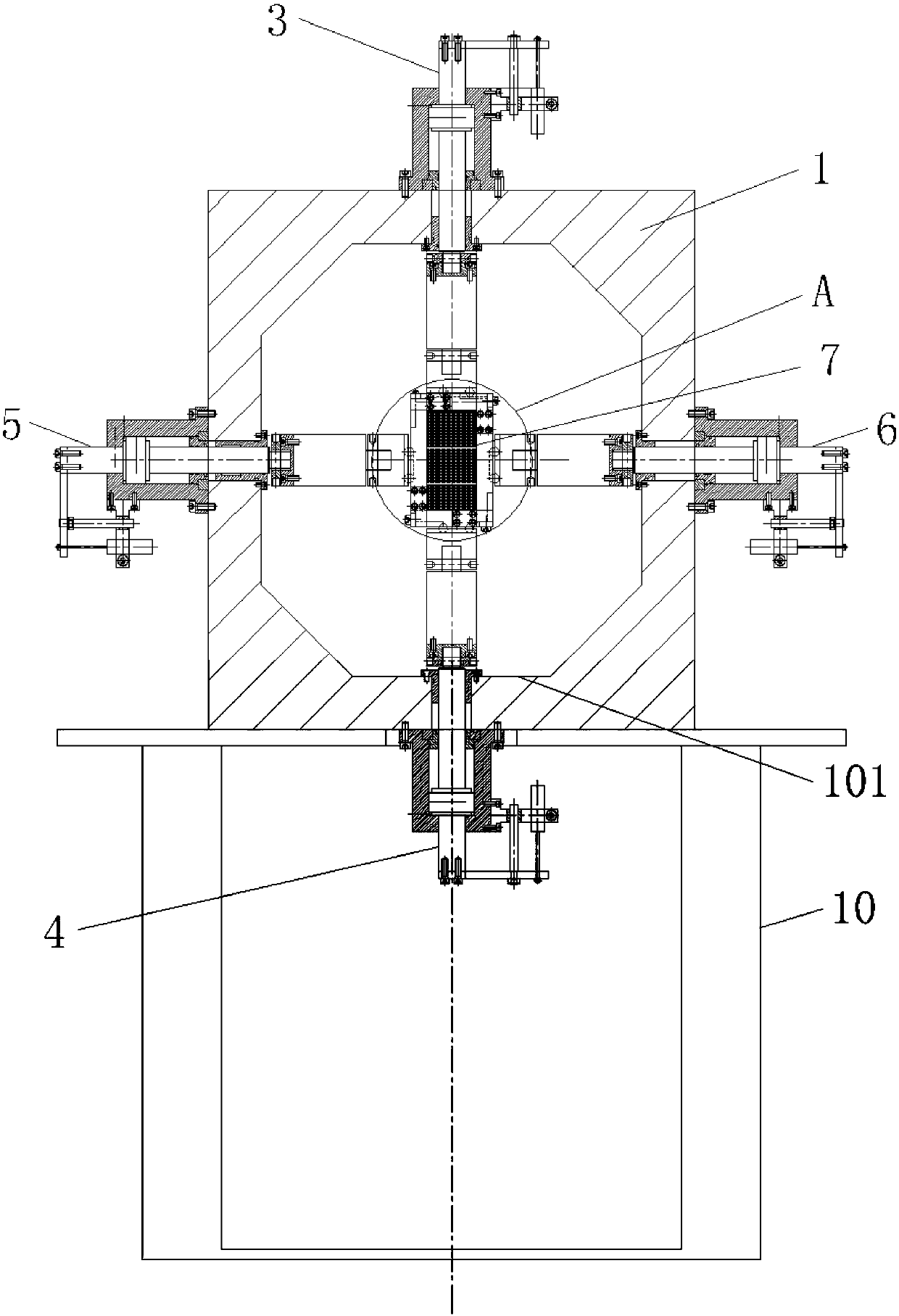

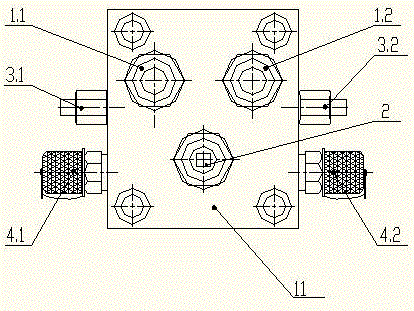

True triaxial dynamic pressure testing machine and method

PendingCN107860663APlay a guiding roleAvoid boundary defectsMaterial strength using tensile/compressive forcesData integrityPrincipal stress

The invention discloses a true triaxial dynamic pressure testing machine and method. The testing machine comprises a true triaxial pressure chamber, a control system, a major principal stress loadingsystem, an intermediate principal stress loading system and a minor principal stress loading system; the major principal stress loading system and the intermediate principal stress loading system comprise actuators, load sensors and pressure heads connected in sequence; the actuators and the load sensors are respectively connected with the control system; the minor principal stress loading systemcomprises test capsules, at least two guide pressure plates and at least two guide slots; the guide pressure plates, the guide slots and the pressure heads correspond to one another; each of the guidepressure plates is contacted with a corresponding pressure head, fixed on the outer side of the corresponding test capsule and can slide in the corresponding guide slot; and the test capsules are connected with the control system. The true triaxial dynamic pressure testing machine disclosed by the invention is simple in structure and convenient to use, and boundary defects in the dynamic true triaxial pressure testing process can be avoided, so that the sample is complete, and the test data are integral.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG +1

