Box type transformer station

A box-type substation and transformer room technology, applied in substations, enclosed substations, substation/switch layout details, etc., can solve the problems of poor natural heat dissipation performance, increased manufacturing cost and maintenance difficulty, and large equipment damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

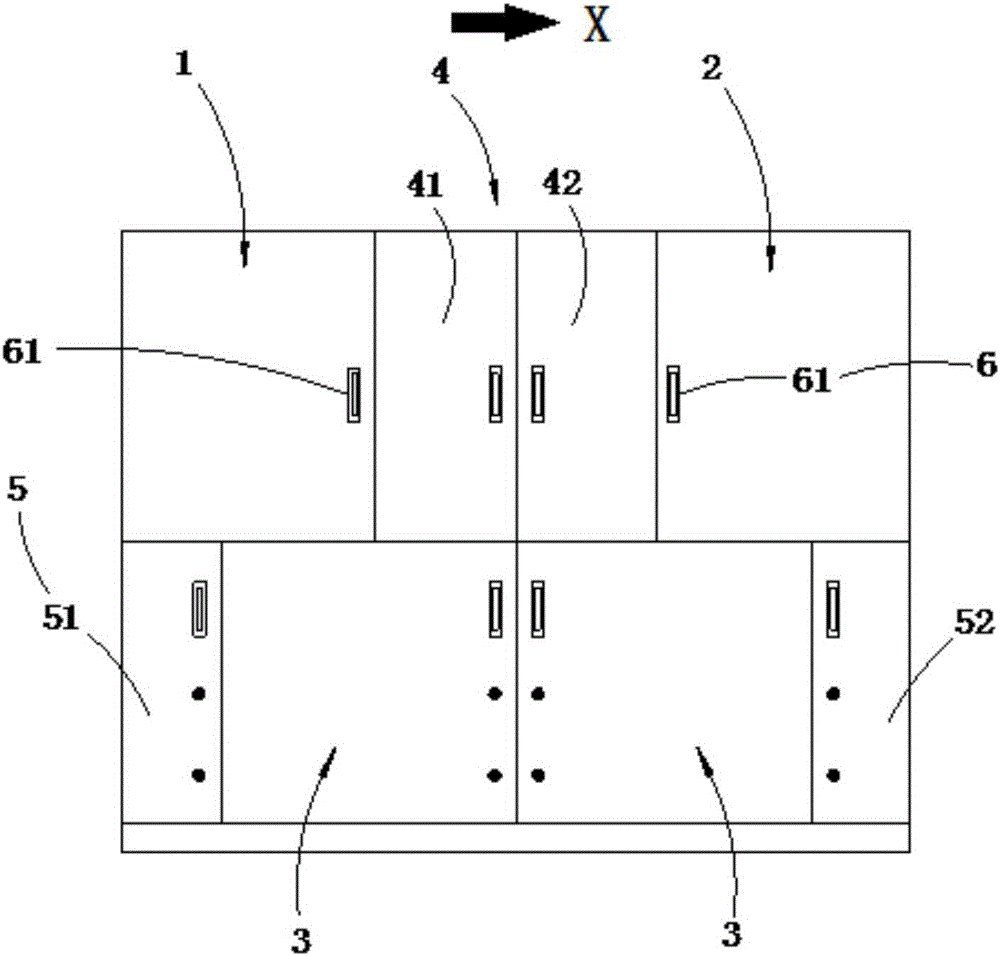

[0108] The invention provides a box-type substation, figure 1 and figure 2 It is the front view and perspective view of the box-type substation, such as figure 1 As shown: the box-type substation is equipped with a high-voltage switch room 1, a low-voltage switch room 2, a transformer room 3, a metering room 4 and a cable room 5. The metering room 4 can also be used as a high-voltage and low-voltage connection area, and the cable room 5 includes high-voltage cables. Room 51 and low-voltage cable room 52; it should be noted that the metering room can be one, and the high-supply high meter or high-supply low meter method is used to save corresponding functional equipment and simplify its structure. It can be called a high-voltage metering room or a low-voltage metering room. Metering room; what adopt in the present embodiment is that high-voltage metering (connection) room 41 and low-voltage metering room 42 can be used as metering cooperation, and wherein high-voltage meter...

