Medium-high voltage cable for smart power grid and preparation method of medium-high voltage cable

A technology for medium and high voltage cables and smart grids, which is applied in the direction of power cables, cable/conductor manufacturing, and power cables with shielding layers/conductive layers, etc., which can solve the problems of power outage time and long maintenance period, power consumption in affected areas, and economic losses and other problems, to achieve good physical and mechanical properties, fast post-maintenance work, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

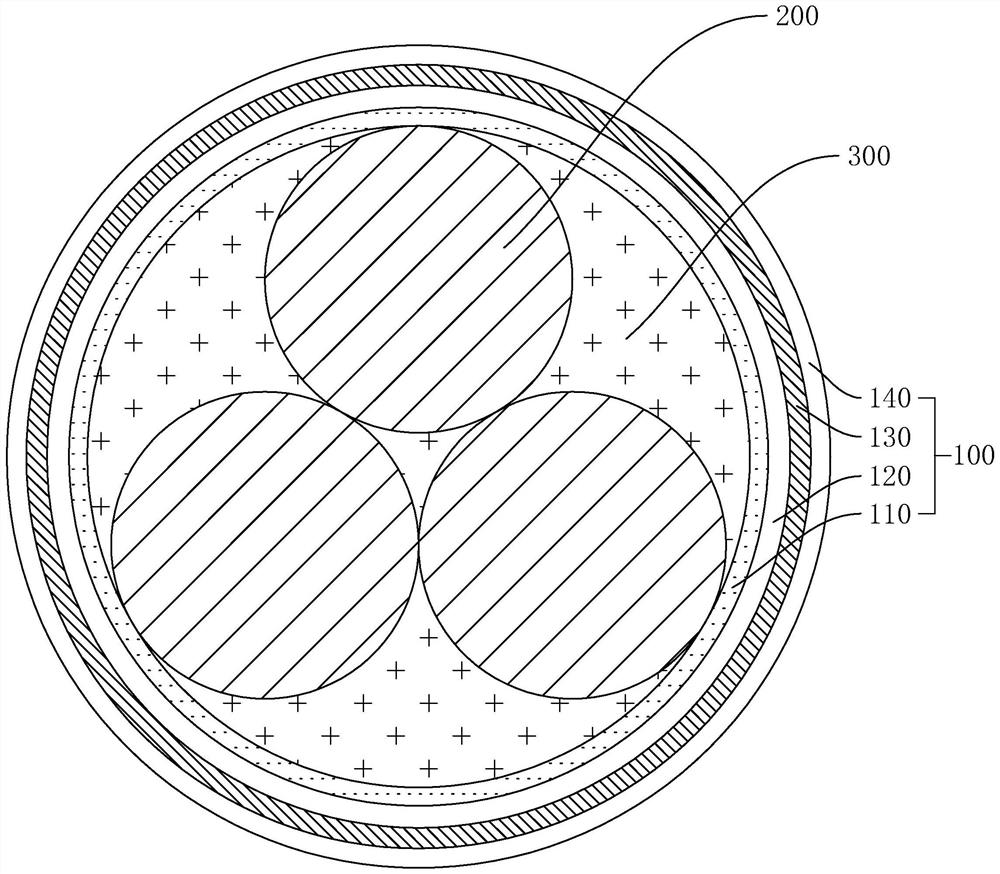

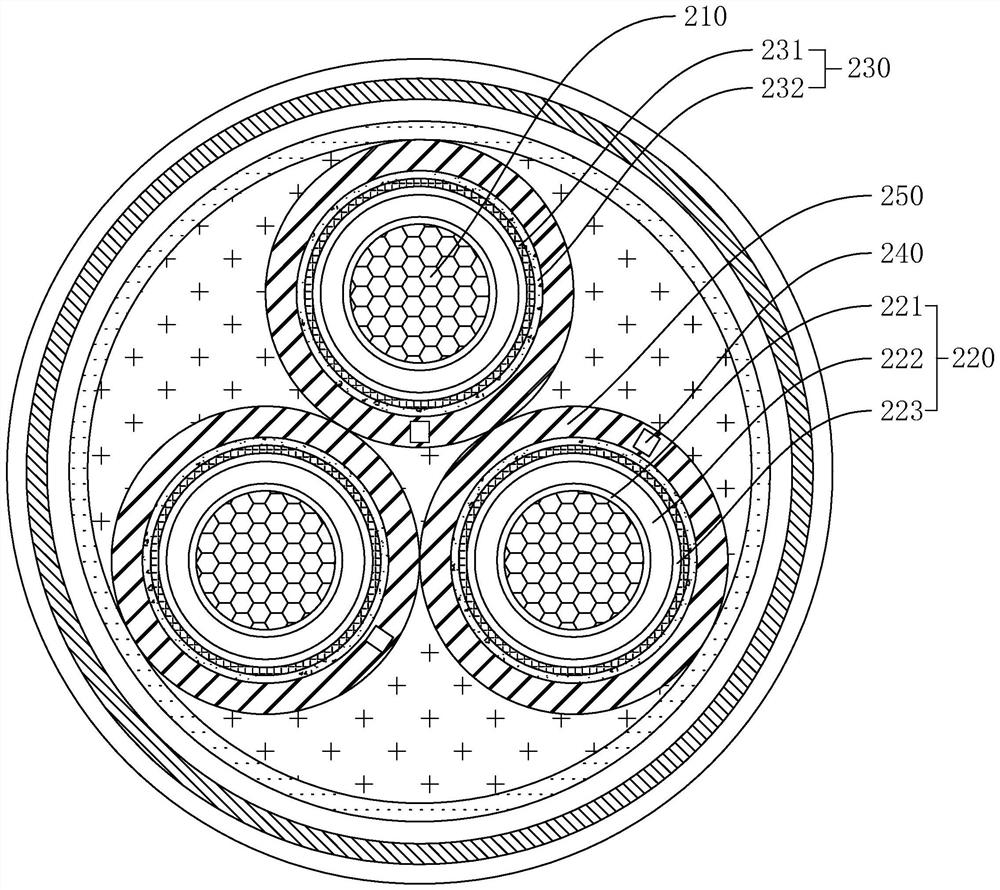

[0033] A medium and high voltage cable for a smart grid provided in this embodiment has a structure such as Figure 1 to Figure 2 As shown, including the cable core 100, three cores 200 are arranged in the cable core 100 in sequence along its own circumferential direction, and two adjacent cores 200 interfere with each other, and the space between the cores 200 and the cable core 100 is filled with polypropylene filler 300.

[0034] The wire core 200 includes a tightly pressed circular copper conductor 210, an insulating layer 220, and a composite shielding layer 230 arranged sequentially from the inside to the outside, and the insulating layer 220 includes a semi-conductive inner shielding layer 221, a cross-linked polyethylene layer 222 and a semiconductive outer shielding layer 223, wherein the semiconductive inner shielding layer 221 and the semiconducting outer shielding layer 223 are both made of a mixture of EVA and conductive carbon black; the composite shielding layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com