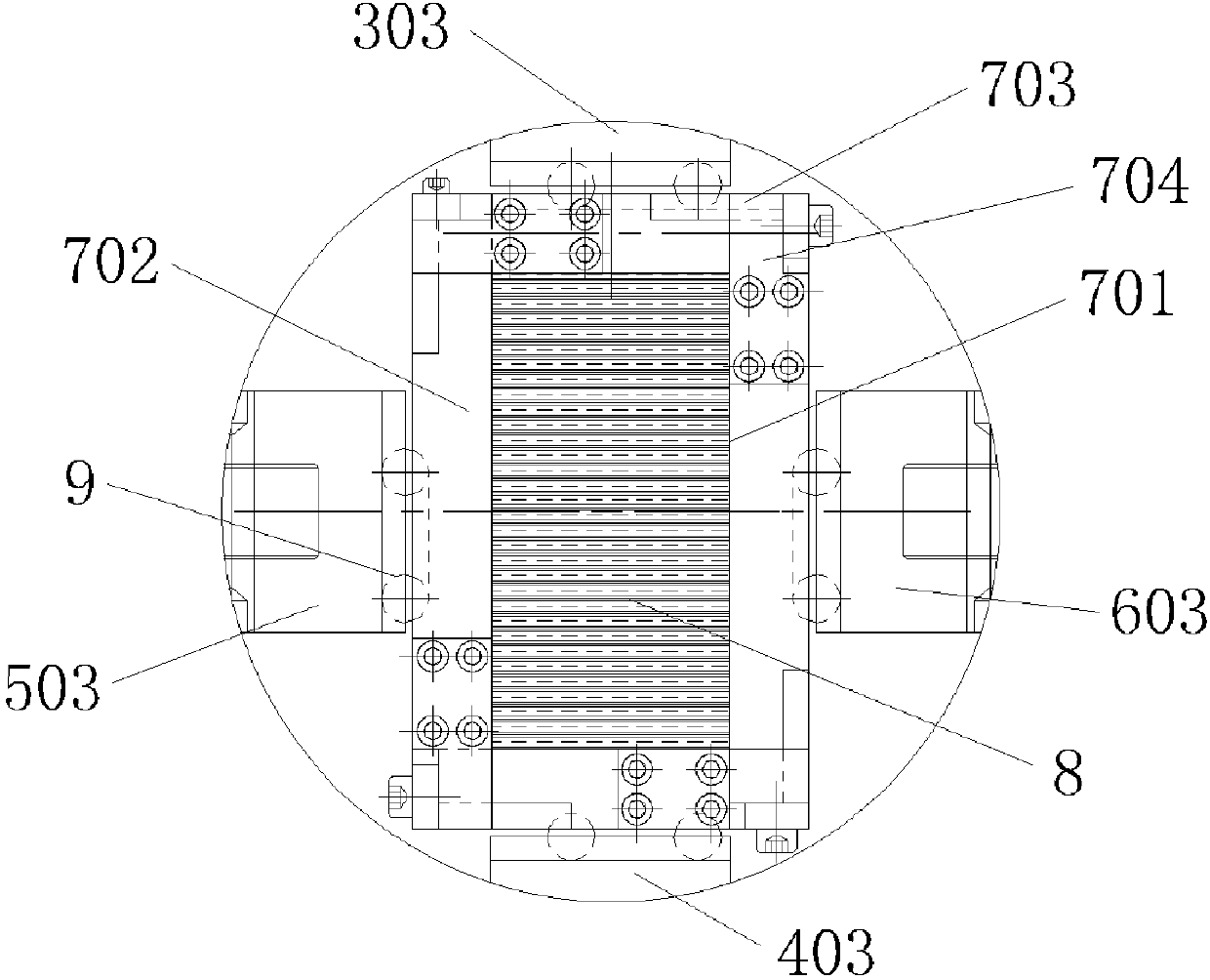

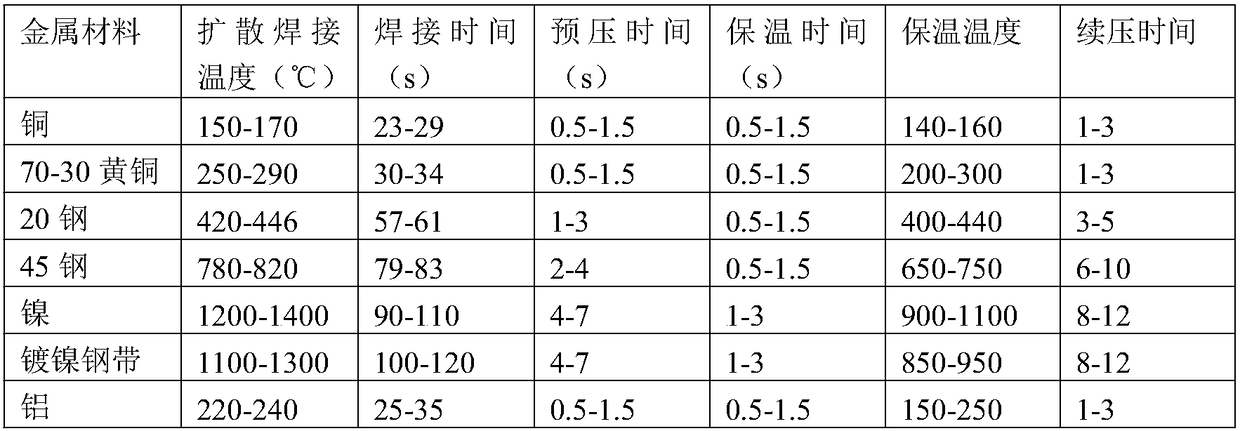

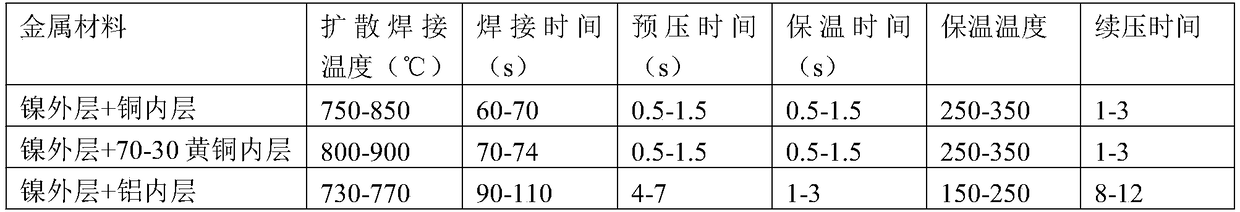

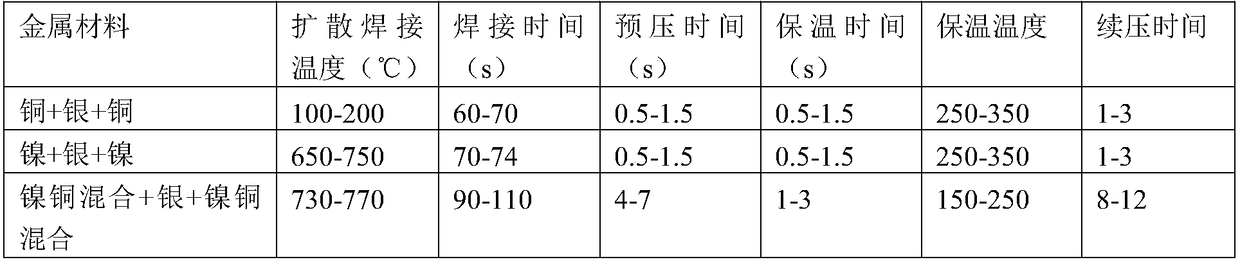

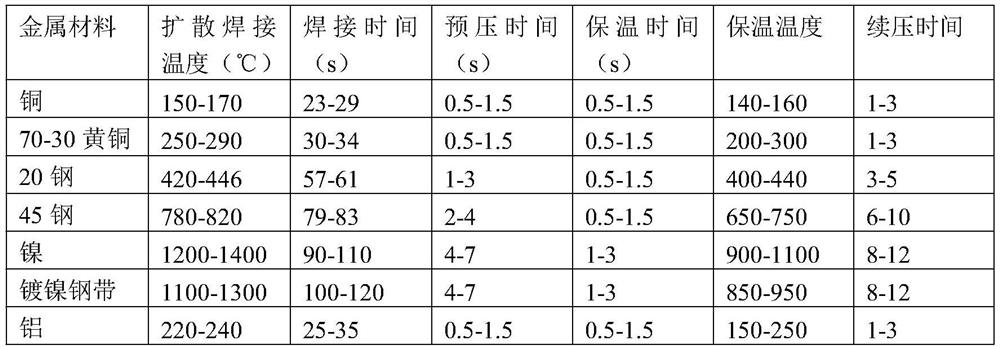

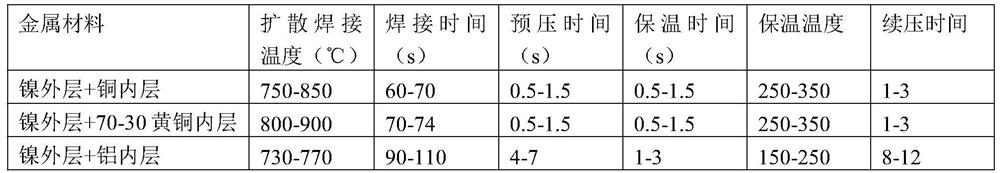

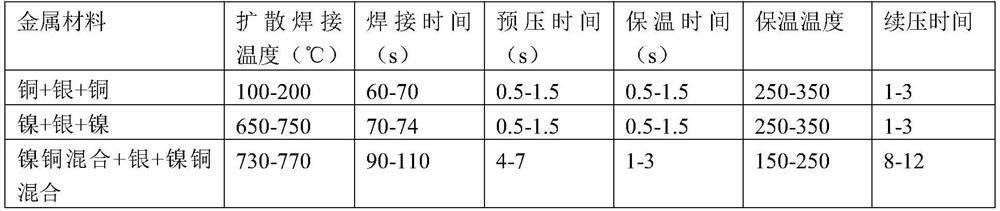

Process for preparing connecting conductor material for power source system of new energy vehicle

ActiveCN108817860ACause operational accidentsReliable electrical connectionCable/conductor manufactureElectrical conductorNew energy

The invention provides a preparation process of a connecting conductor material for a power source system of a new energy vehicle. The preparation process includes discharging, material strip detection, slitting, loading, polymer diffusion welding, surface treatment, punching, polishing, secondary blanking, secondary polishing, electroplating, third-time polishing, sleeving / plastic dipping, inspection, packaging, and the obtaining of the finished product. The polymer diffusion welding step includes first placing the well slit material in a jig for positioning; and a well-positioned to-be-welded material in a graphite welding area for welding. The material has the advantages of strong applicability, strong electrical conductivity, high current resistance, small resistance value and durability. The material is mainly used to connect each unit battery pack in the new energy vehicle power source system to finally form a power system of the electric vehicle.

Owner:JIANGSU K TECH PRECISION TECH +1

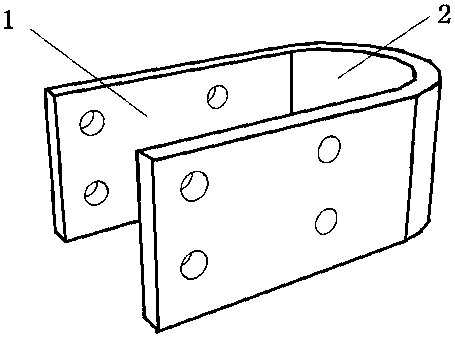

Current guide device for current transformer

PendingCN107644727AReliable electrical connectionReliable conductive connectionTransformers/inductances coils/windings/connectionsEngineeringCopper

The invention belongs to the technical field of electric power security, and particularly relates to a current guide device for a current transformer. The current guide device comprises a connecting portion and two lapping portions connected at two ends of the connecting portion, the lapping portions and the connecting portion form a U-shaped structure, the lapping portions are provided with a plurality of threaded holes, the connecting portion is provided with a plurality of copper strips, and the lapping portions are lapped on a connection pad of the current transformer. A current-carrying loop and conductive current-carrying area are increased, and overheating of the current transformer is prevented. Moreover, without changing the structure of a connection pad of an original current transformer, the current guide device is simple and convenient to mount, and interruption maintenance time is shortened.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU

