Guardrail for a wooden gallery bridge and a construction method thereof

A technology for guardrails and railings, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of inconvenient disassembly of guardrails, poor overall stability, and increased maintenance costs, and achieve easy nailing and fixing, convenient disassembly and assembly, and construction simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

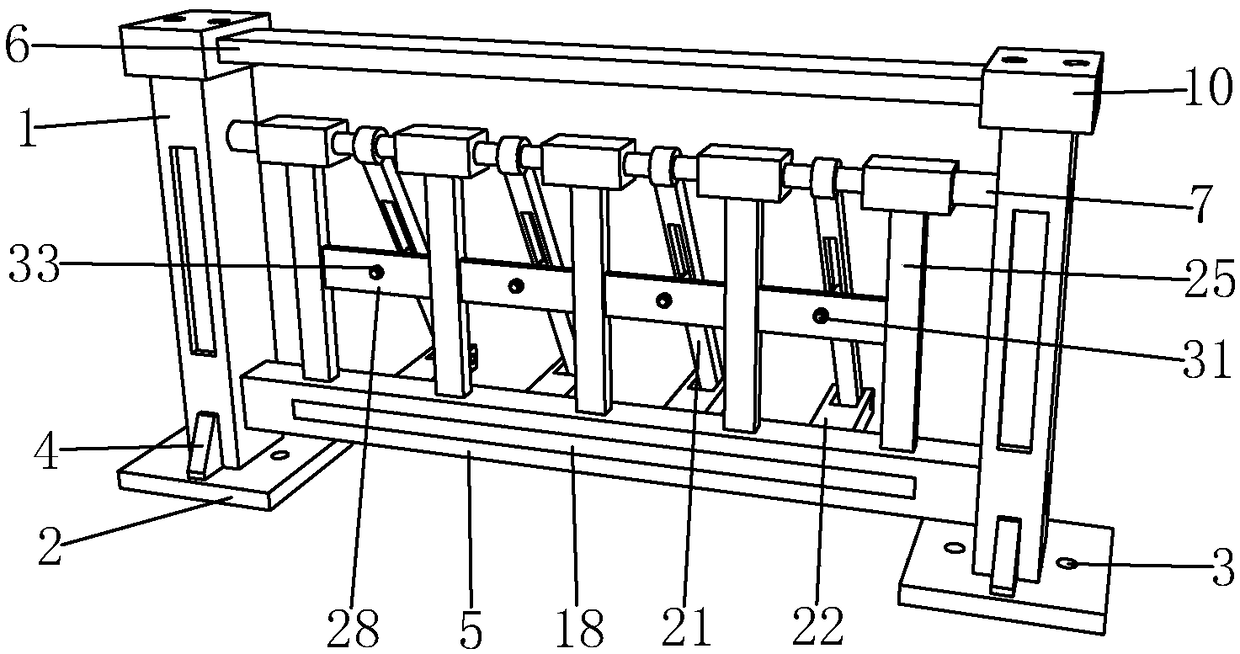

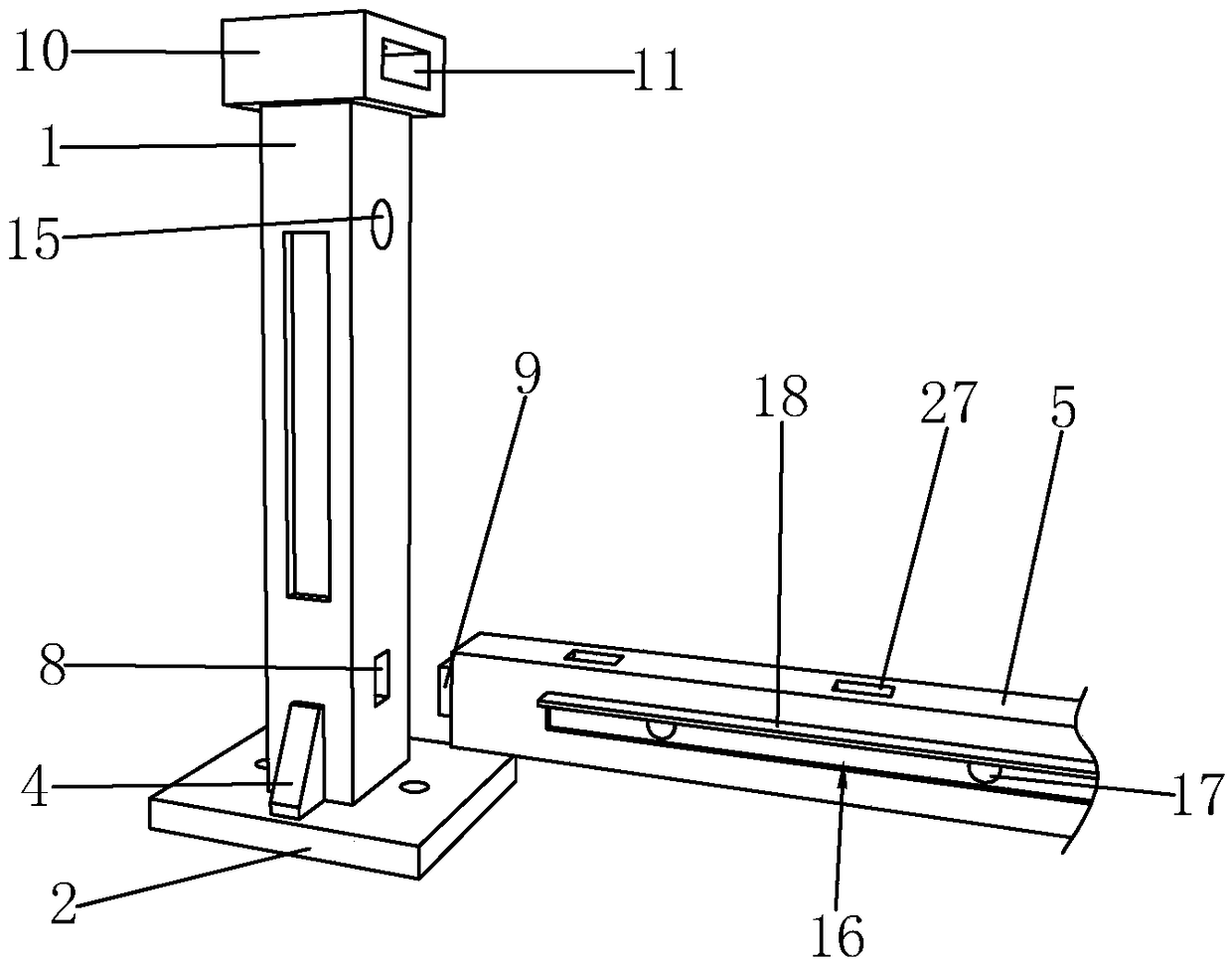

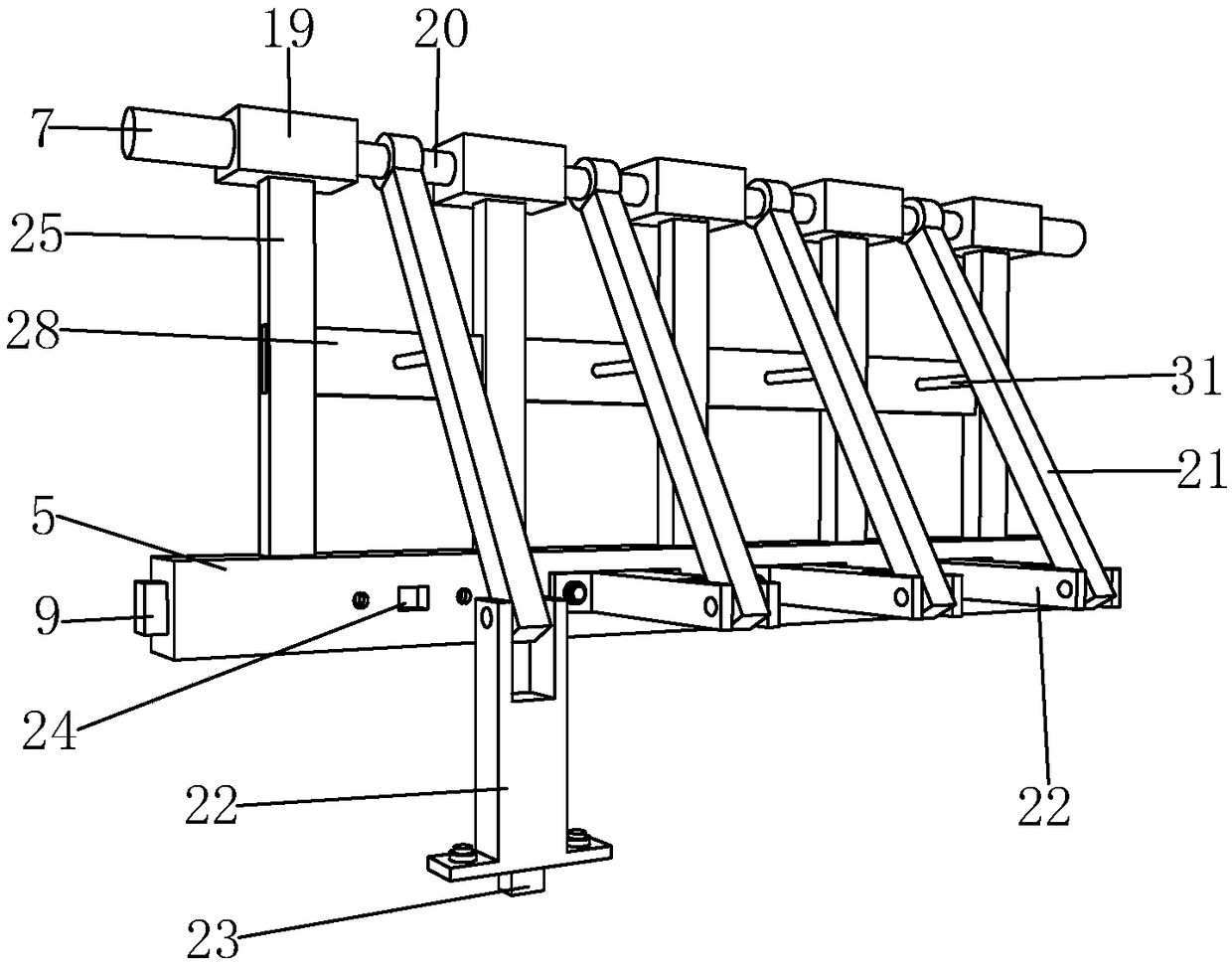

[0032] Such as Figure 1 to Figure 7Shown, be a kind of guardrail that is used for wooden covered bridge of the present invention, comprise column pile 1, the bottom of column pile 1 is provided with mounting plate 2, is provided with anchor hole 3 on the mounting plate 2, drives into ground in anchor hole 3 Nail, so that the column pile 1 is fixed on the ground. A triangular plate 4 is provided between the mounting plate 2 and the column pile 1, which improves the connection strength of the connection between the mounting plate 2 and the column pile 1, is not prone to breakage, and the overall structure is more stable. A crossbar 5, a support rod 6 and a mounting rod 7 are respectively arranged between the poles 1, the side of the pole 1 is provided with a fixed groove 8, and the two ends of the crossbar 5 are respectively provided with a fixed protrusion 9, and a fixed protrusion 9 Matching with the fixed groove 8, the crossbar 5 is easy to construct on site, easy to disass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com