True triaxial dynamic pressure testing machine and method

A dynamic pressure, true triaxial technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of incomplete deformation of the sample, to achieve complete sample, complete test data, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

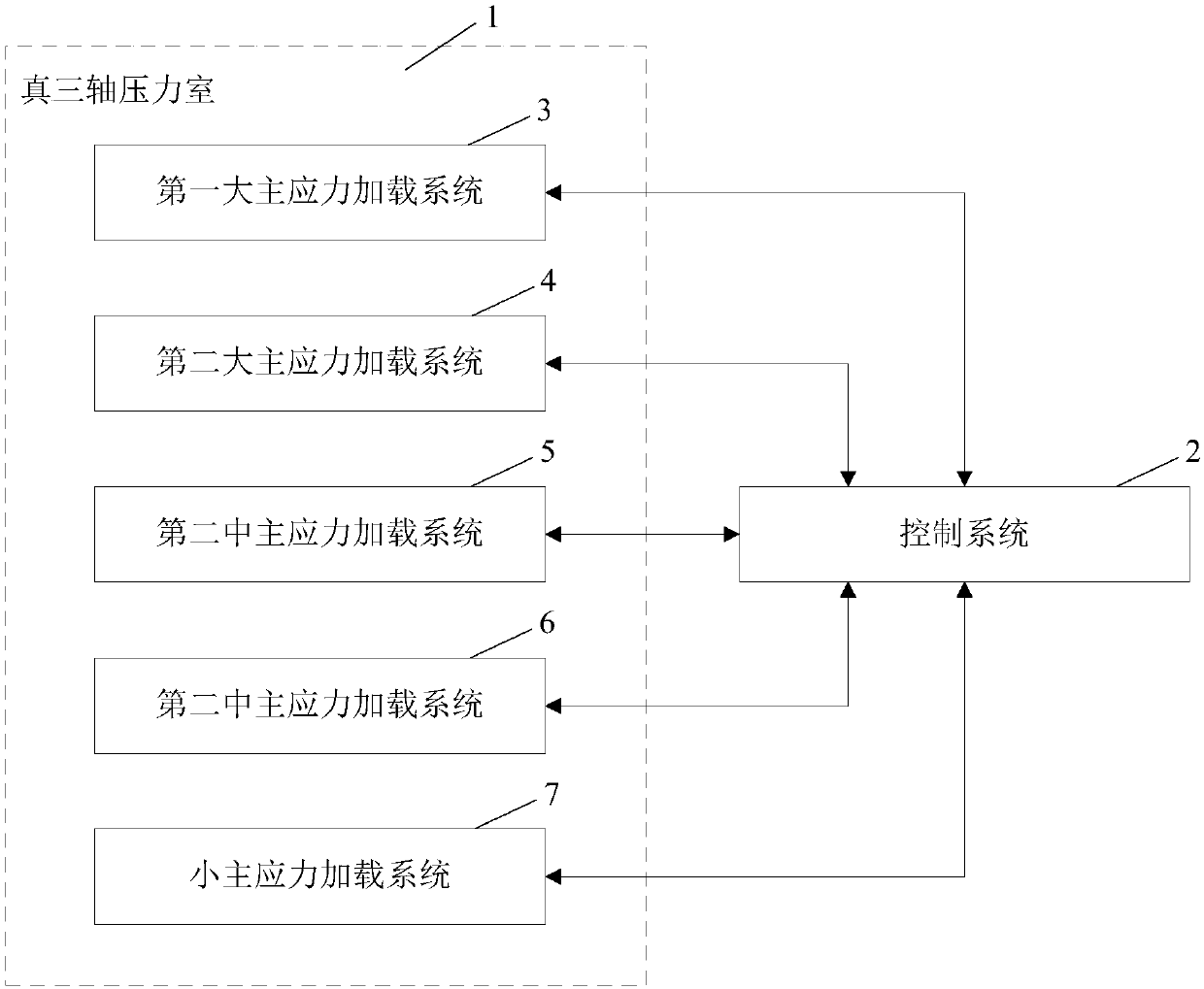

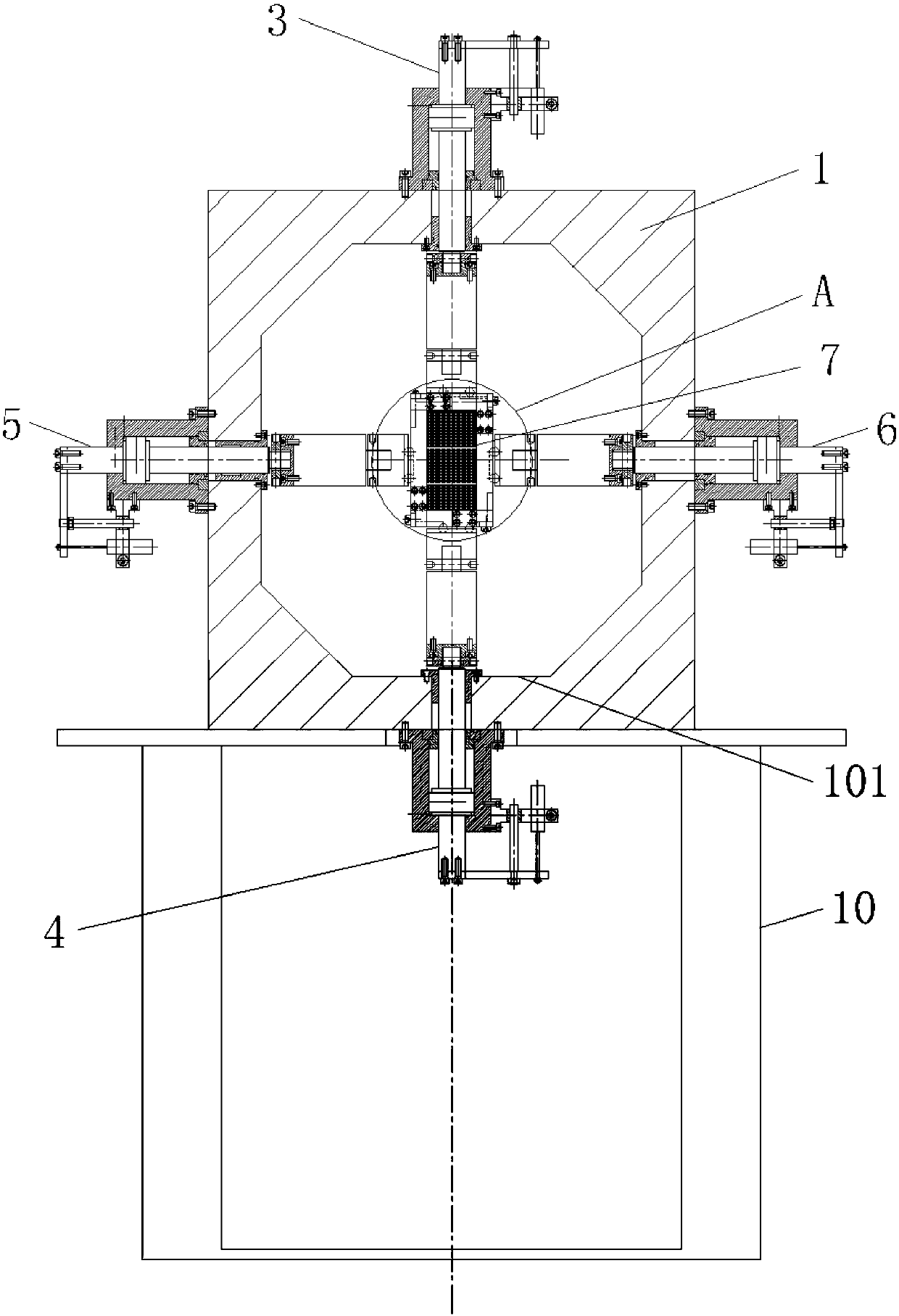

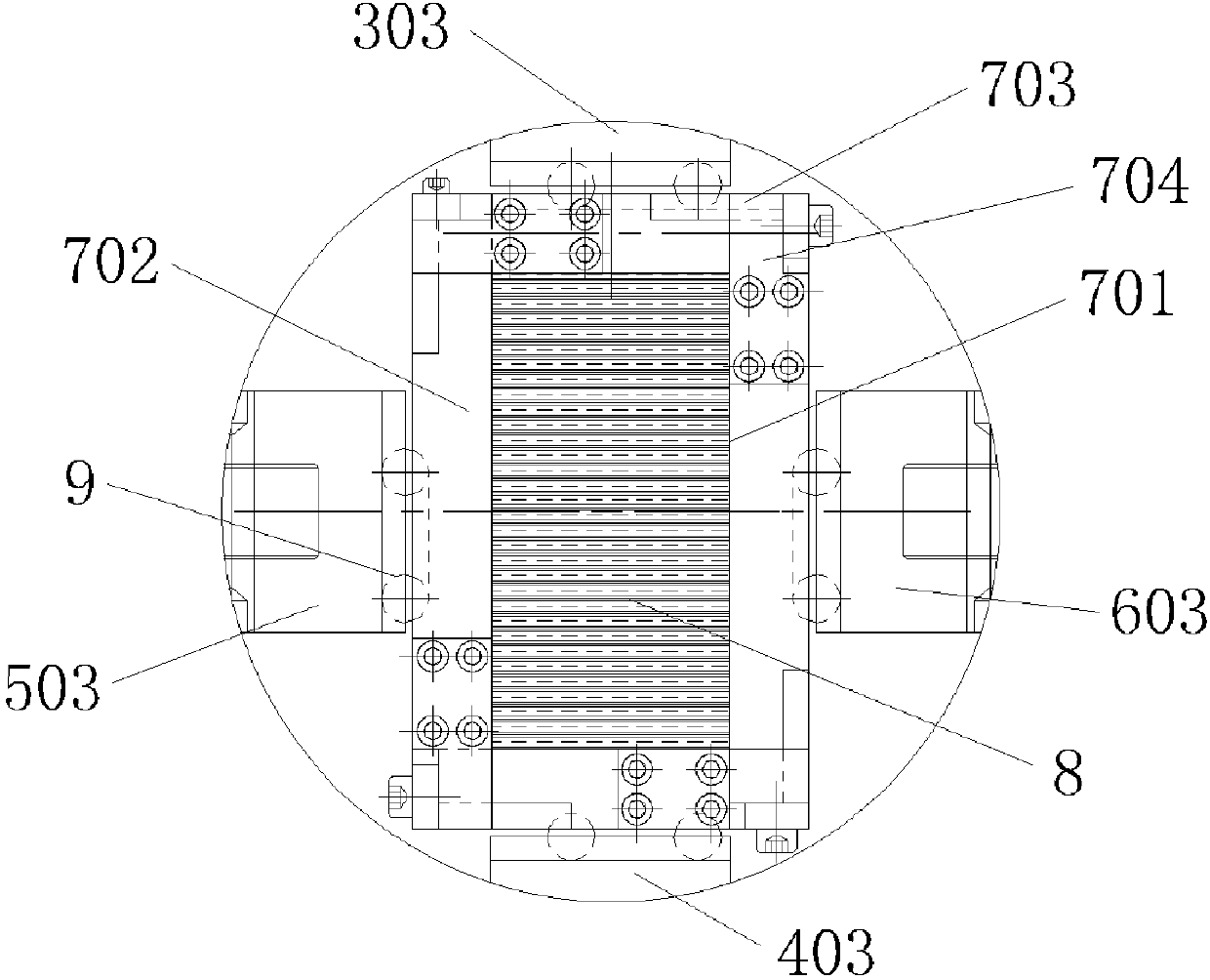

[0039] Such as Figure 1 ~ Figure 4 As shown, this embodiment provides a true triaxial dynamic pressure testing machine, which includes a true triaxial pressure chamber 1, a control system 2, a first major principal stress loading system 3, and a second major principal stress loading system 4. The first medium principal stress loading system 5, the second medium principal stress loading system 6 and the small principal stress loading system 7, the first large principal stress loading system 3, the second large principal stress loading system 4, the first medium principal stress The loading system 5 , the second middle principal stress loading system 6 and the small principal stress loading system 7 are respectively connected with the control system 2 .

[0040] The first major principal stress loading system 3 and the second major principal stress loading system 4 are σ 1 The directional loading system is set at the relative position in the vertical direction of the true tria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com