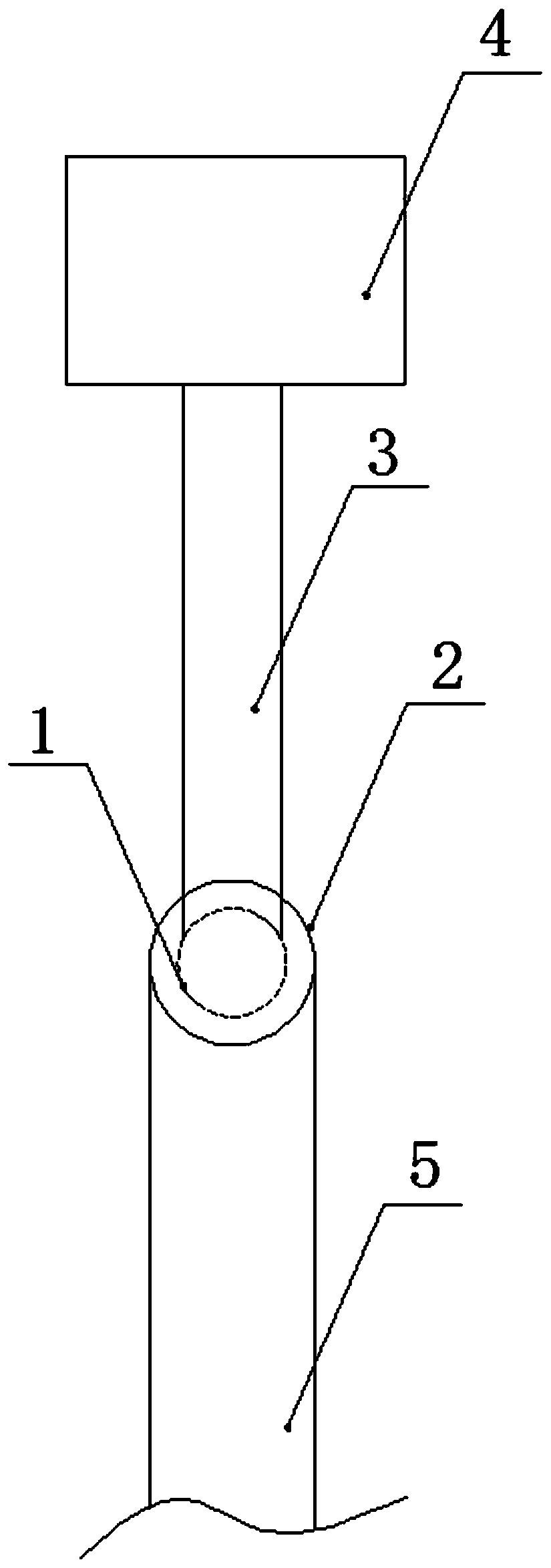

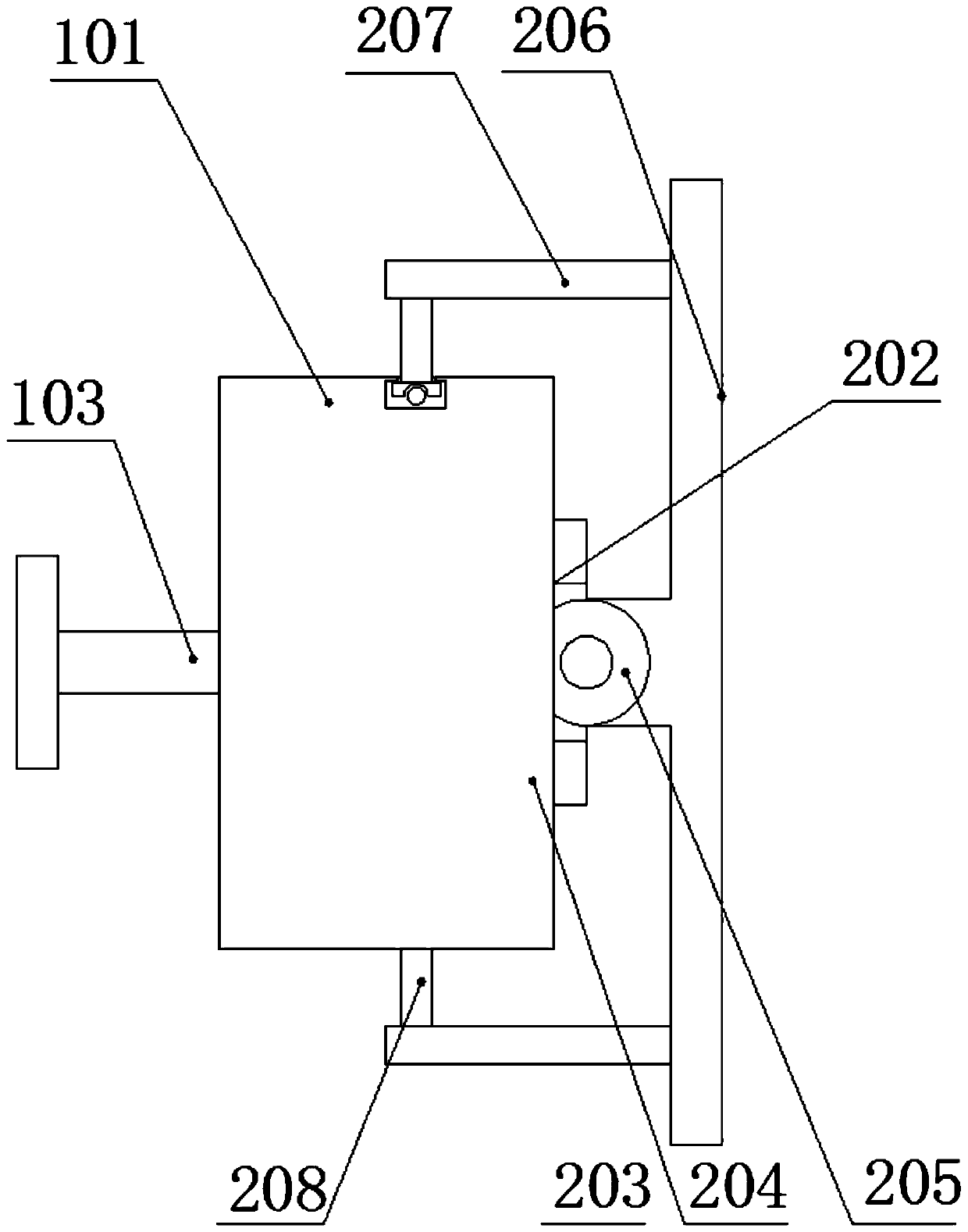

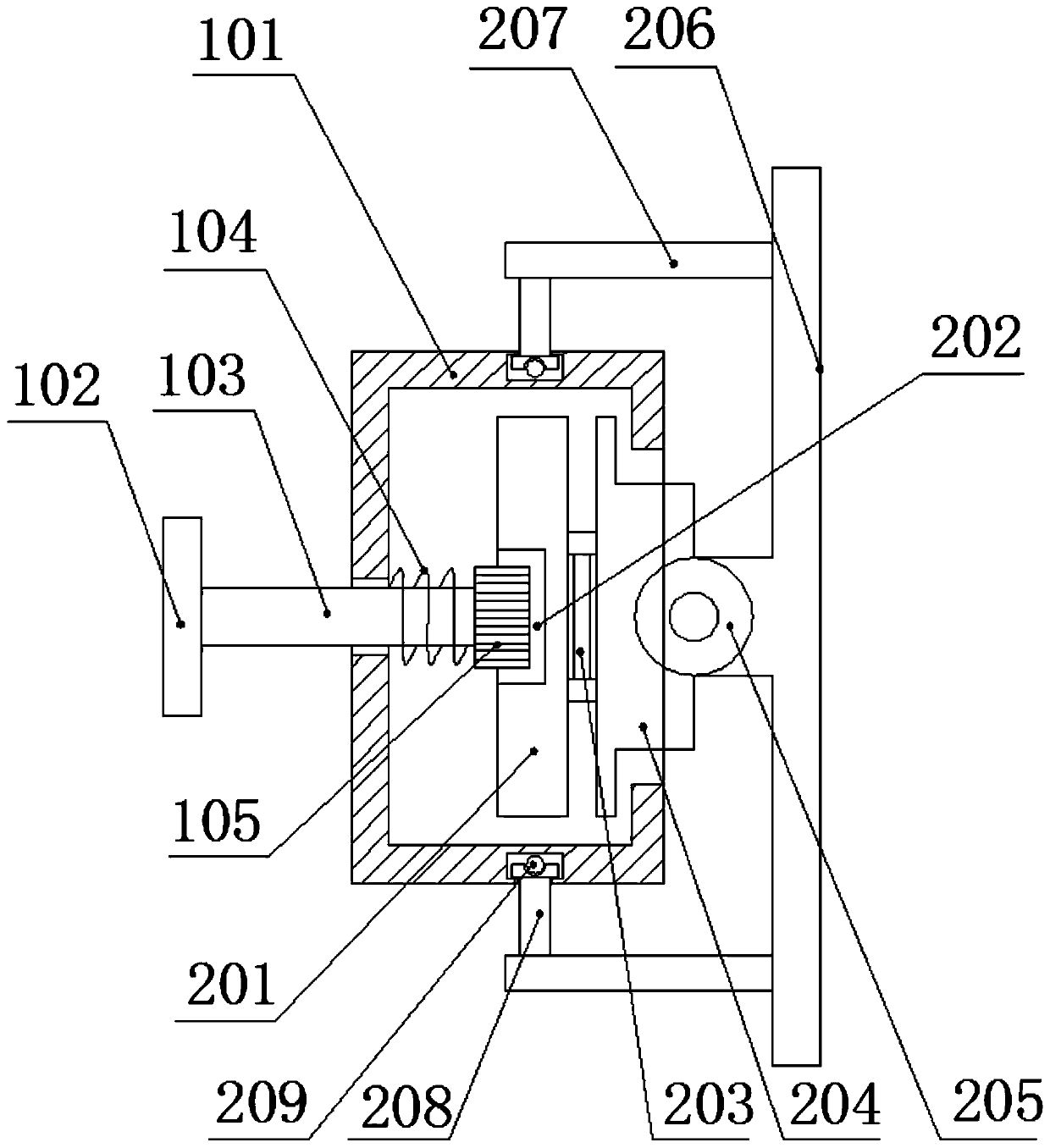

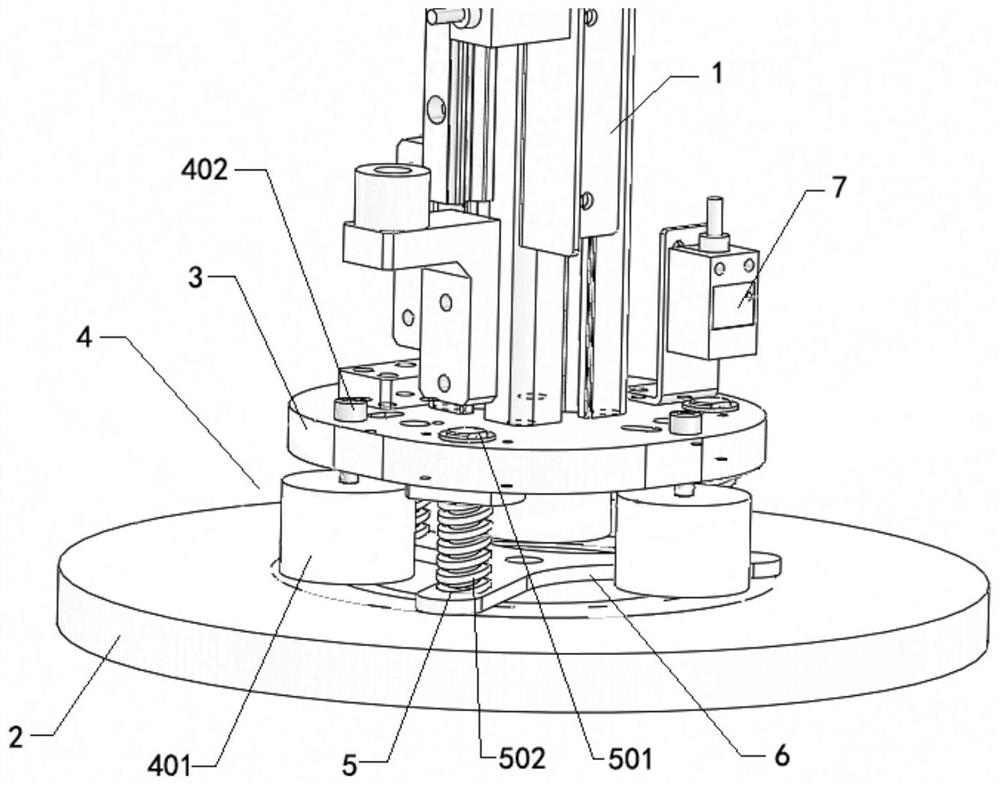

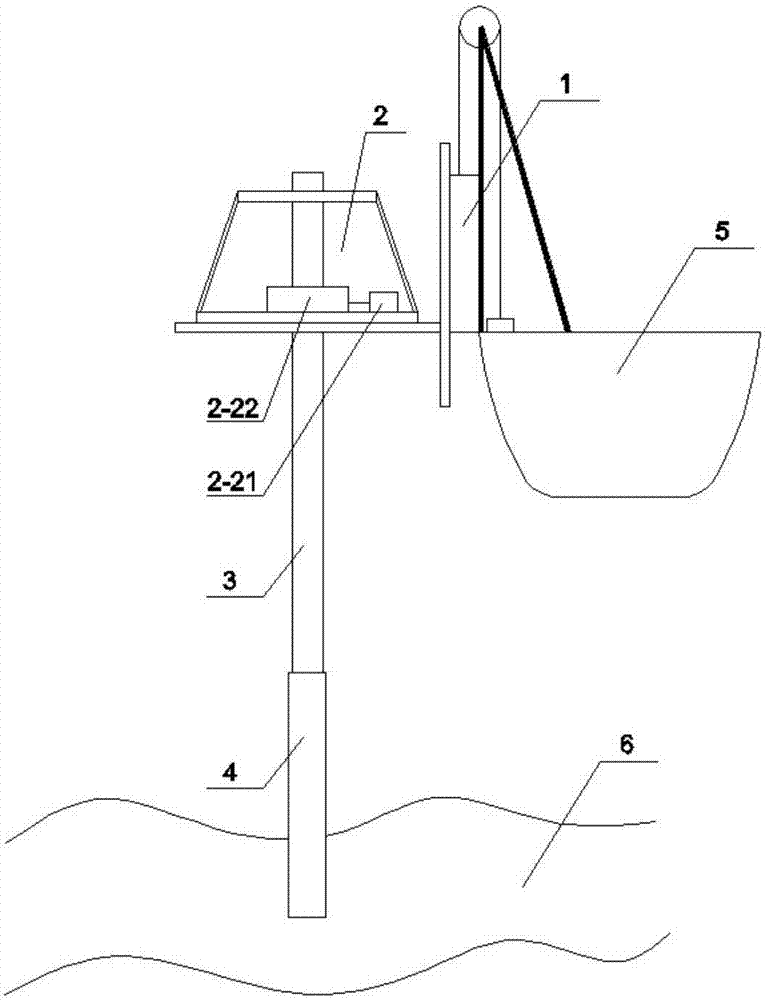

