Motor rotor cooling structure

A technology of cooling structure and motor rotor, which is applied in cooling/ventilation device, magnetic circuit shape/style/structure, electric components, etc., can solve the problems of limited cooling method of motor, short circuit of motor internal winding, and difficulty in reducing high temperature of motor. Significant cooling effect, reducing safety hazards and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

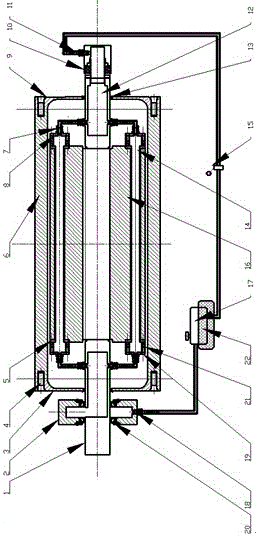

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0011] Motor rotor cooling structure, such as figure 1 As shown, its structure includes: motor rotor shaft 1 with partial holes, oil collector 2, motor front end cover 3, end cover fixing bolt 4, short circuit ring 5, motor stator 6, ferrule type pipe joint 7, outer end of oil ring Cover 8, Motor rear end cover 9, Rotary joint 10, Cooling oil inlet 11, Partial hole motor rotor shaft rear end 12, Rotary bearing 13, Aluminum tube 14, Oil pump 15, Rotor body 16, Oil tank 17, Cooling oil outlet 18. Oil ring fastening bolt 19, skeleton oil seal 20, sealing washer 21, cooling device 22. The partially perforated motor rotor shaft 1 is perforated at the corresponding design position, which is convenient to use the sleeve type pipe joint 7 and the oil pipe to connect with the outer end cover 8 of the oil ring to form a passage, which is convenient for the smooth circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com