Embodiment 2

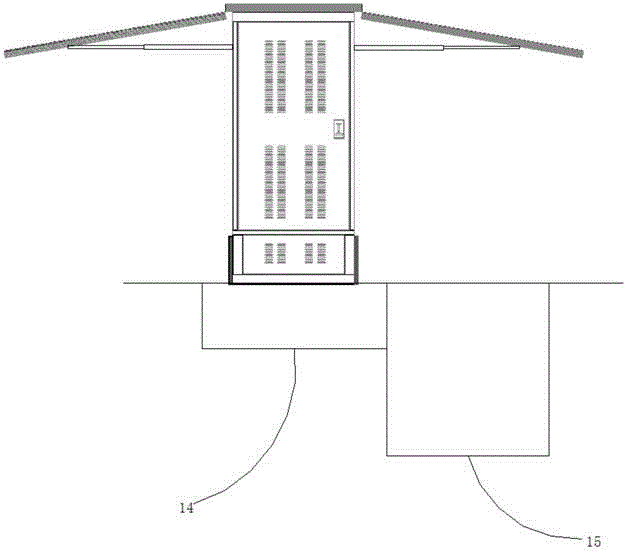

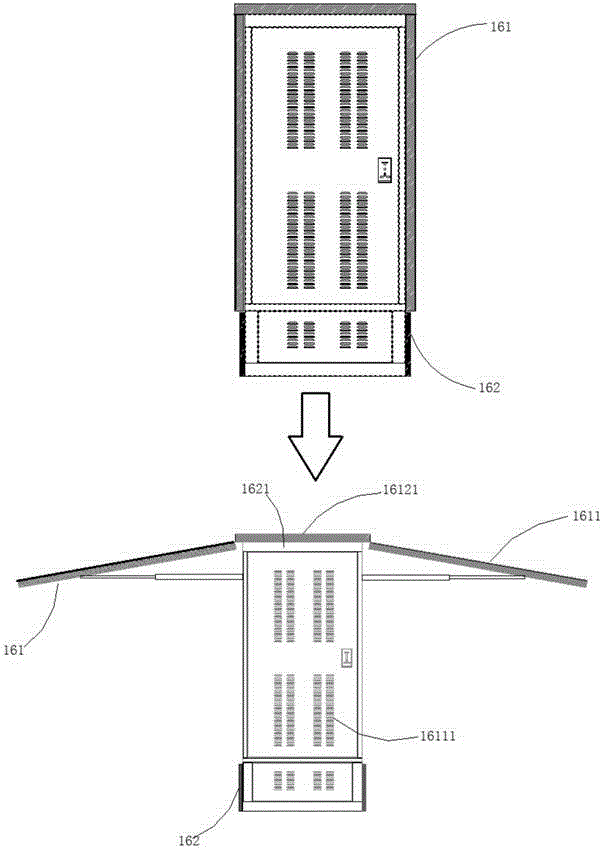

[0113] The only difference between this embodiment and embodiment 1 is that the cable chamber 5, Figure 3-6 is a schematic diagram of the box-type substation, such as image 3 As shown, there is a two-layer structure between the high-voltage cable room 51 and the low-voltage cable room 52. Along the X direction, the upper layer is the high-voltage switch room 1, the metering room 4 and the low-voltage switch room 2, and the lower layer is the transformer room 3; the high-voltage cable room 51 and the low-voltage cable chamber 52 are the same height as the two-layer structure respectively. The improvement of the structure of the cable room 5 can realize that the incoming cables of the box-type substation can be fed in both up and down, and can be expanded to be applicable to situations such as overhead lines that need to be fed in from the top of the box-type substation. Such as Figure 4 As shown, at this time, the incoming cable enters the line from the bottom of the box-t...

Embodiment 3

[0115] The difference between this embodiment and Embodiment 1 is that the bottom surfaces of the high and low voltage switch rooms of the box-type substation in this embodiment are not attached to the top surface of the transformer room respectively, and the side walls of the high and low voltage switch rooms are respectively in contact with the two sides of the transformer room. side walls, such as Figure 7 As shown, as a preferred embodiment, the side wall of the high-voltage switch room 1 in the box-type substation is in close contact with the side wall of the transformer room 3. Similarly, the side wall of the low-voltage switch room 2 is in contact with the side wall of the transformer room 3. The side walls are attached to each other. In addition, the bottom surface of the high-voltage and low-voltage switch rooms is not flush with the top or bottom surface of the transformer room but parallel; The character-shaped structure in the box-type substation is similar, but s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com