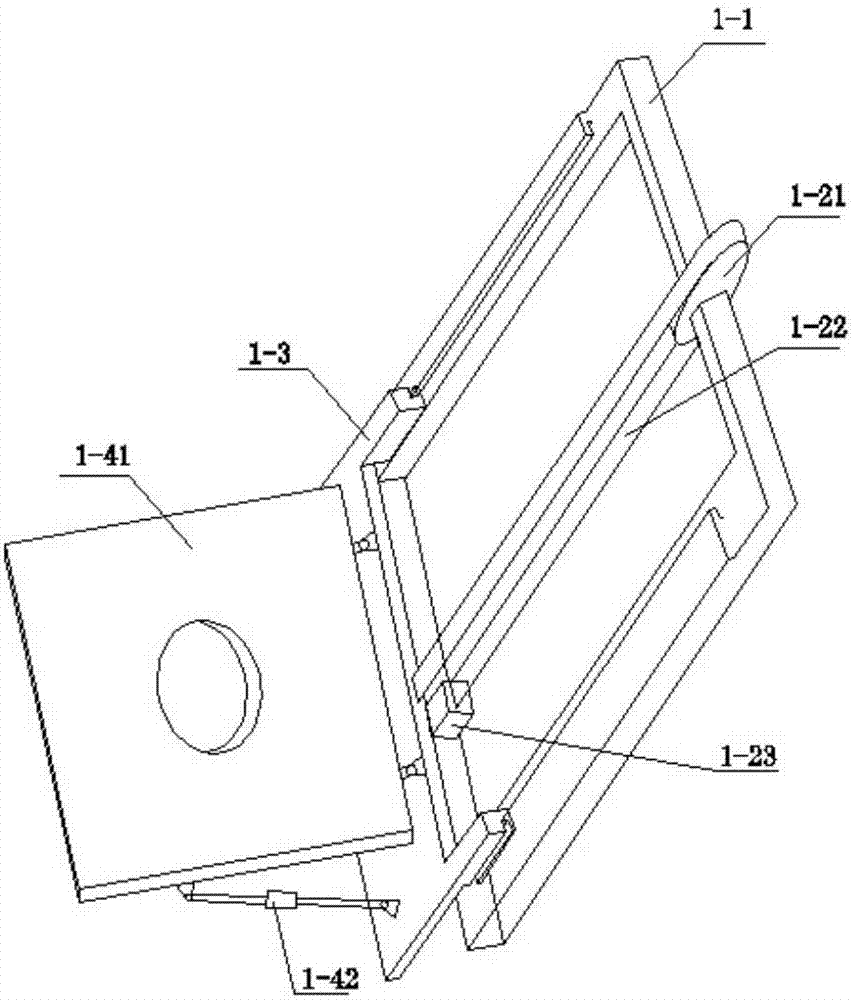

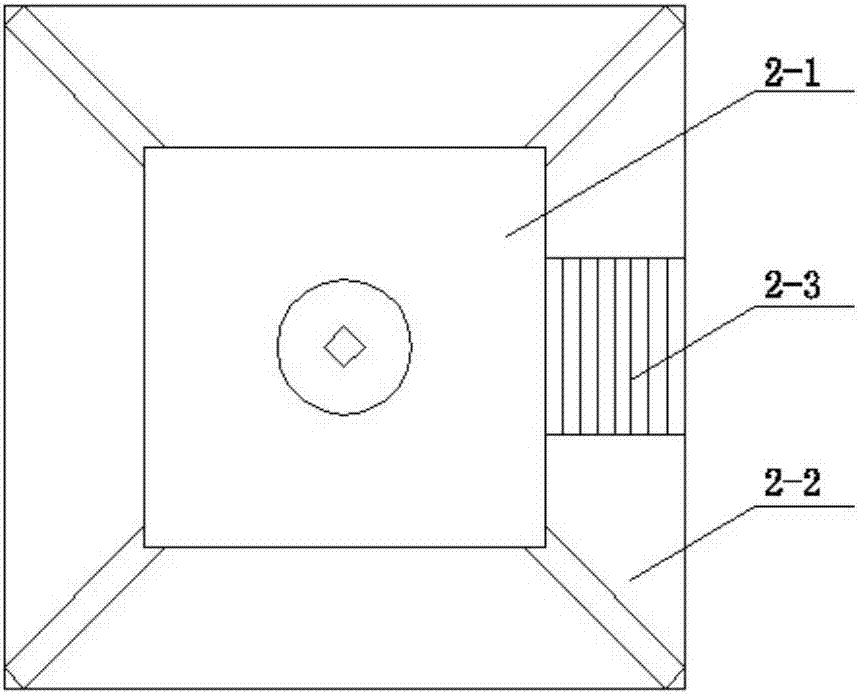

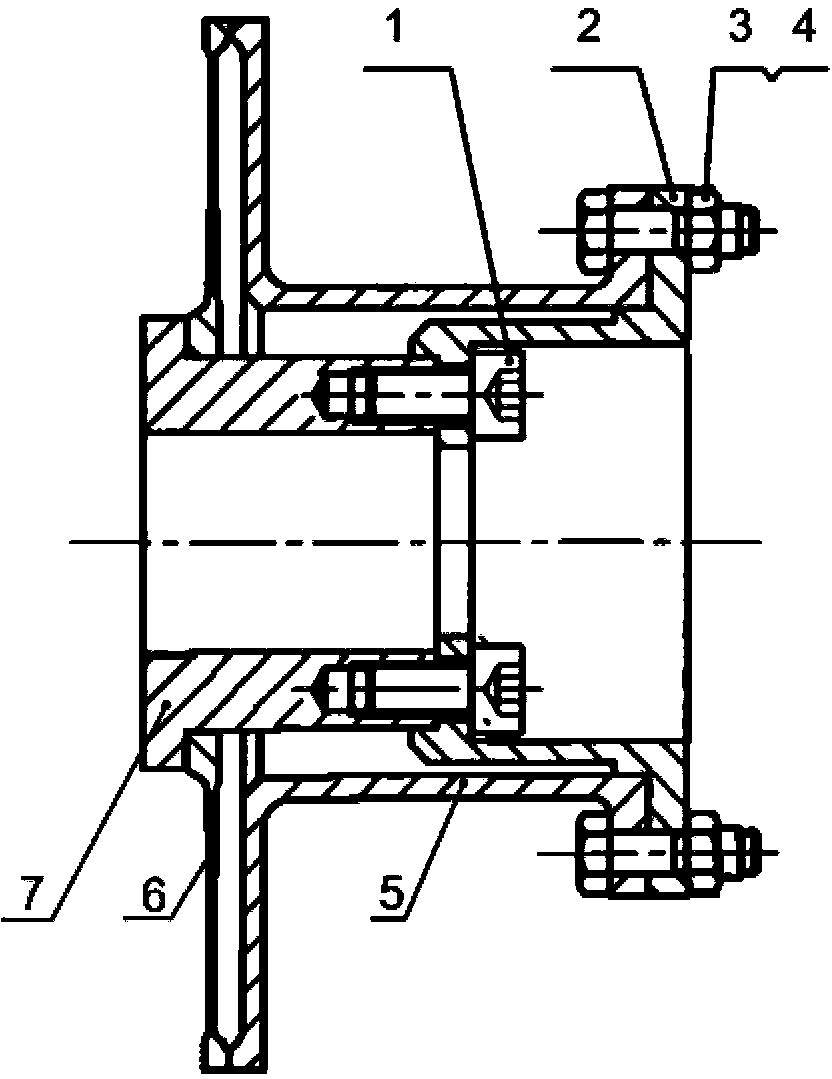

A rotary-occupied river bed sediment sampling device under the action of its own weight

