Method for producing recoverable environmentally-friendly ski

A production method and snowboard technology, applied in the direction of household components, household appliances, and other household appliances, can solve the problems of environmental protection and inability to recycle thermosetting materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

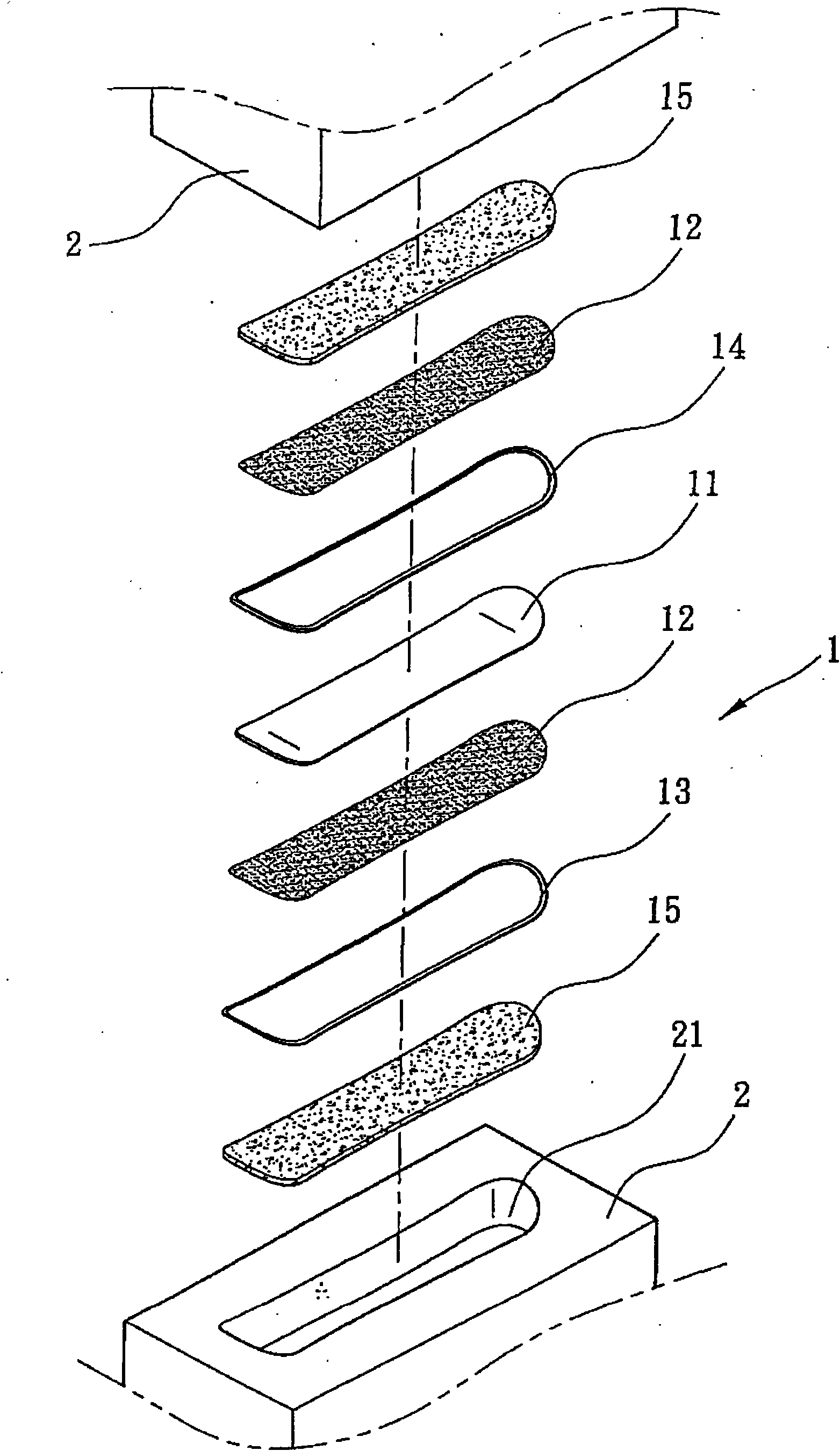

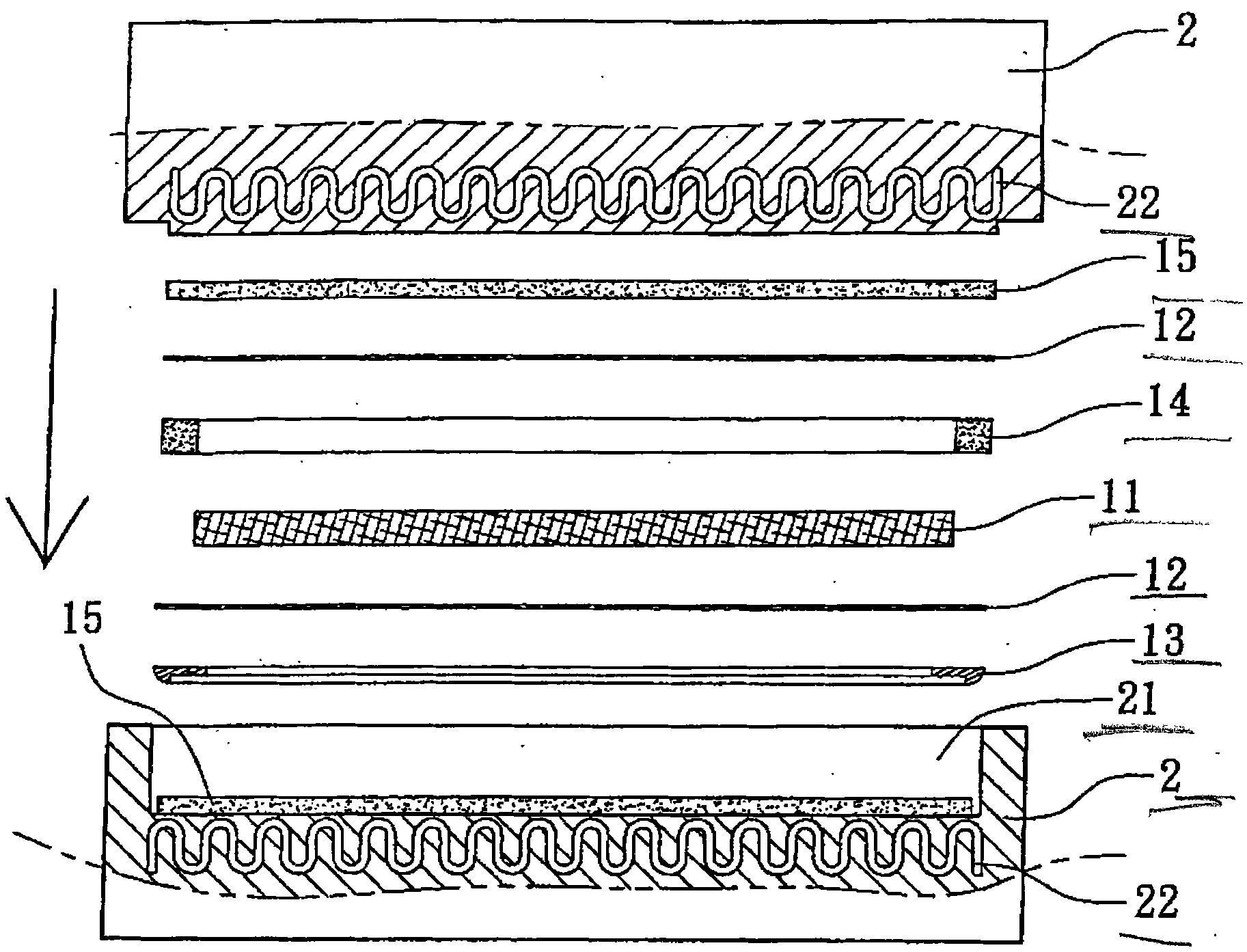

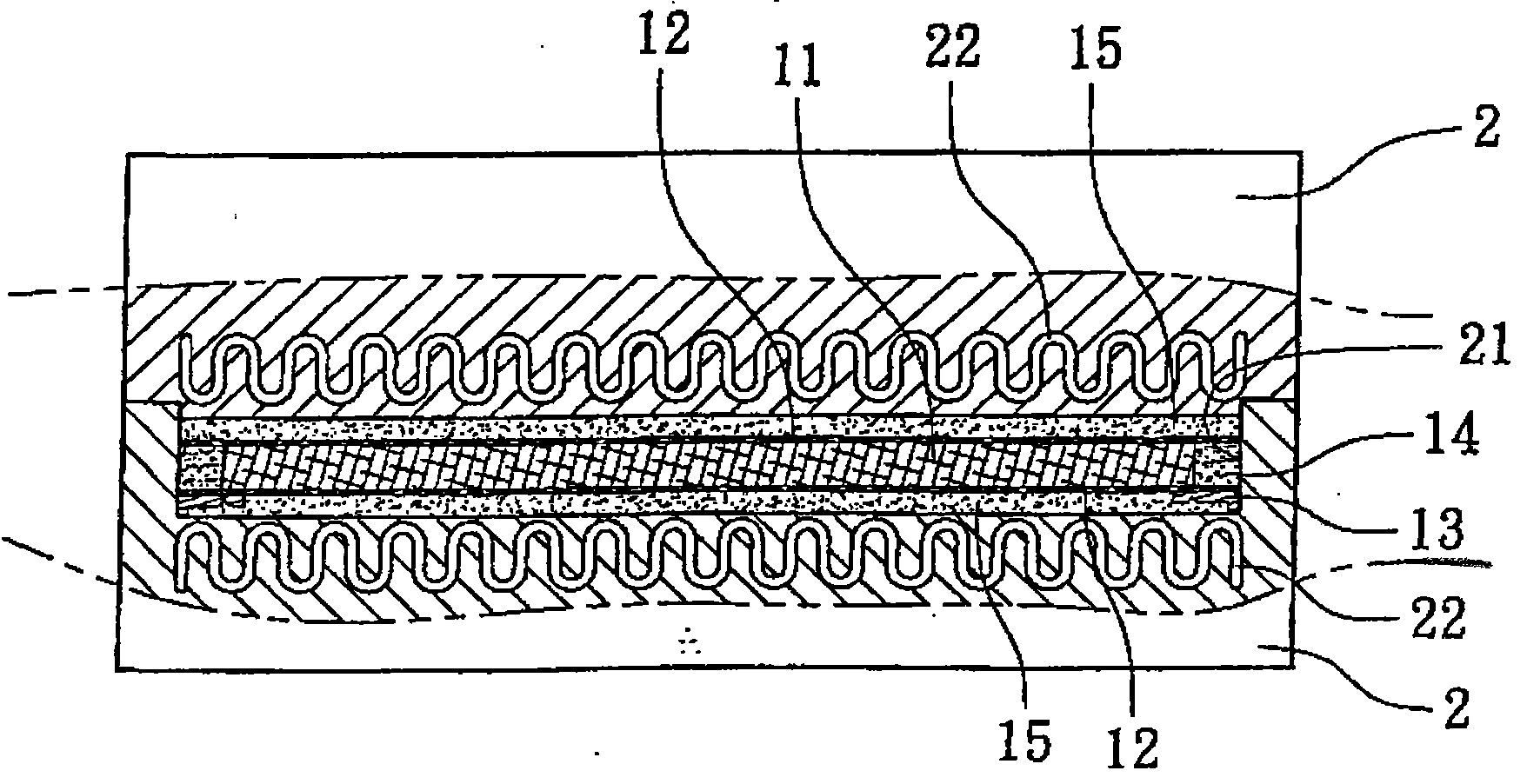

[0029] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the present invention is related to a production method of recyclable and environment-friendly skis. The main method is to use thermoplastic material and glass fiber cloth (sheet) 121 in the first heating mold 3 to utilize the temperature generated by the heating element 31 The thermoplastic material and the glass fiber cloth (sheet) 121 are melted and combined into one body, the heating temperature is 200°C-250°C, and the heating time is 30 minutes to form a thermoplastic bonding material 12, which has adhesion and glass fiber cloth (sheet) )121 strength and can be recycled. Then the steel edge ring 13 and the middle main board 11, and the plastic edge ring 14 and the upper and lower plastic plates 15 etc. around the middle main board 11 periphery are put into the mold cavity 21 of the second heating mold 2 according to the correct position, and then The upper and lower positions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com