Gas cylinder or oil cylinder with self-locking device

A technology of self-locking device and cylinder, applied in the direction of fluid pressure actuating device, etc., can solve the problems of limited self-locking force, causing accidents, unable to open synchronously with active power, etc., and achieves the effect of simple structure and good self-locking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

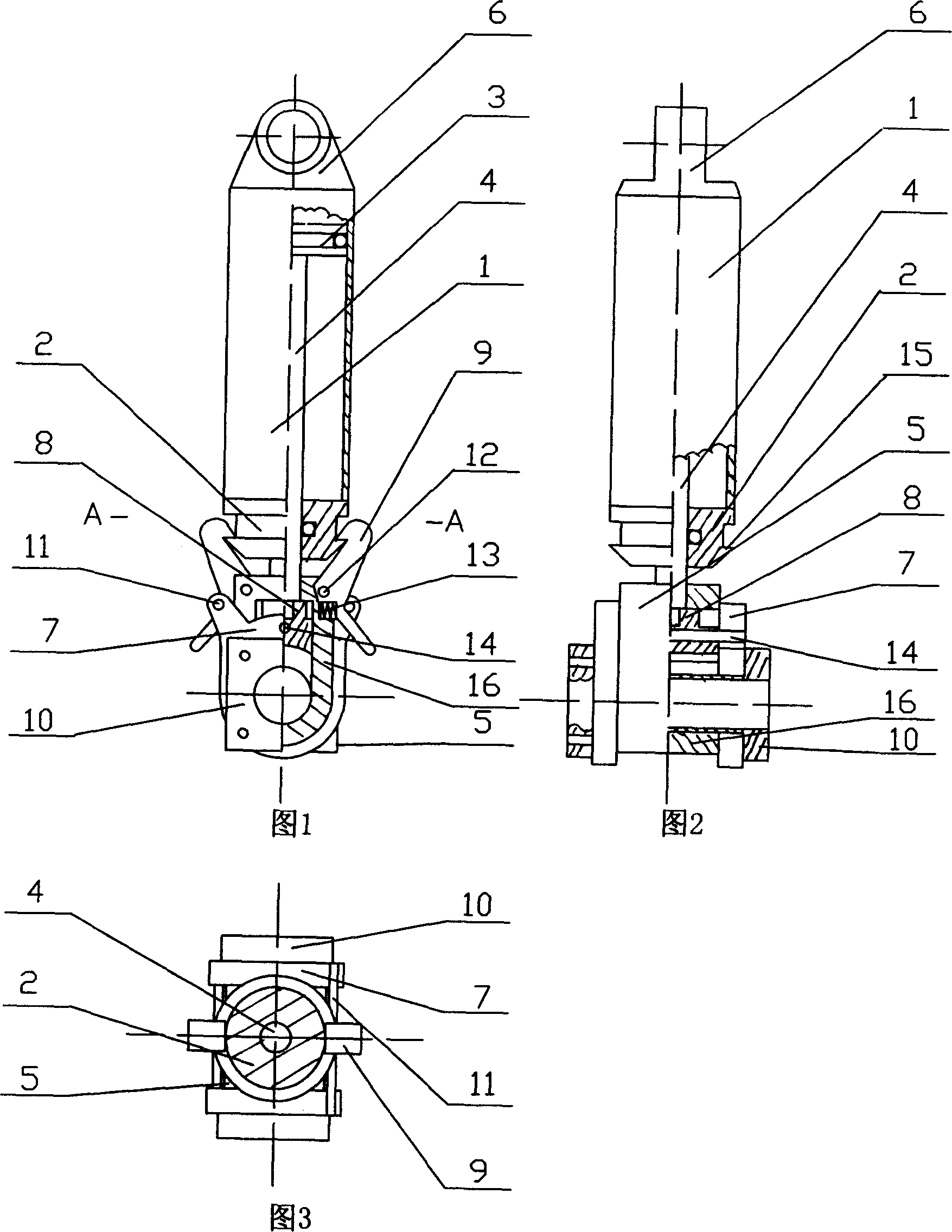

[0011] Referring to Fig. 1, Fig. 2 and Fig. 3, the present invention works like this: the cylinder body 1 is hinged to the fixed end through the lifting lug 6, and the bearing part is connected to the flange shaft 10.

[0012] The opening process of the self-locking device: the pressure medium enters the upper part of the piston 3, pushes the piston 3, and the piston rod 4 starts to move downward, and the slider 8 connected to the end of the piston rod 4 slides in the lock seat 16. The shaft 14 is fixed on both sides of the slider 8, and a shift rod 11 is connected between the two shift forks 7, so the slider 8, shift fork 7, shift rod 11 and piston rod 4 move downward at the same time, and the shift rod 11 presses the lock hook 9 rotates around the pin shaft 12, the upper part of the lock hook 9 is disengaged from the slot 15 on the cylinder head 2, and the lower part presses the spring 13, because there is a gap between the slider 8, the shift fork 7 and the flange shaft 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com