The invention discloses a rotary bank-off advancing type riverbed deposit sampling device under a self-weight effect. The device comprises a liftable operating platform, a power system, a transmission rod and a sampling tube system, wherein the liftable operating platform is fixed to the side face of a surveying vessel; the power system is arranged on the liftable operating platform; the upper end of the transmission rod is arranged in a hole of the power system through a master bushing and is in drive connection with the power system; the lower end of the transmission rod is connected with the sampling tube system; the power system transmits a shear force to the sampling tube system through the transmission rod; the self-weight of the whole transmission rod and that of the sampling tube system are adopted as drilling pressure to drill to a sampling position, and finally the whole sampling tube system is lifted to the surveying vessel to complete sampling work. The device is simple in structure, convenient to disassemble, and suitable for deepwater sampling in a water reservoir, and can prevent a deposit sample from being disturbed.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

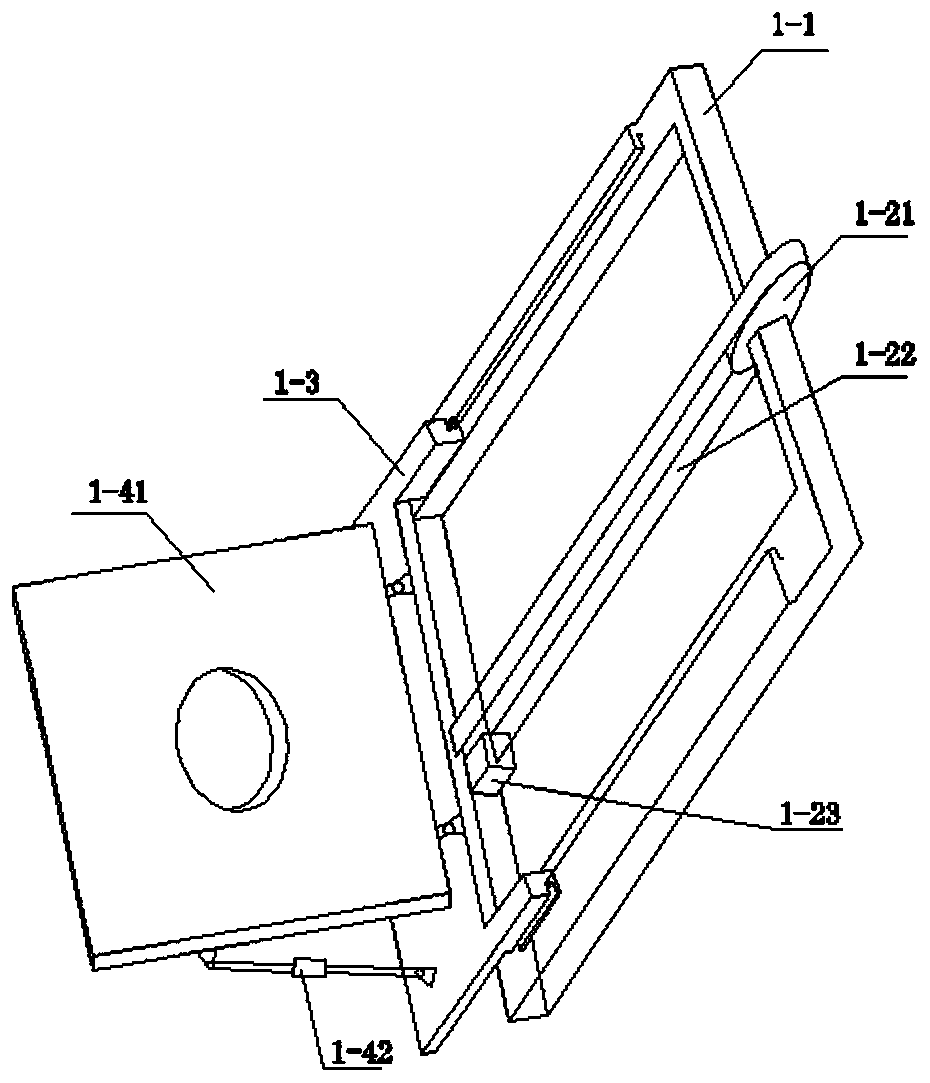

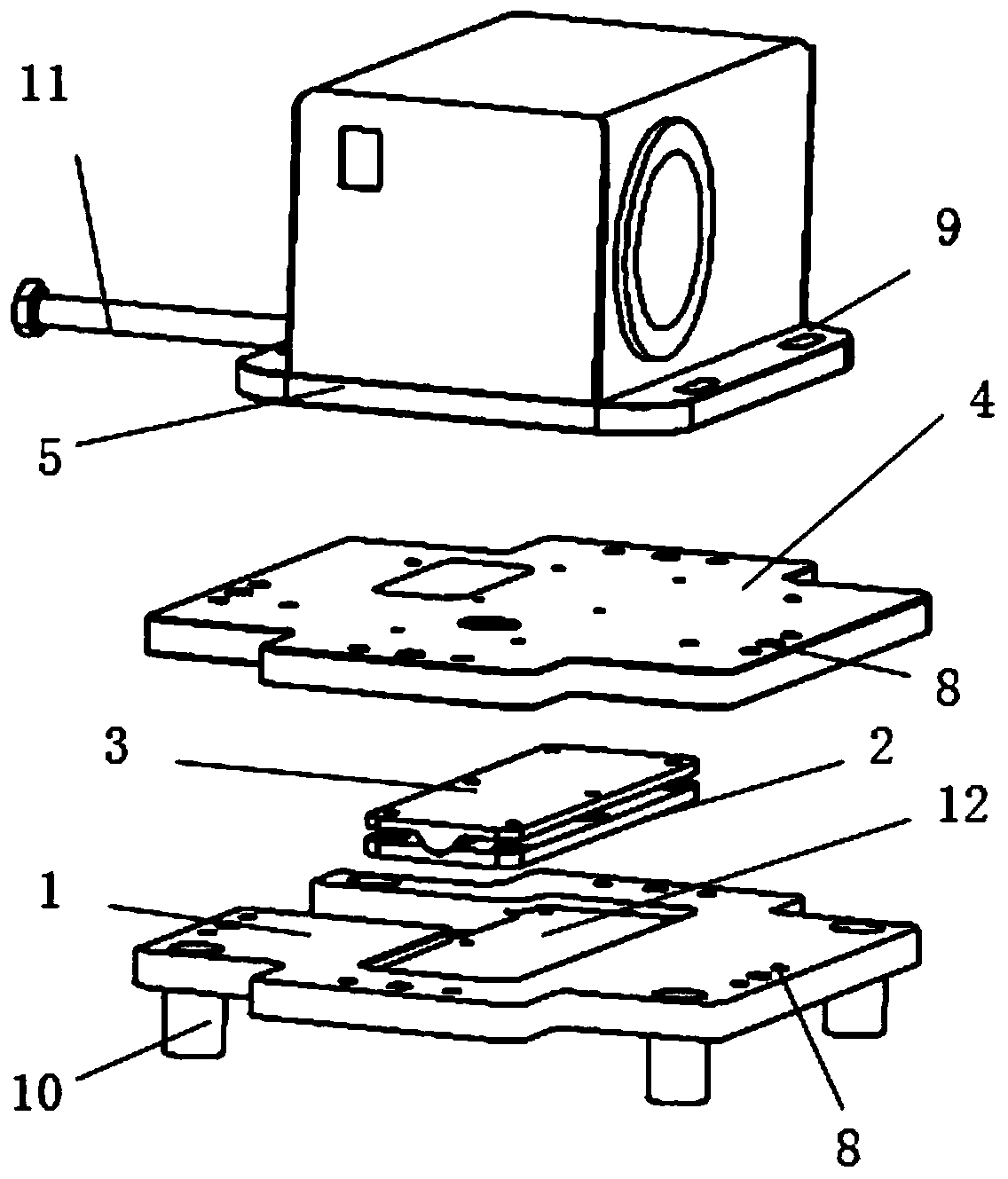

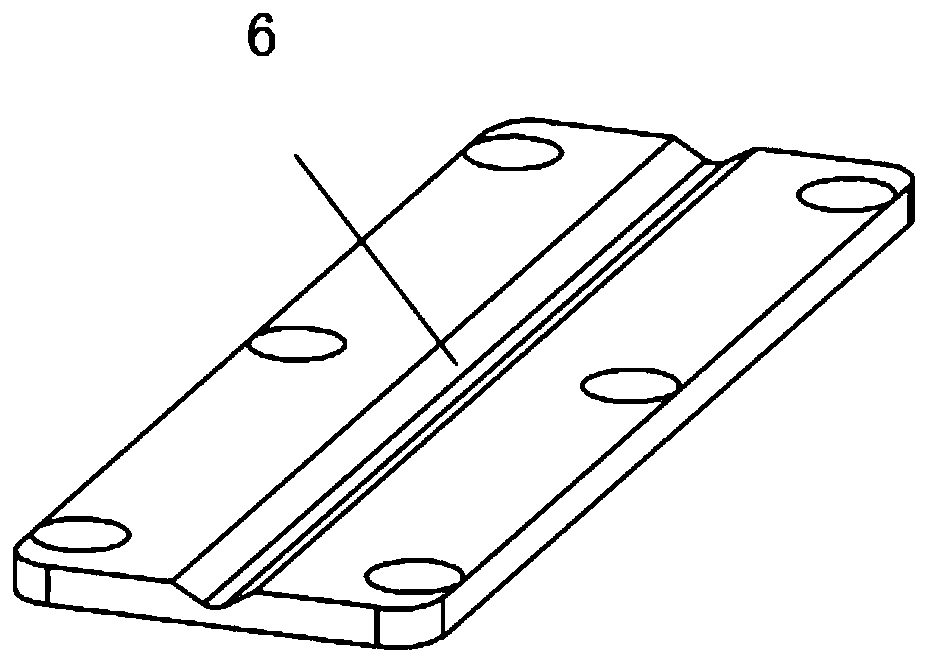

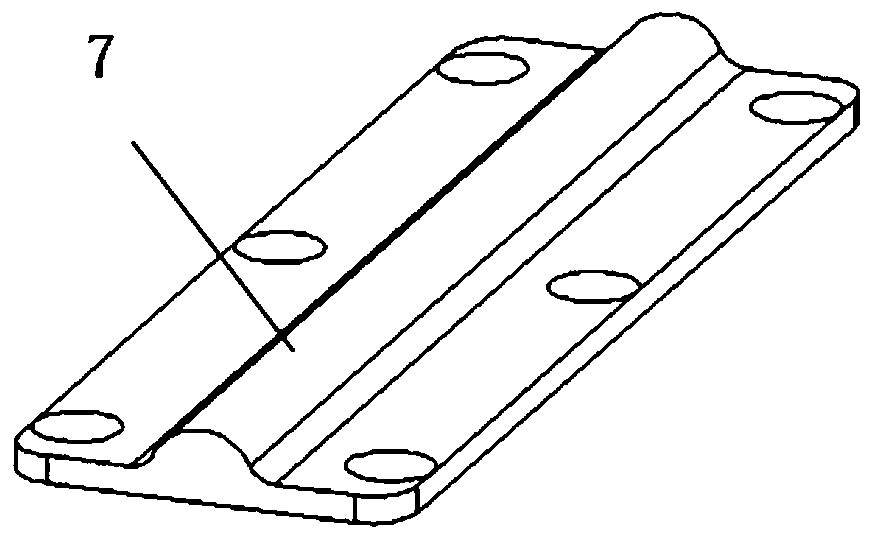

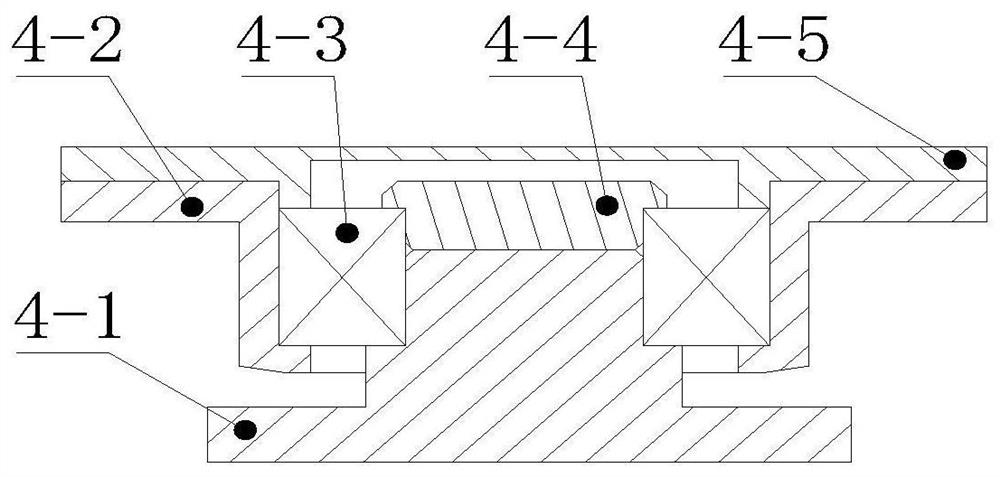

Structure used for realizing adjustable performance of light path in space

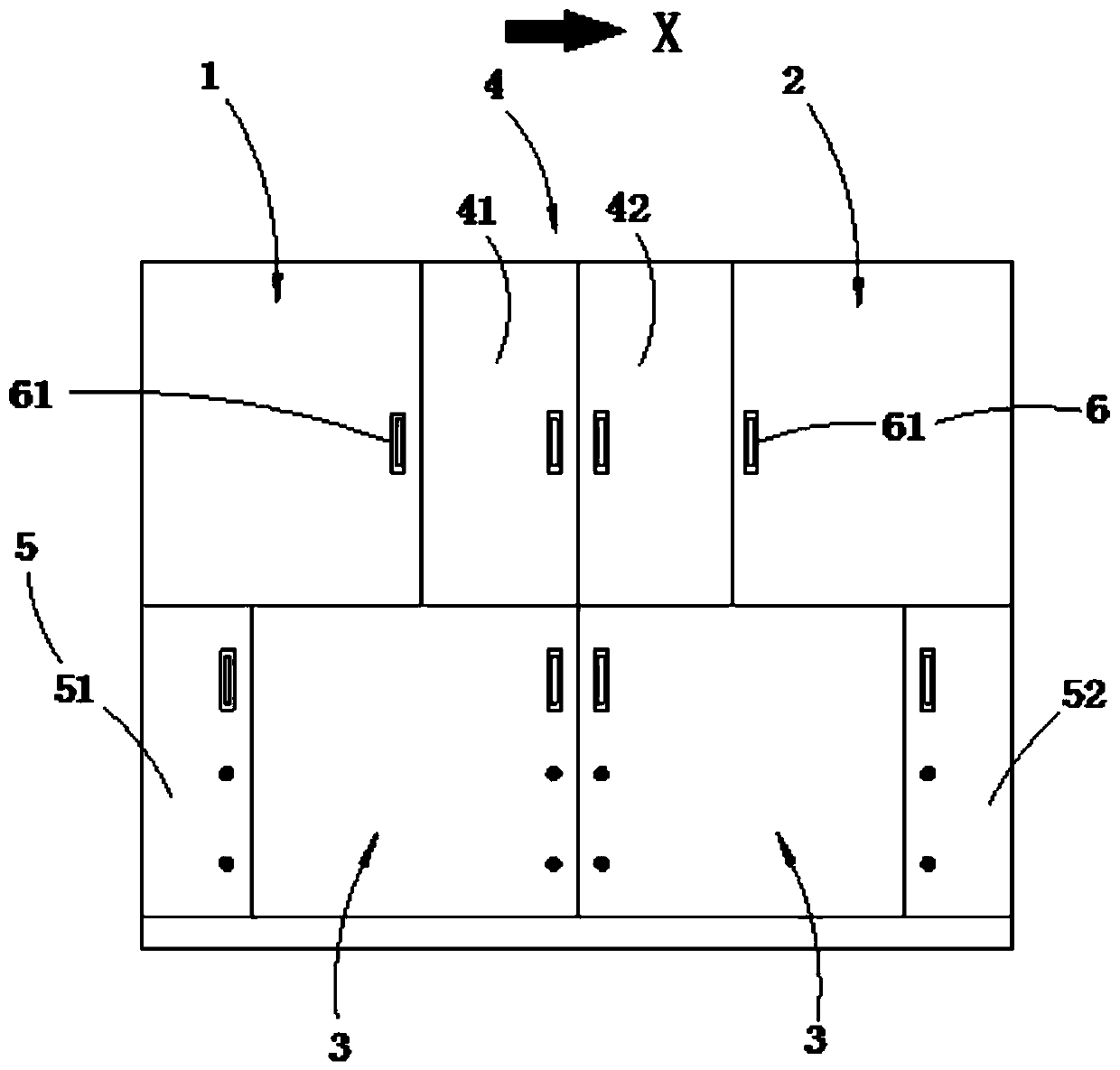

PendingCN110376733ANot affected by external forcesNo cantilever stateColor/spectral properties measurementsOptical elementsGas analysisUltraviolet

The invention relates to the motor vehicle tail gas remote sensing equipment technology field and especially relates to a structure used for realizing adjustable performance of a light path in a space. The structure comprises a fixing bottom plate, a module fixing plate and a module adjusting plate. An adjustment slot is arranged in a middle portion of the fixing bottom plate, and an adjustment embossment which is cooperated with the adjustment slot is arranged at a bottom of the module fixing bottom plate. Two sides of the fixing bottom plate and the module fixing plate are provided with threaded holes. After upper and lower angles of the module fixing plate are adjusted, the module fixing plate passes through the threaded holes through a bolt so that the fixing bottom plate and the module fixing plate are connected. Adjustment holes are arranged on two sides of the module adjusting plate, and an adjustment bolt passes through an adjustment hole and is connected to the module fixing plate. The mechanism can be used to ensure that an ultraviolet telemetering gas analysis module and a tail gas laser telemetering gas analysis module do not affect each other when a light path is adjusted, and a single module can be individually adjusted in horizontal and vertical directions.

