Current guide device for current transformer

A technology of current transformer and electroplating nickel, which is applied in the direction of transformer/inductor coil/winding/connection, etc., which can solve the problems of long power failure time, short power failure time, easy recurrence, etc., and achieve convenient conductive connection, prevent overheating, and increase the area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

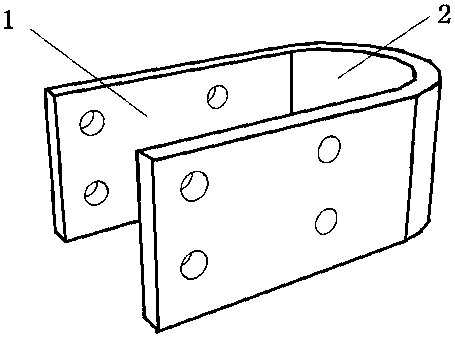

[0020] Such as figure 1 As shown, a current drainage device for a current transformer, wherein the drainage device includes a connecting part 2 and two overlapping parts 1 connected to both ends of the connecting part 2, the overlapping part 1 and the connecting part 2 form a U-shaped structure, and the overlapping The connecting part 1 is provided with 8 threaded holes, the connecting part 2 is provided with a 10mm thick copper strip, and the lapping part 1 is lapped on the wiring palm of the current transformer.

[0021] Wherein, the overlapping part 1 is fixedly connected with the terminal lug of the current transformer by inserting the bolt into the threaded hole.

[0022] Wherein, the diameters of the several threaded holes are 13mm-15mm.

[0023] Preferably, the diameter of the threaded hole is 14mm.

[0024] Among them, the inflection point radius of the U-shaped structure is 19mm-21mm.

[0025] Preferably, the radius of the inflection point of the U-shaped structure...

Embodiment 2

[0032] This embodiment is similar to Embodiment 1, the difference is that two current drainage devices are arranged oppositely on the wiring palm of the current transformer, the original current-carrying loops are increased to three, and the overlapping area is increased by 100% compared with the original one. diversion capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com