Owner:TIANJIN TONGYANG TECH DEV

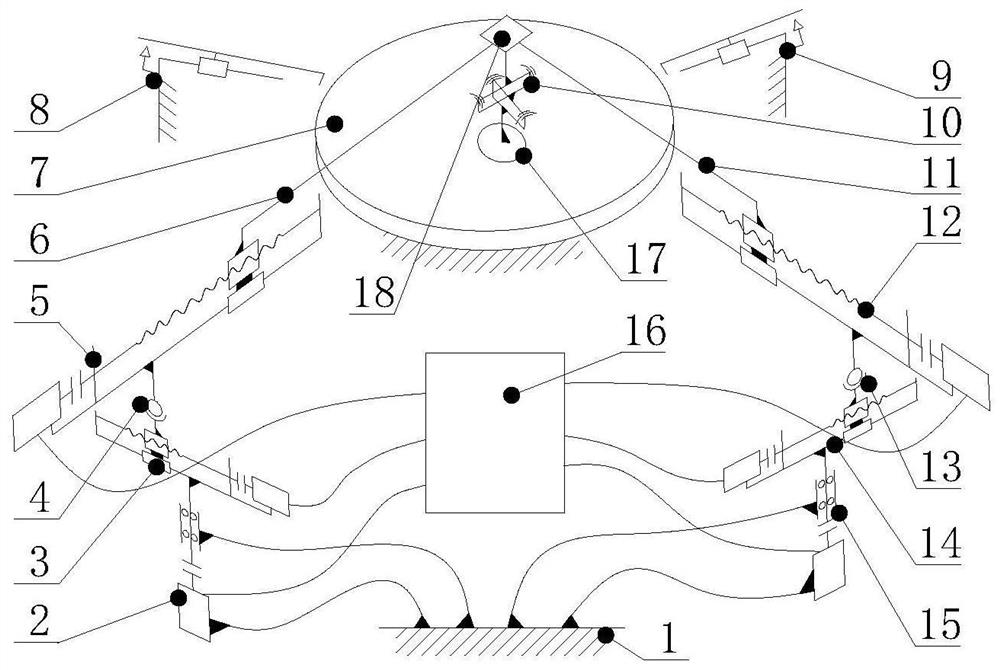

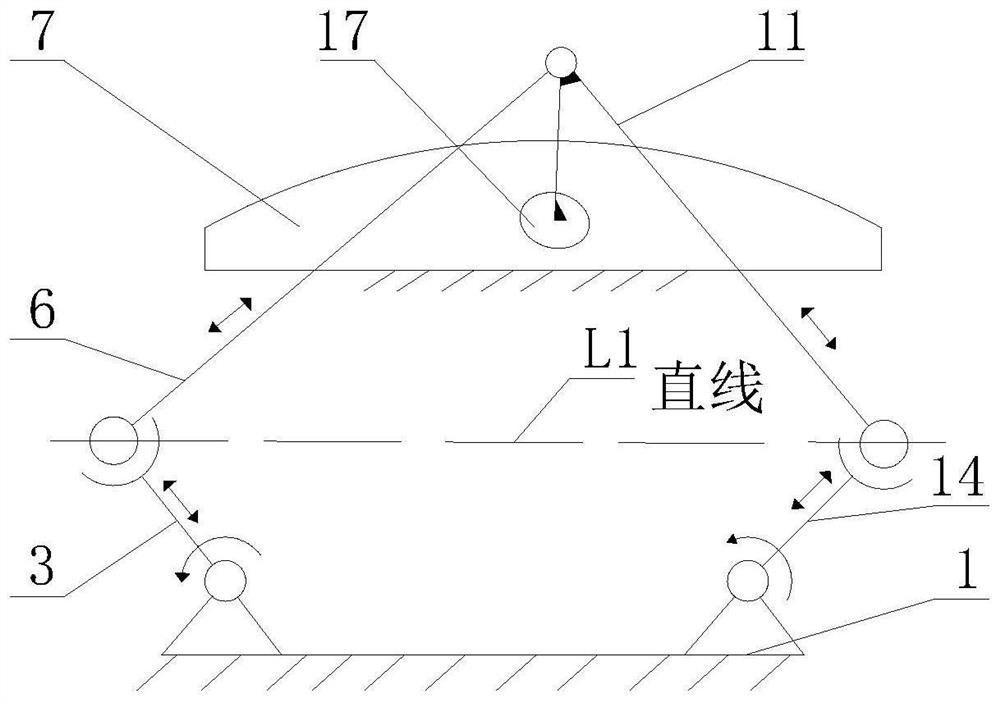

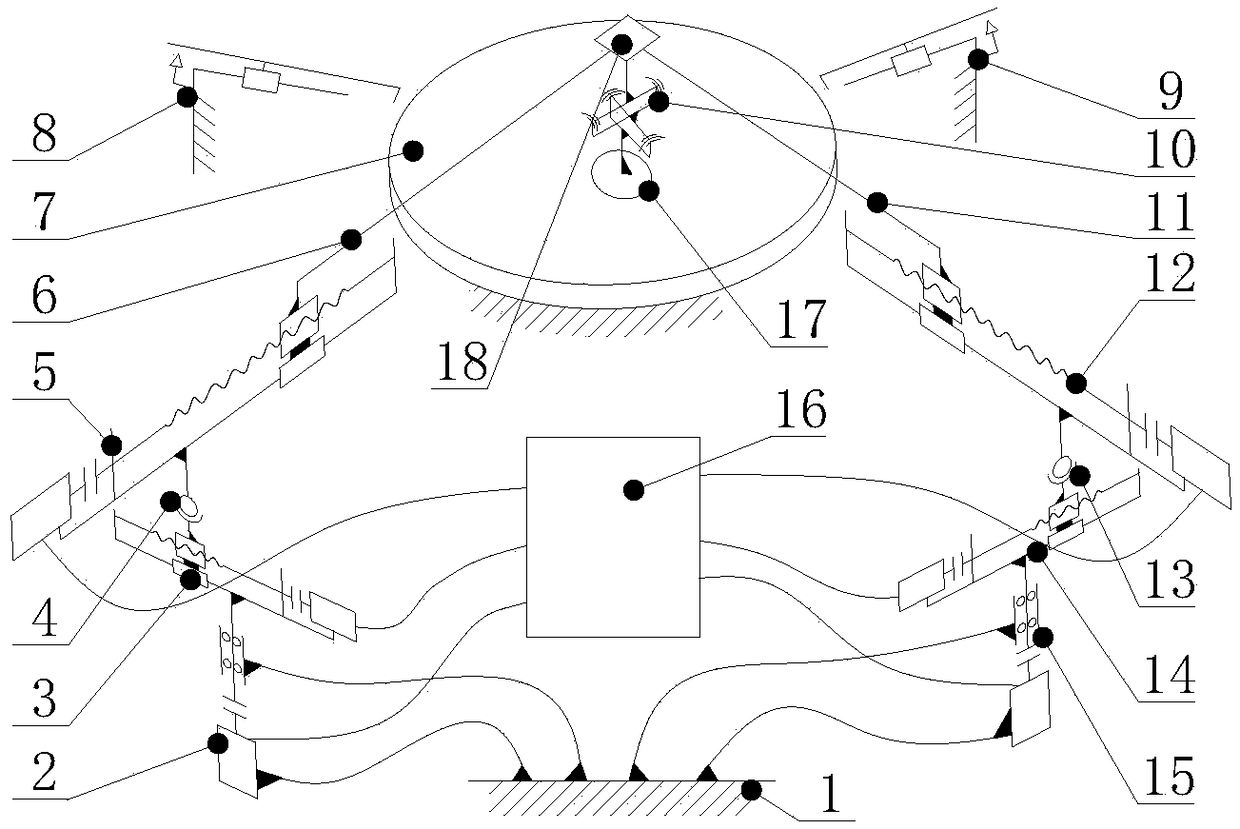

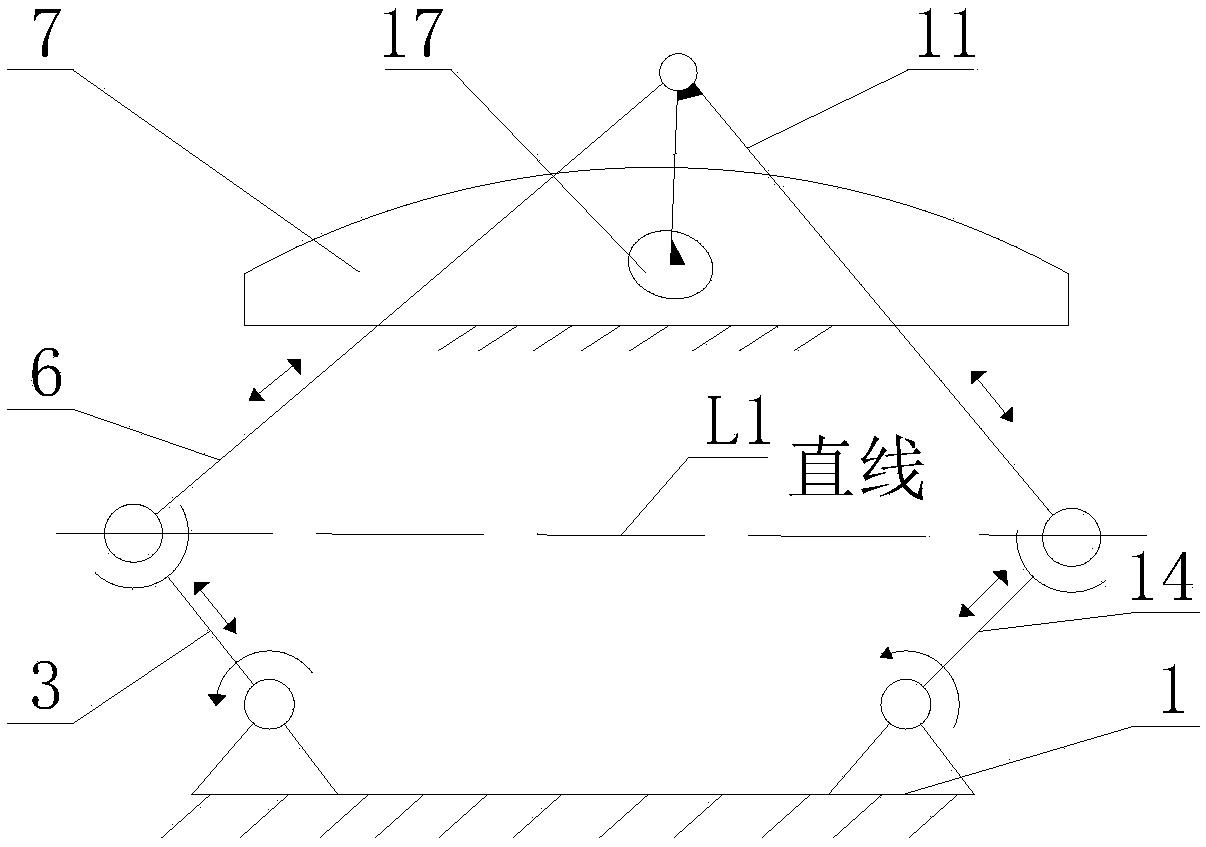

Five-bar linkage for aspheric component polishing

ActiveCN108789019BReasonable structural designSimple and reliable control processGrinding wheel securing apparatusGrinding carriagesCrankPolishing

The invention discloses a five-linkage-rod mechanism for non-spherical element polishing. The mechanism mainly comprises a machine frame, main shafts, crank sliding tables, spherical hinge mechanisms,connecting rod sliding tables, connecting rods, a workpiece, positioning measuring tools, a floating head, a control box, a pitch lap and a rapid disassembling module, the two main shafts, the cranksliding tables, the spherical hinge mechanisms, the connecting rod sliding tables and the connecting rods form the closed two-spherical-hinged three-degree-of-freedom five-rod mechanism, the two positioning measuring tools accurately determine the position of the workpiece relative to the two main shafts, the control box is used for controlling the rotating speed and the rotating angle of the mainshafts, the length of the crank sliding tables and the length of the connecting rod sliding tables through reading codes, and the connecting rods drive the pitch lap to realize polishing machining. The five-linkage-rod mechanism is a mechanism which is based on three-degree-of-freedom five-connecting-rod mechanism based on the two-spherical-hinged three-degree-of-freedom five linkage rods, controllable residence time type polishing is realized according to the traditional manual polishing characteristic design, the mechanism is suitable for various non-spherical elements, the single removal amount can be controlled at the nanometer level, and the advantages of being flexible in movement, high in reliability, high in machining quality, capable of effectively restraining medium-frequency errors and the like are achieved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Cable connector

The invention discloses a cable connector, which comprises a connector body, wherein a cable fixing end is arranged at one end of the connector body; a fastening screw is arranged at the other end of the connector body; a fixed joint is arranged on the fastening screw; a cable clamping head is also arranged on the fixed joint; the cable fixing end is a clamping fixing end; and a layer of insulated rubber is arranged on the surface of each of the fixed joint and the cable clamping head. According to the cable connector, two fixing heads for clamping and fixing a cable are arranged on the body; and the cable at two ends is fastened through the fastening screw, so that the connected part of the cable is prevented from being affected by external force, and does not easily become flexible, thus faults on the cable connector are greatly reduced.

Owner:邹中霞

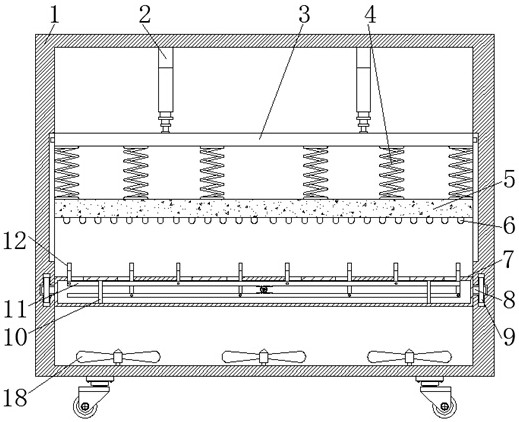

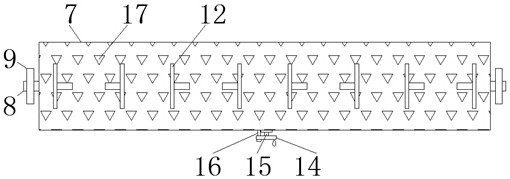

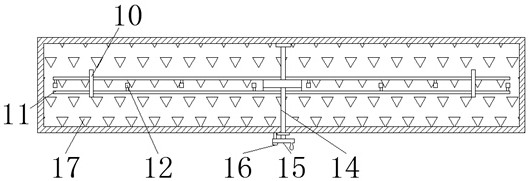

A laser life test fixture

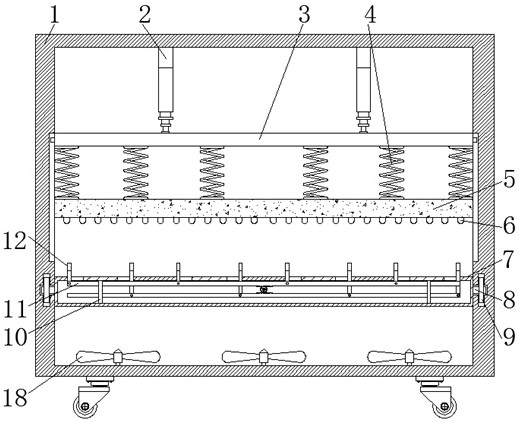

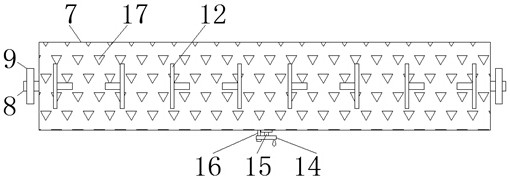

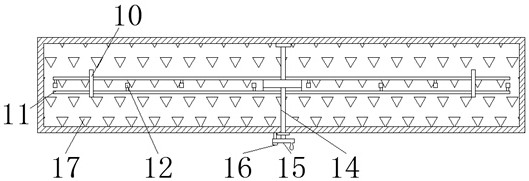

ActiveCN111766043BPrevent side to side movementNot affected by external forcesWork holdersOptical apparatus testingGear wheelErbium lasers

The invention discloses a laser life test fixture, which comprises a main box body, an inner box body, a support rod and a through hole. An electric telescopic rod is fixed on the top of the main box body, and the lower end of the electric telescopic rod is fixed on a fixing plate. And the lower end of the fixed plate is fixed with a spring, the movable rod and the gear are connected to each other, and the gear is fixed on the rotating rod, the end of the rotating rod is fixed with a hand wheel, and the hand wheel is connected to the bolt, and the through hole is opened On the inner box, and the bottom of the main box is fixed with a cooling fan. The laser life test fixing fixture uses two pairs of limit plates to fix the laser to prevent the laser from moving left and right. The movable rod controls the movement of multiple limit plates to fix the laser. Compared with bolt fixing, it is more convenient to use a soft rubber plate. The downward movement of the soft rubber pad causes the laser to be deformed, which can fix the laser and have a certain shock absorption effect to protect the laser from external forces.

Owner:苏州鼎智瑞光智能科技有限公司

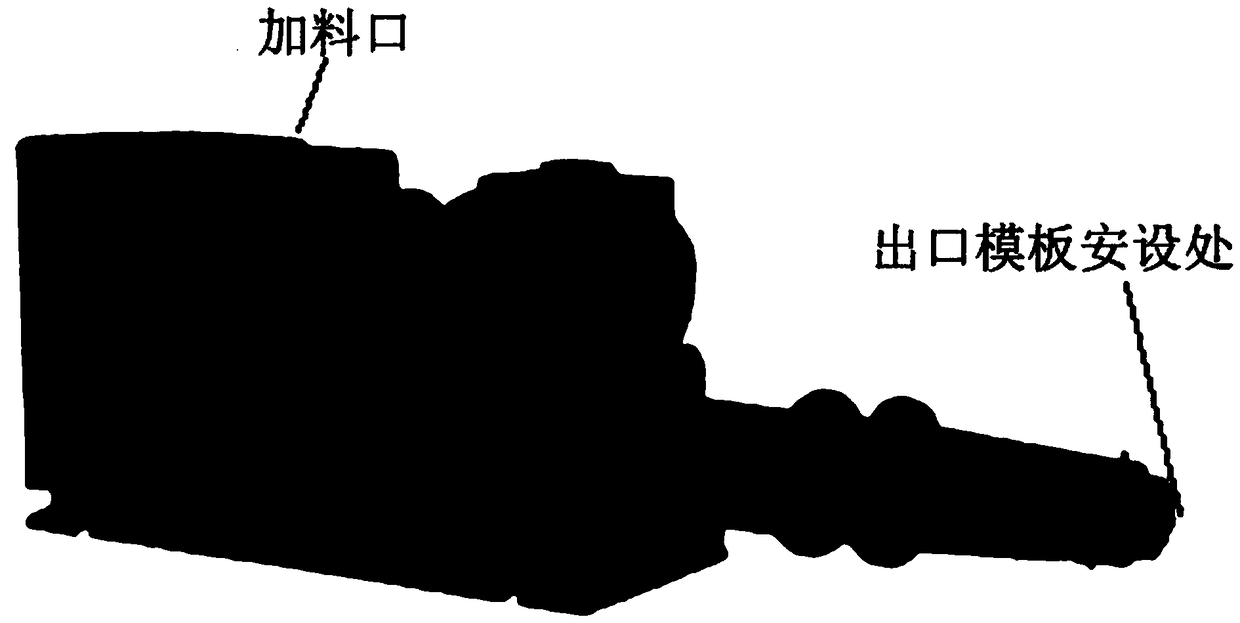

Rodlike aggregate for lightweight castable and preparation method of rodlike aggregate for lightweight castable

ActiveCN108373278AReduce manufacturing costIncrease productivityBuilding reinforcementsBatch productionWater reducer

The invention discloses rodlike aggregate for lightweight castable and a preparation method of the rodlike aggregate for lightweight castable. The preparation method includes: subjecting Guangxi whiteclay, a binding agent and a water reducing agent to dry mixing, then adding water, and mixing to obtain mixed paste; using a vacuum extruder to extrude the obtained mixed paste under conditions thatthe pressure is 1-2MPa, the vacuum degree ranges from -0.085MPa to -0.095MPa, and the temperature during extrusion is 15-25 DEG C so as to obtain a rodlike aggregate blank with the basic diameter being 0.6-3mm; drying and baking to obtain the rodlike aggregate for lightweight castable. By the preparation method, early-stage large-quantity mould preparation and continuous mould replacement processes are avoided, production cost is greatly reduced, production efficiency is increased by 3-5 times as compared with previous production efficiency, continuous automatic production is realized, low cost, low energy consumption and high efficiency are realized, and continuous batch production and high social and economic benefits are realized.

Owner:郑州市裕丰耐火材料有限公司

A preparation process of connecting conductor material for new energy vehicle power supply system

ActiveCN108817860BImprove applicabilityImprove conductivityCable/conductor manufactureElectrical conductorNew energy

The invention provides a preparation process of a connecting conductor material for a power source system of a new energy vehicle. The preparation process includes discharging, material strip detection, slitting, loading, polymer diffusion welding, surface treatment, punching, polishing, secondary blanking, secondary polishing, electroplating, third-time polishing, sleeving / plastic dipping, inspection, packaging, and the obtaining of the finished product. The polymer diffusion welding step includes first placing the well slit material in a jig for positioning; and a well-positioned to-be-welded material in a graphite welding area for welding. The material has the advantages of strong applicability, strong electrical conductivity, high current resistance, small resistance value and durability. The material is mainly used to connect each unit battery pack in the new energy vehicle power source system to finally form a power system of the electric vehicle.

Owner:JIANGSU K TECH PRECISION TECH +1

LED light-emitting board without dark side

InactiveCN108980780AFeel goodIncreased packaging volumeMechanical apparatusLighting heating/cooling arrangementsAluminiumEngineering

The invention discloses an LED light-emitting board without a dark side. The LED light-emitting board without the dark side comprises a light-emitting board body and an LED light bar; a notch is formed in one side of the light-emitting board body and arranged on the shady face; a boss is arranged on the light-emitting face; the LED light bar is installed at the notch of the light-emitting board body; an L-type aluminum connection board is installed on the side face of the box and fixed to the side face of the boss through heat conduction double-faced adhesive tape; and the back face of the L-type aluminum connection board is fixed to the shady face of the light-emitting board body. According to the LED light-emitting board without the dark side, the whole light-emitting face can emit light, the overall product is more attractive, the use effect is good, and the defect that a power line is prone to being pulled and broken can be overcome.

Owner:朴明灿

New box type substation

ActiveCN105762693BReduce difficultySpeed up heat dissipationTransformers/inductances coolingSubstation/switching arrangement cooling/ventilationTransformerControl theory

The invention discloses a novel box type transformer station. The novel box type transformer station at least comprises a high-voltage switch chamber, a low-voltage switch chamber and a transformer chamber, wherein the high-voltage switch chamber, the low-voltage switch chamber and the transformer chamber are in echelonment distribution, and equipment lines in the high-voltage switch chamber, the low-voltage switch chamber and the transformer chamber are M-shaped, U-shaped or V-shaped. Different from the prior art, the novel box-type transformer station enables the volume of the box type transformer station to be reduced by 1 to 3 times compared to a conventional transformer station through innovative adoption of an upper-lower multilayer distribution structure, reduces the area of occupied land, facilitates transportation and decreases the transport cost; and a downward pedestal of the conventional box type transformer station does not have to be manufactured, such that the difficulty of a construction project is reduced, the cost is decreased, and unfavorable influences brought by moisture in the half-embedded pedestal to each device in the box type transformer station can be better avoided.

Owner:袁茂银

Five-linkage-rod mechanism for non-spherical element polishing

ActiveCN108789019AReasonable structural designMechanism control is simple and reliableGrinding wheel securing apparatusGrinding carriagesIntermediate frequencyHinge angle

The invention discloses a five-linkage-rod mechanism for non-spherical element polishing. The mechanism mainly comprises a machine frame, main shafts, crank sliding tables, spherical hinge mechanisms,connecting rod sliding tables, connecting rods, a workpiece, positioning measuring tools, a floating head, a control box, a pitch lap and a rapid disassembling module, the two main shafts, the cranksliding tables, the spherical hinge mechanisms, the connecting rod sliding tables and the connecting rods form the closed two-spherical-hinged three-degree-of-freedom five-rod mechanism, the two positioning measuring tools accurately determine the position of the workpiece relative to the two main shafts, the control box is used for controlling the rotating speed and the rotating angle of the mainshafts, the length of the crank sliding tables and the length of the connecting rod sliding tables through reading codes, and the connecting rods drive the pitch lap to realize polishing machining. The five-linkage-rod mechanism is a mechanism which is based on three-degree-of-freedom five-connecting-rod mechanism based on the two-spherical-hinged three-degree-of-freedom five linkage rods, controllable residence time type polishing is realized according to the traditional manual polishing characteristic design, the mechanism is suitable for various non-spherical elements, the single removal amount can be controlled at the nanometer level, and the advantages of being flexible in movement, high in reliability, high in machining quality, capable of effectively restraining medium-frequency errors and the like are achieved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Laser life test fixing clamp

ActiveCN111766043APrevent side to side movementNot affected by external forcesWork holdersOptical apparatus testingGear wheelErbium lasers

The invention discloses a laser life test fixing clamp comprising a main box body, an inner box body, a supporting rod and a through hole. An electric telescopic rod is fixed at the top end of the main box body; the lower end of the electric telescopic rod is fixed to a fixing plate, a spring is fixed to the lower end of the fixing plate, a movable rod is connected with a gear, the gear is fixed to a rotating rod, a hand-cranking wheel is fixed to the tail end of the rotating rod and connected with a bolt, the through hole is formed in the inner box body, and a cooling fan is fixed to the bottom end of the main box body. According to the laser life test fixing clamp, the limiting plates are matched in pairs to fix the laser; the laser is prevented from moving left and right; movement of the limiting plates is controlled through the movable rod to fix the laser; compared with bolt fixing, the laser is more convenient; the soft rubber plate moves downwards to deform, the soft rubber padwraps the laser, the laser can be fixed, and a certain damping effect is achieved to protect the laser against the influence of external force.

Owner:苏州鼎智瑞光智能科技有限公司

Rotating mechanism mounted on electronic equipment

InactiveCN110131535ASimple structureEnsure that the limit does not moveStands/trestlesCircular discSelf locking

The invention discloses a rotating mechanism mounted on electronic equipment. The rotating mechanism comprises a first rotating rod, a second rotating rod, the electronic equipment connected with thehead part of the first rotating rod, and a rotating outer piece fixedly connected with the tail part of the first rotating rod. The rotating mechanism further comprises a rotary clamping piece rotationally connected with the rotating outer piece; and the rotating outer piece and the rotary clamping piece are in anti-falling self-locking rotary connection. The rotating mechanism mounted on the electronic equipment is simple in structure; on one hand, as a vertical hinge and a transverse hinge are arranged between a disc and a positioning disc, the internal disc still can be not shifted under the influence of criss-cross external force, and the stability of the rotating mechanism is improved.

Owner:DONGGUAN ZHONGKE GUANTENG TECH CO LTD

Flexible pickup device for plate cylinder plugs

PendingCN113043310ALow appearance size requirementsNot strictGripping headsConveyor partsStructural engineeringMechanical engineering

The invention relates to a flexible pickup device for plate cylinder plugs. The device is mounted on a plate cylinder plug pickup driving mechanism, is used for picking up the plate cylinder plugs, and the flexible pickup device comprises a mounting plate, a plug magnetic suction mechanism, an elastic mechanism and a supporting plate, wherein, the mounting plate is mounted on an output shaft of the plate cylinder plug pickup driving mechanism; the plug magnetic suction mechanism is movably connected with the mounting plate; one end of the elastic mechanism is movably connected with the mounting plate, and the other end of the elastic mechanism is fixedly connected with the supporting plate; and when the plate cylinder plug flexible pickup device picks up the plate cylinder plugs, the plug magnetic suction mechanism and the supporting plate are connected with the plate cylinder plugs. Compared with the prior art, and the flexible pickup device has the advantages that the requirement for the appearance size of the plugs is low, the influence on the truss is small, and the grabbing success rate is high.

Owner:SHANGHAI YUNCHENG PLATE MAKING

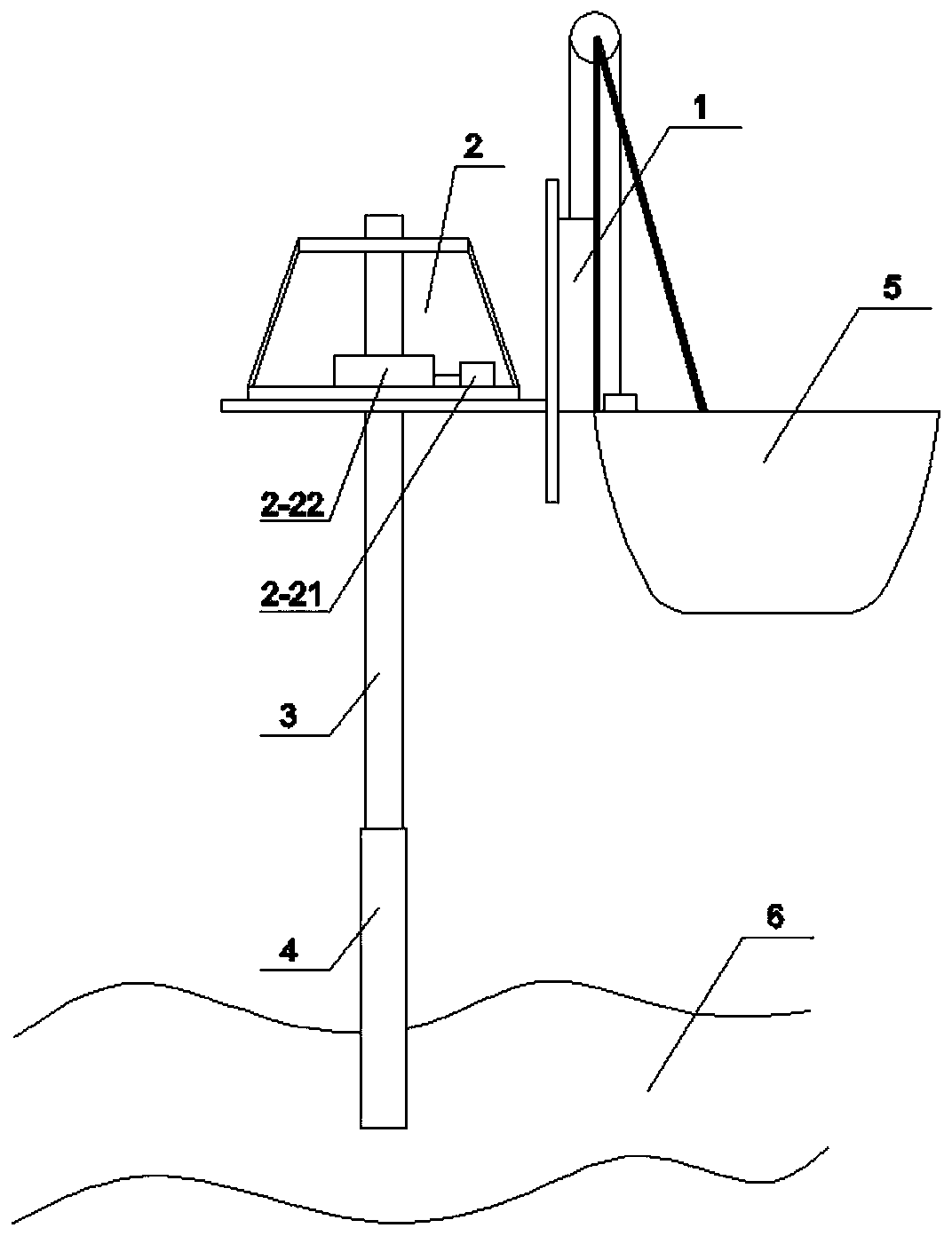

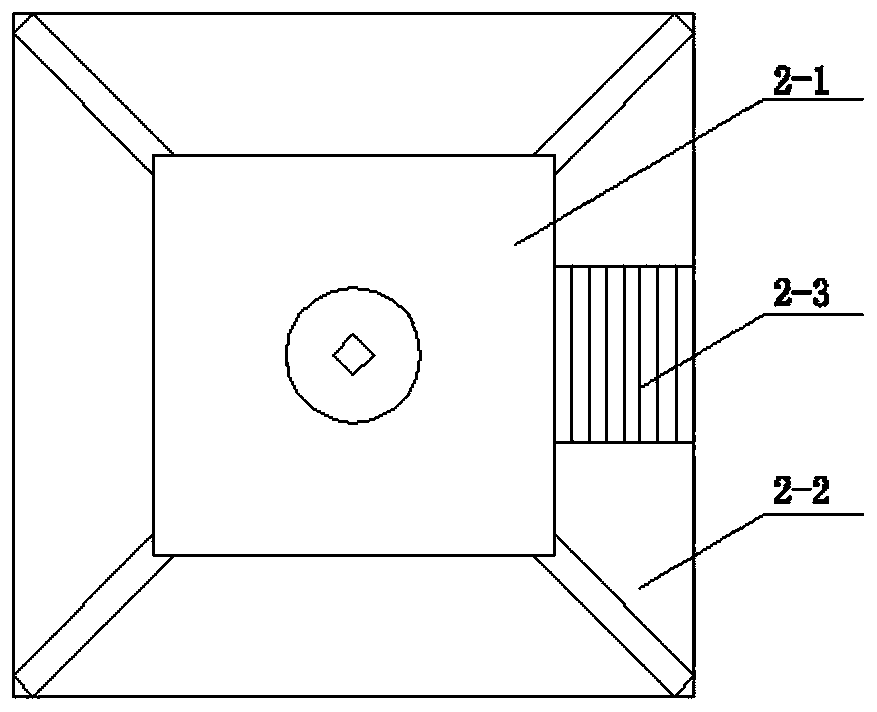

Rotary bank-off advancing type riverbed deposit sampling device under self-weight effect

ActiveCN106872207AReduce designReduce installationWithdrawing sample devicesEngineeringWater reservoir

The invention discloses a rotary bank-off advancing type riverbed deposit sampling device under a self-weight effect. The device comprises a liftable operating platform, a power system, a transmission rod and a sampling tube system, wherein the liftable operating platform is fixed to the side face of a surveying vessel; the power system is arranged on the liftable operating platform; the upper end of the transmission rod is arranged in a hole of the power system through a master bushing and is in drive connection with the power system; the lower end of the transmission rod is connected with the sampling tube system; the power system transmits a shear force to the sampling tube system through the transmission rod; the self-weight of the whole transmission rod and that of the sampling tube system are adopted as drilling pressure to drill to a sampling position, and finally the whole sampling tube system is lifted to the surveying vessel to complete sampling work. The device is simple in structure, convenient to disassemble, and suitable for deepwater sampling in a water reservoir, and can prevent a deposit sample from being disturbed.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

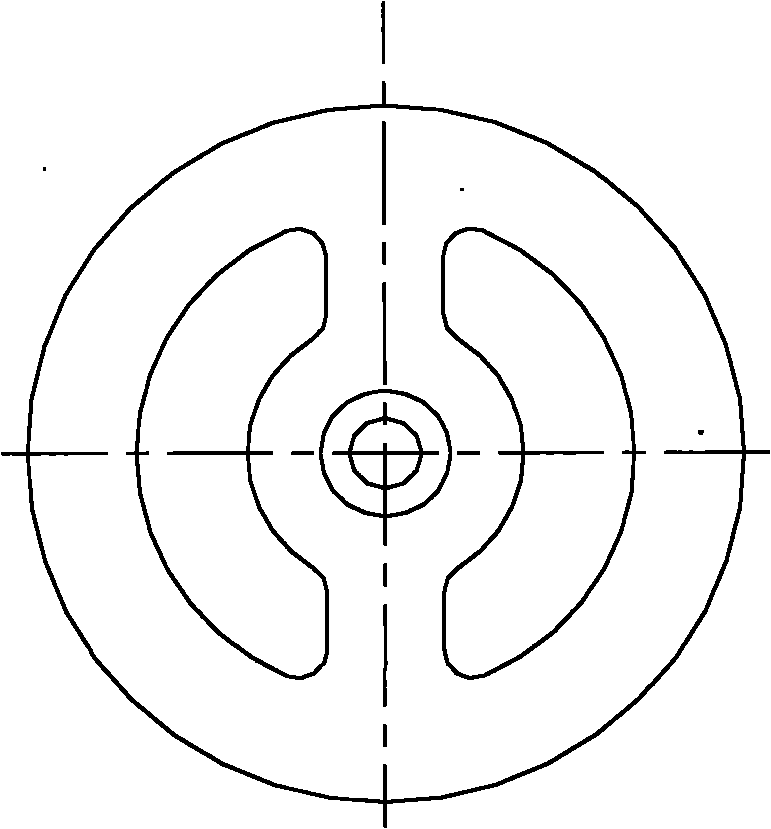

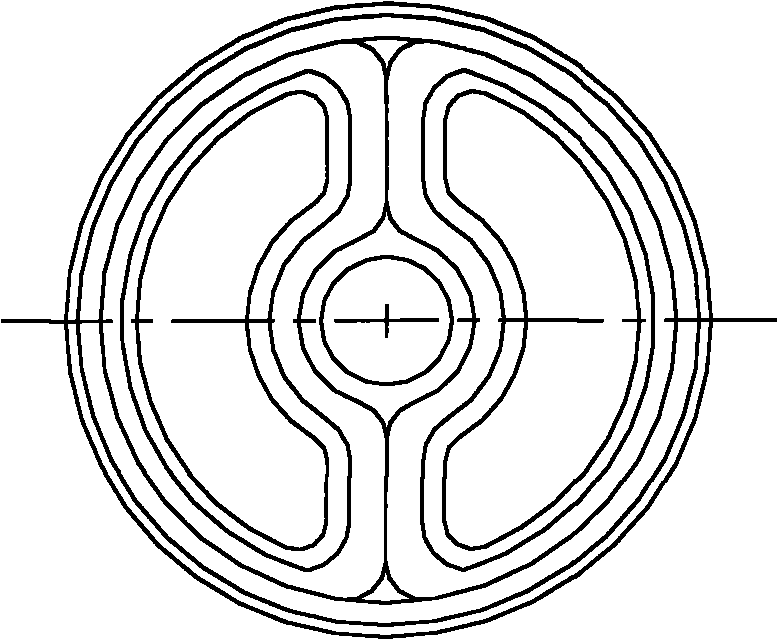

Rigidizing device of film disc flexible coupler assembly

ActiveCN102935911BImprove rigiditySolve the problem of rigidityExternal framesDynamic balanceCoupling

The invention relates to a rigidizing device of a film disc flexible coupler assembly. The device comprises a fixed disc, an adaptation disc, a flexible element film disc and an installation disc. The flexible element film disc is respectively connected with the adaptation disc and the installation disc. The fixed disc is connected with the installation disc and is fastened by inner hexagon screws. The fixed disc is connected with the adaptation disc of the film disc assembly and is fastened by bolts and screws, and rigidizing is conducted on the film disc assembly. The rigidizing device is compact and reasonable in structure, and enables the film disc assembly to achieve rigidity effect to protect flexible elements from effect of external force in transportation. The film disc assembly should be rigidized in assembly and disassembly of the installation disc to protect the film disc. The device can serve as a rigidizing auxiliary tool in dynamic balance. The rigidizing device resolves the rigidizing problem of the film disc flexible coupler assembly.

Owner:无锡创明传动工程有限公司

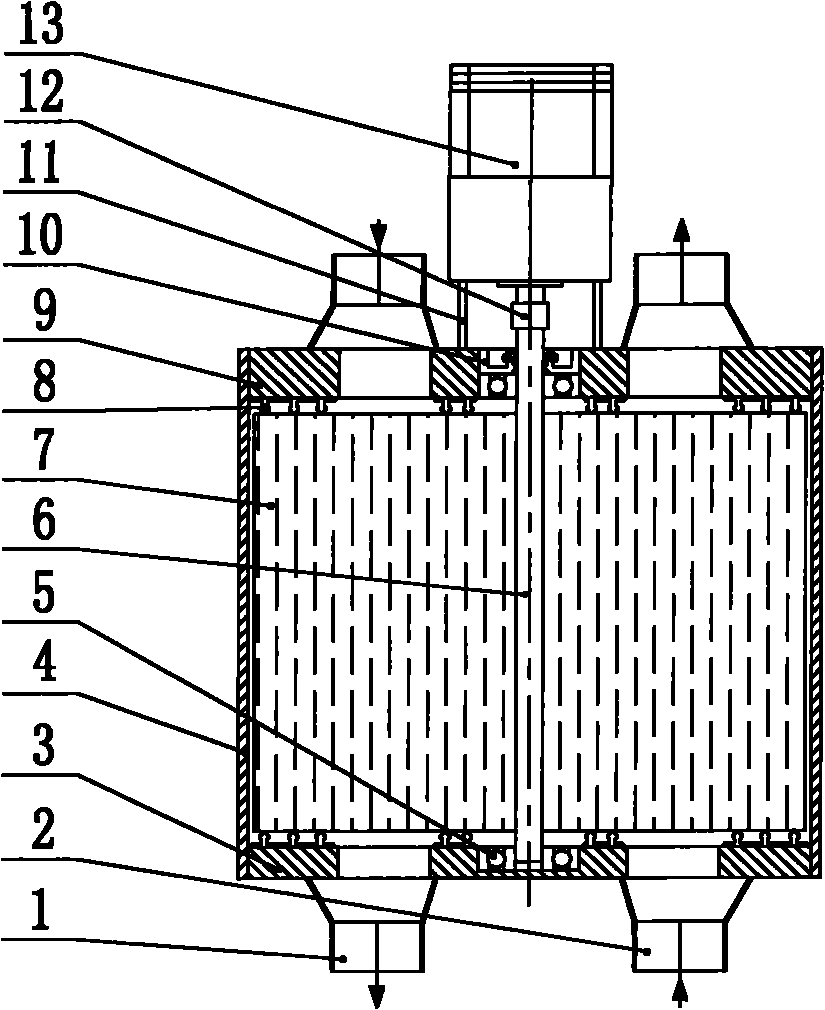

Humidity and enthalpy conversion device used for generation system of proton exchange membrane fuel cell

The invention relates to a humidity and enthalpy conversion device used for a generation system of a proton exchange membrane fuel cell. A power part consists of a speed regulating motor and a motor controller. A humidity and enthalpy conversion part consists of an upper and a lower end plates, an outer barrel and a porous ceramics humidity and enthalpy conversion column provided with a central shaft. The surfaces of the end plates, which come into contact with the porous ceramics humidity and enthalpy conversion column, are fixedly provided with wear resistant rubber seal pads provided with multiple layers of windshield wiper type projections. The shape of the wear resistant rubber seal pads is the same with the shape of the end plates, central holes, air inlets and exhaust outlets are arranged on the wear resistant rubber seal pads, and the central holes, the air inlets and the exhaust outlets are same with central holes, air inlets and exhaust outlets, which are arranged on the endplates. The multiple layers of windshield wiper type projections of the wear resistant rubber seal pads are arranged along the circumference of the end plates, the central holes, the air inlets and the exhaust outlets. Compared with the prior art, the invention has the benefits of small friction between friction pairs, light wear, small rotating torsion, high reliability, simple structure, low cost, low requirement on mounting accuracy and freedom from the impact of connection and mounting outer forces.

Owner:SUNRISE POWER CO LTD

Box type transformer station

ActiveCN105762692AReduce volumeWide range of activitiesBus-bar/wiring layoutsTransformers/inductances coolingMoistureElectrical and Electronics engineering

The invention discloses a box type transformer station. The box type transformer station at least comprises a high-voltage switch chamber, a low-voltage switch chamber and a transformer chamber, wherein the high-voltage switch chamber, the low-voltage switch chamber and the transformer chamber are in echelonment distribution, and equipment lines in the high-voltage switch chamber, the low-voltage switch chamber and the transformer chamber are M-shaped, U-shaped or V-shaped. Different from prior arts, the box-type transformer station enables the volume of the box type transformer station to be reduced by 1 to 3 times compared to a conventional transformer station through innovative adoption of an upper-lower multilayer distribution structure, reduces the area of occupied land, facilitates transportation and decreases the transport cost; and a downward pedestal of the conventional box type transformer station does not have to be manufactured, such that the difficulty of a construction project is reduced, the cost is decreased, and unfavorable influences brought by moisture in the half-embedded pedestal to each device in the box type transformer station can be better avoided.

Owner:袁茂银

A curtain rod with self-locking function

Owner:抚州市王冠实业有限公司

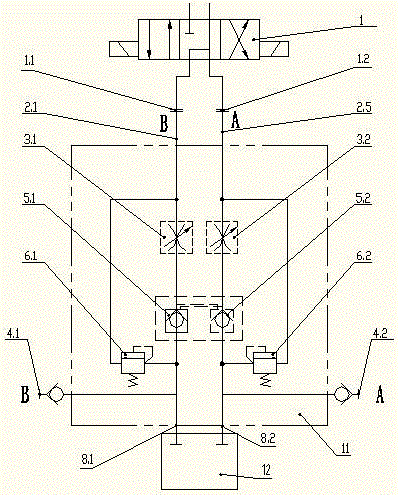

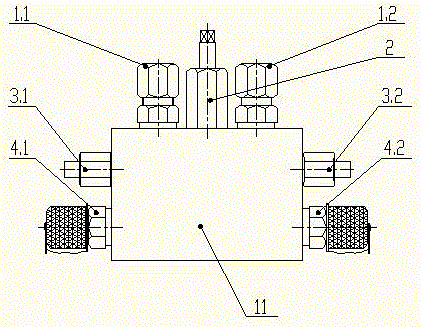

Hydraulic drive multifunctional integrated valve block

ActiveCN104514762BSimple structureReduce volumeServomotor componentsSolenoid valveMarine engineering

The invention discloses a multifunctional integrated valve block of a hydraulic drive, which comprises a cuboid valve body and a three-position four-way solenoid valve; the upper end surface of the valve body is provided with an oil inlet port ferrule joint, an oil return port ferrule joint and A cut-off needle valve, with a B-way throttle valve on the left side and an A-way throttle valve on the right side; B-way relief valve, A-way relief valve, oil outlet, return Oil port; the valve body is equipped with B-way hydraulic control check valve and A-way hydraulic control check valve; oil line B and oil line A are arranged in the valve body; oil line B is between the oil inlet ferrule joint and the oil outlet Two oil circuits connected in parallel between the ferrule joint of the oil return port and the oil return port are respectively provided in the oil circuit A: the speed regulating oil circuit and the overflow oil circuit; the oil outlet and the return port of the three-position four-way solenoid valve The oil port is respectively connected with the ferrule joint of the oil inlet port and the ferrule joint of the oil return port. The invention has the advantages of simple structure, small volume, convenient installation and operation, can significantly reduce oil leakage, and can realize multiple functions.

Owner:JIANGSU YUANWANG INSTR

Rod-shaped aggregate for lightweight castable and preparation method thereof

ActiveCN108373278BReduce replacementRealize continuous automatic productionBuilding reinforcementsDry mixingEconomic benefits

The invention discloses rodlike aggregate for lightweight castable and a preparation method of the rodlike aggregate for lightweight castable. The preparation method includes: subjecting Guangxi whiteclay, a binding agent and a water reducing agent to dry mixing, then adding water, and mixing to obtain mixed paste; using a vacuum extruder to extrude the obtained mixed paste under conditions thatthe pressure is 1-2MPa, the vacuum degree ranges from -0.085MPa to -0.095MPa, and the temperature during extrusion is 15-25 DEG C so as to obtain a rodlike aggregate blank with the basic diameter being 0.6-3mm; drying and baking to obtain the rodlike aggregate for lightweight castable. By the preparation method, early-stage large-quantity mould preparation and continuous mould replacement processes are avoided, production cost is greatly reduced, production efficiency is increased by 3-5 times as compared with previous production efficiency, continuous automatic production is realized, low cost, low energy consumption and high efficiency are realized, and continuous batch production and high social and economic benefits are realized.

Owner:郑州市裕丰耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com